Leister WELDPLAST S2, WELDPLAST S2-PVC, WELDPLAST S2-TPO User Manual

WELDPLAST

S2

S2-PVC

S2-TPO

Leister Process Technologies

Galileo-Strasse 10

CH-6056 Kaegiswil/Switzerland

Tel. +41-41662 74 74

Fax +41-41662 74 16

www.leister.com

sales@leister.com

®

GB

1

2

Leister WELDPLAST S2 / S2-PVC / S2-TPO

Hand extruder

Extrusion welding of the following materials:

WELDPLAST S2 PP / PE-HD / PE-LD

WELDPLAST S2-PVC PP / PE-HD / PE-LD / PVC-U

WELDPLAST S2-TPO PP / PE-HD / PE-LD / TPO

Other materials on enquiry

The welding seam shape of the hand extruder does correspond to norm DVS 2207–4.

DVS : Deutscher Verband für Schweisstechnik

Application

Please read operating instructions carefully before

use and keep for further reference.

Operating instructions

GB

Danger to life!

Danger to life when opening up the tool, as live components and

connections are exposed. Before opening the tool, unplug from the

mains supply. Electrically conducting material (e.g. PE-EL) must not

be welded.

Fire and explosion hazard with incorrect use of the hand extruder

(e.g. overheating of the material), especially near combustible

materials and explosive gases.

The tool must be operated under supervision.

Heat can ignite flammable materials which are not in view.

The machine may only be used by qualified specialists or under

their supervision. Children are not authorized to use this machine.

For personal protection on building sites we strongly recommend

the tool to be connected to a RCCB (Residual Current Circuit

Breaker).

The voltage rating stated on the name plate of the tool must

correspond to the mains voltage.

In case of a power outage, the main switch and the drive must be

switched off (loosen lock).

Danger of getting burned! Do not touch exposed metal parts

and escaping plastizised material. Do not point the hot air flow

and escaping plastizised material in the direction of people or

animals.

Protect tool from dampness and wet.

FI

120

230

Warning

Caution

Connect the tool to a mains socket with protective earth.

Every interruption of the protective earth inside or outside of the

tool is dangerous!

Only use extension cables with protective earth!

1

3

Technical data

Voltage V~ 230

power consumption W 3000

Frequency Hz 50/60

Air flow (20°C) l/min ca. 270

Air temperature °C max. 350

Plastifizer temperature °C max. 260

Welding output (Ø 3 mm) kg/h

PE 0.6 –1.3 PP 0.5 –1.2 *PVC-U 0.9 –1.7 (Average values at 50 Hz)

Welding output (Ø 4 mm) kg/h

PE 1.0 – 2.3 PP 0.9 – 2.0 *PVC-U 1.5 –2.7 (Average values at 50 Hz)

Welding rod mm Ø 3 / Ø 4

Size L × B × Hmm450 × 98 × 260 (without welding shoe)

Weight kg 5.8 (without cable to mains)

Marking of conformity 2

Approval mark

3

Certification scheme CCA

Protection class I 1

* WELDPLAST S2-PVC

Leister Process Technologies, Galileo-Strasse 10, CH-6056 Kaegiswi/Switzerland confirms

that this

product, in the version as brought into circulation through us, fulfils the requirements

of the following EC directives. Directives:

2004/108, 2006/95.

Harmonized Standards:

EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3, EN 61000-6-2,

EN 50366, EN 60335-2-45

Kaegiswil, 06.02.2009

Bruno von Wyl Christiane Leister

Technical Director Owner

Power tools, accessories and packaging should be sorted for environmental-friendly

recycling. Only for EC countries: Do not dispose of power tools into household

waste! According to the European Directive 2002/96 on waste electrical and

electronic equipment and its incorporation into national law, power tools

that

are no longer suitable for use must be separately collected and sent for

recovery in an environmental-friendly manner.

Disposal

Conformity

4

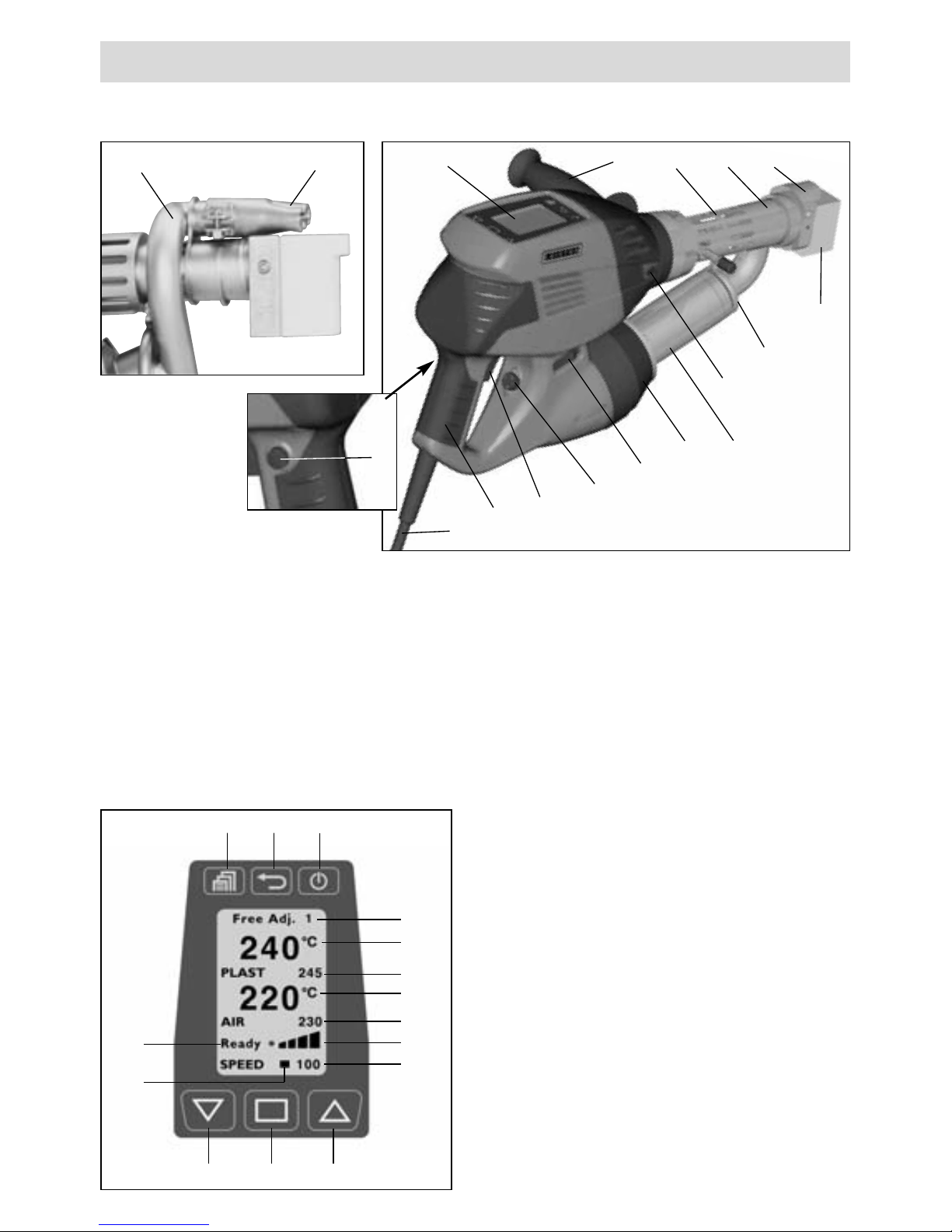

Description of tool

1 Main switch

2 On/off switch drive

3 Potentiometer

4 Drive locking device

5 Display

6 Handle

7 Jacket heating

8 Welding shoe

17 Welding program

18 Actual value plast

19 Set value plast

20 Actual value air

21 Set value air

22 Bar display for drive

23 Welding output display

24 Menu key

25 Back key

26 Stand-by/Enter key

27 Down key

28 Select key

29 Up key

30 Status display for drive

31 Cursor

9 Pre-heating nozzle

10 Tube clamp

11 Protective tube

12 Welding rod opening

13 Tool handle

14 Mains cable

15 Heating element

16 Hot air blower (brush-free)

44 External hot air duct

24

27 28 29

30

31

17

18

19

20

21

22

23

25 26

Multifunctional display

With integrated air ductWith external air duct

1

12

16

8

10

3

2

4

13

5

7

14

11

9

6

15

9

44

5

Operating

Working environment / safety

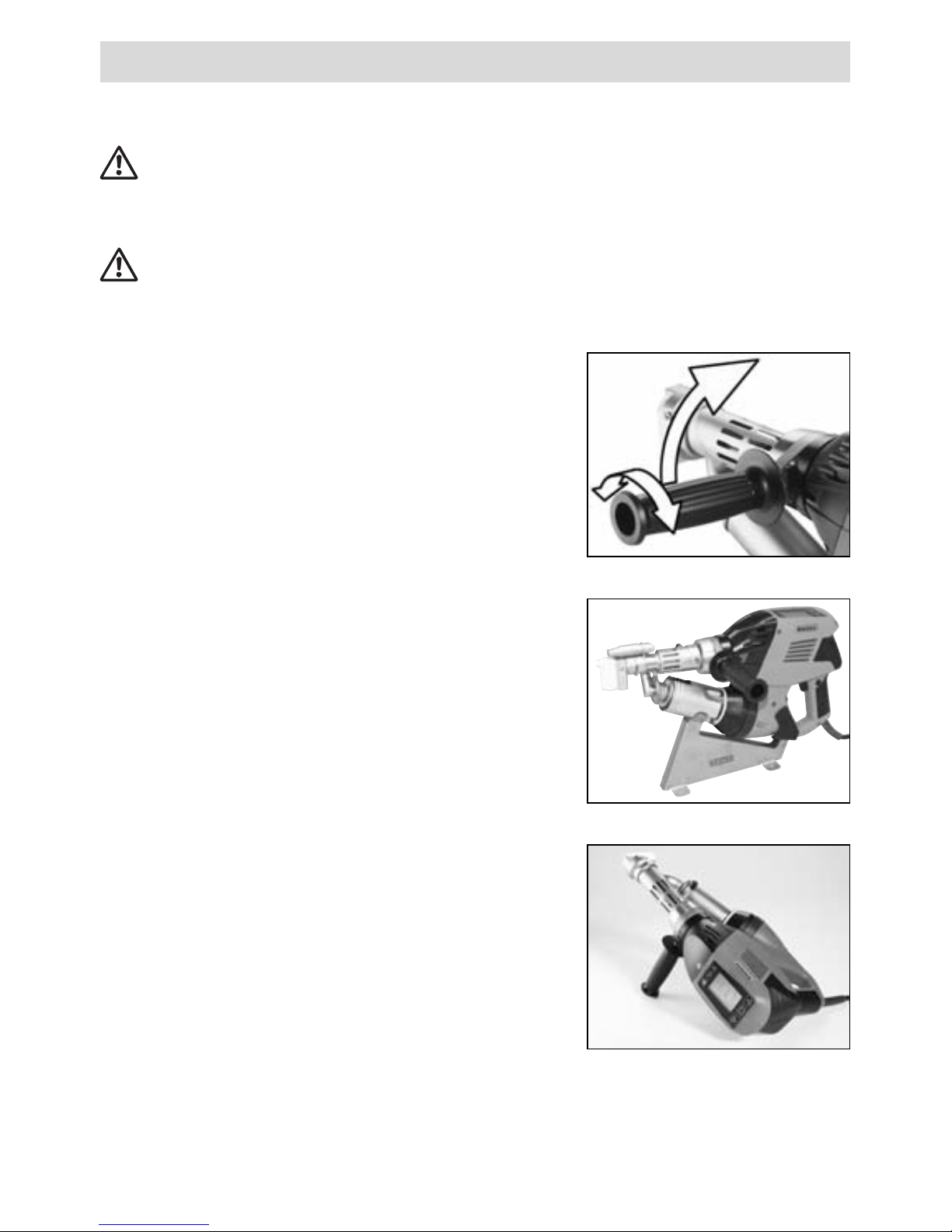

When interrupting the welding, the drive is to be

switched off with the drive on/off switch (2).

With the handle properly adjusted and firmly tightened,

place down the manual extruder on a stable and

fire-proof surface as shown in the figure.

The hand extruder must not be used in inflammable environments or where

explosion hazards exist. Ensure stable positioning during operation. The

connection cable and the welding rod must remain unimpeded and must not

hinder the user or others during operation.

Rest the hand extruder on a fireproof surface! Hot metal parts and the hot-air jet

must have sufficient clearance from the surface and walls.

Handle Adjustment

1. Loosen the clamping by turning the handle (6) in

counterclockwise direction.

2. Adjust handle (6) to the requested working position.

3. Tighten handle clamping again by turning handle (6)

in clockwise direction.

Workplace

For starting operation of and placing down the hand

extruder, Leister offers a universal device stand.

1

2

3

6

Operating

Power supply

When using an extension cable, take care to ensure the minimal cable cross-section:

Extension cables must be approved for the working environment (e.g. outdoors) and labelled

accordingly.

If a generator is used to supply electricity, the rated power of the generator must be 2x the

rated power of the hand extruder.

Length

[m]

Minimum cross-section (at ~230V) [mm2]

Up to 19

2.5

20 – 50 4.0

After switching on the main switch (1), the device directly heats up to the last adjusted set

values. When the set values are reached, a counter in the status indication counts back from

220 seconds to zero. Once this starting procedure has elapsed, the device is ready for welding

(status: Ready*). The operating temperature of the manual extruder is reached after approx.

5 minutes.

After a short-term mains break, the starting procedure is not repeated.

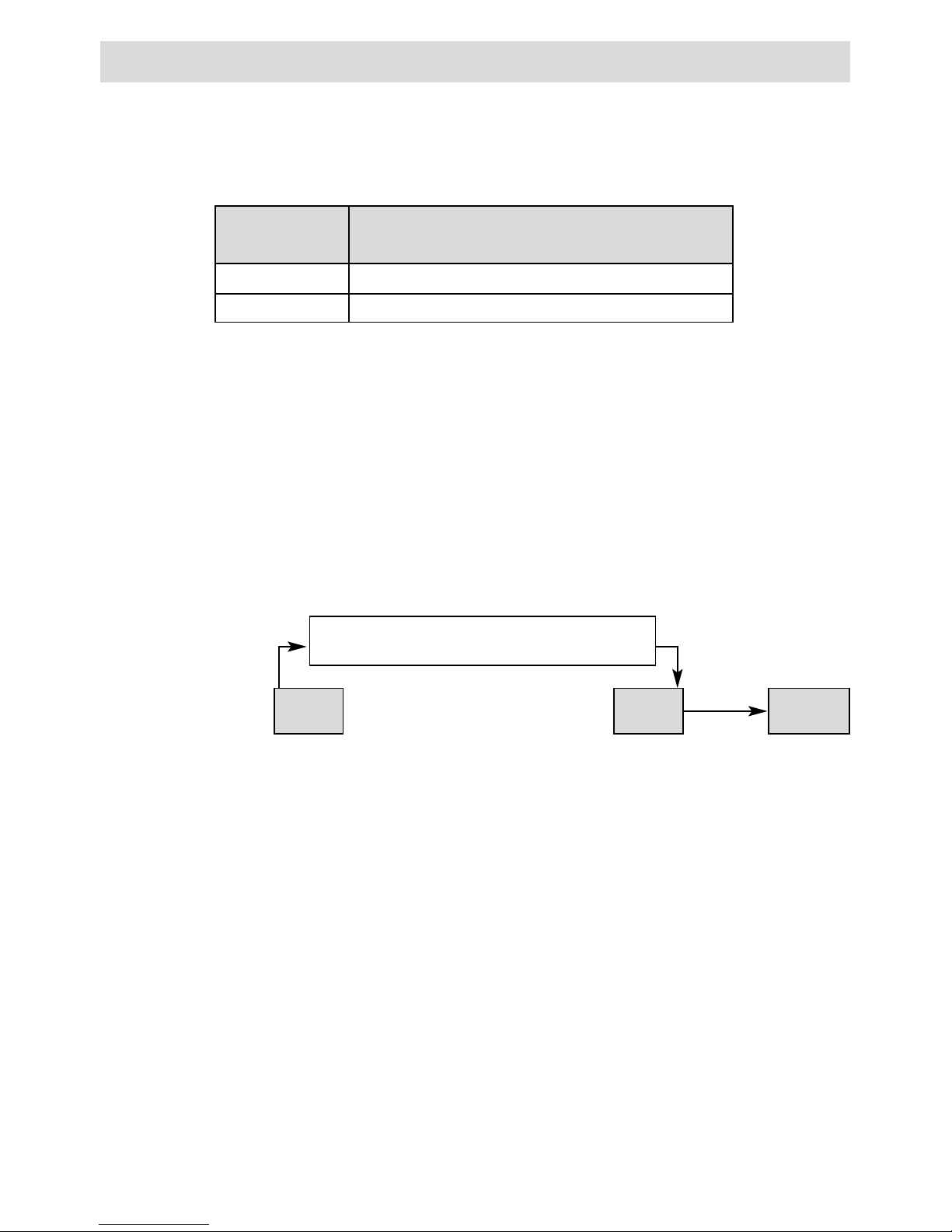

motor disabled

WARM-UP LOCK TIME: 220 SEK.

Heat FREE M READY *

Display

Status display

for drive (30)

Heating until target

value is reached

motor release ready to weld

Starting procedure

Temperature monitoring prevents the hand extruder starting up in a cold state.

Loading...

Loading...