Lennox 12CHP060, 12CHP048, 12CHP042, 12CHP036, 12CHP030 Installation Instructions Manual

...Page 1

INSTALLATION

E1998 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Shipping & Packing List

1 − Assembled heat pump package unit

As soon as the unit is received, inspect the unit for possible

damage during transit. If damage is evident, the extent of

the damage must be noted on the carrier’s freight bill. Make

a separate request for inspection by the carrier’s agent.

If any damages are discovered and reported to the carrier

DO NOT INSTALL THE UNIT, as claim may be denied.

Check the unit rating plate to confirm specifications are

as ordered.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool dust. Breathing this may cause

lung cancer. (Fiberglass wool is known to the State

of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

INSTRUCTIONS

12CHP SERIES UNITS

PACKAGED HEAT PUMP UNIT (2−5 TONS)

504,176M

06/03

Supersedes 01/00

Table of Contents

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . . .

General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearances 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rigging & Setting Unit 4. . . . . . . . . . . . . . . . . . . . . . . . . .

Condensate Drain 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filters 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply & Return Connections 5. . . . . . . . . . . . . . . . . . . .

Outdoor Fan Clearances 5. . . . . . . . . . . . . . . . . . . . . . . .

Compressors 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Electric Heat 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Performance 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Operation 10. . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Parts List 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General

These instructions explain the recommended method of

installation of the heat pump unit, and associated electri

cal wiring.

This unit is designed and approved for use as a self−con

tained air to air outdoor heat pump system.

The units are factory equipped with a transformer and

blower control for applications without auxiliary heat. Elec

tric heat accessory kits (ECH29) can be ordered for field

installation of additional heat where required.

These instructions, and any instructions packaged with

mating components and/or accessories, should be care

fully read prior to beginning installation. Note particularly

any CAUTIONS or Notes in these instructions and all la

bels on the units.

These instructions are intended as a general guide only for

use by qualified personnel and do not supersede any na

tional or local codes in any way. Compliance with all local,

state, provincial or national codes pertaining to this type of

equipment should be determined prior to installation.

Litho U.S.A.

06/03

*2P0603*

Page 1

504,176M

*P504176M*

Page 2

Unit Dimensions − inches (mm)

Model

Model

Model

Model

CORNER WEIGHTS lbs. (kg)

Model

Number

12CHP024 77 35 56 25 61 28 82 37

12CHP030 86 39 63 29 69 31 92 42

12CHP036 117 53 85 39 93 42 125 57

12CHP042 118 54 86 39 94 43 126 57

12CHP048 121 55 88 40 96 44 129 59

12CHP060 127 57 92 42 101 46 135 61

AA BB CC DD

lbs. kg lbs. kg lbs. kg lbs. kg

CENTER OF GRAVITY inches (mm)

Model

Number

12CHP024 217/8 556 261/2 673

12CHP030 217/8 556 261/2 673

12CHP036 233/4 603 311/4 794

12CHP042 233/4 603 311/4 794

12CHP048 233/4 603 311/4 794

12CHP060 23−3/4 603 31−1/4 794

AA

EE FF

inch mm inch mm

GG

BB

INDOOR

COIL

OUTDOOR

COIL

INTAKE

AIR

OUTDOOR

COIL FAN

OUTDOOR

COIL

FORKLIFT

SLOTS

(Front and

Back Only)

BASE RAIL

COMPRESSOR

CONDENSER COIL

INTAKE AIR

TOP VIEW

OUTDOOR COIL

EXHAUST AIR

FRONT VIEW

OUTDOOR COIL

EXHAUST AIR

B

N

C

BLOWER

OPTIONAL

ELECTRIC

HEAT

(Field

BASE RAIL

Installed)

REFRIGERANT

SERVICE

PORTS

ELECTRICAL

INLETS

KK

JJ

DOWNFLOW

RETURN AIR

OPENING

CENTER

OF

GRAVITY

DD

TOP VIEW BASE SECTION

B

HORIZONTAL

SUPPLY AIR

E

OPENING

K

F

BACK VIEW

C

LE

DOWNFLOW

SUPPLY AIR

OPENING

EE

FF

HORIZONTAL

RETURN AIR

OPENING

(048/060)

HORIZONTAL

RETURN AIR

OPENING

CC

J

2 (51)

J

A

M

K

BASE RAIL

FILTER

RACK

CONDENSATE

DRAIN

45/8

(117)

H

BASE RAIL

P

LEFT SIDE

Model

Number

−024 2711/16 703 455/8 1159 455/8 1159 251/4 641 113/16 46 4 102 17/8 48

−030 3111/16 805 455/8 1159 455/8 1159 291/4 743 113/16 46 4 102 17/8 48

−036, −042, −048, −060 3311/16 856 5411/16 1389 495/8 1260 317/16 799 11/8 29 61/4 159 21/4 57

Model

Number

−024 155/8 397 111/2 292 171/2 445 4 102 5 127 463/8 1179 463/8 1179

−030 155/8 397 111/2 292 171/2 445 4 102 5 127 463/8 1179 463/8 1179

−036, −042, −048, −060 171/8 435 12 305 211/2 546 55/8 143 41/8 105 551/4 1403 501/2 1283

A B C D E F G

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

H J K L M N P

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

D

A

27/16

(62)

Page 2

ELECTRIC

HEAT

POWER INLET

OPTIONAL

ELECTRIC HEAT

(Field Installed)

RIGHT SIDE

BLOWER

BASE RAIL

Page 3

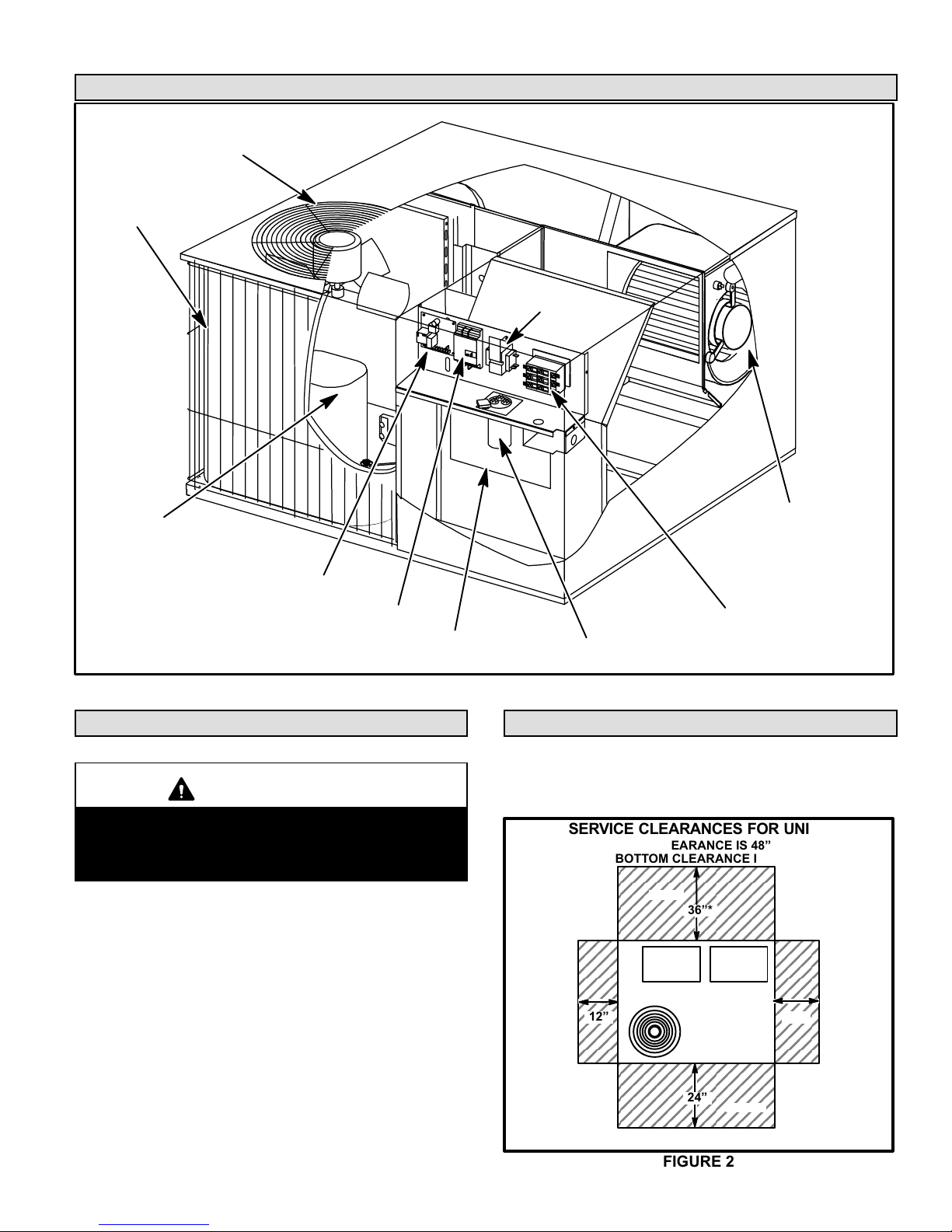

Parts Arrangement

OUTDOOR FAN

OUTDOOR COIL

COMPRESSOR

BLOWER

TRANSFORMER

INDOOR

BLOWER MOTOR

DEFROST CONTROL

BLOWER CONTROL

HEATER BLOCKOFF

(FOR OPTIONAL ELECTRIC HEAT)

FIGURE 1

Requirements

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a qualified installer or service agency.

Unit should be installed in accordance with all national and

local safety codes.

NOTE − For improved start−up performance, the indoor coil

should be washed with suitable detergent to remove any

residue from manufacturing processes.

Limitations for unit and appropriate accessories must also

be observed.

The unit must not be installed with any duct system in the

outdoor air stream. The outdoor fan is not designed to oper

ate against any additional static pressure.

Minimum and maximum operating conditions must be ob

served to assure maximum system performance with mini

mum service required.

CONTACTOR

CAPACITOR

Clearances

In the U.S., units may be installed on combustible floors

made from wood or class A, B, or C roof covering material.

In Canada, units may be installed on combustible floors.

Units must be installed outdoors.

SERVICE CLEARANCES FOR UNITS

TOP CLEARANCE IS 48"

BOTTOM CLEARANCE IS 0"

REAR

36"*

RETURN SUPPLY

LEFT

12"

24"

FRONT

*Rear clearance is 36" with or 2" without an economizer.

FIGURE 2

RIGHT

12"

Page 3

Page 4

Rigging & Setting Unit

Á

Á

Exercise care when moving the unit. Do not remove any

packaging until unit is near the place of installation. A sling

assembly may be used to lift the unit. Spreaders which are

longer than the largest dimension across unit MUST be

used across the top of the unit.

CAUTION

Before lifting a unit, make sure that the weight is dis

tributed equally on the cables so that it will lift evenly.

Units may also be moved or lifted with a forklift while still in

the factory supplied packaging.

FORKS MUST BE A MINIMUM OF 42 INCHES LONG.

NOTE − Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet or inlet.

The unit is designed to be located outdoors with sufficient

clearance for free entrance to air inlet and discharge. Loca

tion must also allow for adequate service access.

Specially designed roof curbs are available for these

units. Using any other roof curb may result in water leaking

into conditioned space. The specified roof curb is de

signed to allow water from the bottom of the condensing

coil to run off.

The unit must be installed on a solid foundation that will not

settle or shift. Adequate structural support must be pro

vided. Maintain minimum clearances as shown in illustra

tion and install unit in level position. Isolate the base from

the building structure to avoid possible transmission of

sound or vibration into conditioned space.

Unit foundation should be raised to a minimum of 3" above

finish grade. In areas which have prolonged periods of tem

perature below freezing and snowfall, the unit should be

elevated above the average snow line. Also extra precau

tion should be taken to allow free drainage of condensate

from defrost cycles to prevent ice accumulation. Unit

should not be located near walkways to prevent possible

icing of surface from defrost condensate.

Avoid placing unit near quiet areas, i.e. sleeping quarters or

study rooms. Normal operating sound levels may be objec

tionable if the unit is placed near certain rooms.

Condensate Drain

TYPICAL CONDENSATE DRAIN

Minimum Pitch

1" (25 mm) per 10’

(3 m) of line

OPEN

VENT

Trap must be deep enough to offset maximum

static difference (Generally, 3 inches minimum).

UNIT

MOUNTING

FRAME

FIGURE 3

Filters

No filters are supplied with the unit. Filters must be

installed ahead of the evaporator coil and must be cleaned

or replaced as necessary. Dirty filters will reduce the air

flow of the unit. Filters should be sized in accordance with

Table 1 below.

TABLE 1

FILTER SIZES

UNIT MODEL FILTER SIZE

12CHP−024, −030 24" X 25"

12CHP−036, −042, −048, −060 30" X 30"

Supply & Return Connections

Duct system should be designed and sized according to

the methods in Manual Q of the Air Conditioning Contrac

tors of America (ACCA).

A closed return duct system shall be used. This shall not

preclude use of economizers or outdoor fresh air intake. It

is recommended that supply and return duct connections

at the unit be made with flexible joints.

The supply and return air duct systems should be de

signed for the CFM and static requirements of the job.

They should NOT be sized to match the dimensions of

the duct connections on the unit.

The packaged heat pumps are equipped with a 3/4" fpt

coupling for condensate line connection. The drain line

must be properly trapped and routed to a suitable drain.

See illustration for proper drain arrangement. The drain

line must pitch to an open drain or pump to prevent clog

ging of the line.

CAUTION

When fastening duct system to side duct flanges on

unit, insert screws through duct flanges only. Do not

insert screws through casing. Outdoor duct must be

insulated and waterproofed.

Page 4

Page 5

Outdoor Fan Clearances

Figure 4 illustrates the critical measurements of the out

door fan system. This dimension should be checked and

fan adjusted accordingly anytime servicing of the outdoor

fan system is required.

OUTDOOR FAN CLEARANCES

A

OPTIONAL ELECTRIC HEAT INSTALLATION

UNIT MODEL NO. A

−024, −030

−036, −042, −048, −060

3"

3−1/2"

FIGURE 4

Compressors

Units are shipped with compressor mountings factory−ad

justed and ready for operation.

CAUTION

Do not loosen compressor mounting bolts.

Optional Electric Heat

The unit is fully equipped for heat pump operation without

auxiliary heat.

Installing Optional Electric Heat Section

1 − Disconnect power and open main control access.

2 − Disconnect the plug separating the high voltage

wire harness.

3 − Remove the high voltage wire harness plug and discard.

4 − Remove the heater blockoff by removing the four

screws holding it in place.

5 − Cut away insulation covering opening, using the hole

in the panel as a template.

6 − Insert the heater into the control panel and fasten in

the same mounting holes. See figure 5.

7 − Plug the heater wiring harness into the wire harness

on the control assembly.

8 − Field wiring of auxiliary heater is separate from unit

power supply. Wire power supply wiring for the heater

to appropriate connections on heater kit.

OPTIONAL

ELECTRIC

HEAT

HEATER

BLOCKOFF

FIGURE 5

Electrical

USE COPPER CONDUCTORS ONLY

All field wiring must be done in accordance with National

Electric Code recommendations, local codes and applica

ble requirements of UL or in accordance with Canadian

Electrical Code, local codes and CSA Standards. Power

wiring, disconnect means, and over−current protection are

to be supplied by installer. See unit rating plate for maxi

mum over−current protection, minimum circuit ampacity, as

well as operating voltage. The power supply must be sized

and protected according to specifications supplied. See

figure 6 for field connection of line voltage wiring and fig

ures 7 and 8 for typical wiring diagrams.

CAUTION

When connecting electrical power and control wir

ing to the unit, waterproof type connectors MUST be

used so that water or moisture cannot be drawn into

the unit during normal operation.

208/230 LINE VOLTAGE WIRING

CONTACTOR

FUSED DISCONNECT SWITCH

(FURNISHED BY INSTALLER)

L1

GROUND

LUG

NOTE − If 208 voltage is supplied, transformer connections must be

made.

FIGURE 6

L2

Page 5

Page 6

Typical Wiring Diagram

(Does not Include 12CHP060)

12CHP Series Heat Pump Packaged Units

FIGURE 7

Page 6

Page 7

Typical Wiring Diagram

12CHP060 Series Heat Pump Packaged Units

FIGURE 8

Page 7

Page 8

Unit must be grounded with separate ground conductor.

18 20

SUCTION

LIQUID

The unit wiring diagram is located inside the unit access

panel. Low voltage control wiring are pigtail leads located

below the main control box and are color coded to match

the connection called out on the wiring schematic.

general guide. These tables should not be used for charg

ing the unit. Minor variations in these pressures may be

expected due to differences in installations. Significant

differences could mean that the system is not properly

charged or that a problem exists with some component in

the system. Used carefully, this table could serve as a use

ful service guide. Table 3 should be used when unit is

If any of the original unit wiring is replaced, the same size

and type wire must be used. Electrical wiring must be

sized to carry minimum circuit ampacity marked on the

unit. Each unit must be wired with a separate branch cir

cuit and be properly fused.

charged during the heating mode. If outdoor ambient is

below 45°F, run unit through defrost cycle first, wait 15

minutes for system pressures to stabilize, then take pres

sures. Data in table 3 is based on 70°F dry bulb return air.

Data in table 4 is based on 80°F dry bulb / 67°F wet bulb

return air. Allow unit operation to stabilize before taking

System Performance

For maximum performance of this heat pump system, the

pressure readings.

TABLE 2

SUCTION SUPERHEAT TABLE

operating temperatures and pressures should be

checked and superheat determined at Standard ARI test

UNIT MODEL NO.

conditions of 82_F outdoor − 80_F indoor dry bulb/67_F

wet bulb. If superheat measured deviates from values in

table below, refrigerant charge should be adjusted ac

cordingly for maximum performance.

Verify system performance using table 3 or table 4 as a

12CHP−030, −036

12CHP−024

12CHP−030

12CHP−036

12CHP−042, −048, −060

TABLE 3

NORMAL OPERATING PRESSURES −− HEATING MODE

70°F db RETURN AIR AIR TEMPERATURE ENTERING OUTDOOR COIL (°F)

SUCTION SUPERHEAT

82_F OD minus 80_F IDDB

/ 67_F IDWB

18 − 20_

MODEL PRESSURE 0° 5° 10° 15° 20° 25° 30° 35° 40° 45° 50° 55° 60°

12CHP−024 17 20 24 28 33 38 43 49 55 62 69 74 81

12CHP−030 14 17 21 25 29 34 39 45 51 56 63 70 78

12CHP−036

12CHP−042

12CHP−048 15 18 22 26 30 35 40 45 51 55 62 68 76

12CHP−060 14 17 21 25 29 34 39 44 50 54 61 67 75

12CHP−024 181 191 200 209 219 228 237 247 256 265 275 284 293

12CHP−030 168 173 179 184 189 195 200 205 211 216 221 227 232

12CHP−036

12CHP−042

12CHP−048 203 211 220 229 237 246 255 263 272 281 289 298 307

12CHP−060 163 170 177 183 190 197 203 210 217 223 230 237 243

14 17 21 25 29 34 39 45 51 56 63 70 78

16 19 23 27 31 36 41 45 51 55 62 68 76

165 172 178 184 191 197 203 210 216 222 229 235 241

167 174 181 187 194 201 207 214 221 227 234 241 247

Page 8

Page 9

TABLE 4

SUCTION

LIQUID

NORMAL OPERATING PRESSURES −− COOLING MODE

80°F db / 67°F wb

RETURN AIR

MODEL PRESSURE 65° 70° 75° 80° 82° 85° 90° 95° 100° 105° 110° 115° 125°

12CHP−024 78 79 81 82 83 84 85 87 89 90 92 93 96

12CHP−030 78 79 81 82 83 84 85 87 89 90 92 93 96

AIR TEMPERATURE ENTERING OUTDOOR COIL (°F)

12CHP−036

12CHP−042

12CHP−048 78 79 80 82 82 83 84 85 86 87 88 90 92

12CHP−060 78 79 80 82 82 83 84 85 86 87 88 90 92

12CHP−024 140 155 170 184 190 199 213 228 243 257 272 286 316

12CHP−030 145 159 173 187 193 202 216 230 244 258 273 287 316

12CHP−036

12CHP−042

12CHP−048 164 180 196 213 219 229 245 261 277 293 309 326 358

12CHP−060 166 182 198 214 220 229 245 261 277 293 308 324 356

LIQUID

Sequence of Operation

75 77 80 82 83 84 87 89 91 94 96 98 103

80 81 82 84 84 85 86 87 88 89 90 92 94

146 161 176 191 197 206 221 236 251 266 281 296 326

155 170 185 200 206 215 230 245 260 275 290 305 335

The defrost control will initiate a defrost cycle if time period

has elapsed and the defrost sensor detects a temperature

Blower Delay − Cooling

When the thermostat is in the cooling mode, the O circuit is

powered which energizes the reversing valve. Upon cool

ing demand, the thermostat closes circuit R and Y. Closing

R and Y closes unit contactor starting compressor and out

door fan. Thermostat automatically closes R to G circuit

which also brings on the indoor blower at the same time.

Upon satisfying cooling demand, thermostat will open

above circuits and open main contactor, stopping com

pressor and outdoor fan.

Blower Delay − Heating

below freezing. At the start of defrost cycle, the defrost con

trol will energize the reversing valve solenoid, shifting the

reversing valve and de−energizing the outdoor fan. The de

frost relay will also close energizing tempering heat for in

creased comfort during defrost , if the unit is so equipped.

The unit will remain in the defrost mode until the defrost

sensor has determined that the frost has been removed

from the coil or a 10 minute time period has elapsed.

DEFROST CONTROL TEST AND

TIME PIN LOCATIONS

JUMPER SHOWN ON T2 PIN

Upon heating demand the thermostat closes circuit R to Y,

closing unit contactor, starting compressor and outdoor

fan. The reversing valve is not energized in the heating

mode. The thermostat again automatically brings on the in

door blower at the same time. Upon satisfying heating de

mand, the thermostat opens above circuits and stops unit

operation.

T1T2T3

Defrost Cycle

If outdoor ambient conditions are such that frost forms on

the outdoor coil, the defrost control monitors the need for

and initiates and terminates defrost cycles as necessary to

maintain system performance. The defrost control is time/

temperature initiated and temperature terminated with a

maximum defrost time (time−out) of 10 minutes. Time be

tween defrost cycles is pre−set at 60 minute intervals at the

factory, but can be field adjusted between 30, 60 or 90 min

utes. See figure 9 for field adjustment of defrost timing.

DEFROST

TEST PINS

T1 = 30 MINUTES

T2 = 60 MINUTES

T3 = 90 MINUTES

DEFROST TIME

PINS

(T1, T2, T3)

FIGURE 9

The defrost control is also equipped with a set of test pins to

aid in troubleshooting of the defrost system. The following

is a brief outline of the testing of the defrost system.

Page 9

Page 10

Defrost sensor will be closed at 32_ F or below. If tempera

tures are such that switch is not closed, jumper between

defrost sensor terminals on defrost control.

Start system in Heating Operation.

Jumper test pins. A 1/4" quick connect terminal crimped

onto a solid wire or brazing rod works well for test jumper.

Closing test pins speeds up time interval by a factor of 256.

Defrost Control Defrost Test Cycle Time

T1−30 minutes 7 seconds

T2−60 minutes 14 seconds

T3−90 minutes 21 seconds

After closing test pins and appropriate cycle time has

elapsed, the reversing valve should shift to defrost mode

and outdoor fan should stop. After 2 seconds of defrost op

eration, reversing valve should shift back to heating opera

tion and outdoor fan should start.

Adjustments − 12CHP060 Only

12CHP060 units are equipped with a variable speed indoor

blower motor. The blower speed is factory−set and should

not require field adjustment; however, air volume can be in

creased by 5 percent, if necessary. Follow the procedure

below.

1 − Disconnect power.

2 − Locate the blower control board wiring harness.

3 − To increase air volume (CFM) in the cooling mode, use a

pin extractor to remove the wire from harness pin posi

tion 5 (violet wire).

4 − To increase air volume (CFM) in the heating mode,

use a pin extractor to remove the wire from harness

pin position 11 (pink wire)

NOTE − If a pin extractor is not available, cut the wire and

tape off both ends.

Maintenance

Periodic inspection and maintenance normally consists of

changing or cleaning filters and (under some conditions)

cleaning the coils.

WARNING

Electric shock hazard. Can cause inju

ry or death. Before attempting to per

form any service or maintenance, turn

the electircal power to unit OFF at dis

connect switch(es). Unit may have

multiple power suppplies.

Filters

Not supplied. Inspect once a month. Replace disposable or

clean permanent type as necessary. DO NOT replace per

manent type with disposable.

Outdoor Motor

The outdoor fan motor is permanently lubricated and re

quires no maintenance.

Outdoor Coil

Dirt should not be allowed to accumulate on the outdoor

coil surface or other parts in the air circuit. Cleaning should

be as often as necessary to keep coil clean. Use a brush,

vacuum cleaner attachment, or other suitable means. If

water is used to clean coil, be sure power to the unit is shut

off prior to cleaning.

NOTE − Care should be used when cleaning the coil so that

the coil fins are not damaged.

Repair Parts List

When ordering parts, include the complete model number

and serial number which are printed on the rating plate lo

cated on the unit.

Control Group

Transformer

Blower Group

Blower Housing Assembly

Blower Wheel

Blower Motor

Blower Motor Mount

Blower Motor Capacitor (if used)

Fan Blade

Fan Motor

Fan Motor Capacitor

Cooling Group

Compressor

Coil−Evaporator

Drier

Cap Tube or Expansion Valve

Contactor

Time Delay Relay

Fan Relay

Capacitor

Coil−Condenser

Defrost Control

Reversing Valve Solenoid

Description Kit Number LENNOX Cat. Number

Low Ambient Control ALOAM111−1 42K88

High Pressure Cut−out Kit AHPSW436−1 42K89

Outdoor Thermostat LB−29740BA 56A87

Timed Off Control ATIMR446−1 42K90

Accessories

Page 10

Loading...

Loading...