Lennox 10GCS-024, 10GCS-030, 10GCS-036, 10GCS-048, 10GCS-060 Installation Instructions Manual

...Page 1

LENNDX

INSTALLATION

,1,_2000Lennox industries Inc

Daltas, Texas, USA

10GCS

12GCS

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

INSTRUCTIONS

10GCS & 12GCS

SERIES UNITS

GAS PACKAGED UNITS (2-5 TONS)

Armstrong # 38152A058

504,245M

08/03

Supersedes 05/00

Unit Dimensions ................................ 2

Parts Arrangement ............................. 4

Shipping & Packing List ......................... 4

General ....................................... 4

Requirements .................................. 4

Clearances .................................... 5

Rigging & Setting Unit ........................... 5

Condensate Drain .............................. 6

Filters ......................................... 6

Supply & Return Connections .................... 6

Installing Vent Hood ............................. 6

Combustion Discharge .......................... 6

Compressors .................................. 7

Gas Piping .................................... 7

LPG/Propane Units, Tanks, & Piping .............. 8

Electrical ...................................... 8

Sequence of Operation ......................... 11

Condenser Fan Clearances ..................... 12

Start-up Check List ............................ 13

Heating Start-up ............................... 13

Burner Adjustments ............................ 14

Manifold Gas Pressure Adjustment ............... 14

High Altitude Information ....................... 14

Unit Controls .................................. 14

Maintenance .................................. 15

Troubleshooting ............................... 15

Led Codes & Flash Rates ....................... 16

Repair Parts & Accessories ..................... 16

_pu Technical

blications

Litho U.S.A.

j -&WARNING

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other ap-

pliance.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

08/03

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Extinguish any open flames.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

504,245M

Page 1

IIIllllllllllllllllllllllllllllllHlllllllll

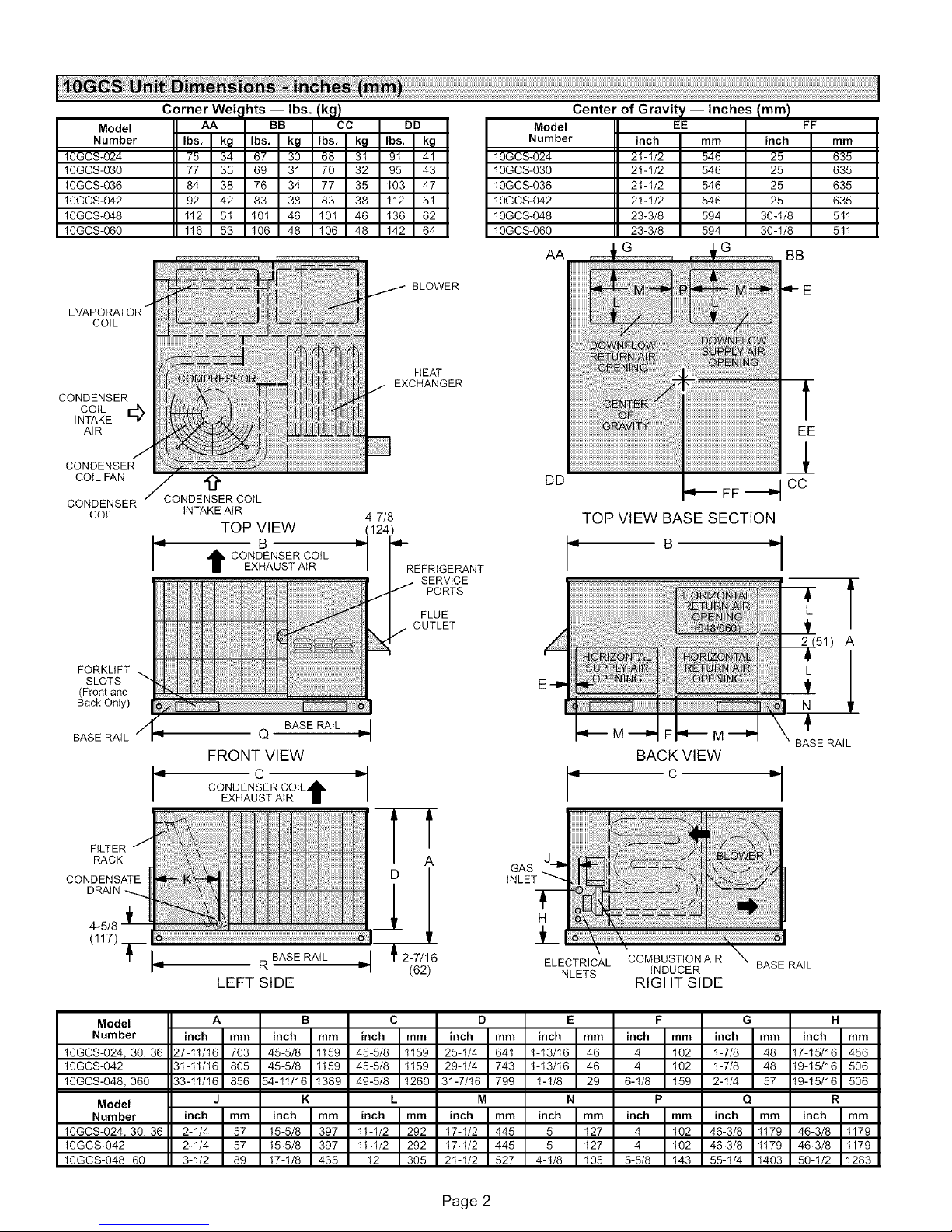

Page 2

Model

Number

t0GCS-024

t0GCS-030

t0GCS-036

10GCS-042

10GCS-048

10GCS-O6O

EVAPORATOR _

COIL

CONDENSER

COIL I_

INTAKE

AIR

CONDENSER

COIL FAN

CONDENSER

COIL

Corner Weights -- Ibs. (kg)

AA BB CC DD

Ibs, kg Ibs. kg Ibs, kg Ibs. kg

75 34 67 30 68 3t 9t 4t

77 35 69 3t 70 32 95 43

84 38 76 34 77 35 t03 47

92 42 83 38 83 38 t12 5t

tt2 5t t01 46 t01 46 t36 62

116 53 106 48 106 48 142 64

.9.

CONDENSER COIL

INTAKE AIR

TOP VIEW

CONDENSER COIL

EXHAUST AIR

4-7/8

(124)

_i rI-REFRIGE RANT

BLOWER

HEAT

EXCHANGER

SERVICE

PORTS

FLUE

OUTLET

Center of Gravity -- inches (mm)

Model EE

Number inch mm

t OGCS-024 2t -1/2 546

t OGCS-03O 21-1/2 546

t OGCS-036 2t -1/2 546

t OGCS-042 21-1/2 546

t OGCS-048 23-3/8 594

1OGCS-O6O 23-3/8 594

AA

G G

DD

inch

25

25

25

25

30-t/8

30-1/8

FF

mm

635

635

635

635

5tt

511

BB

FORKLIFT

SLOTS

(Front and

Back Only)

BASERAIL

BASE RAIL

Q

FRONT VIEW

C

CONDENSER COIL_h,

EXHAUST AIR m

FILTER /

RACK

CONDENSATE

DRAIN

4-5/8 _

(117) ____ _ R BASE RAIL _!

LEFT SIDE

Model A B C D E F G H

Number inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

10GCS-024 t 30 t 36 27-11/16 703 45-5/8 1159 45-5/8 1159 25-1/4 641 1-13/16 46 4 102 1-7/8 48 17-15/16 456

10GCS-042 3t-11/16 805 45-5/8 1159 45-5/8 1159 29-1/4 743 1-13/16 46 4 102 1-7/8 48 19-15/16 506

10GCS-048,060 33-11/16 856 54-11/16 1389 49-5/8 1260 3t-7/16 799 1-1/8 29 6-1/8 159 2-1/4 57 19-15/16 506

Model J K L M N P Q R

Number inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

10GCS-024 t 30 t 36 2-1/4 57 15-5/8 397 11-1/2 292 17-1/2 445 5 127 4 102 46-3/8 1179 46-3/8 1179

10GCS-042 2-1/4 57 t5-5/8 397 tt-1/2 292 t7-t/2 445 5 t27 4 t02 46-3/8 tt79 46-3/8 t179

10GCS-048, 60 3-1/2 89 17-1/8 435 12 305 2t-1/2 527 4-1/8 105 5-5/8 143 55-1/4 1403 50-1/2 1283

4

-(

A

2 -7/16

(62)

M M

J

GAS

INLET

ELECTRICAL COMBUSTION AIR

INLETS INDUCER BASE RAIL

BACK VIEW

BASE RAIL

C

RIGHT SIDE

Page 2

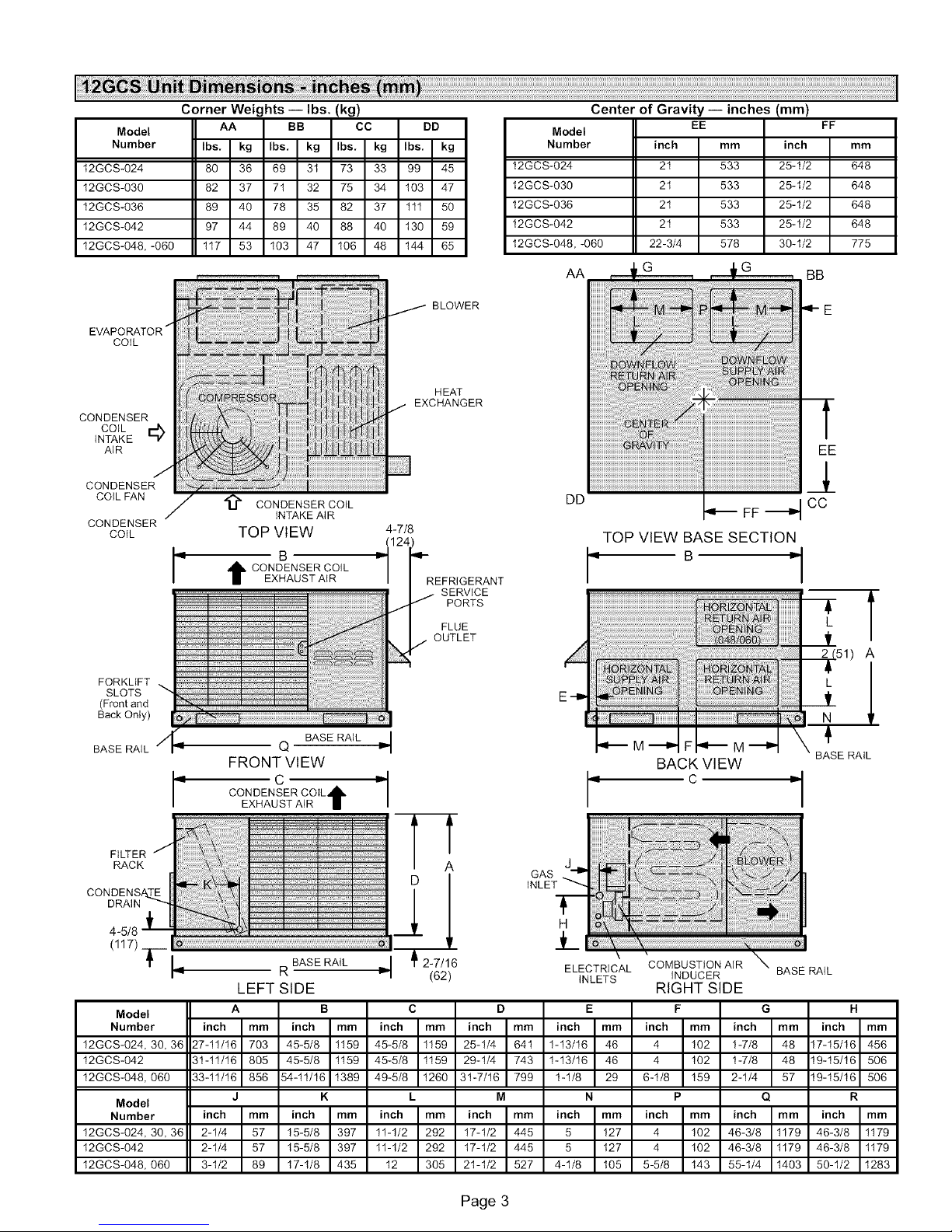

Page 3

Model

Number

12GCS-024

12GCS-030

t2GCS-036

t2GCS-042

12GCS-048, -060

Corner Wei_ hts -- Ibs.

AA BB ''CC DD

Ibs, kg Ibs, kg Ibs, kg Ibs, kg

80 36 69 3t 73 33 99 45

82 37 71 32 75 34 103 47

89 40 78 35 82 37 tll 50

97 44 89 40 88 40 t30 59

117 53 103 47 106 48 144 65

Center of Gravity -- inches (mm)

Model

Number inch mm inch

t2GCS-024 2t 533 25-t/2

t2GCS-030 2t 533 25-t/2

12GCS-036 2t 533 25-1/2

t2GCS-042 2t 533 25-t/2

t2GCS-048, -060 22-3/4 578 30-1/2

AA

EE

G

FF

mm

648

648

648

648

775

BB

EVAPORATOR /

COIL

CONDENSER

COIL _D

INTAKE

AIR

CONDENSER

COILFAN

CONDENSER

COIL

FORKLIFT

SLOTS

(Front and

Back Only)

BASE RAIL

i :!

/

/ '_ CONDENSER COIL

/

t CONDENSER COIL

INTAKE AI R

TOP VIEW 4-7/8

B r_11241_-R

EXHAUST AIR EFRIGERANT

Q BASE RAIL _---I _ M'_I FI_ M "_P

FRONT VIEW BACK VIEW

:_ BLOWER

J

m

i :!i

i

!

HEAT

j EXCHANGER

3

SERVICE

PORTS

FLUE

OUTLET

E

EE

1

DD

FF "_4 CC

TOP VIEW BASE SECTION

B _--

L

V

[(51) A

E-ID

\ BASE RAIL

CONDENSER COIL,_IL

C = = C

EXHAUST AIR II

FILTER

RACK

DRAIN

I BASE RAIL

R ELECTRICAL COMBUSTION AIR

LEFT SIDE INLETS RIGHTINDUCERSIDE BASERAIL

Model A B C D E F G H

Number inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

12GCS-024, 30, 36 27-11/16 703 45-5/8 1159 45-5/8 1159 25-1/4 641 1-13/16 46 4 102 1-7/8 48 17-15/16 456

12GCS-042 3t-tl/16 805 45-5/8 tt59 45-5/8 tt59 29-t/4 743 t-13/16 46 4 t02 t-7/8 48 t9-t5/t6 506

12GCS-048, 060 33-tl/16 856 54-tl/16 t389 49-5/8 t260 3t-7/16 799 t-1/8 29 6-t/8 t59 2-1/4 57 t9-t5/t6 506

Model

Number inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

12GCS-024, 30, 36 2-1/4 57 15-5/8 397 11-1/2 292 17-1/2 445 5 127 4 102 46-3/8 1179 46-3/8 1179

12GCS-042 2-1/4 57 15-5/8 397 11-1/2 292 17-1/2 445 5 127 4 102 46-3/8 1179 46-3/8 1179

12GCS-048, 060 3-1/2 89 17-1/8 435 12 305 21-1/2 527 4-1/8 105 5-5/8 143 55-1/4 1403 50-1/2 1283

J K L M N P Q R

Page 3

GAS

J

Page 4

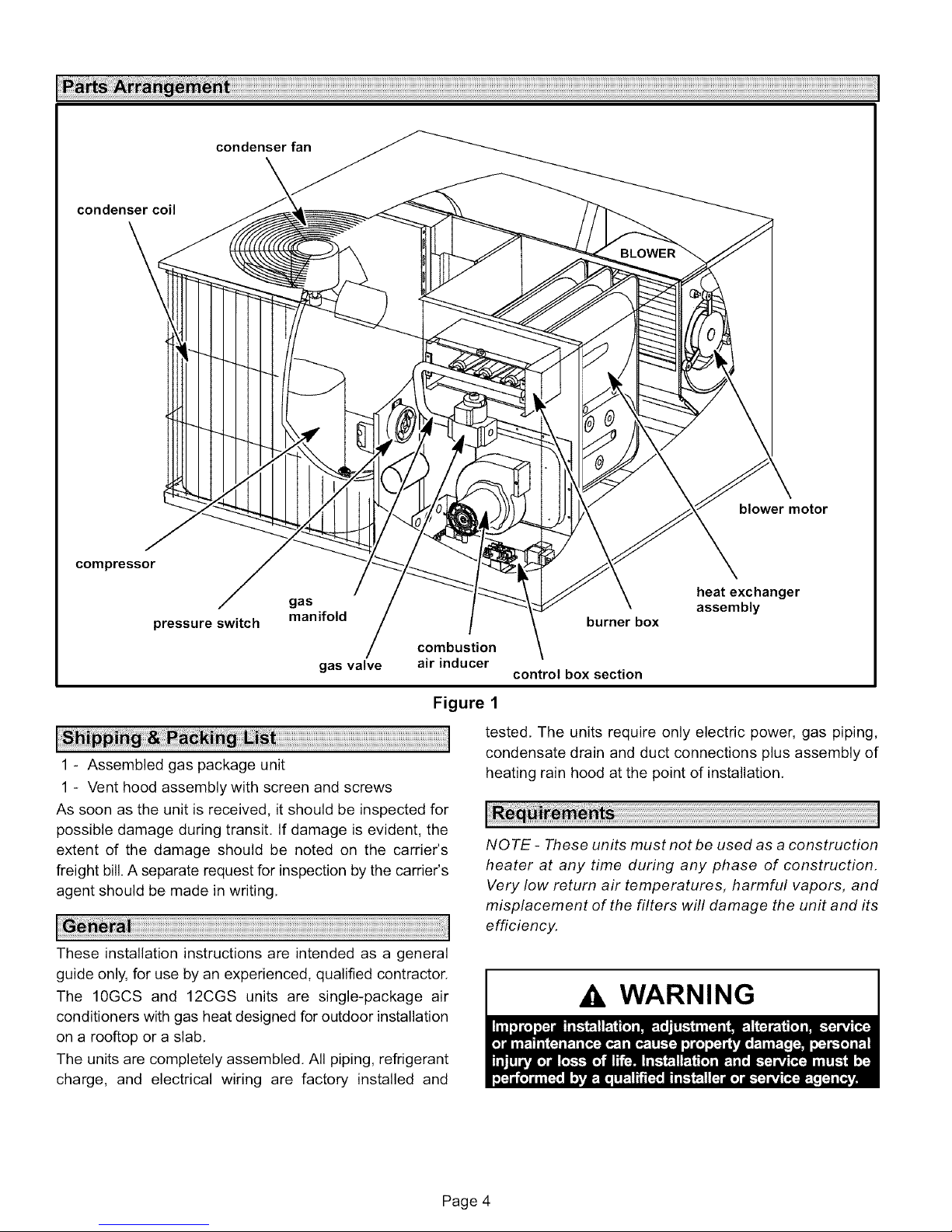

condensercoil

compressor

condenserfan

blower motor

gas

pressure switch

manifold

gas valve

combustion

air inducer

Figure 1

1 - Assembled gas package unit

1 - Vent hood assembly with screen and screws

As soon as the unit is received, it should be inspected for

possible damage during transit. If damage is evident, the

extent of the damage should be noted on the carrier's

freight bill.A separate request for inspection by the carrier's

agent should be made in writing.

These installation instructions are intended as a general

guide only, for use by an experienced, qualified contractor.

The 10GCS and 12CGS units are single-package air

conditioners with gas heat designed for outdoor installation

on a rooftop or a slab.

The units are completely assembled. All piping, refrigerant

charge, and electrical wiring are factory installed and

heatexchanger

assembly

burner box

control box section

tested. The units require only electric power, gas piping,

condensate drain and duct connections plus assembly of

heating rain hood at the point of installation.

NOTE - These units must not be used as a construction

heater at any time during any phase of construction.

Very low return air temperatures, harmful vapors, and

misplacement of the filters will damage the unit and its

efficiency.

WARNING

Page 4

Page 5

WARNING

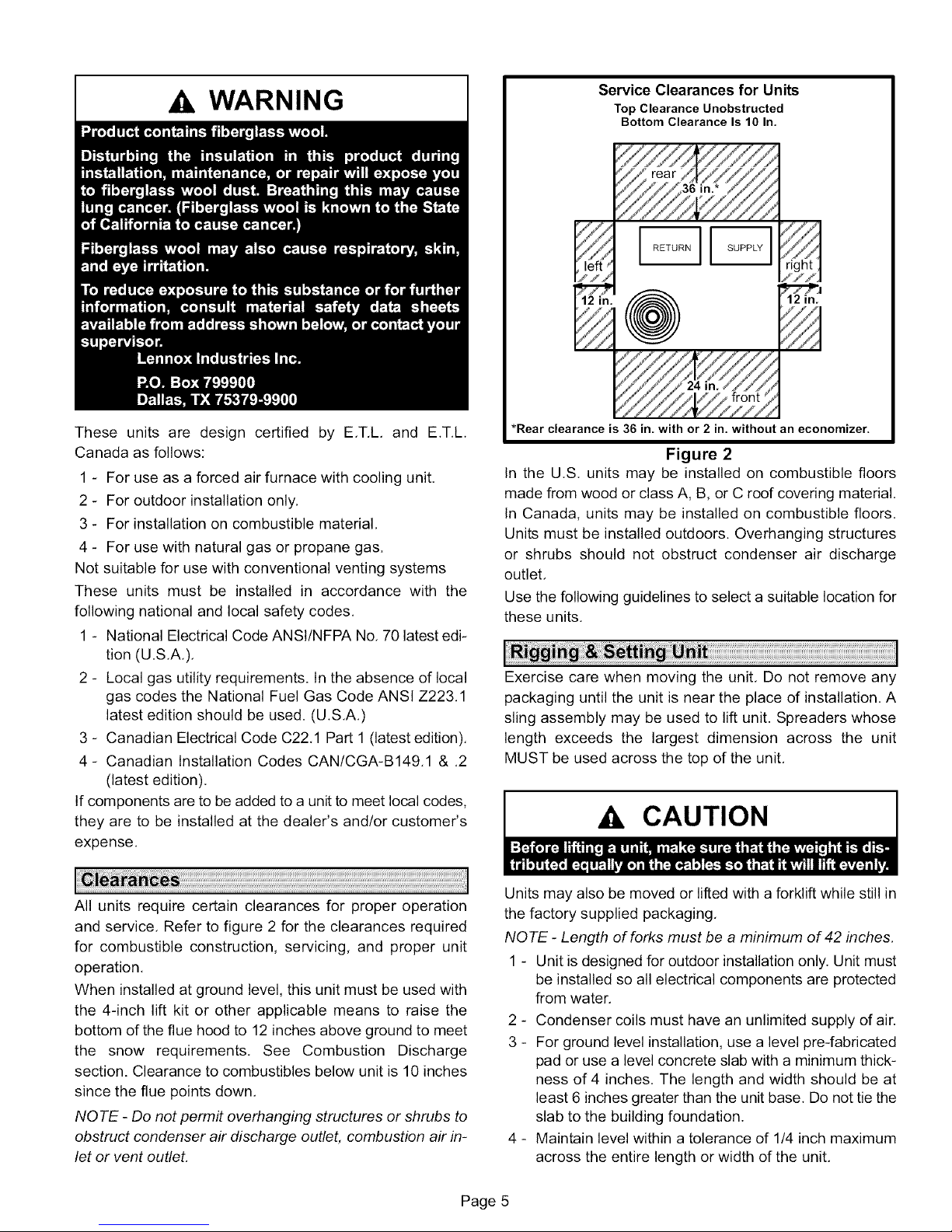

Service Clearances for Units

Top Clearance Unobstructed

Bottom Clearance Is 10 In.

right

ill

12 in.

These units are design certified by E.T.L and E.T.L

Canada as follows:

1 - For use as a forced air furnace with cooling unit.

2 - For outdoor installation only.

3 - For installation on combustible material.

4 - For use with natural gas or propane gas.

Not suitable for use with conventional venting systems

These units must be installed in accordance with the

following national and local safety codes.

1 - National Electrical Code ANSI/NFPA No. 70 latest edi-

tion (U.S.A.).

2 - Local gas utility requirements. In the absence of local

gas codes the National Fuel Gas Code ANSI Z223.1

latest edition should be used. (U.S.A.)

3 - Canadian Electrical Code C22.1 Part 1 (latest edition).

4- Canadian Installation Codes CAN/CGA-B149.1 & .2

(latest edition).

If components are to be added to a unit to meet local codes,

they are to be installed at the dealer's and/or customer's

expense.

*Rear clearance is 36 in. with or 2 in. without an economizer.

Figure 2

In the U.S. units may be installed on combustible floors

made from wood or class A, B, or C roof covering material.

In Canada, units may be installed on combustible floors.

Units must be installed outdoors. Overhanging structures

or shrubs should not obstruct condenser air discharge

outlet.

Use the following guidelines to select a suitable location for

these units.

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. A

sling assembly may be used to lift unit. Spreaders whose

length exceeds the largest dimension across the unit

MUST be used across the top of the unit.

Ak CAUTION

All units require certain clearances for proper operation

and service. Refer to figure 2 for the clearances required

for combustible construction, servicing, and proper unit

operation.

When installed at ground level, this unit must be used with

the 4-inch lift kit or other applicable means to raise the

bottom of the flue hood to 12 inches above ground to meet

the snow requirements. See Combustion Discharge

section. Clearance to combustibles below unit is 10 inches

since the flue points down.

NOTE - Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet, combustion air in-

let or vent outlet.

Units may also be moved or lifted with a forklift while still in

the factory supplied packaging.

NOTE - Length of forks must be a minimum of 42 inches.

1 - Unit is designed for outdoor installation only. Unit must

be installed so all electrical components are protected

from water.

2 - Condenser coils must have an unlimited supply of air.

3 - For ground level installation, use a level pre-fabricated

pad or use a level concrete slab with a minimum thick-

ness of 4 inches. The length and width should be at

least 6 inches greater than the unit base. Do not tie the

slab to the building foundation.

4 - Maintain level within a tolerance of 1/4 inch maximum

across the entire length or width of the unit.

Page 5

Page 6

Thepackagedunitisequippedwitha3/4inchfptcoupling

forcondensatelineconnection.Plumbingmustconformto

localcodes.Use a sealingcompoundon malepipe

threads.

Thedrainlinemustbeproperlytrappedandroutedtoa

suitabledrain.Seefigure3forproperdrainarrangement.

Thedrainlinemustpitchto anopendrainor pumpa

minimumof 1inchper10feetto preventcloggingofthe

line.Sealarounddrainconnectionwithsuitablematerialto

preventairleakageintoreturnairsystem.

Drainpipingshouldnotbesmallerthandrainconnectionat

coil.Anopenventindrainlinewillsometimesberequired

dueto linelength,frictionandstaticpressure.Drains

shouldbeconstructedinamannertofacilitatefutureclean-

ing.

NOTE - The condensate drain fine MUST be trapped to

provide proper drainage.

Typical Condensate Drain

Minimum Pitch

1 in. (25 ram) per

10' (3 m) of line

open

vent

unit

Duct system should be designed and sized according to

the methods in Manual Q of the Air Conditioning

Contractors of America (ACCA).

A closed return duct system shall be used. This shall not

preclude use of economizers or outdoor fresh air intake. It

is recommended that supply and return duct connections

at the unit be made with flexible joints.

The supply and return air duct systems should be designed

for the CFM and static requirements of the job. They

should NOT be sized to match the dimensions of the

duct connections on the unit,

Ak CAUTION

The vent hood is installed by placing screen in hood and

securing with four #8 x 3/8 large blunt sheet metal screws

and four #8 flat speed nuts as shown in figure 4. Place hood

with screen in position and attach with three #8 x 1/2 sheet

metal screws using holes provided.

Vent Hood Installation

,%

Trap must be deep enough to offset maximum mounting

static difference (Generally, 3 inches minimum), frame

Figure 3

No filters are supplied with the unit. Filters must always be

installed ahead of evaporator coil and must be kept clean or

replaced. Dirty filters will reduce the airflow of the unit.

Filters sizes are shown in table 1.

Unit is equipped with an internal filter clip which is located in

indoor coil compartment attached to side of the unit drain

pan.

Table 1

Unit Filter Size

Unit Model Filter Size

-024, -030, -036 24 in. X 25 in.

-042 28 in. X 25 in.

-048 -060 30 in. X 30 in.

o

HOOD 1

screen

Figure 4

The products of combustion are discharged horizontally

through a screened opening on the gas heat side panel.

The horizontal vent system shall terminate at least 4 feet

below, 4 feet horizontally from, or 1 foot above any door,

window, or gravity air inlet into the building. The vent

system shall terminate at least 3 feet above any forced air

inlet located within 10 feet. The bottom of the vent

terminal shall be located at least 12 inches above grade.

Minimum horizontal clearance of 4 feet from electric

meters, gas meters, regulators, and relief equipment is

required.

Page 6

Page 7

Theventoutletmustbeinstalledinalocationthatprevents

buildingdegradationandmustbe consistentwith the

NationalFuelGasCode,Z223.1orCAN/CGA-B149,1&.2,

In addition to the above requirements, consideration must

be given to prevent unwanted ice build-up from the vent

condensate. The vent should not be located on the side of a

building where the prevailing winter winds could trap the

moisture causing it to freeze on the walls or on overhangs

(under eaves), The vent location should not discharge over

a sidewalk, patio or other walkway, where the condensate

could cause the surface to become slippery,

The products of combustion must not be allowed to

accumulate within a confined space and recirculate,

Units are shipped with the compressor mountings

factory-adjusted and ready for operation.

Proper sizing of gas piping depends on the cubic feet per

hour of gas flow required, specific gravity of the gas and

length of run, The current National Fuel Gas Code Z223,1

should be followed in all cases unless superseded by local

codes or gas company requirements, Refer to tables 2 and

3, In Canada see CAN/CGA B,149,1 & ,2 (latest edition),

Table 2

Gas Heat Application Data

Input Rating Output Rating Gas Capaci_

(Btu) (Btu) (FT3 / HR)

50,000 40,000 47

75,000 60,000 70

100,000 80,000 93

125,000 100,000 116

Before connecting piping, check with gas company or

authorities having jurisdiction for local codes or require-

ments. When installing gas supply piping, length of run

from gas meter must be considered in determining pipe

size for 0,5 inch w.c, maximum pressure drop. Do not

use supply pipe smaller than unit gas connection, For

natural gas unit, operating pressure at the unit gas con-

nection must be a minimum of 4.5 inch w.c. and a maxi-

mum of 13,5 w.c. For propane/LP gas units, operating

pressure at the unit gas connection must be a minimum

of 11 inches w.c. and a maximum of 13,5 inches w.c,

Table 3

Gas Pipe Capacity-FT 3 / HR

Length in Feet

10 132

20 92

30 73

40 63

50 56

60 50

70 46

80 43

90 40

100 38

Nominal Iron Pipe Size (inches)

1_ in.

3/4 in. 1 in. 1-1/4 in.

278 520 1050

190 350 730

152 285 590

130 245 500

115 215 440

105 195 400

96 180 370

90 170 350

84 160 320

79 150 305

When making piping connections, a drip leg should be

installed on vertical runs to serve as a trap for sediment or

condensate, A 1/8 inch N,RT. tap accessible for test gauge

connection must be provided in field piping upstream from

gas supply connection to unit. Install a ground joint union

between gas control manifold and the manual main shut-

off valve. See figure 5,

Compounds used on threaded joints of gas piping shall be

resistant to the action of propane/LP gases.

Drip Leg Installation

field provided

1/8 in. p

ground joint

union

manual main

shut-off

piping

support

base of unit

leg support

Figure 5

Pressure Test Gas Piping

When pressure testing gas lines, the gas valve must be dis-

connected and isolated. Gas valve can be damaged if sub-

jected to more than 0,5 psig (14 inch w.c.), See figure 6,

If test pressure is equal to or less than 0,5 psig (14 inch

w.c.) shutoff the manual main shut-off valve before pres-

sure testing to isolate unit from gas supply system.

Page 7

Page 8

Isolate Gas Valve To Pressure Test

Manual Main Shut-off Valve Will Not Hold Test

Pressures in Excess of 0.5 PSIG (14 in. w.c.)

unit

gas valve cap

Ak CAUTION

5 - The furnace and its individual manual shut-off valve

must be disconnected from the gas supply piping sys-

tem during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3,48kPa),

Fiaure 6

NOTE - Codes may require that manual main shut off valve

and union (furnished by installer) be installed ingas line exter-

nal to unit. Union must be of the ground joint type.

,WARNING

After gas piping is complete, carefully check all piping con-

nections (factory and field) for gas leaks, Use soap solution

or other preferred means.

NOTE - In case of emergency shutdown, shut off main

manual gas valve and disconnect main power to unit.

These devices should be properly labeled by installer.

The heating value of the gas may differ with locality, The

value should be checked with the local gas utility.

NQ TE - Units are shipped equipped for natural gas, but can

be converted to LPG/propane with a conversion kit.

NOTE- There may be a local gas utility requirement speci-

fying a minimum diameter for gas piping. All units require a

1/2 inch pipe connection at the gas valve.

Gas piping recommendations:

1 - A drip leg and a ground joint union must be installed in

the gas piping.

A ground joint union is recommended by the man-

ifold/valve,

2 - When required by local codes, a manual shut-off valve

may have to be installed outside of the unit,

3 - Use pipe thread sealing compound resistant to pro-

pane gas sparingly on male threads,

4 - The gas supply should be a separate line and installed

in accordance with all safety codes. After the gas con-

nections have been completed, open the main shut-off

valve admitting normal gas pressure to the mains,

Check all joints for leaks with soap solution or other

material suitable for the purpose,

AkIMPORTANT

6 - A 1/8 inch N.ET. plugged tapping, accessible for test

gage connections, must be installed immediately up-

stream of the gas supply connection to the furnace,

Check the unit rating plate for type of gas that unit is

equipped for. If conversion is required use the approved

conversion kit, The unit may be converted in the field for

use with LPG/propane gas with accessory kit by an

approved licensed pipe fitter or technician,

All LPG/propane gas equipment must conform to the safety

standards of the National Fire Protection Association.

For satisfactory operation, LPG/propane gas pressure must

be a minimum of 11 inches W.C, at the unit under full load,

Complete information regarding tank sizing for

vaporization, recommended regulator settings, and pipe

sizing is available from most regulator manufacturers and

LPG/propane gas suppliers,

Check all connection for leaks when piping is completed,

using a soapy solution,

ALL WIRING SHOULD BE DONE IN ACCORDANCE

WITH NATIONAL ELECTRIC CODE, ANSI/NFPA No. 70

(LATEST EDITION), IN CANADA CSA C22.2 Part 1

(LATEST EDITION), OR WITH LOCAL CODES, WHERE

THEY PREVAIL.

Page 8

Page 9

CO

"4

10GCS Series Gas Packaged Units

LI

UNIT HEATING COOLING

SPEED SPEED

IOGCSO24-50 MEDIUM LOW

IOGCSO24-75 HIGH LOW

IOGCSO3O-5O LOW MEDIUM

IOGCSO30-75 HIGH MEDIUM

EOGCSO36-50 MEDIUM HIGH

IOGCS036-75 HIGH HIGH

IOGCSO3B-IOO HIGH HIGH

IOGCSO¢2-75 HIGH HIGH

IOGCSO42-100 HIGH HIGH

IOGCS048-100 MEDIUM LOW

EOGCSOAB=EB5 HIGH LOW

IOGCS048=I50 HIGH LOW

IOGCS06O-IOO MEDIUM HIGH

EOGCS060-_25 HIGH ÷ HIGH

EOGCSOGO-E50 HIGH HIGH

B3

BLOWER

MOTOR

Typical Wiring Diagram

BA

CONDENSER

FAN MOTOR

510

AUTO RESET

LIMIT SWITCH

C12 518

DUAL CAPACITOR PRESSURE

BG SWITCH

GOMBOSTIONAIR

BLOWER

KI-I

COMPRESSOR

CONTACTOR

C12

DUAL

BK

B_

COMPRESSOR

B_

COMPRESSOR

RD

KI-2

COMPRESSOR

CONTACTOR

L2

B

CONDENSER

FAN MOTOR

• JUMPER REQUIRED

IF JUMPER IS NOT USED,

CONNECT BLUE WIRE ON UNUSEO

TERMINAL TO HEAT.

NOTE-IF ANY WIRE IN THIS APPLIANCE IS REPLACED, IT

MUST BE REPLACED WITH WIRE OF LIKE SIZE, RATING

AND INSULATION THICKNESS.

Z_ USE JUMPER ONLY IF HEAT AND COOL

ARE THE SAME SPEED.

Z_ B6 (CAB) IS ENERGIZED FOR IO SECONDS

AT THE START OF EACH COOLING CYCLE

VT

COMBUSTIOI

GN

A3

$47

MANUAL RESET

ROLLOUTGWITCH ELECTRIC/SENSOR

GVI C4

S21 GAS BLOWER MOTOR

AUTO RESET AUX. VALVE CAPACITOR

LIMIT SWITCH

CONTROL BOX

R GWCY HTG, ACC,

_ CWB'=BLWR

TBI

iD® @

i (_(_ ACB==_OOL

ACB_EAT

GROUND UNUSED

ELECTRODE

BAVAC FLAME @

HOT

A5 BLOWER/IGNITION

CONTROL

TRANsTLRMER[

I :

CONTACTOR

BLUE(C)

YELLOW(Y)

RED(R)

GREEN(G)_

WHITE(W_

SI

THERMOSTAT

I I I i

)- J I I

I

I

_---J I I

_ COMPRES50_

T_ _CONTACTOR_

USE WITH COPPER

CONDUCTORS ONLY

MINIMUM 75°C WIRE

DISCONNECT ALL POWER

BEFORE SERVICING

-- LI

208-230/60/I

L2

SI

"_ THERMOSTAT

--'111

jl

_.1

J

HEAT ANTICIPATION SETTING- 0.75

LINE VOLTAGE FIELD INSTALLED

2,$ VOLT FIELD INSTALLED

NEC/CEC CLASS 2

NOTE-ALL REMAINING WIRES

FACTORY INSTALLED

LENNOXz#_,,,J,_[_. WIRING DIAGRAM

COMBINATION UNITS-ROOFTOP

I 0GC5024-50,75-2, -3-P

I OGCS030-50,75-2, -3-P

10605056-50,75, 100-2, 5-P

I 0GC5042-75, 100-2, -$-P

IOGCS048-100 125, 150-2,-5-P

IOGCSOBO-IO0 IZ5,150-2, -3-P

Supersedes Form No, _ New Form No.

555,466W ] 534,449W

Li_ho U.S,A.

Page 10

-o _"n..

O0

12GCS Series Gas Packaged Units

Typical Wiring Diagram

HEATING COOLING

UNIT SPEED SPEED

12GCS024=50 MEDIUM LOW

12GCS024-75 HIGH LOW

12GCSOSO-50 MEDIUM* MEDIUM

12GC5030-75 HIGH MEDIUM

IZGCSO36-50 MEDIUM HIGH

i2GCS036-75 HIGH * HIGH

i2GCSO3S=IOO HIGH HIGH

12GCS042-75 HIGH HIGH

12GCSO42-100 HIGH ÷ HIGH

12GCSO¢8=IOO MEDIUM* MEDIUM

12GC5048-125 HIGH MEDIUM

12GCSOEO-IO0 MEDIUM HIGH

E2GCSO60=125 HIGH HIGH

?

83

BLOWER

MOTOR

B4

CONDENSER

FAN MOTOR

S_O

AUTO RESET

LIMIT SWITCH

(_) CI2 $18 $21

DUAL CAPACITOR PRESSURE AUTO RESET AUX,

SWITCH LIMIT SWITCH

COMBUSTION

AIR

BLOWER

Bl

COMPRESSOR

* JUMPER REQUIRED

IF JUMPER IS NOT USED,

CONNECT BLUE WIRE ON UNUSED

TERMINAL TO HEAT.

NOTE-IF ANY WIRE IN THIS APPLIANCE IS REPLACED, IT

MUST BE REPLACED WITH WIRE OF LIKE SIZE, RATING

AND INSULATION THICKNESS.

Z_ USE JUMPER ONLY IF HEAT AND COOL

ARE THE SAME SPEED,

/2_ B6 (CAB) IS ENERGIZED FOR IO SECONDS

AT THE START OF EACH COOLING CYCLE

KI-E

COMPRESSOR

CONTACTOR

C12

DUAL

K2

COMPRESSOR

RD

KE-2

COMPRESSOR

CONTACTOR

L2

BA

CONDENSER

FAN MOTOR

CAPACITOR T

COMBUSTIO#

AIR BLOWER

$47

[_ MANUAL RESET

ROLLOUTSWITCH ELECTRIC/SENSOR

GVI C_

GAS BLOWER MOTOR

VALVE CAPACITOR

A3

BLOWER/IGNITION

CONTROL

R G W C Y HTG, ACC.

CWB LWR

TBI _

ACB'=_OOL

ACB=HEAT

GROUND UN'_SED

ELECTRODE

B4VAC FLAME @

_HOT

CONTROL BOX

DL8

TIMED

OELAY

RELAY

TRANSFORMER

Ki

CONTACTOR

BLUE

YE_LLO_ Q'"

RED(R_

GREEN(G_

WHITE(W)

A3

DISCONNECT ALL POWER

BEFORE SERVICING

208-230/60/I

L2

USE WITH COPPER

CONDUCTORS ONLY

MINIMUM 75°C WIRE

_E. SI

THERMOSTAT

--'jII

JI

_1

d

HEAT ANTICIPATION SETTING- 0,75

LINE VOLTAGE FIELD INSTALLED

24 VOLT FIELD INSTALLED

NEC/CEC CLASS 2

NOTE-ALL REMAINING WIRES

FACTORY INSTALLED

I_ENNDX_ ......._oo. WIRINGDIAGRAMo4LO_

COMBINATION UNITS-ROOFTOP

I 2GC5024-50,75-2, -3-P

12GCS03O-50,75-2, -3-P

12GCSO36-50,75, 100-2, -3-P

12GCS042-75, 100-2, -3-P

12GCSO48- IDO, 125-2, -3, -A-P

12GCSOBO- I OO, 125-2, -3, -A-P

Supersede_ Form No. I New Form No-

533,467W ] 534,450W

Lithe U.S,A.

Page 11

Use wiring with a temperature limitation of 75'_C min.; run

the 208 or 230 volt, 60 hertz electric power supply through a

fused disconnect switch to control box of unit and connect

as shown in the wiring diagram located on the inside of the

control access panel,

Unit must be electrically grounded in accordance with local

codes or in the absence of local codes with the National

Electric Code, ANSI/NFPA No. 70 (latest edition) or CSA

C22.2 Part 1(latest edition).

Power supply to the unit must be N.E,C, Class 1, and must

comply with all applicable codes. A fused disconnect

switch should be field provided for the unit, The switch must

be separate from all other circuits, If any of the wire

supplied with the unit must be replaced, replacement wire

must be of the type shown on the wiring diagram.

Electrical wiring must be sized to carry minimum circuit

ampacity marked on the unit. USE COPPER

CONDUCTORS ONLY. Each unit must be wired with a

separate branch circuit and be properly fused.

CAUTION

See figure 9 for field connection of line voltage wiring, See

figure 7 for typical wiring diagram.

208/230 Line Voltage Wiring

contactor

(furnished by installer)

__ C[Z]3 fused disconnect switch

T

ground L2

lug

NOTE - If 208 voltage is suppfied, transformer

connections must be made.

Figure 9

Thermostat

The room thermostat should be located on an inside wall

where it will not be subject to drafts, sun exposure or heat

from electrical fixtures or appliances. Follow

manufacturer's instructions enclosed with thermostat for

general installation procedure, Color coded insulated wires

(# 18 AWG) should be used to connect thermostat to unit,

Four wires are required for cooling,

Heat Anticipator Setting

It is important that the anticipator setpoint be correct. Too

high of a setting will result in longer heat cycles and a

greater temperature swing in the conditioned space,

Reducing the value below the correct setpoint will give

shorter "ON" cycles and may result in the lowering of the

temperature within the conditioned space. Heat

Anticipator Settings: 0.75 AMP

Cooling System

The cooling section is a complete factory package utilizing

an air-cooled condenser. The system is factory-charged

with HCFC-22. The compressor is hermetically sealed,

internally sprung and base mounted with rubber-insolated

hold-down bolts,

Unit compressors have internal protection. In the event

there is an abnormal rise in temperature of the compressor,

the protector will open and cause the compressor to stop,

After the initial installation, the compressor should be

given three false starts (energized just long enough to

make a few revolutions), with 5-7 minutes between

each start, before being put into full time service.

Cooling Sequence of Operation

When the thermostat calls for cooling, "R" is closed to "G"

and "Y" (wiring schematic) which completes the low voltage

control circuit, energizing the compressor, condenser fan

motor and blower motor.

NOTE - At the start of the each cooling demand, the

combustion air blower (draft motor) will operate for 10

seconds,

Blower Delays - Cooling

Blower is controlled by a timing relay delaying blower on 5

seconds and blower off 90 seconds. This feature is

intended to deter insect nesting,

System Performance

For maximum performance of this cooling system, the

operating temperatures and pressure should be checked

and superheat determined at Standard ARI test conditions

of 82 '_F outdoor temperature minus ( - ) 80 ° F indoor dry

bulb / 67 <_F indoor wet bulb. If superheat measured

deviates from values in table 4 below, refrigerant charge

should be adjusted accordingly for maximum performance.

Table 4

Suction Superheat Values

Suction Superheat

Unit Model No. 82"F OD minus 80"F IDDB

/ 67"F IDWB

10GCS-024 18 - 20"

10GCS-030,-036 17- 19°

10GCS-042 18 - 20"

10GCS-048,-060 16- 18"

12GCS-024, -030 18 - 20"

12GCS-036, -042 13 - 15°

12GCS-048, -060 14 - 16"

NOTE - With the proper thermostat and subbase, continu-

ous blower operation is possible by closing the R to G cir-

cuit. Cooling blower delay is also functional in this mode.

Verify system performance using table 5 as a general guide.

Table should not be used for charging unit. Minor variations

in these pressures may be expected due to differences in

installations. Significant differences could mean that the

system is not properly charged or that a problem exists with

some component in the system.

Page 11

Page 12

Table 5

Normal Operating Pressures

80°F db / 87"F wb RETURN AIR Air Temperature Entering Outdoor Coil (°F)

Model Pressure 65° 70° 75 ° 80 ° 82° 85 ° 90° 95° 100° 105 ° 110° 115°

10GC5-024 72 75 79 81 82 83 85 87 88 89 91 92

10GCS-030 67 70 73 75 77 78 81 83 84 84 85 85

10GCS-036 72 75 77 80 81 82 84 86 88 89 91 92

10GCS-042 72 75 78 82 83 84 86 88 89 90 92 93

10GCS-048 75 79 80 81 83 84 85 86 87 88 89 90

10GCS-060 79 79 80 81 81 82 83 84 85 86 87 88

10GCS-024 171 185 199 213 219 229 244 260 267 275 301 327

10GCS-030 186 192 198 215 221 231 247 263 282 300 312 323

10GCS-036 175 191 207 224 230 239 255 271 288 305 320 335

10GCS-042 Liquid 181 197 213 229 235 245 261 277 294 310 328 345

10GCS-048 172 184 197 212 220 235 251 262 279 297 321 335

10GCS-060 192 205 222 236 249 263 277 293 313 331 348 360

12GCS-024 75 77 80 82 83 84 87 88 90 90 91 92

12GCS-030 67 70 73 76 80 78 82 85 86 86 87 88

12GCS-036 73 75 78 80 82 82 85 87 88 89 91 92

12GCS-042 77 78 80 81 81 82 84 85 87 88 89 90

12GCS-048 71 74 75 79 81 81 84 88 87 87 88 89

12GCS-060 74 77 80 81 82 84 85 88 96 96 87 88

12GCS-024 149 164 178 193 195 208 222 237 254 271 289 306

12GCS-030 145 161 178 192 195 207 223 238 254 270 288 305

12GCS-036 156 172 187 203 207 219 234 260 267 284 303 322

12GCS-042 Liquid 159 175 190 208 209 222 237 253 270 298 306 326

12GCS-048 152 168 185 198 209 215 230 246 254 281 298 316

12GCS-060 155 190 205 211 215 230 244 269 276 293 311 332

Used carefully, this table could serve as a useful service

guide. Data is based on 80°F dry bulb / 87°F wet bulb return

air. Allow unit operation to stabilize before taking pressure

readings.

Heating System - Sequence of Operation

When thermostat is calling for heat the draft motor is

energized by the 24 volt relay in the blower ignition control

Suction

Suction

three times. If, at the end of the third trial, a flame still has

not been established, then the blower/ignition control will

try to light again one hour later, The one hour retry is

indefinite, The blower/ignition control can be reset by

interrupting the unit power or the thermostat circuit, When

the thermostat is satisfied the draft motor gas valve is

de-energized. The blower motor will continue to run for 120

seconds after the furnace is shut down.

which closes the 240V contact to the draft motor. When the

speed of the draft motor reaches the proper rpm the

pressure switch closes to power the ignition control.

When PSW on blower/ignition control is energized, a

pre-purge time is initiated (30 seconds nominal). When

pre-purge has expired the main gas valve is energized for

Figure 10 illustrates the critical measurements of the out-

door fan system. This dimension should be checked and

fan adjusted accordingly anytime servicing of the outdoor

fan system is required.

direct ignition. The blower/ignition control will energize the

main gas valve and spark electrode/flame sensor for a

Condenser Fan Clearances

period of 10 seconds. The blower/ignition control will spark

for the full 10 seconds regardless of establishing flame and

A I ' ' \ /'

then look for a signal from the electrode/flame sensor that a

flame has been established. Forty-five (45) seconds

nominal after the initial trial for ignition, the circulating air

blower will start. If the electrode/flame sensor does not

sense that a flame has been established in the 10 second

interval, then the blower/ignition control will open the 24

Unit Model No. A

-024 3 in.

-030,-036,-042,-048,-060 3-1/2 in.

volt contacts to the main gas valve. The blower/ignition

control is designed to repeat this trial for ignition a total of

Figure 10

Page 12

Page 13

Completethefollowingchecksbeforestartingtheunit,

1- Checkthetypeofgasbeingsupplied.Besureitisthe

sameaslistedontheunitnameplate,

2- Makesurethattheventhoodhasbeenproperlyinstalled,

3 - Turn gas valve knob or push gas valve lever to ON

position. Refer to figures 11 and 12.

4 - Turn on electrical power to unit.

5 - Set room thermostat to desired temperature. (If ther-

mostat setpoint temperature is above room tempera-

ture after the pre-purge time expires, main burners will

light).

FORYOURSAFETYREADBEFORELIGHTING

BEFORELIGHTINGsmellallaroundtheappliancearea

forgas.Besuretosmellnexttothefloorbecausesomegas

isheavierthanairandwillsettleonthefloor.

WARNING

WARNING

Honeywell VR8205 Series Gas Valve

o

Gas Valve Shown In Off Position

Figure 11

Robertshaw 7200 Gas Valve

gas valve

selector arm

in off position

WARNING

WARNING

Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

do not try to repair it, call a qualified service technician.

Force or attempted repair may result in a fire or explosion.

This furnace is equipped with a direct ignition control. Do

not attempt to manually light the burners.

1 - Turn off electrical power to unit.

2 - Set thermostat to lowest setting.

Figure 12

To Shut Down:

1 - Turn off electric power to unit.

2 - Depress and turn knob or pull lever to OFF position.

Post Start-up Check List (Gas)

After the entire control circuit has been energized and the

heating section is operating, make the following checks:

1 - Check for gas leaks using soap solution in the unit pip-

ing as well as the supply piping.

2 - Check for correct manifold gas pressures. See "Man-

ifold Gas Pressure Adjustment."

3 - Check the supply gas pressure. It must be within the

limits shown on rating nameplate. Supply pressure

should be checked with all gas appliances in the build-

ing at full fire. At no time should the standby gas pres-

sure exceed 13 inches W.C., nor the operating pres-

sure drop below 5.0 inches W.C. for natural gas units,

11 inches W.C. for propane gas. If gas pressure is out-

side these limits, contact your gas supplier for correc-

tive action.

Page 13

Page 14

4- Adjusttemperaturerisetotherangespecifiedonthe

ratingplate.

Tocheckorchangeburnersor orifices,CLOSEMAIN

MANUALSHUT-OFFVALVEAND SHUTOFFALL

POWERTOTHEUNIT.

1- Opentheunionfittinginthegassupplylinejustup-

streamoftheunitgasvalveanddownstreamfromthe

manualshut-offvalve,

2- RemoveBurnerAccessPanel,

3- Removethefour(4)screws,two(2)onthesideand

two(2)onbottomthatmounttheburnerrackassembly

totheburnerplate.

4- Disconnectwiringto thegasvalveandtheelec-

trode/flamesensor.Removeburnerrackassembly

fromtheunitbypullingback.Burnersarenowac-

cessibletoservice.

5- Reversetheaboveprocedureto replacetheassem-

bly.Makesurethatburnersarelevelandcenteredinto

eachburner'scorrespondingheatexchangertube.

ForLPG / Propane Gas Applications

L,RG./Propane units require a regulator, and a regulator on

the LP.G./Propane tank is also required.

The minimum permissible gas supply pressure is 11 inches

W,C, for purpose of input adjustment.

If at any time ignition is slow and burner does not seem to

be operating correctly, check manifold pressure, It should

be 10,0 inches to 10,5 inches W.C. PRESSURE FOR

LPG/PROPANE.

Furnace is designed to obtain rated input at 10.0 inches

W.C. To check this pressure:

1 - Turn off gas valve.

2- Remove plug on valve marked "OUTLET PRES-

SURE"

3 - Install water manometer.

Turn gas valve ON, If manifold pressure must be adjusted,

remove cap from pressure regulator and turn adjustment

screws clockwise to increase pressure, counterclockwise

to reduce pressure, After checking pressure, turn gas off,

remove manometer fitting and replace pipe plug and

regulator cap. Put furnace in operation and leak check plug

for leaks using soapy solution.

For Natural Gas Applications

The minimum permissible gas supply pressure is 5.0

inches W.C. for purpose of input adjustment,

Gas input must never exceed the input capacity shown on

the rating plate. The furnace is equipped for rated inputs

with manifold pressures as follows:

Natural Gas 3.5 inches W,C,

The manifold pressure can be measured by removing the

pipe plug in the downstream side of the gas valve and

connecting water manometer or gauge.

In no case should the final manifold pressure vary more

than 0.3 inch W.C. from the above specified pressures.

See figures 11 and 12. To adjust the regulator, turn the

adjusting screw on the regulator, turn the adjusting screw

on the regulator clockwise to increase pressure and input;

counterclockwise to decrease pressure and input.

Check the furnace rate by observing gas meter, making

sure all other gas appliances are turned off, The test hand

on the meter should be timed for at least one revolution.

Note the number of seconds for one revolution.

BTU/HR = Cubic Feet Per Revolution X 3600 X Heating Value

INPUT No. Seconds Per Revolution

The heating value of your gas can be obtained from your

local utility,

Example: By actual measurement, it takes 38 seconds for

the hand on the 1-cubic foot dial to make a revolution with a

100,000 Btuh furnace running, The result is 99,750 Btuh,

which is close to the 100,000 Btuh rating of the furnace.

Ratings shown on the rating plate for elevations up to 4,500

feet. For elevations above 4,500 feet, ratings should be

reduced at a rate of four (4) percent for each 1,000 feet

above sea level, See National Fuel Gas Code Z223,1

(latest edition) or the requirements of the

CAN/CGA-B149.1 or B149.2 Installation Code.

Limit Control

This control is located inside the heating compartment and

is designed to open at abnormally high air temperatures. It

resets automatically. The limit switch operates when a high

temperature condition, caused by inadequate blower

supply airflow, occurs, thus shutting down the

blower/ignition control and closing the main gas valve. The

circulating air blower will continue to operate.

Pressure Switch

If the draft motor should fail, the pressure switch prevents the

blower/ignition control and gas valve from being energized,

Spark Electrode and Flame Sensor Rod

The spark electrode and flame sensor rod are part of the

burner assembly. The burner position of the spark

electrode varies by model, The flame sensor rod is always

adjacent to the spark electrode. If the blower/ignition

control does not receive a signal from the flame sensor

indicating that the burners have established flame, the

main gas valve will close after the 10 second ignition trial

period built into the ignition control.

Rollout Switch

The switch is located above the main burners which in the

event of a sustained main burner rollout shuts off the

Page 14

Page 15

blower/ignitioncontrolandclosesthemaingasvalve,To

reset,pushthebuttonon top of the switch,

Auxiliary Limit

This control is located in the side of the circulating air blower

housing. The switch will open and shut off the blower/ignition

control and close the main gas valve should the circulating

blower fail to operate, This control resets automatically,

Normal Maintenance

Periodic inspection and maintenance normally consists of

changing or cleaning filters and (under some conditions)

cleaning the main burners,

Filters

Not supplied. Inspect once a month, Replace disposable or

clean permanent type as necessary, DO NOT replace per-

manent type with disposable,

Motors

Indoor, outdoor fan and vent motors are permanently

lubricated and require no maintenance,

Outdoor Coil

Dirt and debris should not be allowed to accumulate on the

outdoor coil surface or other parts in the air circuit. Cleaning

should be as often as necessary to keep the coil clean. Use

a brush, vacuum cleaner attachment, or other suitable

means, If water is used to clean the coil, be sure the power

to unit is shut off prior to cleaning,

NOTE - Care should be used when cleaning the coil so that

the coil fins are not damaged.

Do not permit the hot condenser air discharge to be ob-

structed by overhanging structures or shrubs,

To Clean Burners

Remove them from the furnace as explained in "Burner In-

structions." Vacuum and/or brush as required,

Vent Outlet

Visually inspect vent outlet periodically to make sure that the

buildup of soot and dirt is not excessive. If necessary, clean

to maintain adequate opening to discharge flue products,

Cleaning Flue Passages & Heating Elements

With proper combustion adjustment the heat exchanger of a

gas-fired furnace will seldom need cleaning. If the heat ex-

changer should become sooted, it can be cleaned as follows:

1 - Remove the burner assembly as outlined in "BURNER

INSTRUCTIONS."

2 - Remove the combustion air inducer.

3 - At the bottom of the heat section, remove the screws

holding the flue collector box, Carefully remove the

flue collector box without ripping the adjacent insula-

tion,

4 - Using a wire brush on a flexible wand, brush out the

inside of each heat exchanger from the burner inlet

and flue outlet ends,

5 - Brush out the inside of the flue collector box.

6 - Run the wire brush down the heat exchanger tubes

from the flue collector end,

7 - If soot buildup is excessive, remove the vent motor

and clean the wheel and housing. Run the wire brush

down the flue extension at the outlet of the vent hous-

ing,

8 - After brushing is complete, blow all brushed areas with

air. Vacuum as needed,

9 - Replace parts in the reverse order they were removed

in steps 1 to 3.

10 - When replacing the flue collector box, be careful not to

tear the adjoining insulation,

11 - Assure that all joints on the vent side of the combustion

system are air tight. Apply a high temperature

(+500 _F) sealing compound where needed,

Draft motor operates and furnace lights but circulating air

blower does not start after the time delay circuit expires

with room thermostat fan switch set to AUTO.

a - Set fan switch to "on2 If blower motor runs, go to step f.

If it does not, check to see if line voltage is being sup-

plied to the high voltage side of the blower time delay

relay (TDR) contacts.

b - If "TDR" is closed, touch the supply air blower motor

housing. If it is hot, the motor may be off on internal

protection. Allow time for the internal overload to reset.

Disconnect power to the unit and check the blower

motor capacitor. If it is defective, replace it with one of

the equal capacitance and voltage.

c -If "TDR" is closed and the blower motor still does not

run, replace the blower motor.

d -If "TDR" is not closed check for 24 volts at W on the

"TDR." If 24 volts are present, replace the blower/igni-

tion control board.

e -If the blower motor runs with the fan switch in the "on"

position but does not run soon after the furnace has ig-

nited with the fan switch in the "Auto" position, check

for loose 24 volt wires between "TDR" and the trans-

former.

Thermostat calls for heat but the draft motor does not

come on,

a -The draft motor has internal protection. If the motor

shell is hot to the touch, allow time for the internal over-

load to reset.

b -If the motor shell is cold with the room thermostat call-

ing for heat, check to see that there is 208/230 volts

between L1 blower/ignition control and black line wire

to draft motor. If no voltage present, check all connec-

tions. If the draft motor still does not operate, then

check for 208/230 volts between combustion blower/

ignition control and black line wire to draft motor. If volt-

age is not present and there is voltage between L1 on

blower/ignition control and black line wire and 24 volts

present at TS, then replace the blower/ignition control,

Draft motor runs but the furnace does not light,

a -Check all connections on the PSW circuit of blower/

ignition control and make sure the rollout switch and

high limit switch are all closed circuits,

Page 15

Page 16

b-Ifelectrode/flamesensorsparksbuthas"0"voltageat

thevalveduringtriesforignition,checkthewiringbe-

tweenvalveandblower/ignitioncontrol,checkvalve

ground.

c-if electrode/flamesensorsparks24 voltsto valve,

flameis establishedbutdoesnothold in, check

groundbetweenmoduleandburner,makesurethat

theelectrode/flamesensorisproperlylocatedinthe

middleof theflamestream,checksystemground.

Checktoseeifelectrode/flamesensorislocatedinthe

flamestreamproperly.

d)Ifelectrode/flamesensorsparks24voltstovalvebut

systemfailstoignite,checktomakesurethatthegas

supplyandgasvalveareon,checktoseeiforifice

plugged,andmakesureelectrode/flamesensorare

properlylocated.

Furnace lights and flame rollout occurs or burners have

delayed ignition.

a) Make sure that the carryovers on adjoining burners

are screwed fast and are level with respect to one

another.

b) Make sure electrode/flame sensor is properly located.

c) Make sure all air is purged from gas lines.

Main burners light, but exhibit erratic flame characteristics.

Check the main burner orifices for obstruction and align-

ment. Removal procedure is described in "Burner Instruc-

tions." Clean or replace burner orifices and burners as

needed.

The following blower/ignition control board (DS1) LED

codes will indicate normal or abnormal operations:

Slow Flash

Normal operation, no call for heat

One flash per second

Fast Flash

Normal operation, call for heat

Two flashes per second.

2 Flash

System lockout - failed to detect or sustain flame

Two flashes in one second with a one second pause.

3 Flash

Pressure switch open or closed

Three flashes in one and one-half seconds with a one sec-

ond pause.

4 Flash

High limit/or rollout switch open

Four flash in two seconds with a one second pause.

5 Flash

Flame sensed and gas valve not energized

Five flashes in two and one-half seconds with a one second

pause.

Steady

Internal failure (micro-controller failure; self-check)

The following repair parts are available from your local dealer. When ordering parts, include the complete model number

and serial number which are printed on the unit rating plate.

Control Group

Rollout Switch

Transformer

Limit Control

Gas Valve

Blower/Ignition Control

Electrode

Flame Sensor

Auxiliary Limit

Pressure Switch

Description Kit Number

Low Ambient Control ALOAM 111-1 42K88

High Pressure Cut-out Kit AHPSW436-1 42K89

Timed Off Control ATIMR446-1 42K90

LP Gas Conversion ALPKTS533-1 42K91

Blower Group

Blower Housing Assembly

Blower Wheel

Blower Motor

Blower Motor Mount

Blower Motor Capacitor (if used)

Combustion Air Inducer

Fan Blade

Fan Motor

Fan Motor Capacitor

Accessories

Heating Group

Gas Manifold

Main Burner Orifices

Main Burners

Heat Exchanger

Cooling Group

Compressor

Evaporator Coil

Drier

Cap. Tube or Expansion Valve

Contactor

Capacitor

Condenser Coil

LENNOX Cat.

Number

Page 16

Loading...

Loading...