Leister TAPEMAT, TAPEMAT Spriegel Operating Instructions Manual

TAPEMAT

Leister Process Technologies

Galileo-Strasse 10

CH-6056 Kaegiswil/Switzerland

Tel. +41 41 662 74 74

Fax +41 41 662 74 16

www.leister.com

sales@leister.com

GB

®

2

Leister TAPEMAT

Hot-Air welding machine

TAPEMAT: Manually guided automatic hot-air welding machine for welding PVC straps from 45 mm to max.

50 mm wide – as the reinforcement for tarpaulins – on horizontal and level surfaces.

TAPEMAT Spriegel: : Manually guided automatic hot-air welding machine for welding PVC straps (reinforcement

strips) 100 mm and 125 mm wide – as the reinforcement for tarpaulins – on horizontal and level surfaces.

Application

Please read operating instructions carefully before use

and keep for future reference.

Operating Instructions

(Translation of the original operating instructions)

GB

Danger to life if you open the equipment, since this reveals

current-conducting

components and connections.

Remove the mains plug from the plug socket before opening the equipment.

Incorrect use of the hot air tool can present a fire and explosion hazard

especially near combustable materials and explosive gases.

Do not touch the element housing and nozzle when hot as they can cause burns.

Allow the tool to cool down. Do not point the hot air flow at people or animals.

Warning

Connect tool to a receptacle with protective earth terminal. Any interruption of

the protective conductor inside or outside the tool is dangerous!

Use only extension cables/cords with protective conductor!

Conductor cross-section: 4 x 2.5mm

2

The tool must be operated under supervision.

Heat can ignite flammable materials which are not in view.

The machine may only be used by qualified specialists or under their supervision.

Children are not authorized to use this machine.

For personal protection, we strongly recommend the tool be connected to an

RCCB (Residual Current Circuit Breaker) before using it on construction sites.

The mains voltage, that is quoted on the equipment must agree with the mains

voltage.

IEC/EN 61000-3-11; Z

max

= 0.039Ω + j 0.024Ω. If necessary, consultate supply

authority.

You must always use a residual current circuit breaker for protection to

persons when working on building sites.

Protect the tool from damp and wet.

FI

230

400

Caution

The equipment must not be lifted using the additional weight.

3

TAPEMAT TAPEMAT Spriegel

Voltage V~ 3 × 400 3 × 400

Power consumption kW 10 10

Frequency Hz 50 / 60 50 / 60

Temperature °C ca. 650 ca. 650

Speed m/min. 4 – 20 4 – 20

Noise level LpA (dB) 83 83

Weld seam width max. mm 50 2 × 20

Tape width mm 50 100 / 125

Dimensions L×W×Hmm 555 × 435 × 370 555 × 435 × 370

Weight kg 35 40

without power supply cord

Mark of conformity 22

Approval mark 33

Certification scheme CCA CCA

Protection class I 11

Technical data and specifications are subject to change without prior notice.

Leister Process Technologies, Galileo-Strasse 10, CH-6056 Kaegiswil/Switzerland

confirms that this

product,

in the version as brought into circulation through us, fulfils the requirements

of the following EC directives.

Directives

:

98/37, 2004/108, 2006/95

Harmonised standards: E

N 12100-1, EN 12100-2, EN 60204-1, EN 55014-1, EN 55014-2,

EN 61000-6-2, EN 61000-3-2, EN 61000-3-11 (Z

max

),

EN 50366, EN 62233, EN 60335-2-45

Kaegiswil, 25.08.2008

Bruno von Wyl Christiane Leister

Technical Director Owner

Power tools, accessories and packaging should be sorted for environmental-friendly recycling. Only for EC

countries: Do not dispose of power tools into household waste! According to the European Directive

2002/96/ on waste electrical and electronic equipment and its incorporation into national law, power tools

that are no longer suitable for use must be separately collected and sent for recovery in an environmentalfriendly manner.

Disposal

Conformity

Technical data

4

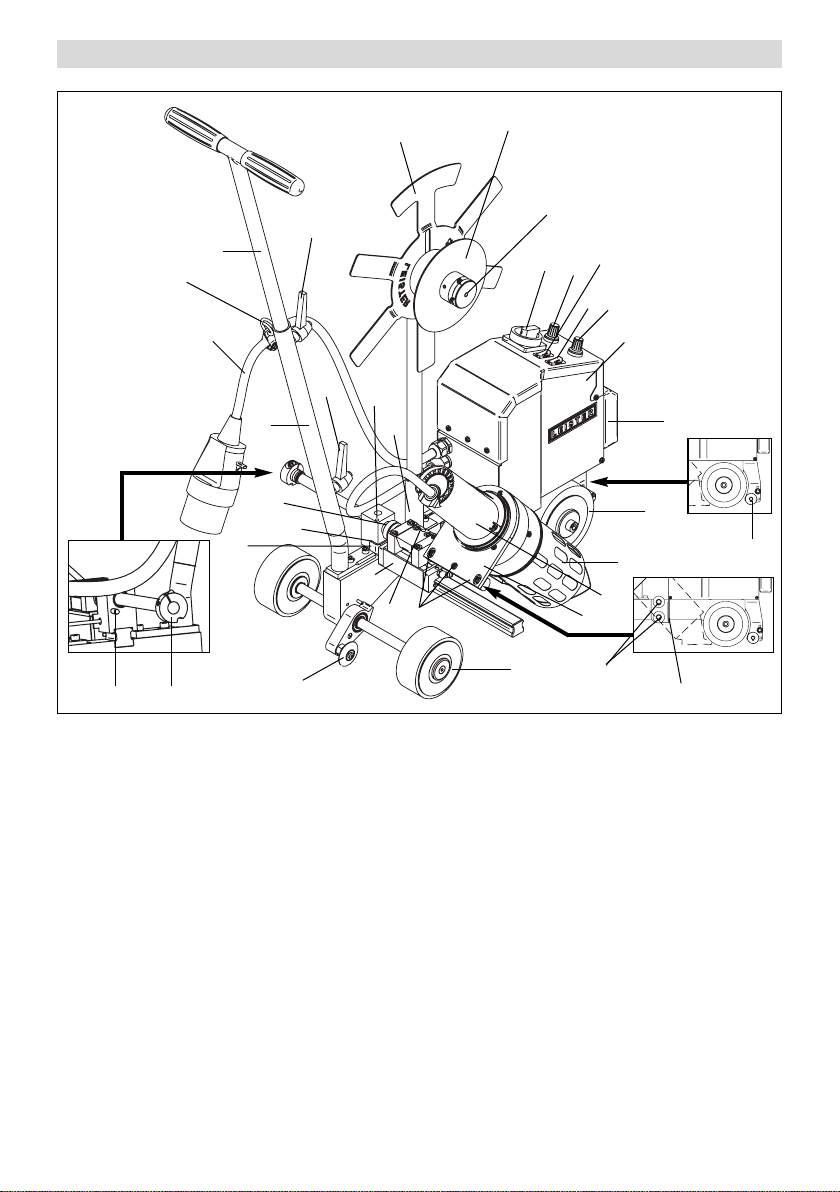

Tool description

1. Mains connection cable

2. Cabinet

3. Main switch

4. Release switch

5. Motor On/Off

6. Speed variation knob

7. Temperature variation knob

8. Welding nozzle

9. Hot air blower

10. Equipment holder

11. Transporting wheel

12. Drive roller / Pressure roller

13. Welding nozzle adjustment screw

14. Welding nozzle adjustment nut

15. Welding nozzle adjustment screws

16. Guiding handle, lower section

17. Guiding handle, upper section

18. Clamping lever, guiding handle joint

19. Clamping lever, height adjustment

20. Retainer (for mains connection cable)

21. Guide roller

22. Additional weight

23. Retaining pin

24. Stop ring

25. Diverting roller

26. Separating wall

27. Strap retaining rollers

28. Sensor

29. Stop screw

30. Contact generator

31. Guide trolley

32. Strap unrolling device

33. Tensioning brake disc

34. Locator (strap unrolling device)

35. Threaded pin

1

2

8

12

27

22

11

3

5

6

7

9

10

13

15

31

30

14

28

16

17

20

18

32

29

34

19

33

21

2423

25

26

4

35

Loading...

Loading...