Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

4HP18LT Series

Split System Heat Pump

Save these instructions for future reference

WARNING

The equipment covered in this manual is to be installed by trained and experienced service

and installation technicians. Improper installation, modification, service, or use can cause

electrical shock, fire, explosion, or other conditions which may cause personal injury , death,

or property damage. Use appropriate safety gear including safety glasses and gloves

when installing this equipment.

W ARNING

Risk of electrical shock. Disconnect all remote power

supplies before installing or servicing any portion of the

system. Failure to disconnect power supplies can result

in property damage, personal injury , or death.

INSTALLATION ....................................................2

CONNECTION DIAGRAM....................................4

TABLE OF CONTENTS

W ARNING

Installation and servicing of air conditioning equipment

can be hazardous due to internal refrigerant pressure

and live electrical components. Only trained and qualified

service personnel should install or service this equipment.

Installation and service performed by unqualified persons

can result in property damage, personal injury , or death.

WARNING

Sharp metal edges can cause injury. When installing

the unit, use care to avoid sharp edges.

START-UP..........................................................13

OPERATION ......................................................18

MAINTENANCE .................................................23

Manufactured By

Allied Air Enterprises, Inc.

A Lennox International Inc. Company

215 Metropolitan Drive

West Columbia, SC 29170

*506470-01*

506470-01 Issue 1007

Page 1

Page 2

INSTALLATION

General

Read this entire instruction manual, as well as the

instructions supplied in separate equipment, before

starting the installation. Observe and follow all

warnings, cautions, instructional labels, and tags.

Failure to comply with these instructions could result

in an unsafe condition and/or premature component

failure.

These instructions are intended as a general guide only for

use by qualified personnel and do not supersede any national

or local codes in any way . The installation must comply with

all provincial, state, and local codes as well as the National

Electrical Code (U.S.) or Canadian Electrical Code (Canada).

Compliance should be determined prior to installation.

4HP18LT condensing units use R410A which is an ozonefriendly HFC refrigerant. The unit must be installed with a

matching indoor coil and line set. A filter drier approved for

use with R410A is inst alled in the unit.

IMPORTANT: This product has been designed and

manufactured to meet ENERGY STAR criteria for energy

efficiency when matched with appropriate coil components.

However, proper refrigerant charge and proper air flow are

critical to achieve rated capacity and efficiency . Inst allation

of this product should follow the manufacturer’s refrigerant

charging and air flow instructions. Failure to confirm proper

charge and airflow may reduce energy efficiency and

shorten equipment life.

Inspection of Shipment

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is found, it should be noted on

the carrier’s freight bill. Take special care to examine the

unit inside the carton if the carton is damaged. Any concealed

damage discovered should be reported to the last carrier

immediately, preferably in writing, and should include a

request for inspection by the carrier’s agent.

If any damages are discovered and reported to the carrier

DO NOT INST ALL THE UNIT, as claim may be denied.

Check the unit rating plate to confirm specifications are

as ordered.

Location of Unit

Outdoor units operate under a wide range of weather

conditions; therefore, multiple factors must be considered

when positioning the unit. The unit must be positioned to

give adequate clearances for sufficient airflow and servicing.

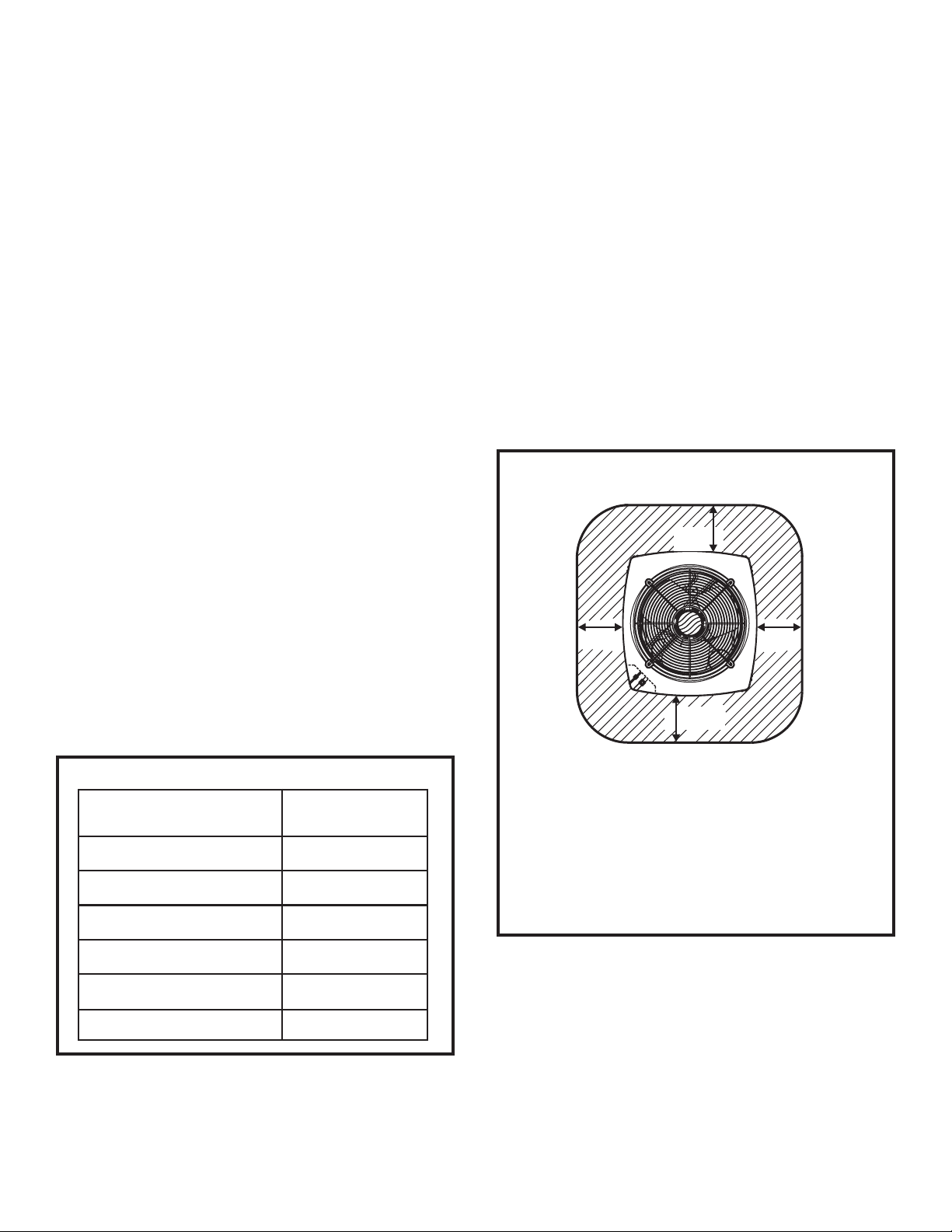

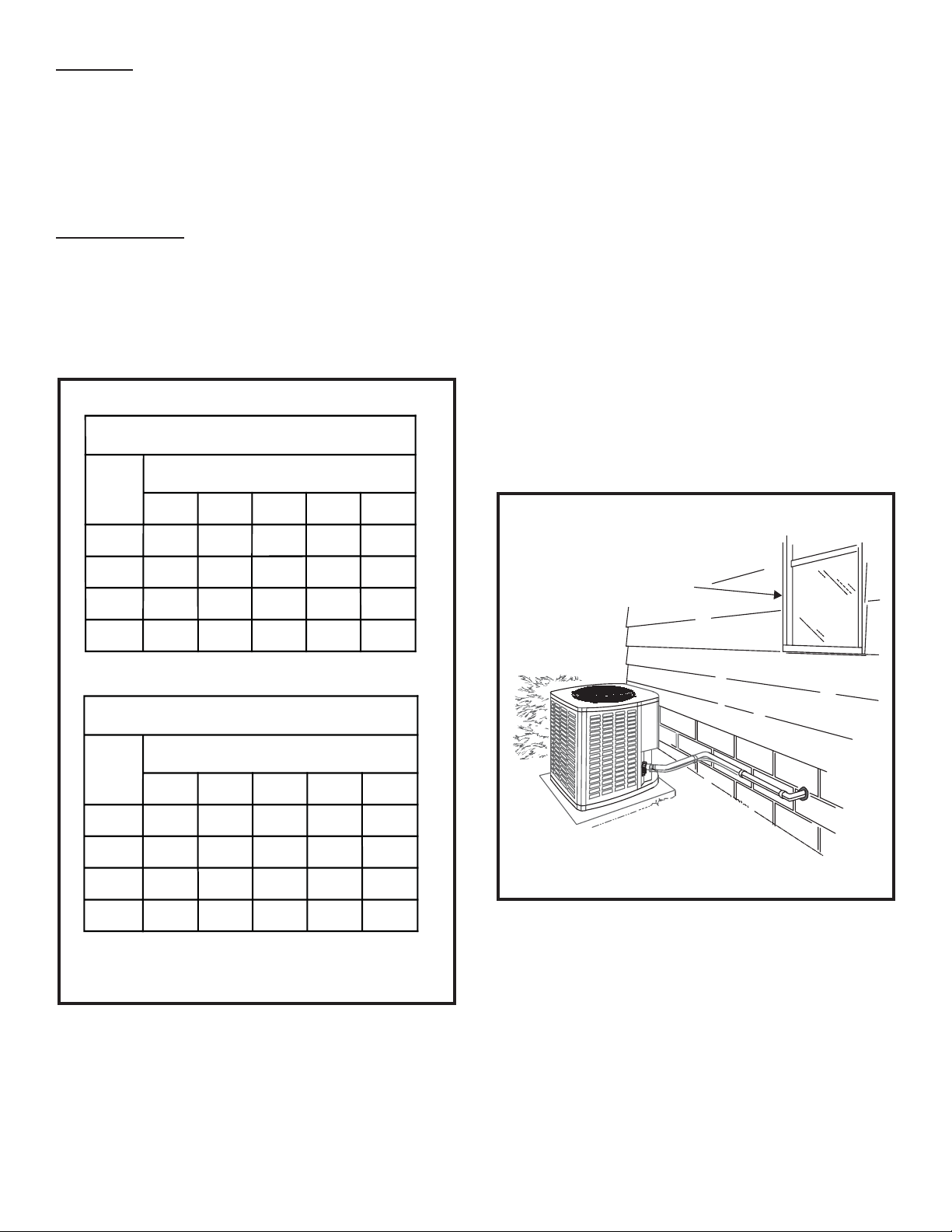

Refer to Figure 1 for installation clearances.

Installation Clearances

36”

36” *

36”

When servicing or repairing HV AC components, ensure the

fasteners are appropriately tightened. T able 1 shows torque

values for fasteners.

Torque Table

Fastener Torque

Stem Caps 8 ft. lbs.

Service Port Caps 8 ft. lbs.

Sheet Metal Screws

#8 Machine Screws

#10 Machine Screws

Compressor Bolts

Table 1

16 in. lbs.

16 in. lbs.

28 in. lbs.

90 in. lbs.

36” *

* A service clearance of 30" must be maintained on

one of the sides adjacent to the control box.

Clearance to one of the other three sides must be

36". Clearance to one of the remaining two sides may

be 12" and the final side may be 6".

A clearance of 24" must be maint ained between units.

48" clearance required on top of unit. Maximum soffit

overhang is 36".

Figure 1

• Place a sound-absorbing material, such as Isomode

under the unit if it will be installed in a location or position

that will transmit sound or vibration to the living area or

adjacent buildings..

506470-01 Issue 1007

Page 2

Page 3

• Install the unit high enough above the ground or roof to

allow adequate drainage of defrost water and prevent

ice buildup.

• In heavy snow areas, do not locate the unit where drifting

snow will occur. The unit base should be elevated above

the depth of average snows.

NOTE: Elevation of the unit may be accomplished by

construction a frame using suitable materials. If a

support frame is constructed, it must not block drain

holes in unit base.

• When installed in areas where low ambient temperatures

exist, locate unit so winter prevailing winds do not blow

directly into outdoor coil.

• Locate unit away from overhanging roof lines which

would allow water or ice to drop on, or in front of, coil or

into unit.

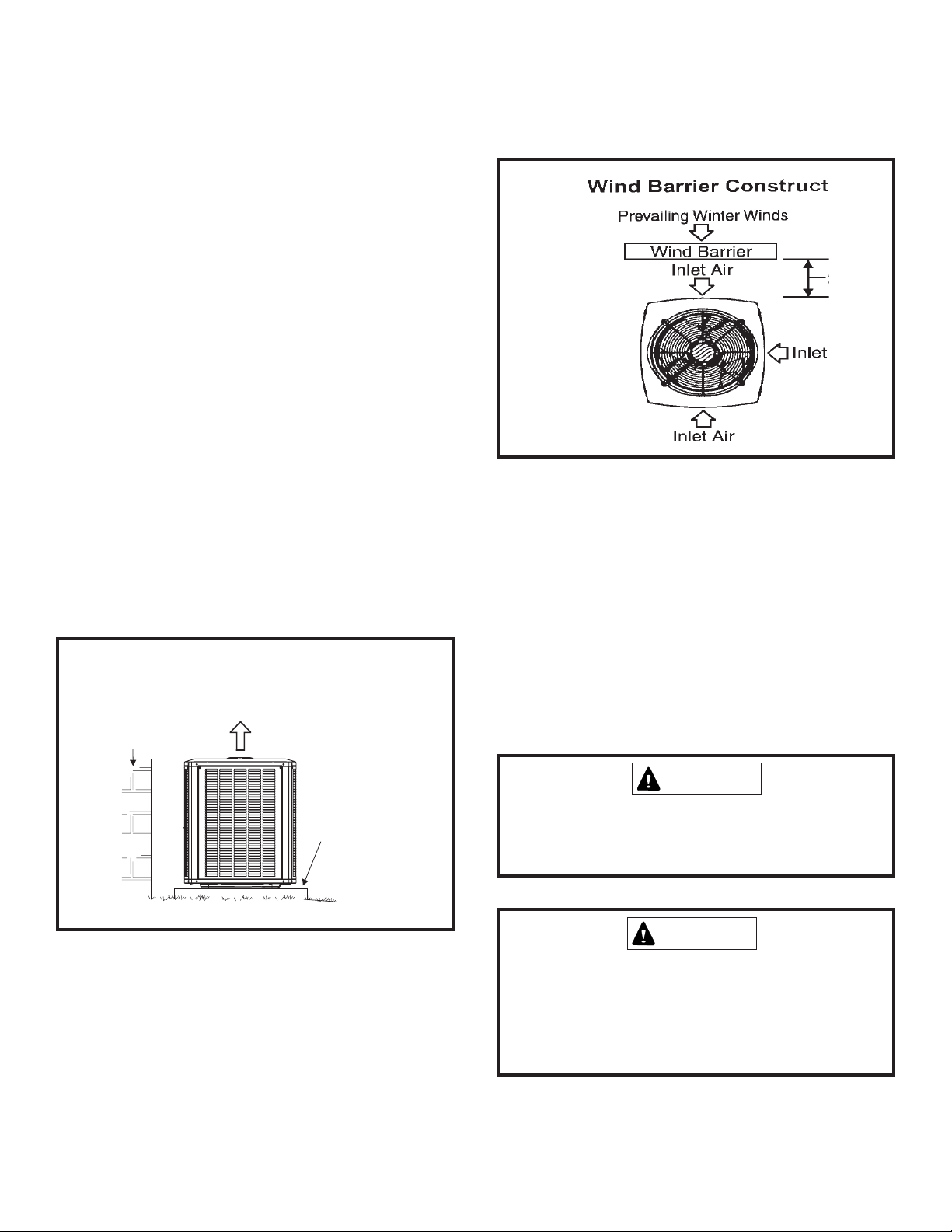

If unit coil cannot be mounted away from prevailing winter

winds, a wind barrier should be constructed (See Figure 3).

Size the barrier at least the same height and width as the

outdoor unit. Mount barrier 24” from the sides of the unit in

the direction of the prevailing winds.

Slab Mounting

When installing a unit at grade level, install on slab high

enough above grade so that water from higher ground will

not collect around the unit (See Figure 2). Slab should have

a slope tolerance away from the building of 2° or 2” per 5’.

This will prevent ice from building up under the unit during a

defrost cycle. Refer to following roof mounting section for

barrier construction if unit must face prevailing winter winds.

Slab Mounting

Discharge Air

Building

Structure

Mounting Slab

Ground Level

Figure 3

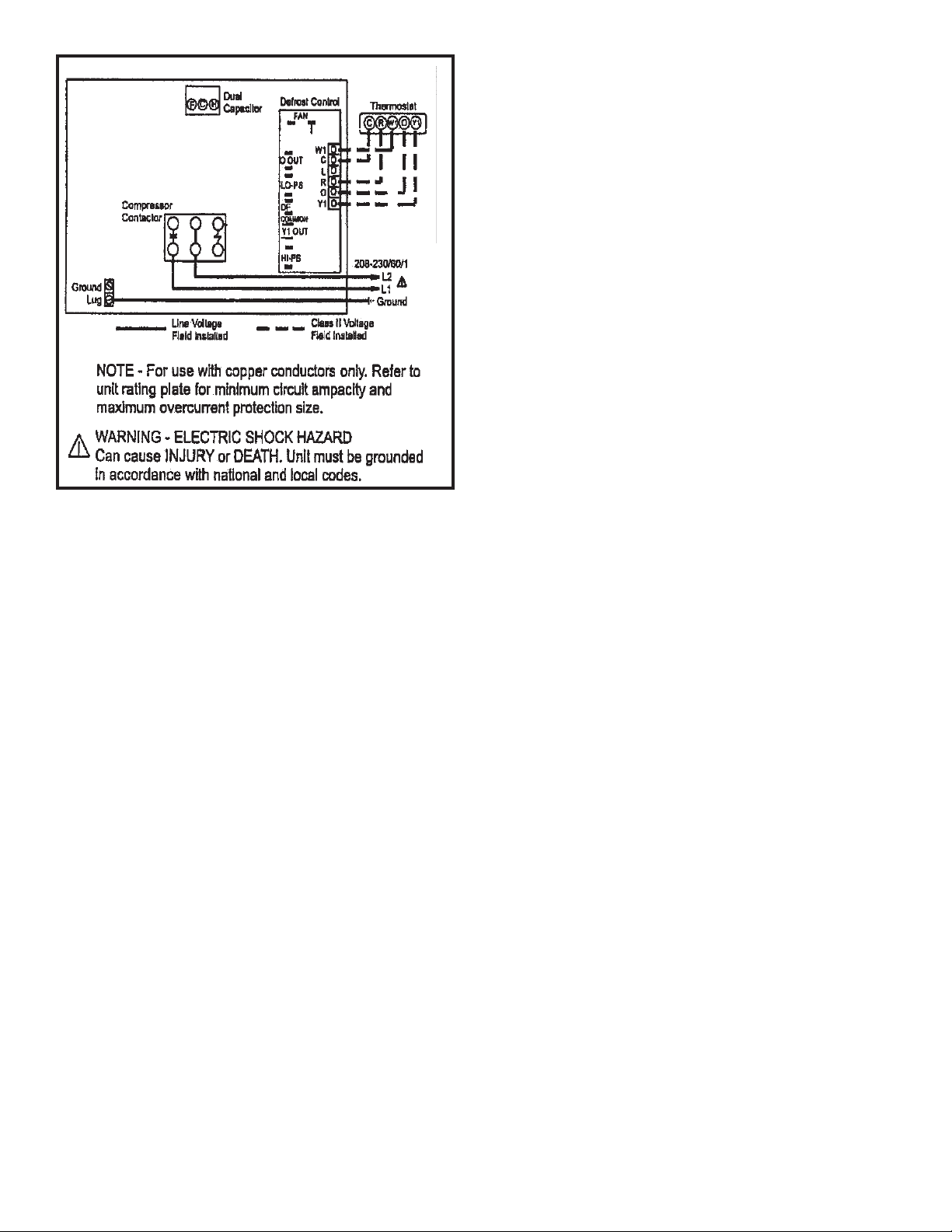

Electrical Wiring

All field wiring must be done in accordance with the National

Electrical Code (NEC) recommendations, Canadian

Electrical Code (CEC) and CSA Standards, or local codes,

where applicable.

Refer to the furnace or blower coil installation instructions

for additional wiring application diagrams and refer to unit

rating plate for minimum circuit ampacity and maximum

overcurrent protection size.

W ARNING

Unit must be grounded in accordance with national and

local codes. Failure to ground unit properly can result in

personal injury or death.

Figure 2

Roof Mounting

Install unit at a minimum of 6” above surface of the roof to

avoid ice buildup around the unit. Locate the unit above a

load bearing wall or area of the roof that can adequately

support the unit. Consult local codes for rooftop applications.

506470-01 Issue 1007

WARNING

Line voltage is present at all components when unit is

not in operation on units with single pole contactors.

Disconnect all remote electric power supplies before

opening access panel. Unit may have multiple power

supplies. Failure to disconnect all power supplies could

result in personal injury or death.

Page 3

Page 4

Figure 4

1. Install line voltage power supply to unit from a properly

sized disconnect switch. Any excess high volt age field

wiring should be trimmed or secured away from the low

voltage field wiring.

Refrigerant Piping

If the 4HP18L T unit is being inst alled with a new indoor coil

and line set, the refrigerant connections should be made as

outlined in this section. If an existing line set and/or indoor

coil will be used to complete the system, refer to this section

as well as the section that follows entitled - Flushing

Existing Line Set and Indoor Coil.

If this unit is being matched with an approved line set or

indoor coil which was previously charged with R-22

refrigerant, the line set and coil must be flushed prior to

installation. If the unit is being used with and existing indoor

coil which was equipped with a liquid line which served as a

metering device (RFCI), the liquid line must be replaced prior

to the installation of the 4HP18L T unit.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections).

Select line set diameters from Table 2 to ensure that oil

returns to the compressor. Size vertical suction riser to

maintain minimum velocity at minimum capacity.

Recommended line length is 50’ or less. If more than 50’

line set is required, contact Technical Services. Table 2

shows the diameters for line sets up to 100’ although vertical

lift applications and trapping requirements need to be

reviewed with Technical Services for line sets over 50’.

2. Ground unit at unit disconnect switch or to an earth

ground. To facilitate conduit, a hole is in the bottom of

the control box. Connect conduit to the control box

using a proper conduit fitting. Units are approved for

use only with copper conductors. 24V Class II circuit

connections are made in the low voltage junction box.

Refer to Figure 4 for high voltage field wiring diagram.

A complete unit wiring diagram is located inside the unit

control box cover.

3. Install room thermostat on an inside wall that is not

subject to drafts, direct sunshine, or other heat sources.

4. Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit. (See Wire Diagram

on page 27.)

5. Do not bundle any excess 24V control wire inside

control box. Run control wire through installed wire tie

and tighten wire tie to provide low voltage strain relief

and to maintain seperation of field-installed low and high

voltage circuits.

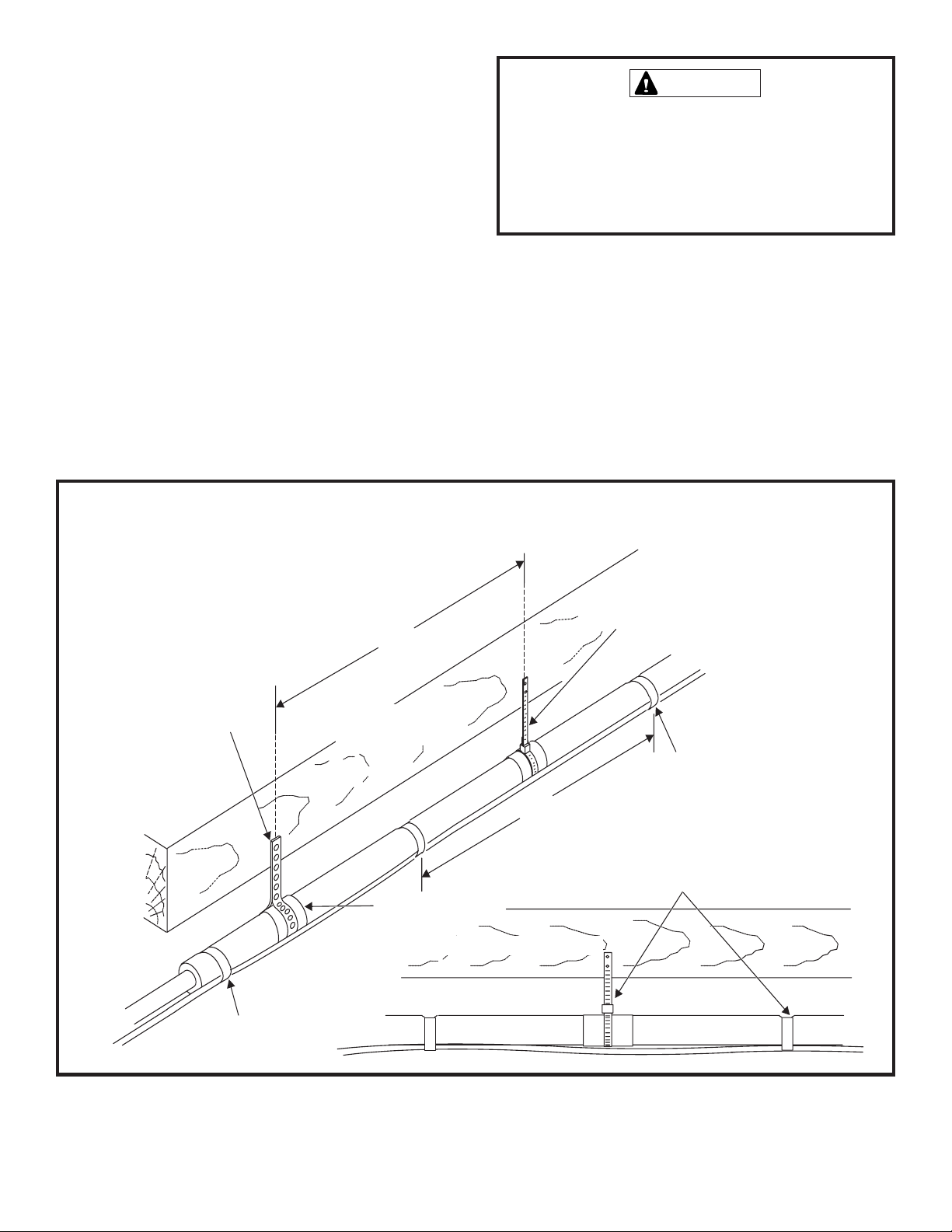

Installing Refrigerant Line

During the installation of an air conditioning system, it is

important to properly isolate the refrigerant line to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling, or floor) may cause objectionable noise when

vibration is translated into sound. As a result, more energy

or vibration can be expected. Close attention to line set

isolation must be observed.

Following are some points to consider when placing and

installing a high-efficiency outdoor unit:

506470-01 Issue 1007

Page 4

Page 5

Placement

Install unit away

from windows

Two 90° elbows installed in lineset

will reduce lineset vibration

Be aware that some localities are adopting sound ordinances

based on how noisy the unit is at the neighbor’s home, not

at the original installation. Install the unit as far as possible

from the property line. When possible, do not install the unit

directly outside a bedroom window . Glass has a verry high

level of sound transmission. Figure 5 shows how to place

the outdoor unit and line set to reduce line set vibration.

Brazing Connection Procedure

1. Cut ends of refrigerant lines square (free from nicks or

dents). Debur the ends. The pipe must remain round; do

not pinch end of line.

2. Before making line set connections, use dry nitrogen to

purge the refrigerant piping. This will help to prevent oxidation and the introduction of moisture into the system.

Line Set Isolation

Illustrations on pages 6 and 7 demonstrate procedures which

ensure proper refrigerant line set isolation. Figure 6 shows

how to install line sets on horizontal runs. Figure 7 shows

how to make a transition from horizontal to vertical. Figure

8 shows how to install line sets on vertical runs.

Refrigerant Line Set Diameters (in.)

Liquid Line

Line Set Length and Size

BTUH

12 f t . 25 ft. 50 ft. 75 ft. 100 ft.

24,000

36,000

48,000

60,000

3/8 3/8 3/8 3/8 3/8

3/8 3/8 3/8 3/8

3/8 3/8 3/8 1/2

3/8 3/8 3/8 1/2

1/2

1/2

1/2

3. Use silver alloy brazing rods (5% or 6% silver alloy for

copper-to-copper brazing or 45% silver alloy for copper-tobrass or copper-to-steel brazing) which are rated for use

with R410A refrigerant.

4. Remove the Schrader core assemblies before brazing to

protect them from damage due to extreme heat. Replace

the cores when brazing is complete.

5. Remove light maroon washers from service valves and

shield light maroon stickers to protect them during brazing.

Wrap a wet cloth around the valve body and copper tube

stub to protect it from heat damage.

Outside Unit Placement & Installation

S uction Line

Line Set Length and Size

BTUH

12 f t . 25 ft. 50 ft. 75 ft. 100 ft.

24,000

36,000

48,000

60,000 1/8 1/8 1-1/8

3/4 3/4

7/8

7/8

3/4 3/4

7/8

7/8

For installations exceeding 50’, contact

T echnical Services.

Table 2

7/8

7/87/8

1-1/8

1-1/8

7/8

1-1/8

1-1/8

1-1/8

Figure 5

506470-01 Issue 1007

Page 5

Page 6

6. Braze the line set to the service valve. Quench the joints

with water or a wet cloth to prevent heat damage to the

valve core and opening port. The tube end must stay

bottomed in the fitting during final assembly to ensure

proper seating, sealing, and rigidity .

7. Install the thermal expansion valve which is sold

separately and which is approved for use with R410A

refrigerant in the liquid line at the indoor coil (see Refrigerant

Metering Device on page 9).

Refrigerant Line Sets: Installing Horizont al Runs

CAUTION

When flushing existing line set and/or indoor coil, be sure to

empty all existing traps. Residual mineral oil can act as an

insulator, preventing proper heat transfer. It can also clog

the thermal expansion valve, reducing system performance

and capacity . Failure to properly flush system as explained

in these instructions will void warranty .

To hang line set from joist or rafter,

use either metal strapping material

or anchored heavy nylon wire ties.

Strapping Material

(around vapor line only)

8’

Floor Joist or

Roof Rafter

Metal Sleeve

Floor Joist or Roof Rafter

Wire Tie

(around vapor line only)

Tape or Wire Tie

8’

Strap the vapor line to the joist or rafter

at 8 intervals then strap the liquid line

’

to the vapor line.

Tape or Wire Tie

Figure 6

506470-01 Issue 1007

Page 6

Page 7

Refrigerant Line Sets: Transition from Vertical to Horizontal

Heavy Nylon

Wall

Stud

Metal Sleeve

Anchored

Wire Tie

Strap Liquid

Line to Vapor

Line

Liquid Line

Vapor Line Wrapped

–

in Armaflex

Figure 7

Muffler-Type

Wall

Stud

Metal Sleeve

Automotive

Hanger

Strap Liquid

Line to Vapor

Line

Liquid Line

Vapor Line Wrapped

–

in Armaflex

Refrigeraant Line Sets: Installing Vertical Runs (new construction shown)

NOTE: Similar installation practices

should be used if line set is to be

installed on exterior of outside wall.

Vapor Line Wrapped

IMPORTANT:

Refrigerant

lines must not

contact structure.

Outside Wall

Wood Block

Between Studs

with Armaflex

Outside Wall

Liquid Line

Caulk

IMPORTANT: Refrigerant

lines must not contact wall.

Vapor Line

Liquid Line

Wire Tie

Inside Wall

Strap

Sleeve

Wire Tie

Wood Block

Wire Tie

Strap

PVC Pipe

506470-01 Issue 1007

Fiberglass

Insulation

Figure 8

Sleeve

Page 7

Page 8

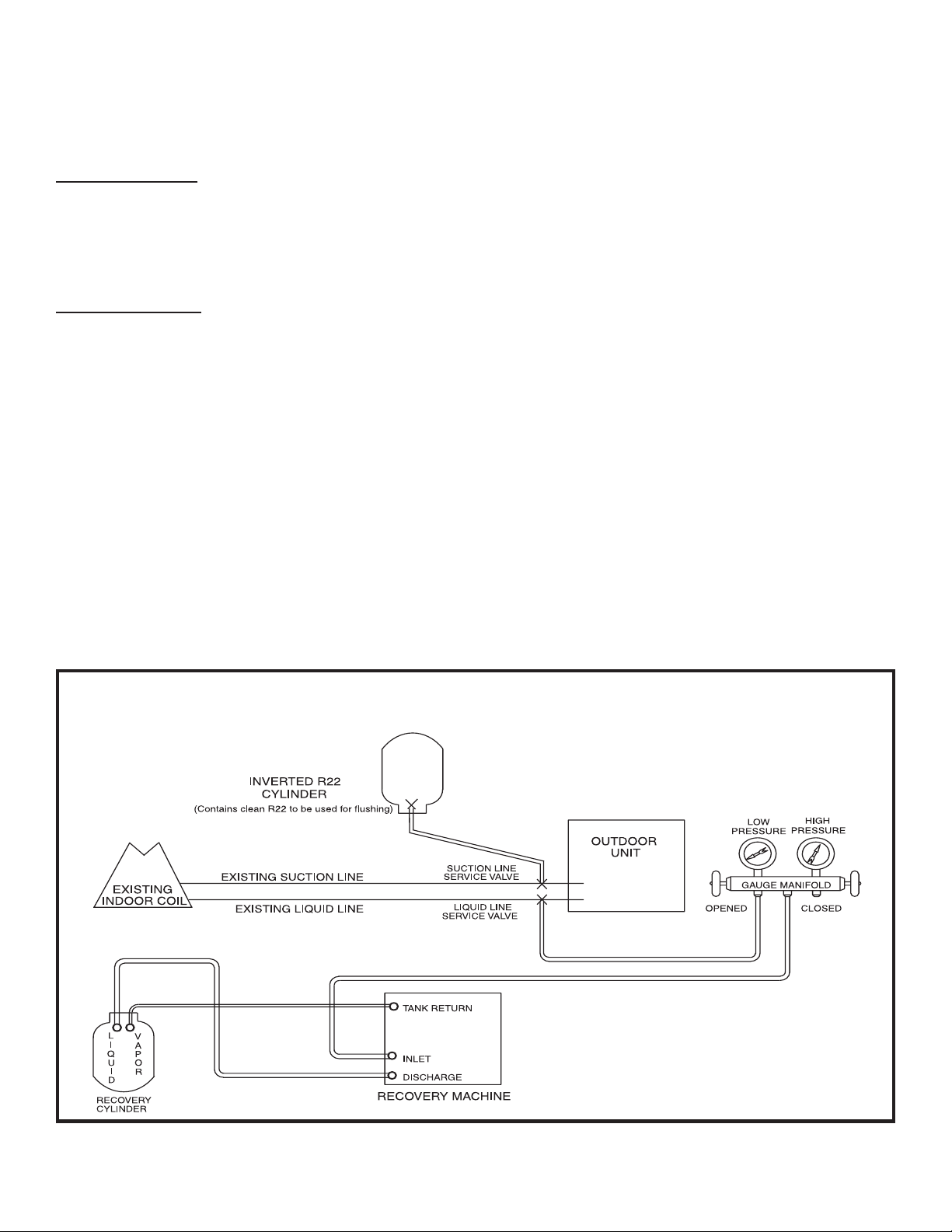

Flushing Existing Line Set and Indoor Coil

This procedure should not be performed on systems

which contain contaminant s, such as compressor burn

out.

Required Euipment

The following equipment is needed to flush the existing line

set and indoor coil (See Figure 9). T wo clean R-22 recovery

bottles, an oil-less recovery machine with a “pump down”

feature, and two sets of gauges (one for use with R-22 and

one for use with R410A).

from the existing system. Refer to the gauges after shutdown

to confirm that the entire system is completely void of

refrigerant. Disconnect the liquid and suction lines from the

existing outdoor unit.

If the existing outdoor unit is equipped with manual shutoff

valves AND new R-22 refrigerant will be used to flush the

system:

Start the existing R-22 refrigerant system in cooling mode

and close the liquid line valve. Pump all the existing R-22

refrigerant back into the outdoor unit.

Flushing Procedure

IMPORTANT: The line set and/or indoor coil must be

flushed with at least the same amount of refrigerant that

previously charged the system. Check the charge in the

flushing cylinder before flushing the unit.

1. Remove existing R-22 refrigerant using the appropriate

procedure.

If the existing outdoor unit is not equipped with shutoff valves,

or if the unit is not operational AND the existing R-22

refrigerant will be used to flush the system:

Disconnect all power to the existing outdoor unit. Connect

the existing unit, a clean recovery cylinder, and the recovery

machine according to the instructions provided with the

recovery machine. Remove all R-22 refrigerant

Flushing Connections

(It may be necessary to bypass the low pressure switches

to ensure complete refrigerant evacuation.)

When the low side system pressures reach 0 psig, close

the suction line valve. Disconnect all power to the existing

outdoor unit. Refer to the gauges after shutdown to confirm

that the valves are not allowing refrigerant to flow back into

the low side of the system. Disconnect the liquid and suction

lines from the existing outdoor unit.

2. Remove the existing outdoor unit. Set the new R410A

unit and follow the brazing connection procedure outlined

previously on this page to make line set connections. Do

not install the R410A thermal expansion valve at this

time.

3. Make low voltage and line voltage connections to the

new outdoor unit. Do not turn on power to the unit or

open the outdoor unit service valves at this time.

Figure 9

506470-01 Issue 1007

Page 8

Page 9

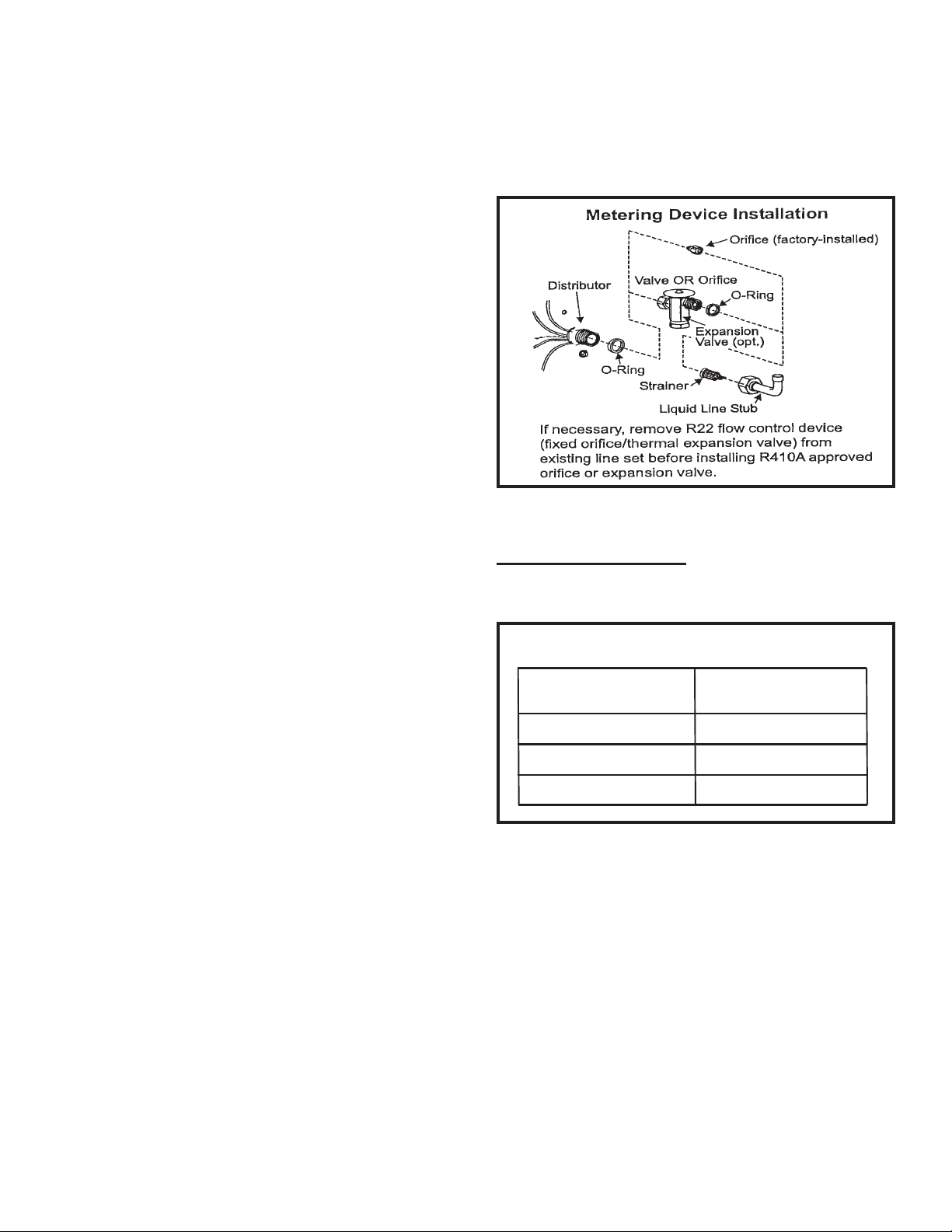

4. Remover the existing R-22 refrigerant flow control orifice

or thermal expansion valve before continuing with flushing

procedures. R-22 flow control devices are not approved for

use with R410A refrigerant and may prevent proper flushing.

Use a field-provided fitting to reconnect the lines.

5. Remove the pressure tap valve cores from the 4HP18L T

units service valves. Connect an R-22 cylinder with clean

refrigerant to the suction service valve. Connect the R-22

gauge set to the liquid line valve and connect a recovery

maching with an empty recovery tank to the gauge set.

6. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to allow

the recovery machine to pull a vacuum on the existing system

line set and indoor coil.

7. Invert the cylinder of clean R-22 and open its valve to

allow liquid refrigerant to flow in to the system through the

suction line valve. Allow the refrigerant to pass from the

cylinder and through the line set and the indoor coil before it

enters the recovery machine.

An R410A system will not operate properly with an R-22

metering device.

Install the refrigerant metering device as shown in Figure

1 1. Do not twist cap tubes when loosening the seal nut from

the orifice housing. Use wrench to back up the distributor.

8. Af ter all of the liquid refrigerant has been recovered, switch

the recovery machine to vapor recovery so that all of the R22 vapor is recovered. Allow the recovery machine to pull a

vacuum on the sytem.

NOTE: A single system flush should remove all of the mineral

oil from the existing refrigerant lines and indoor coil. A second

flushing may be done (using clean refrigerant) if insufficient

amounts of mineral oil were removed during the first flush.

After each system flush, allow the recovery machine to

pull a vacuum on the system at the end of the procedure.

9. Close the valve on the inverted R-22 cylinder and the

gauge set valves. Pump the remaining refrigerant out of

the recovery machine and turn the machine off.

10. Use nitrogen to break the vacuum on the refrigerant

lines and indoor coil before removing the recovery machine,

gauges, and R-22 refrigerant drum. Re-install pressure tap

valve cores into the 4SHP18L T unit’s service valves.

11. Install the fixed orifice (or thermal expansion valve

approved for use with R410A refrigerant) in the liquid line at

the indoor coil.

Refrigerant Metering Device

4HP18LT units are designed for use with TXV systems.

Refer to the appropriate following section for information on

installing the chosen refrigerant metering device.

Figure 10

Expansion Valve Systems

Expansion valves equipped with Chatleff-type fittings are

available from the manufacturer. See Table 3 for proper

TXV for each unit.

TXV Data

MODEL PART NUMBER

4HP18LT- 24

4HP18LT - 36

4HP18LT - 48, -60 H4TXV03

T able 3

To install an expansion valve (See Figure 10 above):

1. Separate the distributor assembly and remove the piston

orifice and used teflon seal. Insert nozzle end of the

expansion valve along with a new teflon seal into the

distributor and tighten to 20 - 30 ft. lbs. Use backup wrench

on all wrench flats. Overtightening will crush the teflon

seal and may cause a leak.

H4TXV01

H4TXV02

506470-01 Issue 1007

2. Attach liquid line portion of distributor assembly along

with new teflon seal to the inlet of the expansion valve.

Tighten to 20 - 30 ft. lbs. Use backup wrench on all wrench

flats. Overtightening will crush the teflon seal and may

cause a leak.

Page 9

Page 10

3. Connect the external equalizer line to the equalizer port

on the suction line and tighten to 8 ft.lbs.

4. Strap the superheat sensing bulb to the suction header.

Suction Line (Ball T ype) Service Valve

Suction line (ball type) service valves function the same way

as the other valves; the difference is in the construction (See

Figure 12).

If installing an expansion valve on an indoor coil that

previously used a fixed orifice, be sure to remove the existing

fixed orifice. Failure to remove a fixed orifice when installing

an expansion valve to the indoor coil will result in improper

operation and damage to the system.

Manifold Gauge Set

Manifold guage sets used with systems charged with R410A

refrigerant must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures 1 - 800 on the high side and a low side of 30”

vacuum to 250 psi with dampened speed to 500 psi. Gauge

hoses must be rated for use at up to 800 psi of pressure

with a 4000 psi burst rating.

Liquid and Suction Line Service Valves

The liquid line and suction line service valves (See Figure

1 1) and service ports are used for leak teating, evacuation,

charging, and checking charge.

Each valve is equipped with a service port which has a

factory-installed Schrader valve. A service port cap protects

the Schrader valve from contamination and serves as the

primary leak seal.

The ball valve is equipped with a service port with a factoryinstalled Schrader valve. A service port cap protects the

Schrader valve from contamination and serves as the

primary seal.

Leak T esting

After the line set has been connected to the indoor and

outdoor units, the line set connections and indoor unit must

be checked for leaks.

To Access the Schrader Port:

1. Remove the service port cap with an adjustable wrench.

2. Connect gauge to the service port.

3. When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Liquid or Suction Line Service V alve:

Remove stem cap with an adjustable wrench.

Use service wrench with a hex-head extension to back the

stem out counterclockwise as far as it will go. Use a 3/16”

hex head extension for liquid line service valves and a 5/

16” extension for suction line service valves.

Replace the stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

To Close Liquid or Suction Line Service V alve:

1. Remove the stem cap with an adjustable wrench.

2. Use a service wrench with a hex-head extension to turn

the stem clockwise to seat the valve. Tighten firmly.

Figure 11

3. Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

506470-01 Issue 1007

Page 10

Page 11

Figure 12

3. Open the high pressure side of the manifold to allow

R410A into the line set and indoor unit. Weigh in a trace

amount of R410A. (A trace amount is a maximum of 2 oz.

of refrigerant or 3 lbs. pressure.) Close the valve on the

R410A cylinder and the valve on the high pressure side of

the manifold gauge set. Disconnect the R410A cylinder.

4. Connect a cylinder of nitrogen with a pressure regulating

valve to the center port of the manifold gauge set. When

using high pressure gas such as nitrogen for this

purpose, be sure to use a regulator that can control the

pressure down to 1 or 2 psig.

5. Adjust nitrogen pressure to 150 psig. Open the valve on

the high side of the manifold gauge set to pressurize the

line set and the indoor coil.

6. After a short period of time, open a refrigerant port to

make sure that an adequate amount of refrigerant has been

added for detection (refrigerant requirements will vary with

lenths). Check all joints for leaks. Purge nitrogen and R410A

mixture. Correct any leaks and rechecks.

Evacuation

Evacuating the system of noncondensables is critical for

proper operation of the unit. Noncondensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Noncondensables and water vapor combine with

refrigerant to produce substances that corrode copper piping

and compressor parts.

WARNING

Refrigerant can be harmful if inhaled. Refrigerant must

always be used and recovered responsibly. Incorrect

or irresponsible use of refrigerant can result in personal

injury or death.

WARNING

Never use oxygen to pressurize refrigeration or air conditioning systems. Oxygen will explode on contact with

oil and could cause personal injury or death.

Using an Electronic Leak Detector

1. Connect the high pressure hose of the manifold gauge

set to the suction valve service port. (Normally the high

pressure hose is connected to the liquid line port; however,

connecting it to the suction ports helps to protect the manifold

gauge set from damage caused by high pressure.)

2. With both manifold valves closed, connect the cylinder of

R410A refrigerant. Open the valve on the R410A cylinder

(vapor only).

W ARNING

Do Not use a compressor to evacuate a system. A void

deep vacuum operation. Extremely low vacuums can

cause internal arcing and compressor failure. Danger

of equipment damage. Damage caused by deep vacuum

operation will void warranty .

Use a thermocouple or thermistor electronic vacuum gauge

that is calibrated in microns. Use an instrument that reads

down to 50 microns.

1. Connect the manifold gauge set to the service valve ports

as follows:

• Low pressure gauge to suction line service valve

• High pressure gauge to liquid line service valve.

2. Connect micron gauge.

3. Connect the vacuum pump (with vacuum gauge) to the

center port of the manifold gauge set.

506470-01 Issue 1007

Page 11

Page 12

4. Open both manifold valves and start vacuum pump.

5. Evacuate the line set and indoor unit to a minimum of

500 microns or lower. During the early st ages of evacuation,

it is desirable to close the manifold gauge valve at least once

to determine if there is a rapid rise in pressure. A rapid rise

in pressure indicates a relatively large leak. If this occurs,

the leak testing procedure must be repeated.

6. When 500 microns or lower is maintained, close the

manifold gauge valves, turn off the vacuum pump, and

disconnect the manifold gauge center port hose from the

vacuum pump. Att ach the manifold gauge center port hose

to a nitrogen cylinder with pressure regulator set to 150 psig

and purge the hose. Open the manifold gauge valves to

break the vacuum in the line set and indoor unit. Close the

manifold gauge valves.

7. Shut off the nitrogen cylinder and remove the manifold

gauge hose from the cylinder. Open the manifold gauge

valves to release the nitrogen from the line set and indoor

unit.

8. Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set and

indoor unit until 500 microns is maintained within a 20 minute

period after shutting off the vacuum pump and closing the

manifold gauge valves.

9. When the requirements above have been met, disconnect

the manifold hose from the vacuum pump. Open the service

valves to break the vacuum in the line set and indoor unit.

506470-01 Issue 1007

Page 12

Page 13

START-UP

3/8 in.

3 oz. Per 5 ft.

Liquid Line Set

Diameter

Oz. per 5 ft. adjust

from 15 ft. line set*

CAUTION

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start-up to prevent

compressor damage as a result of slugging.

1. Rotate fan to check for frozen bearings or binding.

2. Inspect all factory and field-installed wiring for loose

connections.

3. Af ter evacuation is complete, open liquid line and suction

line service valves to release refrigerant charge (contained

in outdoor unit) into system.

4. Replace the stem caps and secure finger tight, then

tighten an additional 1/6 of a turn.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit nameplate.

If not, do not start equipment until the power company has

been consulted and the voltage condition corrected.

6. Set thermostat for cooling demand, turn on power to

indoor blower, and close the outdoor unit disconnect switch

to start the unit.

7. Recheck unit voltage with unit running. Power must be

within range shown on unit nameplate.

Units are factory charged with the amount of R410A

refrigerant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with 15’

line set. For varying lengths of line set, refer to Table 4 for

refrigerant charge adjustment. A blank space is provided

on the unit rating plate to list the actual field charge.

Refrigerant Charge Adjustment

* If line length is greater than 15 ft., add this amount.

If line length is less than 15 ft., remove this amount.

T able 4

IMPORT ANT

Mineral oils are not compatible with R410A. If oil must

be added, it must be a polyolester oil.

If the system is void of refrigerant, clean the system using

the procedure described below.

1. Use dry nitrogen to pressurized the system and check

for leaks. Repair leaks, if possible.

2. Evacuate the system to remove as much of the moisture

as possible.

Refrigerant Charging

This system is charged with R410A refrigerant which

operates at much higher pressures than R-22. The liquid

line drier provided with the unit is approved for use with

R410A. Do not replace it with one designed for use with R-

22. This unit is NOT approved for use with coils which

use capillary tubes as a refrigerant metering device.

R410A refrigerant cylinders are rose colored.

Refrigerant should be added through the suction valve

in the liquid state.

Certain R410A cylinders are identified as being equipped

with a dip tube. These allow liquid refrigerant to be

drawn from the bottom of the cylinder without inverting

the cylinder. Do not turn this type of cylinder upside

down to draw refrigerant.

3. Use dry nitrogen to break the vacuum.

4. Evacuate the system again.

5. Weigh the appropriate amount of R410A refrigerant (listed

on unit nameplate) into the system.

6. Monitor the system to determine the amount of moisture

remaining in the oil. Use a test kit to verify that the moisture

content is withing the kit’s dry color range. It may be

necessary to replace the filter drier several times to achieve

the required dryness level. If system dryness is not

verified, the compressor will fail in the future.

The outdoor unit should be charged during warm weather.

However, applications arise in which charging must occur in

the colder months. The method of charging is determined

by the unit’s refrigerant metering device and the outdoor

ambient temperature.

Measure the liquid line temperature and the outdoor ambient

temperature as outlined below:

506470-01 Issue 1007

Page 13

Page 14

Figure 13

1. Connect the manifold gauge set to the service valve ports

as follows (See Figure 13 above):

• Low pressure gauge to suction line service valve

• High pressure gauge to liquid line service valve

2. Close manifold gauge set valves. Connect the center

manifold hose to an upright cylinder of R410A.

3. If room temperature is below 70°F, set the room

thermostat to call for heat. This will create the necessary

load for properly charging the system in the cooling cycle.

4. Use a digital thermometer to record the outdoor ambient

temperature.

5. When the heating demand has been satisfied, switch the

thermostat to cooling mode with a set point of 68°F. When

pressures have stabilized, use a digital thermometer to

record the liquid and suction line temperatures.

6. The outdoor temperature will determine which charging

method to use. Proceed with the appropriate charging

method.

2. Conduct a leak check, then evacuate as previously

outlined.

3. Weigh in the charge according to the total amount shown

on the unit nameplate.

If weighing facilities are not available or if unit is being

charged during warm weather, use one of the following

procedures.

Charge Using Subcooling Method (Fixed Orifice/TXV

Systems) - Outdoor Temperatures 65°F or Above

If charging a fixed orifice or TXV system when the outdoor

ambient temperature is 65°F or above, the subcooling

method can be used to charge the unit.

1. With the manifold gauge hose still on the liquid service

port and the unit operating stably , use a digital thermometer

to check the liquid line temperature. For best results, use

the same digital thermometer to check both the outdoor

ambient and the liquid line temperatures.

2. At the same time, record the liquid line pressure reading.

3. Use the temperature/pressure chart (T able 5) to determine

Charge Using Weigh-In Method (Fixed Orifice/TXV

Systems) - Outdoor Temperatures Below 65°F

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, use the weigh-in method to charge the

unit. Do this after any leaks have been repaired.

1. Recover the refrigerant from the unit.

506470-01 Issue 1007

the saturation temperature for the liquid line pressure

reading.

4. Subtract the liquid line temperature from the saturation

temperature (according to the chart) to determine subcooling.

Page 14

Page 15

R410A T emperature/Pressure Chart

Temp.

Pressure

(F

32 100.8 74 214.0 116 396.0

33 102.9 75 217.4 117 401.3

34 105.0 76 220.9 118 406.7

35 107.1 77 224.4 119 412.2

36 109.2 78 228.0 120 417.7

37 111.4 79 231.6 121 423.2

38 113.6 80 235.3 122 428.8

39 115.8 81 239.0 123 434.5

40 118.0 82 242.7 124 440.2

41 120.3 83 246.5 125 445.9

42 122.6 84 250.3 126 451.8

43 125.0 85 254.1 127 457.6

44 127.3 86 258.0 128 463.5

45 129.7 87 262.0 129 469.5

46 132.2 88 266.0 130 475.6

47 134.6 89 270.0 131 481.6

48 137.1 90 274.1 132 487.8

49 139.6 91 278.2 133 494.0

50 142.2 92 282.3 134 500.2

51 144.8 93 286.5 135 506.5

52 147.4 94 290.3 136 512.9

53 150.1 95 295.1 137 519.3

54 152.8 96 299.4 138 525.8

55 155.5 97 303.8 139 532.4

56 158.2 98 308.2 140 539.0

57 161.0 99 312.7 141 545.6

58 163.9 100 317.2 142 552.3

59 166.7 101 321.8 143 559.1

60 169.6 102 326.4 144 565.9

61 172.6 103 331.0 145 572.8

62 175.5 104 335.7 146 579.8

63 178.5 105 340.5 147 586.8

64 181.6 106 345.3 148 593.8

65 184.3 107 350.1 149 601.0

66 187.7 108 355.0 150 608.1

67 190.9 109 360.0 151 615.4

68 194.1 110 365.0 152 622.7

69 197.3 111 370.0 153 630.1

70 200.6 112 375.1 154 637.5

71 203.9 113 380.2 155 645.0

72 207.2 114 385.4

73 210.6 115 390.7

72 207.2 114 385.4

73 210.6 115 390.7

Psig

Temp.

(F

Pressure

Psig

Temp.

(F

Pressure

Psig

Table 5

5. Compare the subcooling value with those shown in T able

7. If subcooling is greater than shown, recover some

refrigerant. If subcooling is less than shown, add some

refrigerant.

Subcooling Values

T able 6

Charge Using Approach Method (TXV System) - Outdoor

T emperatures 65°F or Above

The following procedure is intended as a general guide and

is for use on expansion valve systems only . For best results,

indoor temperature should be 70°F to 80°F . Monitor system

pressures while charging.

1. Record outdoor ambient temperature usig a digital

thermometer.

2. Attach high pressure gauge set and operate unit for

several minutes to allow system pressures to stabilize.

3. Compare stabilized pressures with those provided in Table

8. Minor variations in these pressures may be expected

due to differences in installations. Significant differences

could mean that the system is not properly charged or

that a problem exists with some component in the

system. Pressures higher than those listed indicate that

the system is overcharged. Pressures lower than those listed

indicate that the system is undercharged. Verify adjusted

charge using the approach method.

4. Use the same digital thermometer to check liquid line

temperature.

5. Subtract the outdoor ambient temperature from the liquid

line temperture to determine the approach temperature.

506470-01 Issue 1007

Page 15

Page 16

°

Liquid Line Temperature °F

_

=

°

Outdoor Ambient Temperature °F

°

Approach Temperature °F

6. Compare the approach value with those shown in Table

9. If the values do not agree with those provided in Table 8,

add refrigerant to lower the approach temperature or recover

refrigerant from the system to increase the approach

temperature.

Check Charge Using Normal Operating Pressures

Use Table 7 to perform maintenance checks. Table 7 is not

a procedure for charging the system. Minor variations in

these pressures may be due to differences in installations.

Significant deviations could mean that the system is not

properly charged or that a problem exists with some

component in the system.

Approach Values for TXV Systems

T able 7

506470-01 Issue 1007

Page 16

Page 17

L - Liquid S- Suction

V alues provided above are typical pressures. Indoor unit matchup, indoor air quality equipment, and indoor

load will case pressures to vary .

T able 8

506470-01 Issue 1007 Page 17

Page 18

OPERATION

Outdoor unit and indoor blower cycle on demand from the

room thermostat. When the thermostat blower switch is

moved to the ON position, the indoor blower operates

continuously.

Emergency heat is usually used during an outdoor shutdown,

but it should also be used following a power outage if power

has been off for over an hour and the outdoor temperature

is below 50°F . System should be left in the emergency heat

mode at least 6 hours to allow the crankcase heater sufficient

time to prevent compressor slugging.

Filter Drier

The unit is equipped with a large capacity bi-flow filter which

keeps the system clean and dry . If replacement is necessary ,

replace with one of similar design and capacity. The

replacement filter drier must be suitable for use with R410A

refrigerant.

Crankcase Heater

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start-up to prevent

compressor damage as a result of slugging.

Emergency Heat Function (Room Thermostat)

An emergency heat function is designed into some room

thermostats. This feature is applicable when isolation of

outdoor unit is required or when auxiliary electric heat is

stage by outdoor thermostats. When the room thermostat

is placed in the emergency heat position, the outdoor unit

control circuit is isolated from power and the field-supplied

relays bypass the outdoor thermostats. An amber indicating

light simultaneously comes on to remind the homeowner

that the unit is operating in the emergency heat mode.

Defrost System

The defrost system includes two components: the defrost

thermostat and the defrost control.

Defrost Thermostat

The defrost thermostat is located on the liquid line between

the check/expansion valve and the distributor. When the

defrost thermostat senses 42°F or cooler, the thermostat

contacts close and send a signal to the defrost control board

to start the defrost timing. It also terminates defrost when

the liquid line warms up to 70°F.

Defrost Control

The defrost control board includes the combined functions

of time/temperature defrost control, defrost relay , diagnostic

LEDS and terminal strip for field wiring connections (See

Figure 14).

The control provides automatic switching from normal

heating operation to defrost mode and back. During the

compressor cycle (call for defrost), the control accumulates

compressor run time at 30, 60, 90 minute field adjustable

intervals. If the defrost thermostat is closed when the

selected compressor run time interval ends, the defrost relay

is energized and the defrost begins.

Defrost Control Board

P5

O-OUT

LO-PS

DF

Y1-OUT

HI-PS

P1

30

60

90

TEST

K3 Relay

C2

U2

U1

C5

TST PS DF C R O Y1

Defrost Interval

Timing Pins

Test Pins

Compressor Delay Pins

Reversing Valve

Low Pressure Switch

(optional)

Defrost Thermostat

High Pressure Switch

(optional)

Figure 14

506470-01 Issue 1007

FAN

K1 Relay

K2 Relay

L

24V

DS1

DS2

P2

W1

C

L

R

O

Y1

P6

Diagnostic LEDs

24V TerminalStrip

Connections

Page 18

Page 19

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated

compressor run time period during one thermostat run cycle.

This time period must occur before a defrost cycle is initiated.

The defrost interval can be adjusted to 30 (T1), 60 (T2), or

90 (T3) minutes. The defrost timing jumper is factory

installed to provide a 60 minute defrost interval. If the timing

selector jumper is not in place, the control defaults to a 90

minute defrost interval. The maximum defrost period is 14

minutes and cannot be adjusted.

A test option is provided for troubleshooting. The test mode

may be started any time the unit is in the heating mode and

the defrost thermostat is closed or jumpered. If the jumper

is in the TEST position at power up, the control will ignore

the test pins. When the jumper is placed across the TEST

pins for 2 seconds, the control will enter the defrost mode.

If the jumper is removed before an additional 5 second period

has elapsed (7 seconds total), the unit will remain in defrost

mode until the defrost thermostat opens or 14 minutes have

passed. If the jumper is not removed until after the additional

5 second period has elapsed, the defrost will terminate and

the test option will not function again until the jumper is

removed and reapplied.

Compressor Delay

The defrost board has a field-selectable function to reduce

occasional sounds that may occur while the unit is cycling in

and out of the defrost mode. The compressor will be cycled

off for 30 seconds going in and out of the defrost mode when

the compressor delay jumper is removed.

locked out until power to the board is interrupted, then reestablished, or until the jumper is applied to the TEST pins

for 0.5 seconds.

NOTE: The defrost control board ignores input from the

low pressure switch terminals as follows:

• During the TEST mode

• During the defrost cycle

• During the 90 seconds start-up period

• For the first 90 seconds each time the reversing

valve switches heat/cool modes

If the TEST pins are jumpered and the 5 minute delay is

being bypassed, the LO-PS terminal signal is not

ignored during the 90-second start-up period.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The LEDs

flash a specific sequence according to the condition as

shown in Table 9.

Defrost Control Board

Diagnostic LEDs

NOTE: The 30-second “off” cycle is not functional when

jumpering the TEST pins.

Time Delay

The timed-off delay is 5 minutes long. The delay helps to

protect the compressor from short cycling in case the power

to the unit is interrupted or a pressure switch opens. The

delay is bypassed by placing the timer select jumper across

the TEST pins for 0.5 seconds.

Pressure Switch Circuit

The defrost control includes two pressure switch circuits. A

high pressure switch is connected to the board’s HI-PS

terminals(See Figure 14). The low pressure, or loss-ofcharge pressure, switch is connected to the LPS terminals.

During a single demand cycle, the defrost control will lock

out the unit after the fifth time that the circuit is interrupted

by an pressure switch wired to the control board. In addition,

the diagnostic LEDs will indicate a locked-out pressure switch

after the fifth occurrence of an open pressure switch (See

Table 9). The unit will remain

T able 9

506470-01 Issue 1007

Page 19

Page 20

System Diagnostic Module

4HP18LT units contain a diagnostic module for

troubleshouting heat pump system failures. By monitoring

and analyzing data from the compressor and thermostat

demand, the module can accurately detect the cause of

electrical and system related failure without any sensors.

If a system problem occurs, a flashing LED indicator

communicates the failure code.

LED Description

POWER LED (Green) indicates voltage is present at the

power connection of the module.

ALERT LED (Yellow) communicates an abnormal system

condition through a unique flash code. The ALERT LED

will flash a number of times consecutively , pause, and then

repeat the process. The number of consecutive flashes

correlates to a paticular abnormal condition.

Flash Codes

TRIP LED (Red) indicates there is a demand signal from

the thermostat but no current to the compressor is detected

by the module. The TRIP LED typically indicates the

compressor protector is open or may indicate missing

supply power to the compressor.

Interpreting the Diagnostic LEDs

When an abnormal system condition occurs, the diagnostic

nodule displays the appropriate ALER T and/or TRIP LED.

The yellow ALERT LED will flash a number of times

consecutively, pause, and then repeat the process. To

identify a slash code number, count the number of

consecutive flashes. Refer to T able 10 below and T able 1 1

on page 20 for information on the flash codes.

T able 10

506470-01 Issue 1007

Page 20

Page 21

Every time the module powers up, the last ALER T LED flash

code that occurred prior to shutdown is displayed for

60 seconds. The module will continue to display the previous

flash code until the condition returns to normal or 21V AC is

removed from the module. TRIP and ALERT LEDs flashing

at the same time means control circuit voltage is too low for

operation.

Flash Codes (cont.)

24V AC Power Wiring

The diagnostic module requires a constant nominal 24V AC

power supply . The wiring to the module’s R and C terminals

must be directly from the indoor unit or thermostat. The

module cannot be powered by R and C terminals on the

defrost board without experiencing nuisance alerts.

Table 11

506470-01 Issue 1007

Page 21

Page 22

Thermostat Demand Wiring

The diagnostic module requires a thermostat demand signal

to operate properly. The thermostat demand signal input,

labeled Y on the module, should always be connected to

the compressor contactor coil so that when the coil is

energized, the demand signal input is 24VAC. When the

coil is not energized, the demand signal input should be less

than 0.5V AC.

Miswired Module T roubleshooting

Miswired Module Codes

Depending on the system configuration, some ALER T flash

codes may not be active. The presence of safety switches

affects how the system alerts are displayed by the module.

Miswiring the diagnostic nodule will cause false LED codes.

Table 12 Describes LED operation when the module is

miswired and what troubleshooting action is required to

correct the problem.

T able 12

506470-01 Issue 1007

Page 22

Page 23

MAINTENANCE

WARNING

Before performing maintenance operations on system,

turn the electric power to unit OFF at disconnect

switch(es). Unit may have multiple power supplies.

Electrical shock could cause personal injury or death.

Before the start of each heating and cooling season, the

following service checks should be performed by a qualified

service technician.

Inspect and clean outdoor and indoor coils. The outdoor

coil may be flushed with a water hose.

NOTE: It may be necessary to flush the outdoor coil more

frequently if it is exposed to substances which are corrosive

or which block air flow across the coil (such as pet urine,

cottonwood seeds, etc...).

Visually inspect the refrigerant lines and coils for leakes.

Check wiring for loose connections.

Check voltage at the indoor and outdoor units (with units

operating).

Check amperage draw at the outdoor fan motor, compressor ,

and indoor blower motor. Values should be compared with

those given on unit nameplate.

Check, clean (or replace) indoor unit filters.

Check the refrigerant charge and gauge the system

pressures.

Check the condensate drain line for free and unobstructed

flow. Clean drain line, if necessary.

Adjust blower speed for cooling. Measure the pressure drop

over the coil to determine the correct blower CFM.

Belt drive blowers: Check drive belt for wear and proper

tensions.

If insufficient cooling is reported, the unit should be gauged

and refrigerant charge checked (see Refrigerant Charging

on page 13).

506470-01 Issue 1007

Page 23

Page 24

HOMEOWNER INFORMA TION

In order to ensure peak performance, your system must be

properly maintained. Clogged filters and blocked airflow

prevent your unit from operating at its most efficient level.

W ARNING

Turn all electric power to unit OFF at disconnect

switch(es) before performing any maintenance

operations on system. Unit may have multiple power

supplies. Electrical shock could cause personal injury

or death.

Ask your dealer to show you where the indoor unit’s filter is

located. It will be either at the indoor unit (installed internal

or external to the cabinet) or behind a return air grille in the

wall or ceiling in your home. Check the filter monthly and

clean or replace it as needed.

Disposable filters should be replaced with a filter of the same

type and size. If you are unsure of the filter you need for

your system, contact your dealer .

Many indoor units are equipped with reusable foam filters.

These filters can be cleaned with a mild soap and water

solution. Rinse the filter thoroughly and let dry completely

before returning to unit or grille.

The filter and all access panels must be in place any

time the unit is in operation.

Some systems are equipped with an electronic air cleaner,

designed to remove the majority of airborne particles from

the air passing through the cleaner . If your system includes

an electronic air cleaner, ask your dealer for maintenance

instructions.

more frequently if it is exposed to substances which are

corrosive or which block airflow across the coil (such as pet

urine, cottonwood seeds, etc...).

Heat Pump Operation

Heat pump units have several characteristics you should be

aware of:

Heat pumps satisfy heating demand by delivering large

amounts of warm air into the living space. This is quite

different from gas-fired, oil-fired, or electric furnaces which

deliver lower volumes of considerably hotter air to heat the

space.

Do not be alarmed if you notice frost on the outdoor coil in

the winter months. Frost develops on the outdoor coil during

the heating cycle when temperatures are below 45°F. An

electronic control activates a defrost cycle lasting 5 to 15

minutes at preset intervals to clear the outdoor coil of the

frost. A shift in sound type does occur during the defrost

mode.

During the defrost cycle, you may notice steam rising from

the unit. This is a normal occurrence. The thermostat may

engage auxiliary heat during the defrost cycle to satisfy a

heating demand. The unit will return to normal operation at

the conclusion of the defrost cycle.

In case of extended power outage....

If the outdoor temperature is below 50°F and power to the

outdoor unit has been interrupted for 6 hours or longer.

observe the following when restoring power to the heat pump

system.

Set the room thermostat selctor to the “Emergency Heat”

setting to obtain temporary heat for a minimum of 6 hours.

This will allow system refrigerant pressures and

temperatures enough time to return to a stabilized condition.

Inspect and clean indoor coil. The indoor evaporator coil is

equipped with a drain pan to collect condensate formed as

the system removes humidity from the inside air. Have your

dealer show you the location of the drain line and how to

check for obstructions. This also applies to an auxiliary drain,

if one is installed.

Inspect and clean outdoor coil:

Make sure no obstructions restrict airflow to the outdoor unit.

Leaves, trash, or shrubs crowding the unit can cause it to

work harder and use more energy. Keep shrubbery trimmed

away from the unit and periodically check for debris which

collects around the unit.

The outdoor coil may require frequent cleaning, depending

on environmental conditions. Clean the outdoor coil with an

unpressurized water hose to remove surface contaminants

and debris. It may be necessary to flush the outdoor coil

506470-01 Issue 1007

In the “Emergency Heat” mode, all heating demand is

satisfied by auxiliary heat; heat pump operation is locked

out. After a 6 hour “warmup” period, the thermostat can

then be switched to the “Heat” setting and normal heat

operation may resume.

Thermostat Operation

Though your thermostat may vary somewhat from the

description below, its operation will be similar.

Temperature Setting Levers

Most heat pump thermostats have two temperature selector

levers: one for heating and one for cooling. Set the levers

or dials to the desired temperature setpoints for both heating

and cooling. A void frequent temperature adjustment; turning

the unit off and back on before presssures equalize puts

stress on unit compressor.

Page 24

Page 25

Fan Switch

In AUTO or INT (intermittent) mode, the blower operates

only when the thermostat calls for heating or cooling. This

mode is generally preferred when humidity control is a priority .

The ON or CONT mode provides continuous indoor blower

operation, regardless of whether the compressor or auxiliary

heat are operating. This mode is required when constant

air circulation or filtering is desired.

Preservice Check

If your system fails to operate, check the following before

calling for service:

Check to see that all electrical disconnect switches ar ON.

Make sure the thermostat temperature selector is properly

set.

System Switch

Set the system switch for heating, cooling, or auto operation.

The auto mode allows the heat pump to automatically switch

from heating mode to cooling mode to maintain

predetermined comfort settings. Many heat pump

thermostats are also equipped with an emergency heat mode

which locks out heat pump operation and provides temporary

heat supplied by the auxiliary heat.

Indicating Light

Most heat pump thermostats have an amber light which

indicates when the heat pump is operating in the emergency

heat mode.

Temperature Indicator

The temperture indicator displays the actual room

temperature.

Programmable Thermostats

Your system may be controlled by a programmable

thermostat. These thermostats provide the added feature

of programmable time-of-day set points for both heating and

cooling. Refer to the user’s information manual provided

with your particular thermostat for operation details.

Make sure the thermostat system switch is properly set.

Replace any blown fuses, or reset circuit breakers.

Make sure unit access panels are in place.

Make sure air filter is clean.

Locate unit model number and have it handy before calling.

506470-01 Issue 1007

Page 25

Page 26

Start-Up and Performance Checklist

Job Name _____________________________ Job No. ____________ Date ___________

Job Location ___________________________ City _______________ State ___________

Installer _______________________________ City _______________ State ___________

Unit Model No. _________________________ Serial No._____________________________

Service Technician _______________________ Nameplate Voltage _____________________

Rated Load Ampacity _________ Compressor Amperage ________ Outdoor Fan __________

Maximum Fuse or Circuit Breaker ________________________

Electical Connections Tight? Indoor Filter Clean? Supply Voltage (Unit Off) __________

Indoor Blower RPM ___________________ S.P. Drop Over Indoor (Dry) ____________________

Outdoor Coil Entering Air Temperature ________ Voltage with Compressor Operating __________

Outdoor Fan Checked?

Cooling

Liquid Line Pressure _______ Suction Line Pressure _______ Refrigerant Charge Checked?

Heating

Liquid Line Pressure _______ Suction Line Pressure _______ Refrigerant Charge Checked?

Refrigerant Lines: Leak Checked? Properly Insulated?

Service Valves: Fully Opened? Caps Tight?

Thermostat: Calibrated? Properly Set? Level?

Sequence of Operation

Heating Correct? Cooling Correct?

506470-01 Issue 1007

Page 26

Page 27

Wire Diagram

OUTDOOR

FAN

RED

1

CRANKCASE HEATER

L1

208-230/60/1

L2

EQUIPMENT

GROUND

BLUE

BLACK

GREEN

RED

YELLOW

RED

RSC

COMPRESSOR

HR1

S40

BLACK

BLACK

A132

DEFROST

THERMOSTAT

K1-1

S40

Y2

R

C

SOLE

L

Y1

GROUND

LUG

YELLOW

H

RED

C

C12

LT BLUE

RED

A132

BLUE

DUAL CAPACITOR

FCH

CONTACTOR

COMPRESSOR

REVERSING

B1

SR

C

RED

ORANGE

FAN

CMC1

F

PURPLE

YELLOW

RED

YELLOW

VALV E

L

B4

BLACK

RED

FAN

THERMOSTAT

CRW1O

Y2

Y1

BLACK

O-OUT

LO-PS

DF

COMMON

Y1 OUT

HI-PS

DEFROST CONTROL

W1

W1

L

C

C

24V

L

L

R

R

O

O

Y1

Y1

L2

208-230/60/1

1

L1

GROUND

CMC1

FAN

O-OUT

L1

S4

S6

K1

LT BLUE

LO-PS

COMMON

Y1 OUT

S87

BLUE

Y2

Y1

R

C

RED

YELLOW

DF

HI-PS

L

24V

THERMOSTAT

C

W1

C

L

R

O

Y1

Y2

Y1

W1

R

O

KEY COMPONENT

DESCRIPTION

A132 DIAGNOSTIC MODULE

B1 COMPRESSOR

B4 MOTOR - OUTDOOR FAN

C12 CAPACITOR - DUAL

CMC1 CONTROL-DEFROST

HR1 HEATER - COMPRESSOR

K1-1 CONTACTOR - COMPRESSOR

L1 VALVE - REVERSING

S4 SWITCH - HIGH PRESSURE

S6 SWITCH - DEFROST

S40 THERMOSTAT - CRANKCASE

S87 SWITCH - LOW PRESSURE

FOR USE WITH COPPER

1

CONDUCTORS ONLY. REFER

TO UNIT RATING PLATE

FOR MINIMUM CIRCUIT

AMPACITY AND MAXIMUM

OVERCURRENT PROTECTION

SIZE.

WARNING-ELECTRIC SHOCK HAZARD, CAN

CAUSE INJURY OR DEATH. UNIT

MUST BE GROUNDED IN ACCORDANCE

WITH NATIONAL AND LOCAL CODES.

DENOTES OPTIONAL COMPONENTS

LINE VOLTAGE FIELD INSTALLED

CLASS II VOLTAGE FIELD INSTALLED

24 VOLT FACTORY INSTALLED

LO-PS

S87

LOW PRESSURE

SWITCH

HI-PS

S4

HIGH PRESSURE

SWITCH

48630-001

506470-01 Issue 1007 Page 27

Page 28

NOTES

506470-01 Issue 1007 Page 28

Loading...

Loading...