Leister Varimat V Operating Instructions Manual

1

LEISTER Varimat V

Hot Air Automatic Welding Machine

GB

OPERATING INSTRUCTIONS

®

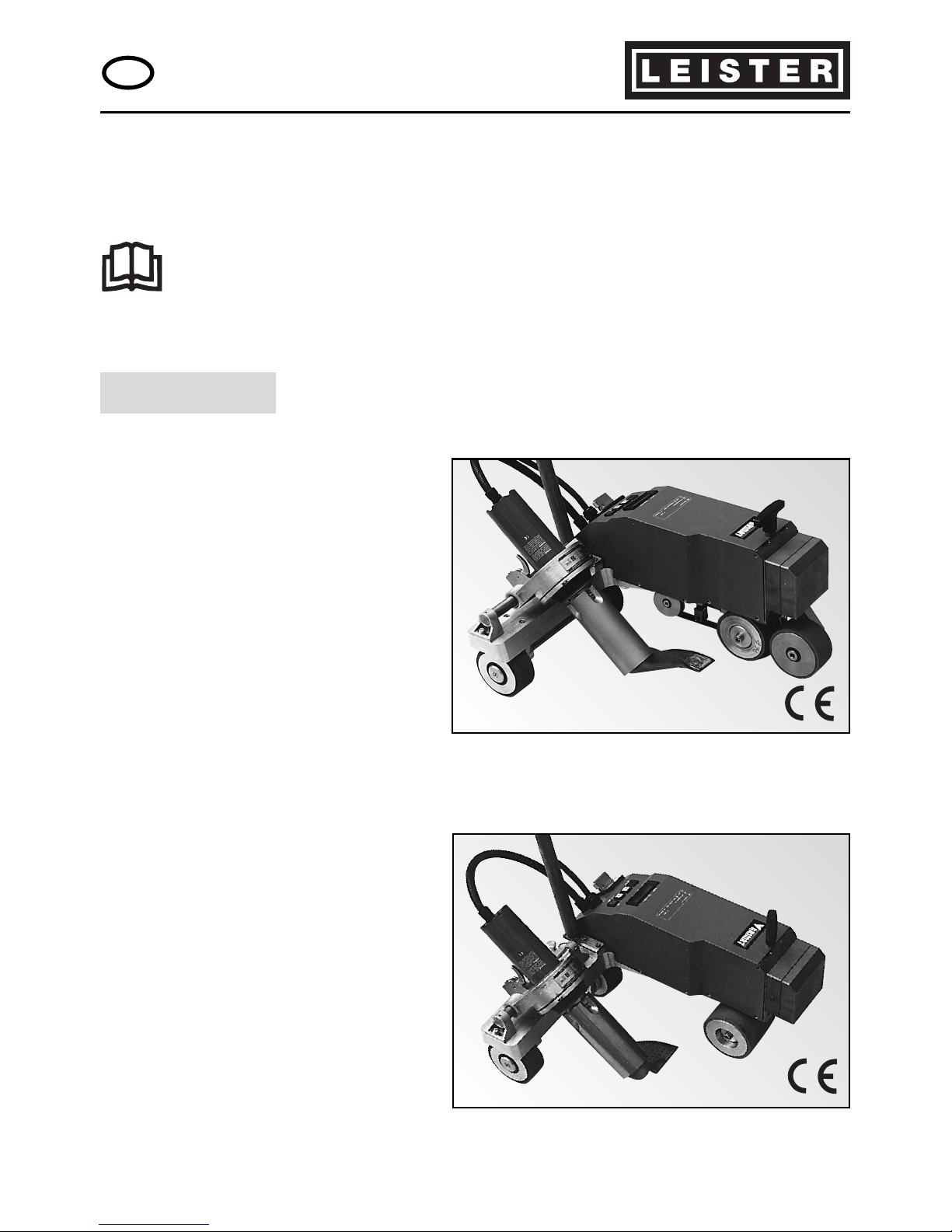

LEISTER Varimat V

Automatic Overlap Welding

Machine

• For overlap welding of roofing

membranes made of PVC, PE,

ECB, EPDM, CSPE, and Modified

Bitumen for areas close to

edges and uneven surfaces.

• Overlap welding of foils and

coated materials. Width of welding seam 20, 40 mm.

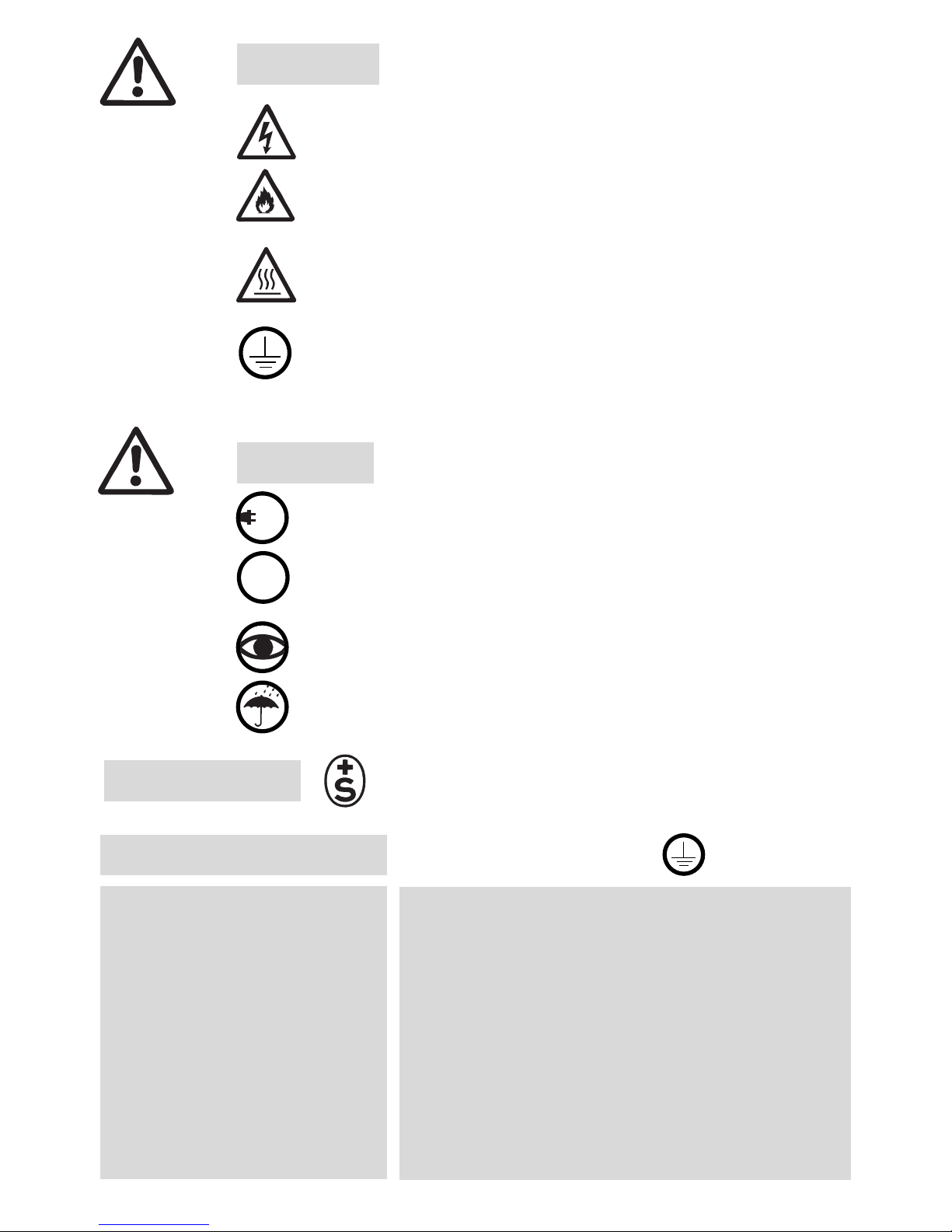

LEISTER Varimat V

Automatic Bitumen Welding

Machine

For overlap welding of Modified

Bitumen sheet. Width of welding

seam 80, 100 or 120 mm.

APPLICATION

LEISTER Process Technologies, Riedstrasse, CH-6060 Sarnen/Switzerland

Tel. +41 41 662 74 74 Fax + 41 41 662 74 16

www.leister.com sales@leister.com

Please read operating instructions carefully before

use and keep for further reference.

2

Incorrect use of the hot air tool can present a fire and

explosion hazard especially near combustable materials and explosive gases.

The tool must be operated under supervision. The heat

can ignite flammable materials which are not in view.

For personal protection, we strongly recommend the

tool be connected to an RCCB (Residual Current Circuit

Breaker) before using it on construction sites.

The voltage rating stated on the tool should correspond

to the mains voltage.

Do not touch the element housing and nozzle when hot

as they can cause burns. Allow the tool to cool down.

Do not point the hot air flow at people or animals.

Protect the tool from damp and wet.

FI

230

400

WARNING

CAUTION

Technical Data

230, 400 230, 400

4600, 5700 4600, 6300

50 / 60 50 / 60

20 – 620 stepless 20 – 620 stepless

0,5 – 5 stepless 0,5 – 5 stepless

ca. 190 (2 weights) ca. 220 (2 weights)

50 – 100 50 – 100

67 67

640 x 430 x 330 640 x 430 x 330

33 with 5 m cable 35 with 5 m cable

Voltage V~

Power consumption W

Frequency Hz

Temperature °C

Drive m/min.

Welding pressure N

Air flow %

Emission level L

pA

(dB)

Size mm

Weight kg

Mains voltage cannot be switched over

Connect tool to a receptacle with protective earth

terminal. Any interruption of the protective conductor

inside or outside the tool is dangerous!

Line/mains extension cables must always have a protective ground conductor!

Danger! Unplug the tool before opening it as live com-

ponents and connections are exposed.

APPROVAL MARKS

Protection Class Ι

DESCRIPTION OF TOOLS LEISTER Varimat V

3

1

2

3

16

1

18

9

5

4

8

15

12

22

23

24

14

11

17

25

21

1. Cable to mains

2. Housing

3. Main switch

4. Key board

5. Display

6. Sensor

7. Locking screw

8. Hot air blower

9. Welding nozzle

10. Tool holder

11. Locking lever

12. Pendulum action roller

13. Adjustment screw for tracking

14. Track-alignment roller

15. Guide roller

16. Adjustable transport roller

17. Transport roller

18. Guide roller

19. Shift spring for transport roller

20. Gate

21. Scale for tool adjustment

22. Additional weight

23. End weight

24. Carrying handle

25. Socket head cap screw

26. Lower guide bar

27. Upper guide bar

28. Clamping lever guide bar

heigh adujstable

29. Cable holder

30. Round belt

31. Clamping lever guide bar

32. Sensor covering

12

30

13

19

20

10

9

12

12 Pendulum action roller

1. Retaining ring

2. Tension ring

3. Rubber buffer

4. Tappet casing

5. Rubber tyre

6. Rubber buffer

7. Tension ring

8. Tightening disk

9. Cylinder screw

2

3

4

5

6

7

8

9

32 7 6

28

31

27

26

29

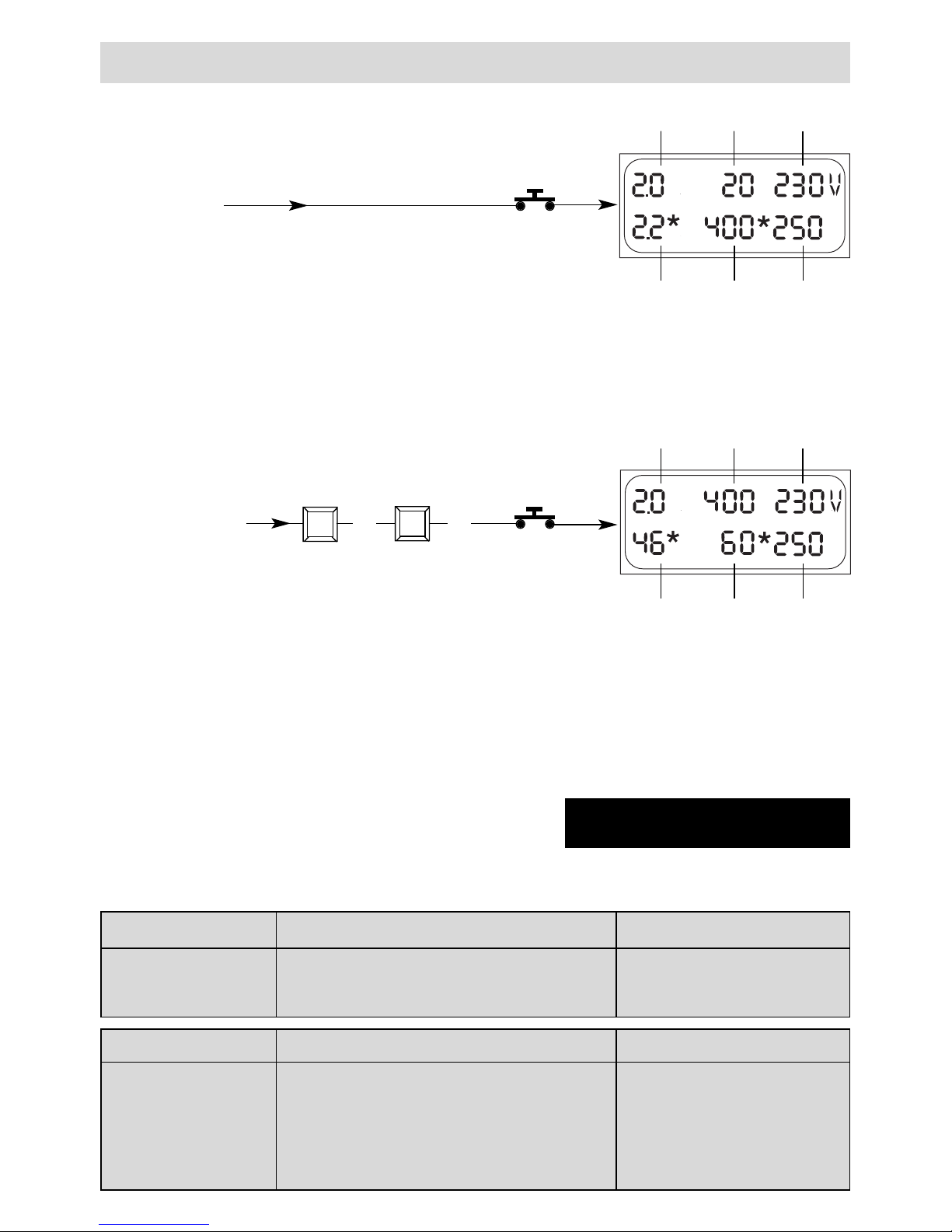

DISPLAY OPTIONS LEISTER Varimat V

4

Main– Level

main switch (3) on

main switch (3) on

Control– Level

+

–

& &

1 3 5

2 4 6

1 3 5

2 4 6

Display of:

1. Welding speed ACTUAL value

2. Welding speed SET value

3. Temperature ACTUAL value

4. Temperature SET value

5. Voltage - ACTUAL value

6. Welded length - ACTUAL value

*

Heating / Drive active

Display of:

1. Welding speed ACTUAL value

2. Welding speed Power consumption in % after start

3. Temperature ACTUAL value

4. Temperature Power consumption in % after start

5. Voltage ACTUAL value

6. Welded length ACTUAL value

Display 4 Drive reason for fault Action

100 % • mains under-voltage reduction of

welding speed

• high welding speed with check welding

large sudden overload procedure/machine

Display 2 Heating reason for fault Action

100 % • mains under-voltage reduction of airflow

100 % • heating element faulty repair

SET value

not achieved

Loading...

Loading...