1

L-300 & L-400

OWNER'S MANUAL

IMPORTANT:

READ THIS MANUAL THOROUGHLY BEFORE OPERATING.

Sales and Service Centers across Canada.

VICTORIA • VANCOUVER • KELOWNA • CALGARY • EDMONTON • WINNIPEG • TORONTO • MONTRÉAL

2

INTRODUCTION

We appreciate your decision to purchase a LEMMER product. With proper maintenance (as

outlined in this manual) you will be assured years of excellent results. For prompt and courteous

service or advice, please contact any of our factory outlets which are listed on page 15.

SPRAY GUN OPERATION

LEMMER Electric Airless Spray Guns operate with a high pressure piston action pump, which

creates the pressure needed to finely atomize all sprayable materials. The piston movement is

obtained through the use of a 120 V, 60c/s oscillating motor. The resulting 120 piston strokes per

second are combined with a durable one-way valve to draw in paint, pressurize the paint, and

spray it out in a finely atomized mist. Since the mist is airless (no air used to convey the paint),

very little overspray is produced. The results are smooth finishes, minimal paint loss, and very easy

clean-up. Since many of today's paints have abrasive qualities, the LEMMER guns have been

specially designed to handle these tough paints. Extensive use of ceramics, and a specially

grooved tungsten carbide piston, make these airless spray guns extremely durable. Ceramics have

the advantage of being harder than tungsten carbide, as well as having very low friction values,

resulting in much less wear when compared to conventional materials.

Piston Control knob

Pump Cylinder

Spring

Valve

Nozzle

Suction Tube

TECHNICAL DATA

L-300 L-400

Power .....................................120 VAC/60HZ .............................. 120 VAC/60HZ...........................

Watts ...................................... 80 W .............................................. 90 W ..........................................

Amps ......................................2.0 A .............................................. 2.0 A ..........................................

Weight .................................... 3.3 lbs.(1.5 kg)............................... 3.5 lbs.(1.6 kg) ...........................

Maximum Volume ..................15 min./gal. .................................... 13 min./gal. ................................

Maximum Viscosity ................100 sec. ......................................... 110 sec. .....................................

Cylinder Material .................... Ceramic ......................................... Ceramic .....................................

Piston Material .......................Grooved tungsten carbide ............. Grooved tungsten carbide .........

Valve Cone ............................Self-centering ceramic ................... Self-centering ceramic ...............

Container ...............................37 oz (1.1Ltr) ................................. 37 oz (1.1Ltr) .............................

3

SAFETY PRECAUTIONS

Personal

1. Injection hazard: Airless Painting Equipment can cause serious injury if the

spray penetrates the skin. Do not point the gun at anyone or any part of the

body. The tip guard provides some protection against accidental injection

injuries, but is mostly a warning device. Never put your hand, fingers or body

over the spray tip. Gloves and clothing do not necessarily offer any protection

either. Always have the tip guard in place while spraying. In case of

penetration seek medical aid immediately! Note to physician: Injection

into skin is a serious traumatic injury. It is important to treat the injury

surgically as soon as possible. Do not delay treatment to research

toxicity. Toxicity is a concern with some exotic coatings injected into

the bloodstream. Consultation with a plastic surgeon or reconstructive

hand surgeon may be advisable. Be prepared to tell the doctor what

fluid was injected.

2. Do not spray paints or other inflammable fluids indoors which have a flash point below 21 degree C/70

degree F.

3. Keep spray area well ventilated. Before spraying, turn off all pilot lights and open flames.

4. Always unplug the spray gun before examining or leaving unattended.

5. Wear a respirator which is approved for the product being sprayed.

6. Extension cords - Use only a 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot

receptacle that will accept the plug on the product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw.

An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. Note: The

smaller the guage number, the heavier the cord is.

Maximum lengths and minimum guages are: 50 feet (15.24M) 16 guage

100 feet (30.48M) 14 guage

Equipment

1. Keep spray gun clean at all times.

2. All parts which are intended to contact paint will not be harmed by strong thinners.

3. Do not submerge the spray gun in any liquids.

4. Do not tilt the spray gun upwards while spraying. For jobs such as ceilings, use the flexible extension.

Failing this, paint could leak from the back of the pump.

5. Do not let the spray gun run without material in it. Material flowing through the pump acts as a cooling

agent.

Grounding Instructions

1. This product should be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is

properly installed and grounded in accordance with all local codes and ordinances. DANGER - Improper use

of the grounding plug can result in a risk of electric shock.

2. If repair or replacement of the cord or plug is necessary, do not connect the grounding wire to either flat blade

terminal. The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

3. Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if in doubt as to whether the product is

properly grounded. Do not modify the plug provided;

if it will not fit the outlet, have the proper outlet

installed by a qualified electrician.

4. This product is for use on a nominal 120 volt circuit,

and has a grounding plug that looks like the plug

illustrated in sketch A. A temporary adapter, which

looks like the adapter illustrated in sketches B and C,

may be used to connect this plug to a 2-pole

receptacle as shown in sketch B if a properly

grounded outlet is not available. The temporary

adapter should be used only until a properly

grounded outlet (sketch A) can be installed by a

qualified electrician. The green colored rigid ear, lug,

or the like extending from the adapter must be

connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adapter is

used, it must be held in place by the screw.

HIGH PRESSURE!

INJECTION HAZARD!

GROUNDING METHODS

Grounded Outlet Adapter

Cover of Grounded

Outlet Box

(A) (B)

Grounding Pin

(C)

Grounding Means

4

OPERATING INSTRUCTIONS

Paint Preparation

1. Thin paint according to paint can instructions. Be certain to use a thinner which is compatible

with paint used. If no thinning instructions are given, a general rule of thumb is 5 to 15%

thinners. (fine finishes up to 35%)

2. Stir paint completely and strain if impurities are seen. The suction tube screen will strain out any

remaining impurities.

3. Use the viscosity cup to measure paint as follows:

Choosing the Correct Nozzle

1. Nozzle size is very important for achieving perfect paint atomization and maintaining a smooth

operating spray gun.

2. First prepare the paint, and then measure the paint’s viscosity as follows:

a) Submerge the Lemmer Viscosity cup in the paint.

b) Lift the cup out of the paint and begin timing.

c) Stop timing when the steady paint stream is first broken.

d) The time recorded is the paint’s viscosity. Should this viscosity

exceed 100 seconds, thin further until 80 - 100 seconds is reached.

3. Now read the nozzle chart and choose the “general use” nozzle which lists the viscosity range

your material falls into. Choice of a round spray or flat spray nozzle is dependent on your

preference. The other round spray nozzles listed are used for more specific spray applications

where “fine tuning” is necessary. Note: The smaller the nozzle size; the smaller the spray

pattern is, the less the volume is, and the thinner the paint must be.

Example: A latex paint was thinned and its viscosity came to 90 seconds. The chart suggests

either an .8mm round spray nozzle or a BLACK flat spray nozzle for this application.

4. This nozzle chart has been made as accurately as possible. Not all paints will exactly comply

due to paint ingredient variations. However, it is an excellent starting point for learning the

basics of airless spray painting

Round Spray Nozzle Flat Spray Nozzle

NOZZLE CHART

ROUND SPRAY

NOZZLE

.4mm

.5mm

.6mm

.7mm

.8mm

1.0mm

PAINT TO BE SPRAYED

THIN PAINTS - lacquer, varnish,

urethane, stains, automotive paints,

industrial enamel & primer, oil paints,

dye, ink and other thin liquids.

general use nozzle for thin paints

THICK PAINTS - latex, oil paint, stains,

(and glue - round nozzle only).

general use nozzle for thick paints

FLAT SPRAY

NOZZLE

BLUE

BLUE

BLUE

BLACK

BLACK

BLACK

CORRECT

VISCOSITY

10 - 15 sec.

10 - 20 sec.

10 - 35 sec.

35 - 45 sec.

35 - 100 sec.

65 - 100 sec.

5

OPERATING INSTRUCTIONS

5. The following diagrams show actual spray pattern results of different round nozzle sizes.

Remember - the thinner the paint is, the smaller the nozzle should be. These spray patterns

are achieved by spraying in one spot for only a fraction of a second.

Poor spray pattern Normal spray pattern Perfect spray pattern

(try a larger nozzle or (sometimes a smaller nozzle (correct nozzle and

thin the paint more) will "tighten-up" the pattern) paint viscosity)

Operation

1. Consult your paint dealer for information on surface preparation and material to be used for

spraying.

2. Prepare your paint and choose correct nozzle.

3. Practice on scrap material before proceeding to spray.

4. Turn control knob counter-clockwise and press trigger to start. CAUTION - when spraying, high

pressure is developed at the nozzle - never put any part of the body near the nozzle.

5. Adjust the control knob so the gun has an even purr, this signifies the best pressure setting for

that particular nozzle and material. If improperly adjusted, the following will result:

Too far counterclockwise - stuttering;

Too far clockwise - even, loud sound and less paint.

6. Any areas which are not to be painted should be masked off or

shielded. This diagram illustrates the best way of spraying a flat

surface with a round spray nozzle. Make smooth passes from side to

side and then up and down.

7. Start and stop your spraying from outside the area to be sprayed and try to avoid any break in

spraying. Move your gun with a steady motion to avoid spots, runs, and irregular finishes.

Keep the gun a constant distance from work surface and make sure it is perpendicular, as

shown below.

8. To prevent paint sags and running, first apply a light-to-medium coat. When this is tacky, apply

another medium coat.

9. When painting outdoors, avoid spraying on windy days. Wind could deposit debris onto your

freshly painted surface, and can also carry paint mist to areas which you do not want to paint;

such as windows, lawn furniture, cars, etc. It is also a good idea when spraying fences to have

a cardboard shield behind to prevent spraying paint directly into the air.

10.Note: It may be necessary to clean the nozzle guard periodically. Be sure to unplug the spray

gun’s electrical cord before doing this.

6

ACCESSORY INSTRUCTIONS

Suction Hose

Installation

1. Remove the paint container and the suction tube.

2. Insert the suction and return fittings firmly.

3. Press the clamp onto the lower end of the hoses.

4. Attach the clamp to the container and adjust the suction hose so

the screen is at the bottom. (Read on before using paint.)

5. Make sure the paint is properly prepared so that the screen is not

sitting in settled solids.

6. The return hose does not have to be below paint level, it’s only

function is to return possible pump by-pass paint.

Priming

1. Prime with thinners which are compatible with your paint, and then

place hoses into the paint.

2. To prime, hold the spray gun beside the container and as low as

possible. Turn the control knob counterclockwise and press the

trigger to start.

3. Priming time is generally between 20 and 40 seconds.

4. When primed, spraying may begin. Do not tilt the gun back while

spraying. Important: when using the suction hose the duty cycle is: half an hour on, and

15 minutes off to cool.

Flexible Extension

Installation

1. Remove spray nozzle.

2. Leave the valve in the pump cylinder.

3. Tighten flexible extension onto the spray

gun using the tabs nearest the gun.

Tightening from the far end will damage

the extension.

4. Remove the protective cap at the front.

5. Leave the swirl head in the flexible

extension and screw the nozzle on.

Tighten the nozzle while holding the front

tabs.

6. To bend the extension, use 2 thumbs in

the center and pull the end of the extension around your thumbs. To prevent

kinking or breaking, do not bend the

extension without using your thumbs.

Note: The suction hose and flexible exten-

sion may be used separately or together, but

keep in mind that some paints may spray

better with only one attachment in use at a

time.

Large

hose

goes

forward.

Make a large

bend to prevent

kinking.

7

MAINTENANCE

Cleaning

1. Only use thinners which are compatible with the paint to clean the gun.

2. Empty excess paint from the gun container and pour in one cup of thinners. Shake the gun

back and forth to flush the container, then spray for 5 seconds to flush pump parts. Properly

discard used thinners. Repeat if necessary.

3. Disassemble pump and clean all parts individually. Be sure the vent hole is clean and free.

CAUTION:

The piston is made of tungsten carbide which is long wearing, but also brittle -

Do

Not drop it or force it in any way.

Disassembly Procedure

STEP 1

1. Disconnect Power Supply.

2. Remove Nozzle.

3. Remove Valve.

4. Remove Container.

5. Remove Suction Tube.

6. Remove locking screw.

STEP 2

1. Push Pump Housing in.

2. Push Pump Housing down (1/4") slightly.

CAUTION - Do not force in any manner, if stuck, clean

first or try penetrating oil.

3. Pull Pump Housing straight out.

STEP 3

1. Pull Piston out. If it is stuck, do not pry or

hammer. See “Freeing a seized piston” on

page 8.

2. Remove Piston Spring. If piston spring

remained on piston, remove it by butting the

steel end of piston on a soft object and then

push the spring off with your fingers.

Pump Cylinder

Spring

Nozzle

Vent Hole

Piston

Valve

Suction tube

Strainer

8

MAINTENANCE

Cleaning

4. Reassemble in reverse order. Turning the control knob counterclockwise will reduce spring

tension for easy pump installation. Note that the guide tabs at the back of the pump must line

up with the gun housing. Firmly tighten the pump locking screw to insure it does not loosen

during operation. Check for correct pump positioning as shown.

Correct Incorrect

5. Dip suction tube into varsol or oil and spray for two seconds.

Then hold the gun with the suction tube out of the varsol (or

oil) and spray until empty. Another method is to remove the

suction tube, turn the gun upside down and pour a little oil

(or penetrating oil) into the forward pump hole. Hold your

finger lightly over the

suction hole

and spray until empty.

This will ensure that the spray gun is properly lubricated for

it’s next use.

Warning: NEVER put your fingers over the

spray nozzle.

6. Using a brush or rag dipped in thinners, clean the outside of

the spray gun. Do not submerge the spray gun in any liquids.

7. Wiping the gun with an oily rag will restore the gun’s new look and make it easier to clean the

next time.

8. Remember - A clean gun will always reward you with trouble free spraying.

Freeing a Seized Piston

This condition is usually caused by incomplete cleaning. Use the following procedure to rectify:

a) Remove nozzle, paint container, suction tube, and locking screw. If the valve is not

stuck, remove it too.

b) Remove pump assembly from gun and clean off all fresh paint with compatible thinners.

c) Place pump assembly into container of lacquer thinner for 1/2 an hour (longer if neces-

sary).

Caution

- read the warnings on lacquer thinner label before using.

d) GENTLY pull piston out of pump cylinder. If the valve was stuck, gently pull it out or use

the piston to push it out. Thoroughly clean all parts. The inside of the pump cylinder is

best cleaned with a 3/8” brush as shown on page 10.

e) Reassemble the spray gun.

suction hole

Loosen locking screw and push

pump in and up to position properly.

Pump sits level and

shows no gaps.

Gap.

9

MAINTENANCE

Parts That Wear

The round spray nozzle and the valve are common wear parts. Their life span depends on how

abrasive the paint is. A basic life expectancy with the use of various paints is:

Lacquer, enamel and clear stain 15 - 30 gallons

Alkyde, and oil stain 10 - 20 gallons

Latex and water base stain 5 - 10 gallons

These parts are easily replaceable and should be replaced when worn to maintain excellent

performance. Visual inspection for wear is as follows: (Operating sprayer with worn parts will

cause abnormal drive line wear).

1. Round spray nozzle - hole size of a new nozzle is shown actual size. Using a wire or

equivalent will help make a comparison between your nozzle and the dot.

New Nozzle Worn Nozzle

New nozzle

actual hole size:

.6mm =

.8mm =

Replace nozzle when hole

becomes larger than:

.6mm =

.8mm =

Round Orifice Large and usually oval orifice

2. Valve - A new valve will allow the gun to prime in approximately two seconds. If it takes eight

seconds or longer, replace the valve.

New Valve Worn Valve

Round and long Formed channels Angled and short Large “pit”

Servicing

If you have any problems with the electrical system, the spray gun should be returned to your

nearest Lemmer Authorized Service Centre.

10

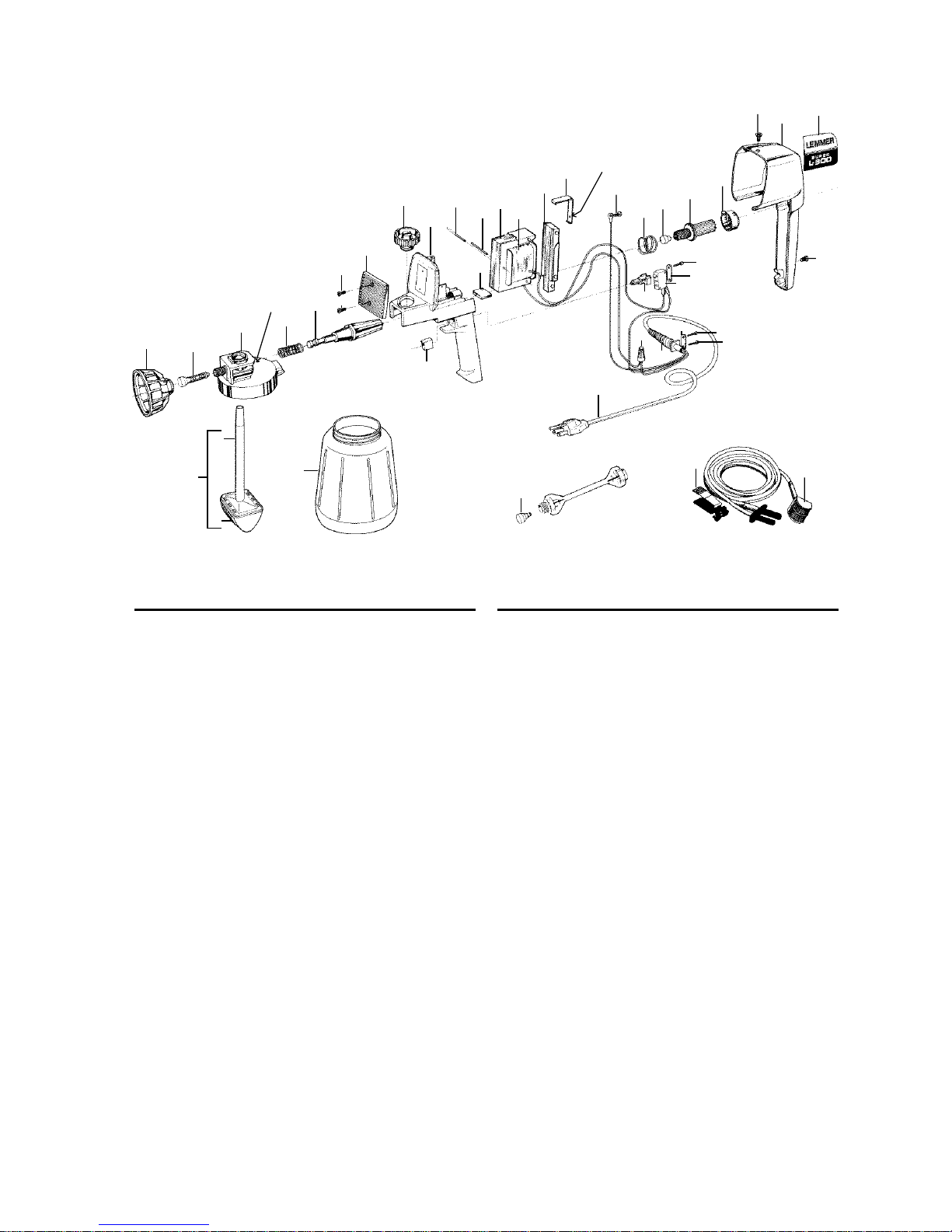

POWER CONVERTER

Just plug into your vehicles lighter

socket to operate any Lemmer cup gun.

A standard car battery will run a cup gun

for about 4 hours and still have lots of

engine starting power.

Cup gun power inverter.........................

................................. Order # L075-165

VALVE KIT

This is a wearing part and having

spares will prevent possible down time.

Each kit contains 2 valves.

................................. Order # L075-103

CONTAINER WITH LID

For storing liquids and paint, or assisting

in quick color changes and thinning.

................................. Order # L075-111

SUCTION HOSE

For spraying out of the original paint

container. It makes the gun lighter and

more maneuverable. Approximately 6

feet long. .................. Order # L075-105

LINE-PRO

For painting 1" to 8" parking lot lines.

The resulting lines are the same as

those produced with large professional

units.

Line-Pro without spray gun (for the

L-400 only) ............... Order # L075-140

FLEXIBLE NOZZLE EXTENSION

To angle or extend the nozzle. For

spraying ceilings, floors, or hard to

reach areas (spray nozzle not included,

use any LEMMER optional nozzle, or

the one on the spray gun).

................................. Order # L075-104

ROUND SPRAY NOZZLES

For general purpose spraying. They

produce a finely atomized conical mist.

The .6mm and .8mm are general sizes

for thin and thick materials respectively.

.4mm for thin materials such as dye &

fluids......................... Order # L075-500

.5mm for fine enamel, etc. ....................

................................. Order # L075-501

.6mm for lacq., enamel, stain, some

latex, etc................... Order # L075-502

.7mm for latex, oil base, etc..................

................................. Order # L075-503

.8mm for latex, oil base, thick stains,

etc. ........................... Order # L075-504

1.0mm for thicker materials. .................

................................. Order # L075-505

FLAT SPRAY NOZZLES

For accurate spraying with less

overspray. Long wearing ceramic orifice

is designed for superior atomization.

Blue nozzle for lacquer, enamel, stain,

etc. ........................... Order # L075-112

Black nozzle for latex, oil base, thick

stains, etc. ................ Order # L075-113

REPAIR KIT

Complete pump assembly. Kit includes

pump cylinder, piston, piston spring, and

2 valves.

Repair kit .................. Order # L075-142

CLEANING BRUSHES

To assist in cleaning the spray gun

(these brushes are not affected by

strong paint thinners).

3/8" dia. for pump cylinder ....................

................................. Order # L075-109

5/8" dia. for general cleaning ................

................................. Order # L075-110

VISCOSITY CUP

An essential item for correct thinning of

paint and for proper nozzle selection.

................................. Order # L075-106

TIP BROACHES

For cleaning out plugged nozzles and

high pressure jets. Unique square

design quickly "reams" out foreign

obstructions.

(Package of 12) ....... Order # L033-021

ACCESSORIES

11

ELECTRIC CUP GUNS PNEUMATIC PISTON ELECTRIC DIAPHRAGM

LINEMARKERS

GAS DIAPHRAGM AIRLESS ACCESSORIES PAINTING SUNDRIES

AIR GUNS & PRESSURE POTS ELECTROSTATIC UNITS HVLP TURBINE & VENTURI UNITS

LEMMER'S full line of equipment comes with FIRST CLASS SERVICE in

numerous locations across CANADA, and a FULL ONE YEAR WARRANTY.

For information on choosing the right sprayer for your job, please

contact your nearest LEMMER outlet.

OTHER LEMMER EQUIPMENT

AUTOMATIC GUNS ELECTRIC PISTON PUMPS

12

PROBLEM:

Motor does not work

Motor hums quietly and

does not pump

Motor works but does not

pump

Sprays but spits occasionally

Poor spray pattern, or

sprays with irregular

clattering noise

Poor spray pattern with

flexible extension

Paint drips from nozzle

Excessive fogging

SOLUTION:

- Check plug connections and

power source

- Dismantle pump and clean

- Use only 120V A.C. Current

- Use only government

approved ext. cords

- Turn counterclockwise to

start

- Insert suction tube in front

hole

- Replace

- Thin accordingly

- Clean

- Replace

- Clean

- Clean (strain paint)

- Fill container

- Replace, see nozzle chart

- Replace

- Thin accordingly

- Adjust to an even hum. This

signifies perfect pressure

- Replace

- Replace

- Replace

- Hand tighten

- Hold sprayer closer

- Replace. See “Nozzle chart”

page 4

- Re-adjust control knob

CAUSE:

- Loose connection at plug or

no power in socket

- Seized piston

- Incorrect power supply

- Incorrect control knob

adjustment

- Sucking air

- Worn or missing valve

- Paint far too thick

- Plugged Nozzle, Valve or

Suction Screen

- Worn pump and/or piston

- Vent hole plugged

- Clogged suction filter

- Sucking air

- Incorrect or worn nozzle

- Worn valve

- Paint is wrong viscosity

- Incorrect control knob

adjustment

- Worn pump and/or piston

- Worn or missing swirl head

- Worn valve

- Loose nozzle

- Holding sprayer too far from

surface

- Incorrect or worn nozzle

- Control knob set too high

TROUBLE SHOOTING GUIDE

NOTE: Always unplug before examining. For further information contact a LEMMER Service Center.

13

1

3

4

5

6

33

34

32

35

7

8

9

11

11

10

31

2

6

13

12

14

15

16

17

18

19

20

21

22

23

21

24

25

26

27

25

30

28

24

24

29

36

37

34

Pos. Part nos. Description Qty.

1 L075-500 .4mm Round spray nozzle

L075-501 .5mm Round spray nozzle

L075-502 .6mm Round spray nozzle

L075-503 .7mm Round spray nozzle

L075-504 .8mm Round spray nozzle 1

L075-505 1.0mm Round spray nozzle

2 L075-506 Valve 1

3 L075-700 Pump cylinder 1

4 L075-508 Piston spring 1

5 L075-701 Piston 1

6 L075-702 Screw 2

7 L075-703 Grill 1

8 L075-513 Locking screw 1

9 L075-704 Drive housing 1

10 L075-517 Damper 1

11 L075-512 Split pin 2

12 L075-705 Stator 1

13 L075-706 Coil 1

14 L075-707 Armature 1

15 L075-522 V-Spring 1

16 L075-708 Screw 1

Pos. Part nos. Description Qty.

17 L075-611 Spring 1

18 L075-523 Rubber bumper 1

19 L075-709 Control knob 1

20 L075-710 Limitor clip 1

21 L075-527 Screw 2

22 L075-711 Housing cover 1

23 L075-712 Name plate set 1

24 L075-713 Screw 4

25 L075-536 Cable clamp 2

26 L075-714 Switch 1

27 L075-715 Switch shaft 1

28 L075-530 Cable grommet 1

29 L075-531 Cable c/w grommet 1

30 L075-534 Wire connector 1

31 L075-716 Switch button 1

32 L075-540 Suction tube with filter 1

33 L075-538 Suction tube 1

34 L075-539 Suction filter 1

35 L075-537 Paint container 1

36 L075-124 Swirl head 1

37 L075-127 Clamp 1

N/S L075-142 Repair kit (pos.3,4,5,2) 1

N/S L075-262 Operators manual 1

Optional accessories.

This vent hole

must be kept

open.

Hole aims towards

back of gun.

L-300 PARTS LIST

14

33

34

32

35

20

1

3

4

2

5

6

7

9

8

9

10

11

12

13

31

14

15

16

16

17

18

19

24

25

26

27

30

25

24

24

29

28

21

21

22

23

34

37

36

L-400 PARTS LIST

Optional accessories.

This vent hole

must be kept

open.

Hole aims towards

back of gun.

Pos. Part nos. Description Qty. Pos. Part nos. Description Qty.

1 L075-500 .4mm Round spray nozzle

L075-501 .5mm Round spray nozzle

L075-502 .6mm Round spray nozzle

L075-503 .7mm Round spray nozzle

L075-504 .8mm Round spray nozzle 1

L075-505 1.0mm Round spray nozzle

2 L075-506 Valve 1

3 L075-700 Pump cylinder 1

4 L075-508 Piston spring 1

5 L075-701 Piston 1

6 L075-513 Locking screw 1

7 L075-719 Drive housing 1

8 L075-605 Damper 1

9 L075-512 Split pin 2

10 L075-705 Stator 1

11 L075-720 Coil 1

12 L075-707 Armature 1

13 L075-522 V-Spring 1

14 L075-721 Handle 1

15 L075-708 Screw 1

16 L075-722 Screw 2

17 L075-611 Spring 1

18 L075-523 Rubber bumper 1

19 L075-709 Control knob 1

20 L075-710 Limitor clip 1

21 L075-527 Screw 2

22 L075-717 Housing cover 1

23 L075-723 Name plate set 1

24 L075-713 Screw 4

25 L075-536 Cable clamp 2

26 L075-714 Switch 1

27 L075-715 Switch shaft 1

28 L075-530 Cable grommet 1

29 L075-531 Cable c/w grommet 1

30 L075-534 Wire connector 1

31 L075-716 Switch button 1

32 L075-540 Suction tube with filter 1

33 L075-538 Suction tube 1

34 L075-539 Suction filter 1

35 L075-537 Paint container 1

36 L075-124 Swirl head 1

37 L075-127 Clamp 1

N/S L075-142 Repair kit (pos.3,4,5,2) 1

N/S L075-262 Operators manual 1

15

SALES AND SERVICE CENTERS ACROSS CANADA.

If you should require any information, assistance, service, or parts, please contact the store from

which the spray gun was purchased, or contact the Lemmer outlet nearest you.

Printed in Canada, #L075-262 manual for L-300/L-400. Aug-98

LEMMER PAINT SPRAYING EQUIPMENT LIMITED WARRANTY

LEMMER Spray Systems Ltd. extends to the original purchaser of its paint spray equipment

a limited one year warranty from the date of purchase against defects in material or

workmanship provided that the equipment is installed and operated in accordance with the

recommendations and instructions written in the owners manual. LEMMER Spray Systems Ltd.

will repair or replace, at its option, defective parts without charge if such parts are returned (still

intact in the original equipment) with transportation charges prepaid to the nearest LEMMER

Spray Systems Ltd. outlet. An original proof of purchase must be attached.

THIS WARRANTY DOES NOT COVER:

Normal wear and/or defects caused by or related to abrasion, corrosion, abuse, negligence,

accident, faulty installation or tampering in a manner which impairs normal operation.

Transportation costs and other incidental, direct, special, or consequential damages or loss.

MONTRÉAL

Lemmer (Qué.) Inc.

2851 Boul. le Corbusier

Chomedey, Laval, Québec H7L 4J5

TEL: (450) 681-8220

FAX: (450) 681-4914

TORONTO

Lemmer Spray Systems (Ont.) Ltd.

7585 Torbram Road, Unit 7-8

Mississauga, Ontario L4T 1H2

TEL: (905) 673-1555

FAX: (905) 673-3201

WINNIPEG

Lemmer Spray Systems (Man.) Ltd.

1198 Sherwin Road

Winnipeg, Manitoba R3H 0V2

TEL: (204) 633-3117

FAX: (204) 694-4763

VICTORIA

Lemmer Spray Systems (B.C.)Ltd.

#102 - 2740 Bridge Street

Victoria, B.C. V8T 5C5

TEL: (250) 383-4464

FAX: (250) 383-5154

VANCOUVER

Lemmer Spray Systems (B.C.) Ltd.

4141 Grandview Highway

Burnaby, B.C. V5C 4J1

TEL: (604) 430-3216

FAX: (604) 430-8017

KELOWNA

(Lemmer agent)

R. Kitchin Paint Spray Equipment Inc.

#3 - 2300 Hunter Road

Kelowna, B.C. V1X6C1

TEL: (250) 717-0223

FAX: (250) 860-3038

CALGARY

Lemmer Spray Systems Ltd.

4624 - 12th Street N.E.

Calgary, Alberta T2E 4R4

TEL: (403) 250-7735

FAX: (403) 291-9095

(head office)

EDMONTON

Lemmer Spray Systems Ltd.

17506 - 105th Avenue

Edmonton, Alberta T5S 1G4

TEL: (403) 486-3674

FAX: (403) 444-2498

16

NOTES

Loading...

Loading...