LELY Tigo 35 S Classic, Tigo 35 ST Classic, Tigo 40 S, Tigo 50 ST, Tigo 35 S Operator's Manual

...Page 1

Lely Tigo

S

L-H007-1104EN

Operator Manual

Page 2

TRADEMARKS, COPYRIGHT AND

DISCLAIMER

Lely, Astronaut, Astri, Atlantis, Attis, AWS, C4C, Calm, Commodus,

Compedes,

Hubble, Juno, L4C, Lely Center, Lelywash, Lotus, Luna, Nautilus, Orbiter,

Qwes, SAE, Shuttle, Splendimo, Storm, T4C, Tigo, Viseo, Voyager, Walkway

and Welger are registered trademarks of the Lely Group. The right of exclusive

use belongs to the companies of the Lely Group. All rights reserved. The

information given in this publication is provided for information purposes only

and does not constitute an offer for sale. Certain products may not be available

in individual countries and products supplied may differ from those illustrated.

No part of this publication may be copied or published by means of printing,

photocopying, microfilm or any other process whatsoever without prior

permission in writing by Lely Holding S.à r.l. Although the contents of this

publication have been compiled with the greatest possible care, Lely cannot

accept liability for any damage that might arise from errors or omissions in this

publication.

The English language manual is the original manual. Translations into other

languages use the English language manual as the source document. Lely

accepts no liability for discrepancies between the original English language

manual and versions in other languages. If there is a conflict over the content

and accuracy of any translated manual, the English language manual is the

authority document.

Cosmix, Discovery, F4C, Fertiliner, Gravitor, Grazeway, Hibiscus,

Manual Contents

Copyright © 2010 Lely Industries NV

All rights reserved

Lely Industries NV

Weverskade 110

3147 PA Maassluis

The Netherlands

Phone: +31 (0)10 59 96 333

Fax: +31 (0)10 59 96 444

Website: www.lely.com

PREFACE

This manual contains the information necessary to operate the Lely Tigo. It

also includes maintenance information that can be done by an operator.

Study and understand this information thoroughly before you operate the Lely

Tigo. Failure to do so could result in personal injury or damage to equipment.

Please consult your local Lely service provider if you do not understand the

information in this manual, or if you need additional information.

All information in this manual has been compiled with care. Lely shall not be

liable for errors or faults in this manual. The recommendations are meant to

serve as guidelines. All instructions, pictures and specifications in this manual

ii

Page 3

Warranty Conditions

Registration

are based on the latest information that was available at the time of publication.

Your Lely Tigo may comprise improvements, features or options that are not

covered in this manual.

For those parts that fail under normal operating conditions, the factory will

make replacement parts available, free of charge, for a period of 12 (twelve)

months from the date of purchase.

warranty shall not apply if the instructions mentioned in this manual have

The

not been followed, or if they have not been followed completely or correctly.

Nor will the warranty apply if you or third parties modify the machine without

our foreknowledge and/or authorisation.

The Serial Number Plate is on the right front of the main frame.The serial

number is also stamped on the front of the main frame.

Always include the serial numbers of your product when you contact your local

Lely service provider or order spare parts.

Serial Number Plate

We suggest you complete the table below with the model type, serial number

and tyre size of your product. This makes sure you can easily find the

information.

Model

Serial number

Tyre size

iii

Page 4

iv

Page 5

Table of Contents

1.

Introduction.........................................................................................................................................1-1

1.1 Introduction..............................................................................................................................1-1

1.2 Drawbar....................................................................................................................................1-3

1.3 Pick-up Unit..............................................................................................................................1-4

1.4 Cutting Unit..............................................................................................................................1-5

1.5 Carriage...................................................................................................................................1-7

1.5.1 Superstructure.........................................................................................................................1-7

1.5.2 Floor Conveyor...................................................................................................................... 1-10

1.5.3 Tailgate..................................................................................................................................1-12

1.5.4 Under-carriage.......................................................................................................................1-14

1.6 Hydraulic System...................................................................................................................1-16

1.7 Drive System..........................................................................................................................1-17

1.8 Control Panel......................................................................................................................... 1-19

1.8.1 Hydraulic Control Panel.........................................................................................................1-19

1.8.2 Comfort System.....................................................................................................................1-21

1.9 Optional Extras.......................................................................................................................1-23

1.9.1 Lely Grinder........................................................................................................................... 1-23

2. Safety...................................................................................................................................................2-1

L-H007-1104EN

2.1 Signal Words............................................................................................................................2-1

2.2 Safety Instructions....................................................................................................................2-1

2.3 Explanation of the Safety Decals.............................................................................................2-3

3. First Use..............................................................................................................................................3-1

3.1 Finish the Superstructure.........................................................................................................3-1

3.2 Adjust the Length of the PTO Shaft.........................................................................................3-2

3.3 Install the PTO Shaft with the Overload Protection..................................................................3-3

3.4 Adjust the Height of the Drawbar.............................................................................................3-4

3.4.1 Drawbar with Spindle...............................................................................................................3-5

3.4.2 Drawbar with Hydraulic Ram...................................................................................................3-6

3.5 Adapt the Electric Power Connection.......................................................................................3-7

3.6 Connect the Electric Cables.....................................................................................................3-8

3.7 Adjust the Load Sense Adjustment Screw...............................................................................3-9

3.8 Examine the Lever Setting of the ALB...................................................................................3-10

4. Before Operation................................................................................................................................4-1

4.1 At First......................................................................................................................................4-1

Table of Contents v

Page 6

4.2 Connect the Cables and Hoses to the Tractor.........................................................................4-2

4.3

Connect the Tigo to the Tractor...............................................................................................4-4

4.4 Adjust the Working Depth of the Pick-up.................................................................................4-6

4.5 Adjust the Height of the Wind Guard........................................................................................4-7

4.6 Fold Up the Open Superstructure............................................................................................4-8

4.7 Select the Number of Knives..................................................................................................4-11

4.8 Drain the Air Container...........................................................................................................4-14

5. Operation.............................................................................................................................................5-1

5.1 Load the Fodder Crop..............................................................................................................5-1

5.2 Remove a Blockage by Moving the Knives Out and In............................................................5-2

5.3 Unload the Tigo........................................................................................................................5-5

6. After Operation...................................................................................................................................6-1

6.1 Disconnect the Tigo from the Tractor.......................................................................................6-1

7. Test and Adjustment..........................................................................................................................7-1

7.1 Remove and Install the Knife Assembly...................................................................................7-1

7.1.1 Remove the Knife Assembly....................................................................................................7-1

7.1.2 Install the Knife Assembly........................................................................................................7-2

7.2 Remove and Install a Single Knife...........................................................................................7-4

7.2.1 Remove a Single Knife............................................................................................................7-4

7.2.2 Install a Single Knife................................................................................................................7-4

7.3 Adjust the Clearance Between the Knives and the Rotor........................................................7-6

7.4 Disengage the Pneumatic Brake when the Tigo is not Connected..........................................7-8

7.5 Test the Overrun Brake............................................................................................................7-9

8. Maintenance........................................................................................................................................8-1

8.1 Scheduled Maintenance...........................................................................................................8-1

8.1.1 Maintenance Before Every Use...............................................................................................8-1

8.1.2 Maintenance After First Operation...........................................................................................8-1

8.1.3 Maintenance After the First 30 Working Hours........................................................................8-1

8.1.4 Maintenance Every 10 Working Hours....................................................................................8-1

8.1.5 Maintenance Every 25 Working Hours....................................................................................8-1

8.1.6 Maintenance Every 100 Working Hours..................................................................................8-2

8.1.7 Maintenance Every 200 Working Hours..................................................................................8-2

8.1.8 Maintenance Every 500 Working Hours..................................................................................8-2

8.1.9 Maintenance Every 3 Months..................................................................................................8-2

8.1.10 Maintenance Every 6 Months..................................................................................................8-2

8.1.11 Maintenance Every 12 Months................................................................................................8-2

8.1.12 Maintenance Every 6 Year.......................................................................................................8-2

8.1.13 Maintenance Before Prolonged Storage..................................................................................8-3

8.1.14 Maintenance After Prolonged Storage.....................................................................................8-3

L-H007-1104EN

vi Table of Contents

Page 7

8.2 Preventive Maintenance on the Tigo........................................................................................8-

8.3 Preventive Maintenance on the Under Carriage....................................................................8-25

L-H007-1104EN

5

8.2.1 Clean the Tigo..........................................................................................................................8-5

8.2.2 Replace the Main Gearbox Oil.................................................................................................8-6

8.2.3 Replace the Floor Conveyor Gearbox Oil................................................................................8-7

8.2.4 Grease the PTO Shaft.............................................................................................................8-8

8.2.5 Grease the Pick-up Guide Wheels...........................................................................................8-9

8.2.6 Grease the Dog Clutch..........................................................................................................8-10

8.2.7 Grease the Bearing of the Lateral Shaft................................................................................8-11

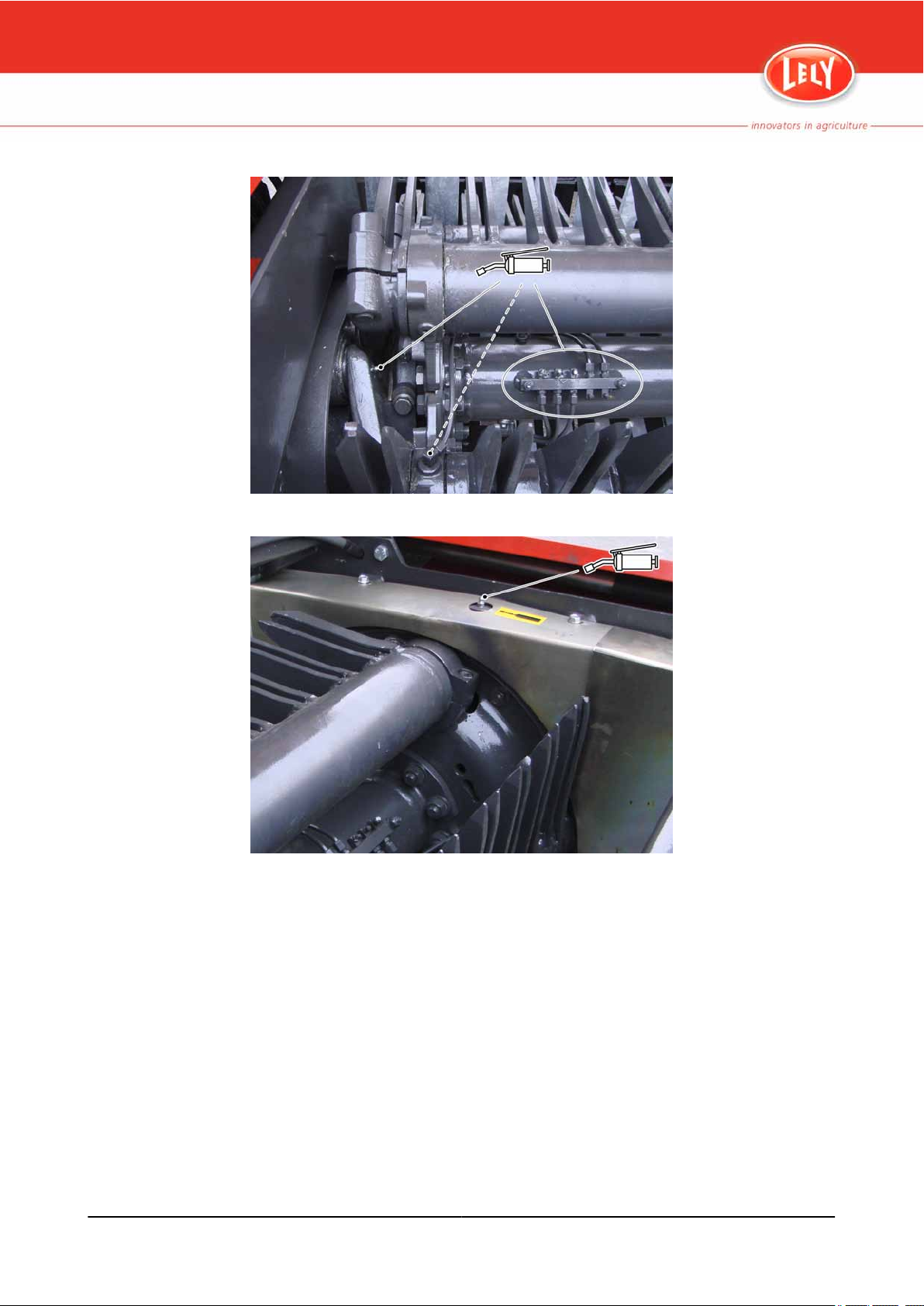

8.2.8 Grease the Cutting Unit.........................................................................................................8-12

8.2.9 Grease the Bearing of the Pick-up Drive Sprocket................................................................8-14

8.2.10 Lubricate the Drive Chains of the Pick-up..............................................................................8-15

8.2.11 Grease the Freewheel Clutch of the Pick-up.........................................................................8-16

8.2.12 Lubricate the Running Wheels of the Floor Conveyor...........................................................8-17

8.2.13 Grease the Bearings of the Floor Conveyor Drive Shaft........................................................8-18

8.2.14 Clean the Filter of the Air Brake System................................................................................8-19

8.2.15 Replace the Hydraulic Filter...................................................................................................8-20

8.2.16 Tighten the Drive Chains.......................................................................................................8-21

8.2.17 Check the Critical Bolts for Tightness....................................................................................8-22

8.3.1 Grease the Pivot Points of the Leaf Spring Suspensions......................................................8-25

8.3.2 Grease the Bearings of the Wheel Brake Cam Shafts...........................................................8-26

8.3.3 Adjust the Taper Roller Bearing.............................................................................................8-27

8.3.4 Measure the Brake Linings....................................................................................................8-28

8.3.5 Adjust the Overrun Brake.......................................................................................................8-29

8.3.6 Adjust the Wheel Brake.........................................................................................................8-30

8.3.7 Torque Tighten the Axle Assembly........................................................................................8-31

8.3.8 Tighten the Floor Conveyor Chains.......................................................................................8-32

8.4 Corrective Maintenance.........................................................................................................8-33

8.4.1 Sharpen the Knives................................................................................................................8-33

9. Diagrams and Tables.........................................................................................................................9-1

9.1 Hydraulic Diagrams..................................................................................................................9-1

9.2 Electric Diagrams.....................................................................................................................9-3

9.3 Bolt and Nut Torque Table.......................................................................................................9-5

9.4 Wheel Nut Torque Table..........................................................................................................9-6

9.5 Tyre Pressure Table.................................................................................................................9-7

9.6 Summary of Grease and Lubrication Points............................................................................9-8

10. Troubleshooting...............................................................................................................................10-1

11. Specifications...................................................................................................................................11-1

Table of Contents vii

Page 8

L-H007-1104EN

viii Table of Contents

Page 9

1.1 Introduction

1. INTRODUCTION

Note:

L-H007-1104EN

This manual covers the Lely Tigo 35S(T) Classic, the Lely Tigo 35S(T),

the Lely Tigo 40S(T) and the Lely Tigo 50S(T) in all variants and with all

options

to your specific model.

The Lely Tigo S is a loader wagon to pick up, cut and collect mown fodder

crops from a swath. It has the following main components:

• a drawbar that can be adjusted in height to match the tractor coupling

• a pick-up unit that picks up the fodder crop and passes it to the cutting unit

• a cutting unit that chops the fodder crop and thrusts it into the carriage

• a carriage with:

• an under-carriage with a single axle or tandem axle

The pick-up unit and the cutting unit are driven by the Power Take-Off (PTO)

of the tractor.

The floor conveyor and hydraulic rams are driven by the hydraulic power

provided by the tractor. The hydraulic control valves are operated either

manually or electrically via a control panel in the tractor cabin.

available. Therefore, parts of this manual may be not applicable

system and optionally to tilt the wagon

• a superstructure to contain the fodder crop

• a floor conveyor to aid loading and unloading

• a tailgate to unload the carriage

Electrical power for the lights and the (optional) electric control system and

signals for braking lights and direction indicators are also provided by the

tractor.

Introduction 1-1

Page 10

1. Superstructure - 2. Tailgate - 3. Carriage - 4. Cutting unit - 5. Pick-up unit - 6. Drawbar

Figure 1. Overview of a Tigo S Series Model

L-H007-1104EN

1-2 Introduction

Page 11

1.2 Drawbar

The drawbar can be either:

straight with a rigid coupling eye

•

• low with a coupling eye that can swivel

The drawbar can be adjusted in height either:

• manually by turning an adjustment spindle (height adjustment range

approximately 30 cm to match the height of the tractor coupling system)

or

• hydraulically (to tilt the wagon to facilitate unloading on a silage clamp. The

maximum clearance between the ground and the pick-up is approximately

70 cm).

The overrun brake (if present) and the parking brake (safety brake) are

integrated with the drawbar. In the case of an overrun brake, the wheels are

provided with a mechanism to allow reverse driving. The parking brake lever

has a nylon break-way rope that shall be attached to the tractor to engage the

parking brake in the event that the coupling fails during riding.

Furthermore, there is a parking jack installed on the main frame. The height of

the parking jack can be adjusted by a telescopic bottom part and turning a

crank.

L-H007-1104EN

1. Hose holders - 2. Parking brake (position A = brake disengaged, position B = brake

engaged) - 3. Break-away rope - 4. Spindle to adjust drawbar height - 5. Optional hydraulic

ram for moving the drawbar - 6. Parking jack - 7. Coupling eye

Figure 2. Overview of the (Low) Drawbar

Introduction 1-3

Page 12

1.3 Pick-up Unit

The pick-up unit picks up the fodder crop from the swath and conveys it to the

cutting unit. The pick-up unit has 5 bars with tines at 54 mm clearance for

optimal pick-up behaviour.

The guide wheels at the sides of the pick-up unit can be adjusted in height to

the pick-up unit follow the terrain contour at the optimal elevation. The guide

let

wheels can be either:

• fixed

or

• swiveled

The wind guard in front of the pick-up unit minimises fodder crop losses due

to air turbulences. It can be adjusted in height to cope with the swath thickness

and the properties of the fodder crop. Optionally, there is a wind guard available

with a roller for short crops.

Two hydraulic rams (one at each side) allow to raise the pick-up unit when

making turns or when travelling over the public road.

The pick-up unit has a built-in protective freewheel clutch that allows the rotor

with the tines to rotate freely in the event that the tines touch the ground when

driving reverse.

1. Wind guard - 2. Pick-up tines - 3. Guide wheel - 4. Hydraulic ram to move the pick-up unit

- 5. Optional swivelled guide wheel

Figure 3. Overview of the Pick-up Unit

L-H007-1104EN

1-4 Introduction

Page 13

1.4 Cutting Unit

The rotor of the cutting unit has 3 or 5 cylindrical bars in bearings with tines

thrust the fodder crop from the pick-up unit through an assembly of knives

that

into the carriage. There are 2 tines per knife (one at each side of the knife).

Each tine bar has a lever with a roller. The roller follows a flattened circular

track (cam track) so that the tines make a swinging movement upon each cycle

of the rotor. As a result, the tines maintain a horizontal attitude from a point

somewhere between the knives up to the point where they are withdrawn from

the conveyor channel. This causes the cut fodder to be pushed upwards into

the carriage.

The knife assembly can have two groups of knives. The upper group is always

present and is divided into two sub-groups. It can have 17 knives at maximum.

The lower group is optional and can have 16 knives at maximum. Using the

Lely Tigo Tool, each group or one of both sub-groups can be moved in and

out. This allows to have 5, 17, 21 or 33 knives in, thus different cut sizes down

to 38 mm. Because small cut sizes are normally used for silage forage, the

optional lower knife group is also called the 'silage knife group'.

With two optional hydraulic rams (one at each side), it is possible to move out

all knives at once, for example to solve a blockage problem.

The knives are kept in place by buckle springs that let them deflect when

foreign objects pass the cutting unit.This Trimatic™ release system prevents

damage to the cutting unit.

L-H007-1104EN

The knife assembly can be easily detached and rolled out on (optional)

transport wheels. Knives can be taken out by hand individually for sharpening

or replacement.

1. Pick-up tine - 2. Cylindrical bar with tines - 3. Lever with roller- 4. Rotational path of the

swinging tine bars - 5. Cam track - 6. Conveyor channel - 7 Knife - 8. Buckle spring

Figure 4. Working Principle of the Pick-up Unit and Cutting Unit

Introduction 1-5

Page 14

1. Rotor - 2. Lely Tigo Tool installed on the cam of the sub-group - 3. Upper knife group

Figure 5. Overview of the Cutting Unit

1. Sub-group that is in - 2. Sub-group that is out - 3. Lower knife group

Figure 6. Cutting Unit with Lower Knife Group (Sub-group of Upper Knife Group

Moved Out)

L-H007-1104EN

1-6 Introduction

Page 15

1.5 Carriage

1.5.1 Superstructure

Usually the carriage will be enlarged with a superstructure. This can be either:

an open superstructure consisting of 4 posts, a bow and lattice side walls,

•

a semi-closed front wall, a rear tarpaulin, 14 rigging ropes at the top and 2

rigging ropes at the sides. Optionally there can be a front-top tarpaulin

(recommended for loading short cut fodder crop).

or

• a (relatively) closed superstructure with closed metal plate side walls, a

semi-closed front wall, a rear tarpaulin and 14 rigging ropes at the top

The open superstructure can be folded down to park the wagon in a barn or

hangar. Folding up and down can be done either:

• manually using a rocker lever

or

• hydraulically

L-H007-1104EN

1. Optional front-top tarpaulin - 2. Rear tarpaulin - 3. Side rigging rope - 4. Top rigging rope -

5. Front wall - 6. Lattice side wall

Figure 7. Open Superstructure

Introduction 1-7

Page 16

1. Semi-closed front wall - 2. Closed metal plate side wall - 3. Rear tarpaulin - 4. Top rigging

rope

Figure 8. Closed Superstructure

L-H007-1104EN

1-8 Introduction

Page 17

L-H007-1104EN

Top: standard version with brace arm - Bottom: optional hydraulic version

Figure 9. Open Superstructure Folding Mechanism

Introduction 1-9

Page 18

1.5.2 Floor Conveyor

Upon harvesting, a pile of fodder builds up above and behind the conveyor

channel of the cutting unit. Periodically, the floor conveyor must be activated

shift the pile towards the (closed) tailgate to keep the conveyor channel open

to

and to compress the fodder crop. The floor conveyor is also used to unload

the carriage.

The floor conveyor consists of a wooden floor with two parallel metal gutters

and equidistant metal slats. The slats are dragged over the floor by closed loop

chains in the gutters. The chains are driven by an hydraulic motor that can be

operated:

• from a control valve near the motor

and

• from a second control valve that is either:

• part of the tractor hydraulic system

or

• electrically controlled from the operator panel in the tractor cabin

1. Wooden floor - 2. Gutter - 3. Closed loop chain - 4. Slat

Figure 10. Floor Conveyor

L-H007-1104EN

1-10 Introduction

Page 19

L-H007-1104EN

1. Control valve - 2. Rod for control from the position next to the tailgate (position A = conveyor

off, position B = conveyor on) - 3. Hydraulic motor

Figure 11. Hydraulic Motor of the Floor Conveyor

Introduction 1-11

Page 20

1.5.3 Tailgate

The tailgate hangs from the tailgate boom bar with 3 hinges and is locked at

the bottom-left and bottom-right side. The locks can be unlocked with a lever

at the rear left-bottom side of the carriage.

There are also latches at the top-left and top-right side of the tailgate. These

are operated with a lever at the rear side of the tailgate. When locked, the

tailgate can be lifted to a wide open position using the left and right hydraulic

lifting arms. Lifting and lowering is done from the control panel in the tractor

cabin.The locks at the bottom-left and bottom-right side of the tailgate open/

close automatically in this case.

Whether the tailgate must be just unlocked or wide open depends on the

overhead space available at the unloading site. Use wide open whenever

possible.

The button on the wire mesh on the inside of the carriage serves as a sensor

to detect the carriage full status.

1. Hydraulic lifting arm - 2. Latch - 3. Latch lever (position A = latch locked to enable tailgate

lifting, position B = latch unlocked) - 4. Tailgate - 5. Rear lights and indicators - 6. Lock lever

(push in the direction of the arrow to unlock the tailgate) - 7. Lock - 8. Hydraulic ram for

automatic unlocking

Figure 12. Tailgate

L-H007-1104EN

1-12 Introduction

Page 21

L-H007-1104EN

Figure 13. Tailgate Just Open (left) and Wide Open (right)

Introduction 1-13

Page 22

1.5.4 Under-carriage

In case of a single wheel axle, the axle is fixed to the under-carriage without

springs. For the tandem axle version, both wheel axles are suspended from

packages of leaf springs. The wheels are fixed (i.e. not steered). Various tyre

types are available.

All wheels are provided with a brake that can be activated:

mechanically by the parking brake

•

and

• mechanically by an (optional) overrun mechanism that is activated when

the tractor slows down or when riding downwards from a slope (however,

a freewheel mechanism in the wheels allows reverse driving)

or

• hydraulically by a hydraulic brake signal provided by the tractor

or

• pneumatically by a pneumatic brake signal and pneumatic power

(compressed air) provided by the tractor

In the case of a pneumatic brake ram, the brake force can be adapted to the

load in the carriage. This can be done either:

• manually via a lever (4 settings)

or

• automatically (Automatic Load-sensitive Brake system, ALB). For this

system, the lever that controls the brake force valve is connected to the leaf

spring package. The further the leaf springs deflect, thus the more load, the

higher the brake force.

If there are two wheel axles and hydraulic or pneumatic brake rams, the parking

brake is only connected to the front wheel brakes.

Optionally, mudguards can be mounted above the wheels.

1. Leaf spring suspension (only for tandem axle version) - 2. Brake ram - 3. Brake cam shaft

- 4. Parking brake connection

L-H007-1104EN

Figure 14. A Brake Configuration

1-14 Introduction

Page 23

L-H007-1104EN

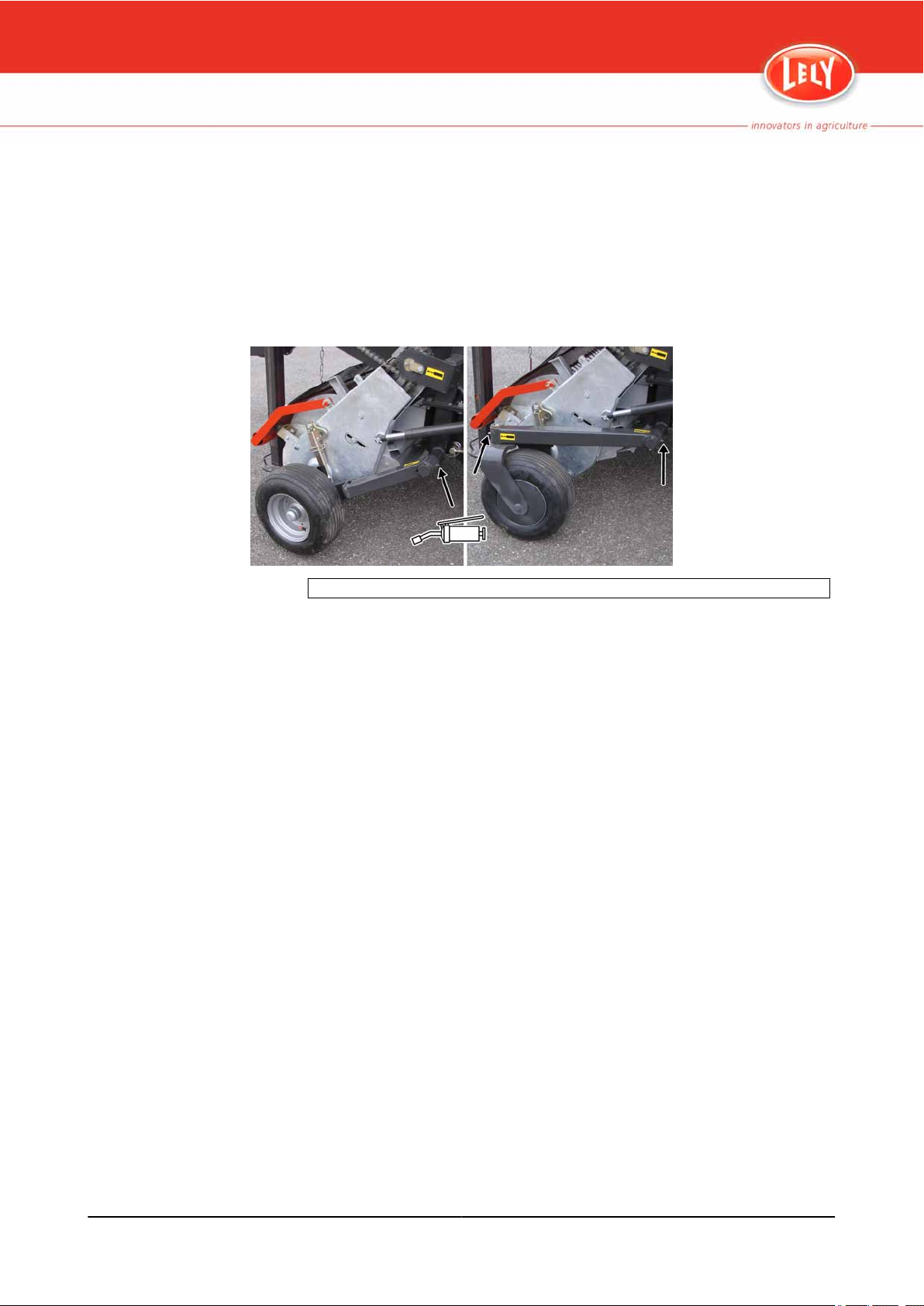

Left: version for manual setting (position A = air brake disabled, position B = carriage empty,

position C = carriage half full, position D = carriage full) - Right: ALB version

Figure 15. Pneumatic Break Force Valve

Introduction 1-15

Page 24

1.6 Hydraulic System

The hydraulic system can be used in combination with three different types of

tractor hydraulic systems:

conventional fixed displacement pump (the pump runs continuously and a

•

valve recycles the over-pressure)

• load sensing system (the pump capacity is controlled to deliver pressure

and flow on demand)

• closed centre system (the pump runs continuously but there is no recycle

flow if no valve is operated)

Most of the control valves are either:

• in a control panel in the tractor cabin (manually controlled valves)

or

• electrically controlled by an electric control panel in the tractor cabin

(Comfort system). In this case, the control valves are mounted under a

cover at the front-right side of the carriage.

1. Pin latch to hold the cover open - 2. Cover - 3. Label with valve assignments - 4. Hole in

cover (push a screwdriver through the hole to unlock the cover) - 5. Hydraulic hoses from/to

tractor - 6. Control panel connection - 7. Filter - 8. Valve block with control valves

Figure 16. Hydraulic Control Valves (Comfort System)

L-H007-1104EN

1-16 Introduction

Page 25

1.7 Drive System

The pick-up unit and the cutting unit are driven by the PTO connection of the

tractor. The transmission is as follows:

L-H007-1104EN

1. The

2. The PTO shaft drives the (angular) gear box via an overload protection.

3. The gear box is connected to the dog clutch that allows to engage/

4. The lateral shaft drives the rotor of the cutting unit via 3 gearwheels.

5. The middle gearwheel drives the pick-up unit via:

6. The pick-up unit shaft with the sprocket wheel drives the rotor with the

PTO of the tractor drives the telescopic PTO shaft of the Tigo. This

PTO shaft can be either:

• wide angle (max. 70°) at the tractor side and normal angle (max. 35°)

at the Tigo side

or

• wide angle at both sides (recommended in case of a movable

hydraulic drawbar)

disengage the lateral shaft. The lever for manual operation of the clutch

is at the front side of the Tigo. If the pick-up unit is lifted, an override

mechanism disengages the clutch, independent of the clutch lever

position.

• a sprocket wheel/chain transmission to a double sprocket wheel on

a mount on the main frame

• a sprocket wheel/chain transmission from the double sprocket wheel

to the sprocket wheel on the shaft of the pick-up unit

This configuration of two sprocket wheel/chain transmissions allows

the pick-up unit to be lifted/lowered.

tines via a freewheel clutch.

The overload protection on the PTO shaft is dedicated to the Tigo and prevents

damage to the cutting unit when it is jammed by a foreign object. If the shaft

torque exceeds 1400 Nm, the overload protection cuts off the transmission.

The overload protection can be reset by disengaging the dog clutch at low

rotational PTO speed (remove the blockage before engaging the clutch again).

The freewheel clutch of the pick-up unit allows the tines to rotate freely and,

therefore, protects the tines when the pick-up unit is not driven and the tines

touch objects on the ground during reverse driving.

Note:

Introduction 1-17

For details of the PTO shaft, see the manual of the PTO shaft.

Page 26

1. Safety cover of the overload protection - 2. Cover above the cutting unit (to open, release

the rubber hand grip at the front and use the strut in the lower right corner to hold the cover

open) - 3. Dog clutch lever (position A = clutch engaged, position B with lock = clutch

disengaged)

Figure 17. Dog Clutch Lever

1. End of lateral shaft (can be turned manually using the Lely Tigo Tool) - 2. Sprocket wheel

- 3. Chain - 4. Chain tensioner - 5. Lely Tigo Tool (stowed away) - 6. Mechanism to override

the dog clutch lever when the pick-up unit is lifted

L-H007-1104EN

Figure 18. External Parts of the Drive System

1-18 Introduction

Page 27

1.8 Control Panel

Most functions can be operated from a control panel that can be installed in

the tractor cabin. The control panel can be either hydraulic or electric.

1.8.1 Hydraulic Control Panel

The hydraulic control panel is connected to the tractor and the Tigo with

hydraulic hoses and has a mount that allows to install/uninstall the panel by

hand. The valves in the hydraulic control panel are to select a device, not to

extend/retract the corresponding ram. This is done via a control valve of the

tractor.

Lever 1: To lift and lower the pick-up unit

Set the lever to "Open" (the other levers should be set to "Closed").

1.

2. Lift/lower the pick-up unit using the general control valve of the tractor.

3. Set the lever back to "Closed".

Note:

WARNING

CAUTION

L-H007-1104EN

Note:

Leave the lever in the position "Open" and the general control valve in

the position for lowering during fodder crop loading.

Lever 2: To lift and lower the tailgate

Make sure that no persons are behind the tailgate.

Make sure that the tailgate latches are locked.

1. Set the lever to "Open" (the other levers should be set to "Closed").

2. Lift/lower the tailgate lifting arm using the general control valve of the

tractor.

3. Set the lever back to "Closed".

The tailgate will be unlocked/locked automatically.

Lever 3: To lift and lower the drawbar (if a hydraulic drawbar is present)

1. Set the lever to "Open" (the other levers should be set to "Closed").

2. Lift/lower the drawbar using the general control valve of the tractor.

3. Set the lever back to "Closed".

Lever 4: To fold the open superstructure up and down (if an open

superstructure with hydraulic ram is present)

1. Set the lever to "Open" (the other levers should be set to "Closed").

2. Fold up/down the open superstructure using the general control valve

of the tractor.

3. Set the lever back to "Closed".

To move the floor conveyor:

Introduction 1-19

Page 28

• The

hydraulic motor of the floor conveyor is directly connected to a second

general control valve of the tractor, so there is no lever to select it. The

control valve located near the hydraulic motor should be open to allow

control from the tractor cabin. The speed varies with the speed of the tractor

engine.

1. Select rams to lift/lower the pick-up unit - 2. Select rams to lift/lower the tailgate - 3. Select

ram to move the drawbar (optional) - 4. Select ram to fold the open superstructure (optional)

- 5. Panel mount - position A = closed, position B = open (select)

Figure 19. Hydraulic Control Panel

L-H007-1104EN

1-20 Introduction

Page 29

1.8.2 Comfort System

The Comfort system provides an electric control panel that is connected to the

Tigo with a cable and a connector and has a mount that allows to install/

uninstall the panel by hand.

S1: To lift and lower the pick-up unit

Hold in top position to lift the pick-up unit.

1.

2. Set to bottom position to lower the pick-up unit and to keep it low during

fodder loading.

3. Set to centre position to stop lifting/lowering, possibly leaving the pickup in an intermediate position.

S2: To lift and lower the drawbar (if a hydraulic drawbar is present)

1. Hold in top position to lift the drawbar.

2. Hold in bottom position to lower the drawbar.

3. Release to centre position to stop lifting/lowering the drawbar or when

the drawbar is at the upper/lower position.

S3: To move the knife assembly in and out (if hydraulic rams are present)

1. Hold in top position to move the knives in (the number of knives that

move in should be set in advance using the Lely Tigo Tool).

2. Hold in bottom position to move the knives out.

3. Release to centre position to stop moving out/in or when the knives are

fully out or in.

L-H007-1104EN

Note:

WARNING

CAUTION

Note:

S4: To move the floor conveyor

1. Make sure that the control valve located at the hydraulic motor is open

to allow control from the tractor cabin.

2. Set to bottom position to move the floor conveyor.

3. Set to centre position to stop the floor conveyor.

The top position has no function.

S5: To lift and lower the tailgate

Make sure that no persons are behind the tailgate.

Make sure that the tailgate latches are locked.

1. Hold in top position to lift the tailgate.

2. Hold in bottom position to lower the tailgate.

3. Release to centre position to stop lifting/lowering the tailgate or when

the tailgate is at the wide open/closed position.

The tailgate will be unlocked/locked automatically.

S6: To fold the open superstructure up and down (if an open superstructure

with hydraulic ram is present)

• Hold in top position to fold up the open superstructure.

Introduction 1-21

Page 30

• Hold in bottom position to fold down the open superstructure (only if the

carriage is empty).

• Release

to centre position to stop folding the open superstructure up/down

or when the open superstructure is fully folded up/down.

H1: Buzzer (optional)

• Sounds when both the floor conveyor is activated and the carriage is full

(sensor on the tailgate activated). Releasing switch S4 will end the sound.

S1 Lift/lower the pick-up unit - S2 Lift/lower the drawbar (optional) - S3 Move the knives in/out

(optional) - S4 Move the floor conveyor - S5 Lift/lower the tailgate - S6 Fold the open

superstructure up/down (optional) - H1 Buzzer for carriage full alert (optional) - H Plug to

connect the control panel to the Tigo - Bottom: control panel in mount

Figure 20. Electric Control Panel (Comfort System)

L-H007-1104EN

1-22 Introduction

Page 31

1.9 Optional Extras

1.9.1 Lely Grinder

The Lely grinder quickly and correctly sharpens the knives of the Lely Tigo. A

blunt

is moved at the correct angle across the blade of the knife.

knife is installed in a supporting frame. To sharpen the knife, the grinder

L-H007-1104EN

Figure 21. Lely Grinder

Introduction 1-23

Page 32

L-H007-1104EN

1-24 Introduction

Page 33

2.1 Signal Words

2. SAFETY

This chapter contains safety instructions you must obey when you use or do

maintenance on your Lely Tigo. It also explains the safety decals on the Lely

Tigo.

Note the use of the signal words DANGER, WARNING and CAUTION. The

signal word for each message uses the following guidelines:

DANGER

WARNING

CAUTION

Note:

2.2 Safety Instructions

L-H007-1104EN

Danger: Indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury.

Warning: Indicates a potentially hazardous situation that, if not avoided,

could result in death, serious injury or product damage, and includes

hazards that are exposed when guards are removed.

Caution: Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury or damage to the product or property.

Note: This shows extra information that may help the reader.

General safety instructions:

• Read this manual completely before operating the Tigo. If anything is not

clear, please contact your local dealer.

• Use the Tigo only for the purpose for which it was designed.

• Follow all safety regulations, including those in this manual and instructions

or warnings indicated on the machine.

• Always be alert on hazards and unusual signs (such as leakage and noise).

Observe all safety precautions.

• Let the Tigo be operated, driven and maintained by authorised persons

only.

• Use protective clothing, gloves, safety glasses and ear protectors, if

necessary.

• Keep people and objects away from moving parts.

• Always use a tractor with a cab.

• Clean the safety decals regularly so that they can be read at all times.

Replace the safety decals if necessary.

Safety instructions for preparing operation:

• Always connect the Tigo to the tractor as described in this manual. Only

connect the Tigo to a tractor trailer hitch that complies with your local

regulations.

Safety 2-1

Page 34

• Make sure the front axle weight of the tractor is sufficient and that you do

not exceed the rear axle weight.

• Never

connect the Tigo to the tractor when the tractor engine is still running.

• Depressurize the hydraulic system before you connect hydraulic hoses.

• If the Tigo has a hydraulic or pneumatic brake, connect the brake hose(s)

to the tractor.

• Make sure all safety guards and protection devices are installed and

function correctly.

• Always test the brakes before operation. Never drive the Tigo with damaged

brakes.

• Make sure all the lights on the Tigo operate correctly. Make sure the lights

are not covered by dirt.

• Before traveling:

• make sure the (hydraulic) drawbar is in the transport position

• make sure the parking jack is lifted and locked

• make sure the pick-up unit is lifted

• make sure the tailgate is closed and locked

• make sure that all other movable parts (such as the foldable

superstructure and covers) are locked

Safety instructions for driving on public roads:

• Always obey your local road traffic regulations.

• Use flashing lights or other safety signs, when necessary.

• Be alert on the maximum height when approaching bridges, tunnels,

electrical lines etc.

• Do not allow passengers unless there is an extra seat in the tractor. Persons

shall never be transported in or on the Tigo.

• Do not operate the hydraulics when driving on the public road.

Safety instructions for operation:

• Operate the Tigo in a safe manner.

• Make sure no people are in the danger zone when the Tigo is in operation.

This is especially important when you work near or on areas that are

accessible to the public.

• Make sure there are no objects in the field that could be thrown up by the

Tigo.

• Do not stand in or on the Tigo.

• Do not make sudden curves when driving uphill or downhill.

• Always reduce your driving speed when driving downhill.

• Do not disconnect the clutch or change gears on a slope.

• Do not exceed the maximum load or maximum axle loads.

Safety instructions for ending operation:

L-H007-1104EN

• Depressurize the hydraulic system before you disconnect hydraulic hoses.

• Always park the Tigo on a flat stable ground.

2-2 Safety

Page 35

• Before disconnecting the Tigo from the tractor:

make sure the parking jack is on the ground

•

• make sure the parking brake is engaged

• make sure the wheel wedges are placed

Safety instructions for maintenance and troubleshooting:

• Stop the tractor engine, the Power Take-Off (PTO) and all moving parts

before doing maintenance or troubleshooting. Never reach into moving

parts or parts that may come life.

• Install the wheel wedges to prevent the Tigo from moving before doing

maintenance.

• Make sure the covers are well locked if they are open.

• Obey the maintenance schema in this manual.

• Do not modify the Tigo.

• Only use genuine Lely parts.

2.3 Explanation of the Safety Decals

L-H007-1104EN

Read the manual and the safety instructions before operating the

machine.

Stay away from the tailgate as long as the tractor may drive

backwards or the tailgate may be operated.

Keep hands away from (external) machine parts as long as they

may come live.

Safety 2-3

Page 36

Keep hands away from internal machine parts as long as the

machine is not completely stationary or may come live.

Do not step on the floor conveyor as long as its hydraulic motor is

moving or may come live.

Stop the tractor engine and remove the key from the tractor ignition

lock before doing troubleshooting or maintenance.

L-H007-1104EN

Release the pressure of the hydraulic and/or pneumatic system

before doing troubleshooting or maintenance.

Stay away from the pick-up unit as long as the PTO shaft is

connected and the tractor engine is running.

2-4 Safety

Page 37

L-H007-1104EN

Regularly check the wheel nuts for tight

fit.

Do not exceed the maximum PTO speed of 540 rpm.

Do not exceed the maximum driving speed of 25 km/h.

Safety 2-5

Page 38

L-H007-1104EN

2-6 Safety

Page 39

3. FIRST USE

3.1 Finish the Superstructure

L-H007-1104EN

1. Hook

2. Fasten the rear tarpaulin between the bow and the tailgate boom using

3. Fasten the (optional) front-top tarpaulin to the front wall using the

the top rigging ropes between the hooks on the front wall and the

hooks on the bow, thereby leading the ropes through the lugs on the

middle crossbar (if applicable). In case of the open superstructure, also

attach the side rigging ropes by looping them through the lugs on the

bow corners and hooking the springs at the ends of the ropes to the lugs

on the front wall corners.

the mounting rod at the bow side. Secure the mounting rod with a linch

clip at both sides.

mounting rod. Secure the mounting rod with a linch clip at both sides.

Tighten the other side of the tarpaulin to the lugs on the side walls using

the expander ropes (one at each side).

1. Mounting rod - 2. Optional front-top tarpaulin - 3. Expander rope - 4. Bow - 5. Mounting rod

for rear tarpaulin - 6. Side rigging rope - 7. Top rigging rope - 8. Front wall

Figure 22. Finish the Open Superstructure

First Use 3-1

Page 40

3.2 Adjust the Length of the PTO Shaft

CAUTION

The first time you connect the Tigo to each tractor, refer to the instructions

supplied with the PTO shaft and make sure the minimum and maximum

overlap of the two parts of the PTO shaft is correct.

Disconnect the two halves of the telescopic PTO shaft.

1.

2. Hold the two PTO shaft halves next to each other in the shortest

operating position.

3. Mark the shortest operating position on the outer safety guard tube.

4. Substract 40 mm from the first mark and mark it with a second mark.

5. Remove the safety guard tubes from the PTO shaft halves.

6. Shorten the outer safety guard tube of the PTO shaft at the second mark.

7. Shorten the inner safety guard tube by the same distance.

8. Shorten the inner and outer PTO shaft halves by the same distance.

9. Deburr and clean the safety guard tubes and the PTO shaft halves.

10. Install the safety guard tubes on the PTO shaft halves.

11. Connect the two PTO shaft halves.

Figure 23. Shorten the Inner Safety Guard Tube and the PTO-shaft halves

Figure 24. Mark the Outer Safety Guard Tube of the PTO shaft

L-H007-1104EN

3-2 First Use

Page 41

3.3 Install the PTO Shaft with the Overload Protection

1. Clean and grease the profile of the main drive shaft of the Tigo.

Loosen and turn out the clamping cone of the overload protection.

2.

3. Open the maintenance hole in the guard cone. Slide the overload

protection (with the connected PTO shaft) onto the drive shaft so that

the location hole points towards the maintenance hole.

4. Position the location hole for the clamping cone above the ring groove

of the shaft.

5. Turn the clamping cone into the location hole and tighten firmly

(approximately 70 Nm) while moving the hub slightly to and fro in

longitudinal direction.

6. Check if the seat of hub of the overload protection is tight and firm by

compression and tensioning movements.

7. Close the maintenance hole in the guard cone.

L-H007-1104EN

1. Clamping cone - 2. Location hole - 3. Ring groove of the main drive shaft

Figure 25. Install the PTO Shaft with the Overload Protection

First Use 3-3

Page 42

3.4 Adjust the Height of the Drawbar

The height of the drawbar should be adjusted so that, when the Tigo is

connected to the tractor in travelling position, the upper edge of the front

crossbeam

is important for the optimal performance of the pick-up unit. The way to adjust

the height depends on the type of drawbar. In both cases the tractor and the

Tigo should be on a flat ground, with the Tigo connected to the tractor and the

parking jack slightly above the ground.

of the main frame is approximately 118 cm above the ground. This

Figure 26. Optimal Drawbar Height

L-H007-1104EN

3-4 First Use

Page 43

3.4.1 Drawbar with Spindle

Note:

Note that the threads at the left and the right side of the spindle are

opposite.

Release both counter nuts of the spindle.

1.

2. Adjust the spindle as necessary.

3. Tighten both counter nuts.

L-H007-1104EN

1. Spindle - 2. Counter nuts

Figure 27. Adjust the Height of a Drawbar with a Spindle

First Use 3-5

Page 44

3.4.2 Drawbar with Hydraulic Ram

1. Release the pressure of the hydraulic ram.

Remove the split pin of the pin of the piston rod end eye. Do not yet

2.

remove the pin.

3. Loosen the hexagon locking bolt of the piston rod.

4. Lower the parking jack until it rests on the ground.

5. Remove the pin of the eye of the piston rod end.

6. Screw the piston rod end in or out as necessary.

7. Re-insert the pin through the eye of the piston rod end.

8. Lift the parking jack slightly above the ground by turning its crank.

9. Verify if the drawbar height is correct. If this is not the case, repeat the

steps 4 - 9.

10. Tighten the hexagon locking bolt of the piston rod.

11. Re-install the split pin to secure the pin of the piston rod end eye.

1. Hexagon locking bolt - 2. Piston rod end - 3. Split pin - 4. Pin

Figure 28. Adjust the Height of a Drawbar with Hydraulic Ram

L-H007-1104EN

3-6 First Use

Page 45

3.5 Adapt the Electric Power Connection

In case of the Comfort system, the electric cable to be connected to the tractor

does not only transfer the light signals, but also the electric power for the

hydraulic control valve system. For this, the tractor shall provide continuous

power on the 54g terminal (+) and the 31 terminal (-) of the 7-pole socket on

the tractor side. It is best to have these terminals wired directly to the tractor

battery with 2.5 mm2 wire and a fuse of 16 A for the anode (+).

Figure 29. Direct Continuous Power Wire for the Comfort System

L-H007-1104EN

First Use 3-7

Page 46

3.6 Connect the Electric Cables

1. Connect

the cable of the lighting system to the 7 pole socket at the right

front of the Tigo.

2. If the Tigo has a Comfort System, connect the cable of the control panel

to the socket near the hydraulic valves under the cover at the front right

side.

1. Socket for lighting system cable (including power for the Comfort system) - 2. Socket for

control panel (Comfort system)

Figure 30. Connect the Electric Cables

L-H007-1104EN

3-8 First Use

Page 47

3.7 Adjust the Load Sense Adjustment Screw

In case of the Comfort system, there is a Load Sense adjustment screw that

needs adjustment depending on the hydraulic system of the tractor.

CAUTION

L-H007-1104EN

Only make adjustments when there is no pressure on the hydraulic system

(preferably switch off the tractor).

for a conventional fixed displacement pump system: screw out to the end

•

point

• for a load sensing system: screw in to the end point

• for a closed centre system: screw in to the end point

Figure 31. Adjust the Load Sense Adjustment Screw

First Use 3-9

Page 48

3.8 Examine the Lever Setting of the ALB

If the Tigo has an Automatic Load-sensitive Brake system:

Make sure that the length of the lever of the automatic load responsive

•

regulating valve is the same as the length described on the Wabco or

Haldex performance label.

Figure 32. Examine the Lever Setting of the ALB Valve

L-H007-1104EN

3-10 First Use

Page 49

4.1 At First

4. BEFORE OPERATION

When the Tigo is not connected to the tractor, it shall rest on its parking jack,

the parking brake shall be engaged and the wheel wedges shall be placed.

maintenance (greasing, replacement of lubricating oil, cleaning of filters

• All

etc.) should have been done according to the maintenance schema. The

knives of the cutting unit should be sharp and well adjusted.

• Make sure that the tyres are at the right air pressure (page 9-7).

• Make sure that the wheel nuts are tight (page 9-6).

• Make sure that all safety covers are in a good condition and closed.

• Make sure that all hoses and cables are in good condition.

• Make sure that hinged assembly parts (tailgate, foldaway open

superstructure, covers etc.) are locked.

L-H007-1104EN

Before Operation 4-1

Page 50

4.2 Connect the Cables and Hoses to the Tractor

WARNING

WARNING

Make sure there are no persons near the Tigo when you connect it to the

tractor.

When connecting hydraulic hoses, take care not to swap the pressure

side and the return side by mistake.

Reverse the tractor to the drawbar and make sure the tractor and the

1.

Tigo are aligned.

2. If the Tigo does not have a Comfort system:

• Connect the red-marked hydraulic hose of the hydraulic control panel

to a single acting control port of the tractor.

• Connect the red-marked hydraulic hose of the hydraulic motor of the

floor conveyor to another single acting control port of the tractor.

• Connect the blue-marked common return hydraulic hose to a

pressure-free return port of the tractor.

3. If the Tigo has a Comfort system:

• Connect the red-marked hydraulic hose to a single acting control port

of the tractor.

• Connect the blue-marked hydraulic hose to a pressure-free return

port of the tractor.

4. If the Tigo has a load sensing hose:

• Connect the red-marked hydraulic hose to a hydraulic power outlet

of the tractor.

• Connect the red-marked load sensing hose (hose with smallest

diameter) to the load sensing port of the tractor.

• Connect the blue-marked hydraulic hose to a pressure-free return

port of the tractor.

5. If the Tigo has a hydraulic brake system:

1. Connect the hydraulic brake hose to the tractor trailer brake

socket.

2. Make sure that the brakes operate correctly.

6. If the Tigo has a pneumatic brake system:

1. Make sure that the sealing rings in the brake coupling heads are

clean and in good condition.

2. Connect the red-marked air hose to a red marked air socket on

the tractor.

3. Connect the yellow-marked hose to a yellow marked air socket

on the tractor.

4. Make sure that the brakes operate correctly and that there is no

air leaking through the coupling head seals.

7. Connect the plug of the electric cable to the 7-pole socket of the tractor.

8. Make sure all the lights on the Tigo operate correctly.

L-H007-1104EN

4-2 Before Operation

Page 51

9. Install

the control panel (either hydraulic or electric) on the mount in the

tractor cabin.

1. Red-marked hydraulic hose - 2. Blue-marked hydraulic hose - 3. Red-marked load sensing

hose - 4. Red-marked air hose - 5. Yellow-marked air hose - 6. Red-marked hydraulic brake

system hose

Figure 33. Hydraulic and Pneumatic Hoses

L-H007-1104EN

Before Operation 4-3

Page 52

4.3 Connect the Tigo to the Tractor

WARNING

WARNING

CAUTION

Make sure there are no persons near the Tigo when you connect it to the

tractor.

Always switch off the tractor engine and remove the ignition key before

you leave the tractor cab.

Do not move the Tigo with the parking jack in its lowest position.

1.

Make sure that the tractor coupling system is aligned with the drawbar

of the Tigo. Align the drawbar in height by turning the crank of the parking

jack.

2. Connect the Tigo to the tractor:

1. Bring the drawbar coupling eye into the coupling fork of the

tractor.

2. Install the pin.

3. Secure the pin with the pin lock.

3. If the Tigo has a parking brake lever with a nylon break-away rope,

attach the rope end to the tractor.

4. Retract the parking jack:

1. Turn the crank of the parking jack clockwise to release the parking

jack foot from the ground. Turn until the telescopic part of the

stand is fully upwards (otherwise, the pin can not be inserted in

step 4).

2. Remove the pin that locks the stand.

3. Lift the telescopic part of the stand by the hand grip on the foot

plate.

4. Re-install the pin.

5. Pull down the hinge locking pin and swivel the hinge towards the

front crossbar.

6. Release the hinge locking pin.

L-H007-1104EN

5. If the Tigo has a hydraulic drawbar, lower the drawbar to the transport

position.

WARNING

4-4 Before Operation

Make sure the tractor PTO is disengaged before you connect the PTO

shaft to the tractor PTO.

6. Connect the PTO shaft to the tractor PTO.

7. Secure the PTO guard against rotating by fixing its chain to a rigid part

of the tractor.

8. Remove the wheel wedges and store them in the mounts under the

carriage, behind the (rear) wheels.

9. Disengage the parking brake by pulling the lever a bit forward, then fully

backward.

Page 53

L-H007-1104EN

1. Crank - 2. Pin - 3. Hinge - 4. Hinge locking pin - 5. Stand - 6. Telescopic bottom part of the

stand with foot plate

Figure 34. Move the Parking Jack to the Top Position

Figure 35. Connect to the Tractor

Before Operation 4-5

Page 54

4.4 Adjust the Working Depth of the Pick-up

The pick-up tines should be slightly above the ground during loading fodder

crop. They should never scratch along the ground. Stony ground requires a

higher setting. Adjust the working depth as follows:

Lift the pick-up unit.

1.

2. On both sides of the pick-up:

1. Remove the linch clip from the slotted bar.

2. Adjust the guide wheel to the applicable position and re-install the

linch clip into the corresponding slot of the slotted bar.

3. Make sure that the position of the guide wheels is the same at both sides.

4. Lower the pick-up unit to the ground and make sure that the working

depth is correct.

1. Linch clip - 2. Slotted bar

Figure 36. Adjust the Working Depth of the Pick-up Unit

L-H007-1104EN

4-6 Before Operation

Page 55

4.5 Adjust the Height of the Wind Guard

The optimal height of the wind guard depends on the type of fodder crop. Fine

fodder crop requires a somewhat lower setting than coarse fodder crop. As a

starting

Set the wind guard height as follows:

1. Remove the linch clip from the lug on the drawbar from which the wind

2. Suspend the wind guard chain from the lug at the appropriate link.

3. Re-install the linch clip.

point, adjust the height so that the wind guard just touches the swath.

guard chain is suspended.

L-H007-1104EN

1. Wind Guard - 2. Chain - 3. Lug with linch clip

Figure 37. Adjust the Height of the Wind Guard

Before Operation 4-7

Page 56

4.6 Fold Up the Open Superstructure

In case of an open superstructure without a hydraulic ram:

Take the rocker lever that is stowed on the axle support cross beam.

1.

2. Install the rocker lever by sticking its fork on the stud on the rung, then

swiveling the rocker lever on the pin. Secure the rocker lever using the

linch clip.

3. Remove the R-clip from the pin that holds the brace arm.

4. Release the brace arm by pulling its hand grip.

5. Pull the rocker lever downwards to fold up the superstructure.

6. Re-install the brace arm on the pin and secure it with the R-clip.

7. Remove the linch clip that secures the rocker lever and remove the

rocker lever from the pin and the stud.

8. Stow the rocker lever on the axle support cross beam.

Folding down is done in the same way, but then pushing the rocker lever

upwards in step 5.

In case of an open superstructure with a hydraulic ram, just operate the ram.

CAUTION

Always mind the available overhead space when driving through doors,

tunnels etc.

L-H007-1104EN

4-8 Before Operation

Page 57

L-H007-1104EN

1. Rocker lever - 2. Stud - 3. Pin for rocker lever - 4. Linch clip - 5. Brace arm - 6. Pin for brace

arm - 7. R-clip

Figure 38. Fold the Open Superstructure - Mount Rocker Lever, Release Brace

Arm and Fold

Before Operation 4-9

Page 58

Figure 39. Fold the Open Superstructure - Secure Brace Arm and Remove

Rocker Lever

L-H007-1104EN

4-10 Before Operation

Page 59

4.7 Select the Number of Knives

Using the Lely Tigo Tool, select the appropriate number of knives by moving

movable upper sub-group and/or the (optional) lower knife group in or out.

the

Note:

L-H007-1104EN

The (optional) lower knife group does not have a sub-group dat can be

moved in or out. It is only possible to move the whole lower knife group

in or out.

To move the (sub-)group out:

1. Place the Lely Tigo Tool on the cam of the (sub-)group (right side of the

Tigo).

2. In case of the upper sub-group:

1. Pull the Lely Tigo Tool slightly counterclockwise and hold it to

release the tension from the safety link.

2. Release the safety link from the pin.

3. Pull the Lely Tigo Tool clockwise to move the (sub-)group out.

To move the (sub-)group in:

1. Place the Lely Tigo Tool on the cam of the (sub-)group (right side of the

Tigo).

2. Pull the Lely Tigo Tool counterclockwise to move the (sub-)group in.

3. In case of the upper sub-group:

1. Hold the Lely Tigo Tool pulled counterclockwise.

2. Attach the safety link to the pin.

4. Remove the Lely Tigo Tool.

Before Operation 4-11

Page 60

1. Cam - 2. Safety link - 3. Pin - 4. Knife - 5. Lely Tigo Tool - Upper figure: 17 knives in, lower

figure: 5 knives in

Figure 40. Select the Number of Knives of the Upper Knife Group

L-H007-1104EN

4-12 Before Operation

Page 61

L-H007-1104EN

1. Cam - Position A = in, position B = out

Figure 41. Select the Knives of the (Optional) Lower Knife Group

Before Operation 4-13

Page 62

4.8 Drain the Air Container

If the Tigo has a pneumatic brake:

Use a wire to pull the pin of the drain valve to drain the water from the air

•

container of the brake system (located under the carriage, behind the (rear)

wheel). If the drainage valve is clogged, screw it out, clean it and screw it

in again.

WARNING

Make sure the pressure of the pneumatic brake system is not less than

5 bar before you start driving (read the pressure gauge of the tractor

pneumatic system).

Figure 42. Drain the Water From the Air Container of the Brake System

L-H007-1104EN

4-14 Before Operation

Page 63

5. OPERATION

5.1 Load the Fodder Crop

WARNING

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

L-H007-1104EN

Make sure no persons are near the Tigo when you engage the PTO.

Make sure no persons are within a 25 meter radius of the Tigo during

operation.

Do not exceed the maximum PTO speed of 540 rpm.

Always switch off the tractor engine before you leave the tractor cab.

Do not operate the Tigo without safety guards or covers, or if the safety

guards or covers are damaged.

Always operate the Tigo with the safety guards or covers down and

engaged in the clamping blocks.

Always keep the tailgate closed when you drive on public roads.

1.

Position the tractor at the beginning of the swath.

2. Carefully engage the PTO at the lowest possible engine speed.

3. Slowly increase the speed of the PTO to the maximum of 540 rpm.

4. Lower the pick-up unit to the ground.

5. Drive the tractor over the swath. The pick-up performance is best at

higher speeds.

6. Before making a (sharp) turn:

• Lift the pick-up unit.

• Disengage the PTO.

7. Regularly activate the floor conveyor to move the collected fodder crop

to the rear. When the (optional) buzzer sounds upon activating the floor

conveyor, the Tigo is full. In that case stop loading:

1. Lift the pick-up to the top position.

2. Disengage the PTO.

3. Return to the unloading site.

Operation 5-1

Page 64

5.2 Remove a Blockage by Moving the Knives Out and In

WARNING

Never reach into the pick-up unit, the cutting unit or the conveyor

channel, when the tractor engine is still running.

Disengage the PTO.

1.

2. Move the knives out:

• If the cutting unit has no hydraulic rams for moving the knives in and

out:

1. Place the Lely Tigo Tool on the cam of the turnbuckle.

2. Push the Lely Tigo Tool clockwise and remove the locking plate

that locks the turnbuckle fork.

3. Pull the Lely Tigo Tool counterclockwise.

• If the cutting unit has hydraulic rams for moving the knives in and out:

use the control panel.

3. Engage the PTO at the lowest possible speed.

4. If the overload protection is reset (so that the Tigo is driven again), move

the knives in:

• If the cutting unit has no hydraulic rams for moving the knives in and

out:

1. Pull the Lely Tigo Tool on the cam of the turnbuckle clockwise.

2. Lock the turnbuckle fork with the locking plate.

3. Remove the Lely Tigo Tool from the cam.

• If the cutting unit has hydraulic rams for moving the knives in and out:

use the control panel.

L-H007-1104EN

WARNING

5. If the blockage has been resolved, the procedure ends here. Otherwise,

proceed with the next steps.

6. Disengage the PTO.

7. Move the knives out (see step 2).

8. Stop the tractor engine.

9. Disengage the dog clutch.

10. Rotate the gear in reverse using the Lely Tigo Tool as a crank on the

end of the lateral shaft.

11. Remove the blocking object(s).

Remove the Lely Tigo Tool from the lateral shaft before engaging the dog

clutch.

12. Engage in the dog clutch.

13. Start the tractor engine.

14. Engage the PTO.

15. Move the knives in (see step 4).

5-2 Operation

Page 65

L-H007-1104EN

Figure 43. Rotate the Gear Manually

Operation 5-3

Page 66

1. Lely Tigo Tool (installed on the cam of the turnbuckle) - 2. Lip to be locked by the locking

plate - 3. Locking plate on turnbuckle fork

Figure 44. Move All Knives Out (Top) and In (Bottom)

L-H007-1104EN

5-4 Operation

Page 67

5.3 Unload the Tigo

WARNING

WARNING

WARNING

Make sure that no persons are behind the tailgate.

Make sure no persons are in the carriage when the floor conveyor is

activated.

Make sure no persons are near the Tigo when the hydraulic drawbar is

raised or lowered.

1.

Position the rear of the Tigo to the appropriate location.

2. If the overhead space allows lifting of the tailgate:

1. Make sure that the tailgate is locked in the tailgate latches.

2. Lift the tailgate.

3. If the overhead space does not allow lifting of the tailgate:

1. Unlock the tailgate latches.

2. Unlock the tailgate.

4. If the Tigo has a hydraulic drawbar and will be unloaded on a silage

clamp:

• Tilt the Tigo by lowering the drawbar. The increased clearance

between the pick-up unit and the ground decreases the risk of

damaging the pick-up unit.

L-H007-1104EN

5. Activate the floor conveyor (either from the tractor cabin or from the

control valve next to the tailgate).

6. If the Tigo is empty, stop the floor conveyor.

7. If the Tigo was tilted, bring the drawbar back to the transport position.

8. If the tailgate was lifted, lower the lifting arms until the tailgate is locked.

9. If the tailgate was not lifted:

1. Drive the Tigo to a place where the overhead space allows lifting

of the tailgate.

2. Lift the tailgate.

3. Lower the lifting arms until the tailgate is locked.

Figure 45. Tilt the Tigo by Lowering the (Optional) Hydraulic Drawbar

Operation 5-5

Page 68

L-H007-1104EN

5-6 Operation

Page 69

6. AFTER OPERATION

6.1 Disconnect the Tigo from the Tractor

WARNING

WARNING

WARNING

WARNING

WARNING

L-H007-1104EN

Unload the Tigo before you disconnect it from the tractor.

Always position the tractor on solid ground before you disconnect the

Tigo from the tractor.

Make sure there are no persons near the Tigo when you disconnect it

from the tractor.

Always switch off the tractor engine before you leave the tractor cab.

Always engage the parking brake and install wheel wedges before you

disconnect the Tigo from the tractor.

1.

Lower the parking jack:

1. Pull down the hinge locking pin and swivel the parking jack

forward.

2. Remove the pin that locks the stand (hold the telescopic part of

the stand by the hand grip on the foot plate).

3. Lower the telescopic part of the stand.

4. Re-install the pin of the stand.

5. Turn the crank of the parking jack counterclockwise until the foot

plate rests on the ground.

WARNING

2. Turn the parking jack crank further until the coupling eye of the drawbar

does not longer rest on the coupling fork of the tractor.

3. If the Tigo has a parking brake lever with a nylon break-away rope,

loosen the rope from the tractor.

4. Engage the parking brake by pulling the lever forward beyond the slack

point.

5. Place the wheel wedges (these are stowed under the carriage, behind

the (rear) wheels).

6. If the Tigo is hydraulically or pneumatically braked from the tractor:

• Disconnect the brake hoses and put the hose ends in the hose

holders on the drawbar.

7. Disconnect the hydraulic hoses from the tractor and put the hose ends

in the hose holders on the drawbar.

8. Unplug the electric cable from the tractor.

9. Unmount the (hydraulic or electric) control panel and remove it from the

tractor cabin.

Make sure the tractor PTO is disengaged before you disconnect the PTO

shaft from the tractor PTO.

10. Loosen the safety chain of the PTO guard at the tractor side.

After Operation 6-1

Page 70

11. Disconnect

the PTO shaft from the tractor PTO. At the side of the Tigo,

the PTO shaft may stay connected with the overload protection on the

main drive shaft.

12. Disconnect the Tigo from the tractor:

1. Remove the pin lock.

2. Remove the pin.

3. Drive the tractor away from the Tigo.

13. Do the 10 hours maintenance.

L-H007-1104EN

6-2 After Operation

Page 71

7. TEST AND ADJUSTMENT

7.1 Remove and Install the Knife Assembly

7.1.1 Remove the Knife Assembly

1. Move the knives out.

Loosen the turnbuckle forks at the left and the right side of the knife

2.

assembly: