Leister Twinny T Operating Instructions Manual

LEISTER Twinny T

Combination wedge automatic

hot air welding machine

Please read operating instructions carefully before use and

keep for further reference.

GB

OPERATING INSTRUCTIONS

®

• Overlap max. 125 mm / 5 inch

• Type of seam Welding seams are produced in accordance with

DVS 2225 part I and BAM. Other dimensions are possible

on request

DVS: German Welding Association

BAM: Federal Institute for Materials Research and Testing, Berlin.

The LEISTER Twinny T is a combination wedge automatic hot air welding machine

for overlap welding and manufacturing of films and geomembrane liners in

tunnels as well as in earthwork and civil engineering. The heat transmission

occurs through optimum combination of contact and hot air.

APPLICATION

Type

Heating System

Civil engineering

Tunnel

construction

combination

wedge long

Type of Material Material Thickness

PE-HD, PE-C, PFA, PD, PP

PVC-P, PE - LD, ECB, EVA

0,8 – 2,0 mm

/ 32 – 80 mil

1,0 – 3,0 mm

/ 40 – 120 mil

tube nozzle

short

PE-HD, PE-C, PFA, PD, PP

PVC-P, PE - LD, ECB, EVA

0,3 – 1,0 mm

/ 12 – 40 mil

0,3 – 2,0 mm

/ 12 – 80 mil

LEISTER Process Technologies, Riedstrasse, CH-6060 Sarnen/ Switzerland

Tel. +41 41 662 74 74 Fax + 41 41 662 74 16

www.leister.com sales@leister.com

2

Danger! Unplug the tool before opening it as live components and connections are exposed.

Incorrect use of the hot air tool can present a fire and

explosion hazard especially near combustible materials

and explosive gases.

The tool must be operated under supervision. The heat

can reach combustible materials which are out of sight.

For personal protection, we strongly recommend the

tool be connected to an RCCB (Residual Current Circuit

Breaker) before using it on construction sites.

The voltage rating stated on the tool should correspond

to the mains voltage.

Do not touch the element housing and hot wedge

when hot as they can cause burns. Allow the tool to

cool down. Do not point the hot air flow in the direction

of people or animals.

Protect the tool from damp and wet.

FI

120

230

WARNING

CAUTION

TECHNICAL DATA

APPROVAL MARKS

Voltage V~

Power consumption W

Frequency Hz

Temperature °C /°F

Welding pressure N/lbs (pound)

Drive m/min. /feet

Emission level L

pA

(dB)

Size LxBxH mm

Weight kg

Connect the tool to a socket outlet with a protective

earth conductor. Any interruption of the protective

earth conductor inside or outside the tool is dange-

rous! Use only extension cables with a protective earth

conductor!

100, 120, 200, 230 #

1600, 1900, 2200, 2300

50 / 60

max. 560 stepless

max. 1000 stepless

0,8– 3,2 stepless

71

340 × 360 × 245

7,9

(Civil engineering below ground) / 6,9 (tunnel construction)

# mains

voltage

cannot be

switched

over

Protection class Ι

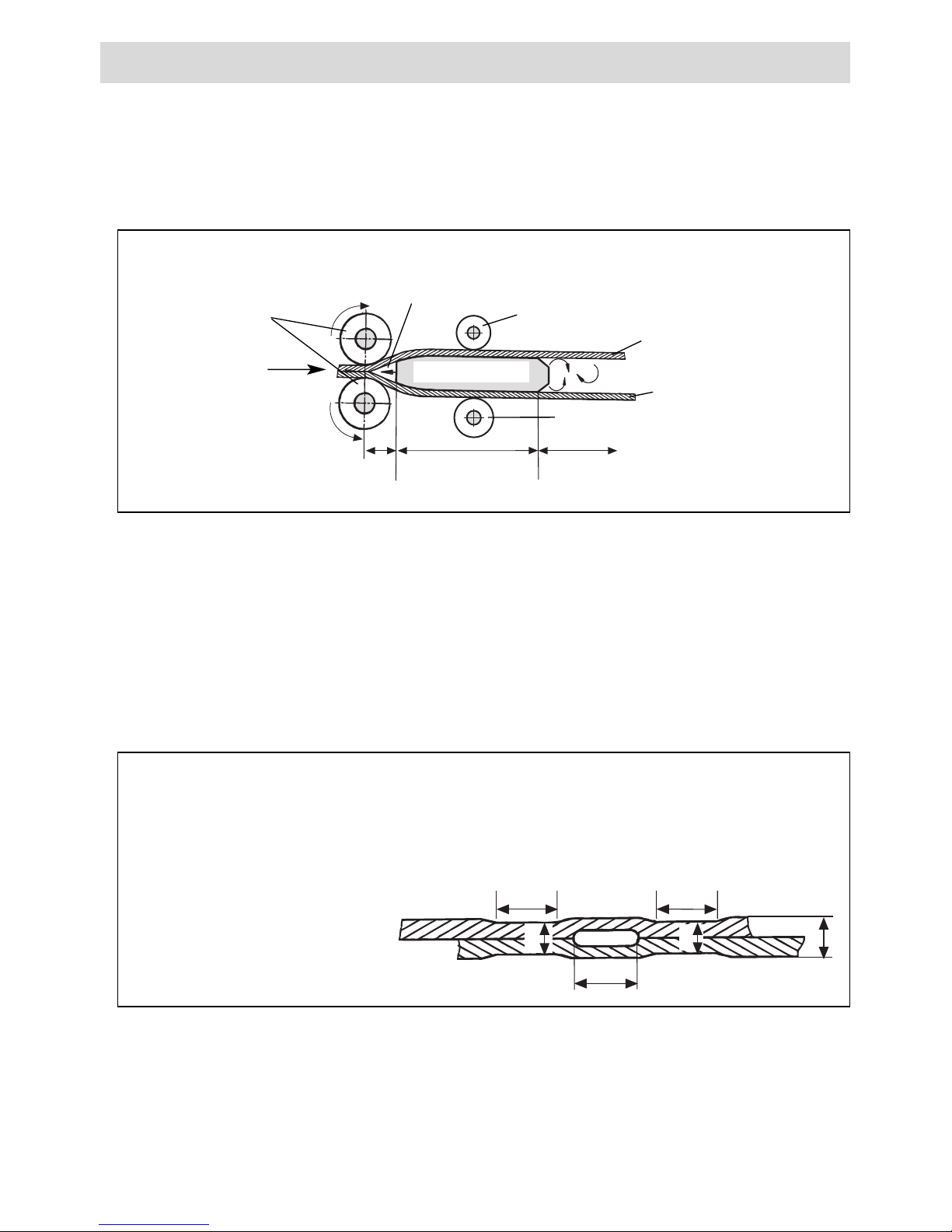

Cross sectional diagram of an overlap weld

Seam thickness reduction = A – B

A : Thickness of the upper and lower membrane

B: Thickness of the welded seam

C : Welded section 1

D: Welded section 2

E : Test channel

B

CD

A

B

E

• Welding Pressure → steplessly adjustable. The welding pressure is transmitted

via a toggle lever to the pressure rollers. The swivel head guarantees the

equalisation of the pressure to both welded sections (C and D) as well as on a

welded seam without test channel.

This allows T-joints to be welded easily. During the welding process the welding

pressure adjusts itself linearly to the change in material thickness of the

geomembrane liner.

• Drive

→ Double drive system, is steplessly adjustable and electronically con-

trolled. The automatic control system with tachogenerator is designed in such

a way, that the adjusted welding speed remains constant independently of

the load. The power transmission to the drive/pressure rollers works through a

three stage planetary gear.

• Heating system

→ The hot air temperature is steplessly adjustable and electro-

nically controlled. The heat transmission occurs with optimum combination of

all the advantages of contact hot air. The flexible combination wedge contains three heating zones:

DESCRIPTION OF FUNCTIONS LEISTER Twinny T

Material plasticising

with hot air

Contact heating Pre-heating, drying

cleaning of the material

3

Combiwedge

Drive/pressure roller

Welding direction

Hot air outlet

Pinch roller

Upper geomembrane liner

Lower geomembrane liner

Guide roller

Heating system cross sectional diagram

M

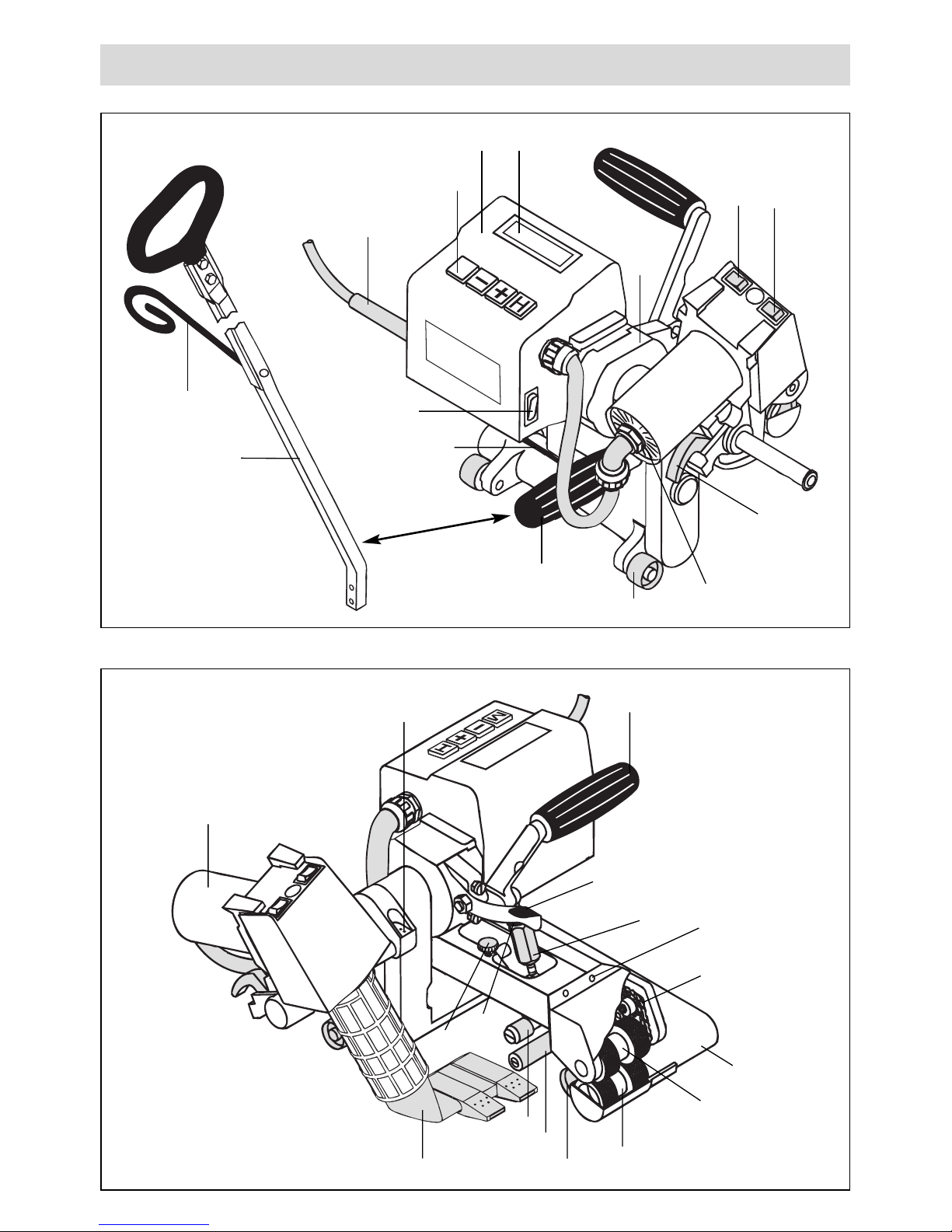

Description of tool LEISTER Twinny T

1

2

4

Frontal view

Back view

1

31

2 5

4

10

16

6

9

7

3

8

28

12

13

24

29

27

23

22

21

20

19

18

11

17

30

25

26

15

14

Loading...

Loading...