Page 1

INSTALLATION

2011 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property.

Installation and service must be performed by a licensed

professional installer (or equivalent) or a service agency.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs and HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

INSTRUCTIONS

Merit® Series 14ACX Units

CONDENSING UNITS

506645−01

07/11

Supersedes 11/10

TABLE OF CONTENTS

Shipping and Packing List 1. . . . . . . . . . . . . . . . . . . . . . . .

General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Unit Parts Arrangement 3. . . . . . . . . . . . . . . . . . .

Model Number Identification 3. . . . . . . . . . . . . . . . . . . . . .

Operating Manifold Gauge Set and Service Valves 4. . .

Recovering Refrigerant from Existing System 6. . . . . . .

New Unit Placement 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and Installing Louvers 8. . . . . . . . . . . . . . . . . .

New or Replacement Line Set 9. . . . . . . . . . . . . . . . . . . . .

Brazing Connections 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Line Set and Indoor Coil 14. . . . . . . . . . . . . . . .

Installing Indoor Metering Device 15. . . . . . . . . . . . . . . .

Leak Test Line Set and Indoor Coil 16. . . . . . . . . . . . . . .

Evacuating Line Set and Indoor Coil 17. . . . . . . . . . . . .

Electrical Connections 18. . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Unit Delivered Void of Charge 22. . . . . . . . . . .

Unit Start−Up 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Refrigerant 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Operation 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up and Performance Checklist 30. . . . . . . . . . . . . .

Shipping and Packing List

Litho U.S.A.

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox Engineering Handbook. Coils

previously charged with HCFC−22 must be flushed.

NOTICE TO INSTALLER

Check the unit for shipping damage and listed times below

are intact. If damaged, or if parts are missing, immediately

contact the last shipping carrier.

1 Assembled outdoor unit

1 Refrigerant flow control kit (fixed orifice)

1 Liquid line filter drier

General

It is critical for proper unit operation to place outdoor unit on an

UNIT PLACEMENT

elevated surface as described in Unit Placement section on page 7.

BRAZING LINE SET TO SERVICE VALVES

It is imperative to follow the brazing technique illustrated starting on

page 11 to avoid damaging the service valve’s internal seals.

07/11 506645−01

14ACX Air Conditioners, which will also be referred to in

this instruction as the outdoor unit, uses HFC−410A

refrigerant. This outdoor unit must be installed with a

matching indoor unit and line set as outlined in the Lennox

14ACX Engineering Handbook.

This outdoor unit is designed for use in systems that use

one of the following refrigerant metering devices:

Thermal expansion valve (TXV)

Fixed orifice

Page 1

*2P0711* *P506645-01*

Page 2

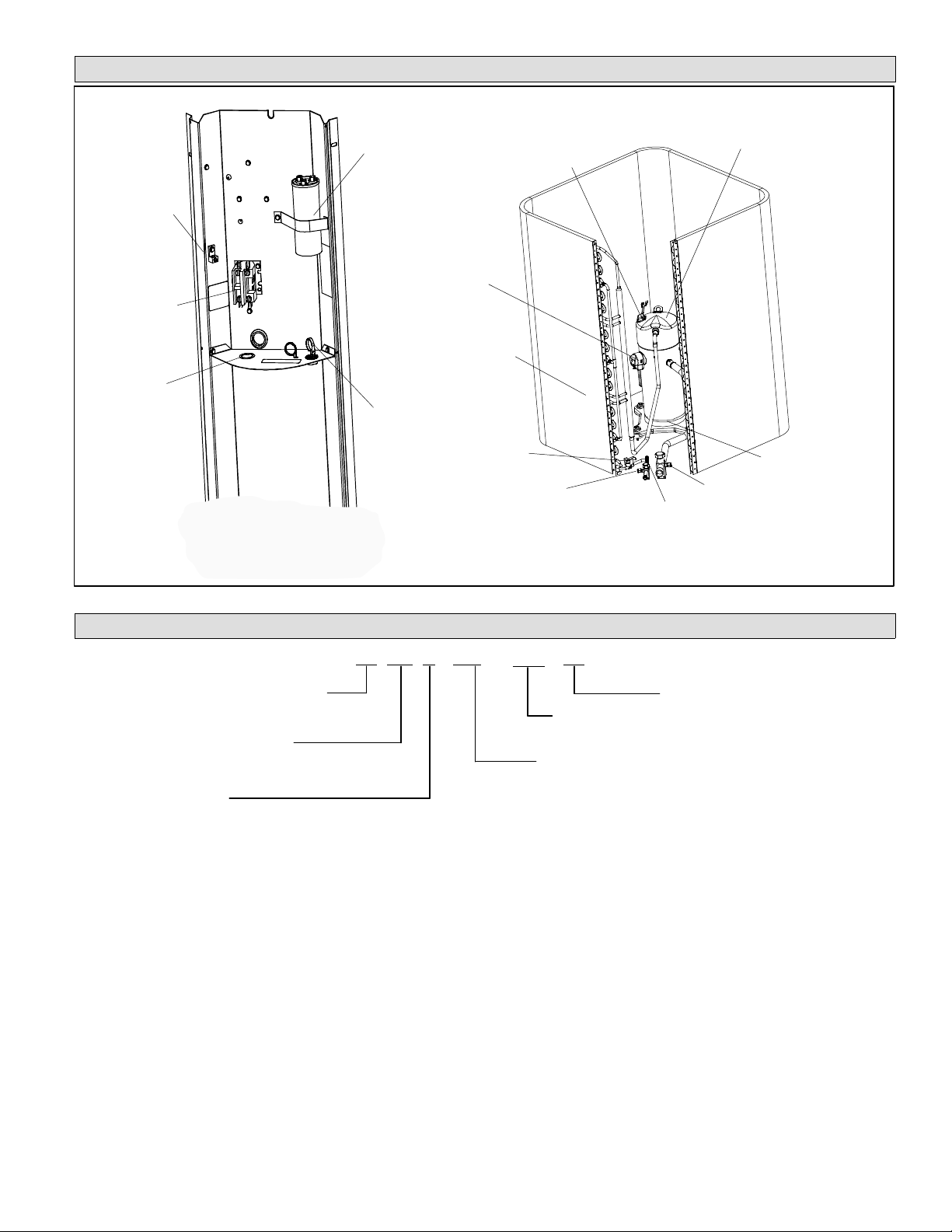

Unit Dimensions − Inches (mm)

A

OUTDOOR

COIL FAN

COMPRESSOR

A

DISCHARGE AIR

B

SUCTION AND LIQUID

LINE CONNECTION

OPTIONAL UNIT STANDOFF KIT (4)

SIDE VIEW

Model Numbers A B

14ACX−018−230 24−1/4 (616) 29−1/4 (743)

14ACX−024−230 28−1/4 (724) 33−1/4 (845)

14ACX−030−230 28−1/4 (724) 37−1/4 (946)

14ACX−036−230 28−1/4 (724) 37−1/4 (946)

14ACX−042−230 28−1/4 (724) 29−1/4 (743)

14ACX−041−230 and 14ACX−048−230 28−1/4 (724) 37−1/4 (946)

14ACX−059−230 32−1/4 (819) 37−1/4 (946)

14ACX−047−230 and 14ACX−060−230 32−1/4 (819) 33−1/4 (845)

(FIELD INSTALLED)

SIDE VIEW

506645−01

Page 2

Page 3

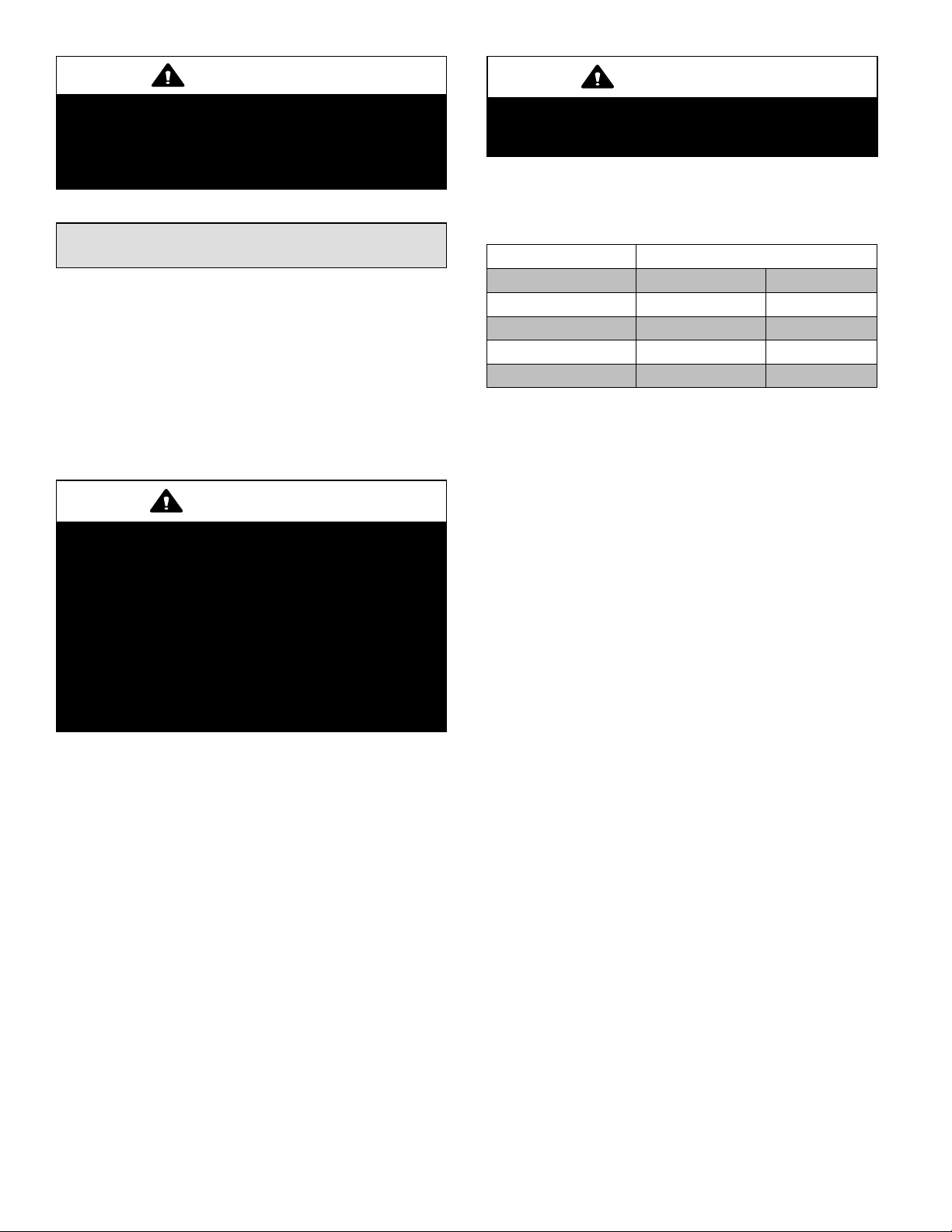

Typical Unit Parts Arrangement

NOTE Plumbing layout and compressor type may vary between model sizes.

CONTROL

GROUND LUG

CONTACTOR

CUTOUT FOR HIGH

VOLTAGE CONDUIT

NOTE − −041, −047, −048, −059 and −060 only are equipped with crankcase thermostat (S40) and

crankcase heater (HR1).

(K1)

DUAL RUN

CAPACITOR

(C12)

DISCHARGE LINE

COMPRESSOR

HARNESS

CONNECTION

OUTDOOR COIL

CONTROL WIRE

LOOP

CRANKCASE HEATER

THERMOSTAT (S40)

LIQUID LINE SERVICE VALVE

THERMAL SWITCH

(S173) (−036 AND

−060 ONLY)

SEE NOTE

COMPRESS0R (B1)

CRANKCASE HEATER

SEE NOTE

(HR1)

SUCTION LINE SERVICE VALVE

HIGH PRESSURE SWITCH (S4)

Model Number Identification

Nominal SEER

Unit Type

AC = Air Conditioner

Refrigerant

X = R−410A

Figure 1. Typical Unit Parts Arrangement

AC X14 024 −

−−

230

13

Voltage

230 = 208/230V−1phase−60hz

Cooling Capacity − Tons

018 = 1.5

024 = 2

030 = 2.5

036 = 3

041 = 3.5

042 = 3.5

047 = 4

048 = 4

059 = 5

060 = 5

Minor Revision Number

Page 3

14ACX SERIES

Page 4

CAUTION

IMPORTANT

Physical contact with metal edges and corners while

applying excessive force or rapid motion can result in

personal injury. Be aware of, and use caution when

working near these areas during installation or while

servicing this equipment.

Operating Manifold Gauge Set and

Service Valves

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

TORQUE REQUIREMENTS

When servicing or repairing heating, ventilating, and air

conditioning components, ensure the fasteners are

appropriately tightened. Table 1 lists torque values for

fasteners.

IMPORTANT

Only use Allen wrenches of sufficient hardness (50Rc −

Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory−torqued (from 9 ft−lbs for

small valves, to 25 ft−lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using an

Allen wrench rated at less than 50Rc risks rounding or

breaking off the wrench, or stripping the valve stem

recess.

See the Lennox Service and Application Notes #C−08−1

for further details and information.

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and fitted

snugly over the cap before tightening.

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. Table 1 provides

torque values for fasteners.

Table 1. Torque Requirements

Parts Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

USING MANIFOLD GAUGE SET

When checking the system charge, only use a manifold

gauge set that features low loss anti−blow back fittings.

Manifold gauge set used with HFC−410A refrigerant

systems must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures of 0 − 800 psig on the high side and a low

side of 30" vacuum to 250 psig with dampened speed to

500 psi. Gauge hoses must be rated for use at up to 800

psig of pressure with a 4000 psig burst rating.

OPERATING SERVICE VALVES

The liquid and vapor line service valves are used for

removing refrigerant, flushing, leak testing, evacuating,

checking charge and charging.

Each valve is equipped with a service port which has a

factory−installed valve stem. Figure 2 provides information

on how to access and operating both angle and ball service

valves.

506645−01

Page 4

Page 5

Operating Angle Type Service Valve:

1. Remove stem cap with an appropriately sized wrench.

2. Use a service wrench with a hex−head extension (3/16" for liquid line valve sizes and 5/16" for vapor line valve sizes) to back

the stem out counterclockwise as far as it will go.

SERVICE PORT CAP

SERVICE PORT CORE

(VALVE STEM SHOWN

TO INDOOR

UNIT

(VALVE STEM SHOWN OPEN)

INSERT HEX WRENCH HERE

CLOSED) INSERT HEX

WRENCH HERE

SERVICE PORT

CORE

TO OUTDOOR UNIT

ANGLE−TYPE SERVICE VALVE

(BACK−SEATED OPENED)

When service valve is OPEN, the service port is

open to linE set, indoor and outdoor unit.

Operating Ball Type Service Valve:

1. Remove stem cap with an appropriately sized wrench.

2. Use an appropriately sized wrenched to open. To open valve,

rotate stem counterclockwise 90°. To close rotate stem

clockwise 90°.

TO INDOOR UNIT

TO OPEN ROTATE STEM

COUNTERCLOCKWISE 90°.

TO CLOSE ROTATE STEM

CLOCKWISE 90°.

SERVICE PORT

SERVICE PORT

CORE

SERVICE PORT

CAP

TO OUTDOOR

UNIT

BALL (SHOWN

CLOSED)

VALV E

STEM

STEM CAP

STEM CAP

ANGLE−TYPE SERVICE VALVE

(FRONT−SEATED CLOSED)

WHEN SERVICE VALVE IS CLOSED, THE SERVICE PORT IS OPEN

TO

THE LINE SET AND INDOOR UNIT.

To Access Service Port:

A service port cap protects the service port core from contamination and

serves as the primary leak seal.

1. Remove service port cap with an appropriately sized wrench.

2. Connect gauge set to service port.

3. When testing is completed, replace service port cap and tighten as

follows:

With torque wrench: Finger tighten and

torque cap per table 1.

Without torque wrench: Finger tighten and

use an appropriately sized wrench to turn

an additional 1/6 turn clockwise.

Reinstall Stem Cap:

Stem cap protects the valve stem from damage and serves as the

primary seal. Replace the stem cap and tighten as follows:

9

10

8

11

12

7

6

With Torque Wrench: Finger tighten and

then torque cap per table 1.

Without Torque Wrench: Finger tight-

en and use an appropriately sized

wrench to turn an additional 1/12 turn

clockwise.

9

10

8

11

12

7

6

1/6 TURN

1

2

3

4

5

1/12 TURN

1

2

3

4

5

NOTE A label with specific torque requirements may be affixed to the stem cap. If the label is present, use the specified torque.

Figure 2. Angle and Ball Service Valves

Page 5

14ACX SERIES

Page 6

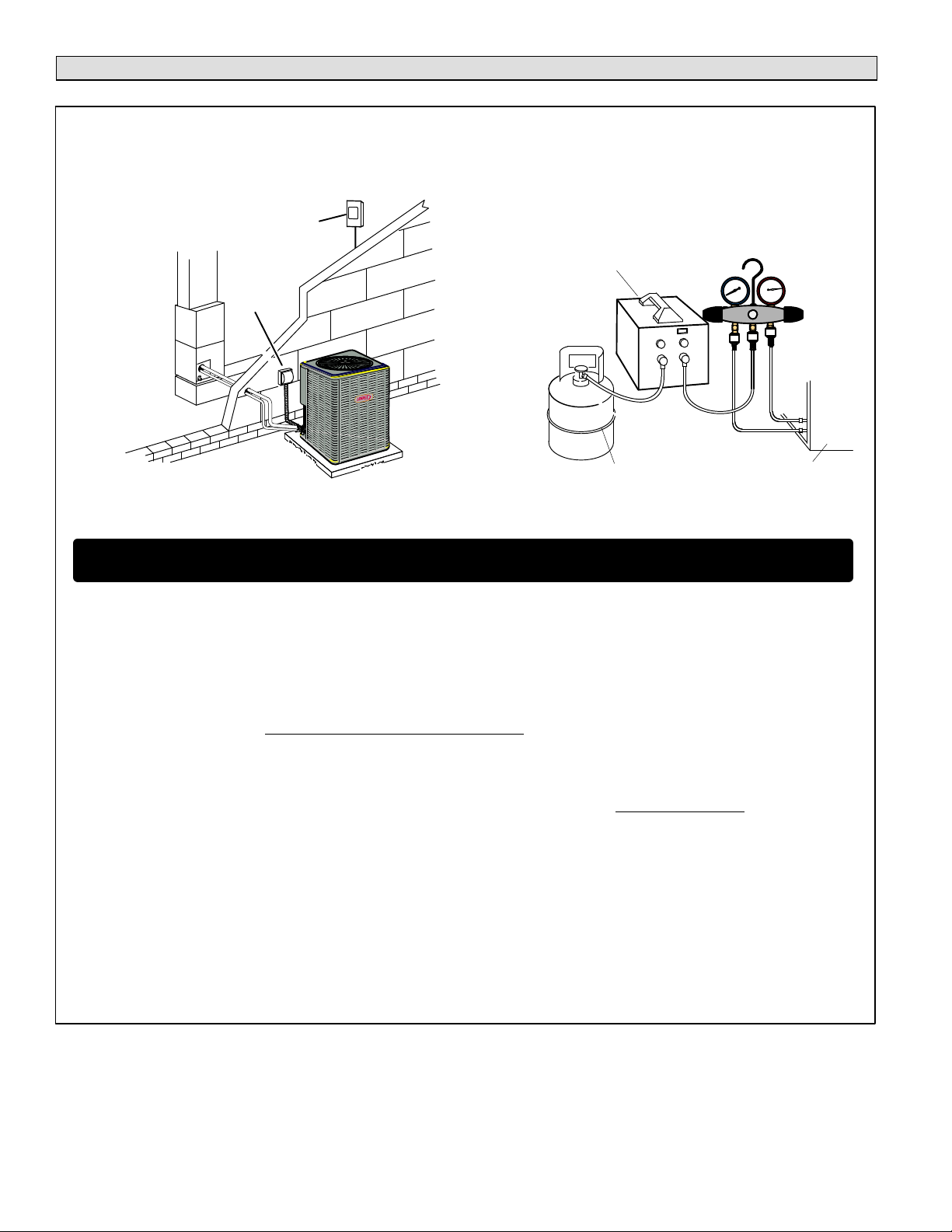

Recovering Refrigerant from Existing System

Use the following procedure to recover refrigerant from an existing system (indoor coil, line set and outdoor unit).

DISCONNECT POWER

Disconnect all power to the existing outdoor unit at the service

12

disconnect switch or main fuse box/breaker panel.

MAIN FUSE BOX/BREAKER PANEL

SERVICE

DISCONNECT

SWITCH

RECOVERING REFRIGERANT

Remove existing HCFC−22 refrigerant using one of the following procedures:

3

IMPORTANT Some system configurations may contain higher than normal refrigerant charge due to either large internal coil volumes,

and/or long line sets.

CONNECT MANIFOLD GAUGE SET

Connect a gauge set, clean recovery cylinder and a recovery

machine to the service ports of the existing unit. Use the

instructions provided with the recovery machine to make the

connections.

MANIFOLD GAUGES

RECOVERY MACHINE

LOW

CLEAN RECOVERY

CYLINDER

OUTDOOR UNIT

HIGH

METHOD 1:

Us this method if the existing outdoor unit is not equipped with shut−off valves, or if the unit is not operational and you plan to use the existing

HCFC−22 to flush the system.

Remove all HCFC−22 refrigerant from the existing system. Check gauges after shutdown to confirm that the entire system is completely void of

refrigerant.

METHOD 2:

Use this method if the existing outdoor unit is equipped with manual shut−off valves, and you plan to use new HCFC−22 refrigerant to flush the

system.

The following devices could prevent full system charge recovery into the outdoor unit:

Outdoor unit’s high or low−pressure switches (if applicable) when tripped can cycle the compressor OFF.

Compressor can stop pumping due to tripped internal pressure relief valve.

Compressor has internal vacuum protection that is designed to unload the scrolls (compressor stops pumping) when the pressure ratio meets

a certain value or when the suction pressure is as high as 20 psig. (Compressor suction pressures should never be allowed to go into a vacuum.

Prolonged operation at low suction pressures will result in overheating of the scrolls and permanent damage to the scroll tips, drive bearings and

internal seals.)

Once the compressor can not pump down to a lower pressure due to one of the above system conditions, shut off the vapor valve. Turn OFF the

main power to unit and use a recovery machine to recover any refrigerant left in the indoor coil and line set.

Perform the following task:

A Start the existing HCFC−22 system in the cooling mode and close the liquid line valve.

B Use the compressor to pump as much of the existing HCFC−22 refrigerant into the outdoor unit until the outdoor system is full. Turn the outdoor unit

main power OFF and use a recovery machine to remove the remaining refrigerant from the system.

NOTE It may be necessary to bypass the low pressure switches (if equipped) to ensure complete refrigerant evacuation.

C When the low side system pressures reach 0 psig, close the vapor line valve.

D Check gauges after shutdown to confirm that the valves are not allowing refrigerant to flow back into the low side of the system.

Figure 3. Refrigerant Recovery Procedure

506645−01

Page 6

Page 7

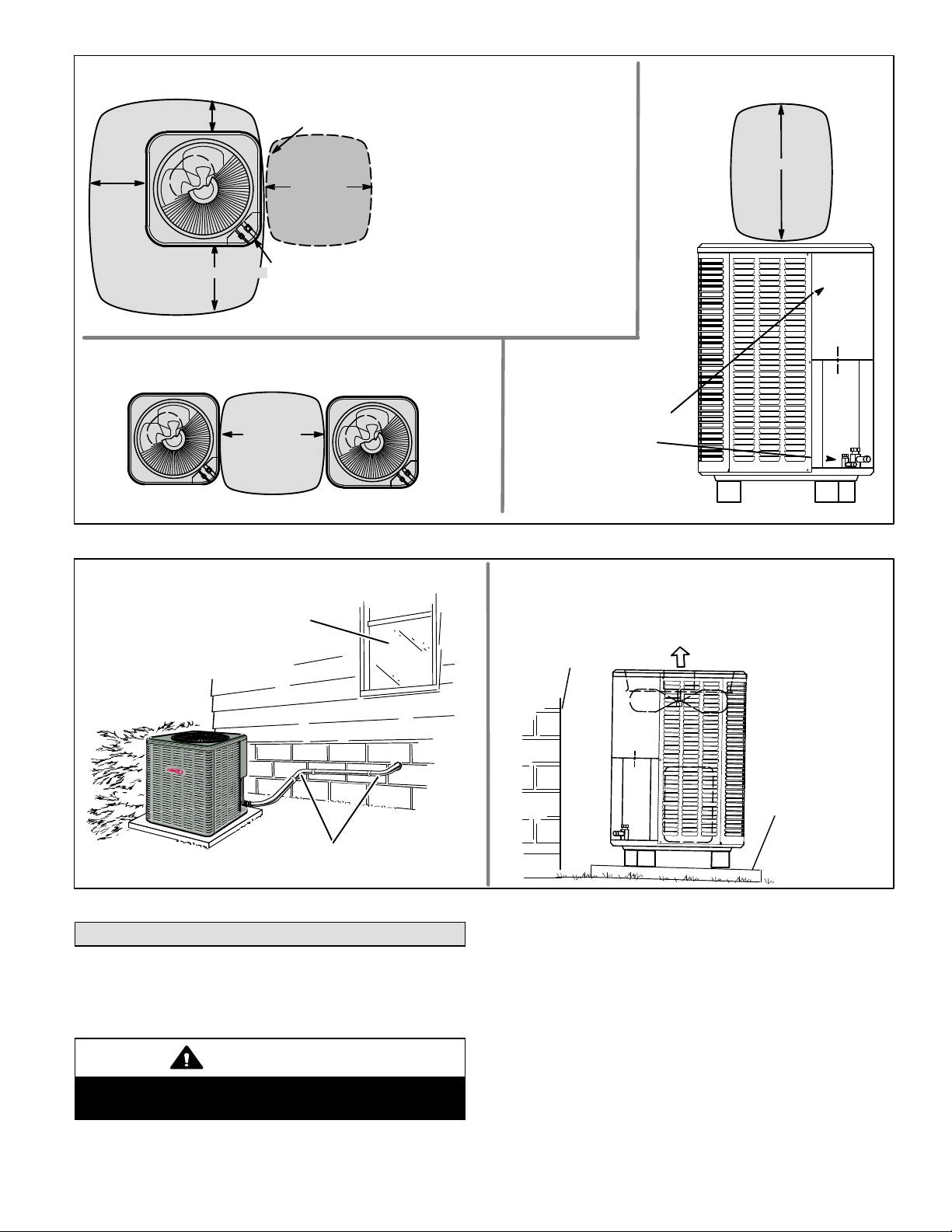

CLEARANCE ON ALL SIDES INCHES (MILLIMETERS)

MINIMUM CLEARANCE

ABOVE UNIT

12 (305)

6 (152)

36 (914)

ACCESS PANEL

30 (762)

LINE SET

CONNECTIONS

MINIMUM CLEARANCE BETWEEN

TWO UNITS

24 (610)

Figure 4. Installation Clearances

NOTES:

Clearance to one of the other three

sides must be 36 inches (914mm).

Clearance to one of the remaining

two sides may be 12 inches

(305mm) and the final side may be

6 inches (152mm).

ACCESS PANEL

LINE SET

CONNECTIONS

48 (1219)

DETAIL A

INSTALL UNIT AWAY

FROM WINDOWS

TWO 90 ELBOWS INSTALLED IN LINE SET

WILL REDUCE LINE SET VIBRATION

Figure 5. Placement, and Slab Mounting

New Unit Placement

See Unit Dimensions on page 2 for sizing mounting slab,

platforms or supports. Refer to figure 4 for mandatory

installation clearance requirements.

POSITIONING CONSIDERATIONS

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

DETAIL B

Install unit level or, if on a slope, maintain slope tolerance of 2 degrees

(or 2 inches per 5 feet [50 mm per 1.5 m]) away from building structure.

BUILDING

STRUCTURE

Consider the following when positioning the unit:

Some localities are adopting sound ordinances based

on the unit’s sound level registered from the adjacent

property, not from the installation property. Install the

unit as far as possible from the property line.

When possible, do not install the unit directly outside

a window. Glass has a very high level of sound

transmission. For proper placement of unit in relation

to a window see the provided illustration in figure 5,

detail A.

DISCHARGE AIR

MOUNTING

SLAB

GROUND LEVEL

Page 7

14ACX SERIES

Page 8

PLACING UNIT ON SLAB

When installing unit at grade level, the top of the slab

should be high enough above grade so that water from

higher ground will not collect around the unit. The slab

should have a slope tolerance as described in figure 5,

detail B.

ROOF MOUNTING

Install the unit at a minimum of 4 inches (102 mm) above

the surface of the roof. Ensure the weight of the unit is

properly distributed over roof joists and rafters. Redwood

or steel supports are recommended.

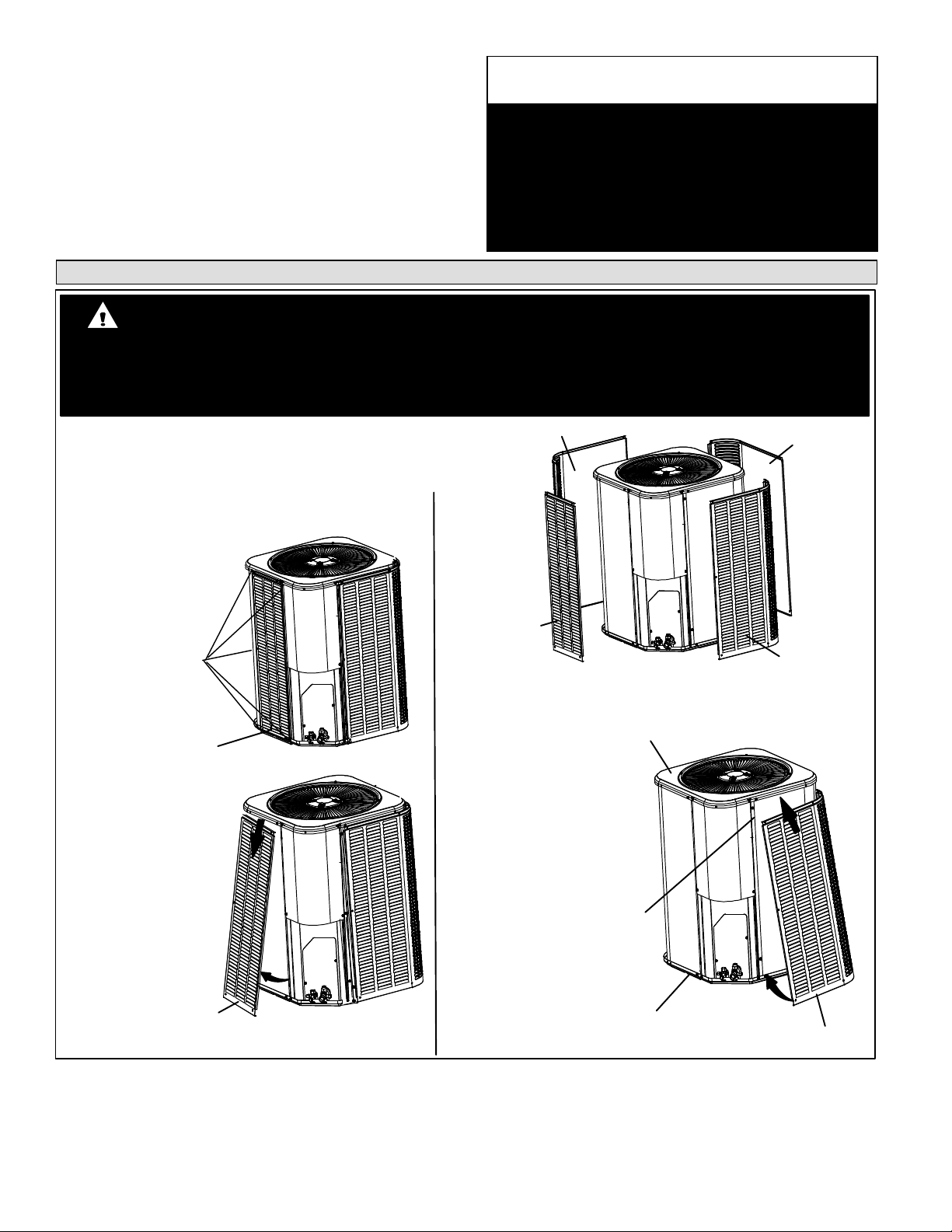

Removing and Installing Louvers

WARNING

To prevent personal injury, or damage to panels, unit or structure, be sure to observe the following:

While installing or servicing this unit, carefully stow all removed panels out of the way, so that the panels will not cause injury to personnel,

nor cause damage to objects or structures nearby, nor will the panels be subjected to damage (e.g., being bent or scratched).

While handling or stowing the panels, consider any weather conditions, especially windy conditions, that may cause panels to be blown

around and battered.

NOTICE

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roofing material may absorb oil and cause the

rubber to swell when it comes into contact with oil. The

rubber will then bubble and could cause leaks. Protect

the roof surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow this

notice could result in damage to roof surface.

When removing the unit panels. Remove panel A first, then B, C and

finally D. When reinstalling panels, reverse that order starting with panel

D, C, B and finally A.

REMOVAL

STEP 1

TO REMOVE PANEL,

REMOVE MOUNTING

SCREWS SECURING

PANEL TO THE UNIT.

PANEL A

STEP 2

SLIGHTLY LIFT PANEL A IN

ORDER TO CLEAR SIDE

LIPS OF PANEL FROM

BASE OF UNIT.

STEP 3

TILT PANEL OUT SLIGHTLY

AND PULL DOWNWARD

TO REMOVE.

REPEAT STEPS 1, 2 AND

3 TO REMOVE PANELS B,

C AND FINALLY D.

PANEL A

PANEL B

WARNING

PANEL A

INSTALLATION

STEP 1

STARTING WITH PANEL D,

INSERT PANEL UNDER UNIT

TOP CAP LIP AND LIFT

SLIGHTLY TO CLEAR SIDE LIP

OF PANEL FROM BASE.

STEP 2

MOVE PANEL IN TOWARDS UNIT.

ALIGN LEFT/RIGHT SIDE LIPS OF

PANEL WITH GROOVE INSERTS

ALONG LEFT/RIGHT SIDE OF UNIT.

SIDE

GROOVE

STEP 3

SECURE PANEL, WITH

MOUNTING SCREWS.

REPEAT STEPS 1 AND 2 TO

INSTALL PANELS C, B AND

FINALLY A.

PANEL C

PANEL D

TOP CAP

BASE

PANEL D

506645−01

Figure 6. Louvers

Page 8

Page 9

New or Replacement Line Set

This section provides information on new installation or

replacement of existing line set. If a new or replacement

line set is not required, then proceed to Brazing

Connections on page 11.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (braze connections) to the indoor unit

coil (flare or braze connections). Use Lennox L15 (braze,

non−flare) series line set, or use field−fabricated refrigerant

lines as listed in table 2.

NOTE − When installing refrigerant lines longer than 50

feet, see the Lennox Refrigerant Piping Design and

Fabrication Guidelines, CORP. 9351−L9, or contact

Lennox Technical Support Product Applications for

assistance.

To obtain the correct information from Lennox, be sure to

communicate the following points:

Model (14ACX) and size of unit (e.g. −060).

Line set diameters for the unit being installed as listed

in table 2 and total length of installation.

Number of elbows and if there is a rise or drop of the

piping.

If refrigerant lines are routed through a wall, seal and

isolate the opening so vibration is not transmitted to the

building. Pay close attention to line set isolation during

installation of any HVAC system. When properly isolated

from building structures (walls, ceilings. floors), the

refrigerant lines will not create unnecessary vibration and

subsequent sounds.

Recommended topping−off POE oils are Mobil EAL

ARCTIC 22 CC or ICI EMKARATE RL32CF.

MATCHING WITH NEW OR EXISTING INDOOR COIL

AND LINE SET

The RFC1−metering line consisted of a small bore copper

line that ran from condenser to evaporator coil. Refrigerant

was metered into the evaporator by utilizing

temperature/pressure evaporation effects on refrigerant in

the small RFC line. The length and bore of the RFC line

corresponded to the size of cooling unit.

If the 14ACX is being used with either a new or existing

indoor coil which is equipped with a liquid line which served

as a metering device (RFCI), the liquid line must be

replaced prior to the installation of the 14ACX unit.

Typically a liquid line used to meter flow is 1/4" in diameter

and copper.

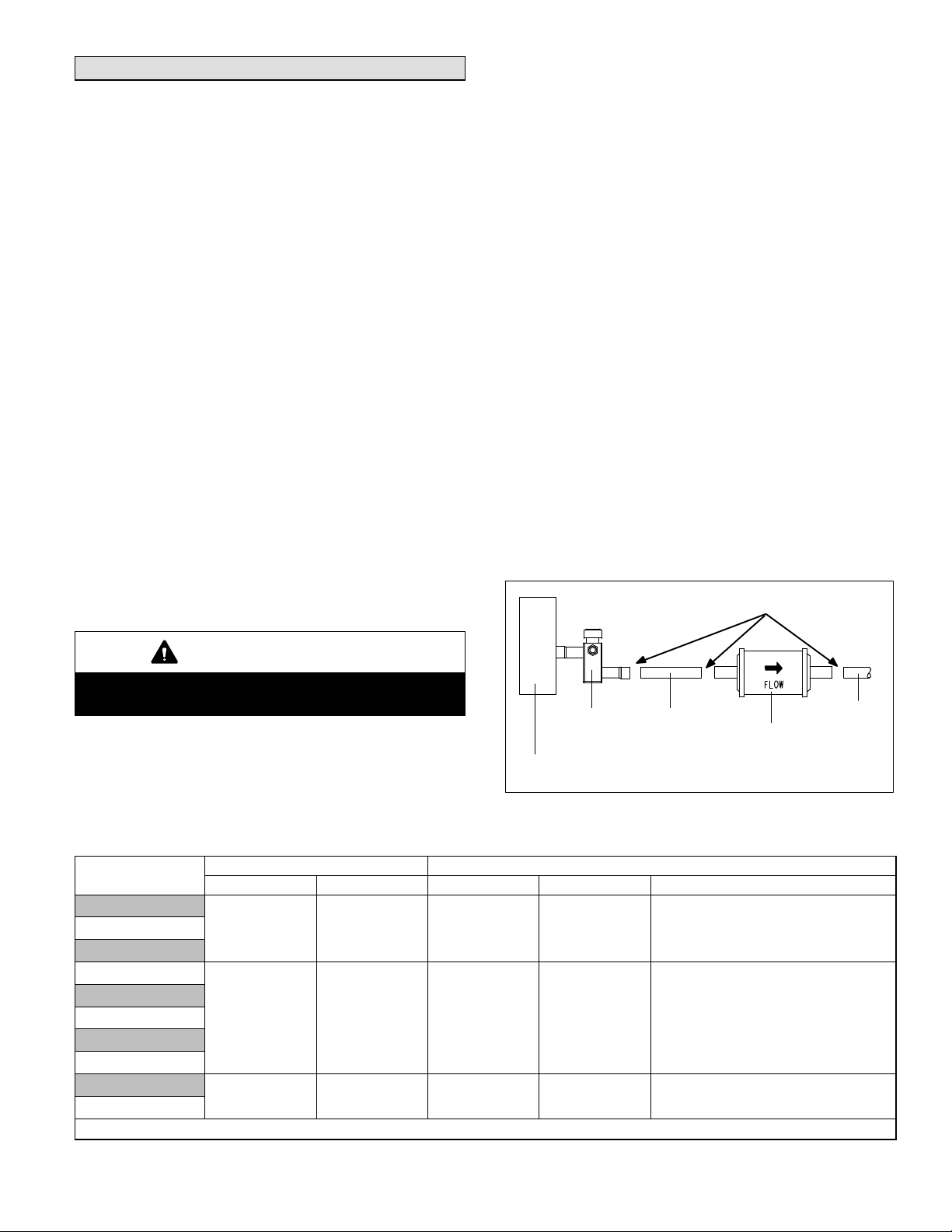

LIQUID LINE FILTER DRIER INSTALLATION

The filter drier (one is shipped with each 14ACX unit) must

be field installed in the liquid line between the outdoor unit’s

liquid line service valve and the indoor coil’s metering

device (fixed orifice or TXV) as illustrated in figure 7. This

filter drier must be installed to ensure a clean,

moisture−free system. Failure to install the filter drier will

void the warranty. A replacement filter drier is available

from Lennox. See Brazing Connections page 11 for

special procedures on brazing filter drier connections to

the liquid line.

BRAZE CONNECTION POINTS

IMPORTANT

Mineral oils are not compatible with HFC−410A. If oil

must be added, it must be a Polyol ester oil.

The compressor is charged with sufficient Polyol ester oil

for line set lengths up to 50 feet. Recommend adding oil to

system based on the amount of refrigerant charge in the

system. No need to add oil in system with 20 pounds of

refrigerant or less. For systems over 20 pounds − add one

ounce of every five pounds of refrigerant.

Table 2. Refrigerant Line Set Inches (mm)

Model Number

14ACX−018−230

14ACX−024−230

14ACX−030−230

14ACX−036−230

14ACX−041−230

14ACX−042−230

14ACX−047−230

14ACX−048−230

14ACX−059−230

14ACX−060−230

NOTE Some applications may required a field provided 7/8" to 1−1/8" adapter

Valve Field Size Connections Recommended Line Set

Liquid Line Suction Line Liquid Line Suction Line L15 Series Line Sets

3/8 in. (10 mm) 3/4 in. (19 mm) 3/8 in. (10 mm) 3/4 in. (19 mm)

3/8 in. (10 mm) 7/8 in. (22 mm) 3/8 in. (10 mm) 7/8 in. (22 mm)

3/8 in. (10 mm) 1−1/8 in. (29 mm) 3/8 in. (10 mm) 1−1/8 in. (29 mm) Field Fabricated

LIQUID

LINE

OUTDOOR

UNIT

LIQUID LINE

SERVICE VALVE

LINE

LIQUID LINE

FILTER DRIER

igure 7. Typical Liquid Line Filter Drier Installation

L15−41 15 feet to 50 feet (4.6 meters to

15 meters)

L15−65 15 feet to 50 feet (4.6 meters to

15 meters)

Page 9

14ACX SERIES

Page 10

LINE SET

INSTALLATION

Line Set Isolation The following illustrations are

examples of proper refrigerant line set isolation:

REFRIGERANT LINE SET TRANSITION

FROM VERTICAL TO HORIZONTAL

ANCHORED HEAVY NYLON

WIRE TIE OR AUTOMOTIVE

MUFFLER-TYPE HANGER

AUTOMOTIVE

MUFFLER-TYPE HANGER

IMPORTANT Refrigerant lines must not contact structure.

REFRIGERANT LINE SET INSTALLING

VERTICAL RUNS (NEW CONSTRUCTION SHOWN)

NOTE Insulate liquid line when it is routed through areas where the

surrounding ambient temperature could become higher than the

temperature of the liquid line or when pressure drop is equal to or greater

than 20 psig.

IMPORTANT Refrigerant lines must not contact wall

OUTSIDE WALL

VAPOR LINE

LIQUID LINE

WALL

STUD

STRAP LIQUID LINE TO

VAPOR LINE

LIQUID LINE

NON−CORROSIVE

METAL SLEEVE

VAPOR LINE − WRAPPED

IN ARMAFLEX

REFRIGERANT LINE SET INSTALLING

HORIZONTAL RUNS

To hang line set from joist or rafter, use either metal strapping material

or anchored heavy nylon wire ties.

WIRE TIE (AROUND

VAPOR LINE ONLY)

8 FEET (2.43 METERS)

STRAPPING

MATERIAL (AROUND

VAPOR LINE ONLY)

TAPE OR

WIRE TIE

FLOOR JOIST OR

ROOF RAFTER

8 FEET (2.43 METERS)

NON−CORROSIVE

METAL SLEEVE

STRAP THE VAPOR LINE TO THE JOIST

OR RAFTER AT 8 FEET (2.43 METERS)

INTERVALS THEN STRAP THE LIQUID

LINE TO THE VAPOR LINE.

TAPE OR

WIRE TIE

WIRE TIE

INSIDE WALL

WOOD BLOCK

BETWEEN STUDS

SLEEVE

VAPOR LINE WRAPPED

WITH ARMAFLEX

OUTSIDE

WALL

PVC

PIPE

FIBERGLASS

INSULATION

CAULK

STRAP

NON−CORROSIVE

METAL SLEEVE

WIRE TIE

WOOD BLOCK

WIRE TIE

STRAP

LIQUID

LINE

NOTE Similar installation practices should be used if line set is

to be installed on exterior of outside wall.

FLOOR JOIST OR

506645−01

ROOF RAFTER

Figure 8. Line Set Installation Guidelines

Page 10

Page 11

Brazing Connections

Use the procedures outline in figures 9 and 10 for brazing

line set connections to service valves.

IMPORTANT

Polyol ester (POE) oils used with HFC−410A

refrigerant absorb moisture very quickly. It is very

important that the refrigerant system be kept closed

as much as possible. DO NOT remove line set caps

or service valve stub caps until you are ready to make

connections.

WARNING

Danger of fire. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing

torch to a pressurized system may result

in ignition of the refrigerant and oil

mixture − Check the high and low

pressures before applying heat.

WARNING

When using a high pressure gas such as

dry nitrogen to pressurize a refrigeration

or air conditioning system, use a

regulator that can control the pressure

down to 1 or 2 psig (6.9 to 13.8 kPa).

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing

operations. Perform operations only in well−ventilated

areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and flux.

IMPORTANT

Connect gauge set low pressure side to vapor line

service valve and repeat procedure starting at

paragraph 4 for brazing the liquid line to service port

valve.

IMPORTANT

Allow braze joint to cool before removing the wet rag

from the service valve. Temperatures above 250ºF can

damage valve seals.

IMPORTANT

Use silver alloy brazing rods with 5% minimum silver

alloy for copper−to−copper brazing. Use 45% minimum

alloy for copper−to−brass and copper−to−steel brazing.

WARNING

Fire, Explosion and Personal Safety

Hazard.

Failure to follow this warning could

result in damage, personal injury or

death.

Never use oxygen to pressurize or

purge refrigeration lines. Oxygen,

when exposed to a spark or open

flame, can cause fire and/or an explosion, that could result in property

damage, personal injury or death.

Page 11

14ACX SERIES

Page 12

CUT AND DEBUR

Cut ends of the refrigerant lines square (free from nicks or dents)

1

and debur the ends. The pipe must remain round. Do not crimp end

of the line.

CUT AND DEBUR

LINE SET SIZE MATCHES

SERVICE VALVE CONNECTION

SERVICE VALVE

COPPER TUBE

REDUCER

CONNECTION

STUB

CAP AND CORE REMOVAL

Remove service cap and core from

2

both the suction / vapor and liquid line

service ports.

SERVICE PORT

CAP

SERVICE

PORT

CORE

LIQUID LINE SERVICE

VALV E

SERVICE

PORT

CORE

SERVICE

PORT CAP

SUCTION / VAPOR LINE

SERVICE VALVE

LINE SET SIZE IS SMALLER

THAN CONNECTION

REFRIGERANT LINE

DO NOT CRIMP SERVICE VALVE

CONNECTOR WHEN PIPE IS

SMALLER THAN CONNECTION

ATTACH THE MANIFOLD GAUGE SET FOR BRAZING LIQUID AND SUCTION / VAPOR LINE SERVICE

VALVES

3

Flow regulated nitrogen (at 1 to 2 psig) through the low−side refrigeration gauge set into the liquid line service port valve, and out of the suction /

vapor line service port valve.

A Connect gauge set low pressure side to

liquid line service valve (service port).

B Connect gauge set center port to bottle of

nitrogen with regulator.

C Remove core from valve in suction / vapor

line service port to allow nitrogen to escape.

SUCTION / VAPOR SERVICE PORT MUST BE

OPEN TO ALLOW EXIT POINT FOR NITROGEN

VAPOR LINE

INDOOR

UNIT

LIQUID LINE

ATTACH

GAUGES

C

LIQUID LINE SERVICE

SUCTION /

VAPOR LINE

SERVICE

VALV E

VALV E

HIGHLOW

B

OUTDOOR

UNIT

WHEN BRAZING LINE SET TO

A

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

USE REGULATOR TO FLOW

NITROGEN AT 1 TO 2 PSIG.

NITROGEN

506645−01

Figure 9. Brazing Procedures

Page 12

Page 13

WRAP SERVICE VALVES

To help protect service valve seals during brazing, wrap water saturated cloths around service valve bodies and copper tube stubs. Use

4

additional water saturated cloths underneath the valve body to protect the base paint.

FLOW NITROGEN

Flow regulated nitrogen (at 1 to 2 psig) through the refrigeration gauge set into the valve stem port connection on the liquid service valve and

5

out of the suction / vapor valve stem port. See steps 3A, 3B and 3C on manifold gauge set connections

BRAZE LINE SET

Wrap both service valves with water saturated cloths as illustrated here and as mentioned in step 4, before brazing to line set. Water

6

saturated cloths must remain water saturated throughout the brazing and cool−down process.

LIQUID LINE SERVICE VALVE

WHEN BRAZING LINE SET TO

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

IMPORTANT Allow braze joint to cool. Apply

additional water saturated cloths to help cool brazed

joint. Do not remove water saturated cloths until piping

has cooled. Temperatures above 250ºF will damage

valve seals.

LIQUID LINE

WATER SATURATED

CLOTH

WARNING

1. FIRE, PERSONAL INJURY, OR PROPERTY

DAMAGE will result if you do not wrap a water

saturated cloth around both liquid and suction line

service valve bodies and copper tube stub while

brazing in the line set! The braze, when complete,

must be quenched with water to absorb any residual

heat.

2. Do not open service valves until refrigerant lines and

indoor coil have been leak−tested and evacuated.

Refer to procedures provided in this supplement.

SUCTION / VAPOR LINE

PREPARATION FOR NEXT STEP

After all connections have been brazed, disconnect manifold gauge set from service ports. Apply additional water saturated cloths to both

7

services valves to cool piping. Once piping is cool, remove all water saturated cloths. Refer to the unit installation instructions for the next step

in preparing the unit.

SUCTION / VAPOR LINE

SERVICE VALVE

WATER SATURATED

CLOTH

WHEN BRAZING LINE SET TO

SERVICE VALVES, POINT FLAME

AWAY FROM SERVICE VALVE.

Figure 10. Brazing Procedures (continued)

Page 13

14ACX SERIES

Page 14

Flushing Line Set and Indoor Coil

Flushing is only required if existing indoor coil and line set are to be used. Otherwise proceed to Installing Indoor Metering

Device on page 15.

TYPICAL EXISTING FIXED ORIFICE

1A

DISTRIBUTOR

ASSEMBLY

A On fully cased coils, remove the coil access and plumbing panels.

B Remove any shipping clamps holding the liquid line and distributor as-

sembly.

C Using two wrenches, disconnect liquid line from liquid line orifice hous-

ing. Take care not to twist or damage distributor tubes during this process.

D Remove and discard fixed orifice, valve stem assembly if present and

Teflon® washer as illustrated above.

E Use a field−provided fitting to temporary reconnect the liquid line to the

indoor unit’s liquid line orifice housing.

COIL SHOWN)

DISTRIBUTOR TUBES

LIQUID LINE ORIFICE HOUSING

REMOVE AND DISCARD

WHITE TEFLON

(IF PRESENT)

TEFLON® RING

FIXED ORIFICE

®

SEAL

LIQUID LINE ASSEMBLY

(INCLUDES STRAINER)

REMOVAL PROCEDURE (UNCASED

OR

BRASS NUT

1B

TWO PIECE PATCH PLATE

(UNCASED COIL ONLY)

CONNECT GAUGES AND EQUIPMENT FOR

FLUSHING PROCEDURE

2

INVERTED HCFC−22

CYLINDER CONTAINS

CLEAN HCFC−22 TO BE

USED FOR FLUSHING.

A

1

VAPOR LINE

SERVICE VALVE

EXISTING

INDOOR

UNIT

LIQUID LINE SERVICE

VALV E

VAPOR

LIQUID

D

RECOVERY

CYLINDER

A Inverted HCFC−22 cylinder with clean refrigerant to the vapor service

valve.

B HCFC−22 gauge set (low side) to the liquid line valve.

C HCFC−22 gauge set center port to inlet on the recovery machine with an

empty recovery tank to the gauge set.

D Connect recovery tank to recovery machines per machine instructions.

OUTDOOR

B

NEW

UNIT

OPENED

C

RECOVERY MACHINE

GAUGE

MANIFOLD

LOW HIGH

CLOSED

TANK

RETURN

INLET

DISCHARGE

TYPICAL EXISTING EXPANSION VALVE REMOVAL

PROCEDURE (UNCASED COIL SHOWN)

ORIFICE

HOUSING

EQUALIZER

LINE

STUB END

TEFLON

RING

VAPOR

CHECK

EXPANSION

VALV E

®

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

LINE

TEFLON

RING

®

SENSING

LINE

LIQUID

LINE

LIQUID LINE

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER

LINE FITTING

SENSING BULB

A On fully cased coils, remove the coil access and plumbing panels.

B Remove any shipping clamps holding the liquid line and distributor

assembly.

C Disconnect the equalizer line from the check expansion valve

equalizer line fitting on the vapor line.

D Remove the vapor line sensing bulb.

E Disconnect the liquid line from the check expansion valve at the liquid

line assembly.

F Disconnect the check expansion valve from the liquid line orifice

housing. Take care not to twist or damage distributor tubes during this

process.

G Remove and discard check expansion valve and the two Teflon® rings.

H Use a field−provided fitting to temporary reconnect the liquid line to the

indoor unit’s liquid line orifice housing.

FLUSHING LINE SET

The line set and indoor unit coil must be flushed with at least the

3

same amount of clean refrigerant that previously charged the

system. Check the charge in the flushing cylinder before

proceeding.

A Set the recovery machine for liquid recovery and start the

recovery machine. Open the gauge set valves to allow the

recovery machine to pull a vacuum on the existing system line

set and indoor unit coil.

B

B Invert the cylinder of clean HCFC−22 and open its valve to allow

liquid refrigerant to flow into the system through the vapor line

valve. Allow the refrigerant to pass from the cylinder and through

the line set and the indoor unit coil before it enters the recovery

machine.

C After all of the liquid refrigerant has been recovered, switch the

recovery machine to vapor recovery so that all of the HCFC−22

vapor is recovered. Allow the recovery machine to pull down to 0

the system.

D Close the valve on the inverted HCFC−22 drum and the gauge

set valves. Pump the remaining refrigerant out of the recovery

machine and turn the machine off.

506645−01

Figure 11. Removing Metering Device and Flushing

Page 14

Page 15

Installing Indoor Metering Device

This outdoor unit is designed for use in systems that use

either an fixed orifice (RFC) (included with outdoor unit), or

expansion valve metering device (purchased separately)

at the indoor coil.

See the Lennox 14ACX Engineering Handbook for

approved expansion valve kit match ups. The expansion

valve unit can be installed internal or external to the indoor

coil. In applications where an uncased coil is being

installed in a field−provided plenum, install the expansion

valve in a manner that will provide access for field servicing

of the expansion valve. Refer to below illustration for

reference during installation of expansion valve unit. .

After installation of the indoor coil metering device,

proceed to Leak Test Line Set and Indoor Coil on page 16.

INDOOR EXPANSION VALVE INSTALLATION

TWO PIECE

PATCH PLATE

(UNCASED

COIL ONLY)

DISTRIBUTOR

TUBES

DISTRIBUTOR

ASSEMBLY

MALE EQUALIZER LINE

FITTING (SEE

EQUALIZER LINE

INSTALLATION FOR

FURTHER DETAILS)

(Uncased Coil Shown)

LIQUID LINE

ORIFICE

HOUSING

STUB

END

TEFLON

RING

EQUALIZER

LINE

VAPOR

EXPANSION

VALV E

®

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

LINE

TEFLON

RING

LIQUID LINE

Sensing bulb insulation is required if

mounted external to the coil casing. sensing

bulb installation for bulb positioning.

EQUALIZER LINE INSTALLATION

A Remove and discard either the flare seal cap or flare nut

with copper flare seal bonnet from the equalizer line port

on the vapor line as illustrated in the figure to the right.

B Remove and discard either the flare seal cap or flare nut

with copper flare seal bonnet from the equalizer line port on

the vapor line as illustrated in the figure to the right.

®

SENSING

LINE

A Remove the field−provided fitting that temporary

reconnected the liquid line to the indoor unit’s distributor

assembly.

B Install one of the provided Teflon® rings around the

stubbed end of the expansion valve and lightly lubricate

the connector threads and expose surface of the Teflon

ring with refrigerant oil.

C Attach the stubbed end of the expansion valve to the

liquid line orifice housing. Finger tighten and use an

appropriately sized wrench to turn an additional 1/2 turn

clockwise as illustrated in the figure above, or 20 ft−lb.

D Place the remaining Teflon® washer around the other

end of the expansion valve. Lightly lubricate connector

threads and expose surface of the Teflon® ring with

refrigerant oil.

E Attach the liquid line assembly to the expansion valve.

Finger tighten and use an appropriately sized wrench to

turn an additional 1/2 turn clockwise as illustrated in the

figure above or 20 ft−lb.

SENSING BULB INSTALLATION

A Attach the vapor line sensing bulb in the proper

orientation as illustrated to the right using the clamp and

screws provided.

NOTE Confirm proper thermal contact between vapor line

and expansion bulb before insulating the sensing bulb once

installed.

B Connect the equalizer line from the expansion valve to

the equalizer vapor port on the vapor line. Finger tighten

the flare nut plus 1/8 turn (7 ft−lbs) as illustrated below.

VAPOR LINE

BULB

12

ON LINES SMALLER THAN

7/8", MOUNT SENSING

BULB AT EITHER THE 3 OR

9 O’CLOCK POSITION.

BULB

®

1/2 Turn

11

10

9

8

7

1/8 Turn

11

10

9

8

7

12

1

2

3

4

5

6

12

1

2

3

4

5

6

FLARE SEAL CAP

OR

FLARE NUT

COPPER FLARE

SEAL BONNET

MALE BRASS EQUALIZER

LINE FITTING

VAPOR LINE

VAPOR LINE

BULB

NOTE NEVER MOUNT ON BOTTOM OF LINE.

Figure 12. Installing Indoor Expansion Valve

Page 15

ON 7/8" AND LARGER LINES,

MOUNT SENSING BULB AT

EITHER THE 4 OR 8 O’CLOCK

12

POSITION. NEVER MOUNT ON

BOTTOM OF LINE.

BULB

14ACX SERIES

Page 16

IMPORTANT

Leak Test Line Set and Indoor Coil

The Environmental Protection Agency (EPA) prohibits

the intentional venting of HFC refrigerants during

maintenance, service, repair and disposal of appliance.

Approved methods of recovery, recycling or reclaiming

must be followed.

IMPORTANT

If this unit is being matched with an approved line set

or indoor unit coil which was previously charged with

mineral oil, or if it is being matched with a coil which

was manufactured before January of 1999, the coil

and line set must be flushed prior to installation. Take

care to empty all existing traps. Polyol ester (POE) oils

are used in Lennox units charged with HFC−410A

refrigerant. Residual mineral oil can act as an

insulator, preventing proper heat transfer. It can also

clog the expansion device, and reduce the system

performance and capacity.

Failure to properly flush the system per the

instructions below will void the warranty.

CONNECT GAUGE SET

A Connect an HFC−410A manifold gauge set high pressure

1

hose to the vapor valve service port.

NOTE Normally, the high pressure hose is connected to

the liquid line port. However, connecting it to the vapor port

better protects the manifold gauge set from high pressure

damage.

B With both manifold valves closed, connect the cylinder of

HFC−410A refrigerant to the center port of the manifold gauge

set.

NOTE Later in the procedure,

the HFC−410A container will be

replaced by the nitrogen

container.

IMPORTANT

Leak detector must be capable of sensing HFC

refrigerant.

After completing the leak testing the line set and indoor coil

as outlined in figure 13, proceed to Evacuating Line Set

and Indoor Coil on page 17.

WARNING

When using a high pressure gas such as

dry nitrogen to pressurize a refrigeration

or air conditioning system, use a

regulator that can control the pressure

down to 1 or 2 psig (6.9 to 13.8 kPa).

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal injury

or death.

HIGHLOW

MANIFOLD GAUGE SET

OUTDOOR UNIT

B

A

2

506645−01

TO VAPOR

SERVICE VALVE

NITROGEN

HFC−410A

TEST FOR LEAKS

After the line set has been connected to the indoor and outdoor units, check the line set connections and indoor unit for leaks. Use the

following procedure to test for leaks:

A With both manifold valves closed, connect the cylinder of HFC−410A refrigerant to the center port of the manifold gauge set. Open the valve

on the HFC−410A cylinder (vapor only).

B Open the high pressure side of the manifold to allow HFC−410A into the line set and indoor unit. Weigh in a trace amount of HFC−410A. [A

trace amount is a maximum of two ounces (57 g) refrigerant or three pounds (31 kPa) pressure]. Close the valve on the HFC−410A cylinder

and the valve on the high pressure side of the manifold gauge set. Disconnect the HFC−410A cylinder.

C Connect a cylinder of dry nitrogen with a pressure regulating valve to the center port of the manifold gauge set.

D Adjust dry nitrogen pressure to 150 psig (1034 kPa). Open the valve on the high side of the manifold gauge set in order to pressurize the line set

and the indoor unit.

E After a few minutes, open one of the service valve ports and verify that the refrigerant added to the system earlier is measurable with a leak

detector.

F After leak testing disconnect gauges from service ports.

Figure 13. Leak Test

Page 16

Page 17

Evacuating Line Set and Indoor Coil

CONNECT GAUGE SET

NOTE Remove cores from service valves (if not already done).

1

A Connect low side of manifold gauge set

with 1/4 SAE in−line tee to vapor line

service valve

B Connect high side of manifold gauge

set to liquid line service valve

C Connect micron gauge available

connector on the 1/4 SAE in−line tee.

D Connect the vacuum pump (with

vacuum gauge) to the center port of the

manifold gauge set. The center port

line will be used later for both the

HFC−410A and nitrogen containers.

NITROGEN

HFC−410A

VACUUM PUMP

OUTDOOR

UNIT

A

B

A34000 1/4 SAE TEE WITH

SWIVEL COUPLER

500

C

MICRON

GAUGE

MANIFOLD

GAUGE SET

TO VAPOR

SERVICE VALVE

TO LIQUID LINE

SERVICE VALVE

LOW

D

EVACUATE THE SYSTEM

A Open both manifold valves and start the vacuum pump.

2

B Evacuate the line set and indoor unit to an absolute pressure of 23,000 microns (29.01 inches of mercury).

NOTE During the early stages of evacuation, it is desirable to close the manifold gauge valve at least once. A rapid rise in pressure

indicates a relatively large leak. If this occurs, repeat the leak testing procedure.

NOTE The term absolute pressure means the total actual pressure within a given volume or system, above the absolute zero of

pressure. Absolute pressure in a vacuum is equal to atmospheric pressure minus vacuum pressure.

C When the absolute pressure reaches 23,000 microns (29.01 inches of mercury), perform the following:

Close manifold gauge valves

Close valve on vacuum pump

Turn off vacuum pump

Disconnect manifold gauge center port hose from vacuum pump

Attach manifold center port hose to a dry nitrogen cylinder with pressure regulator set to 150 psig (1034 kPa) and purge the hose.

Open manifold gauge valves to break the vacuum in the line set and indoor unit.

Close manifold gauge valves.

D Shut off the dry nitrogen cylinder and remove the manifold gauge hose from the cylinder. Open the manifold gauge valves to release the

dry nitrogen from the line set and indoor unit.

E Reconnect the manifold gauge to the vacuum pump, turn the pump on, and continue to evacuate the line set and indoor unit until the

absolute pressure does not rise above 500 microns (29.9 inches of mercury) within a 20−minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

F When the absolute pressure requirement above has been met, disconnect the manifold hose from the vacuum pump and connect it to an

upright cylinder of HFC−410A refrigerant. Open the manifold gauge valve 1 to 2 psig in order to release the vacuum in the line set and

indoor unit.

G Perform the following:

Close manifold gauge valves.

Shut off HFC−410A cylinder.

Reinstall service valve cores by removing manifold hose from service valve. Quickly install cores with core

tool while maintaining a positive system pressure.

Replace stem caps and secure finger tight, then tighten an additional one−sixth (1/6) of a turn as illustrated.

RECOMMEND

MINIMUM 3/8" HOSE

10

9

11

8

7

HIGH

1/6 TURN

12

1

5

6

2

3

4

Figure 14. Evacuating System

Page 17

14ACX SERIES

Page 18

WARNING

Danger of Equipment Damage. Avoid deep vacuum

operation. Do not use compressors to evacuate a

system. Extremely low vacuums can cause internal

arcing and compressor failure. Damage caused by

deep vacuum operation will void warranty.

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing

operations. Perform operations only in well ventilated

areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and flux.

Evacuating the system of non−condensables is critical for

proper operation of the unit. Non−condensables are

defined as any gas that will not condense under

temperatures and pressures present during operation of

an air conditioning system. Non−condensables and water

suction combine with refrigerant to produce substances

that corrode copper piping and compressor parts.

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

capable of accurately measuring down to 50 microns.

Electrical

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to the furnace or air handler installation instructions

for additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

24VAC TRANSFORMER

Use the transformer provided with the furnace or air

handler for low-voltage control power (24VAC − 40 VA

minimum)

SIZE CIRCUIT AND INSTALL SERVICE

DISCONNECT SWITCH

Refer to the unit nameplate for minimum circuit ampacity, and maximum

fuse or circuit breaker (HACR per NEC). Install power wiring and properly

sized disconnect switch.

MAIN FUSE BOX/

BREAKER PANEL

SERVICE

DISCONNECT

SWITCH

NOTE Units are approved for use only with copper conductors.

Ground unit at disconnect switch or to an earth ground.

WARNING

Electric Shock Hazard. Can cause injury or death. Unit must be grounded in accordance with national and

local codes.

Line voltage is present at all components when unit is not in operation on units with single-pole contactors.

Disconnect all remote electric power supplies before opening access panel. Unit may have multiple power

supplies.

INSTALL THERMOSTAT

Install room thermostat (ordered separately) on an inside wall

approximately in the center of the conditioned area and 5 feet (1.5m) from

the floor. It should not be installed on an outside wall or where it can be

affected by sunlight or drafts.

THERMOSTAT

5 FEET

(1.5M)

NOTE 24VAC, Class II circuit connections are made in the control

panel.

506645−01

Page 18

Page 19

ROUTING HIGH VOLTAGE/ GROUND AND CONTROL WIRING

HIGH VOLTAGE / GROUND WIRES

Any excess high voltage field wiring should be trimmed and

secured away from any low voltage field wiring. To facilitate a

conduit, a cutout is located in the bottom of the control panel.

Connect conduit to the control panel using a proper conduit fitting.

LOW VOLTAGE CONTROL WIRING

NOTE Wire tie provides low voltage control wire strain relief and to

maintain separation of field installed low and high voltage circuits.

NOTE For proper voltages, select thermostat wire (control wires)

gauge per table above.

NOTE Do not bundle any excess 24VAC control wires inside

control panel.

Install low voltage wiring from outdoor to indoor unit and from thermostat

to indoor unit as illustrated.

A Run 24VAC control wires through hole with grommet and secure with

provided wire tie.

B Make 24VAC thermostat wire connections. Locate the two wires from the

contactor and make connection using field provided wire nuts:

S Yellow to Y1

S Black to C (common)

WIRE RUN LENGTH AWG# INSULATION TYPE

LESS THAN 100’ (30 METERS) 18 TEMPERATURE RATING

MORE THAN 100’ (30 METERS) 16 35ºC MINIMUM.

HIGH VOLTAGE

CONNECTIONS

(CONTACTOR)

GROUND

HIGH VOLTAGE

FIELD WIRING

LOW VOLTAGE

FIELD WIRING

FACTORY

WIRING

THERMOSTAT

R

W1

Y

G

C

POWER

HEAT

COOLING

INDOOR

BLOWER

COMMON

SINGLE PHASE

INDOOR UNIT

R

W

Y

G

C

CONTROL

HIGH VOLTAGE

FLEXIBLE

CONDUIT

YELLOW

BLACK

B

WIRING

OUTDOOR

UNIT

Y1

C

A

GROMMET AND

WIRE TIE

Figure 15. Typical Field Wiring Diagram

Page 19

14ACX SERIES

Page 20

506645−01

CRANKCASE HEATER (HR1)

Figure 16. Typical Factory Wiring Diagram (Copeland Compressor)

Page 20

HIGH PRESSURE SWITCH

(S4) LIQUID LINE

CRANKCASE THERMOSTAT (S40)

Page 21

THERMAL PROTECTION

SWITCH (S5 OR S173)

CRANKCASE HEATER (HR1)

Figure 17. Typical Factory Wiring Diagram (Interlink Compressor)

Page 21

HIGH PRESSURE SWITCH

(S4) LIQUID LINE

CRANKCASE THERMOSTAT (S40)

14ACX SERIES

Page 22

Servicing Units Delivered Void of Charge

If the outdoor unit is void of refrigerant, clean the system

using the procedure described below.

1. Leak check system using procedure outlined in this

instruction.

2. Evacuate the system using procedure outlined in this

instruction.

3. Use nitrogen to break the vacuum and install a new

filter drier in the system.

4. Evacuate the system again using procedure outlined

in this instruction.

5. Weigh in refrigerant using procedure outlined under

Start−Up and Charging Procedures.

6. Monitor the system to determine the amount of

moisture remaining in the oil. It may be necessary to

replace the filter drier several times to achieve the

required dryness level. If system dryness is not

verified, the compressor will fail in the future.

Unit Start−Up

2. Inspect all factory− and field−installed wiring for loose

connections.

3. After evacuation is complete, open the liquid line and

suction line service valve stems (Operating Service

Valves on page 4) to release the refrigerant charge

(contained in outdoor unit) into the system.

4. Replace the stem caps and tighten to the value listed

in table 1.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit’s

nameplate. If not, do not start the equipment until you

have consulted with the power company and the

voltage condition has been corrected.

6. Connect manifold gauge set for testing and charging

using figure 18 as a guideline.

7. Set the thermostat for a cooling demand. Turn on

power to the indoor indoor unit and close the outdoor

unit disconnect switch to start the unit.

8. Recheck voltage while the unit is running. Power must

be within range shown on the unit nameplate.

9. Check system for sufficient refrigerate using the

procedures outlined in under System Refrigerant.

IMPORTANT

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start−up to prevent

compressor damage as a result of slugging.

1. Rotate fan to check for binding.

GAUGE SET

CONNECTIONS FOR TESTING AND CHARGING

SUCTION LINE

B

SERVICE PORT

CONNECTION

AClose manifold gauge set valves and connect

the center hose to a cylinder of HFC−410A.

Set for liquid phase charging.

BConnect the manifold gauge set’s low pressure

side to the suction line service port.

CConnect the manifold gauge set’s high

pressure side to the liquid line service port.

DPosition temperature sensor on liquid line near

liquid line service port.

LIQUID PHASE

REFRIGERANT TANK

CHARGE IN

DIGITAL SCALE

System Refrigerant

This section outlines procedures for:

1. Connecting gauge set for testing and charging;

2. Checking and adjusting indoor airflow;

3. Adding or removing refrigerant.

MANIFOLD GAUGE SET

LOW

HIGH

OUTDOOR UNIT

A

506645−01

TEMPERATURE SENSOR

(LIQUID LINE)

TEMPERATURE

D

SENSOR

TO LIQUID

LINE SERVICE

VALV E

C

Figure 18. Manifold Gauge Set Setup and Connections

Page 22

Page 23

CHECKING AIR FLOW AT INDOOR COIL

Check airflow using the Delta−T (

DT) process using the illustration in figure 19.

Temp.

of air

entering

indoor

coil ºF

A

Wet−bulb ºF

53º

DRY

BULB

80 24 24 24 23 23 22 22 22 20 19 18 17 16 15

78 23 23 23 22 22 21 21 20 19 18 17 16 15 14

76 22 22 22 21 21 20 19 19 18 17 16 15 14 13

74 21 21 21 20 19 19 18 17 16 16 15 14 13 12

Dry−bulb

72 20 20 19 18 17 17 16 15 15 14 13 12 11 10

70 19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

T

C

Drop

19º

All temperatures are

expressed in ºF

DT

air flowair flow

INDOOR

COIL

B

B

64º

Figure 19. Checking Indoor Airflow over Evaporator Coil using Delta−T Chart

START: Determine how refrigerant is metered

WET

BULB

A

72º

BULB

DRY

1. Determine the desired DTMeasure entering air temper-

ature using dry bulb (A) and wet bulb (B). DT is the intersecting value of A and B in the table (see triangle).

2. Find temperature drop across coilMeasure the coil’s dry

bulb entering and leaving air temperatures (A and C). Temperature Drop Formula: (T

3. Determine if fan needs adjustmentIf the difference between

the measured T

+

3º, no adjustment is needed. See examples: Assume DT =

and the desired DT (T

Drop

) = A minus C.

Drop

–DT) is within

Drop

15 and A temp. = 72º, these C temperatures would necessitate stated actions:

Cº T

53º 19 – 15 = 4 Increase the airflow

58º 14 – 15 = −1 (within +3º range) no change

62º 10 – 15 = −5 Decrease the airflow

4. Adjust the fan speedSee indoor unit instructions to in-

– DT = ºF ACTION

Drop

crease/decrease fan speed.

Changing air flow affects all temperatures; recheck temperatures to confirm that the temperature drop and DT are within

3º.

+

WHEN TO CHARGE?

Best during warm weather

Can charge in colder weather by determining

best charge method? Determine by:

A Metering device type

B Outdoor ambient temperature

REQUIREMENTS:

Sufficient heat load in structure

Indoor temperature between 70-80ºF (21−26ºC)

Manifold gauge set connected to unit

Thermometers:

− to measure outdoor ambient temperature

− to measure liquid line temperature

− to measure suction line temperature

Figure 20. Determining Charge Method

TXV

65ºF

(18.3ºC) and

Above

APPROACH OR

SUBCOOLING

metering

device?

64ºF

(17.7ºC) and

Below

WEIGH-IN

Which

40ºF

(4.4ºC) and

Above

RFC

39ºF

(3.8ºC) and

Below

WEIGH-INSUPERHEAT

Page 23

14ACX SERIES

Page 24

WEIGH IN (RFC AND TXV)

CALCULATING SYSTEM CHARGE FOR OUTDOOR UNIT VOID OF CHARGE

If the system is void of refrigerant, first, locate and repair any leaks and then weigh in the refrigerant charge into the

unit. To calculate the total refrigerant charge:

Adjust amount. for variation

Amount specified on

nameplate

in line set length listed on

line set length table below.

Total charge

+

=

Refrigerant Charge per Line Set Length

Liquid Line

Set Diameter

3/8" (9.5 mm)

*If line length is greater than 15 ft. (4.6 m), add this amount. If

line length is less than 15 ft. (4.6 m), subtract this amount.

NOTE Insulate liquid line when it is routed through areas where the surrounding ambient temperature could become higher than the

temperature of the liquid line or when pressure drop is equal to or greater than 20 psig.

NOTE The above nameplate is for illustration purposes only. Go to actual nameplate on outdoor unit for charge information.

Ounces per 5 feet (g per 1.5 m)

adjust from 15 feet (4.6 m) line set*

3 ounce per 5’ (85 g per 1.5 m)

Figure 21. Using HFC−410A Weigh In Method

USE WEIGH-IN METHOD

Weigh-in or remove refrigerant

based upon line length

(17.7ºC) and

Below

If value is greater than shown (high

approach), add refrigerant; if less

than shown (liquid temperature too

close to ambient temperature, low

approach), remove refrigerant.

APPº (Approach) Values(F:+/−1.0° [C: +/−0.6°])

64ºF

65ºF (18.3ºC)

and Above

ABOVE or

BELOW

If refrigerant is added or

removed, retest to confirm

that unit is properly charged.

1. Confirm proper airflow across coil using figure 19.

2. Compare unit pressures with table 4, Normal Operating

Pressures.

3. Set thermostat to call for heat (must have a cooling load

between 70-80ºF (21−26ºC).

4. Connect gauge set.

5. When heat demand is satisfied, set thermostat to call for

cooling.

6. Allow temperatures and pressures to stabilize.

7. Record outdoor ambient temperature:

AMBº =_________

8. Record liquid line temperature:

LIQº = __________

9. Subtract to determine approach (APPº):

LIQº_____ − AMBº _____ = APPº_____

10. Compare results with table below.

ºF (ºC)* −018 −024 −030 −036 −041 −042 −047 −048 −059/−060

65 (18)

75 (24)

85 (29)

95 (35)

105 (41)

115 (45)

*Temperature of air entering outdoor coil.

4 (2.2) 2 (1.1) 2 (1.1) 2 (1.1) 3 (1.7) 6 (3.3) 9 (5.0) 7 (3.9) 8 (4.4)

5 (2.8) 4 (2.2) 4 (2.2) 5 (2.8) 3 (1.7) 6 (3.3) 9 (5.0) 8 (4.4) 9 (5.0)

6 (3.3) 4 (2.2) 6 (3.3) 8 (4.4) 4 (2.2) 8 (4.4) 8 (4.4) 8 (4.4) 9 (5.0)

5 (2,8) 4 (2.2) 5 (2.8) 7 (3.9) 4 (2.2) 8 (4.4) 8 (4.4) 8 (4.4) 9 (5.0)

3 (1.7) 4 (2.2) 5 (2.8) 6 (3.3) 4 (2.2) 8 (4.4) 8 (4.4) 8 (4.4) 9 (5.0)

3 (1.7) 3 (1.7) 4 (2.2) 6 (3.3) 5 (2.8) 8 (4.4) 8 (4.4) 9 (5.0) 9 (5.0)

Figure 22. HFC−410A Approach TXV Charge

Page 24

506645−01

Page 25

USE WEIGH-IN METHOD

Weigh-in or remove refrigerant

based upon line length

64ºF (17.7ºC)

and below

BLOCK OUTDOOR COIL: [sometimes necessary with lower

temperatures] Use cardboard or plastic sheet to restrict the

airflow through the outdoor coil to achieve pressures from

325−375 psig (2240−2585 kPa). Higher pressures are needed

to check charge. Block equal sections of air intake panels and

CARDBOARD OR

PLASTIC SHEET

If refrigerant is added or

removed, verify charge using

the Approach Method.

If value is LESS

than shown, add

refrigerant.

move coverings sideways until the liquid pressure is in the

above noted ranges.

MORE or

ABOVE or

BELOW

If value is MORE than shown,

remove refrigerant.

LESS

65ºF (18.3ºC)

and above

1. Confirm proper airflow across coil using figure 19.

2. Compare unit pressures with table 4, Normal

Operating Pressures.

3. Set thermostat to call for heat (must have a cooling load

between 70-80ºF (21−26ºC)

4. Connect gauge set

5. Measure outdoor ambient temperature

6. When heat demand is satisfied, set thermostat to call for

cooling

7. Allow temperatures and pressures to stabilize.

NOTE − If necessary, block outdoor coil to maintain 325

− 375 psig.

8. Record liquid line temperature:

LIQº = ______

9. Measure liquid line pressure and use the value to

determine saturation temperature (see table 3):

SATº = ______

10. Subtract to determine subcooling (SCº):

SATº_____ − LIQº _____ = SCº _____

11. Compare results with table below.

SCº (Subcooling) Values (F:+/−1.0° [C: +/−0.6°])

ºF (ºC)* −018 −024 −030 −036 −041 −042 −047 −048 −059/−060

65 (18)

75 (24)

85 (29)

95 (35)

105 (41)

115 (45)

*Temperature of air entering outdoor coil.

10 (5.6) 10 (5.6) 11 (6.1) 13 (7.2) 9 (5.0) 10 (5.6) 6 (3.3) 8 (4.4) 8 (4.4)

6 (3.3) 7 (3.9) 8 (4.4) 9 (5.0) 7 (3.9) 7 (3.9) 6 (3.3) 8 (4.4) 7 (3.9)

6 (3.3) 8 (4.4) 6 (3.3) 7 (3.9) 7 (3.9) 8 (4.4) 6 (3.3) 8 (4.4) 8 (4.4)

6 (3.3) 9 (5.0) 6 (3.3) 8 (4.4) 7 (3.9) 8 (4.4) 6 (3.3) 8 (4.4) 7 (3.9)

10 (5.6) 9 (5.0) 7 (3.9) 9 (5.0) 7 (3.9) 8 (4.4) 6 (3.3) 8 (4.4) 6 (3.3)

10 (5.6) 10 (5.6) 8 (4.4) 10 (5.6) 6 (3.3) 7 (3.9) 5 (2.8) 7 (3.9) 6 (3.3)

Figure 23. HFC−410A Subcooling TXV Charge

Page 25

14ACX SERIES

Page 26

START: Measure outdoor ambient temperature

USE WEIGH-IN METHOD

Weigh-in or remove refrigerant

based upon line length

SUPERHEAT RFC

ºF* 50 52 54 56 58 60 62 64 66 68 70 72 74 76

40 15 18 20 23 26 29 32 34 38 41 43 46 48 51

45 13 16 18 21 24 27 30 33 36 39 41 44 46 49

50 11 14 16 19 22 25 28 31 34 37 39 42 44 47

55 9 12141720232730333638404244

60 7 10121518212427303335384043

65 - 6 10 13 16 19 21 24 27 30 33 36 38 41

70 - - 7 1013161921242730333639

75 - - - 6 9 121518212428313437

80 - - - - 5 8 12 15 18 21 25 28 31 35

85 - - - - - - 8 11 15 19 22 26 30 33

90 - - - - - - 5 9 131620242731

95 - - - - - - - 6 101418222529

100 --------81216212428

If refrigerant is

REMOVED, retest to

confirm that unit is

properly charged.

105 --------5913172226

110 ---------611152025

115 ----------8141824

* Dry−bulb temperature (ºF) of entering outdoor ambient air.

Wet Bulb (air entering indoor coil)

40ºF

(4.4ºC) and

Above

SHº (Superheat) Values (+/−5ºF)

(3.8ºC) and

ABOVE or

BELOW

39ºF

Below

1. Confirm proper airflow across coil using figure 19.

2. Compare unit pressures with table 4, Normal

Operating Pressures.

3. Use SUPERHEAT to correctly charge unit or to

verify the charge is correct.

4. Set thermostat to call for heat (must have a cooling

load between 70-80ºF (21−26ºC)

5. Connect gauge set.

6. When heat demand is satisfied, set thermostat to

call for cooling.

7. Allow temperatures and pressures to stabilize.

8. Measure the suction line pressure and use the use

value to determine saturation temperature (table

3):

SATº =_________

9. Record suction line temperature:

VAPº =_________

10. Subtract to determine superheat (SHº):

VAPº − _____ SATº ______ = SHº______

11. Record the wet bulb temperature (air entering

indoor coil):

WB =_______

12. Record outdoor ambient temperature.

13. Compare results with table to the left.

NOTE − Do not attempt to charge system where a

dash appears, system could be overcharged.

Superheat is taken at suction line service port.

Suction line superheat must never be less than 5ºF

at the suction line service port.

If value is LESS than

shown, then REMOVE

refrigerant.

MORE or

LESS

If value is MORE

than shown, then

ADD refrigerant.

If refrigerant is

ADDED, retest to

confirm that unit is

properly charged.

Figure 24. HFC−410A Superheat RFC Method

Table 3. HFC−410A Temperature Pressure (Psig)

°F °C Psig °F °C Psig

−40 −40.0 11.6 60 15.6 170

−35 −37.2 14.9 65 18.3 185

−30 −34.4 18.5 70 21.1 201

−25 −31.7 22.5 75 23.9 217

−20 −28.9 26.9 80 26.7 235

−15 −26.1 31.7 85 29.4 254

−10 −23.3 36.8 90 32.2 274

−5 −20.6 42.5 95 35.0 295

0 −17.8 48.6 100 37.8 317

5 −15.0 55.2 105 40.6 340

10 −12.2 62.3 110 43.3 365

15 −9.4 70.0 115 46.1 391

20 −6.7 78.3 120 48.9 418

25 −3.9 87.3

30 −1.1 96.8 130 54.4 476

35 1.7 107 135 57.2 507

40 4.4 11 8 140 60.0 539

45 7.2 130

50 10.0 142

55 12.8 155

125 51.7 446

145 62.8 573

150 65.6 608

506645−01

Page 26

Page 27

Table 4. HFC−410A Normal Operating Pressures (Liquid +10 and Suction +5 psig)

Use this table to perform maintenance checks; it is not a procedure for charging the

system. Minor variations in these pressures may be due to differences in installations.

IMPORTANT

Significant deviations could mean that the system is not properly charged or that a

problem exists with some component in the system.

Model −018 −024 −030 −036 −041 −042 −047 −048 −059/−060

**Temp.

5F (5C)

Expansion Valve (TXV)*

65 (18) 230 / 138 225 / 135 226 / 129 238 / 132 233 / 142 236 / 138 233 / 139 238 / 136 239 / 133

70 (21) 244 / 139 242 / 137 241 / 131 254 / 135 239 / 142 253 / 140 252 / 140 256 / 138 258 / 135

75 (24) 265 / 140 260 / 138 259 / 134 273 / 138 256 / 143 273 / 141 272 / 141 277 / 139 278 / 136

80 (27) 286 / 140 282 / 140 281 / 138 293 / 140 278 / 144 296 / 142 294 / 142 299 / 140 300 / 137

85 (29) 307 / 142 304 / 141 301 / 140 316 / 142 299 / 145 318 / 143 315 / 142 320 / 139 323 / 138

90 (32) 330 / 143 326 / 142 324 / 141 340 / 143 321 / 145 341 / 144 338 / 144 343 / 140 346 / 139

95 (35) 351 / 144 351 / 142 348 / 142 366 / 144 343 / 146 366 / 146 361 / 144 369 / 141 370 / 140

100 (38) 380 / 144 376 / 144 372 / 143 392 / 145 366 / 147 392 / 147 387 / 144 395 / 142 396 / 142

105 (41) 407 / 145 403 / 145 399 / 144 420 / 147 389 / 148 417 / 148 413 / 145 422 / 144 415 / 143

110 (43) 436 / 146 433 / 145 428 / 145 449 / 148 421 / 149 445 / 149 442 / 148 450 / 146 449 / 145

115 (45) 466 / 147 463 / 147 456 / 146 480 / 149 452 / 151 475 / 151 465 / 148 481 / 148 476 / 147

Fixed Orifice (RFC)*

65 (18) 232 / 124 228 / 125 229 / 128 241 / 131 228 / 131 248 / 135 232 / 125 240 / 126 244 / 125

70 (21) 248 / 127 244 / 127 243 / 129 258 / 134 245 / 135 266 / 138 249 / 129 260 / 129 263 / 128

75 (24) 267 / 131 261 / 131 261 / 132 277 / 136 263 / 138 285 / 141 268 / 133 281 / 133 281 / 131

80 (27) 286 / 135 284 / 134 284 / 135 298 / 139 284 / 141 305 / 143 286 / 136 301 / 135 303 / 134

85 (29) 307 / 138 303 / 137 305 / 138 321 / 141 306 / 144 327 / 145 312 / 140 324 / 138 324 / 136

90 (32) 328 / 141 325 / 140 327 / 140 342 / 143 327 / 146 349 / 147 332 / 142 346 / 140 347 / 139

95 (35) 351 / 143 347 / 142 349 / 142 366 / 145 348 / 148 372 / 149 357 / 144 371 / 142 370 / 141

100 (38) 375 / 146 370 / 144 372 / 144 392 / 147 372 / 149 396 / 150 379 / 146 395 / 144 394 / 143

105 (41) 400 / 148 394 / 146 396 / 146 416 / 149 395 / 151 421 / 152 406 / 149 420 / 146 418 / 145

110 (43) 426 / 150 420 / 148 422 / 148 446 / 151 424 /153 447 / 153 430 / 150 447 / 148 444 / 146

115 (46) 457 / 153 447 / 150 449 / 150 480 / 152 453 / 155 476 / 154 460 / 152 473 / 150 471 / 147

*Values shown are typical pressures; indoor unit match up, indoor air quality equipment, and indoor load will cause the pressures to vary.

**Temperature of the air entering the outside coil.

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Page 27

14ACX SERIES

Page 28

System Operation

UNIT COMPONENTS

IMPORTANT

Some scroll compressor have internal vacuum protector

that will unload scrolls when suction pressure goes

below 20 psig. A hissing sound will be heard when the

compressor is running unloaded. Protector will reset

when low pressure in system is raised above 40 psig. DO

NOT REPLACE COMPRESSOR.

High Pressure Switch (S4)

14ACX units are equipped with a high-pressure switch that

is located in the liquid line of the compressor as illustrated

in figure on page 2 and figure 25 for the location of the

manual reset button..

MANUAL RESET

BUTTON

Figure 25. High Pressure Switch (S4) Manual Reset

The switch is a Single Pole, Single Throw (SPST),

manual−reset switch which is normally closed and

removes power from the compressor when discharge

pressure rises above factory setting at 590 + 10 psi. The

manual−reset button can be identified by a red cap that is

press to preform the reset function.

Thermal Protection Switch (S173) Compressor

Mounted

Some units are equipped with a compressor mounted

normally closed temperature switch that prevents

compressor damage due to overheating caused by

internal friction. The switch is located on top of the

compressor casing (see figure 1). This switch senses the

compressor casing temperature and opens at 239−257°F

(115°C−125°C) to shut off compressor operation. The

auto−reset switch closes when the compressor casing

temperature falls to 151−187°F (66°C−86°C), and the

compressor is re−energized. This single−pole, single−throw

(SPST) bi−metallic switch is wired in series with the 24V Y

input signal to control compressor operation.

Crankcase Heater (HR1) and Thermostat Switch

(S40) (−041 through −060 models only)

These models are equipped with either a 40 or 70 watt

belly−band type crankcase heater. HR1 prevents liquid

from accumulating in the compressor. HR1 is controlled by

a single−pole, single−throw thermostat (SPST) switch

(S40) located on the liquid line (see figure 1 for location).

When liquid line temperature drops below 50°F the

thermostat closes energizing HR1. The thermostat will

open, de−energizing HR1 once liquid line temperature

reaches 70° F.

Maintenance

DEALER

Maintenance and service must be performed by a qualified

installer or service agency. At the beginning of each

cooling season, the system should be checked as follows:

Outdoor Unit

1. Outdoor unit fan motor is pre−lubricated and sealed.

No further lubrication is needed.

2. Visually inspect all connecting lines, joints and coils for

evidence of oil leaks.

3. Check all wiring for loose connections.

4. Check for correct voltage at unit (unit operating).

5. Check amp draw on outdoor fan motor.