Page 1

INSTALLAT I STRUCTIO

Gas

(2,4)PG E/SG(13/15)

Heatin ectric Coolin

SAFETY ................................................. 2

INSTALLATION ....................................... 2

START-UP ............................................ 10

OPERATION ........................................ 11

MAINTENANCE ................................... 13

Series

Package Unit

TABLE OF CONTENTS

CONTROL SYSTEM DIAGNOSTICS .. 14

WIRING DIAGRAMS ............................ 15

Manufactured By

A.A.C.

A Lennox International Inc. Company

421 Monroe Street

Bellevue, OH 44811

6AS-HREB

II!il!iilIIIllUI!11II o

I A CAUTION1

The installation of the furnace, wiring, warm air ducts, venting, etc. must conform to the requirements of the

National Fire Protection Association; the National Fuel Gas Code, ANSI Z223.1 (latest edition) and the

National Electrical Code, ANSl/NFPA No. 70 (latest edition) in the United States; the Canadian Installation

Codes CAN/CGA-B149.1 & .2 (latest edition) and the Canadian Electrical Code Part 1, CSA 22.1 (latest

edition) in Canada; and any state or provincial laws, local ordinances, or local gas utility requirements. Local

authorities having jurisdiction should be consulted before installation is made. Such applicable regulations

or requirements take precedence over the general instructions in this manual.

# 48111B005 Save these instructionsfor future reference Page 1

Page 2

SAFETY INSTALLATION

The following is a list of safety rules and precautions that

must be followed when installing this furnace.

1. Use only with the type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specified in the Location section on page 3 of these

instructions.

3. Adequate clearance must be provided around the vent

hood as specified in the Clearances section on page 4

of these instructions.

4.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifi-

cally for the detection of leaks to check all connec-

tions, as specified in Gas Supply and Piping

beginning on page 6 of these instructions.

Always install furnace to operate within the furnace's

intended temperature-rise range with a duct system

which has an external static pressure within the allowable

range, as specified in Temperature Rise on page 11 of

these instructions. See furnace rating plate.

These instructions must be hung on or near the

furnace in a conspicuous place.

These units are single package air conditioners with gas

heat designed for outdoor installation on a rooftop or a slab.

The units are completely assembled. All piping, refrigerant

charge, and electrical wiring are factory installed and

tested. The units require only electric power, gas piping,

condensate drain, and duct connections, plus assembly of

the heating vent hood at the point of installation.

If components are to be added to a unit to meet local

codes, they are to be installed at the dealer's and/or

customer's expense.

The size of unit for the proposed installation should be based

on heat loss/heat gain calculation made according to the

methods of Air Conditioning Contractors of America (ACCA).

These installation instructions are intended as a

general guide only, for use by an experienced, quali-

fied contractor.

These units are listed by UL:

6.

The furnace is not recommended for use for temporary

heating of buildings or structures under construction

unless certain installationand operating conditions are

adhered to, as specified in the Location section on

page 3 of these instructions.

• For use as a forced air furnace with cooling unit.

For outdoor installation only.

For installation on combustible material.

For use with natural gas or propane gas.

(Conversion kit required for propane gas application.)

These units are not suitable for use with conventional

venting systems.

IMPORTANT: This product has been designed and manu-

factured to meet ENERGY STAR criteria for energy effi-

ciency. However, proper refrigerant charge and proper air

flow are critical to achieve rated capacity and efficiency.

Installation of this product should follow the manufacturer's

refrigerant charging and airflow instructions. Failure to

confirm proper charge and airflow may reduce energy

efficiency and shorten equipment life.

inspection

As soon as the unit is received, it should be inspected for

possible damage during transit. Ifdamage is evident, the

extent of the damage should be noted on the carrier's

freight bill. A separate request for inspection by the

carrier's agent should be made in writing.

Page 2 # 48111 B005

Page 3

Location • Air filters must be replaced upon construction completion.

Use the following guidelines to select a suitable location

for the unit.

1. Unit is designed for outdoor installation only. Unit must

be installed so all electrical components are protected

from water.

2. Condenser coils must have an unlimited supply of air.

3. For ground level installation, use a level prefabricated

pad or use a level concrete slab. Do not tie the slab to

the building foundation.

4. Maintain level within a tolerance of 1/4" maximum

across the entire length or width of the unit.

5. Do not locate the unit where the combustion air supply

will be exposed to any of the following substances:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine-based swimming pool chemicals

Water softening chemicals

Deicing salts or chemicals

Carbon tetrachloride

Halogen-type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

Chlorinated laundry products

Hydrochloric acid

The input rate and temperature rise must be set per

the unit rating plate.

100% outdoor air must be provided for combustion air

requirements during construction, installation of this unit

in its intended outdoor location will accomplish this.

The heat exchanger, components, duct system, air

filter(s), and evaporator coil must be thoroughly

cleaned following final construction cleanup.

Following the final cleaning, all furnace operating

conditions (including ignition, input rate, temperature

rise, and venting) must be verified according to these

instructions.

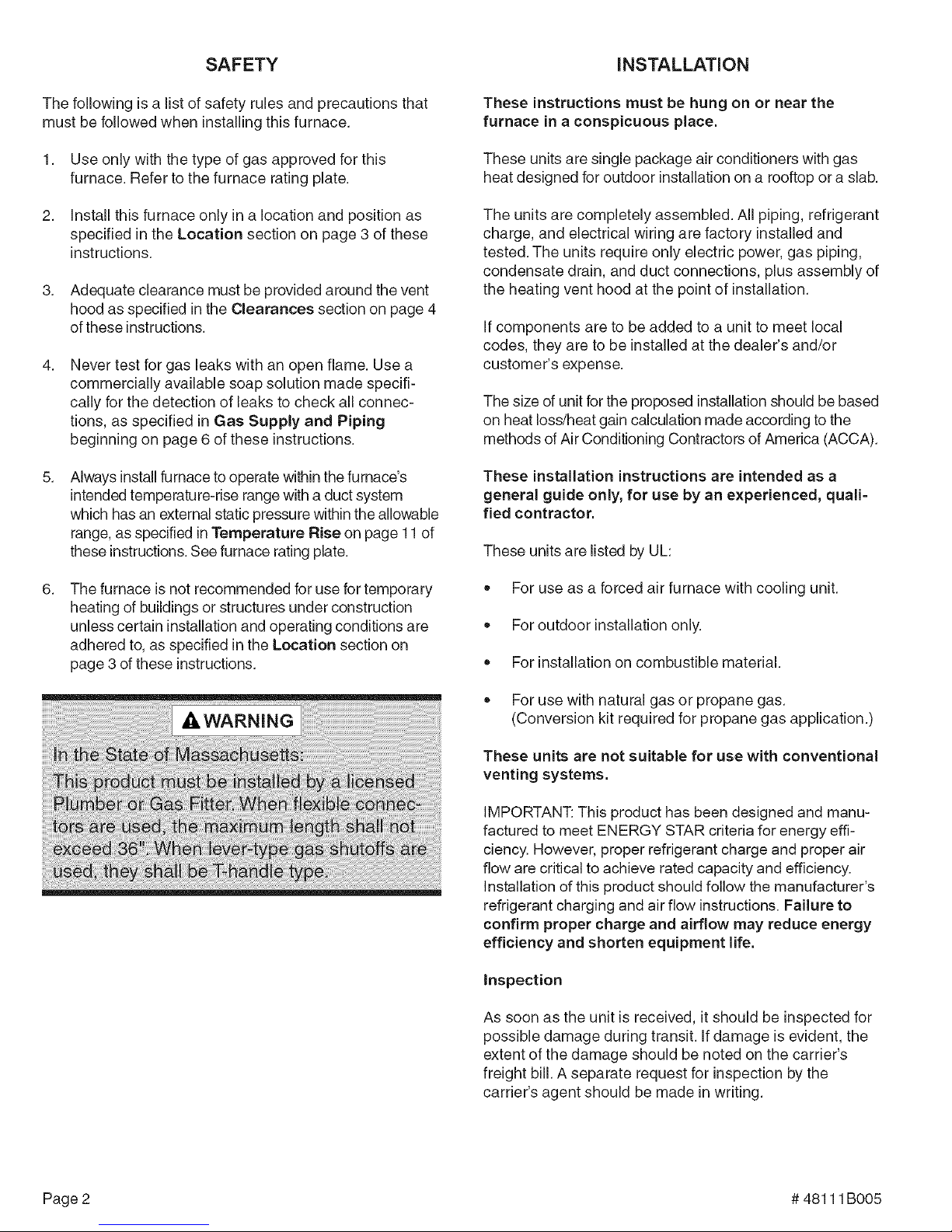

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. An

accessory lift kit can be purchased to aid in rigging (see

Figure 1). Spreaders whose length exceed the largest

dimension across the unit must be used across the top

of the unit. Recommended spreader length: 3 ton and

smaller package units- 44", 3.5 ton and larger units - 54".

Units may also be moved or lifted with a forklift while still in

the factory-supplied packaging. The lengths of the forks

of the forklift must be a minimum of 42".

Use of unit as a construction heater during any phase of

construction is not recommended. Very low return air

temperatures, harmful vapors, and operation of the unit

with clogged or misplaced filters will damage the unit.

However, if the installation and operating conditions

specified below are followed, use of this unit for heating of

buildings or structures under construction is permissible:

The vent hood must be installed per these installation

instructions.

A room thermostat must control the furnace. The use

of fixed jumpers that will provide continuous heating is

not allowed.

The return air duct must be provided and sealed to

the unit.

Return air temperature must be maintained between

60°F (16°0) and 80°F (27°0).

Air filters must be installed in the system and must be

maintained during construction.

# 48111 BOO5 Page 3

Using Accessory Lift Kit

Spreaders

(Field Supplied)

To avoid possible

damage to unit

panels from lifting

clevis, place

packing material

between clevis

and panels before

lifting unit.

Figure 1

Page 4

Roof Curb Installation

If a roof curb is used, follow the manufacturer's installation

instructions and be sure that all required clearances are

observed (see following Clearances section).

Roof Curb Assembly

Figure 2

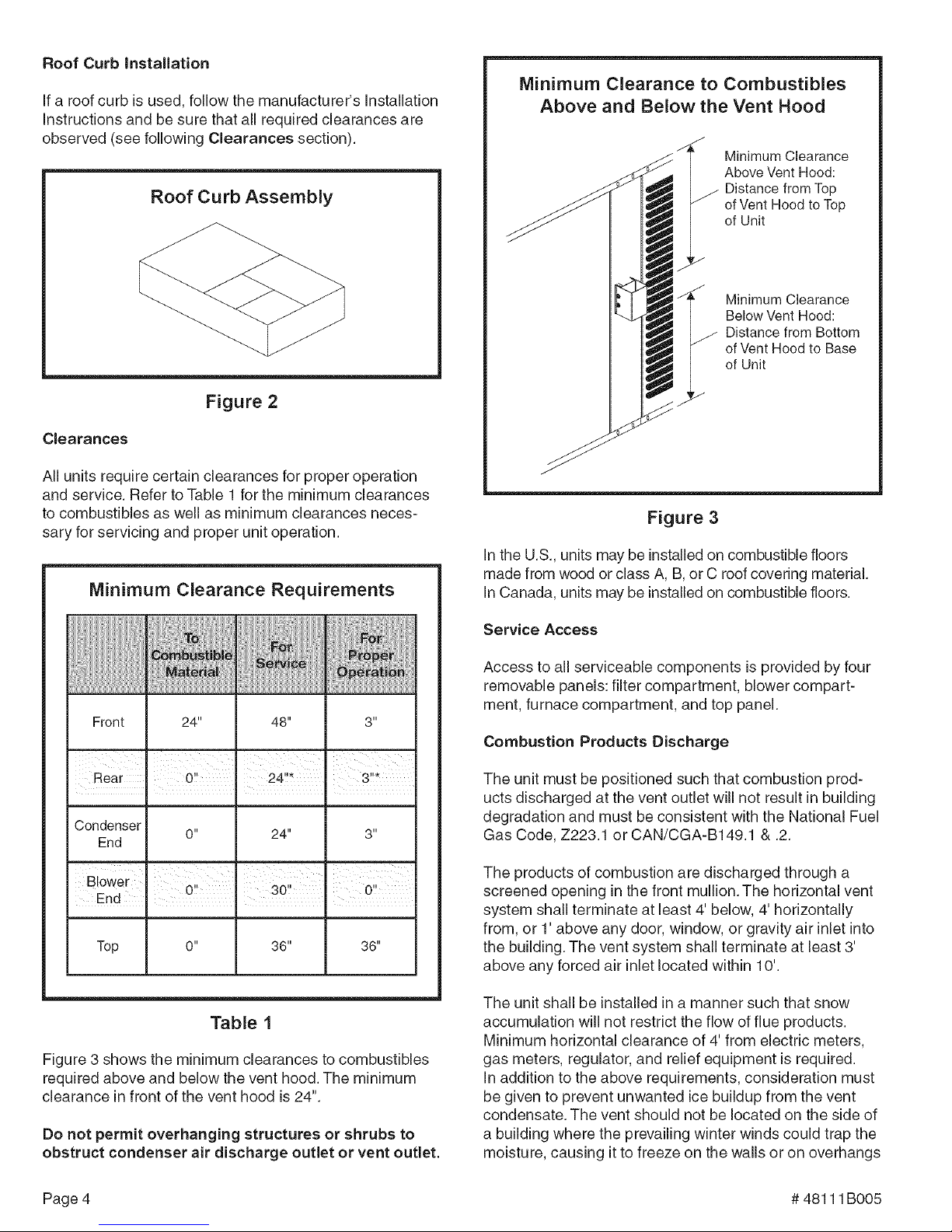

Clearances

All units require certain clearances for proper operation

and service. Refer to Table 1 for the minimum clearances

to combustibles as well as minimum clearances neces-

sary for servicing and proper unit operation.

Minimum Clearance Requirements

Minimum Clearance to Combustibles

Above and Below the Vent Hood

Minimum Clearance

Above Vent Hood:

Distance from Top

of Vent Hood to Top

of Unit

Minimum Clearance

Below Vent Hood:

Distance from Bottom

of Vent Hood to Base

of Unit

Figure 3

In the U.S., units may be installed on combustible floors

made from wood or class A, B, or C roof covering material.

In Canada, units may be installed on combustible floors.

Front 24" 48" 3"

Rear 0!! 24!!* 3!!_

Condenser

End

Blower , '

End . . ,

Top 0" 36" 36"

0" 24" 3"

0!' 30" 0!!

n n

Table 1

Figure 3 shows the minimum clearances to combustibles

required above and below the vent hood. The minimum

clearance in front of the vent hood is 24".

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet or vent outlet.

Service Access

Access to all serviceable components is provided by four

removable panels: filter compartment, blower compart-

ment, furnace compartment, and top panel.

Combustion Products Discharge

The unit must be positioned such that combustion prod-

ucts discharged at the vent outlet will not result in building

degradation and must be consistent with the National Fuel

Gas Code, Z223.1 or CAN/CGA-B149.1 & .2.

The products of combustion are discharged through a

screened opening in the front mullion. The horizontal vent

system shall terminate at least 4' below, 4' horizontally

from, or 1' above any door, window, or gravity air inlet into

the building. The vent system shall terminate at least 3'

above any forced air inlet located within 10'.

The unit shall be installed in a manner such that snow

accumulation will not restrict the flow of flue products.

Minimum horizontal clearance of 4' from electric meters,

gas meters, regulator, and relief equipment is required.

In addition to the above requirements, consideration must

be given to prevent unwanted ice buildup from the vent

condensate. The vent should not be located on the side of

a building where the prevailing winter winds could trap the

moisture, causing it to freeze on the walls or on overhangs

Page 4 # 48111 B005

Page 5

(undereaves).Theventlocationshouldnotdischarge

overasidewalk,patio,orotherwalkwaywherethecon-

densatecouldcausethesurfacetobecomeslippery.

kWARNING

The products of combustion must not be allowed to

accumulate within a confined space and recirculate.

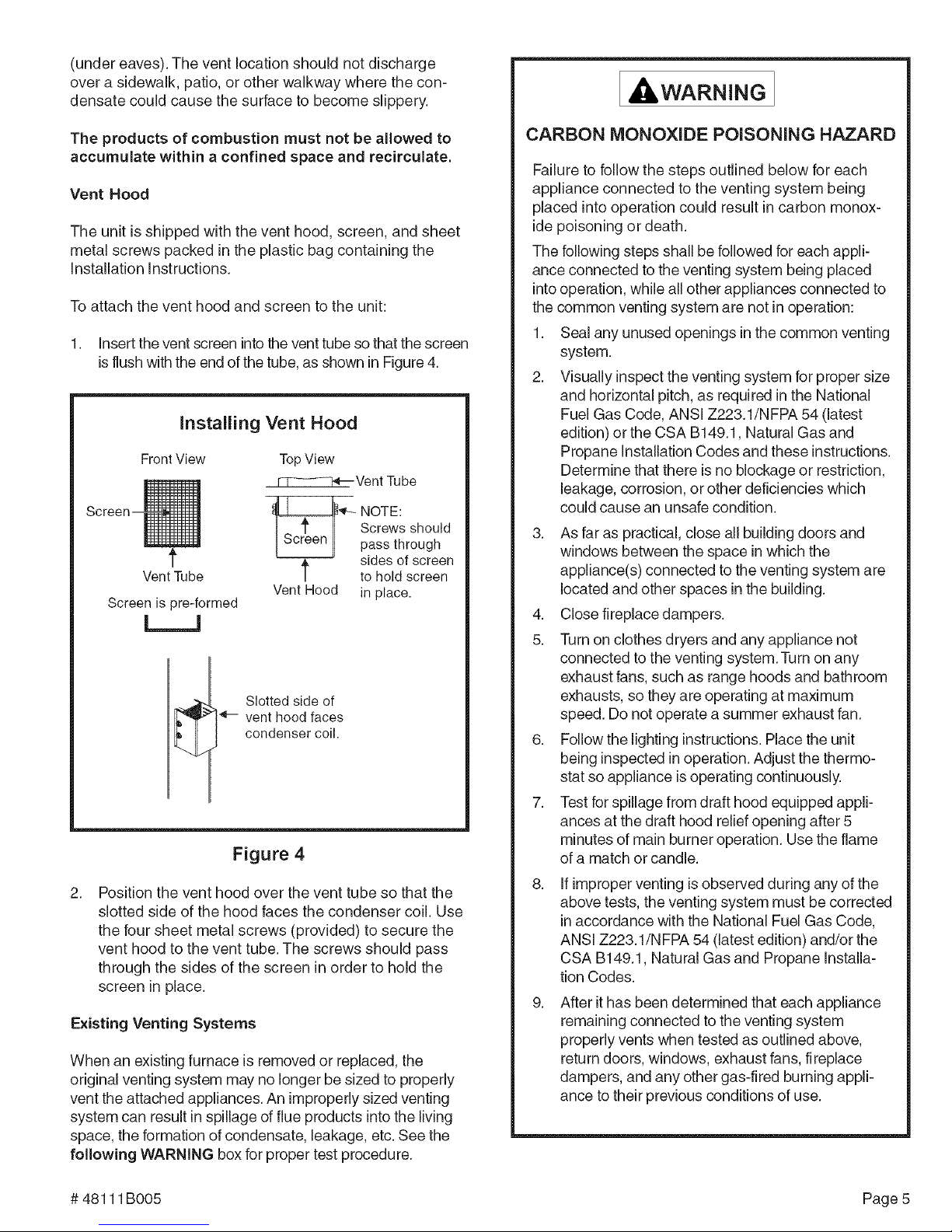

Vent Hood

The unit is shipped with the vent hood, screen, and sheet

metal screws packed in the plastic bag containing the

Installation Instructions.

To attach the vent hood and screen to the unit:

1. Insert the vent screen into the vent tube so that the screen

is flush with the end of the tube, as shown in Figure 4.

Installing Vent Hood

FrontView TopView

_Vent Tube

'_-- OTE:

Screws should

pass through

sides of screen

VentTube

Screen is lore-formed

t to hold screen

Vent Hood in place.

L__J

_-- vent hood faces

condenser coil.

Slotted side of

Figure 4

2. Position the vent hood over the vent tube so that the

slotted side of the hood faces the condenser coil. Use

the four sheet metal screws (provided) to secure the

vent hood to the vent tube. The screws should pass

through the sides of the screen in order to hold the

screen in place.

Existing Venting Systems

When an existing furnace is removed or replaced, the

original venting system may no longer be sized to properly

vent the attached appliances. An improperly sized venting

system can result in spillage of flue products into the living

space, the formation of condensate, leakage, etc. See the

following WARNING box for proper test procedure.

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monox-

ide poisoning or death.

The following steps shall be followed for each appli-

ance connected to the venting system being placed

into operation, while all other appliances connected to

the common venting system are not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch, as required in the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition) orthe CSA B149.1, Natural Gas and

Propane Installation Codes and these instructions.

Determine that there is no blockage or restriction,

leakage, corrosion, or other deficiencies which

could cause an unsafe condition.

3. As far as practical, close all building doors and

windows between the space in which the

appliance(s) connected to the venting system are

located and other spaces inthe building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they are operating at maximum

speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the unit

being inspected in operation. Adjust the thermo-

stat so appliance is operating continuously.

7. Test for spillage from draft hood equipped appli-

ances at the draft hood relief opening after 5

minutes of main burner operation. Use the flame

of a match or candle.

8.

If improper venting is observed during any of the

above tests, the venting system must be corrected

in accordance with the National Fuel Gas Code,

ANSI Z223.1/N FPA 54 (latest edition) and/or the

CSA B149.1, Natural Gas and Propane installa-

tion Codes.

9.

After it has been determined that each appliance

remaining connected to the venting system

properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers, and any other gas-fired burning appli-

ance to their previous conditions of use.

# 48111B005 Page 5

Page 6

CondensateDrain

1. Remove screw on cover nearest side opening.

ThePGE/SGpackageunitisequippedwitha3/4"FPT

couplingforcondensatelineconnection.Plumbingmust

conformtolocalcodes.Useasealingcompoundonmale

pipethreads.

The condensate drain line must be properly trapped

and routed to a suitable drain. See Figure 5 for proper

drain arrangement. The drain line must pitch to an open

drain or pump to prevent clogging of the line. Seal around

the drain connection with suitable material to prevent air

leakage into the return air system.

Typical Condensate Drain Connection

Unit /_ Drain Connection

1.00" Min.

,, 3oo:,

2. Lift end of cover slightly and push to slide back screw/

pin free from duct flange.

3. Slide duct cover out the side duct opening.

Removing Bottom Duct Covers

®

(b

1. Remove screw and lift.

2. Slide cover to free back pin.

Figure 6

Base_ J

' Max. '_

Positive Liquid Seal Required _

Figure 5

Ductwork

Ductwork should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors

of America (ACCA).

A closed return duct system shall be used. This shall not

preclude use of economizers or outdoor fresh air intake. It

is recommended that supply and return duct connections

at the unit be made with flexible joints.

The supply and return air duct systems should be de-

signed for the CFM and static requirements of the job.

They should not be sized by matching the dimensions

of the duct connections on the unit.

Outdoor ductwork must be insulated and waterproofed.

Equipment is shipped for side ductwork connection. The

unit can be converted to bottom ductwork connection by

removing the duct covers located over the bottom duct

openings and placing these covers over the side duct

openings (see Figure 6).

To remove the bottom duct cover over supply opening:

Filters

Air filters are to be used with this heating/cooling unit.

Filters are not factory supplied in the unit. However, a filter

frame accessory isavailable from the manufacturer that

allows filters to be installed within the unit. if the filter

frame accessory isnot used, a filter must be installed in

the duct work by the installer. Filters must always be

installed ahead of the evaporator coil and must be kept

clean or replaced. Dirty filters will reduce the airflow of the

unit. Filters should be sized in accordance with Table 2.

Gas Supply and Piping

Refer to the furnace rating plate to make sure the furnace

isequipped to burn the gas supplied (natural or propane).

See LPG/Propane Units, Tanks, and Piping on page 7

for more information on converting to propane gas.

Gas supply piping should be installed in accordance with

local codes and the regulations of the utility. In the ab-

sence of local codes, the latest edition of the National Fuel

Gas Code ANSI Z223.1 (in the U.S.), orthe Natural Gas

and Propane installation Codes CAN/CGA B149.1 &

Page 6 # 48111 B005

Page 7

Minimum Required Surface Area

for Disposable Filters

24,000 2.67

30,000 I 3.33

36,000

|

4.00

codes. An 1/8" NPT plugged tapping, accessible for test

gauge connection, must be installed immediately up-

stream of the gas supply connection to the unit. A sedi-

ment trap (drip leg) shall be installed as close as practical

to the gas supply inlet of the unit.

The furnace must be isolated from the gas supply piping

system by closing the individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psig

(3.5 kPa) or 14" W.C. If the piping system is to be tested at

pressures in excess of 1/2 psig (3.5 kPa), the furnace and

its appliance main gas valve must be disconnected from

the gas supply piping system.

48,000

I

5.33

60,000 _ 6.67

Table 2

B149.2 (in Canada), should be followed. Piping must be of

adequate size to prevent undue pressure drop. Consult

the local utility or gas supplier for complete details on

special requirements for sizing gas piping.

The gas supply line should be routed through the grom-

met on the side of the unit. Refer to Figure 7 to locate this

access opening.

Gas and Electrical Access

Gas Line

After gas piping is complete, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means. Some soaps

used for leak detection are corrosive to certain metals.

Carefully rinse piping thoroughly after leak detection has

been completed.

Thermostat _C)

Entry

Line Voltage

Entry

Figure 7

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use

a connector which has previously serviced another gas

appliance.

Pipe connections must be tight, and a non-hardening pipe

compound resistant to liquefied petroleum gases should

be used.

Install a manual shutoff valve in the gas connection to the

unit, external to the casing, in accordance with local

# 48111B005 Page 7

LPG/Propane Units, Tanks, and Piping

Units are shipped equipped for natural gas, but can be

converted to LPG/propane in the field by an approved

licensed technician.

All LPG/propane gas equipment must conform to the safety

standards of the National Fire Protection Association.

Page 8

Forsatisfactoryoperation,LPG/propanegaspressure

mustbeaminimumof11"W.C.attheunitunderfullload.

Completeinformationregardingtanksizingforvaporiza-

tion,recommendedregulatorsettings,andpipesizingis

availablefrommostregulatormanufacturersandLPG/

propanegassuppliers.

Checkallconnectionsforleakswhenpipingiscompleted,

usingasoapysolution.Somesoapsusedforleakdetec-

tionare corrosive to certain metals. Carefully rinse

piping thoroughly after completing leak detection.

Thermostat

The room thermostat should be located on an inside wall

where it will not be subject to drafts, sun exposure, or heat

from electrical fixtures or appliances. Follow the

manufacturer's instructions enclosed with thermostat for

general installation procedure. Color-coded insulated wires

(#18 AWG) should be used to connect thermostat to unit.

Four wires are required for cooling. The heat anticipator

setting is 0.7 amp.

Compressor

Units are shipped with compressor mountings factory-

adjusted and ready for operation. Caution: Do not

loosen compressor mounting bolts.

Electrical Wiring

All wiring should be done in accordance with the

National Electrical Code, ANSI/NFPA No. 70 (latest

edition); Canadian Electrical Code Part 1, CSA C22.1

(latest edition); or local codes where they prevail. Use

wiring with a temperature limitation of 75°C minimum. Run

the 208 or 230 volt, 60 hertz electric power supply through

a fused disconnect switch to the connection box of the unit

and connect as shown in the wiring diagram located on

the inside of the control access panel.

Power supply to the unit must be N.E.C. Class 1, and must

comply with all applicable codes. A fused disconnect switch

should be field provided for the unit. The switch must be

separate from all other circuits. If any of the wire supplied

with the unit must be replaced, replacement wire must be of

the type shown on the wiring diagram. Electrical wiring must

be sized to carry minimum circuit ampacity marked on the

unit. Use copper conductors only. Each unit must be wired

with a separate branch circuit and be properly fused.

Page 8 # 48111 B005

Page 9

Typical Wiring Connections

WITHOUT ECONOMIZER WITH ECONOMIZER

THERMOSTAT OUTDOOR UNIT THERMOSTAT OUTDOOR UNIT

-%

[_ GREEN

SINGLE PHASE

THREE PHASE

BLUE

YELLOW

BLACK

ORANGE

ECONOMIZER

[]

(Not Used)

@

POWER WIRING

208/230-1-80

(80°CMIN. WIRE)

POWER WIRING ............

24V CONTROL WIRING .......

(NEC CLASS 2)

GROUND

SCREW

@ @

GROUND

SCREW

POWERWIRING

200/230-3-80, 480/575-3-80

(90°C MIN.WIRE)

............ POWER WIRING

....... 24V CONTROL WIRING

(NEC CLASS 2)

Figure 8

# 48111B005 Page 9

Page 10

START-UP

For Your Safety Read Before Lighting

Pre-Start Check List

Gas Valves

Regulator Gas

Adjustment Control

Cap Knob

Complete the following checks before starting the unit:

1. Check the type of gas being supplied. Be sure it isthe

same as listed on the unit nameplate.

2. Make sure that the vent hood has been properly installed.

To Light Burners:

1. Turn off electrical power to unit.

2. Turn the thermostat to lowest setting.

3. Turn the gas control knob, or slide the gas control

switch, to the "ON" position (see Figure 9).

4. Turn on electrical power to the unit.

5. Set the room thermostat to the desired temperature.

(If the thermostat "set" temperature is above room

temperature, the burners will light after the pre-purge

time expires.)

To Shut Down Burners:

1. Turn off electrical power to unit.

Inlet Pressure Tap Outlet Pressure Tap

1/8" NPT (Manifold Pressure)

1/8" NPT

Regulator

Adjustment GasControl Switch

Inlet Pressure Tap

1/8" NPT

Outlet Pressure Tap

(Manifold Pressure)

1/8" NPT

Figure 9

propane gas with the burners in operation. If gas

pressure is outside these limits, contact the gas

supplier for corrective action.

4. Adjust temperature rise to be within the range speci-

fied on the rating plate.

2. Turn the gas control knob, or slide the gas control

switch, to the "OFF" position (see Figure 9).

Post-Start Check List

After the entire control circuit has been energized and the

heating section is operating, make the following checks:

1. Check for gas leaks, using soapy solution, in the unit

piping as well as the supply piping.

2. Check for correct manifold gas pressures (see following

Checking and Adjusting Gas input section).

3. Check the supply gas pressure. It must be within the

limits shown on the rating plate. Supply pressure

should be checked with all gas appliances in the

building at full fire. At no time should the supply

pressure during standby exceed 13" W.C., nor should

it be less than 5" W.C. for natural gas or 11"W.C. for

Page 10

Checking and Adjusting Gas input

For purpose of input adjustment, the minimum permis-

sible gas supply pressure is 5" W.C. for natural gas and

11" W.C. for propane.

Gas input must never exceed the input capacity shown on

the rating plate. The furnace is equipped for natural gas

rated inputs with manifold pressure of 3.5" W.C.

The manifold pressure can be measured by shutting off the

gas, removing the pipe plug inthe downstream side of the

gas valve, and connecting a water manometer or gauge. To

adjust the regulator, turn the adjusting screw on the regula-

tor clockwise to increase pressure and inputor counter-

clockwise to decrease pressure and input.The final

manifold pressure should not vary more than 0.3" W.C.

from the above specified pressure. See Figure 9 to assist

in locating the regulator on the gas valve.

# 48111B005

Page 11

ForNaturalGas:Checkthegasinputratebyobserving

thegasmeter,whenavailable,makingsureallothergas

appliancesareturnedoff.Thetesthandonthemeter

shouldbetimedforatleastonerevolution.Notethe

numberofsecondsforonerevolution.

BTU/HR= Cubic Feet Per Revolution x 3600 x Heating

INPUT # Seconds Per Revolution Value

OPERATION

Cooling System

The cooling system is a complete factory package utilizing an

air-cooled condenser. The compressor ishermetically sealed

and base mounted with rubber-insulated hold-down bolts.

The heating value of the gas can be obtained from the local

utility company.

For Propane Gas: The only check for the gas input rate is

to properly adjust the manifold pressure using a manometer.

Typical manifold set point for installationsat altitudes from 0

to 4500 feet above sea level is 10.0" W.C.

Temperature Rise

Check the temperature rise and, if necessary, adjust

blower speed to maintain temperature rise within the

range shown on the unit rating plate.

High Altitude

Ratings are shown on the rating plate for elevations up to

4500 feet. For elevations above 4500 feet, ratings should

be reduced at a rate of 4% for each 1000 feet above sea

level. See the National Fuel Gas Code Z223.1 (latest

edition) or the Canadian Installation Codes CAN/CGA-

B149.1 & B149.2 for further details.

Secure Owner's Approval

When the system is functioning properly, secure the

owner's approval. Show the owner the location of all

disconnect switches and the thermostat. Instruct the

owner on how to start and stop the unit and how to adjust

temperature settings within the limitations of the system.

Unit compressors have internal protection. In the event there

is an abnormal rise in the temperature of the compressor,

the protector will open and cause the compressor to stop.

Cooling Sequence of Operation

When the thermostat calls for cooling, R is closed to G and

Y (see the wiring diagrams found on pages 15and 16). This

action completes the low voltage control circuit, energizing

the compressor, condenser fan motor, and blower motor.

Blower Delay - Cooling

The circulating air blower is controlled by a timing circuit in

the integrated blower/ignition control. Timings are not

adjustable. Blower "on" delay is 5 seconds after the

compressor starts and blower "off" timing is 90 seconds

after the cooling system shuts down.

System Performance

For maximum performance of the cooling system, operat-

ing temperatures and pressure should be checked.

Superheat should be determined at Standard ARI test

conditions of 82°F outdoor and 80°F indoor dry bulb/67°F

wet bulb. If superheat measured deviates from values

found in Table 3, refrigerant charge should be adjusted

accordingly for maximum performance.

Suction Superheat

# 48111B005 Page 11

24 22°

PGE13

SG13 30, 36, 42, 20°

48, 60

24, 30 15°

PGE15

SG15

" 481 60 10°

Table 3

Page 12

HeatingSystem Circulating Air Blower

With the proper thermostat and sub-base, continuous

blower operation is possible by closing the R to G circuit.

Cooling blower delay is also functional in this mode.

Heating Sequence of Operation

1. When the thermostat calls for heat, the combustion

blower is energized by the ignition control.

2. When the speed of the combustion blower reaches

proper RPM, the pressure switch closes, initiating the

pre-purge timing (30 seconds nominal).

3.

When pre-purge has expired, the ignition control

energizes the gas valve, the spark electrode, and the

flame sensor. The igniter sparks for 10 seconds, and the

flame sensor senses that flame has been established. If

the flame sensor does not sense that flame has been

established in the 10-second interval, then the ignition

control will de-energize the gas valve.

4.

The ignition control is designed to repeat this "trial for

ignition" a total of three times. If, at the end of the third

trial, a flame still has not been established, the ignition

control will repeat the trial for ignition sequence 1 hour

later. The 1-hour retry is indefinite. The ignition control

can be reset by interrupting the unit power or the

thermostat circuit.

Depending on the package unit model, the blower motor will

be either a multi-tap PSC motor or a variable speed motor.

PSC Motor

The circulating air blower is controlled by a timing circuit in the

integrated blower/ignition control. Timings are not adjustable.

Cooling - Blower "on" delay is 30 seconds after call for

cooling. Blower "off" delay is 90 seconds after the cooling

system shuts down.

Heating- Blower "on" delay is 30 seconds nominal after

burner ignition. Blower "off" delay is approximately 120

seconds after the thermostat is satisfied.

Variable Speed Motor

Units equipped with a variable speed circulation air blower

motor will deliver a constant airflow within a wide range of

external static pressures. Other features of this variable

speed motor include:

Soft Start/Stop -The variable speed motor will slowly

ramp up to normal operating speed. This minimizes noise

and increases comfort by eliminating the initial blasts of air

encountered with standard motors. At the end of a cooling

or heating cycle, the motor will slowly ramp down.

Thirty seconds (nominal) after the initial trial for

ignition, the circulation air blower will start.

Circulation Airflow Adjustments - The controls include

a variable speed motor interface board. The ADJUST tap

can be used to raise (+) or lower (-) the airflow by 15%.

6.

When the thermostat is satisfied, the combustion

blower and gas valve are de-energized. The circulat-

ing air blower motor will continue to run for a short

period after the thermostat is satisfied.

Heating and Cooling Airflows -The units are factory set

for the correct heating and cooling airflows. However,

airflow changes can be made by moving the position of

the HEAT and COOL taps (see Table 4).

Adjusting Airflow (Variable Speed Motor Equipped Units Only)

24, 30 68 NORM 800 90C

36 68 100C 110,

36 90 NORM 100C 110,

42, 48; 60 83 NORM 160C 120,

42, 48, 60 110 NORM 160C 120,

42, A8,.,60 i38 160C 120,

m

_OC

ett_

iiilDii_iiiiD!!ii

ADJUST, HEAT,

and COOL Taps

and Dehumidify

Resistor

on interface

Board

" .....A_S_

Table 4

Page 12 # 48111 B005

Page 13

Continuous Blower-The comfort level of the living

space can be enhanced when using this feature by

allowing continuous circulation of air between calls for

cooling or heating. The continuous circulation of air occurs

at half the full cooling airflow rate. To use this feature,

place the thermostat fan switch into the ON position.

Cooling Airflow Ramp Up - At the beginning of a call for

cooling, the blower will run at 80% of full airflow for 7.5

minutes. This improves the system's moisture removal and

saves blower power during cooling start.

Reduced Airflow Operation (Dehumidification) - For

situations where humidity control is an issue, the variable

speed motor can be connected to operate at a 25%

reduction in the normal airflow rate. The variable speed

motor interface board provides for connection of a humi-

distat on the HUM terminal. When a humidistat is con-

nected, the dehumidifier resistor on the interface must be

cut. The humidistat should be wired to open during high

humidity, which will reduce blower airflow.

Safety Controls

The control circuit includes the following safety controls:

MAINTENANCE

Limit Control

This control is located inside the heating compartment and is

designed to open at abnormally high air temperatures. It

resets automatically. The limit control operates when a high

temperature condition, caused by inadequate airflow, occurs.

This causes the ignition control to close the gas valve. The

circulation air blower continues to operate in this situation.

Pressure Switch

The pressure switch prevents the gas valve and igniter

from being energized if there is insufficient combustion air

due to a failed combustion blower or a blocked vent.

Flame Sensor

Ifthe ignitioncontrol does not receive a signal from the flame

sensor indicating thatthe burners have established flame, the

gas valve closes after the 10-second trial for ignition period.

Rollout Switch

The switch is located above the main burners. In the event

of a sustained flame rollout, the rollout switch causes the

ignition control to close the gas valve. To reset, push the

button on top of the switch.

Auxiliary Limit (42, 48, and 60 units only)

This control is located in the side of the circulation air

blower housing. The switch causes the ignition control to

close the gas valve should the circulation blower fail to

operate. This control resets automatically.

It is recommended that this furnace be inspected by a

qualified service technician at the beginning of each

heating season.

Filters

Filters should be checked at least every 6 weeks. Dispos-

able filters should be replaced when dirty, and cleanable

filters should be cleaned regularly. It is important to keep the

air filters clean, as dirty filters can restrict airflow and the

blower and induced draft motors depend upon sufficient air

flowing across and through them to keep from overheating.

Lubrication

The blower motor and induced draft motor are pre-lubricated

by the manufacturer and do not require further lubricating

attention. However, the motors should becleaned periodi-

cally to prevent the possibility of overheating due to an

accumulation of dust and dirt on the windings or on the

motor exterior.

Burners

Light the burners and allow to operate for a few minutes to

establish normal burning conditions. Observe the burner

flames. Compare this observation to Figure 10 on page 14

to determine if proper flame adjustment is present. Flame

should be predominantly blue in color and strong in appear-

ance. Check that all burners are lit, and that the flame does

not impinge on the sides of the heat exchanger.

Distorted flame or yellow tipping of the natural gas burner

flame, or long yellow tips on propane, may be caused by

# 48111B005 Page 13

Page 14

lintaccumulationordirtinsidetheburnerorburnerports,

attheairinletbetweentheburnerandmanifoldpipe,or

obstructionsovertheburnerorifice.

Useasoftbrushorvacuumtocleantheaffectedareas.

Typical Flame Appearance

Heat

Exchanger

Burner

Gas Burner

Manifold Flame

(Blue Only)

Figure 10

Outdoor Coil

Dirt and debris should not be allowed to accumulate on the

outdoor coil surface or other parts inthe air circuit. Cleaning

should be as often as necessary to keep coil clean. Use a

brush, vacuum cleaner attachment, or other suitable means.

If water is used to clean the coil, be sure the power to unit is

shut off prior to cleaning. Care should be used when

cleaning the coil so that the coil fins are not damaged.

Do not permit the hot condenser air discharge to be

obstructed by overhanging structures or shrubs.

CONTROL SYSTEM DIAGNOSTICS

Fault Codes

Slow Flash

Fast Flash Two flashes

2 Flash

3 Flash

4 Flash

5 Flash and gas valve

Steady -- Micro-controller

One flash

per second

pei Second

Two flashes

in second with

1-second pause

Three flashes in

1.5 seconds with

1-second pause

Four flashes in

2 seconds with

1-second pause

Five flashes in

2.5 seconds _ith

1-second pause

Normaloperation:

Nocallfor heat

Normaloperation:

Callfor heat

System lockout:

Failedto detect

or sustainflame

Pressure switch

openorC!osed

High limit or

rollout switch

open

Flame sensed

not energized

Internal failure:

failure; self-check

Table 5

Vent Outlet

Visually inspectvent outlet periodically to make sure there is

no buildup of soot and dirt. If necessary, clean to maintain

adequate opening to discharge flue products.

Page 14 # 48111 B005

Page 15

NOTE:

IF ANY OF THE ORIGINAL WIRE iS REPLACED, THE SAME SIZE AND TYPE WIRE MUST BE USED.

USE COPPER CONDUCTOR ONLY, MIN. 75°C WIRE.

WARNING- ELECTRIC SHOCK HAZARD. UNIT MUST BE GROUNDED iN ACCORDANCE WITH

NATIONAL AND LOCAL CODES.

HEAT ANTICIPATION SETTING: 0.70 AMP

LINE VOLTAGE FIELD INSTALLED

>Z

o_

c_

L2

L

z,

ra

COMPRESSOR

cE

COMPRESSOR

CONTACTOR

K1-2

KI-f

_- COMPRESSOR

- CONTACTOR

1_ BLK

DUAL

CAPACITOR

C12_ BRN

;IGNITION CONTROL

: J i-;

,A3 _O m<,

i L1 CMB BLWR < o < z;

SEE CHART

FOR WIRING

M'

I

_B. BL

_ CAPACITOF M(

i-

i

o_

CONDENSER

FAN MOTOR

DIAGNOSTICS

The following ignition control board LED codes will indicate normal or abnormal operations:

SLOW FLASH Normal operation, no call for heat.

FAST FLASH Normal operation, call for heat.

2 FLASH System lockout.

3 FLASH Pressure switch senses incorrect pressure.

4 FLASH Main limit open or rollout switch open.

5 FLASH Flame sensed and gas valve not energized.

STEADY Internal failure (micro-controller failure; self check).

PRESSURE [4___$I8

SWITCH

AUX. LIMIT

SWITCH

(iF USED)

HIGH PRESSURE

SWITCH THERMOSTAT

(iF USED) BLU

:, FUSE ; / l [ /

GRODND G>:,> | /

I ]i w>:,> / ! i

I;I i @LED O> _ -_ ]

Y>:>--q l CONTACTOR

FLAME':l /

LO_._..O.._/Y._-'b._/__........ _Z._.."_ Y_- / y

_1 I _ZH Blower Speed Chart

_] I w _I I Unit Factory Shipped Settings

ROLLOUT (_$471 'T' .

SWITCH _ L [ _ C.oohng H.eatmg HEAT (BLU) COOL (BLK)

z:J J mput mput

_L_ 24 68 MED LOW

30 68 MED* MED

GV1

r- .....

...... J

GAS

VALVE

MOTOR

SPEED TAPS

36

36

42

42

48

48

48

6O

6O

6O

68

90

83

110

83

110

138

83

110

138

MED

HIGH*

LOW*

LOW*

LOW

LOW

MED*

LOW

LOW

MED

HiGH

HiGH

LOW

LOW

MED

MED

MED

HiGH

HiGH

HiGH

Connection Diagram

Single Stage Heat, Single Phase

PIN 48129-001

JUMPER REQUIRED

IF THE JUMPER IS NOT USED, CONNECT BLUE WIRE TO

THE HEAT TERMINAL.

Page 16

_L1

K1-1

COMPRESSOR

:TI_CONTACTO R

__ _BLK

it DUAL

A1321 ___ CAPACITOR

208/230V-1-60

COMPRESB;ORt_

A1321R

7

CONDENSER

FAN MOTOR

COMPRESSOr

CONTACTOR

K1-2

L2

L

TRANSFORMER

INDOOR

SLOWER

MOTOR

NOTE:

IF ANY OF THE ORIGINAL WIRE IS REPLACED. THE

SAME SIZE AND TYPE WIRE MUST BE USED. USE

COPPER CONDUCTOR ONLY, MIN. 75°C WIRE.

WARNING-

ELECTRIC SHOCK HAZARD. UNIT MUST BE GROUNDED

IN ACCORDANCE WITH NATIONAL AND LOCAL CODES.

HEAT ANTICIPATION SETTING: 0.70 AMP

LINE VOLTAGE FIELD INSTALLED

DIAGNOSTICS

HIGH PRESSURE

SWITCH THERMOSTAT

(IF USED) YEL ): $1

l_ YEL

i

RED :24VAC

FUSE

The following ignition control board LED codes will

indicate normal or abnormal operations:

ORN

GRN

I_HUM A54 ;

ICM BOARD i

SEE i

I BLOWER SPEED i

:=EM

CHART

i

i ADJUST HEAT COOL I

_O NORM o o A Ao "

: (a B ">oB_ I

pY2 0 o c o-, c oo i

(TEST) o D > D,0

L,,

IIIIIIIIIIIIIIII

INDOOR BLOWER |

MOTOR B3J

Blower Speed Chart

Unit Factory Shipped Settings

SLOW FLASH Normal operation, no call for heat.

FAST FLASH Normal operation, call for heat.

2 FLASH System lockout.

3 FLASH Pressure switch senses incorrect pressure.

4 FLASH Main limit open or rollout switch open.

5 FLASH Flame sensed and gas valve not energized,

STEADY Internal failure (micro-controller failure; self check),

Connection Diagram

Single Stage Heat, Variable Speed, Single Phase

PIN 48107-001

Cooling

Input

24

30

36

36

42

42

48

48

48

60

60

60

Heating

Input

68

68

68

90

83

110

83

110

138

83

110

138

ADJUST

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

HEAT

A

A

B

A

C

C

C

C

A

C

C

A

COOL

B

A

A

A

C

C

B

B

B

A

A

A

Loading...

Loading...