Leister Uniplan E Operating Instructions Manual

1

LEISTER Uniplan E

Automatic hot air welding machine

Read the operating instructions carefully before use and

keep for future reference.

GB

OPERATING INSTRUCTIONS

LEISTER Uniplan E

Overlap Automatic Welding Machine

• Overlap and tape welding of coated fabric covers, foils and sealing membranes

made of PVC-P, PE, ECB, CSPE, EPDM, PVDF etc. as well as PE coated tape fabric

for lorries, tents, agricultural covers, building trade, biotopes, swimming pools,

marquees, boat covers, inflatable boats, advertising hoardings etc.

Welding seam width 20 or 30 mm

APPLICATION

®

LEISTER Process Technologies, Riedstrasse, CH-6060 Sarnen/Switzerland

Tel. +41 41 662 74 74 Fax +41 41 662 74 16 www.leister.com

sales@leister.com

Voltage V~

Frequency Hz

Power consumption W

Temperature °C

Airflow (50-100%) l/min.

Drive speed m/min.

Noise emission level L

pA

(dB)

Dimensions mm

Weight kg

TECHNICAL DATA

230 # 120 # 100 #

50 / 60 50 / 60 50 / 60

2300 1800 1500

20 – 620 20 – 620 20 – 620

max. 300 max. 250 max. 250

1.0 – 7.5 1.0 – 7.5 1.0 – 7.5

67 65 65

420×270 ×210 420×270 ×210 420×270 ×210

11.5 11.5 11.5

# Mains voltage is not reversible

CCA certified

Protection Class Ι

FI

230

120

WARNING

CAUTION

Approval Marks

2

Danger! Unplug the tool before opening it, as live components and connections are exposed.

Incorrect use of hot air tools can present a fire and explosion

hazard, particularly in the proximity of flammable materials

and explosive gases.

The tool must be operated under supervision.

Heat can ignite flammable materials which are not in view.

For personal protection, we strongly recommend the tool to

be connected to an RCCB (Residual Current Circuit Breaker)

before using it on construction sites.

The rated voltage stated on the tool must correspond with

the mains voltage.

Danger of getting burned! Do not touch the end of the

heater tube and nozzle when they are hot. Let the tool

cool down. Do not point the hot air flow in the direction of

people or animals.

Protect the tool from damp and wet.

Connect tool to a receptacle with protective earth terminal.

Any disconnection of the protective conductor in or outside

the tool is dangerous!

Only use extension lead with protective conductor.

3

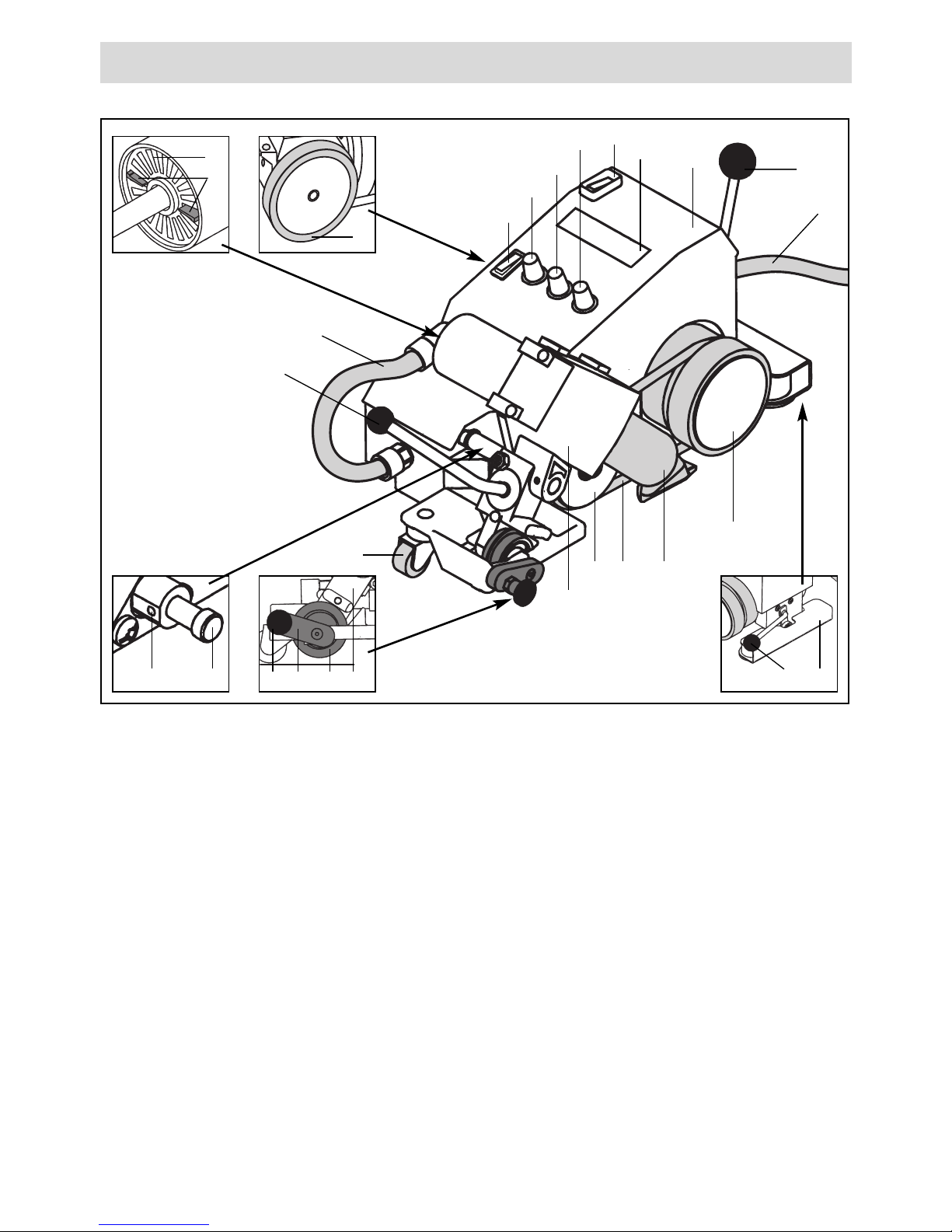

TOOL DESCRIPTION Overlap 20/30 mm LEISTER Uniplan E

1

2

17

18

3

78

4

25 12

24 23

13

14

9

6

22

5

27 26

19

20

Main components

1. Housing/chassis

2. Mains cable

3. Hot air blower

4. Welding nozzle

5. Connection hose

6. Drive/pressure roller

7. Pressure belt

8. Guide roller

9. Drive roller

10. Steering roller

11. Lifting device

12. Support bracket

13. Air filter

14. Manual air vane

15. Display

15

21

Operating components

16. Lifting device lever

17. Main switch

18. Drive switch

19. Potentiometer for welding speed

20. Potentiometer for air flow

21. Potentiometer for air temperature

22. Swivel lever

Steering equipment

23. Guide roller lever

24. Guide roller knob

25. Guide roller

Automatic drive

26. Switch pin

27. Set screw

1116

16

10

4

OPERATION LEISTER Uniplan E

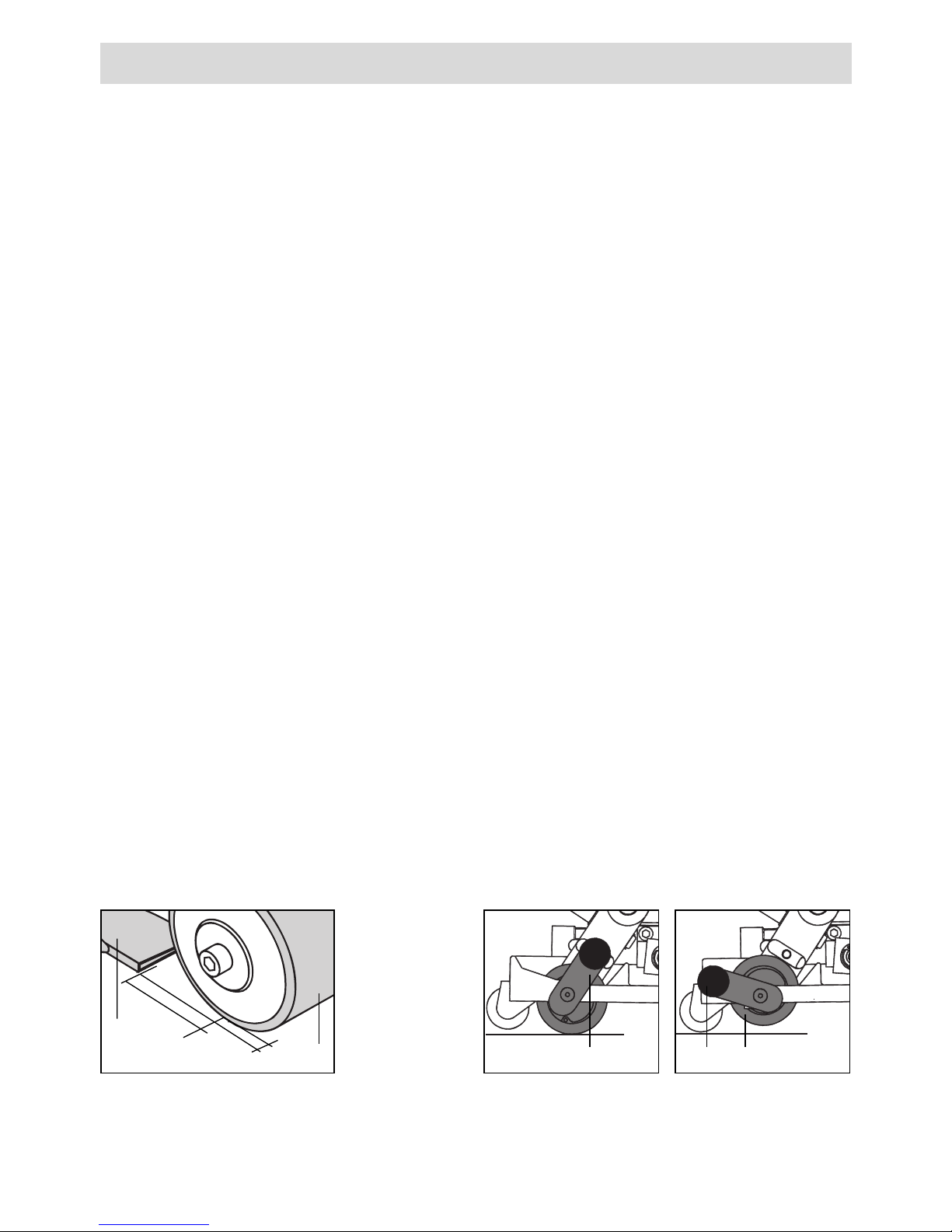

Operational condition

• Check the nozzle’s basic setting. (Detail A)

• Automatic drive

Automatic drive is adjusted as required, depending on nozzle position by means

of switch pin (26) and set screw (27).

• Guide roller

According to the application, the guide roller (25) is set to "active" (operational) or

"deactive" (non-operational) by means of guide roller knob (24) and guide roller

lever (23) (see Details B and C). The guide roller (25) causes the automatic welding

machine to carry out a straight run to the edge of the welding seam.

• Connect tool to the mains. Mains voltage must correspond with the voltage

rating stated on the tool.

• Switch on tool using main switch (17). Hot air blower (3) starts automatically.

• Important: undervoltage

In case the maximum temperature is not reached, reduce air volume by means of

manuel air vane (14) and potentiometer for air flow (20).

Tool positioning

• Swivel hot air blower (3) using swivel lever (22) up to the stop.

• Operate lifting device (11) by means of lifting device lever (16) so that

drive/pressure roller (6) and drive roller (9) are at no-load.

• If welding is being carried out by means of guide roller (25), lock guide roller lever

(23) into support bracket (12) (see Detail B).

• Position automatic welding machine into the overlap of the material to be welded.

The outside edge of drive/pressure roller (6) and guide roller (25) must line up with

the overlap edge of the material to be welded.

• Activate lifting device (11) by means of lifting device lever (16) so that the automatic welder is ready to start.

Detail A Detail B Detail C

1–2 mm

40 – 50mm

6

4

24 2523

Guide roller

operational

Guide roller

non-operational

OPERATION LEISTER Uniplan E

5

Welding parameters

• Set potentiometer for welding speed (19) to required value.

• Set potentiometer for air flow (20) to required value.

• Set potentiometer for air temperature (21) to required value.

• The pressure derives from the actual weight of the automatic hot air welding

machine. Use additional weight if necessary.

Welding process

• Swivel hot air blower (3) up to the stop using swivel lever (22). The welding process

starts automatically via automatic drive.

• If necessary, the tool can be started manually by means of the drive switch (18).

• Check welding process. Adjust welding parameters using potentiometers (19), (20)

and (21) if necessary.

• When welding has finished, swing hot air blower (3) to the stop by means of swivel

lever (22). Welding process stops automatically.

• After completing welding work, set potentiometer for air temperature (21) to zero

so that the hot air blower (3) cools down.

•Switch off tool at the main switch (17).

• Disconnect tool from the mains.

• Assembling additional weight

– Attach additional weight holder (29) to the

Uniplan E tool by means of cylindrical head

screw M8x20 (28).

– Put additional weight (30) into additional

weight holder (29).

Accessory additional weight

28

29

30

Speed m/ft

Air-Vol %

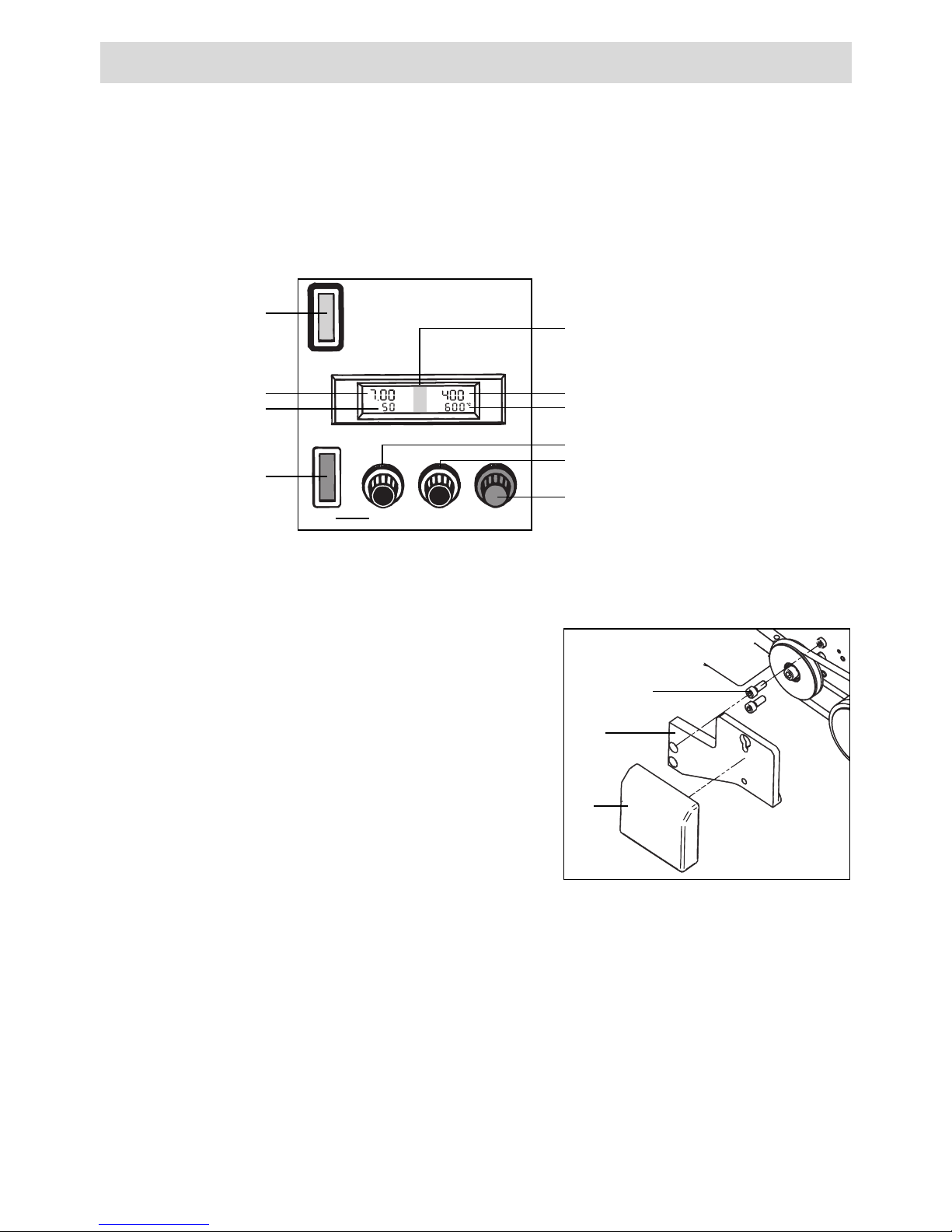

ON Speed Air-Vol % Temperature

Temperature

(17) Main switch

Temperatur ACTUAL- value

Display (15)

Temperatur SET- value

Potentiometer for welding speed (19)

Potentiometer for air flow (20)

Potentiometer for air temperature (21)

Welding speed

Air flow

(18) Drive switch

Loading...

Loading...