Leister WELDPLAST S1 Operating Instructions Manual

®

Leister Technologies AG

Galileo-Strasse 10

CH-6056 Kaegiswil/Switzerland

Tel. +41 41 662 74 74

Fax +41 41 662 74 16

www.leister.com

sales@leister.com

2

21

40

59

78

97

D

GB

F

I

E

NL

WELDPLAST

S1

2

Bedienungsanleitung (Original-Bedienungsanleitung)

Bedienungsanleitung vor Inbetriebnahme aufmerksam

lesen und zur weiteren Verfügung aufbewahren.

Leister WELDPLAST S1

Hand-Schweissextruder

Anwendung

• Extrusionsschweissen von folgenden Materialien:

PP / PE-HD / PVC-U / PVC-C / PVDF

• Weitere Materialen auf Anfrage

Warnung

Lebensgefahr beim Öffnen des Gerätes, da spannungsführende Komponenten und

Anschlüsse freigelegt werden. Vor dem Önen des Gerätes Netzstecker aus der Steckdose

ziehen.

Feuer- und Explosionsgefahr bei unsachgemässem Ge brauch des Hand-Schweissextruders (z.B. Überhitzung von Material) besonders in der Nähe von brennbaren

Materialien und explosiven Gasen.

Verbrennungsgefahr! Blanke Metallteile und austretende Masse nicht in heissem

Zustand berühren. Gerät abkühlen lassen. Heissluftstrahl und austretende Masse

nicht auf Personen oder Tiere richten.

Gerät an eine Steckdose mit Schutzleiter anschliessen. Jede Unterbrechung des Schutzleiters innerhalb oder ausserhalb des Gerätes ist gefährlich!

Nur Verlänge rungs kabel mit Schutzleiter verwenden!

Vorsicht

Nennspannung, die auf dem Gerät angegeben ist, muss mit der Netzspannung

übereinstimmen.

Bei Ausfall der Netzspannung müssen Hauptschalter und Antrieb ausgeschaltet werden

(Arretierung lösen).

FI-Schalter beim Einsatz des Gerätes auf Baustellen ist für den Personenschutz dringend

erforderlich.

Blendungsgefahr ! Direkter Blickkontakt mit dem LED-Lichstrahl ist zu vermeiden.

Gerät muss beobachtet betrieben werden. Wärme kann zu brennbaren Materialien

gelangen, die sich ausser Sichtweite befinden.

Gerät darf nur von ausgebildeten Fachleuten oder unter deren Aufsicht benützt

werden. Kindern ist die Benützung gänzlich untersagt.

Gerät vor Feuchtigkeit und Nässe schützen.

D

3

Konformität

Leister Technologies AG, Galileo-Strasse 10, CH-6056 Kaegiswil/Schweiz bestätigt, dass dieses Produkt

in der von uns in Verkehr gebrachten Ausführung die Anforderungen der folgenden EG-Richtlinien erfüllt.

Richtlinien: 2006/42, 2004/108, 2006/95, 2011/65

Harmonisierte Normen: EN 12100, EN 55014-1, EN 55014-2, EN 61000-6-2, EN 61000-3-2,

EN 61000-3-3, EN 62233, EN 60335-2-45, EN 50581

Kaegiswil, 20.10.2014

Bruno von Wyl, CTO Andreas Kathriner, GM

Entsorgung

Elektrowerkzeuge, Zubehör und Verpackungen sollen einer umweltgerechten Wiederverwertung

zugeführt werden. Nur für EU-Länder: Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäß der Europäischen Richtlinie 2002/96 über Elektro- und Elektronik-Altgeräte und ihrer

Um setzung in nationales Recht müssen nicht mehr gebrauchsfähige Elektrowerkzeuge getrennt

gesammelt und einer umweltgerechten Wiederverwertung zugeführt werden.

Technische Daten

Spannung V~ 100 120 230

Leistung W 1500 1800 1600

Frequenz Hz 50/60 50/60 50/60

Luft-Temperatur °C max. 360

Plastifizier-Temperatur °C max. 260

Ausstoss (Ø 3 mm) kg/h HD-PE 0.2 – 0.5; PP 0.2 – 0.5

Ausstoss (Ø 4 mm) kg/h HD-PE 0.3 – 0.8; PP 0.3 – 0.75

Schweissdraht mm Ø 3 / Ø 4

Emissionspegel L

pA

(dB) 76 (K = 3 dB)

Masse L × B × H mm 435 × 264 × 91 (ohne Schweissschuh)

Gewicht kg 4.7 (ohne Netzanschlussleitung)

Konformitätszeichen

Sicherheitszeichen

Schutzklasse I

Technische Änderungen vorbehalten

4

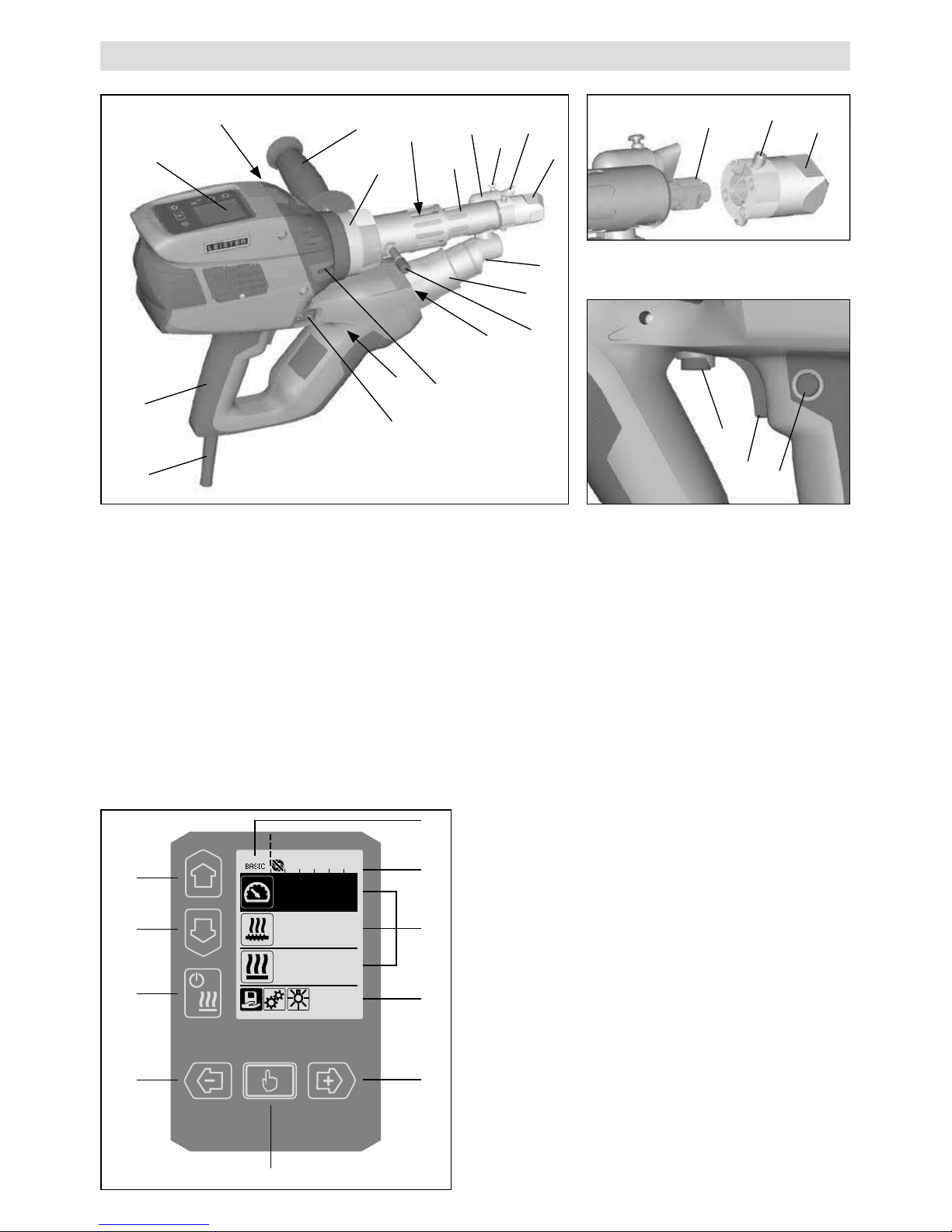

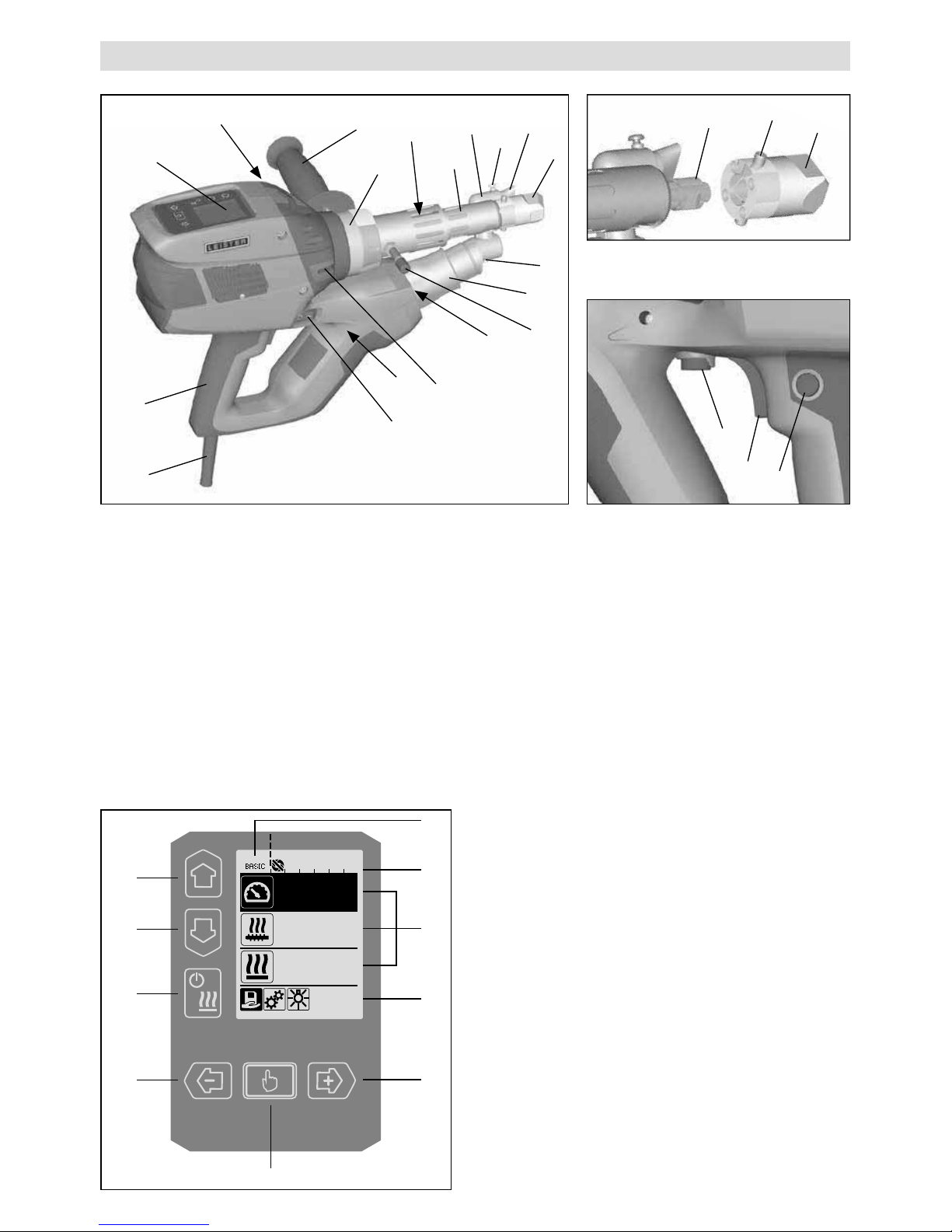

Gerätebeschreibung

1 Hauptschalter

2 Ein-/Ausschalter Antrieb

3 Potentiometer

4 Arretierung Antrieb

5 Display

6 Handgri

7 Mantelheizung

8 Schweissschuh

9 Vorwärmdüse

10 Schutzrohr

11 Schweissdraht-Einführung

12 Gerätegri

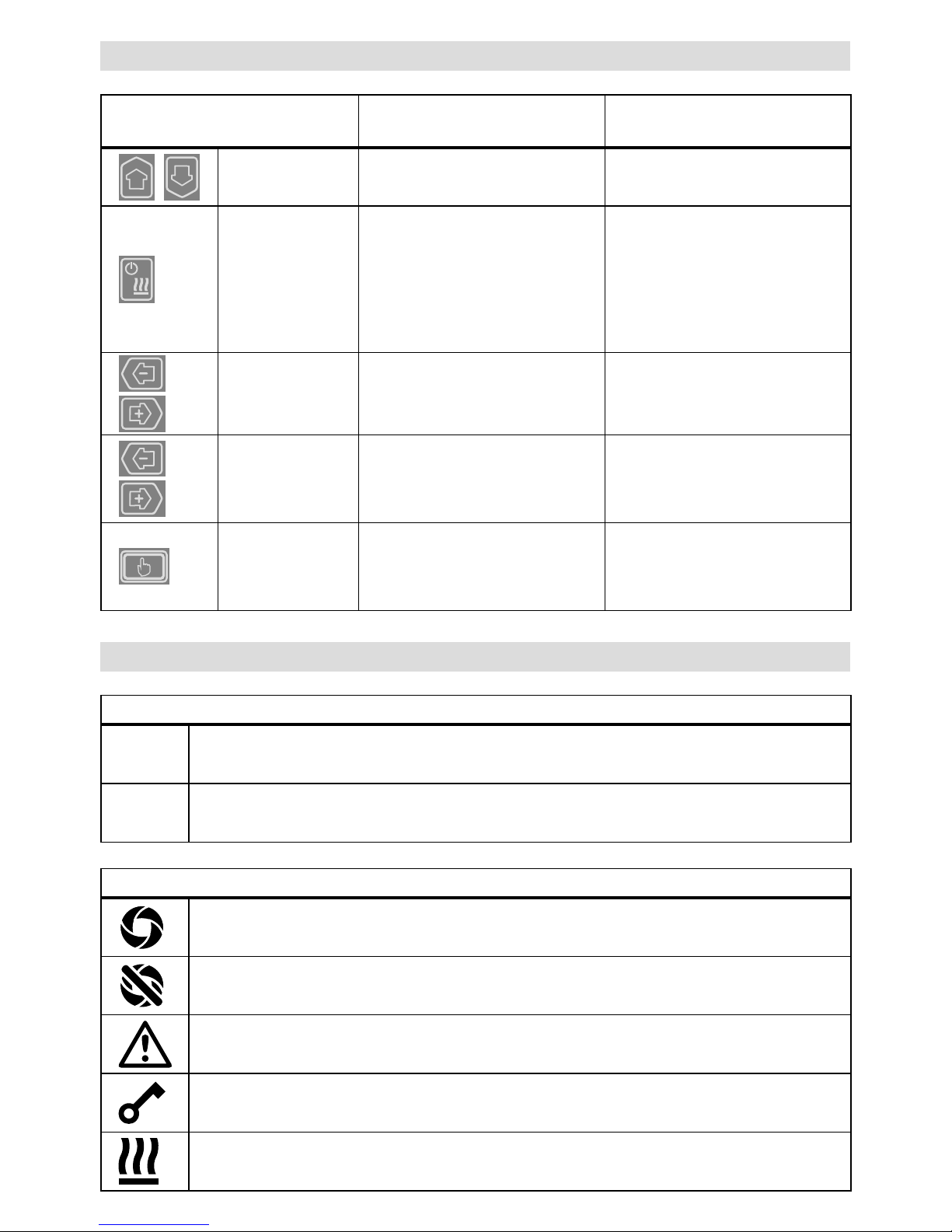

Bedieneinheit

21 Taste «Auf»

22 Taste «Ab»

23 Taste Heizung «Ein / Aus»

24 Taste «Minus»

25 Taste «Bestätigen»

26 Taste «Plus»

Display

27 Funktionsanzeige

28 Arbeitsanzeige

29 Statusanzeige «Bereich 1»

30 Statusanzeige «Bereich 2»

13 Netzanschlussleitung

14 Heizelement - Schutzrohr

15 Gebläse (bürstenlos)

16 Heissluftführung

17 Extrudierdüse

18 Klemmschraube Schweissschuh

19 Klemmschraube Vorwärmdüse

20 Klemmschelle

31 LED-Beleuchtung

32 Ablagebolzen

33 Klemmschraube Heissluftführung

2

3

4

18

8

17

%

100

°C

230

°C

260

25

28

30

27

26

21

22

23

24

29

1

5

6

7

8

19

10

11

12

13

14

15

16

20

9

31

11

32

33

5

Bedieneinheitsbeschreibung

Displaybeschreibung

Statusanzeige «Bereich 1» (29)

PE-HD

Aktuell ausgewähltes Profil. Bei Profilnamen mit mehr als 6 Zeichen werden zuerst die ersten

6 Zeichen angezeigt, anschliessend die verbleibenden Zeichen.

1m16s Verbleibende Zeit bis Antrieb freigegeben wird (1 min. / 16 sek.)

Statusanzeige «Bereich 2» (30)

Antrieb freigegeben

Antrieb nicht freigegeben

Warnung vorhanden (Kohlenbürsten / Antrieb)

Tastensperre (erscheint nur bei aktiver Tastensperre)

Luft- und Plastifizier-Heizung ist eingeschaltet

Tastaturmodus

Aktuelle Auswahl in der

Arbeitsanzeige

Aktuelle Auswahl in der

Funktionsanzeige

Auf (21)

Ab (22)

Verändern der Position innerhalb

der Arbeitsanzeige

Wechsel von der Funktionsanzeige in die Arbeitsanzeige

Heizung

Ein / Aus (23)

Keine Funktion

Wechsel vom Schweissmodus

in Abkühlvorgang

Wechsel von Abkühlvorgang in

den Schweissmodus

Wechsel von Startanzeige in

den Schweissmodus

Minus (24)

Plus (26)

(kurz drücken)

Einstellen des gewünschten

Sollwertes in 5°C - bzw.

5% - Schritten.

Verändern der Position in der

Funktionsanzeige

Minus (24)

Plus (26)

(drücken und

halten)

Einstellen des gewünschten Sollwertes in 10°C - bzw.

10% -Sch rit te n.

Verändern der Position in der

Funktionsanzeige

Bestätigen (25)

Eingestellter Wert wird direkt

übernommen und die Auswahl

springt direkt in die

Funktionsanzeige zurück

Ausgewählte Funktion wird

ausgeführt

6

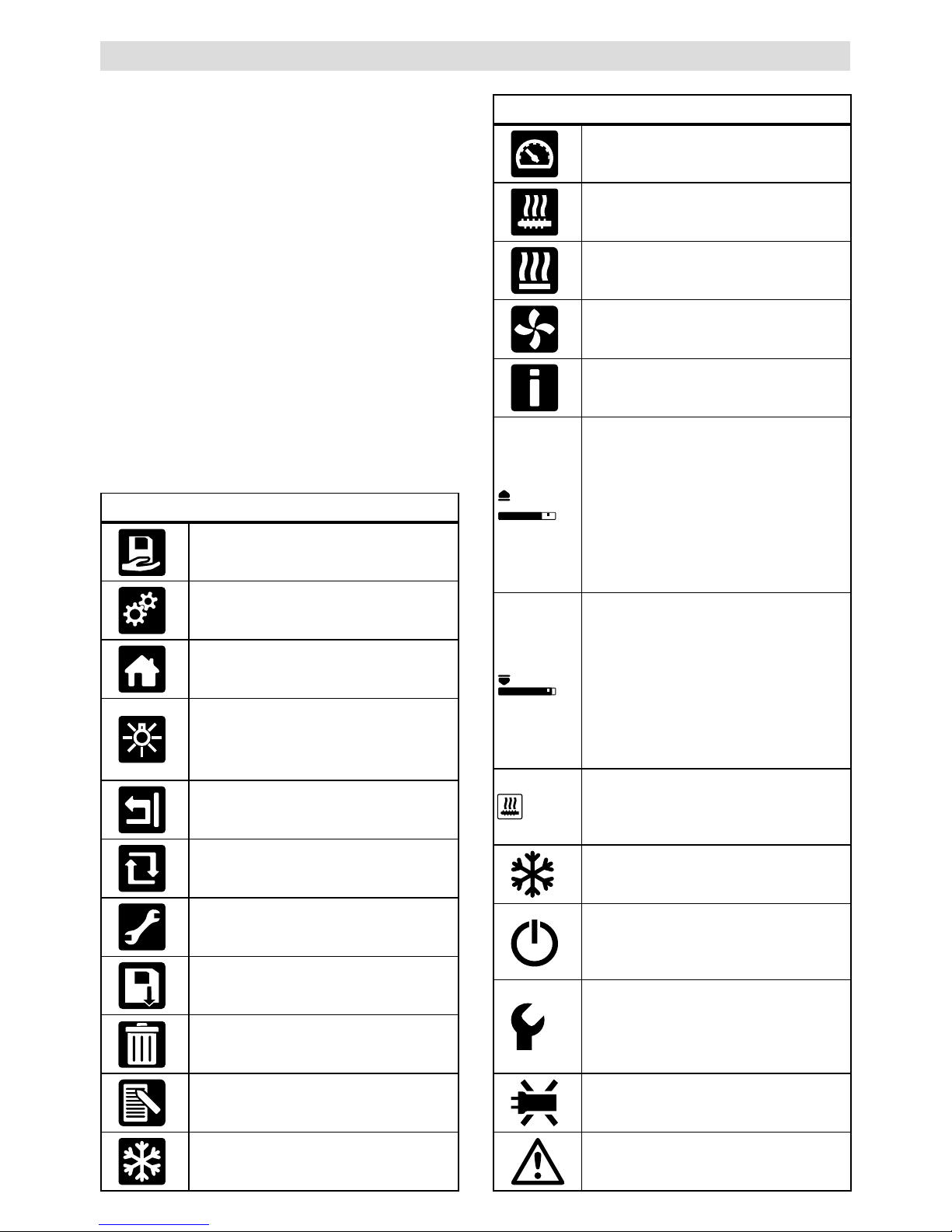

Funktions- und Arbeitsanzeige

• In der Funktions- und Arbeitsanzeige definiert

immer das markierte dargestellte Feld oder Symbol

die aktuelle Auswahl.

• In der Arbeitsanzeige werden immer die Istwerte

angezeigt, ausser wenn eine Position ausgewählt

ist, erscheint der Sollwert.

• Ist «Show Set Values» aktiviert erscheint der Istund Sollwert (klein).

Funktionsanzeige (27)

Freie und vordefinierte Profile

auswählen

Einstellungen

Zurück zur Arbeitsanzeige

(direktes Verlassen eines Menüs)

LED ein-/ ausschalten.

Diese Funktion ist nur vorhanden,

wenn die LED aktiviert wurde.

Eine Ebene zurück

Einstellungen oder Stundenzähler

zurücksetzen

Service Menü

(nur über Passworteingabe verfügbar)

Speichern

Ausgewählte Position löschen

Ausgewählte Position bearbeiten

Abkühlvorgang einleiten

Arbeitsanzeige (28)

Sollwert:

Ausstossmenge Antrieb [%]

Sollwert:

Plastifizier-Temperatur [°C / °F]

Sollwert:

Luft-Temperatur [°C / °F]

Sollwert:

Luftmenge [%]

Informationsfenster

°C

200

230

Der Pfeil nach oben und der Fortschrittsbalken zeigen an, dass der

Sollwert (Markierung im Fortschrittsbalken) noch nicht erreicht ist (zu kalt).

Der blinkende Wert ist der Istwert. Der

Wert neben dem Fortschrittsbalken ist

der eingestellte Sollwert.

°C

250

230

Der Pfeil nach unten und der Fortschrittsbalken zeigen an, dass der Sollwert (Markierung im Fortschrittsbalken)

noch nicht erreicht ist (zu heiss). Der

blinkende Wert ist der Istwert. Der

Wert neben dem Fortschrittsbalken ist

der eingestellte Sollwert.

°C

250

230

Ist «Show Set Values» aktiviert,

wird die Isttemperatur (gross) und die

Solltemperatur (klein) dargestellt.

Abkühlvorgang

Gerät im Standby-Modus. Das Gerät

wird nach Ablauf des Zählers den

«Cool down modus» starten

Gerät hat einen Fehler. Zusätzlich

erscheint ein Fehlercode (Gerät nicht

mehr einsatzbereit). Autorisierte

Service-Stelle kontaktieren

Heizelement-Luft defekt

Gerätetemperatur zu hoch.

Gerät abkühlen lassen.

7

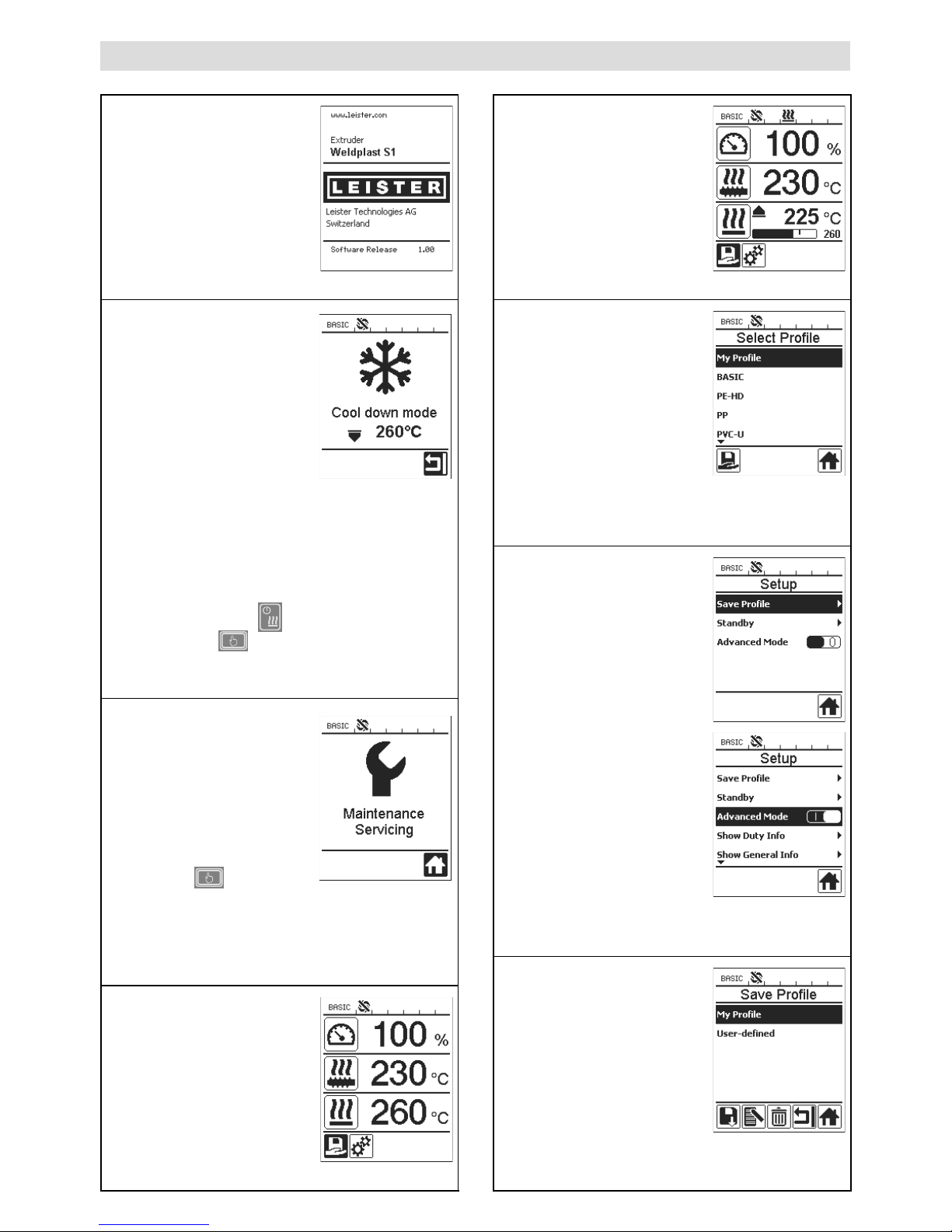

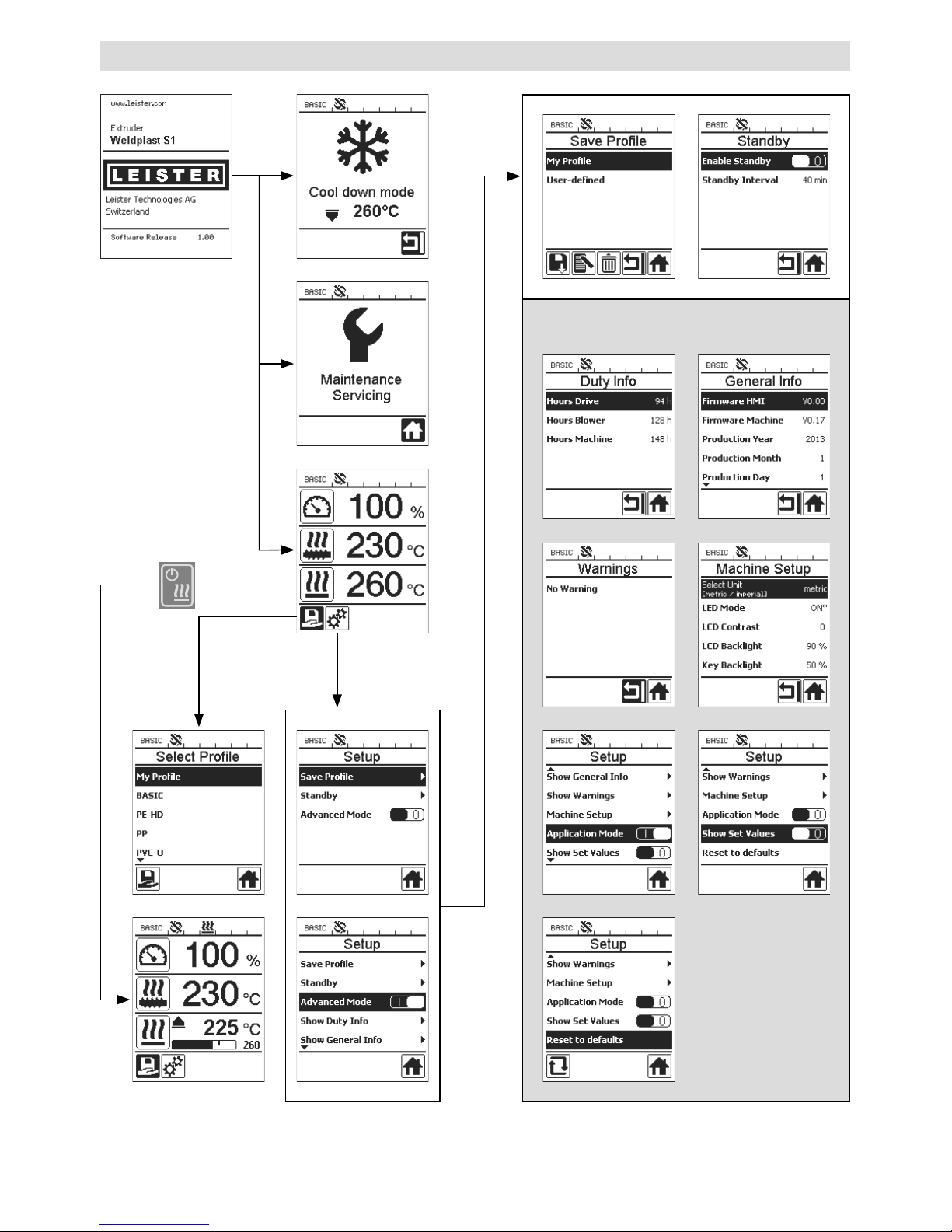

Aufstartanzeige

Schweissen

Anzeige während dem

Aufheizvorgang

Select Profile

(Profilauswahl)

Wählen Sie ein von Ihnen

definiertes oder ein durch

Leister vorgegebenes Profil

aus. Die Profilauswahl ist

unter dem Kapitel «Select

Profile» Seite 13 detailliert

beschrieben.

Setup (Einstellung)

In der Grundeinstellung

gelangen Sie über das

Menü «Setup» in die Profil-

speicherung und in

die Standbyfunktion.

Durch auswählen des

«Advanced Mode» stehen

diverse weitere Einstellungsmöglichkeiten zur Verfügung.

Save profile

(Freie Profile definieren)

Die freie Profilspeicherung

ist unter dem Kapitel

«Profile definieren»

Seite 15 / 16 detailliert

beschrieben.

Aufstartanzeige

Anzeige beim Aufstart mit

Software Release der

Leistungseinheit.

Cool down mode

(Abkühlen)

In diesem Modus sind

die Heizungen ausgeschaltet und das Gerät ist

im Abkühlmodus. Ist beim

Einschalten des Gerätes

die Vorwärmlufttemperatur

grösser als 100 °C, wechselt das Gerät automatisch in den «Cool down mode». Der Vorgang ist

abgeschlossen, wenn die Vorwärmlufttemperatur 2 min. unter 100 °C liegt.

Sollen die Heizungen wieder eingeschaltet werden,

muss die Taste (23)

«Heizung Ein/Aus» oder

die Taste (25) «Bestätigen» gedrückt.

werden.

Maintenance servicing

(Wartungsservice)

Ist das Wartungsintervall für

den Antriebsmotor erreicht,

erscheint nach der Aufstartanzeige «Maintenance

Servicing».

Mittels

Taste (25)

«Bestäti-

gen»

kann weiter

gearbeitet

werden. Das Gerät muss zwingend zu

Ihrer Service stelle gebracht werden.

Startanzeige

In der Startanzeige werden

alle Sollwerte dargestellt.

Die Heizung ist noch nicht

eingeschaltet, es können

jedoch alle Sollwerte bereits

eingestellt werden.

Übersicht der Arbeitsanzeige

8

Übersicht der Arbeitsanzeige

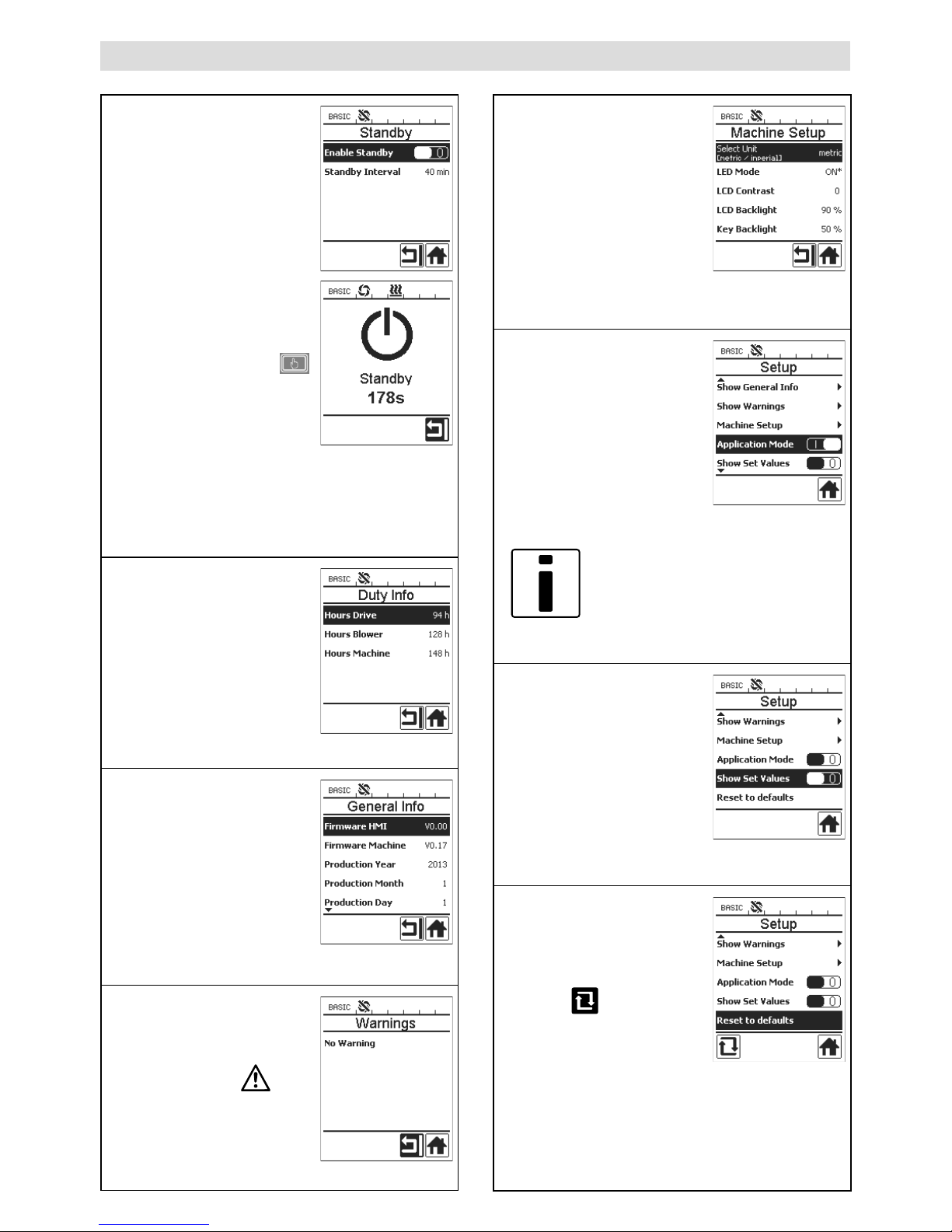

Standby (Bereitschaft)

Ist der Standbymodus

aktiviert und wird während

der unter «Standby Interval»

definierten Zeit keine Taste

auf der Bedieneinheit oder

der Ein- / Ausschalter

Antrieb (2) betätigt, wechselt

das Gerät automatisch in

die Standbyanzeige. Wird

während den folgenden

180 sek. die Taste (25)

«Bestätigen» nicht gedürckt,

startet automatisch der

Abkühlmodus.

Duty Info

Hours Drive: aktuelle Laufzeit

des Antriebs (rückstellbar).

Hours Blower: aktuelle

Laufzeit des Gebläses.

Hours Machine: aktuelle

Laufzeit der Maschine.

General Info

Firmware HMI: Softwareversion der Displayeinheit

(Kommunikationsmodul).

Firmware Machine: Softwarerevision Leistungseinheit.

Production Info: Angaben zum

Produktionszeitpunkt.

Warnings

Liegt eine Warnung vor, wird

dies in der Statusanzeige

durch das Symbol

signalisiert. Im Menü

«Warnings» finden Sie

genauere Angaben zur

aktuellen Warnung.

Machine Setup

Die Einstellungen der

Maschine sind unter

dem Kapitel «Maschinen

Einstellungen» detailliert

beschrieben.

Application Mode

Ist der «Application Mode»

aktiviert, haben Sie in der

Arbeitsanzeige detaillierte

Angaben zur Ist-Plastifizier-

Temperatur und Auslastung

von Heissluftgebläse und

Plastifizier-Heizung.

Plast : 80 % 222 °C

Heat : 40 % 197 °C

Amb. : 25 °C

Mains : 50 Hz

Ist «Show Set Values»

aktiviert, wird die

Ist-Temperatur (gross) und

die Soll-Temperatur (klein)

dargestellt.

Reset to defaults

Wird das Menü «Reset to

defaults» ausgewählt und

durch Auswählen der

Funktion

bestätigt,

werden sämtliche Kundenspezifischen Profile gelöscht.

Einstellungen welche über

das Setup Menü verändert

wurden, werden auf

Werkseinstellung zurückgesetzt.

9

Menüführung

Nur im «Advanced Mode» verfügbar

10

Arbeitsumgebung / Sicherheit

Vor Inbetriebnahme Netzanschlussleitung (13) und Stecker sowie Verlängerungskabel auf

elektrische und mechanische Beschädigung überprüfen.

Der Hand-Schweissextruder darf nicht in explosionsgefährdeter bzw. entzündbarer Umgebung eingesetzt werden. Auf sicheren Stand bei der Arbeit achten. Netzanschlussleitung und

Schweissdraht müssen frei beweglich sein und dürfen den Anwender oder Dritte bei der Arbeit

nicht behindern.

Hand-Schweissextruder auf feuerfeste Unterlage stellen! Heisse Metallteile und Warmluftstrahl

müssen genügend Abstand zu Unterlage und Wänden haben.

Einstellung Handgri

Arbeitsplatz

1

2

3

1

Durch Drehen des Hand -

gris (6) gegen den

Uhrzeiger sinn Klemmung

lösen.

2

Handgri (6) in die ge-

wünschte Arbeitsposition

bringen.

3

Durch Drehen des Hand-

gris (6) im Uhrzeigersinn

Klemmung wieder festziehen.

Zur Inbetriebnahme und Ablage

des Hand-Schweissextruders bietet

Leister eine Geräte ablage an.

Bei Unterbruch der Schweiss arbeiten ist der Antrieb mit dem Ein-/Aus-

schalter Antrieb (2) abzuschalten.

Den Hand-Schweissextruder mit entsprechend eingestelltem und fest

ange zoge nem Handgri (6) gemäss Abbildung auf eine stabile, feuerfeste

Unterlage oder Ablagebolzen (32) stellen.

Handgri

Demontage / Montage Handgri

Demontage Handgri

1

Durch Drehen des Handgris (6) gegen den Uhrzeigersinn

Klemmung lösen.

2

Mittels Drücken auf den Handgri (6) und auf die Klemmschelle

(20) önet sich der Verschluss (siehe Pfeile). Handgri (6) mit

Klemmschelle (20) entnehmen.

Montage Handgri erfolgt in umgekehrter Reihenfolge.

1 2

Verschluss

Handgri (6)

Klemmschelle (20)

Verbrennungsgefahr! Gerät abkühlen lassen

11

Verlängerungskabel

• Bei Verwendung von Verlängerungskabeln auf den Mindestquerschnitt achten:

• Verlängerungsleitung muss für den Einsatzort (z.B. im Freien)

zugelassen und entsprechend gekennzeichnet sein.

• Bei Verwendung eines Aggregates zur Energieversorgung gilt

für dessen Nennleistung: 2 × Nennleistung Hand-Schweiss–

extruder.

Länge

[m]

Mindest-Querschnitt

(bei 100 – 230V~) [mm

2

]

Bis 19

2.5

20 – 50 4.0

• Schalten Sie den Extruder über den Hauptschalter (1) ein. Je nach Vorwärmlufttemperatur erscheint auf

dem Display (5) die Aufstartanzeige oder «Cool down mode». Durch Drücken der Taste (23) «Heizung Ein /

Aus»

, wird der Aufheizvorgang gestartet.

• Ist das Gerät betriebsbereit, schaltet die LED-Beleuchtung (31) automatisch ein (Werkseinstellung).

• Mittels Ein-/Ausschalter Antrieb (2) kann der Antrieb gestartet werden.

Starten des Gerätes

Gerät an Nennspannung anschliessen. Nennspannung, die auf dem Gerät angegeben ist,

muss mit der Netzspannung übereinstimmen.

• Nach Bedarf den entsprechenden Schweissschuh (8), die entsprechende Vowärmdüse (9) sowie die Heiss-

luftführung (16) montieren (Wechsel von Zubehör Seite 18).

• Schweissdraht (ø 3 oder 4 mm) in die Schweissdraht-Einführung (11) einführen.

• Der Schweissdraht wird automatisch durch die Schweissdraht-Einführung (11) eingezogen.

Drahtzuführung muss ohne Widerstand erfolgen.

ACHTUNG!

Gerät immer mit Schweissdraht betreiben, jedoch niemals gleichzeitig in beide

Schweissdraht-Einführungen Schweissdraht einführen.

• Mittels Potentiometer (3) kann die Geschwindigkeit des Schweissdrahteinzuges eingestellt werden.

• Masseförderung mit Ein-/Ausschalter Antrieb (2) unterbrechen.

• Die Vorwärmdüse (9) auf die Schweisszone richten.

• Mit pendelnden Bewegungen die Schweisszone vorwärmen.

• Das Gerät auf die vorbereitete Schweisszone aufsetzen und den Ein-/Ausschalter Antrieb (2) wieder betätigen.

• Testschweissung gemäss Schweissanleitung des Materialherstellers und nationaler Normen oder Richtlinien

vornehmen. Testschweissung überprüfen.

• Temperatureinstellung, Ausstossmenge und Luftmenge nach Bedarf anpassen (siehe Kapitel, Einstellen

Schweissparameter, Seite 12).

• Bei einem längeren Schweissvorgang kann der Ein-/ Ausschalter Antrieb (2) mittels Arretierung Antrieb (4)

im Dauerbetrieb gehalten werden.

ACHTUNG!

• PVC-U und PVC-C werden im Menü vom PVC-U verarbeitet.

• Um Korrosionsschäden beim Verarbeiten von PVC-U, PVC-C, ECTFE, PVDF etc. zu vermeiden, empfehlen wir

nach Beendigung der Schweissarbeiten den Hand-Schweissextruder mit HD-PE zu spühlen.

Schweissvorgang

12

Ausschalten des Gerätes

• Arretierung Antrieb (4) lösen und den Ein-/Ausschalter Antrieb (2) loslassen.

• Schweissmaterial im Schweissschuh (8) entfernen.

• Durch Drücken der Taste (23) «Heizung Ein / Aus»

und mittels Taste (25) «Bestätigen» wird die Heizung

ausgeschaltet und das Gerät startet den Abkühlvorgang «Cool down mode».

• Nach dem Abkühlvorgang schaltet das Gebläse automatisch ab und auf dem Display (5) erscheint die Startanzeige.

• Hauptschalter (1) ausschalten.

Netzanschlussleitung vom elektrischen Netz trennen.

Einstellen eines Parameters

• Muss eine Sollwertvorgabe (z.B Soll- Plasttemperatur) verändert werden, kann durch Drücken der Tasten 21 / 22

«Auf»

oder «Ab» der entsprechende Sollwert ausgewählt werden. Solange der Sollwert markiert

dargestellt wird, kann er über die Tas te n 24 / 2 6 «Plus»

oder «Minus» verändert werden. Beim

WELDPLAST S1 sind vier Sollwerte einstellbar:

Ausstossmenge (max. Ausstoss wenn Potentiometer auf Stufe 5 steht, bzw. auf 100% eingestellt ist).

Plastifizier-Temperatur Luft-Temperatur Luftmenge

• In der Arbeitsanzeige können

max. drei Elemente dargestellt

werden.

• Weitere Elemente werden

durch Drücken der Tasten

21 / 22 «Auf»

oder

«Ab»

erreicht.

• Die Ausstossmenge kann während dem Extrudieren direkt über das Potentiometer (3) in 5 %-Schritten

verstellt werden. Der Bereich geht dabei von min. 35 % bis zur max. eingestellten Ausstossmenge.

Der aktuell eingestellte Wert ist dabei immer in der Arbeitsanzeige sichtbar.

Der in der Arbeitsanzeige eingestellte Wert ist als Maximum-Wert zu verstehen. Mit dem Potentiometer (3)

kann nur bis zu diesem eingestellten Maximum-Wert eingestellt werden. Typischerweise ist dieser deshalb auf

100 % eingestellt.

• Ist die Ausstossmenge mit dem minimalen Ausstoss (35 %) zu gross, muss auf die Schweissdrahtdicke 3 mm

gewechselt werden.

• Ist die Ausstossmenge mit dem maximalen Ausstoss (100 %) zu klein, muss auf die Schweissdrahtdicke 4 mm

gewechselt werden.

13

Select Profile (Profilauswahl)

• Auswahl eines vordefinierten oder freien Profils

• Der WELDPLAST S1 verfügt über sechs vordefinierte Leister-Profile und bis zu zehn frei definierbare Profile:

Schweissprofile

Max. Ausstoss

[%]

Soll- Plastifizier-

Temperatur

[°C / °F]

Soll- Luft-

Temperatur

[°C / °F]

Luftmenge

[%]

1 BASIC einstellbar einstellbar einstellbar einstellbar

2 PE-HD 100 230 260 100

3 PP 100 240 260 100

4 PVC-U 100 200 300 100

5 PVDF 100 250 320 100

6 – 16 freie Profile einstellbar einstellbar einstellbar einstellbar

• Durch die Auswahl des Symbols

in der Funktionsanzeige (27) gelangen Sie in das Menü «Select Profile».

Eines dieser sechs vordefinierten (1 – 6) oder ein kundenspezifisches freies Profil (7 – 16) kann mit den

Tasten 21/ 22 «Auf»

und «Ab» ausgewählt werden.

• Werden Sollwerte (Profile 2 – 16) während dem Betrieb verändert, werden diese nicht im Profil gespeichert !

• Wird die Maschine aus- / eingeschaltet, erscheinen immer wieder die im Profil definierten Werte.

• Möchten Sie beim Wiedereinschalten der Maschine die zuletzt eingestellten Werte benützen, müssen Sie das

Profil BASIC (1) auswählen.

• Das aktuell ausgewählte Profil ist links in der Statusanzeige «Bereich 1» (29) sichtbar.

Überwachung der Schweissparameter

• Die aktuelle Plastifizier- und Luft-Temperatur wird ständig überwacht. Weicht ein Istwert vom entsprechenden

Sollwert ab, wird dies in der Arbeitsanzeige (28) angezeigt («Show Set Values» nicht aktiviert).

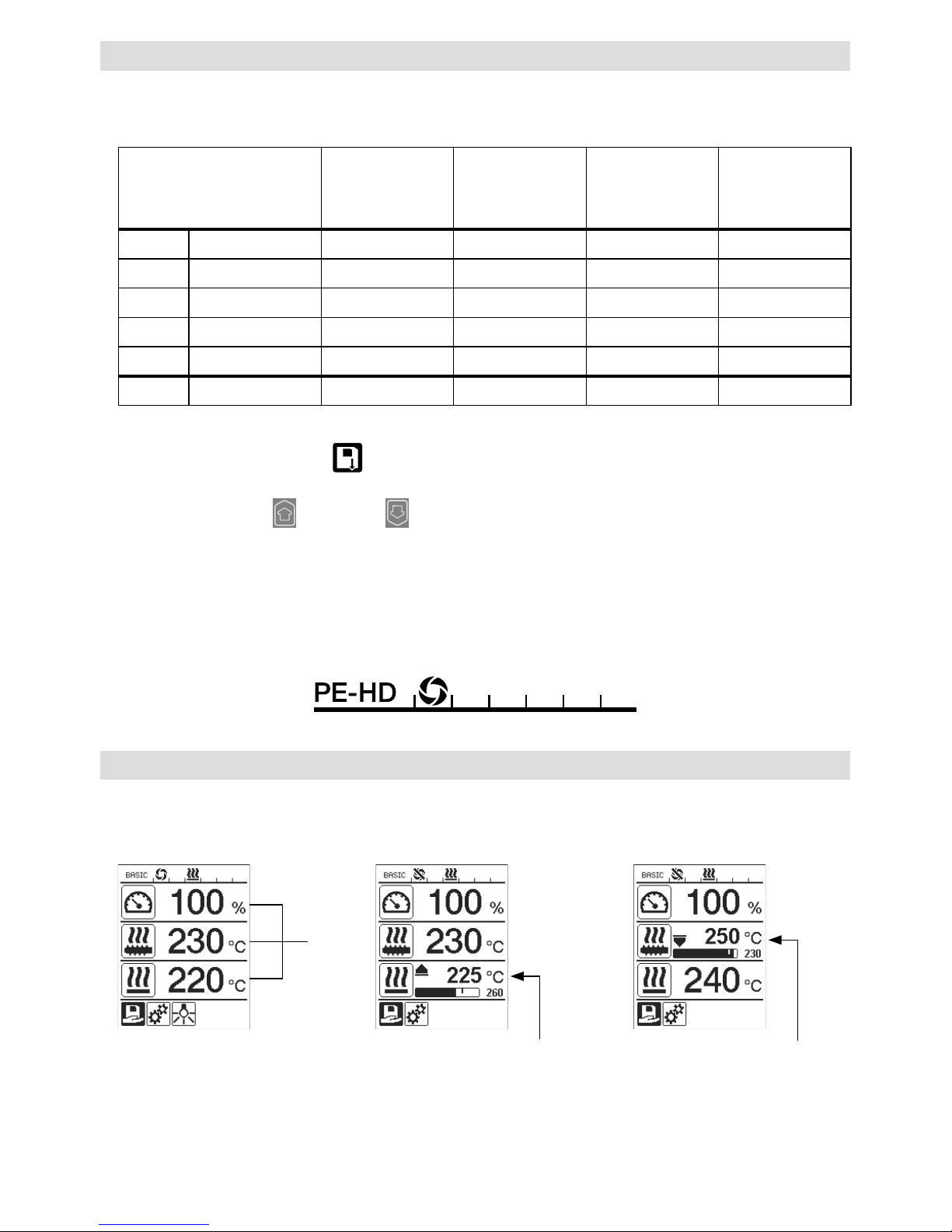

• Istwert entspricht

dem Sollwert.

• Istwert Luft-Temperatur zu tief.

Aufheizvorgang wird blinkend

signalisiert (Pfeil nach oben

und Fortschrittsbalken).

• Istwert Plastifizier-Temperatur

zu hoch.

Abkühlvorgang wird blinkend

signalisiert (Pfeil nach unten

und Fortschrittsbalken).

28

14

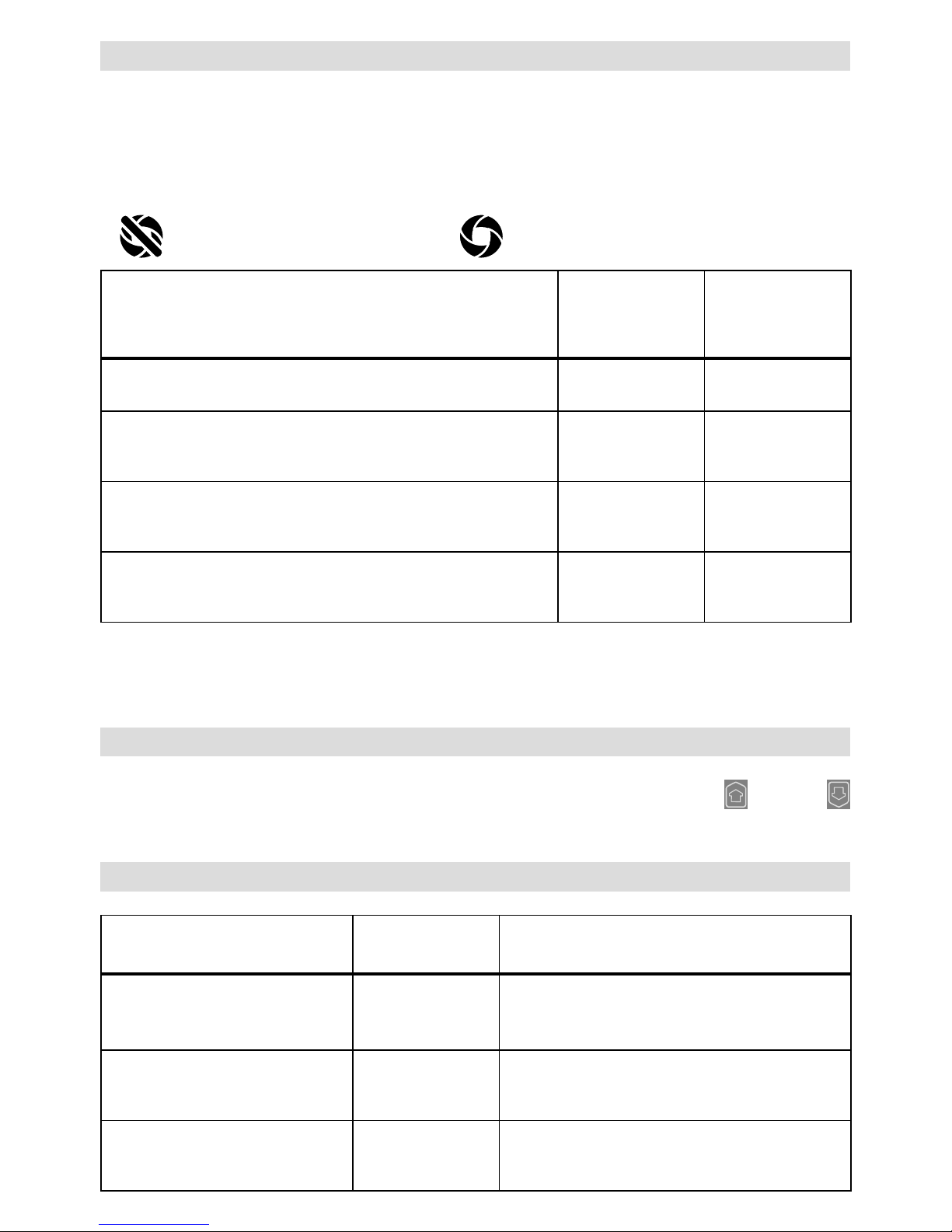

Freigabe Antrieb

• Für die Freigabe des Antriebs gibt es vier verschiedene Wartezeiten (siehe Tabelle). Diese sind von der

Ist-Plastifizier-Temperatur sowie von der eingestellten Soll-Plastifizier-Temperatur abhängig. Die Vorwärmluft

hat keinen Einfluss auf die Freigabe des Antriebs.

• Die Freigabezone beginnt, sobald die Ist-Plastifizier-Temperatur grösser als die Solltemperatur – 20 K ist.

• Zugehöriges Symbol in der Statusanzeige:

Antrieb ist nicht freigegeben Antrieb freigegeben

Ist-Plastifizier-Temperatur beim

Einschalten der Heizung oder verstellen

der Soll-Plastifizier-Temperatur

SollPlastifizierTemperatur

Freigabezeit nach

Erreichen der

Freigabezone

Soll-Plastifizier-Temperatur – 5K

< Ist-Plastifizier-Temperatur

—

Antrieb wird direkt

freigegeben

Soll-Plastifizier-Temperatur – 20K

< Ist-Plastifizier-Temperatur

< Soll-Plastifizier-Temperatur – 5K

— 30 sek.

Soll-Plastifizier-Temperatur – 20K

> Ist-Plastifizier-Temperatur

(Unterhalb der Freigabezone)

> 190°C 2 min. 30 sek

Soll-Plastifizier-Temperatur – 20K

> Ist-Plastifizier-Temperatur

(Unterhalb der Freigabezone)

< 195°C 3 min. 30 sek

• Kann der WELDPLAST S1 die Ist-Plastifizier-Temperatur bei freigegebenem Antrieb für mehr als 10 sek. nicht in

der Freigabezone halten, wird der Antrieb wieder gesperrt. Sobald das Gerät die Freigabezone wieder erreicht

hat, wird der Antrieb nach einer in der Tabelle definierten Zeit wieder freigegeben.

Netzunterbruch

Zustand Antrieb vor

Netzunterbruch

Dauer

Netzunterbruch

Zustand WELDPLAST S1

nach Netzunterbruch

Antrieb freigegeben

Arbeitsanzeige Schweissen

≤ 5 sek

Das Gerät startet ohne Wiederanlaufschutz auf

und wechselt direkt in den Zustand vor dem

Netzunterbruch

Antrieb freigegeben

(Vorwärmluft > 100 °C)

> 5 sek

Das Gerät wechselt direkt in den

«Cool down modus»

Antrieb freigegeben

(Vorwärmluf t < 100 °C)

> 5 sek

Das Gerät startet und auf dem Display (5)

erscheint die Startanzeige.

• Durch gleichzeitiges Drücken von mindestens zwei Sekunden der Tasten 21 / 22 «Auf»

und «Ab»

wird die Tastensperre aktiviert bzw. deaktiviert.

Tastensperre

15

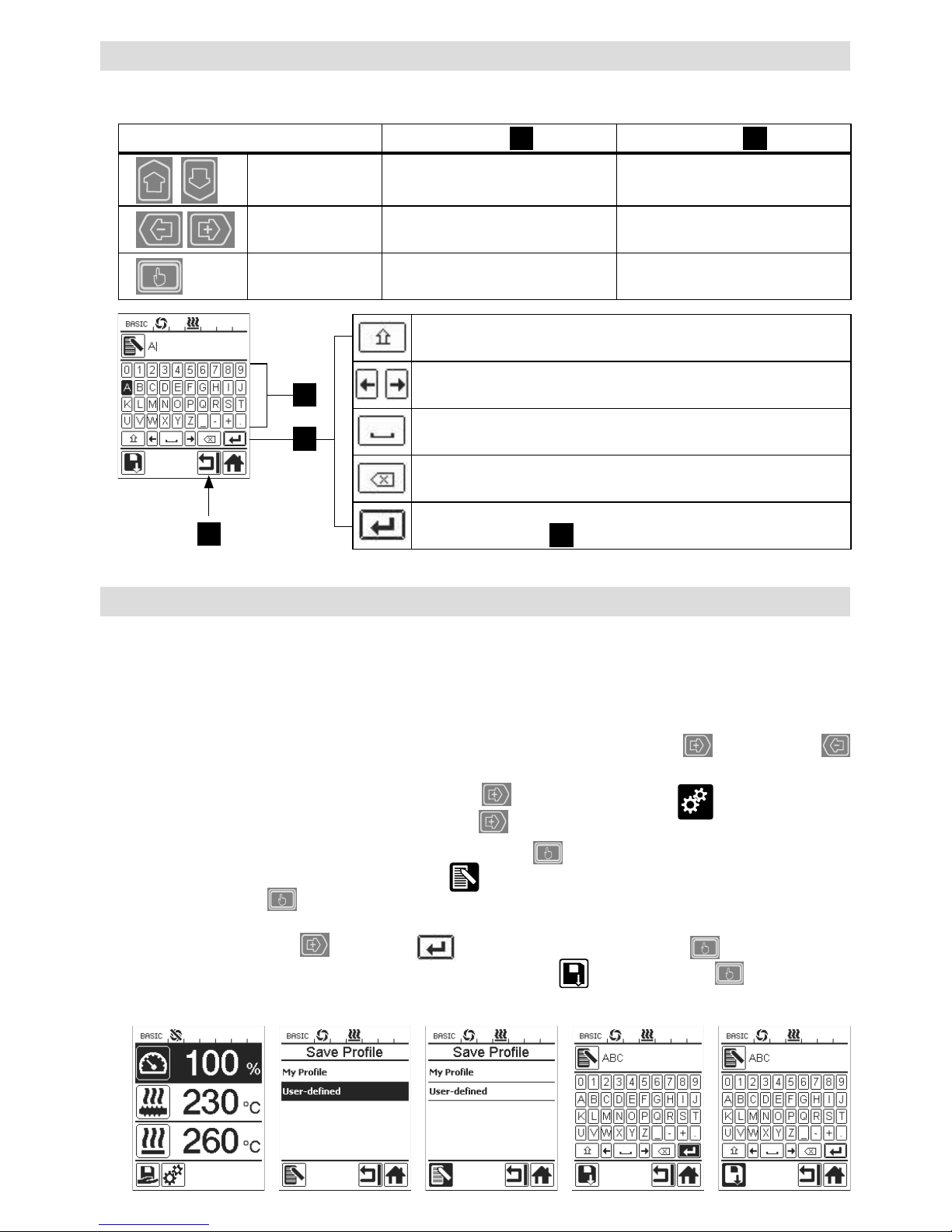

Eingabe von Namen oder Passwörtern

• Über den Tastaturmodus können Namen definiert oder Passwörter mit maximal 12 Zeichen eingegeben werden.

Tastaturmodus Zeichenauswahl Symbolauswahl

Auf (21)

Ab (22)

Vertikale Zeichenauswahl

Minus (24)

Plus (26)

Horizontale Zeichenauswahl Auswahl der Symbole

Bestätigen (25)

Das ausgewähltes Zeichen

bestätigen

Das ausgewähltes Symbol

bestätigen

Wechsel zwischen Gross- und Kleinschreibung

Cursorposition im Namen verschieben

Leerschlag einfügen

Löschen eines einzelnen Zeichens (Zeichen links von Cursor)

Durch Auswählen dieses Symbols Wechsel auf

Funktionsanzeige

27

27

34

35

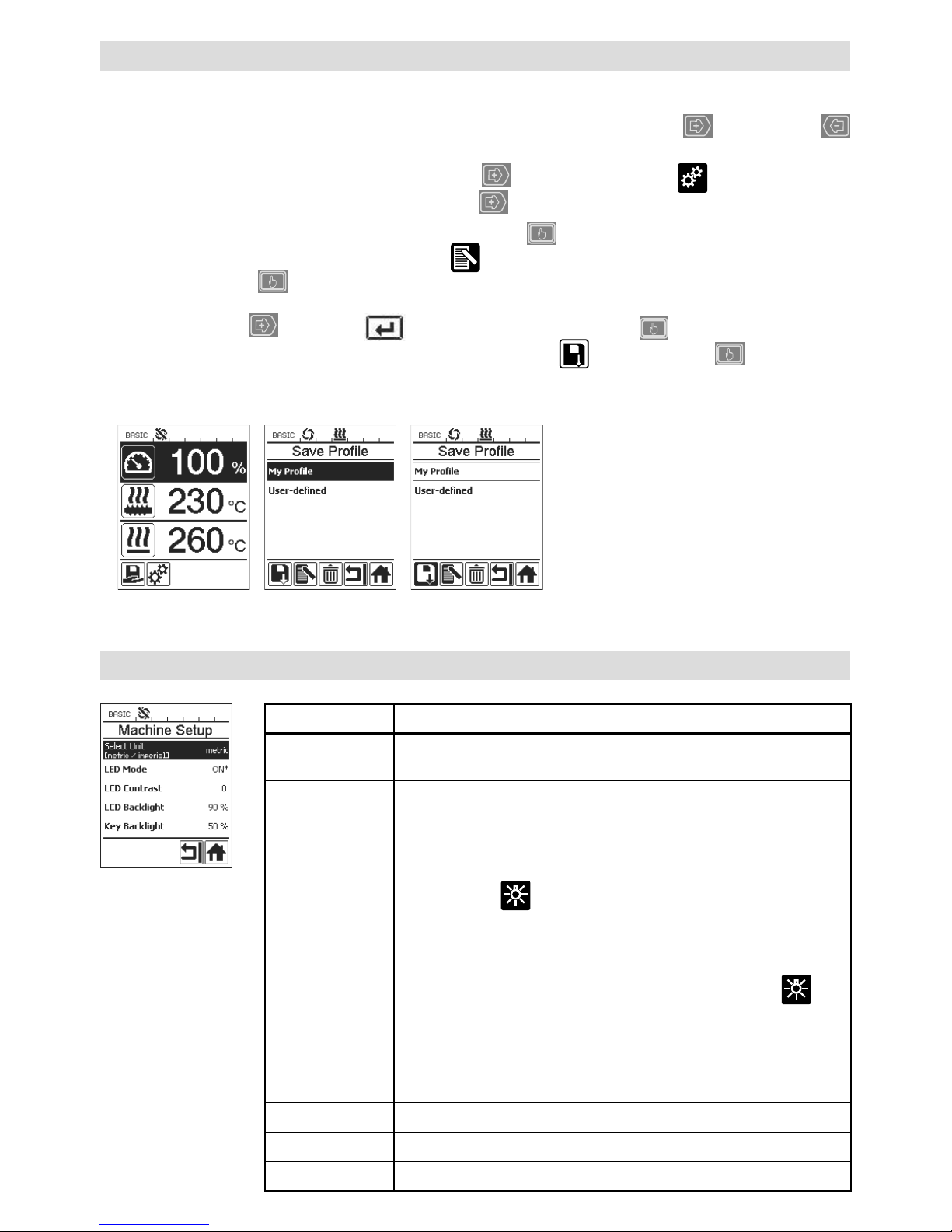

Profile definieren

• Im Menü «Save Profile» können Sollwerteinstellungen der max. Ausstossmenge, Plastifizier- Luft-Temperatur

und Luftleistung unter einem von Ihnen gewünschten Namen abspeichert werden (siehe Kapitel «Eingabe von

Namen oder Passwörtern»).

• Erstellen eines neuen Profils:

– In der Arbeitsanzeige (28) gewünschte Sollwerte mittels Tasten 24 / 26 «Plus»

oder «Minus»

einstellen.

– In der Funktionsanzeige (27) mit Taste 26 «Plus»

das Menü Einstellungen auswählen.

– Im Menü «Setup» die Auswahl mit Taste 26 «Plus»

«Save Profile» auswählen.

– Das Profil «User-defined» auswählen und mittels Taste (25)

bestätigen.

– In der Funktionsanzeige (27) das Symbol

«Ausgewählte Position bearbeiten» auswählen und

mittels Taste (25) bestätigen.

– Gewünschten Profilnamen eingeben (siehe Kapitel «Eingabe von Namen oder Passwörtern»), anschliessend

mit der Taste 26 «Plus»

das Symbol auswählen und mittels Taste (25) bestätigen.

– In der Funktionanzeige (27) ausgewähltes Symbol «Speichern» mittels Taste (25) bestätigen. Das

Profil wurde erfolgreich gespeichert und ausgewählt.

3534

16

Profile definieren

• Editieren eines bestehenden Profils (ausgenommen Leister-Profile):

– In der Arbeitsanzeige (28) gewünschte Sollwerte mittels Tasten 24 / 26 «Plus»

oder «Minus»

einstellen.

– In der Funktionsanzeige (27) mit Taste 26 «Plus»

das Menü Einstellungen auswählen.

– Im Menü «Setup» die Auswahl mit Taste 26 «Plus»

«Save Profile» auswählen.

– Das zu editierende Profil auswählen und mittels Taste (25)

bestätigen.

– In der Funktionsanzeige (27) das Symbol

«Ausgewählte Position bearbeiten» auswählen und

mittels Taste (25) bestätigen.

– Gewünschter Profilnamen eingeben (siehe Kapitel Eingabe von Name oder Passwörter), anschliessend mit

Taste 26 «Plus»

das Symbol auswählen und mittels Taste (25) bestätigen.

– In der Funktionanzeige (27) ausgewähltes Symbol «Speichern» mittels Taste (25) bestätigen. Das

Profil wurde erfolgreich gespeichert und ausgewählt.

Maschinen-Einstellungen

Menü Funktion

Select Unit

Einstellung der verwendeten Einheit:

– metrisch / imperial

LED Mode

LED Modus:

– ON*: Die LED-Beleuchtung kann nur eingeschaltet werden,

wenn der Antrieb freigegeben ist. Sobald der Antrieb freigegeben ist, erscheint in der Funktionszanzeige (27) das

LED-Symbol

. Über dieses kann die LED-Beleuchtung nach

Wunsch ein- / ausgeschaltet werden. Der LED-Modus wird nicht

verändert.

– ON: Die LED-Beleuchtung ist immer eingeschaltet.

In der Funktionszanzeige (27) wird das LED-Symbol

eingeblendet. Über dieses kann die LED nach Wunsch

ein- / ausgeschaltet werden.

Der LED-Modus wird nicht verändert.

– OFF: Die LED-Beleuchtung ist immer ausgeschaltet.

LCD Contrast Einstellen des LCD-Kontrastes

LCD Backlight Einstellen der Display-Hintergrundbeleuchtung

Key Backlight Einstellen der Tastatur-Hintergrundbeleuchtung

17

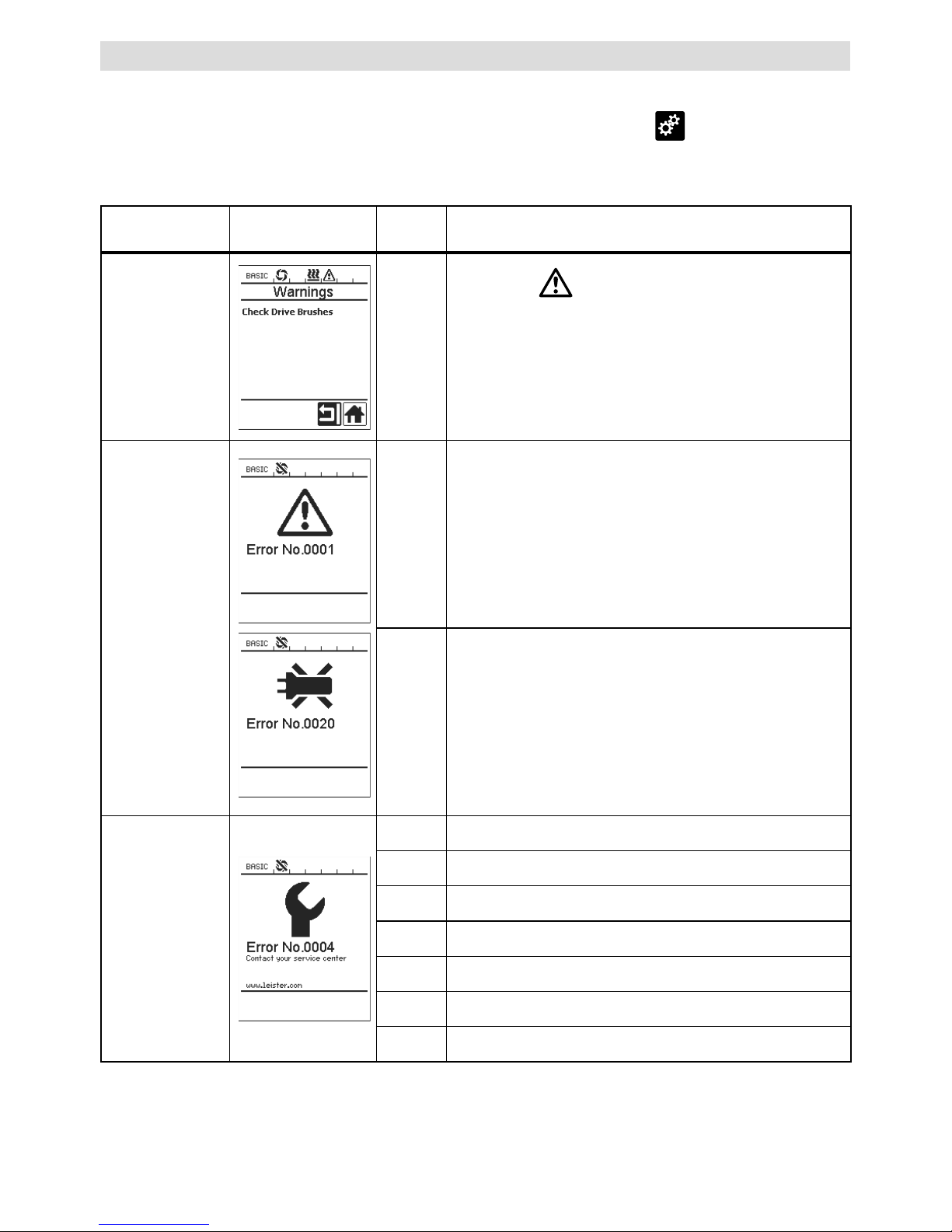

Warnung und Fehlermeldungen

• Liegt eine Warnung vor, kann der Anwender ohne Einschränkung weiter arbeiten. Genauere Informationen

zur Warnung können über die Funktionsanzeige (27) im Menü Einstellungen

unter «Show Warnings»

abgerufen werden.

• Tritt ein Fehler auf, schaltet das Gerät alle Heizungen aus und der Antrieb wird nicht mehr freigegeben.

Art der

Meldung

Anzeige

Feler-

Code

Fehlerbeschreibung

Warnung

—

Warnsymbol

in der Statusanzeige (30).

Die Kohlenbürsten des Antriebs müssen gewechselt

werden.

Nach dem ersten Erscheinen des Warnsymbols kann der

Antrieb noch für 5 h betrieben werden. Anschliessend

erscheint die Fehlermeldung «Error No.0400» und der

Antrieb wird nicht mehr freigegeben.

Fehler

0001

Übertemperatur des Gerätes.

Gerät abkühlen lassen.

0020 Heizelement für Luft defekt.

Fehler !

Leister Service

Center

kontaktieren

0004 Fehler der Hardware.

0008 Thermoelement der Luft defekt.

0010 Thermoelement des Plast defekt.

0040 Heizelement des Plast defekt.

0100 Gebläse defekt.

0200 Fehler Kommunikation.

0400 Kohlenbürsten / Antrieb oder Übertemperatur Antrieb.

18

Verbrennungsgefahr!

Nur mit temperaturfesten Handschuhen arbeiten.

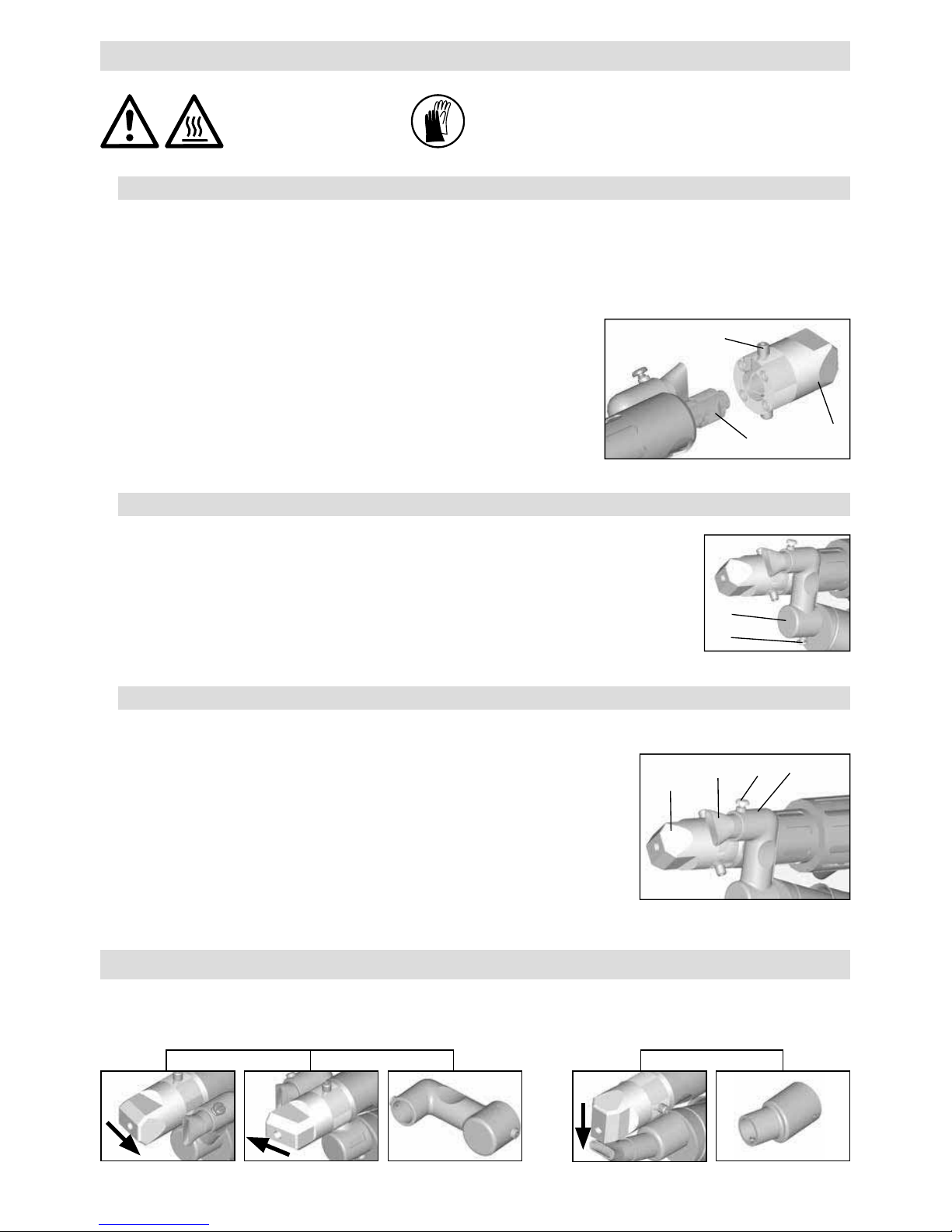

Wechsel des Schweissschuhs

• Demontage

– Das betriebswarme Gerät abschalten und vom elektrischen Netz trennen.

– Den Schweissschuh (8) durch Lösen der Klemmschrauben (18) von der Extrudierdüse (17) entfernen.

– Die Extrudierdüse (17) bei jedem Schweissschuhwechsel von

Schweissgutrückständen reinigen und sicherstellen, dass sie

festgeschraubt ist.

• Montage

– Einen der Schweissnaht angepassten Schweissschuh (8) auf die

Extrudierdüse (17) schieben und durch Anziehen der Klemmschrauben (18) be fes tigen.

18

8

17

Wechsel der Vorwärmdüse

• Demondage

– Bei der Vorwärmdüse (9) die Klemmschraube (19) lösen und

Vorwärmdüse (9) von der Heissluftführung (16) abziehen.

• Montage

– Vorwärmdüse (9) auf die Heissluftführung (16) schieben.

Auf parallele Ausrichtung zum Schweissschuh (8) achten.

– Klemmschraube (19) anziehen.

8

9

19 16

Wechsel der Heissluftführung

• Demontage

– Klemmschraube (33) lösen. Heissluftführung (16) kann abgezogen oder in

die gewünschte Schweissrichtung gedreht werden.

– Entsprechende Heissluftführung (16) montieren (siehe Kapitel Schweissrichtung).

– Klemmschraube (33) festziehen.

Schweissrichtung

Schweissrichtung Heissluftführung Schweissrichtung Heissluftführung

Wechsel von Zubehör

• Für die ausgewählte Schweissrichtung die passende Heissluftführung.

33

16

19

• Aus technischen und sicherheitsrelevanten Gründen darf ausschliesslich nur Leister-Zubehör verwendet werden.

• Zuberhör unter www.leister.com

Zubehör

Vorwärmdüse

• Damit bei der grossen Auswahl an Schweissschuhen eine optimale Vorwärmung erreicht wird, bietet Leister

Technologies AG verschiedene Vorwärmdüsen an.

Schweissschuh

Schweissnahtbreite

mm

Vorwärmdüsen

Breite 21 mm

Länge 26 mm

Breite 21 mm

Länge 42 mm

ø 14 mm

Länge 58 mm

abgewinckelt

ø 14 mm

Länge 46 mm

Kehlnaht

5 / 6

• (b) •

8 / 10

• (b) •

12

• (b) •

Ecknaht

• (b) •

V-Naht

3 / 4

•• (a)

5 / 6

•• (a)

8 / 10

•• (a)

Schweissschuh-Sortiment

• Leister Technologies AG bietet für alle gebräuchlichen Nahtformen entsprechende Schweissschuhe in diversen

Grössen an

:

Rohling

Kehlnaht

Ecknaht V-Naht

a) DVS-Schweissschuhe analog WELDPLAST S2-PVC.

b) Abgewinckelte Vorwärmdüse für optimale Vorwärmung bei radialen Rohrschweissungen.

Heissluftführung

20

• Netzanschlussleitung (13) und Stecker auf elek

trische und mechanische Beschädigungen überprüfen.

• Die Extrudierdüse (17) bei jedem Schweissschuhwechsel von Schweissgutrückständen befreien.

Wartung

• Reparaturen sind ausschliesslich von autorisierten Leister-Service-Stellen ausführen

zu lassen.

Diese gewährleisten innert 24 Stunden einen fachgerechten und zuverlässigen

Reparatur-Service mit Original-Ersatzteilen gemäss Schaltplänen und Ersatzteillisten.

• Erscheint beim WELDPLAST S1 nach dem Einschalten des Gerätes die Anzeige

«Maintenacne servicing», sollte der Antriebsmotor (Kollektor und Kohlenbürsten) von

einer autorisierten Leister-Service-Stelle kontrolliert und allenfalls ersetzt werden. Die Anzeige verschwindet automatisch nach 10 Sekunden oder kann durch

Drücken der Taste (25) «Bestätigen» direkt übersprungen werden.

Service und Reparatur

• Für dieses Gerät gelten die vom direkten Vertriebspartner/Verkäufer gewährten Garantie- oder Gewährleistungsrechte ab Kaufdatum. Bei einem Garantie- oder Gewährleistungsanspruch (Nachweis durch Rechnung oder

Lieferschein) werden Herstellungs- oder Verarbeitungsfehler vom Vertriebspartner durch Ersatzlieferung oder

Reparatur beseitigt. Heizelemente sind von der Gewährleistung oder Garantie ausgeschlossen.

• Weitere Garantie- oder Gewährleistungsansprüche werden im Rahmen des zwingenden Rechts ausgeschlossen.

• Schäden, die auf natürliche Abnutzung, Überlastung oder unsachgemässe Behandlung zurückzuführen sind,

werden von der Gewährleistung ausgeschlossen.

• Keine Garantie- oder Gewährleistungsansprüche bestehen bei Geräten, die vom Käufer umgebaut oder verändert

wurden.

Gewährleistung

21

Operating Instructions (Translation of the original operating instructions)

Read the operating instructions carefully before starting

the device and keep them for future reference.

Leister WELDPLAST S1

Extrusion Welder

Application

• Extrusion welding of the following materials:

PP / PE-HD / PVC-U / PVC-C / PVDF

• Other materials on enquiry

Warning

Opening the device is extremely dangerous, since live parts and connections are exposed.

Remove the plug from the socket before opening the device.

Danger of fire and explosion if the extrusion welder is used incorrectly (e.g. overheating

of material), particularly near combustible materials and explosive gases.

Danger – can cause burns ! Do not touch bare metal parts and emerging material while

hot. Allow the device to cool. Do not direct stream of hot air or emerging material towards

people or animals.

Connect device to power socket with protective earth conductor. Any break in the

protective earth conductor inside or outside the device is dangerous!

Only use extension cables with a protective earth conductor!

Caution

The nominal voltage indicated on the device must correspond to the mains voltage. If

power failure occurs, the main switch and drive must be switched o (release locking

device).

When using the device on building sites, a residual current circuit breaker is essential

for the safety of persons there.

Risk of dazzling! Avoid direct eye contact with the LED light beam.

The device must not be left unattended when in use. Heat can reach combustible

materials which are out of sight.

The device may only be used by trained personnel or under their supervision. Children

may not use the device under any circumstances.

Keep away from wet and damp areas.

GB

22

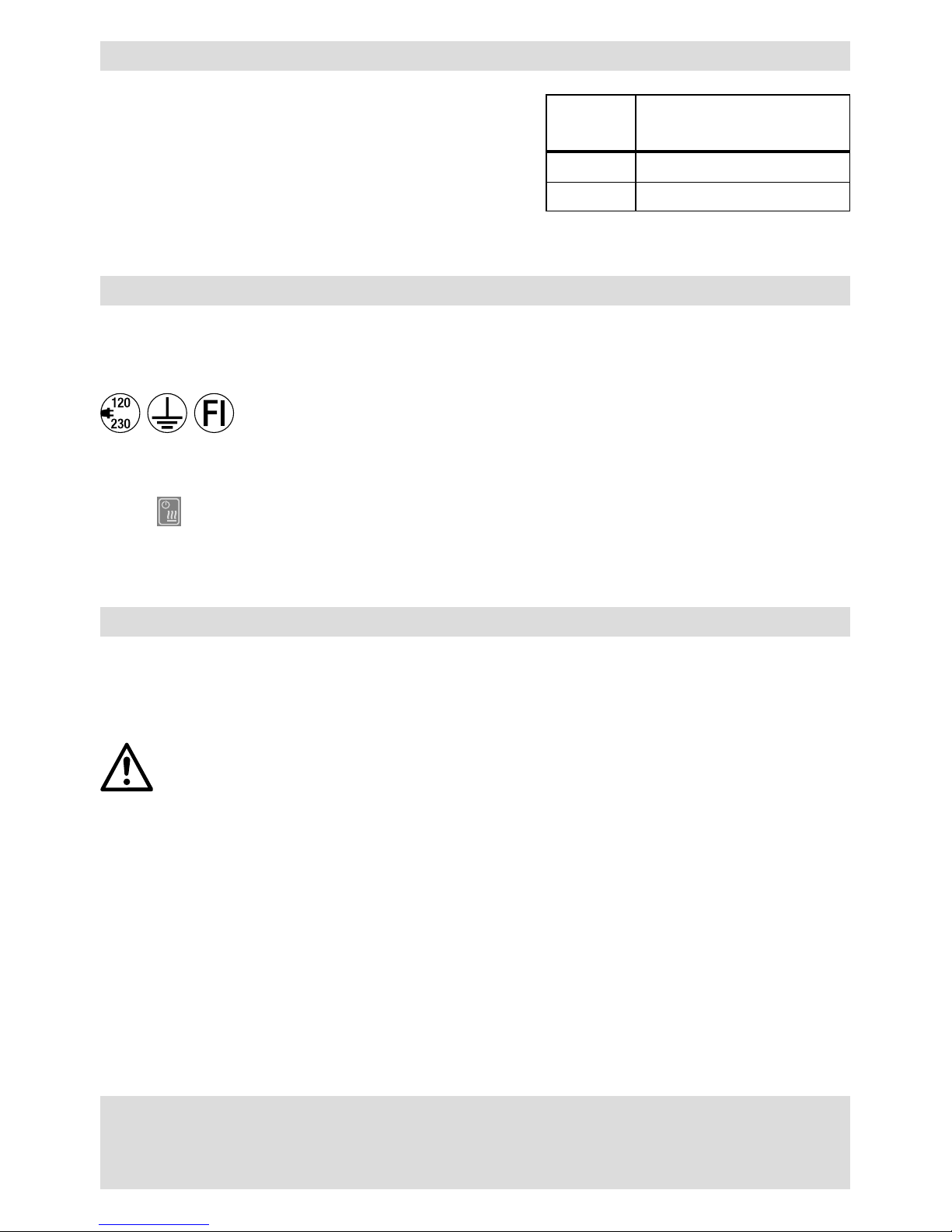

Voltage V~ 100 120 230

Power consumption W 1500 1800 1600

Frequency Hz 50/60 50/60 50/60

Air temperature °C max. 360

Plasticizing temperature °C max. 260

Output (Ø 3 mm) kg/h HD-PE 0.2 – 0.5; PP 0.2 – 0.5

Output (Ø 4 mm) kg/h HD-PE 0.3 – 0.8; PP 0.3 – 0.75

Filler rod mm Ø 3 / Ø 4

Emission level L

pA

(dB) 76 (K = 3 dB)

Dimensions L × w × h mm 435 × 264 × 91 (without welding shoe)

Weight kg 4.7 (without power supply cord)

Conformity mark

Mark of approval

Protection class I

The right to make technical changes is reserved

Conformity

Leister Technologies AG, Galileo-Strasse 10, CH-6056 Kaegiswil/Switzerland confirms that this product

in the version put into circulation by us, fulfils the requirements of the following EC directives.

Directives: 2006/42, 2004/108, 2006/95, 2011/65

Harmonised standards: EN 12100, EN 55014-1, EN 55014-2, EN 61000-6-2, EN 61000-3-2,

EN 61000-3-3, EN 62233, EN 60335-2-45, EN 50581

Kaegiswil, 20.10.2014

Bruno von Wyl, CTO Andreas Kathriner, GM

Disposal

Power tools, accessories and packaging should be recycled. For EU countries only: do not

dispose of power tools in your household rubbish! According to the European Directive 2002/96

on waste electrical and electric equipment and its implementation in national law, power tools

which can no longer be used must be collected separately and recycled.

Technical Data

23

Device Description

1 Main switch

2 On/o switch for drive

3 Potentiometer

4 Drive locking device

5 Display

6 Guide handle

7 Jacket heating

8 Welding shoe

9 Pre-heating nozzle

10 Protection tube

11 Filler rod insertion point

12 Device grip

Operating unit

21 Key «Up»

22 Key «Down»

23 Key heating «on / o»

24 Key «Minus»

25 Key «Confirmed»

26 Key «Plus»

Display

27 Function display

28 Working display

29 Status display «Section 1»

30 Status display «Section 2»

13 Power supply cord

14 Heating element protection tube

15 Blower (brushless)

16 Hot air duct

17 Extruder nozzle

18 Clamping screw welding shoe

19 Clamping screw pre-heating nozzle

20 Gripper clamp

31 LED light

32 Buer bolt

33 Clamping screw hot air guidance

2

3

4

18

8

17

%

100

°C

230

°C

260

25

28

30

27

26

21

22

23

24

29

1

5

6

7

8

19

10

11

12

13

14

15

16

20

9

31

11

32

33

24

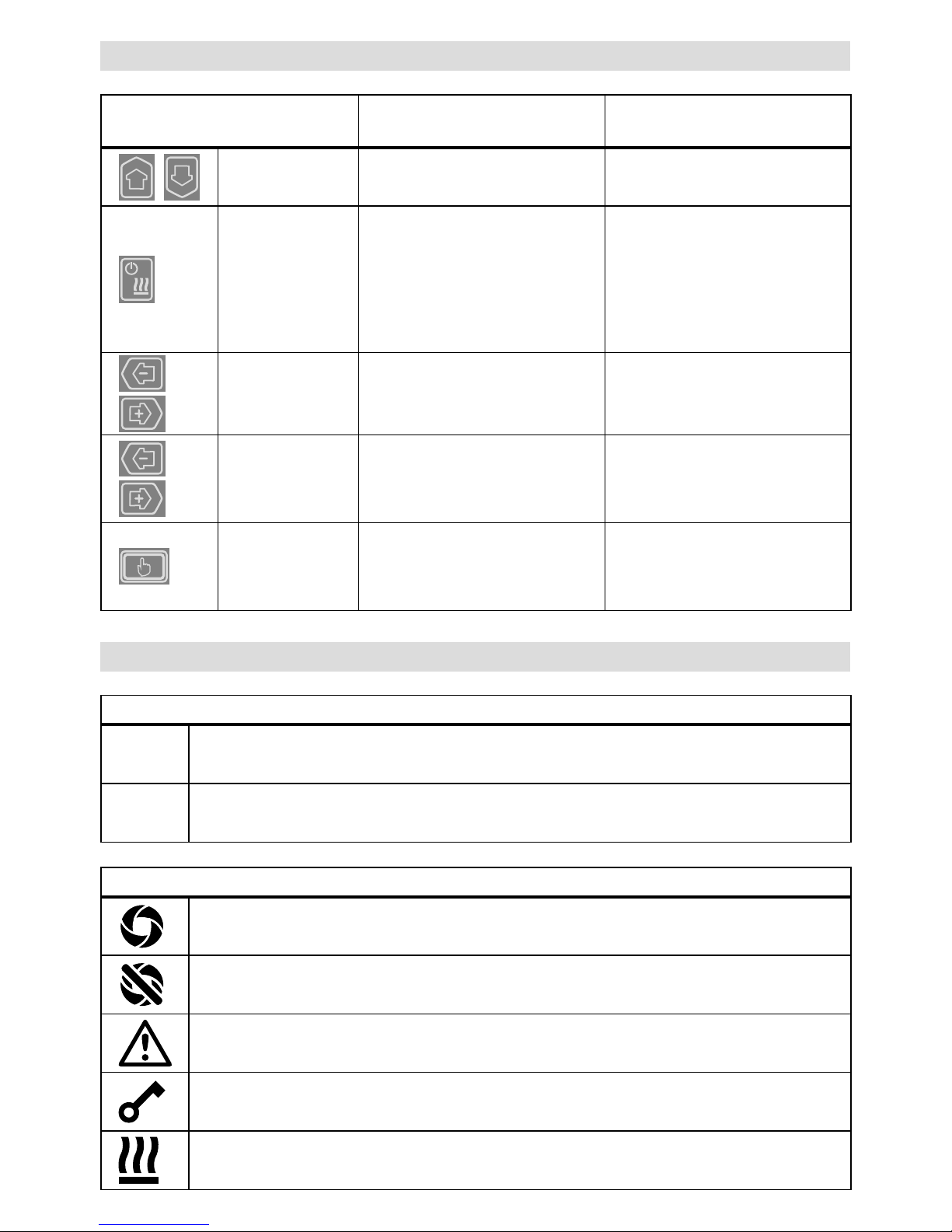

Operating unit description

Display description

Status display «Section 1» (29)

PE-HD

Profile currently selected. If profile names consist of more than 6 characters, the first 6 characters

are shown first, followed by the remaining characters.

1m16s Time remaining until the drive is released (1 min. 16 sec.)

Status display «Section 2» (30)

Drive released

Drive not released

Warning (carbon brushes / drive)

Key lock (only appears when key lock is activated)

Air and plasticizing heating is switched on

Keyboard mode

Current selection in the working

display

Current selection in the function

display

Up (21)

Down (22)

Changes the item within the working display

Changes from the function display

to the working display

Heating

on/o (23)

No function

Changes from welding mode to the

cooling process

Changes from the cooling process

to welding mode

Changes from the start display to

welding mode

Minus (24)

Plus (26)

(press briefly)

Sets the required setpoint in 5°C or

5% stages.

Changes the item in the function

display

Minus (24)

Plus (26)

(press and hold)

Sets the required setpoint in 10°C

or 10% stages.

Changes the item in the function

display

Confirmed (25)

Set value is adopted straight away

and the selection goes straight back

to the function display

Selected function is executed

25

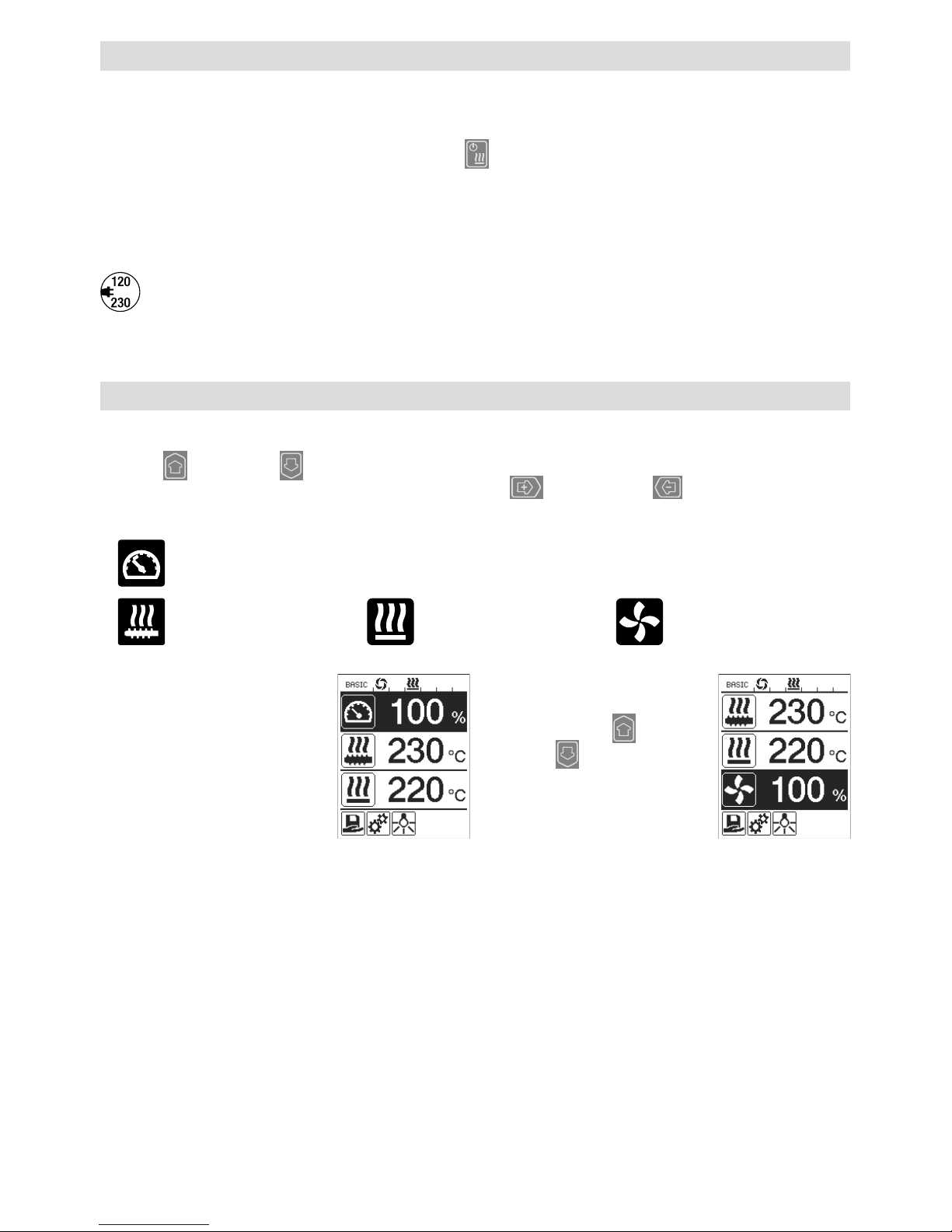

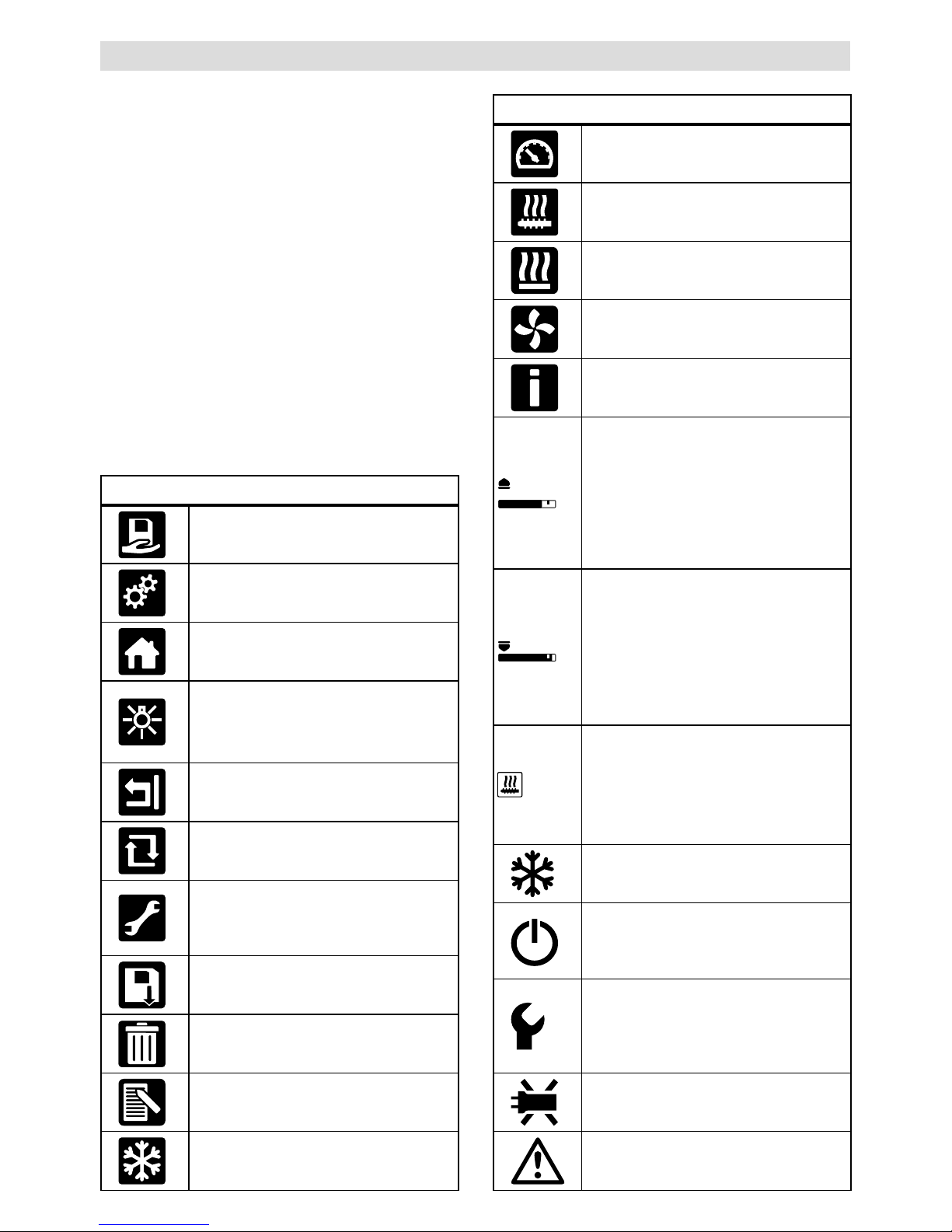

Function and working display

• On the function and operating display, the field or icon

that is highlighted always indicates what is currently

selected.

• The actual values are always shown in the working

display, unless an item is selected, in which case the

setpoint is displayed.

• If «Show Set Values» is activated, both the actual

value and the setpoint are displayed (small font size).

Function display (27)

Select freely definable and predefined

profiles

Settings

Return to working display

(exits a menu directly)

Switch LED on/o.

This function is only available if the LED

has been activated.

Go back one level

Reset settings or hour counter

Service menu

(can only be accessed by entering the

password)

Save

Delete the selected item

Edit the selected item

Start cooling process

Function display (28)

Setpoint:

Drive output volume [%]

Setpoint:

Plasticizing temperature [°C/°F]

Setpoint:

Air temperature [°C/°F]

Setpoint:

Air volume [%]

Information box

°C

200

230

The arrow pointing upward and the

progress bar indicate that the setpoint

(shown on the progress bar) has not yet

been reached (too cold). The flashing

value is the actual value. The value

next to the progress bar is the setpoint.

°C

250

230

The arrow pointing downward and the

progress bar indicate that the setpoint

(shown on the progress bar) has not yet

been reached (too hot). The flashing

value is the actual value. The value

next to the progress bar is the setpoint.

°C

250

230

If «Show Set Values» is activated,

both the actual temperature (large font

size) and the set temperature (small

font size) are displayed.

Cooling process

Device in standby mode. Once the

counter has counted down, the device

will start «Cool down mode».

An error has occurred. An error code

also appears (the device is no longer

ready for use). Contact an authorized

service center.

Heating element air faulty

Device temperature too high.

Allow the device to cool down.

26

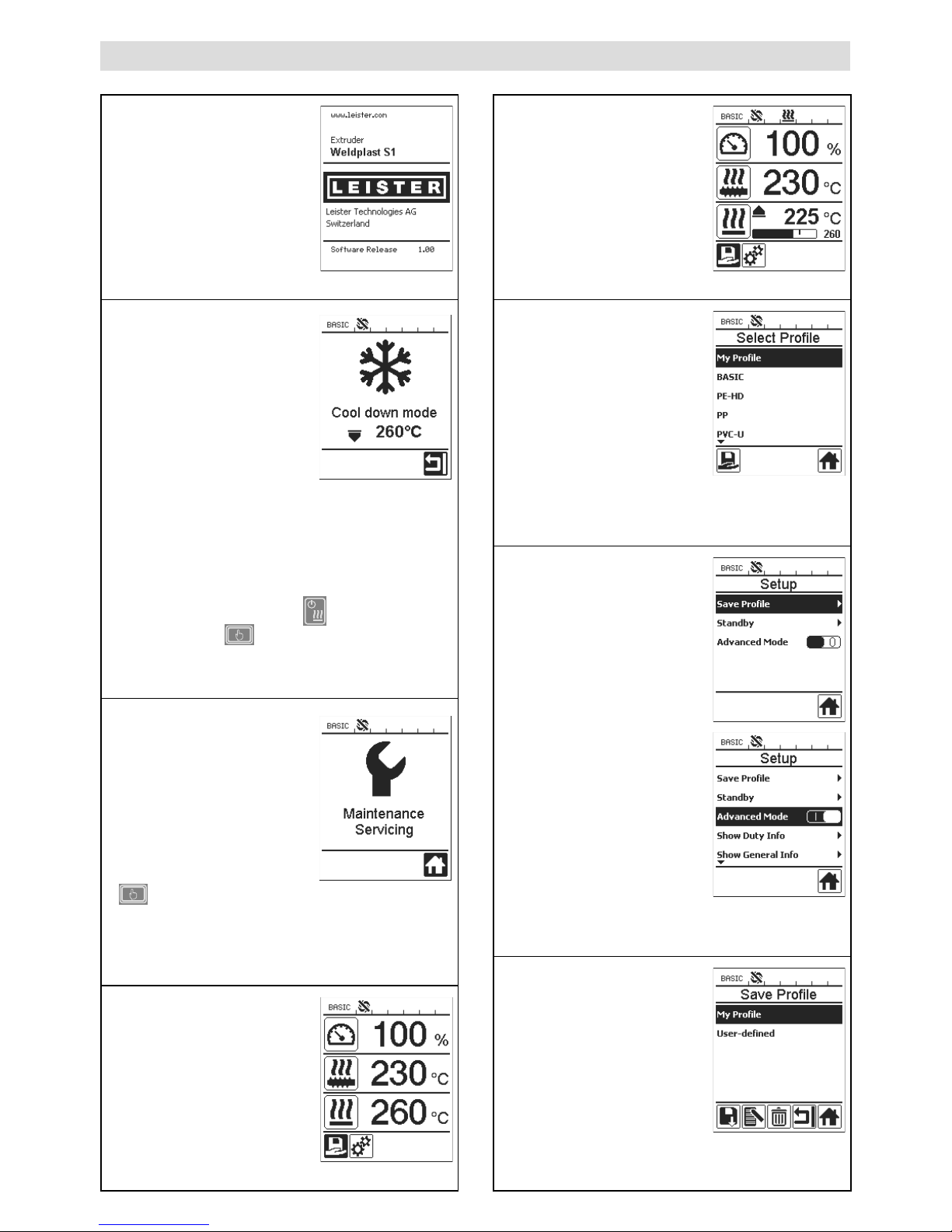

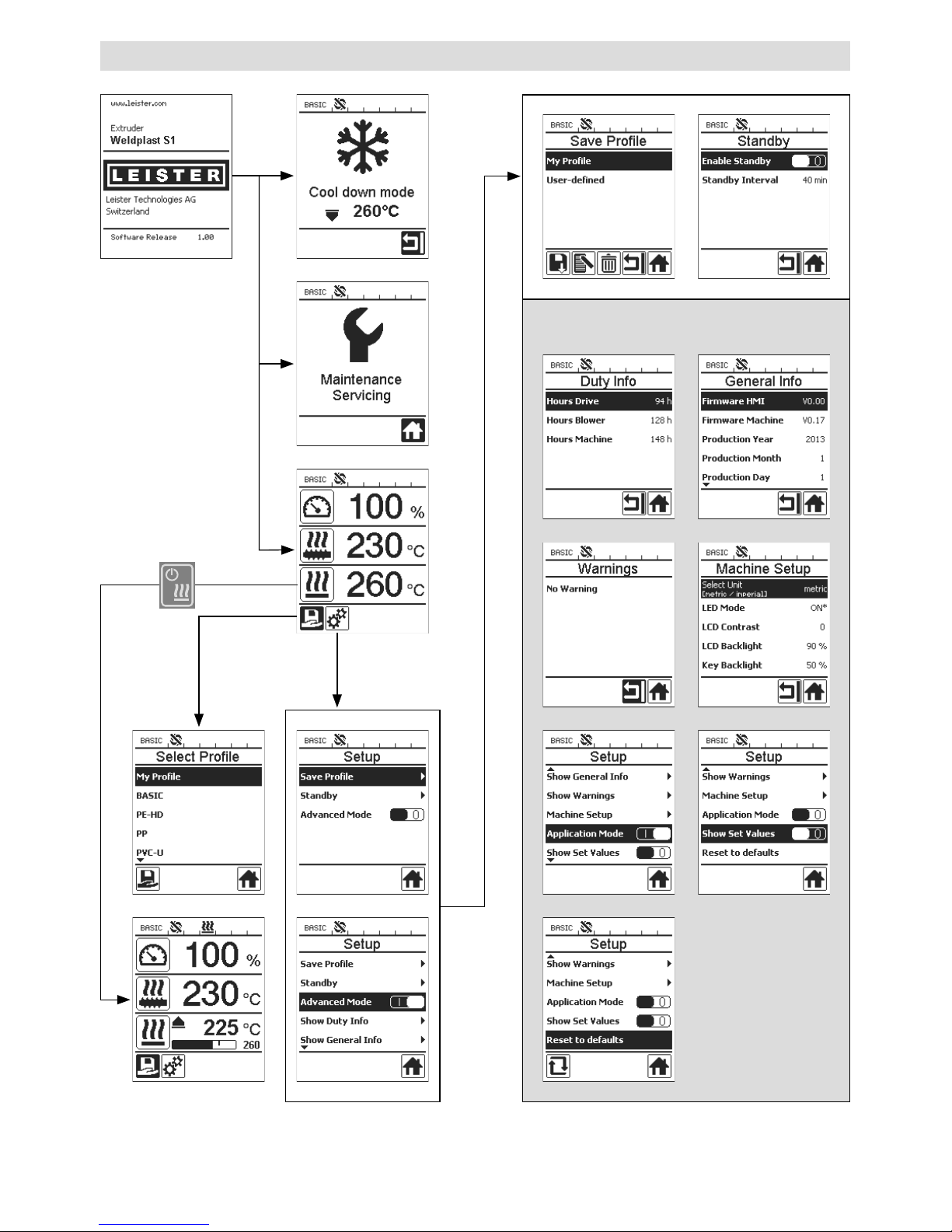

Welding startup display

Display during the heating

process

Select Profile

Select a user-defined profile

or one defined by Leister. The

process of selecting a profile

is described in detail in the

«Select Profile» chapter on

page 32.

Setup

In the basic setting, you can

save profiles and access

the standby function via the

«Setup» menu.

Select «Advanced Mode»

to access a range of other

settings options.

Save profile

The process of saving freely

definable profiles is described

in detail in the «Defining

profiles» chapter on page

34/35.

Startup display

Display on startup with the

software release of the output

unit.

Cool down mode

In this mode, the heating is

switched o and the device

is in cool down mode. If the

pre-heating air temperature

is more than 100°C when

the device is switched

on, the device switches

automatically to «Cool down

mode». The cooling process is complete when

the pre-heating air temperature has been below

100°C for 2 mins.

To switch the heating back on again, press the

«Heating on/o» key (23)

or the «Confir-

med» key (25) .

Maintenance servicing

When the maintenance

interval for the drive motor

is reached, «Maintenance

Servicing» appears after

the startup display.

You can

carry on working by pressing

the

«Confirmed» key (25)

. You must take the

device to your service center.

Start display

The start display shows all

setpoints.

At this point, the heating is

not switched on but you can

set all setpoints.

Working display overview

27

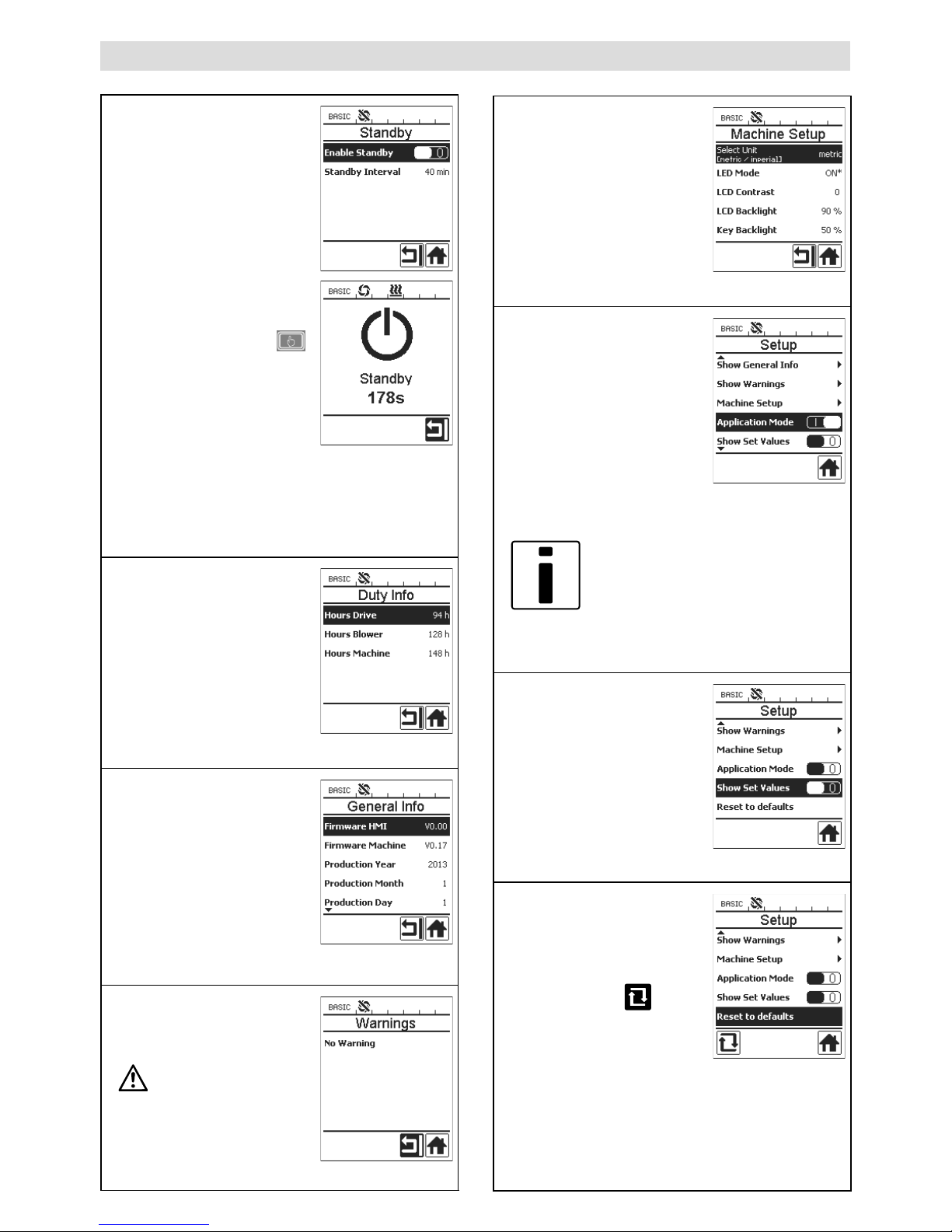

Working display overview

Standby

If standby mode is activated

and the user does not press

a key on the operating unit or

the on/o switch for drive

(2) during the time set as

the «Standby Interval», the

device automatically switches

to the standby display. If

the user does not press the

«Confirmed» key (25)

in the next 180 seconds, cool

down mode starts automatically.

Duty Info

Hours Drive: Current runtime

of the drive (can be reset).

Hours Blower: Current runtime of the blower.

Hours Machine: Current

runtime of the machine.

General Info

Firmware HMI: Software

version of the display unit

(communication module).

Firmware Machine: Software

version of the output unit.

Production Info: Information

about the production date.

Warnings

If there is a warning pending,

this is indicated by the

symbol in the status

display. The «Warnings»

menu contains more detailed

information about the current

warning.

Machine Setup

The machine settings are

described in detail in the

«Machine Setup» chapter.

Application Mode

If „Application Mode“ is

activated, the operating

display will provide detailed

information on the actual

plasticizing temperature

and the capacity utilization

of the hot-air blowers and

plasticizing heating.

Plast : 80 % 222 °C

Heat : 40 % 197 °C

Amb. : 25 °C

Mains : 50 Hz

If «Show Set Values» is

activated, both the actual

temperature (large font

size) and the set temperature (small font size) are

displayed.

Reset to defaults

If the “Reset to defaults”

menu is selected and

confirmed by selecting the

relevant function

,

all customer-specific profiles

will be deleted. Settings that

have been changed via the

Setup menu will be reset to

the factory settings.

28

Menu navigation

Only available in «Advanced Mode»

29

Risk of burning! Let the device cool

Work environment / Safety

Before putting into operation, check power supply cord (13) and connector as well as extension

cable for electrical and mechanical damages.

The extrusion welder must not be used in areas where there is danger of explosion or flammable

materials. Ensure a safe posture during work. The power cable and filler rod must be free to move

and must not obstruct the user or third parties during work.

Place extrusion welder on a fire resistant base. Hot metal parts and hot streams of air must be

kept at a safe distance from the base and walls.

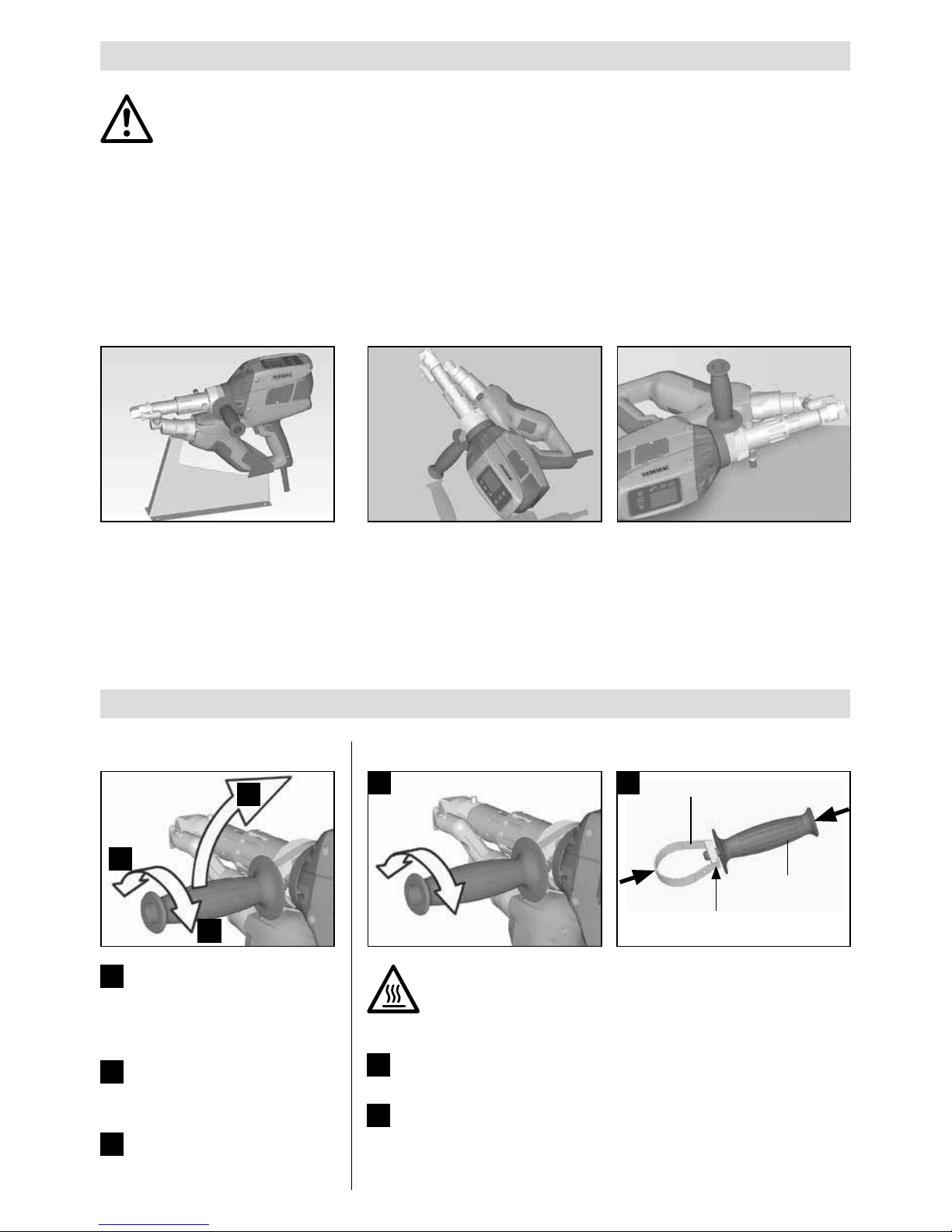

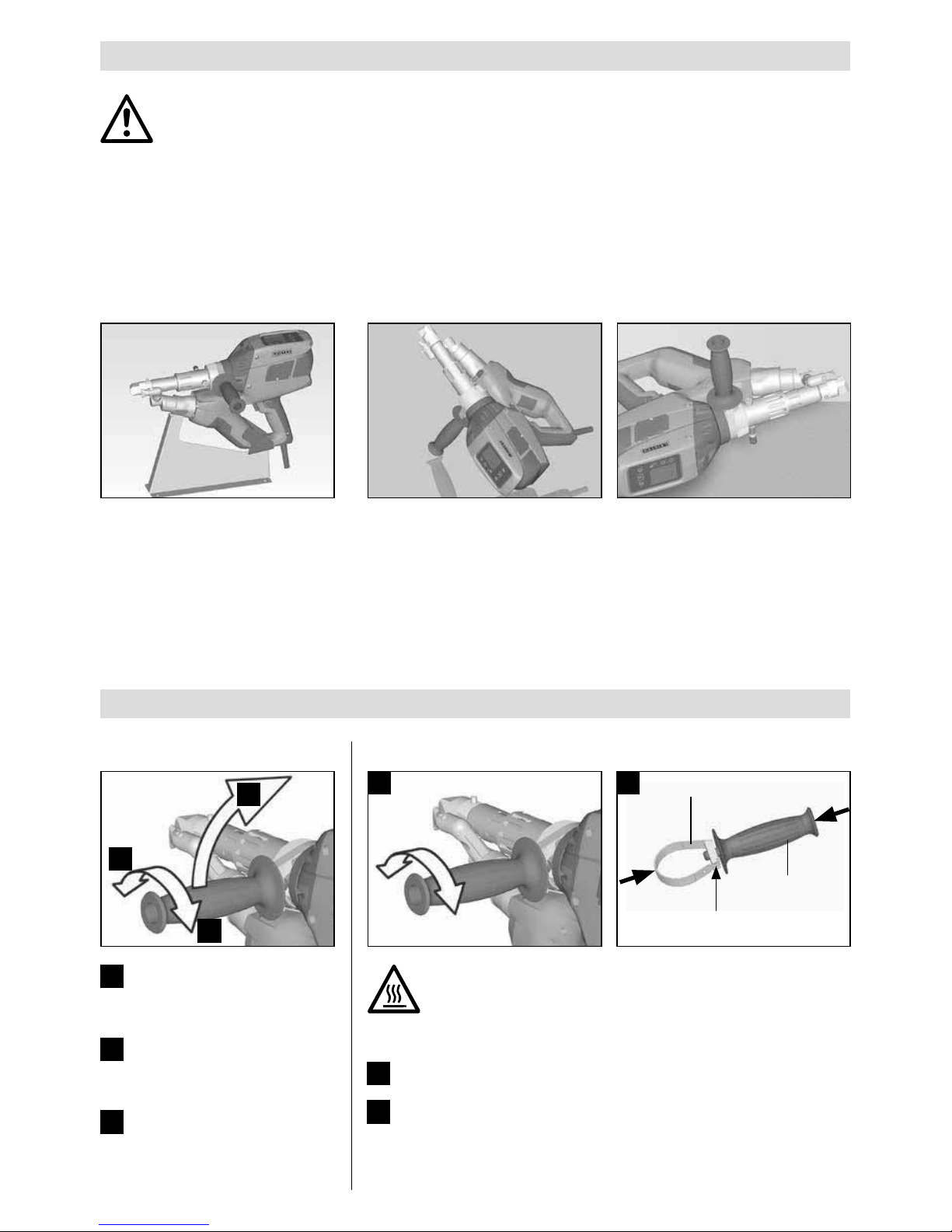

Setting the guide handle

Workplace

1

2

3

1

Loosen clamp by turning

the guide handle (6) anticlockwise

2

Move the guide handle (6)

into the desired operating

position.

3

Tighten clamp again by turning

guide handle (6) clockwise

Leister provides a stand for

commissioning and holding

the extrusion welder

When not welding, the drive should be switched o with the drive on/o

switch (2).

Place the extrusion welder with correspondingly set and firmly tightened

guide handle (6) on a stable, fireproof base or buer bolt (32) as shown

in the illustration.

Guide handle

Removing/Fitting the handle

Removing the handle

1

Turn the handle (6) anticlockwise to loosen the clamp.

2

Press on the handle (6) and the gripper clamp (20) to open the lock

(see arrows). Remove the handle (6) using the gripper clamp (20).

To fit the handle, follow the steps in reverse order.

1 2

Lock

Handle (6)

Gripper clamp (20)

30

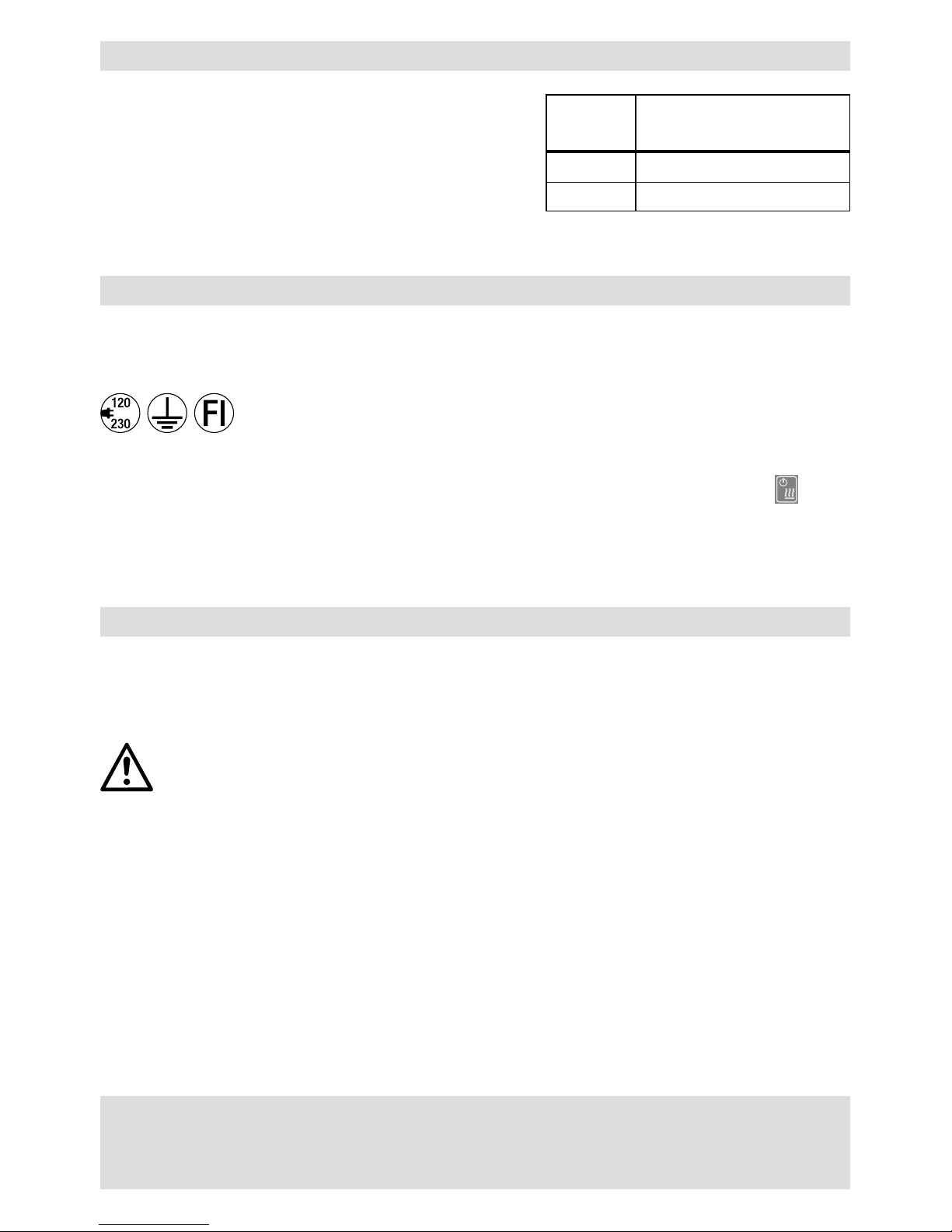

Extension cables

• Ensure the minimum cross-section when using extension

cables:

• The extension cable must be approved for the site of use (e.g.

in the open air) and marked correspondingly.

• When using a power unit for power supply, its nominal power

rating is: 2 × nominal power rating of the extrusion welder.

Length

[m]

Minimum cross-section

(at 100 – 230V~) [mm

2

]

Up to 19

2.5

20 – 50 4.0

• Switch the extruder on at the main switch (1). Depending on the pre-heating air temperature, either the startup

display or «Cool down mode» will appear on the display (5). Press the «Heating on/o» key (23)

to start

the heating process.

• If the device is ready for operation, the LED light (31) will switch on automatically (factory setting).

• Press the on/o switch for drive (2) to start the drive.

Starting the device

Connect the device to the nominal voltage. The nominal voltage specified on the device

must match the mains voltage.

• Install the relevant welding shoe (8), pre-heating nozzle (9), and hot air duct (16) if necessary (Changing

accessories, page 37).

• Insert the filler rod (ø 3 or 4 mm) into the filler rod insertion point (11).

• The filler rod is automatically drawn through the filler rod insertion point (11).

There must be no resistance when the rod is inserted.

CAUTION!

Always operate the device with the filler rod, but never feed the filler rod into both filler rod

insertion points at the same time.

• The speed at which the filler rod is drawn in can be set using the potentiometer (3).

• Pause the delivery of material using the on/o switch for drive (2).

• Direct the pre-heating nozzle (9) onto the area to be welded.

• Pre-heat the area to be welded with oscillating movements.

• Place the device on the prepared welding area and press the on/o switch for drive (2) again.

• Carry out a test weld according to the welding instructions from the material manufacturer and the national

standards or directives. Check the test weld.

• Adjust the temperature setting, output volume, and air volume as necessary (see "Setting the welding parameters" chapter, page 31).

• During a longer period of welding, the on/o switch for drive (2) can be kept in continuous operation using

the drive locking device (4).

CAUTION!

• PVC-U and PVC-C are processed in the menu of PVC-U.

• To prevent corrosion when processing PVC-U, PVC-C, ECTFE, PVDF etc., we recommend flushing the extrusion

welder with HD-PE when you have finished welding.

Welding process

Loading...

Loading...