Page 1

GAS UNITS j _:_bic=lo.s

_ Techrlloal

KITS AND ACCESSORIES LithoU,S.A,

©1997 Lennox industries inc.

Datlas, Texas

503,770M

10/97

FURNACE TRANSITION KIT

INSTALLATION INSTRUCTIONS FOR FURNACE TRANSITION KIT CAT# 16L23

(LB-89657A), CAT# 16L24 (LB-89657B), AND CAT# 16L25 (LB-89658A),USED WHEN

CONVERTING FROM G14 UNITS TO G26 UNITS (UPFLOW)

Package 1of 1 contains:

1 - Supply airtransition

1 - External Filter rack (used with kit CAT# 16L23 and

16L24)

1 - Internal filter rack top piece (used with kit CAT#

16L25)

1 - Internal filter rack bottom piece (used with kit

CAT# 16L25)

1 - Filter rack door

1 - Roll of adhesive-backed foam tape (1/8" thick x

5/16" wide)

8- Insulation pins

8- Insulation washers

1 - 1/2" CPVC x 1/2"PVC bushing

2 - Wire ties (used with kit CAT# 16L25)

Check all components for shipping damage. Consult

last carrier immediately if damage is found.

Table 1 shows furnace transition kit usage. These kits

are used when replacing an existing G14 upflow

furnace with a G26 upflow furnace. It allows

installation of the G26 furnace without modification

of the existing supply and side return air plenums.

Bottom return air applications do not require the

provided filter rack,

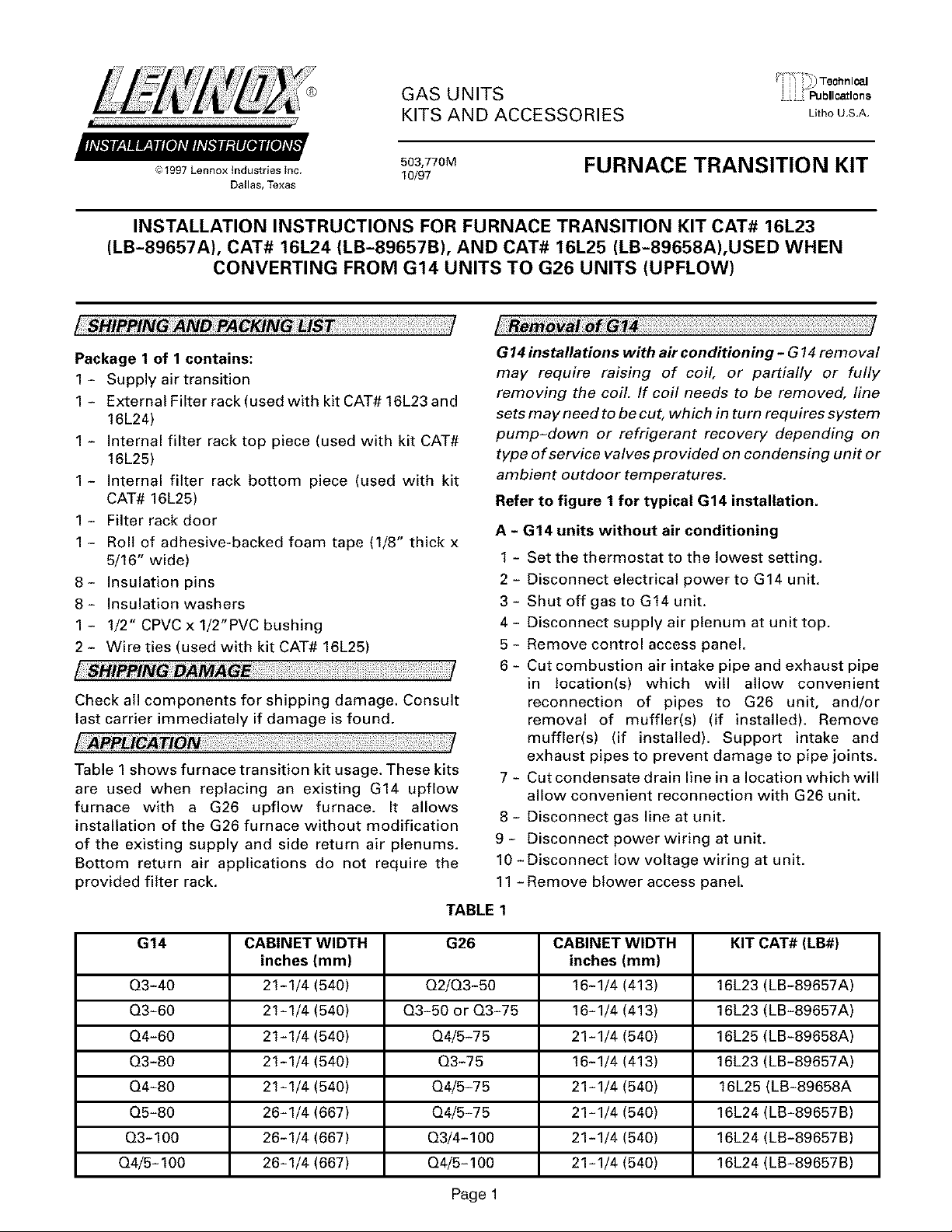

TABLE 1

G14 installations with air conditionh_g - G14removal

may require raising of coil, or partially or fully

removing the coil. If coil needs to be removed, line

sets may need to be cut, which in turn requires system

pump-down or refrigerant recovery depending on

type of service valves provided on condensing unit or

ambient outdoor temperatures.

Refer to figure 1 for typical G14 installation.

A - G14 units without air conditioning

1 - Set the thermostat to the lowest setting,

2 - Disconnect electrical power to G14 unit,

3- Shut off gas to G14 unit.

4 - Disconnect supply air plenum at unit top.

5 - Remove control access panel,

6 - Cut combustion air intake pipe and exhaust pipe

in location(s) which will allow convenient

reconnection of pipes to G26 unit, and/or

removal of muffler(s) (if installed). Remove

muffler(s) (if installed), Support intake and

exhaust pipes to prevent damage to pipe joints,

7 - Cut condensate drain line in a location which will

allow convenient reconnection with G26 unit.

8 - Disconnect gas line at unit.

9 - Disconnect power wiring at unit.

10 -Disconnect low voltage wiring at unit.

11 -Remove blower access panel.

G14 CABINET WIDTH G26 CABINET WIDTH KIT CAT# (LB#)

inches (mm) inches (mm)

Q3-40 21-1/4 (540) Q2/Q3-50 16-1/4 (413) 16L23 (LB-89657A)

Q3-60 21-1/4 (540) Q3-50 or Q3-75 16-1/4 (413) 16L23 (LB-89657A)

Q4-60 21-1/4 (540) Q4/5-75 21-1/4 (540) 16L25 (LB-89658A)

Q3-80 21-1/4 (540) Q3-75 16-1/4 (413) 16L23 (LB-89657A)

Q4-80 21-1/4 (540) Q4/5-75 21-1/4 (540) 16L25 (LB-89658A

Q5-80 26-1/4 (667) Q4/5-75 21-1/4 (540) 16L24 (LB-89657B)

Q3-100 26-1/4 (667) Q3/4-100 21-1/4 (540) 16L24 (LB-89657B)

Q4/5-t00 26-1/4 (667) Q4/5-100 21-1/4 (540) 16L24 (LB-89657B)

Page 1

Page 2

12- Removefilterfrominsideof unit(if present).

Units with side return air - Disconnect side

return air plenum at unit.

Units with bottom return air - Disconnect unit

base from return air plenum.

13 -Remove G14 unit,

B - 614 units with air conditioning

IMPORTANT

1 - Set the thermostat to the lowest setting.

2- Disconnect electrical power to G14 and

condensing unit.

3- Shut off gas to G14 unit.

4 - Remove control access panel.

5 - Cut and remove any section of intake pipe which

blocks access to air conditioning coil. Cut intake

and exhaust pipe at a location(s) which will

provide convenient reconnection of pipe(s) to

G26 unit and/or removal of muffler(s) (if

installed). Remove muffler(s) (if installed),

Support intake and exhaust pipe to prevent

damage to pipe joints.

6

Remove coil access panel.

7-

Disconnect coil cabinet/supply air plenum at G14

unit top. If coil/coil cabinet can be lifted enough

to provide vertical clearance for removal of G14

unit, support coil/coil cabinet at needed height

and go to step 11. Ifnot, prepare coil for removal.

8

If condensing unit has fully functional service

valves and outdoor ambient conditions permit

operating compressor, pump-down refrigerant

system; if not, recover refrigerant.

Cut line sets and coil drain line in a location which

will provide convenient reconnection. Move and

support to allow for coil removal,

10 -Slide coil from coil cabinet/supply air plenum.

11 - Cut G14 heat exchanger condensate drain line in

a location which wilt provide convenient

reconnection with G26 unit.

12 -Disconnect gas line at unit.

13 -Disconnect power wiring at unit.

14 -Disconnect low voltage wiring at unit.

15-Remove blower access panel.

16 -Remove filter from inside unit (if present)

Units with side return air - Disconnect side

return air plenum at unit.

Units with bottom return air - Disconnect unit

base from return air plenum,

Page 2

Page 3

FLEXIBLE ISOLATION

HANGER

EXHAUST PIPE

TYPICAL G14 INSTALLATION

FLEXIBLE BOOT

/ SUPPLY AIR j ......

ii AIR

i

J ...... /_ _ RETURN

ii

f-f i i

ii j- ....

i" --- FLEXIBLE BOOT IN

RETURN AIR PLENUM

SUPPLY AIR PLENUM

INSULATED PAST FIRST ELBOW

FLEXIBLE BOOT IN PLENUM --

MUFFLER

CONDENSATE DRIP LEG

=

MANUAL

MAIN SHUT OFF

VALVE

GAS SUPPLY PIPING

CONTROL

ACCESS PANEL

............. 0

BLOWER RETURN AIR PLENUM

GP_ ELECTRICAL CONDUIT

RETURN AIR PLENUM

INSULATED PAST FIRST

ELBOW

FLEX BLE BOOT N

ISOLATION PADS (ISOMODE) (4) ._

Note - Installation must conform with these

instructions and the installation instructions

packaged with the G26 furnace.

Closet installations - G26 cabinet depth is 2-3/8"

(60.5ram) larger than G14. The G26 may be installed

one inch (25turn) closer to rear of closet (if space

permits) by rotating supply air transition 180 degrees

from that shown in figure 4 or5.

COMPARTMENT i

ACCESSFANEL !

FIGURE 1

A - Filter Rack Installation (Side Return Only)

Note - Filter rack is not used in bottom return air

applications.

I - External Filter Rack

(Used with kit CAT#16L23 and16L24)

1 - Lay G26 unit on its side and cut out return air

opening in cabinet. See figure 4.

2- Filter rack is shipped for right side installation

and for 16 inch (40.6 cm) filter size. If application

requires left side orientation, convert as shown in

figure 2. If application requires 20 inch (50.8 cm)

filter size convert as shown in figure 3.

Page 3

Page 4

Note - It is recommended that rack be converted

to 20 inch filter size if filter is installed elsewhere

in return air duct.

3-In applications where rack uses a 16 inch

(50.8cm) filter, remove filler piece before cutting

rack opening. See figure 4.

4 - Cut four strips from rollofadhesive-backedfoam

tape (provided) to fit filter rack flanges, Apply to

flanges.

5 - Secure filter rack to cabinet as shown in figure 4.

6 - Cut opening in filter rack as shown in figure 4,

7 - In applications where rack uses a 16 inch (50,8cm)

filter, remove rack from cabinet, re-install filler

piece, then re-install rack to cabinet.

8-Install existing filter, unless filter is located

elsewhere in the return air duct,

9- Attach door to filter rack with thumb screws

provided.

II - Internal Filter Rack

(Used with kit CAT#16L25)

Note - If filter is not to be located inside of unit,

installation of this filter kit is not required.

1 - Lay G26 unit on its side and cut out return air

opening in cabinet at knockout guides, See G26

installation instructions.

2 - Install filter rack top and bottom inside unit as

shown in figure 5, tn right side installations

wiring must be carefully worked around.

3 - Install existing filter,

4 - Slide door into filter rack bottom seam and align

with filter rack top securing hole. Attach with

thumb screws provided.

5- Securewiring awayfrom filter access areawith two

provided wire ties. Use existing screws in existing

screw locations to prevent accidental damage to

control board(s)/wiring by drilling of new holes.

B - Supply Air Transition Installation

1 - Cut four strips from roll ofadhesive-backedfoam

tape (provided) to fit supply air transition flanges

at G26 unit connection. Apply to flanges. See

figure 4 or 5,

2- Position supply air transition on unit top as

shown in figure 4 or 5.

3- If required, internally insulate transition with

foil-faced insulation (field provided) and fasten

with kit provided insulation pins and washers,

4- Use four screws and/or bend cabinet flanges

over transition tips to secure transition.

C - Unit Installation

1 - Align unit with existing supply air plenum (coil

cabinet in air conditioning applications) and

return air plenum.

Note - If required, use existing G14 isomode pads

to achieve this alignment.

2 - Make connections to unit, In bottom return air

applications, follow the instructions provided

with the G26 unit, note especiallythe warnings in

the "Return Air Opening Guidelines" section.

3 - ff air conditioning coil was removed, re-install

coil, reconnect line set and coil drain. See

condensing unit installation instructions for

re-processing of refrigerant system.

Note - Coil drain line must not be connected to

heat exchanger condensate drain line. If lines

were connected, debris from evaporator could

affect heat exchanger operation.

4- Make tow voltage wiring entrance to unit on

opposite side from return air connection to

prevent blocking filter access. Connect as

illustrated in G26 installation instructions.

5 - Connect high voltage wiring as outlined in G26

installation instructions,

6- Connect gas piping as outlined in G26

installation instructions.

Consult local codes for flexible connector

installation restrictions on G26 furnace.

7 - Connect venting as outlined in G26 installation

instructions.

Note - Mufflers can not be used in G26

installation. Check existing venting for size

(diameter and length). It should meet the

specifications as outlined in G26 installation

instructions.

8 - Connect heat exchanger condensate drain line as

shown in figure 6 and as outlined in G26 unit

installation instructions, (A 1/2" PVCto 1/2" CPVC

bushing is provided for connecting PVC to

existing CPVC condensate line,)

9 - Continue with Unit Start-up Section as outlined

in G26 installation instructions.

Note - See G26 installation instructions for heat

anticipation settings.

Page 4

Page 5

EXTERNAL FILTER RACK CONVERSION KIT CAT# 16L23 AND 16L24)

FILLER PIECE_ ... --_

FRAME

HOLDING ANGLE _ -_.

SECURING SCREW

16 INCH (40.6 CM)_ I

BOTTOM HOLDING ANGLE _

From Right S de to Left S de Conf gurat on

A= C

........

I

f

Right side configuration I_ Intermediate step

To convert to left side configuration:

1 - Remove screws securing filler piece to frame. See detail A.

2 - Flip filler piece 180 degrees and secure to bottom of frame. See detail B.

3 - Remove bottom holding angle, flip 180 degrees and secure to top of frame. See detail B.

4 - Flip frame 180 degrees to give orientation as in detail C.

EXTERNAL FILTER RACK CONVERSION (KIT CAT# 16L23 AND 16L24)

SECURING

SCREW _--_-_____ =

FRAME

FILLER PIECE --

HOLDING

ANGLE

From 16 inch (40.6 cm) Filter Size to 20 inch (50.8 cm)

E_> Left side configuration

FIGURE 2

LeftSide Orientation Shown

NOTE - THIS CONVERSIONISALSO RECOMMENDED IF

__ FILTERIS NOT INSTALLED IN RACK, BUT IS LOCATED

ELSEWHEREIN RETURNAIR DUCT.

TO convert from 16 inch (40.6 cm)

to 20 inch (50.8 cm) filter size:

1 - Remove screws securing filler piece to frame.

2 - Remove holding angle from filler piece. Discard filler piece.

16 INCH

(40.6 CM)

FILTER

_. 3- Re-secure ho d ng ang e to top of frame.

20 INCH (50.8 CM)

FILTER

FIGURE 3

Page 5

Page 6

ADHESIVE-BACKED

FOAMTAPE

INSTALLATION OF SUPPLY AIR TRANSITION

AND EXTERNAL FILTER RACK (KIT CAT# 161.23 AND 16L24)

_ SUPPLY AIR TRANSITION

SECURING SCREWS

(2 each side)

SUPPLY AIR TRANSITION

SMALL END OF TRANSITION

INSTALL LARGE END OF TRANSITION

TO FRONT OF UNIT.

(If unit in installed one inch further

to the rear rotate transition 180 degrees.)

CUT OPENING IN CABINET USING

CABINET KNOCKOUT GUIDES

KED

FOAM TAPE

EXISTING BLOWER

DECK SCREWS (3)

ii

FILTER RACK

FILTER RACK DOOR

THUMB SCREW -_. _;_

CUT OPENING IN FILTER RACK AS FOLLOWS:

Note - In 16 inch (40.6 cm) filter applications, remove filler piece before cutting opening.

1 - Measure horizontally from rear of G14 to existing return air opening to give dimension "A'.

Mark vertical bend line. (If supply air transition was rotated 180 degrees add one inch.)

2 - Measure vertically from floor to existing G14 return air opening to give dimension "B"

Mark horizontal bend line.

3 - Transfer remaining two sides from G14 to G26 and mark.

4- Add 1/2" to these lines and mark cut lines.

5 - Cut out opening and bend flanges out toward return air plenum.

B

EXISTING BASE

SCREWS (3)

FIGURE 4

Page 6

Page 7

INSTALLATION OF SUPPLY AIR TRANSITION AND INTERNAL FILTER RACK

SUPPLY AIR TRANSITION (KIT CAT# 16L25)

SECURING SCREWS NOTE - FILTERRACK INSTALLATION REQUIRED

(2 each side) ,_

ADHESIVE-BACKED

FOAM TAPE

T

SUPPLY AIR TRANSITION

ONLYIF FILTERWILL BE INSTALLED INSIDE OF UNIT

CABINET SIDE

;MALL END OF TRANSITION

BLOWER DECK

\

"D" HOLES (Left side

installation holes)

"C" HOLES (Right side

installation holes

FILTER RACK TOP

;TALL LARGE END

OF TRANSITION TO

FRONT OF UNIT.

(If unit in installed one inch

further to the rear, rotate

transition 180 degrees.)

INSTALL FILTER RACK TOP AS FOLLOWS:

(Right side installation shown)

1 - Loosen blower deck screws. Remove center two.

2 - Cut away any interfering insulation at A.

3 - Slide filter rack top between blower deck and cabinet and

push back to align "C" holes (right side installation holes).

(For left side installation flip bracket and use "D'holes.)

4 -Secure with existing screws.

5 - Fasten filter rack top with two additional self-drilling self

tapping screws at B approximately one inch from edge. See

view A.

6 - Re-tighten remaining blower deck screws.

EXISTING BLOWER

DECK SCREWS

EXISTING BASE SCREWS

FILTER RACK TOP

,I,I,IB }3

1 inch

(25 mm)

VIEW A

// CABINET SIDE

A

J

"_ FILTER RACK BOTTOM

"FILTER RACK DOOR

THUMB SCREW

"FILTER RACK BOTTOM

1

VIEW A CABINETBASE

INSTALL FILTER RACK BOTTOM AS FOLLOWS:

(Right side installation shown)

(Flip bracket for left side installation)

1 - Loosen base screws. Remove center two.

2 - Cut away any interfering insulation at A.

3 - Slide filter rack bottom between base and cabinet,

4 - Align center two holes and secure with existing screws.

5 - Re-tighten remaining base screws.

FIGURE 5

Page 7

Page 8

1/2 INCH CPVC

G26 CONDENSATE ASSEMBLY

(Forleft or right installation - left shown)

HEAT EXCHANGER COIL

COMBUSTION AIR

BLOWER BRACKET _ //

COLD

HEADER

BOX

VENT TERMINATION

MUST BE

HIGHER THAN COIL

i i

Y

LEFT SIDE OF CABINET

PLUG PROVIDED WITH G26

CONDENSATE TRAP

1/2"PVC X 1/2"MPT ADAPTER PROVIDED WITH G26

1/2" PVC X 1/2" CPVC BUSHING (KIT PROVIDED)

(Bushing fits in one direction only. One end fits inside of 1/2 PVC

adapter or coupling while 1/2 CPVC fits inside the other.)

Note - Bushing may be installed further downstream with a

1/2 inch coupling instead of with 1/2 inch adapter (shown).

NOTE - USE ADHESIVE SUITABLE FOR CPVC AND

PVC WHEN JOINING THESE TWO MATERIALS

FIGURE 6

Page 8

Loading...

Loading...