Lennox 10T50 Installation And Setup Manual

Equipment Interface

Module Installation and

Setup Guide

(10T50)

507240-03

3/2019

Supersedes 11/2018

TABLE OF CONTENTS

Shipping and Packing List .................................................................2

Application and Requirements ..........................................................2

Indoor Transformer Requirements ................................................... 2

Equipment ....................................................................................... 2

Installation ...........................................................................................5

Conguration Setup ........................................................................... 5

EIM, 24VAC Furnace and Lennox Communicating Heat Pumps .... 5

EIM, Lennox Communicating Furnace and 24VAC Heat Pump ...... 5

Unit Type Jumpers ........................................................................... 5

Heat Stage Jumper Positions .......................................................... 6

Air Temperature Sensor Connections .............................................. 6

Lennox Communicating Terminal Connections ............................... 6

Dual-Fuel Terminal Connections ..................................................... 7

Conventional Terminal Connections ................................................ 7

LED Indicators ................................................................................. 7

Soft Disable ..................................................................................... 8

iComfort Wi-Fi Commissioning (Conventional Outdoor Unit) .......... 8

iComfort S30 Commissioning (Conventional Outdoor Unit) ............ 9

Operating Environment Specications ............................................9

Unit Dimensions ...............................................................................10

Duel-Fuel Operations .......................................................................10

Field Wiring ....................................................................................... 11

Alert Codes and Troubleshooting ...................................................17

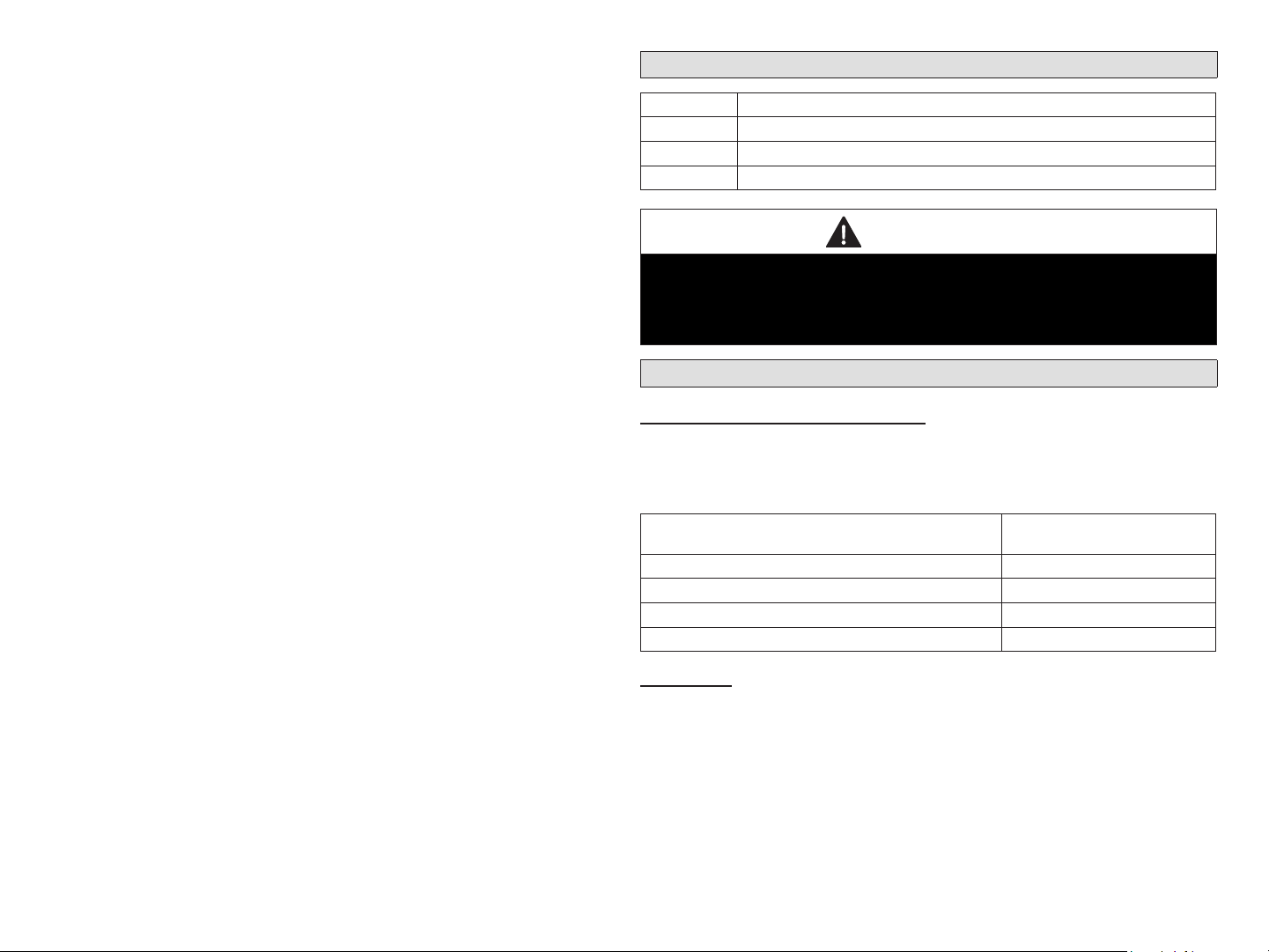

Shipping and Packing List

Quantity Description

1 Equipment Interface Module.

1 Installation and setup guide

1 Warranty certicate

WARNING

Improper installation, adjustment, alteration, ser vice or maintenance can

cause property damage, personal injury or loss of life.

Installation and service must be performed by a li censed professional

HVAC installer (or equivalent) or a service agency.

Application and Requirements

Indoor Transformer Requirements

The following lists the required indoor unit transformer rating (VA) for

specic congurations.

Table 1. System VA Loading Chart

Conguration

2-Stage HP, 3-Stage Electric heat 70

2-Stage HP, 2-Stage Furnace (with tempering) 70

2-Stage HP, 2-Stage Furnace (without tempering) 50

2-Stage AC, 2-Stage Furnace 40

Equipment

The Equipment Interface Module (EIM) is used with an Lennox

communicating thermostat (iComfort Wi-FI® or iComfort® S30) using the R,

i+, i-, and C terminals. The EIM is the interface between non-communicating

HVAC equipment and Lennox communicating HVAC equipment. The

control supports the following equipment applications:

Minimum Transformer Rating

(VA)

NOTE: EIM will support single-stage outdoor units with single-stage or

variable-stage indoor furnaces.

2

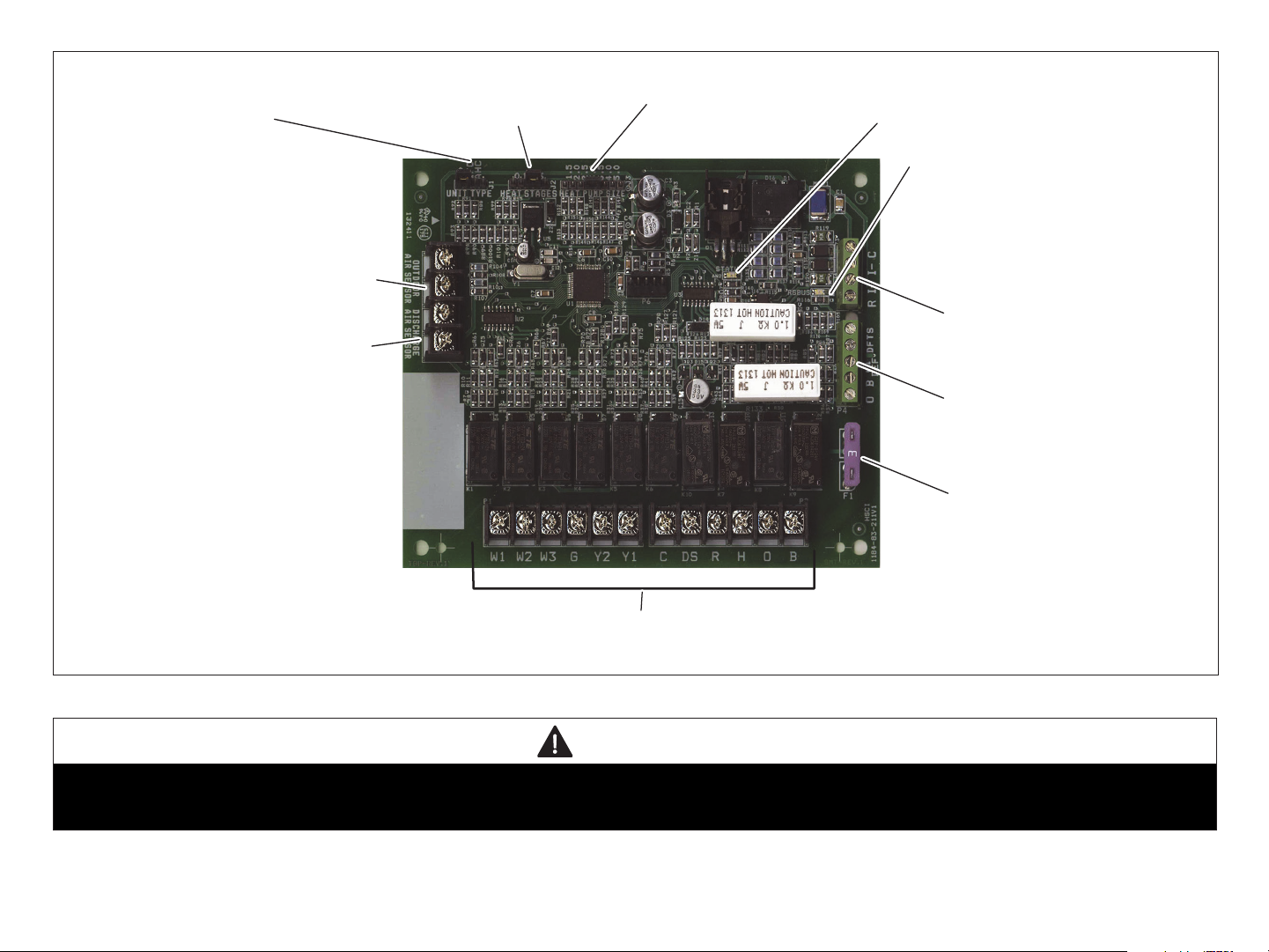

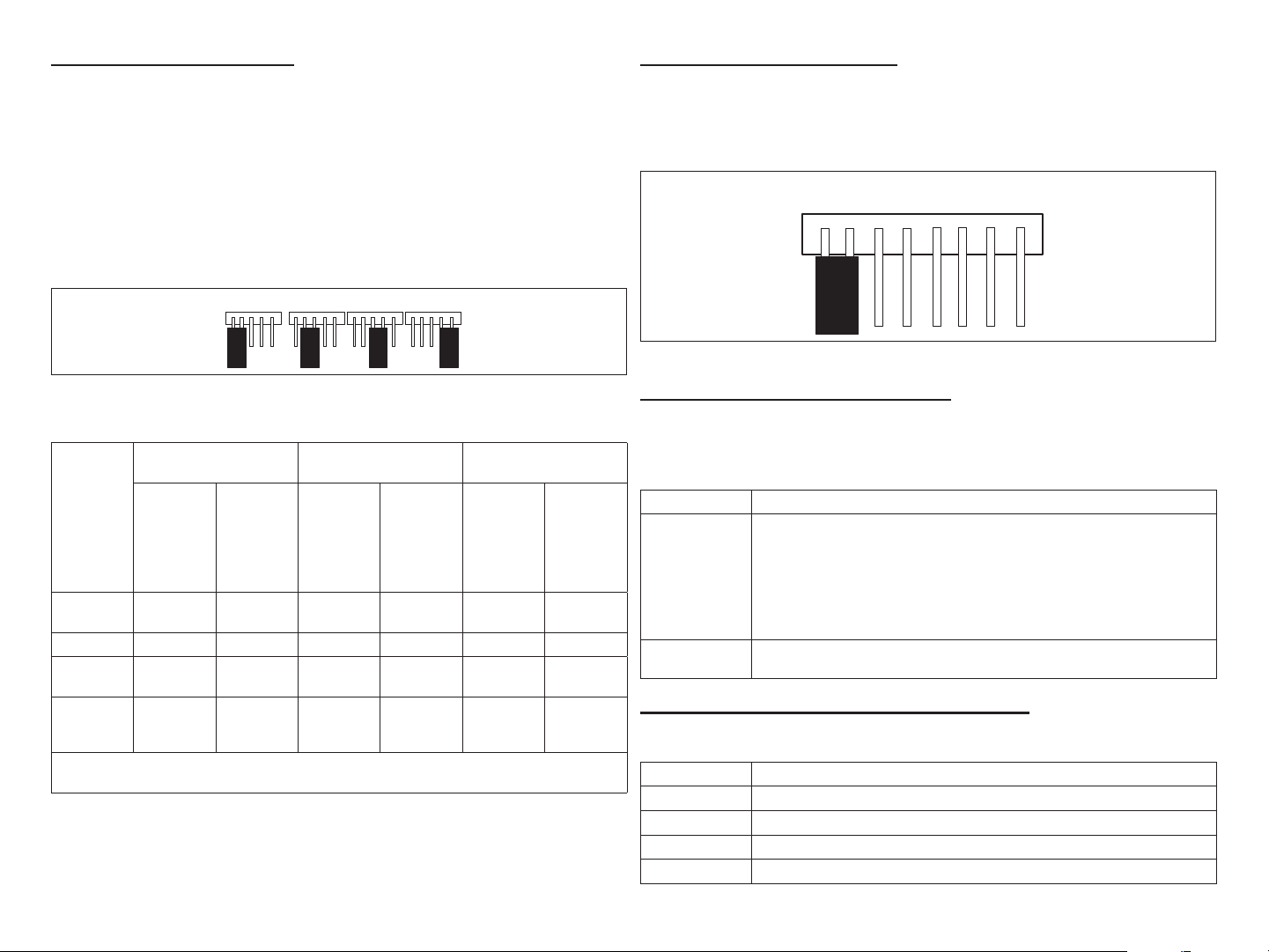

OUTDOOR AIR SENSOR

CONNECTIONS

DISCHARGE AIR

SENSOR CONNECTIONS

LENNOX COMMUNICATING

CONNECTIONS

NON-COMMUNICATING TERMINALS

STATUS LED

COMMUNICATION INDICATOR

LED

DUAL-FUEL

CONNECTIONS

UNIT TYPE JUMPER

TERMINALS

HEAT STAGES

JUMPER TERMIINALS

HEAT PUMP CAPACITY

JUMPER TERMINALS

3 AMP FUSE

Figure 1. Terminals and LEDs

CAUTION

Electrostatic discharge can aect electronic components. Take precautions during unit installation and service to protect the unit’s electronic controls.

Precautions will help to avoid control exposure to electrostatic discharge by putting the unit, the control and the technician at the same electrostatic

potential. Neutralize electrostatic charge by touching hand and all tools on an unpainted unit surface before performing any service procedure

3

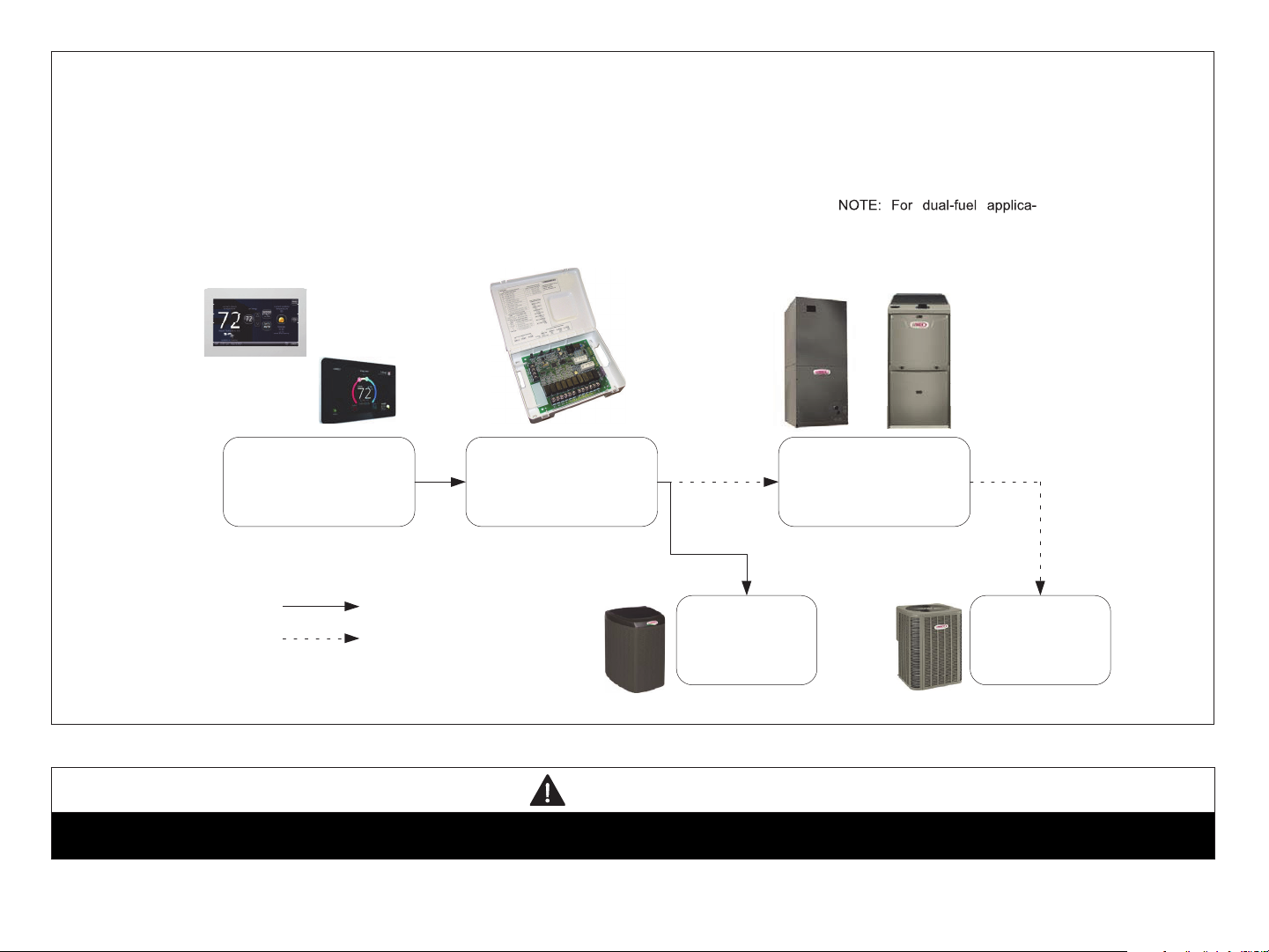

ICOMFORT

WI-FI

EIM with Air Hander or Furnace (Indoor Unit)

and either a Air Conditioner or Heat Pump

(Outdoor Unit)

tions, additional components

may need to be added, see figure

5 on page 8.

ICOMFORT

S30

Lennox Communcating

Thermostat

Wiring Legend

4−wire communicating

24VAC conventional

Equipment Interface

Model (EIM)

Lennox

communicating

Air Conditioner or

Heat Pump

(Outdoor Unit)

Figure 2. System View

24VAC Air Handler or

Furnace (Indoor Unit)

24VAC Air

Conditioner

or Heat Pump

(Outdoor Unit)

WARNING

Controls in this module are sensitive to moisture. Do NOT secure this module to the sheet metal cabinet where moisture may condense during periods

of high humidity. Secure the module to a nearby wooden stud, if possible.

4

Installation

HP IFC AHC

2. Set the EIM Heat Stage Jumper (see “Table 3. Heat Stage Jumpers” on

page 6) to the applicable number of furnace heat stages or number

of electric heat stages.

IMPORTANT

The Lennox communicating thermostat paired with the Equipment

Interface Module (EIM) will work with most 24VAC furnaces, air handlers,

air conditioners and heat pumps (up to 2-stages of cooling and 3-stages

of heat).

The Lennox communicating thermostat without the Equipment Interface

Module (EIM) will work with Lennox communicating HVAC equipment.

1. Remove the module cover.

2. Mount the Equipment Interface Module (EIM) near the indoor unit.

3. Use the wiring diagrams reference in the sectoin titled “Field Wiring”

on page 11 to complete the wiring connections for the specic

application and conguration.

Conguration Setup

How the EIM is congured is determined by the system components.

NOTE: Changing jumper positions after the control has been powered-up

requires recommissioning for the change to be recognized.

NOTE: When the Equipment Interface Module is replaced, recommissioning

the Lennox communicating thermostat will also need to be reaccomplished. See the Lennox communicating thermostat Setup

Guide for recommissioning procedure.

The following examples are two typical congurations used with the EIM.

There are other applications as well and are address in the wiring diagrams

section titled “Field Wiring” on page 11. Those diagrams will indicate all

required jumper settings on the EIM and wiring connections.

3. Use the Lennox communicating thermostat to complete the

commissioning procedure.

EIM, Lennox Communicating Furnace and 24VAC Heat Pump

See “Figure 12. Dual-Fuel - Lennox Communicating Furnace with

Conventional Heat Pump” on page 12f or wiring details.

1. Set the EIM Unit Type Jumper to Heat Pump.

2. Set the EIM Heat Stage Jumper (see “Table 3. Heat Stage Jumpers”

on page 6) to the applicable number of heat pump heating stages.

3. Use the Lennox communicating thermostat to complete the

commissioning procedure.

NOTE: For two-stage heat pump go to the heat pump defrost control,

locate P3 - low ambient thermostat pins and disable this function

by removing the installed jumper and relocating it to one pin only.

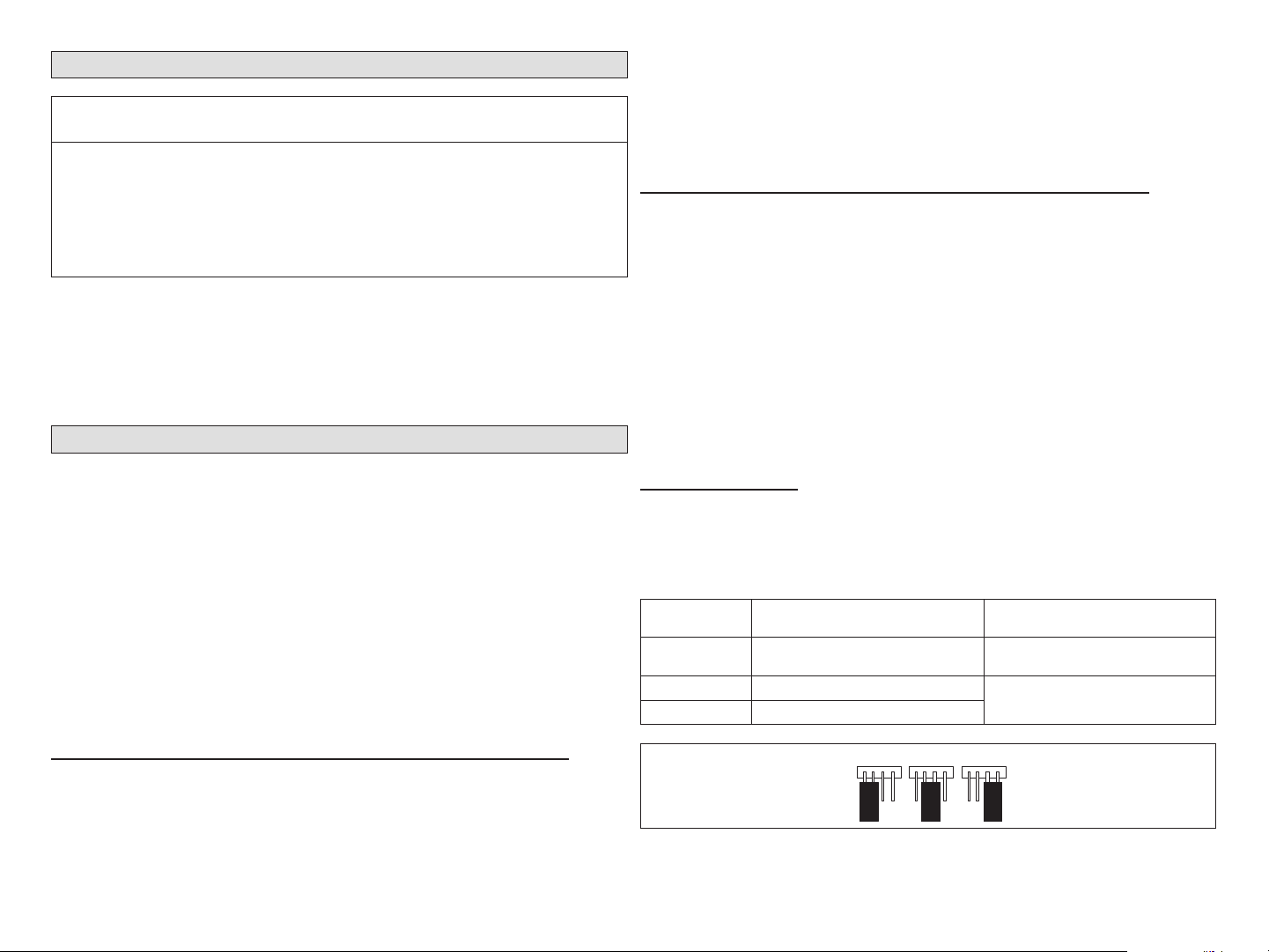

Unit Type Jumpers

Set the unit type jumper for the type of indoor unit being by using the

following table and gure. The factory default setting is IFC. If jumper is

missing from the jumper pins, then alarm 130 is activated.

Table 2. Unit Type Jumpers Positions

Jumper

Position

HP

IFC Conventional Furnace

AHC Conventional Air Handler

Indoor Unit Outdoor Unit

Lennox Communicating Furnace

Conventional Heat Pump

Conventional Heat Pump or air

conditioner

EIM, 24VAC Furnace and Lennox Communicating Heat Pumps

See “Figure 13. Dual-Fuel - Conventional Furnace with Lennox Communicating

Heat Pump” on page 12 for wiring details.

1. Set the EIM Unit Type Jumper to IFC.

Figure 3. Unit Type Jumper Positions

5

Heat Stage Jumper Positions

0 1 2 3

0

5

0

5

0

The factory default setting is position 2 (two heat stages). If jumper is

missing from the jumper pins, then alarm 130 is activated. Depending on

the type of equipment and system set up being used:

• Set the number of stages of electric heat (air handler) when jumper pin

selection is AHC selection.

• Set the number of stage of gas heat (Furnace) when jumper pin selection

is IFC.

• Set the number of stages of the compressor when jumper pin selection

is HP.

24VAC Heat Pump Size Setting

Heat pump size must be congured when using a non-communicating heat

pump using the Heat Pump Size jumper (see gure 4 and table 5). Factory

default setting is for 3.0 (3-ton). If jumper is missing from jumper pins then

alarm 130 is activated.

1.52.

Figure 5. Conventional Heap Pump Capacity Jumper Setting

2.

3.

3.

4.05.

Figure 4. Heat Stage Jumper Positions

Table 3. Heat Stage Jumpers

Air Handler Heat

Stages

Electric Heat

Number of

Label

(Position)

0

1 1 100% 1 100% 1 100%

2

(default)

3 3

NOTE: If jumper is missing, setting defaults to single stage. Changing jumper position

Stages

No Electric

Heat

2

after power-up requires recommission for the change to be recognized.

Percentage

0 1 100% 1 100%

50%,

100%

33.5%,

66.5%,

100%

Furnace Heat Stages Heat Pump Stages

Stage

Gas Stages

Number of

2

2

Percentage

Stage

70%.

100%

70%,

100%

Stages

Compressors

Number of

2

2

Percentage

70%.

100%

70%.

100%

Stage

Air Temperature Sensor Connections

Refer to “Figure 1. Terminals and LEDs” on page 3 for various terminal

locations.

Table 4. Outdoor Air and Discharge Air Sensors

Label Function / Description

Show ambient temperatures (optional if weather feed is acceptable or

outdoor unit is a communicating unit; use X2658 Outdoor Sensor - 2

Outdoor Air

Sensor

Discharge Air

Sensor

terminals).

NOTE: Wiring distance between the EIM and the outdoor temperature

sensor can not exceed 150 feet (45 meters) when wired with

minimum 22AWG (Recommend) 18AWG dedicated twoconductor thermostat cable.

Optional for diagnostics of indoor air; use 88K38 Discharge Air Sensor 2 terminals.

Lennox Communicating Terminal Connections

Table 5. Communicating Terminals

Label Function / Description

R 24VAC communication power Input

i+ Communication high – data line

i- Communication low – data line

C 24VAC communication common power Input

6

Loading...

Loading...