Page 1

INSTALLATION/

E2006 Lennox Industries Inc.

Dallas, Texas, USA

SERVICE

INSTRUCTIONS

®

Humiditrol

Accessory (EDA) Units

ACCESSORIES

505,021M

02/06

Supersedes 01/06

Humiditrol

The Dave Lennox Signaturet Collection Humiditrol® Enhanced Dehumidification Accessory (EDA) is designed for

installation with a Lennox R−410A split−system outdoor unit

and an air handler or a furnace with a variable speed blower. This accessory is designed for indoor installations in either upflow or horizontal air discharge applications. This

unit is for use only on R−410A systems with thermal

expansion valves.

Prior to installation, study the decision tree on page

16 to confirm that all application requirements for

EDA installation are met.

NOTE − For downflow application, refer to Installation Instruction Supplement, Installing EDA Unit in Downflow

Configuration 505,134M.

Shipping & Packing List

S 1 − Assembled EDA indoor unit

S 1 − Bag assembly (includes check/flow restrictor for

use on EDA coil, EDA notification label).

S 1 − Outdoor fan relay and wiring harness (used only

with outdoor units equipped with variable speed fan

motors)

Check the components for shipping damage. If any damage is found, immediately contact the last carrier.

Other Required Components

Separately-ordered components are restricted to those

listed in the Engineering Handbook and the price book:

S SignatureStat

included],

− Single-stage (81M26)

− Multi−stage (81M27)

− Multi−stage heat-pump (81M28)

S Twisted Pair Wire (84X49) for outdoor sensor to ther-

mostat − Required for use with SignatureStatt.

®

EDA Series Unit

t

thermostat [Outdoor Sensor (46M98)

Table of Contents

EDA Series Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . .

Other Required Components 1. . . . . . . . . . . . . . . . . . . .

General Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Dimensions and Arrangement 3. . . . . . . . .

Component Functions 4. . . . . . . . . . . . . . . . . . . . . . . . . .

General Installation Information 5. . . . . . . . . . . . . . . . .

Electrical Wiring 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDA Installation Flow Chart & Procedures 5. . . . . . . .

Leak Testing, Evacuation, Charging 8. . . . . . . . . . . . . .

Insulating and Sealing the Unit 9. . . . . . . . . . . . . . . . . .

Other System Components 9. . . . . . . . . . . . . . . . . . . . .

How the EDA Unit Works 10. . . . . . . . . . . . . . . . . . . . . . .

Cooling Mode with Dehumidification ON 10. . . . . . . . . .

Cooling Mode (Dehumidification OFF) 11. . . . . . . . . . . .

Heating Mode (Heat Pump Applications) 11. . . . . . . . . .

Air Resistance Table 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Parts List 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decision Tree 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information

NOTE − These instructions are intended as a general guide

and do not supersede local codes in any way. Consult authorities having jurisdiction before installation.

The Humiditrol® EDA unit will operate to dehumidify, as required, when ambient temperatures are below 95ºF. When

temperatures reach 95ºF, the cooling and dehumidification

requirements will both be satisfied by the increased system runtime. In applications that include a Humiditrol

EDA unit, a call to activate the dehumidification mode at or

above 95ºF is unnecessary and would not be issued or allowed by the SignatureStatt room thermostat.

Prior to system checkout, consider the outdoor ambient

temperature. REMEMBER, the EDA unit does NOT

function in temperatures at or above 95ºF. Plan testing

to be conducted when temperatures are between 65ºF and

95ºF to ensure proper EDA set up and checkout operation.

S 75VA 24VAC indoor unit transformer (12P61) − Re-

quired when EDA unit is installed with a two-stage heat

pump system.

S Humiditrol

plications information in Lennox Engineering Handbook)

®

EDA Insulation and Piping Kit (refer to ap-

02/06 505,021M

The approved application for the EDA Series unit is

restricted to those listed in the Engineering Handbook and price book.

*2P0206* *P505021M*

Enhanced Dehumidification

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

IMPORTANT

Litho U.S.A.

®

Page 2

WARNING

11/16

20−3/4

11/16

This cased product contains fiberglass wool. Disturbing the insulation during installation, maintenance, or repair will expose you to fiberglass wool

dust. Breathing this may cause lung cancer. (Fiberglass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

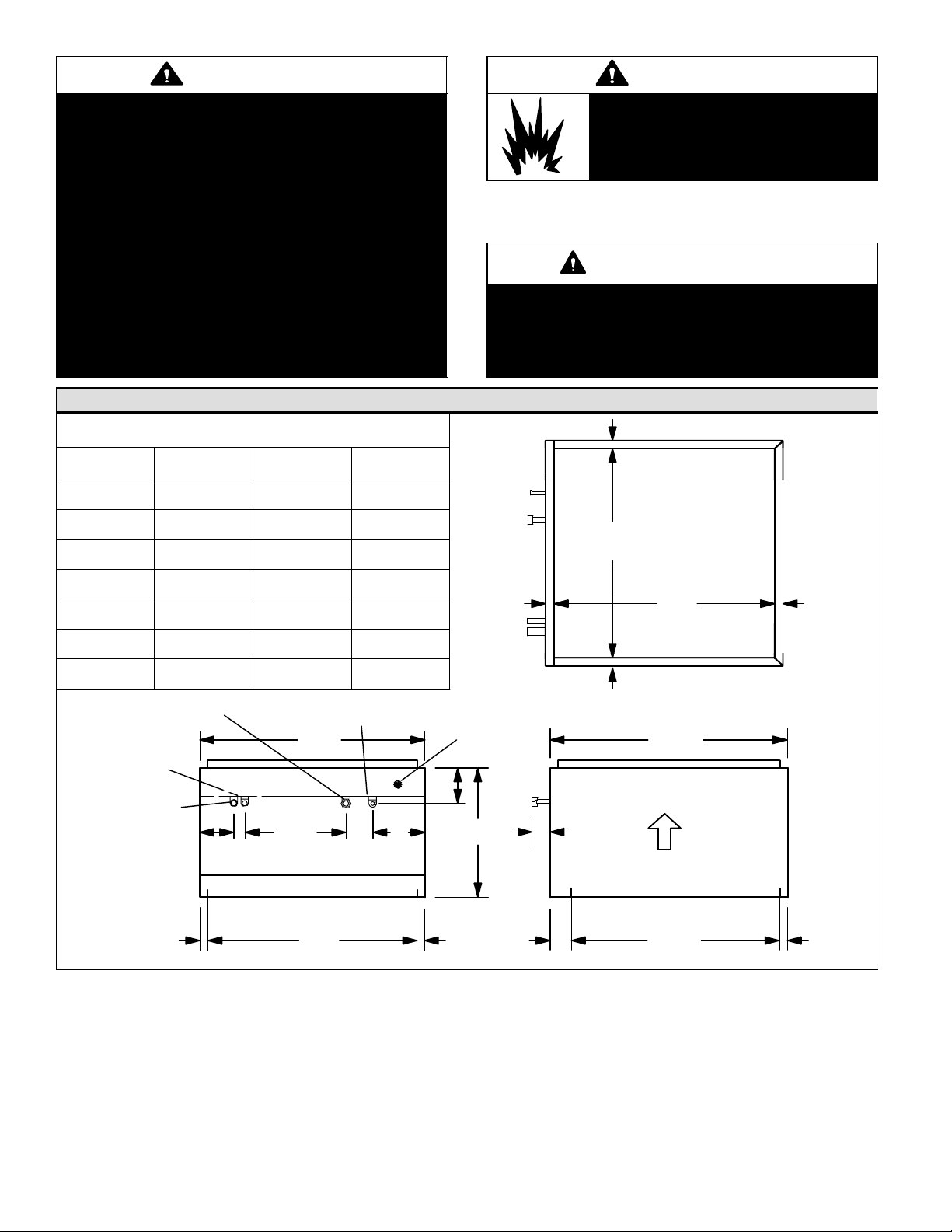

Unit Dimensions

WARNING

Risk of explosion or fire. Can cause

injury or death. Recover all refrigerant

to relieve pressure before opening the

system.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of refrigerant (CFC’s, HFC’s, and HCFC’s) as of

July 1, 1992. Approved methods of recovery, recycling or reclaiming must be followed. Fines and/or incarceration may be levied for noncompliance.

EDA Model Dimensions − Inches (mm)

Dimension EDA−024B EDA−036C EDA−060D

A 17−1/2 (445) 21 (533) 24−1/2 (622)

B 12−1/4 (311) 12−1/4 (311) 14 (356)

C 16−1/8 (422) 19−5/8 (498) 23−1/8 (587)

D 16−1/8 (422) 19-5/8 (498) 23−1/8 (587)

E 1−3/8 (35) 3−1/8 (79) 4−7/8 (124)

F 3−1/8 (79) 4−7/8 (124) 6−5/8 (168)

G 3 (76) 3−1/4 (83) 4−3/4 (121)

Check/Flow Restrictor

to Vapor Line Tee

Liquid Line to

Indoor TXV

Liquid Line

From Outdoor

Unit

E

1

(25)

To Charge Compensator

side connection

A

9−1/2

(241)

2−1/2

(64)

F

G

Electrical

Inlet

B

(17)

1−3/4

(44)

11/16 (17)

D

11/16 (17)

OUTLET

AIR

OPENING

(527)

22−1/4

(565)

(17)

EDA 01/06

11/16 (17)

INLET AIR OPENING INLET AIR OPENING

C

11/16 (17)

1−7/16 (37)

20−1/8

(511)

Page 2

11/16 (17)

Page 3

Installation Dimensions and Arrangement

EDA UNIT

(TRANSITION

See Note 2)

INDOOR

COIL

EDA−024B: 12−1/2

EDA−036C: 12−1/2

EDA−060D: 14

Varies by indoor

coil model; see

LENNOX

Engineering

Handbook.

12" (min.)

TRANSITION

(See Note 1)

FURNACE

TYPICAL

UP−FLOW

POSITION

(Furnace Shown)

TYPICAL HORIZONTAL

POSITION (Furnace Shown)

AIR FLOW

UP-FLOW FURNACE

NOTES:

1. Transition is required for all air handlers; dimension

width and depth is dependent upon the air handler

and the EDA model used.

2. Transition is required between indoor coil and EDA

if 5 ton EDA unit is used with small profile furnace.

Figure 1

Varies by air

handler model; see

Handbook for

40

AIR FLOW

LENNOX

Engineering

dimensions.

UP-FLOW AIR

HANDLER

Page 3

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 4

Component Functions

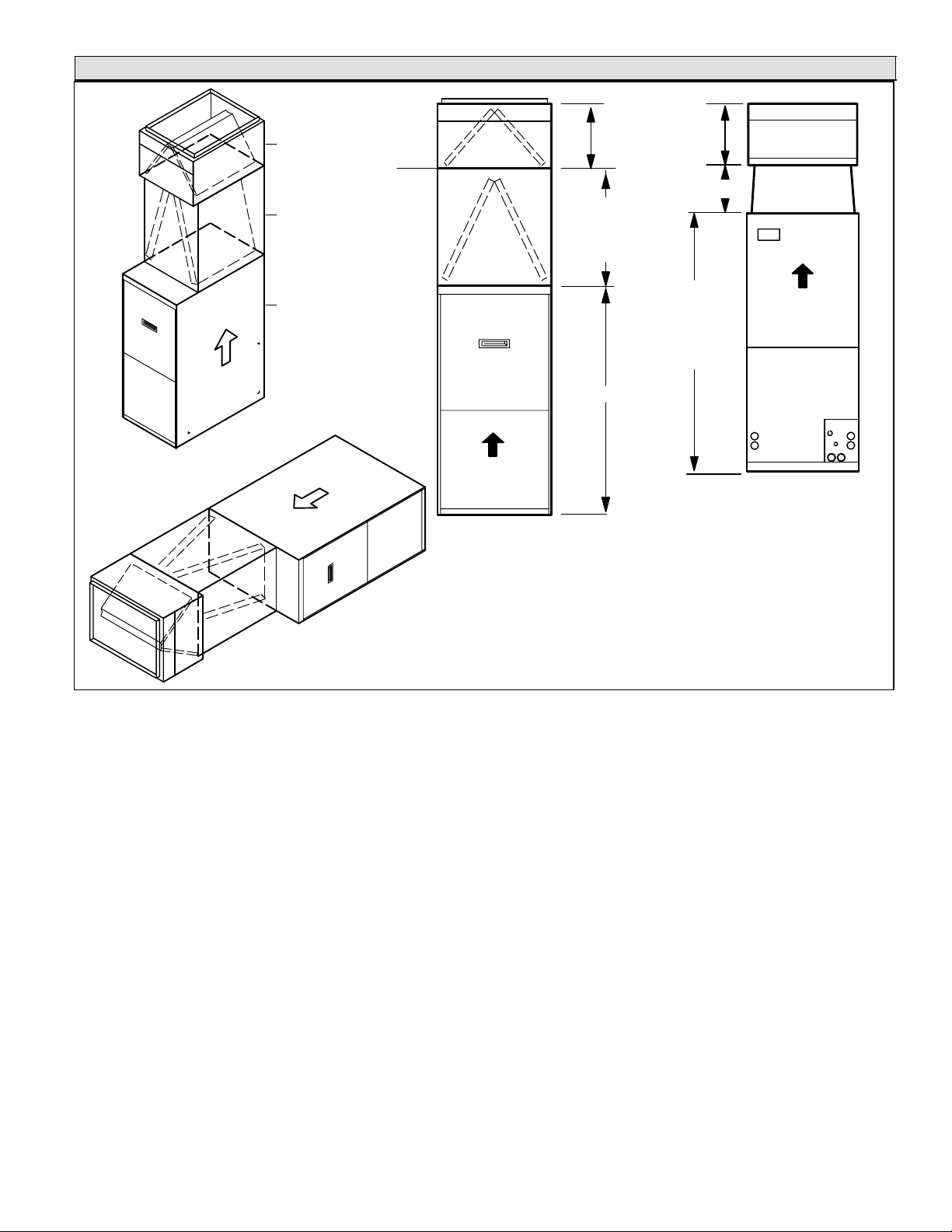

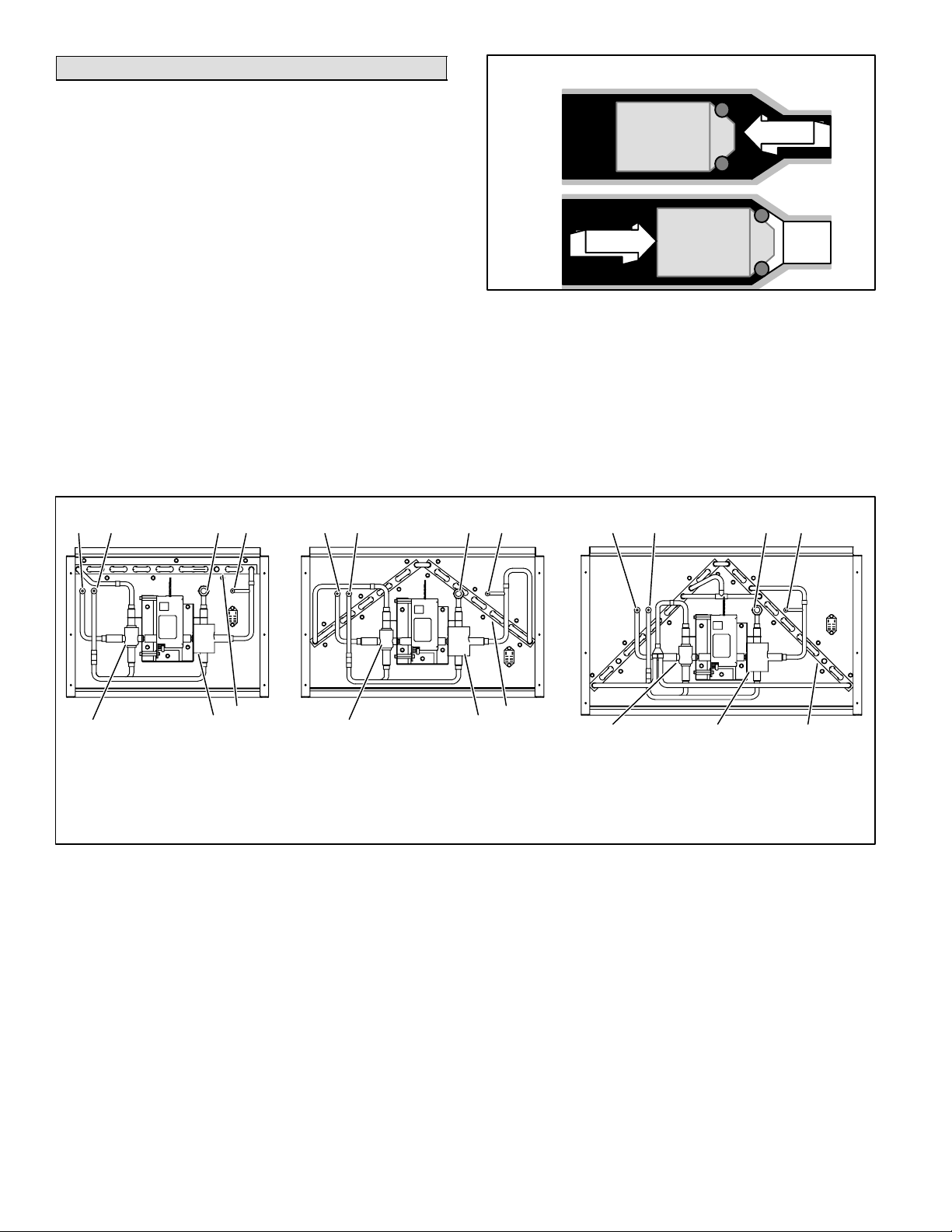

Check/Flow Restrictor Operation

Charge CompensatorThe charge compensator

(shown in figure 5) serves to maintain the proper amount of

refrigerant circulating in larger systems. [Some systems

do not require a charge compensator, but do require a simi-

FROM

VAPOR

LINE

TEE

CHECK/FLOW

RESTRICTOR FLOATS IN

CHATLEFF CONNECTOR

GREATER

PRESSURE

lar kit to connect into the system (see Engineering Handbook)]

The charge compensator stores excess refrigerant when

the EDA coil is active and returns it to the system during

FROM

VAPOR

LINE

TEE

GREATER

PRESSURE

O−RING SEALS

CHECK/FLOW

RESTRICTOR

normal cooling or heating operations. When the EDA coil is

active, less charge is required to obtain the proper amount

of subcooling because of the additional coil surface and

the cooler air which passes over the EDA coil.

Check/Flow RestrictorThe check function of the

check/flow restrictor (shown in figure 2) prevents refrigerant from flowing into the inactive components during times

when the EDA coil is inactive. The flow restrictor controls

the rate of return of charge to the system from the charge

compensator and the EDA coil when the system changes

from "EDA coil active" to "EDA coil inactive."

Valve AssemblyThe first valve of the diverting valve assembly (figure 3, E) directs the flow of refrigerant to either

bypass the EDA coil (EDA coil is inactive) or pass through

the EDA coil (EDA coil is active).The second valve (figure 3

F) directs the flow of refrigerant back to the liquid line when

the first valve (E) allows flow through the EDA coil. When

the EDA coil is inactive, the second valve (F) provides a

vent path to the suction line, draining the EDA coil and

charge compensator of liquid refrigerant.

Figure 2

EDA Unit Parts Arrangement

AB CD A B CD A B C D

EDA−024B

EDA−036C EDA−060D

EDA

UNIT

EDA

UNIT

EFEF

3−WAY DIVERTING VALVE ASSEMBLY

A − Liquid Line From Outdoor Unit

B − Liquid Line to Indoor TXV

C − Check/Flow Restrictor to Vapor

Line Tee

EDA COIL

3−WAY DIVERTING VALVE ASSEMBLY

D − To Charge Compensator side connection (1/4" line must be brazed closed on systems that do not

require the installation of a charge compensator)

E − EDA inactive mode − bypasses the EDA EDA active mode − allows refrigerant flow through EDA

F − EDA inactive mode − vent path to suction line; EDA active mode − directs refrigerant flow back to

liquid line

EDA COIL

3−WAY DIVERTING VALVE ASSEMBLY

Figure 3

EF

EDA COIL

EDA 01/06

Page 4

Page 5

General Installation Information

Releasing Air Charge

NOTE − EDA units use dry air as a holding charge.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause personal injury, loss

of life, or damage to property.

Installation and service must be performed by a

qualified installer or service agency.

The EDA unit may be used in upflow or horizontal discharge installations. Slots around the inlet end of the EDA

cabinet are provided to secure the EDA unit to the duct

flanges of indoor coil/air handler cabinets. Use field-provided #8 x 1" long SDST screw (usually 6 required).

CAUTION

Physical contact with metal edges and corners

while applying excessive force or rapid motion can

result in personal injury. Be aware of, and use

caution when working nearby these areas during

installation or while servicing this equipment.

Refrigeration

All EDA coils are shipped with a combination check/flow

restrictor. The restrictor is provided in the bag assem-

bly and must be installed. Refer to the appropriate high

and/or low side installation instructions for information on

the appropriate line sets. Refer to Lennox Refrigerant Piping guide (Corp. 9351−L9) for proper size, type, and application of field−fabricated lines.

CAUTION

The EDA coil is shipped from the factory pressurized with dry air. Pierce a hole in the coil’s rubber

plug vapor line seal to relieve the pressure before removing the seals.

Ensure that the coil is void of pressure. Remove the rubber

plug from the lines.

NOTE − If there is no pressure when the plugs are pierced,

check the unit for leaks before continuing with the installation.

Refrigerant Line Connections

NOTE − When connecting lines, be careful to avoid damaging the 3−way diverting valve access panel. Place a wet rag

against the piping plate and around the EDA unit line connections. A wet rag heat shield must be in place during

brazing to guard against damage to the paint.

Electrical Wiring

Electrical wiring diagrams are provided in figures 12 and 13

(see pages 14 and 15). Some modifications to certain units

may be necessary. Review the diagrams before installation to ensure all necessary components are on hand at

time of installation.

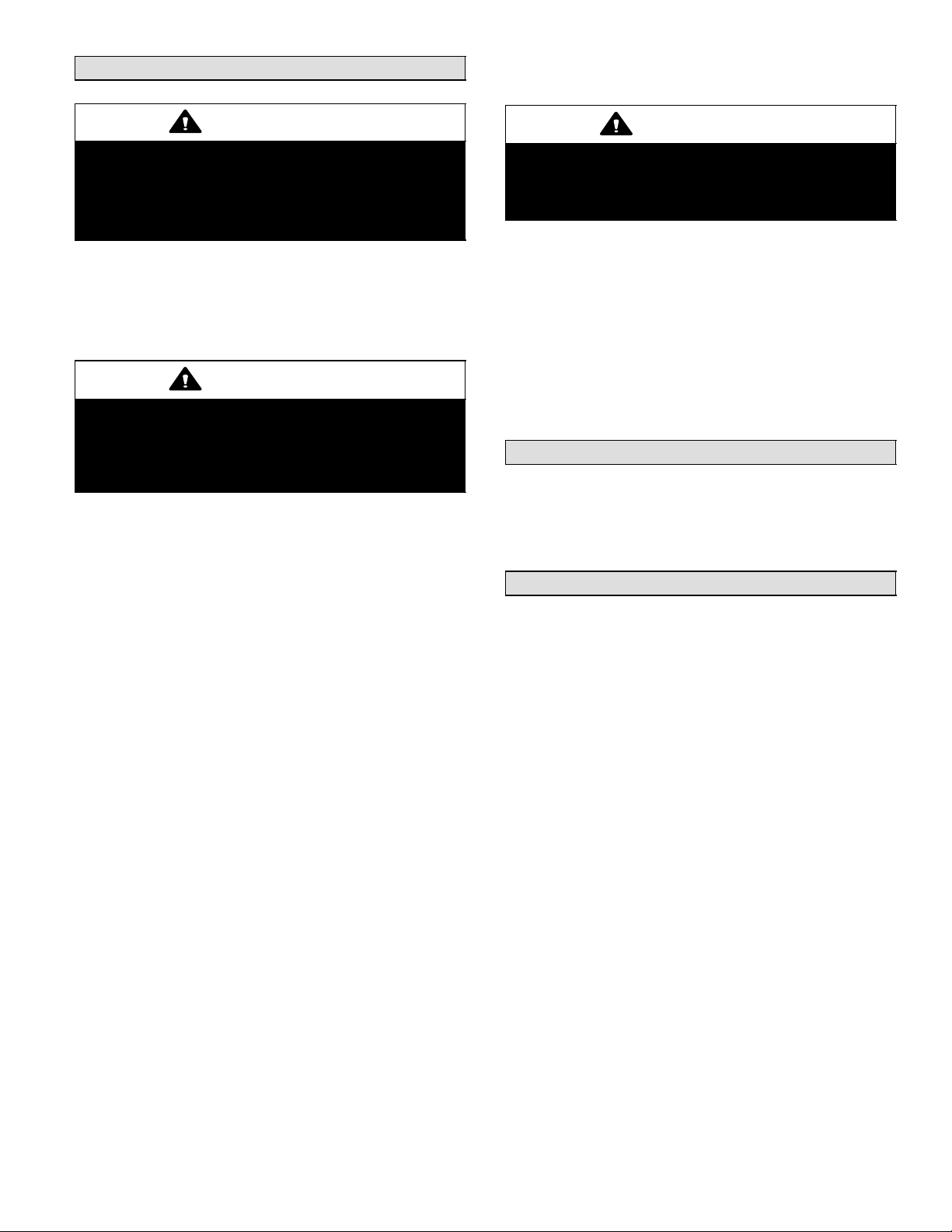

EDA Installation and Checkout Flow Chart

Follow the procedures in the flow chart in figure 4 while referring to the illustration in figure 5 to install the EDA: and

associated components.

Page 5

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 6

EDA Installation & Checkout Flow Chart

start

ARE

ALL REQUIRED

PARTS

AVAILABLE

?

YES

Installation Process

ENSURE ALL POWER IS OFF

INSTALL EDA UNIT IN DUCT

SYSTEM

INSTALL THE CHARGE

COMPENSATOR (IF REQUIRED)

IN CONVENIENT LOCATION

(SEE FIGURE 5)

NO

Required Parts (all applications)

EDA Unit, with check/flow restrictor & label

Appropriate SignatureStatt Thermostat

46M98 − Outdoor Sensor

84X49 − Twisted Pair Wire

Appropriate Insulation and Piping Kit

PROCURE

MISSING PARTS

MAKE WIRING CONNECTIONS

AS SHOWN IN FIGURES 12 & 13

(SEE PAGES 14 AND 15)

INSTALL EDA" LABEL ON

OUTDOOR UNIT

POWER UP THE INDOOR UNIT

Required Parts (2−Stage Heat Pump appl.)

12P61 − 75VA Transformer (for HP applications)

Check Dehumidification Operation

SET COOLING SETPOINT ON ROOM THERMOSTAT

TO 2 DEGREES ABOVE INDOOR TEMPERATURE

(OUTDOOR UNIT WILL TURN OFF)

NOTE − A Humiditrol® EDA−equipped system is allowed

to operate and cool room temperature below set point

(but only by 2ºF) when trying to satisfy a persisting humidity set point.

SET DEHUMIDIFICATION SETPOINT TO 5% BELOW

CURRENT ROOM RELATIVE HUMIDITY

MAKE ALL REFRIGERATION

CONNECTIONS, BEING SURE

TO INSTALL THE CHECK/FLOW

RESTRICTOR (SEE FIGURE 5)

LEAK CHECK THE SYSTEM

WITH 3−WAY VALVE ASSEMBLY

SET TO EVACUATE" (SEE

FIGURE 7)

INSULATE ALL REFRIGERANT

LINES

EVACUATE THE SYSTEM AS

DESCRIBED IN THE OUTDOOR

UNIT INSTALLATION

INSTRUCTIONS

INSTALL OUTDOOR SENSOR

CHECK THAT 3−WAY VALVE

ASSEMBLY IS SET TO

COOLING" POSITION AS

SHOWN IN FIGURE 7

ENABLE HUMIDITROL ON

ROOM THERMOSTAT (SEE

FIGURE 8)

SET THERMOSTAT FOR

MAXIMUM COOLING

OPEN REFRIGERANT VALVES

TURN OUTDOOR UNIT MAIN

POWER ON

CHECK CHARGE AND CHARGE

AS NEEDED (SEE PAGE 8)

DEHUMIDIFICATION

IS

THE

OUTDOOR

TEMPERATURE

BELOW

95ºF

?

YES

OUTDOOR UNIT:

COMPRESSOR IN HIGH STAGE;

FAN IN LOWEST SPEED;

EDA:

3−WAY VALVE ASSEMBLY TO DEHUMIDIFICATION"

POSITION

INDOOR UNIT:

FAN IN DEHUMIDIFICATION SPEED

CHECK THE TEMPERATURE DIFFERENCE

ACROSS THE EDA COIL AND THE LIQUID LINE

TEMPERATURES AS NOTED IN FIGURE 9 ON

PAGE 10

IS DE−ACTIVATED;

NO

OPERATION AT A

TEMPERATURE IS

CHECK FOR

CORRECT

TIME WHEN

AMBIENT

BELOW 95ºF.

EDA 01/06

Figure 4

Page 6

Page 7

Electrical Inlet

To Charge

Compensator side

connection (some

applications)

Check/Flow

Restrictor to Vapor

Line Tee

Liquid Line to

Indoor TXV

Liquid Line From

Outdoor Unit

EDA

Typical Installation (Horizontal Air Handler shown)

EDA UNIT

Check/Flow-

Restrictor

Details

FITTING IN

EDA UNIT

AIR

FLOW

IMPORTANT!

RESTRICTOR MUST BE INSERTED WITH O−RING

END OF RESTRICTOR TOWARD EDA UNIT FITTING.

TORQUE CHATLEFF CONNECTION TO 20 FT. LBS.

MUST BE INSULATED

Liquid

TXV

Line

INDOOR

UNIT

air−flow

Vapor

Line

TEFLON SEAL

1/4" PORT MUST

BE BRAZED

CLOSED

CHECK/FLOW

RESTRICTOR

AND O−RING

System without

compensator

NO CHARGE

COMPENSATOR

OR 1/4" LINE

Liquid Line from

Outdoor Unit

Liquid Line to

Indoor TXV

ELECTRICAL

INLET

LIQUID LINE FROM

OUTDOOR UNIT

6 ft. max.

BETWEEN CHARGE

COMPENSATOR AND EDA USING

1/4" LINE PROVIDED IN CHARGE

COMPENSATOR KIT

TYPICAL HORIZONTAL POSITION INSTALLATION

MUST BE

INSULATED

TO CHARGE

COMPENSATOR SIDE

CONNECTION

CHECK/FLOW

RESTRICTOR TO

VAPOR LINE TEE

LIQUID LINE

TO INDOOR

TXV

2 ft. max.

DROP TO CHARGE

COMPENSATOR

TO CHECK/FLOW

RESTRICTOR ON EDA

Compensator

USE REDUCER(S) FROM

CHARGE COMPENSATOR KIT

(WHEN REQUIRED)

VAPOR LINE

FROM

OUTDOOR

UNIT

7/8 X 7/8 X

1/4" TUBING

CONNECTION − MUST

BE AT LOWEST POINT

OF THE COMPENSATOR

Liquid

Line

Charge

Details

3/8 TEE

CHARGE

COMPENSATOR

Vapor

Line

VAPOR

LINE

FROM

INDOOR

COIL

OUTDOOR

UNIT

VAPOR LINE FROM

INDOOR COIL

1/4" TUBING

CONNECTION −

MUST BE ON

BOTTOM OF

COMPENSATOR

TO CHECK/FLOW

RESTRICTOR ON EDA

7/8 X 7/8 X

3/8 TEE

UPFLOW POSITION

CHARGE

COMPENSATOR

VAPOR LINE FROM

OUTDOOR UNIT

USE REDUCER(S)

FROM CHARGE

COMPENSATOR KIT

(WHEN REQUIRED)

USE REDUCER(S)

FROM CHARGE

COMPENSATOR KIT

(WHEN REQUIRED)

Figure 5

Page 7

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 8

Leak Testing, Evacuating, Charging

IMPORTANT

The 3−way diverting valve actuator shaft setscrew

(see figure 7) is factory set and is not to be adjusted.

3−way Diverting Valve Operation

NOTE − During system operation, the 3-way valve requires

24-volt power to drive between cooling and dehumidification.

The 3−way diverting valve is actually two valves connected

by a common shaft, designed to open one valve while closing the other, and vice versa. For evacuating (with power

off), the diverting valve can be REPOSITIONED using its

actuator lever, a long setscrew that has been factory-set to

a precise point on the common shaft. Do not loosen (unscrew) the setscrew. Should the setscrew become

loose, carefully follow the note in figure 6 to position

and tighten it.

Re−aligning Setscrew

NOTE − Actuator shaft setscrew is factory set and must not be adjusted. If the set screw should become loose, use a pliers to grip the

shaft where shown (1) and rotate the shaft (in direction of the black

arrow) until the pin stops (inset shows pin and stops). Press the red

button (2) in the direction of the white arrow and move the lever (3)

to the forward position and tighten setscrew to 60 in-lbs torque.

2

1

IMPORTANT

Prior to starting the outdoor unit for charging, be

sure the 3-way valve is energized and in the cooling" (forward) position (see figure 7).

3. Very little charge is required for the additional volume

of the EDA unit. When in normal cooling, the components will all be occupied by vapor that has very little

weight. At most (depending on the model) an additional 1/4 pound of refrigerant may be required.

4. When shifting from dehumidify mode to cooling, or

vice versa, wait at least 10 minutes for the system to

reach stable operating pressure before checking temperatures and pressures, or adjusting refrigerant

charge.

NOTE − Prior to starting the outdoor unit for charging,

set the thermostat to call for cooling (dehumidification

OFF). It will take about 90 seconds for the 3−way diverting valve to energize and shift to the cooling position. To ensure that the 3-way diverting valve is energized and in the cooling" (forward) position, observe

the position of the 3-way diverting valve actuator shaft

setscrew in figure 7; if properly shifted, the setscrew

will be in the forward position.

Setting 3−Way Diverting Valve to

Evacuate Position

1. PUSH RED TAB IN DIRECTION INDICATED.

2. PUSH ACTUATOR SHAFT DOWN TOWARD THE

CENTER−OF−TRAVEL POSITION

1

3

STOP

PIN

SHAFT

STOP

Figure 6

Leak Testing, Evacuating, Charging

1. Set the 3−way diverting valve actuator shaft to the center (evacuate) position for leak testing and evacuation

(see figure 7). IMPORTANT! The actuator shaft

must be set as described to allow the EDA to evacuate more quickly.

2. Refer to instructions provided with the outdoor unit for

leak testing, evacuating and charging procedures.

EDA 01/06

2

COOLING

(FORWARD)

EVACUATE

(CENTER)

DEHUMIDIFICATION

(REARWARD)

Figure 7

5. The charge must be checked with the system in cooling operation (dehumidification OFF). After testing

and charging as required, set the thermostat to force

a demand for dehumidification.

Page 8

Page 9

Insulating and Sealing the Unit

IMPORTANT

All piping, metering devices, and connections must

be insulated to prevent moisture damage caused by

sweating.

Seal the unit so that warm air is not allowed into the cabinet. This is especially important when the unit is installed in

an unconditioned area. Make sure the liquid line entry

points are sealed with either refrigerant tube insulating material or with Permagum (see figure 5 on page 7).

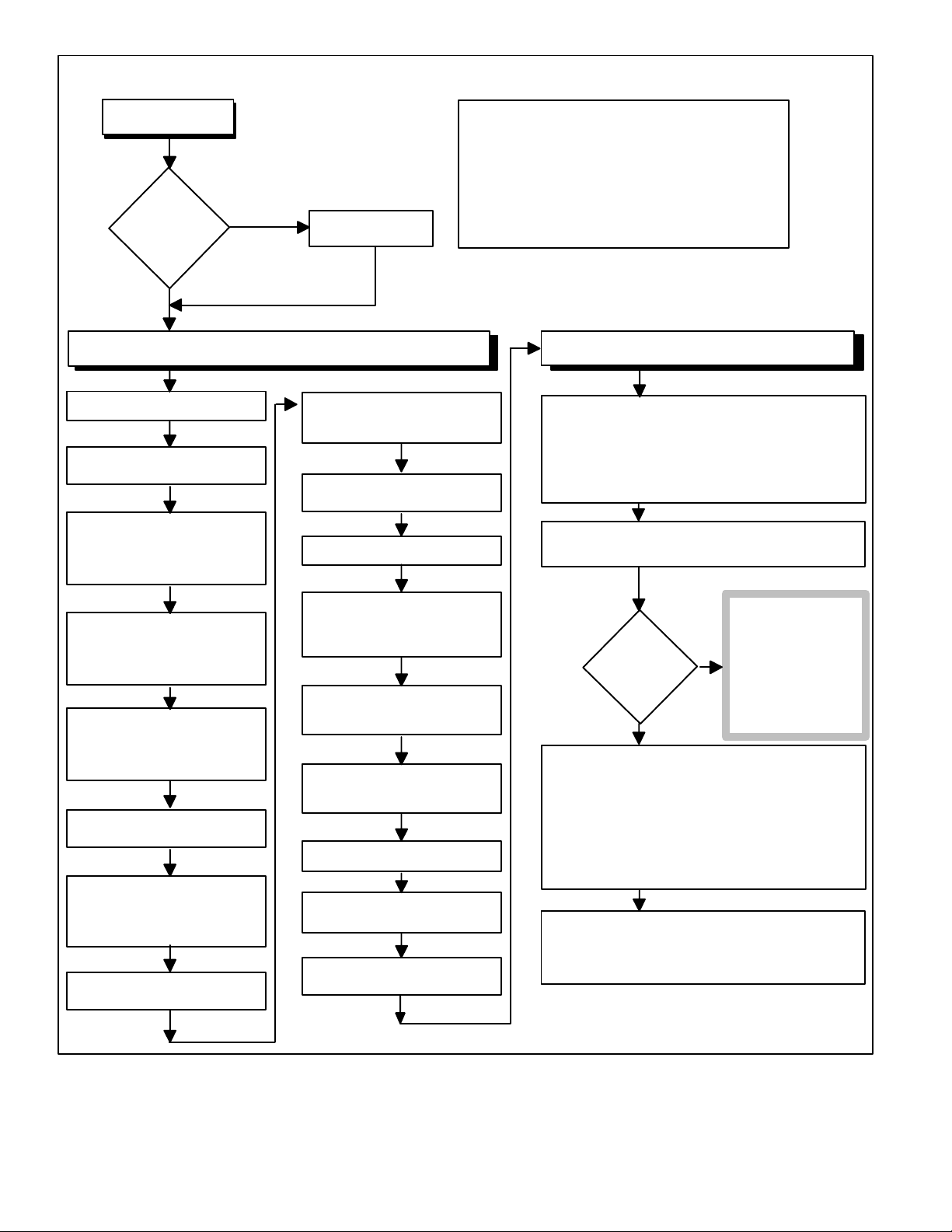

Then, select HUMIDITROL mode from the DEHUMIDIFY

menu (follow the path: MENU −> DEHUMIDIFY). The user

control sequence is also shown in figure 8, C through H;

specifically:

S Turn on Humiditrol − D & E

S Set level of dehumidification − F through H (adjustment

range is from 45% to 60% and is factory set to 50%)

If HUMIDITROL is enabled and the outdoor sensor is disconnected, operation is NOT allowed in dehumidification

mode. This is indicated by the display of "OUTSIDE ERR"

on the SignatureStatt thermostat Home screen.

Other System Components

Blower Control

EDA units are to be applied with an indoor unit that has a

variable speed motor (VSM). Refer to the indoor unit installation instruction for setting blower speed.

Thermostat and Sensor

IMPORTANT

A SignatureStatt thermostat and properly-

connected outdoor sensor is REQUIRED for the

EDA unit to function properly. Twisted pair wire

(84X49 or equivalent) is REQUIRED between the

SignatureStat and the outdoor sensor.

Install the remote sensor on the outside of a northern wall

of the home, away from direct sunlight or other heat

sources that may affect its sensitivity.

Refer to the SignatureStatt thermostat Installation

Instructions for installation, wiring, and setup. Also refer to

the SignatureStatt Thermostat Programming Guide for

programming and settings.

To configure the thermostat for operation with a Humidi-

®

trol

system, first enable HUMIDITROL in the thermostat’s

installer settings (follow the path: MENU −> INSTALLER

SETTINGS −> HUMIDITROL − see figure 8, A and B).

Setting Thermostat

Installer Setup

INSTALLER SETTINGS Y

AUTO CHANGEOVER ON

EER ON

DEADBAND 4.0°F

HUMIDITROL OFF

MAIN MENU SELECT B

AB

User Controls

MAIN MENU

PROGRAM

HEAT / COOL

HUMIDIFY ↓

DEHUMIDIFY

HOME SELECT

CD

DEHUMIDIFY MODE

OFF

HUMIDITROL

DEHUM MENU SELECT

EF

DEHUMIDIFY

CONTROL

%

50

DEHUM MENU SELECT

↑

↓

GH

Figure 8

HUMIDITROL

DISABLE

ENABLE

INSTALL MENU SELECT

DEHUMIDIFY MENU

MODE OFF

DEHUMIDIFY 50%

MAIN MENU SELECT

DEHUMIDIFY MENU

MODE HUMIDITROL

DEHUMIDIFY 50%

MAIN MENU SELECT

DEHUMIDIFY MENU

MODE HUMIDITROL

DEHUMIDIFY 55%

MAIN MENU SELECT

Page 9

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 10

EDA Unit Operation

The EDA coil is added to an HVAC system downstream of

the indoor coil. In dehumidification mode, the coil becomes

an extension of the condenser coil and injects heat into the

indoor air stream.

This dehumidification mode allows significantly improved

control of the humidity in the conditioned space without

overcooling the space. The assembly includes a set of

3−way diverting valves which will either route refrigerant

through the EDA coil, or cause the refrigerant to bypass

the EDA coil, depending on the mode of operation.

Operation Notes

1. IMPORTANT REMINDER! Dehumidification will not

occur when the outside temperature is at or above

95ºF.

2. When operating in cooling (or heat pump heating)

mode, all temperatures and pressures will be as in a

normal system.

3. When the thermostat is in HUMIDITROL mode, and

after a cooling demand has been satisfied but a dehumidification demand persists and the room temperature is not more than 2°F below the setpoint, the air

handlers will operate at reduced airflow with the compressor at high speed.

4. When the unit is in the dehumidification

mode, the display will show a raindrop"

icon with an imbedded negative sign and

the current relative humidity to its right.

Cooling Mode (Dehumidification ON)

If the room thermostat’s cooling demand has been satisfied but the dehumidification setting has not been satisfied,

the unit continues to run in dehumidification mode. The

room thermostat sends a signal to the EDA unit’s 3−way diverting valve assembly to begin operating in the dehumidification mode.

Figure 9 shows refrigerant flowing from the outdoor unit,

entering the EDA, passing through the first 3−way diverting

valve, then entering the EDA coil. There, heat from the

warm refrigerant is transferred into the indoor air stream.

The refrigerant exits the coil through the second 3−way diverting valve and into the indoor coil expansion valve.

During dehumidification, the indoor air blower (and outdoor

fan, if an outdoor relay is used) operates at a lower air volume. The cool, dehumidified air leaving the indoor coil is

warmed as it passes over the EDA coil. Air temperature

rise across the EDA coil can be from 10° to 25°F, depending on the operating ambient and air-conditioned space

conditions.

The warm vapor−liquid−refrigerant mixture entering the

EDA unit from the outdoor unit will be subcooled in the EDA

unit and enter the expansion valve at a lower-than-normal

temperature. Liquid temperatures can be in the 65° to 70°F

range, with a 10° to 40°F temperature change across the

EDA.

OUTDOOR UNIT

Cooling Cycle with EDA Coil Active (Model EDA−036C shown)

VAPOR

LINE VALVE

LIQUID

LINE

VALV E

7/8 x 7/8 x

3/8 TEE

CHECK/FLOW

RESTRICTOR

(flow permitted)

See note 2 See note 2

NOTE 1. With EDA Coil Active, expect a 10 to 25ºF air temperature rise across EDA coils.

NOTE 2. With EDA Coil Active, expect a 10 to 40ºF liquid line temperature change across EDA coils.

NOTE 3. Charge compensator and 1/4" line not required on all systems. See Engineering Handbook.

CHARGE COMPENSATOR

(holding some refrigerant)

See note 3.

3−WAY

DIVERTING

VALV E

See note 1See note 1

CHECK/

EXPANSION

VALV E

Figure 9

air flow

INDOOR COIL

INDOOR

BLOWER

INDOOR

UNIT

EDA 01/06

Page 10

Page 11

Cooling Mode (Dehumidification OFF)

Figure 10 illustrates refrigerant flow in cooling mode (dehumidification mode OFF),

Cooling Cycle with EDA Coil Inactive (Model EDA−036C shown)

The liquid refrigerant from the outdoor unit enters the EDA

module . Since there is no demand for dehumidification,

the 3−way diverting valve assembly directs the flow back

out of the EDA module to the indoor unit expansion valve.

VAPOR

LINE VALVE

LIQUID

LINE

VALV E

OUTDOOR UNIT INDOOR UNIT

NOTE 1. In Cooling Mode, no air temperature change across EDA coils.

NOTE 2. In Cooling Mode, no liquid line temperature change across EDA coils.

NOTE 3. Charge compensator and 1/4" line not required on all systems. See Engineering Handbook.

7/8 x 7/8 x

3/8 TEE

CHECK/FLOW

RESTRICTOR

(flow restricted)

See note 2 See note 2

CHARGE COMPENSATOR

(NOT holding refrigerant)

See note 3.

3−WAY

DIVERTING

VALV E

See note 1See note 1

EXPANSION

air flow

CHECK/

VALV E

Figure 10

Heating Mode (Heat Pump Applications)

Figure 11 illustrates refrigerant flow in the heating mode.

In heat pump application heating mode, a system that includes an EDA unit will operate as a conventional heat

pump. The EDA unit does not operate in this mode.

INDOOR COIL

INDOOR

BLOWER

Heat Pump Heating Cycle with EDA Coil Inactive (Model EDA−036C shown)

OUTDOOR UNIT

VAPOR

LINE VALVE

LIQUID

LINE

VALV E

NOTE 1. In Heating Mode, no air temperature change across EDA coils.

NOTE 2. In Heating Mode, no liquid line temperature change across EDA coils.

NOTE 3. Charge compensator and 1/4" line not required on all systems. See Engineering Handbook.

7/8 x 7/8 x

3/8 TEE

CHECK/FLOW

RESTRICTOR

(flow restricted)

See note 2 See note 2

CHARGE COMPENSATOR

See note 3.

See note 1See note 1

CHECK/

EXPANSION

VALV E

Figure 11

air flow

INDOOR COIL

INDOOR

BLOWER

INDOOR UNIT

Page 11

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 12

Check List

instructions; also, see figure 5)

p

gp

(but only by 2F) when try

n Checkpoint What to Check Action

Thermostat and

Sensor

Thermostat Humiditrol® Installer Settings Confirm HUMIDITROL is enabled (see figure 8)

Thermostat Humiditrol® User Settings Confirm HUMIDITROL − Dehumidify − ON is selected (see figure 8)

Thermostat Humiditrol® User Settings Confirm Relative Humidity setting (see figure 8)

Indoor Unit Variable-Speed Blower Settings Confirm Settings for D": CFM = 60% to 65% of 2nd-stage cool

Insulation Charge Compensator

Insulation Liquid Line

Insulation Vent Line to Suction Line

Charge Compensator

Check/Flow Restrictor

System Charge Refrigerant With unit running in cooling mode, check and confirm system is

Outdoor Unit Fan Relay Confirm (if unit has variable speed outdoor fan) relay is installed

Outdoor Unit EDA Label Confirm label is installed in prominent location and will be easily

NOTE − System will NOT operate in dehumidification mode with outdoor temperature at or above 95ºF.

Operational Status Dehumidification Mode Record supply air temperature and confirm temperature that it is

Operational Status Dehumidification Mode On units with variable speed outdoor fan, check that fan operates

Wiring Confirm Sensor connected to SignatureStatt using twisted pair

wire (see wiring diagram figure 13)

(see indoor unit installation instructions and table 1, below)

Confirm insulation is properly installed (see charge compensator kit

1/4"Line Confirm 1/4" port oriented downward (see charge compensator

details, figure 5)

3/8" Line Confirm restrictor installed/oriented properly (see check/flow restric-

tor details figure 5)

properly charged (see outdoor unit installation instructions).

properly (see wiring diagram figures 12 and 13)

visible during servicing.

higher than in cooling mode.

at approximately 250 rpm (lowest speed).

Table 1

®

Demand Signals − Humiditrol

Operating Sequence System Demand System Response

Thermostat Demand Relative Humidity

System Type Step

Cooling Operation − No call for dehumidification

Single-stage outdoor unit 1 ON (na) ON ON Acceptable 24 VAC High 100

Two-stage outdoor unit Y1 1 ON − ON ON Acceptable 24 VAC Low 70

Two-stage outdoor unit Y2 2 ON ON ON ON Acceptable 24 VAC High 100

Demand for Dehumidification and Cooling

Single-stage outdoor unit 1 ON (na) ON ON Demand 24 VAC High 100

Two-stage outdoor unit Y1 1 ON − ON ON Demand 24 VAC Low 70

Two-stage outdoor unit Y2 2 ON ON ON ON Demand 24 VAC High 100

Dehumidification Mode Only − No Cooling Demand

Single-stage outdoor unit 1 ON (na) ON ON Demand 0 VAC High 50 − 70*

Two-stage outdoor unit Y2 2 ON ON ON ON Demand 0 VAC High 50 − 70*

* NOTE − Blower CFM speed (percentage) will vary depending on selected indoor equipment (furnace, coil blower, etc.).

Y1 Y2 O G Status D

EDA Enabled

Com-

pressor

Blower

CFM

(Cool) %

Comments

Compressor and indoor

blower follow thermostat

demand

Cooling operation has

priority

A Humiditrol® EDA−

equipped system is allowed

to operate and cool room

temperature below set point

(but only by 2ºF) when trying to satisfy a persisting

humidity set point; it is not

allowed to operate at all

when outdoor temperature

is >95ºF.

EDA 01/06

Page 12

Page 13

Air Resistance

Si

(twisted

3

Table 2 shows air volume and total air resistance for the

available EDA models.

Table 2

Air Resistance

Air Volume Total Air Resistance

Model No.

EDA−024B

EDA−036C

EDA−060DB

cfm L/s in. w.g. Pa

400 190 0.05 12

600 285 0.10 25

800 380 0.15 37

1000 470 0.22 55

600 285 0.05 12

800 380 0.08 20

1000 470 0.11 27

1200 565 0.15 37

1400 660 0.20 50

1000 470 0.05 12

1200 565 0.06 15

1400 660 0.08 20

1600 755 0.10 25

1800 850 0.11 27

2000 945 0.13 32

2200 1040 0.15 37

Repair Parts

S 3−way diverting valve assembly

S Check/flow restrictor

S EDA Relay

S Outdoor unit relay

S Teflon seals

Wiring Diagrams

Typical condensing unit and heat pump wiring diagrams

are provided in figures 12 and 13. Some modifications to

certain units may be necessary.

Connect the EDA unit with the indoor and outdoor units,

and to the thermostat. Be sure the outdoor sensor is

installed and connected to the SignatureStatt thermostat’s outdoor sensor terminal block. Table 3 shows the requirements for control wiring.

Table 3

Control Wiring Requirements

Units: (all) (with LSOM) (without LSOM)

Indoor unit to:

SignatureStatt

10* 8 9* 7

Out-

Signatu-

door

reStatt

unit

9* 6 8* 4

8* 5 7* 3

9* 7 8* 6

Outdoor

unit

System

type

2 stage

AC

1 stage

AC

2 stage

HP

1 stage

HP

gnatureStatt to

Sensor

pair)

Humiditrol®

EDA

2

*Includes conductor for 2−stage heat

Page 13

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 14

1st, cut yellow

wire here.

Typical EDA/Condensing Unit Wiring Diagram

*OUTDOOR RELAY

NOT REQUIRED WITH SINGLE-

SPEED OUTDOOR FAN

2nd, rewire yellow

wire as shown

Blue

B4

Yellow

FAN

Black

2

75

Yellow

Yellow

Use Wirenuts

Purple

K1

Black

Black

BLACK

BLACK

RED

YELLOW

BLUE

BLACK

BROWN

Purple

PURPLE

RED

5

1

INDOOR

UNIT

3

Orange

EDA

Red

Violet

VALV E

ACTUATOR

SEE CONTROL WIRING BELOW

FOR THERMOSTAT WIRING

DSY1 JUMPER − MUST BE

REMOVED FOR HUMIDITROL

OPERATION

Y1Y2 JUMPER − ONLY

REMOVE IF 2−STAGE COOLING

OUTDOOR

UNIT

FAN RELAY (NOT REQUIRED

WITH SINGLE-SPEED

OUTDOOR FAN)

RED (NOT REQUIRED FOR

APPLICATIONS WITHOUT LSOM)

PURPLE

BLACK

YELLOW

BLUE (NOT REQUIRED FOR SINGLE STAGE)

BLACK

BROWN (NOT REQUIRED FOR

APPLICATIONS WITHOUT LSOM)

OUTDOOR WIRING

(VSM APPLICATION

ONLY)

EDA

UNIT

Control Wiring

RED

BLACK

PURPLE

Figure 12

INDOOR

UNIT

SignatureStatt

THERMOSTAT

TWISTED PAIR

Y1Y2 JUMPER − IN FOR

SINGLE− STAGE COOLING;

REMOVED FOR 2−STAGE

COOLING

OUTDOOR

SENSOR

(46M98)

EDA 01/06

Page 14

Page 15

Typical EDA/Heat Pump Wiring Diagram

*OUTDOOR RELAY

NOT REQUIRED WITH SINGLE-

SPEED OUTDOOR FAN

2nd, rewire

yellow wire

as shown

1st, cut

yellow wire

here.

OUTDOOR

WIRING

(VSM

APPLICATION

ONLY)

B4

FAN

Blue

Yellow

Black

Use Wirenuts

Yellow

2

75

Yellow

Purple

K1

Black

Black

BLACK

BLACK

Purple

PURPLE

RED

5

1

BLUE

BROWN

BLUE

3

Orange

EDA

Violet

INDOOR

UNIT

VALV E

ACTUATOR

DSY1 JUMPER − MUST BE

REMOVED FOR HUMIDITROL

OPERATION

SEE CONTROL WIRING BELOW

FOR THERMOSTAT

WONNECTIONS

RO JUMPER − MUST BE

REMOVED FOR HEAT PUMP

APPLICATION

Y1Y2 JUMPER − ONLY

REMOVE IF 2−STAGE COOLING

OUTDOOR

UNIT

RED

FAN RELAY (NOT REQUIRED

WITH SINGLE-SPEED

OUTDOOR FAN)

PURPLE

BLACK

YELLOW

BLUE

BROWN (NOT REQUIRED FOR APPLICATIONS WITHOUT LSOM)

BLUE (NOT REQUIRED FOR SINGLE STAGE)

EDA

UNIT

Control Wiring

Figure 13

RED

BLACK

PURPLE

INDOOR

UNIT

SignatureStatt

THERMOSTAT

OUTDOOR

SENSOR

TWISTED PAIR

Y1Y2 JUMPER − IN FOR

SINGLE− STAGE COOLING;

REMOVED FOR 2−STAGE

COOLING

(46M98)

Page 15

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Page 16

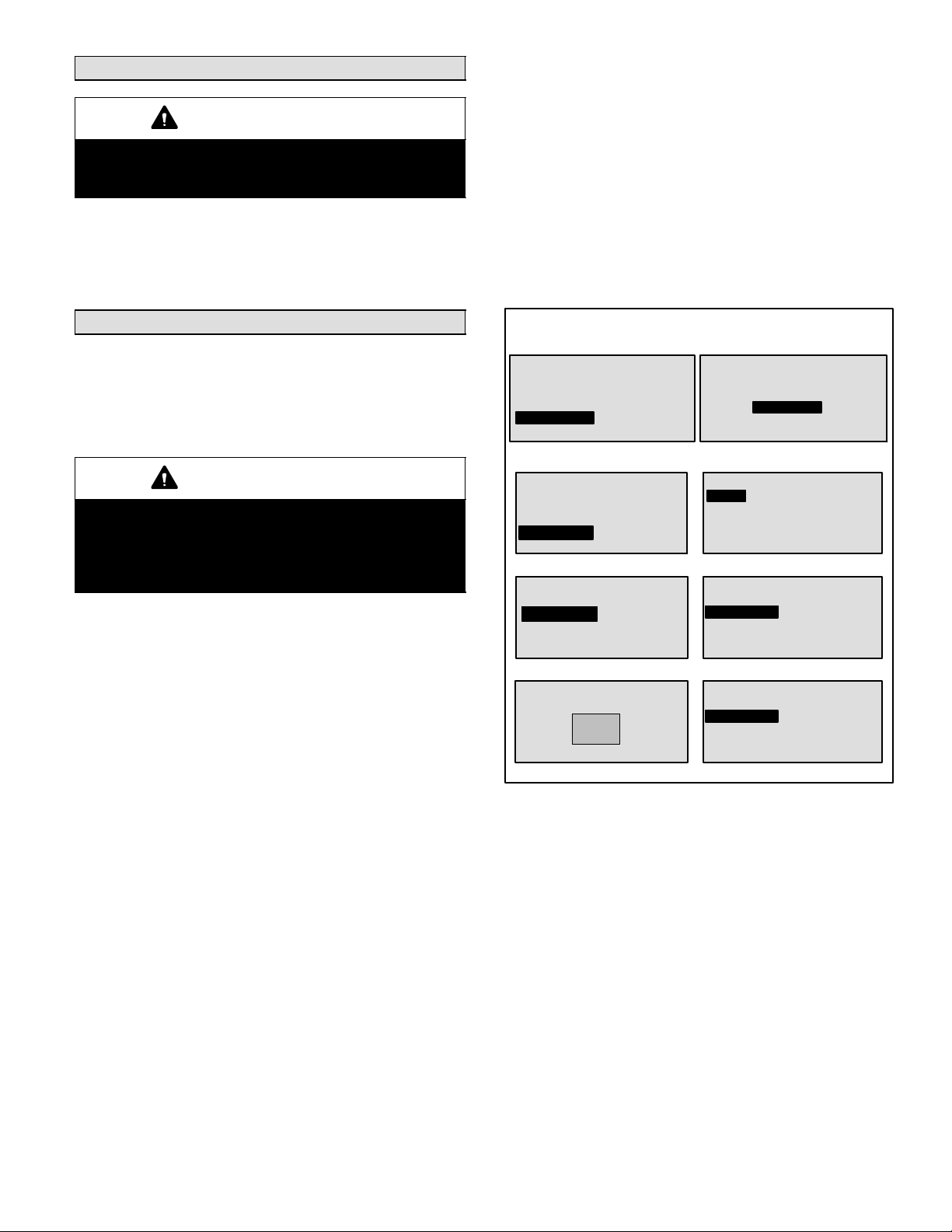

START

Is

dealer

R−410A & EDA

trained

?

YES

Zoning

application?

YES

Humiditrol

NO

NO

Obtain R−410A &

EDA training

matchup listed in

EDA Engineering

®

Enhanced Dehumidification Accessory (EDA)

Desired

equipment

Handbook?

YES

Decision Tree

Must use one of

NO

Must use one of

these outdoor units:

XC21, XP19, XC13, XP13

ONLY!

these variable

speed indoor

units:

CBX32MV, CBWMV,

G60UHV, G60DFV,

G61MPV ONLY!

Must be valid ARI rated match (refer to outdoor unit Engineering Handbook)

[If furnace]

Select indoor

coil

MUST BE TXV ONLY

Application

Not Approved

DO NOT

INSTALL

NOTE − Lennox warranties do

not cover damage or defect

resulting from operation with

system components (indoor unit,

outdoor unit, and refrigerant

control devices) which do not

match or meet the specifications

recommended by Lennox. This

unit intended to operate with

variable speed air handlers − see

Lennox Engineering Handbook

for approved matches.

Upflow/horizontal

NOTE − AIR HANDLER REQUIRES

FIELD−FABRICATED TRANSITION

BETWEEN BLOWER OUTLET

AND EDA COIL.

(REFER TO EDA ENGINEERING HANDBOOK)

X = PREFERRED MATCH−UP

A = ALLOWED FOR PHYSICAL MATCH−UP TO EVAPORATOR

CAPACITY −024B −036C −060D

−018 X A

−024 X A

−030 X A

−036 X A

−042 X

−048 X

−060 X

HUMIDITROL® EDA

94M41 94M42 94M43

Select Piping Kit

(REFER TO EDA ENGINEERING HANDBOOK AND

INSULATION & PIPING KIT INSTRUCTIONS 505,021M)

CAPACITY OUTDOOR UNIT MODEL PIPING KIT

Select EDA

−018 XC13 98M62

−024 XC13 98M62

−030 XC13, XP13 98M22

−036 XC13 98M22

−042 XC13 98M22

−048 XC13 98M22

−060 XC13 98M22

Upflow/

Horizontal

XP13 94M44

XP13, XP19, XC21 94M44

XP13, XP19, XC21 94M44

XP13 94M44

XP13, XP19, XC21 94M44

XP13, XP19, XC21 94M44

How

installed

?

Downflow

NOTE − REQUIRES ADDITIONAL

FIELD−FABRICATED SUPPORT

FRAME & TRANSITION; SEE

INSTALLATION SUPPLEMENT

505,134M

Downflow

EDA 01/06

INSTALL

SYSTEM

Figure 14

Page 16

Loading...

Loading...