Leister LHS CLASSIC 20S, LHS CLASSIC 20L, LHS CLASSIC 40S, LHS CLASSIC 40L, LHS CLASSIC 60S Operating Instructions Manual

...

Leister LHS CLASSIC

Air Heater

1

Please read operating instructions carefully before use and

keep for further reference.

GB

OPERATING INSTRUCTIONS

The Leister Air Heater type LHS CLASSIC are suitable for building into machines,

installations or appliances and are designed for continuous operation.

• Drying and heating processes of various types.

• Shrinking and welding packaging films and moulded parts.

• Heating conveyor ovens or heat tunnels.

• Activating and loosening solvent free adhesives and melt adhesives.

• Sterilizing packaging materials such as bottles, corks and containers.

• Separating and fusing synthethic fibres and fabrics.

• Soldering processes on thin metal parts.

• Speeding up mixing processes and dissolving foams which can arise during

mixing and filling operations.

• Welding thermoplastic materials.

• Removing plastic mould flash.

• Putting a shine on plastic surfaces.

APPLICATION

Leister Process Technologies, Riedstrasse, CH-6060 Sarnen/Switzerland

Tel. +41 41 662 74 74 Fax + 41 41 662 74 16

www.leister.com sales@leister.com

®

LHS CLASSIC 20S

LHS CLASSIC 20L

LHS CLASSIC 40S

LHS CLASSIC 40L

LHS CLASSIC 60S

LHS CLASSIC 60L

Technical Data LHS LHS LHS LHS LHS

CLASSIC 20S CLASSIC 40S CLASSIC 40L CLASSIC 60S CLASSIC 60L

Voltage V~ 100 - 230 100 - 230 3×230-3×440 3×230-3×480 3×230-3×480

Frequency Hz 50/60 50/60 50/60 50/60 50/60

Power consumption

kW 1.0 / 2.0 2.0 / 4.0 2.0 / 4.0 4.0 / 6.0 8.0 - 16.0

Min. air flow l/min. 200 300 300 400 600

Max. temperature°C 600 600 600 600 600

Ambient °C <65 <65 < 65 < 65 <65

temperature

Weight kg 0.55 0.85 0.95 3.15 3.65

Size mm 252×97×87 261×112×98 291×112×98 379×116×137 379×116×137

Mark of conformity

2222 2

Mark of Approval

3333 3

Certification scheme CCA CCA CCA CCA CCA

Protection class I

11

Protection class II

444

2

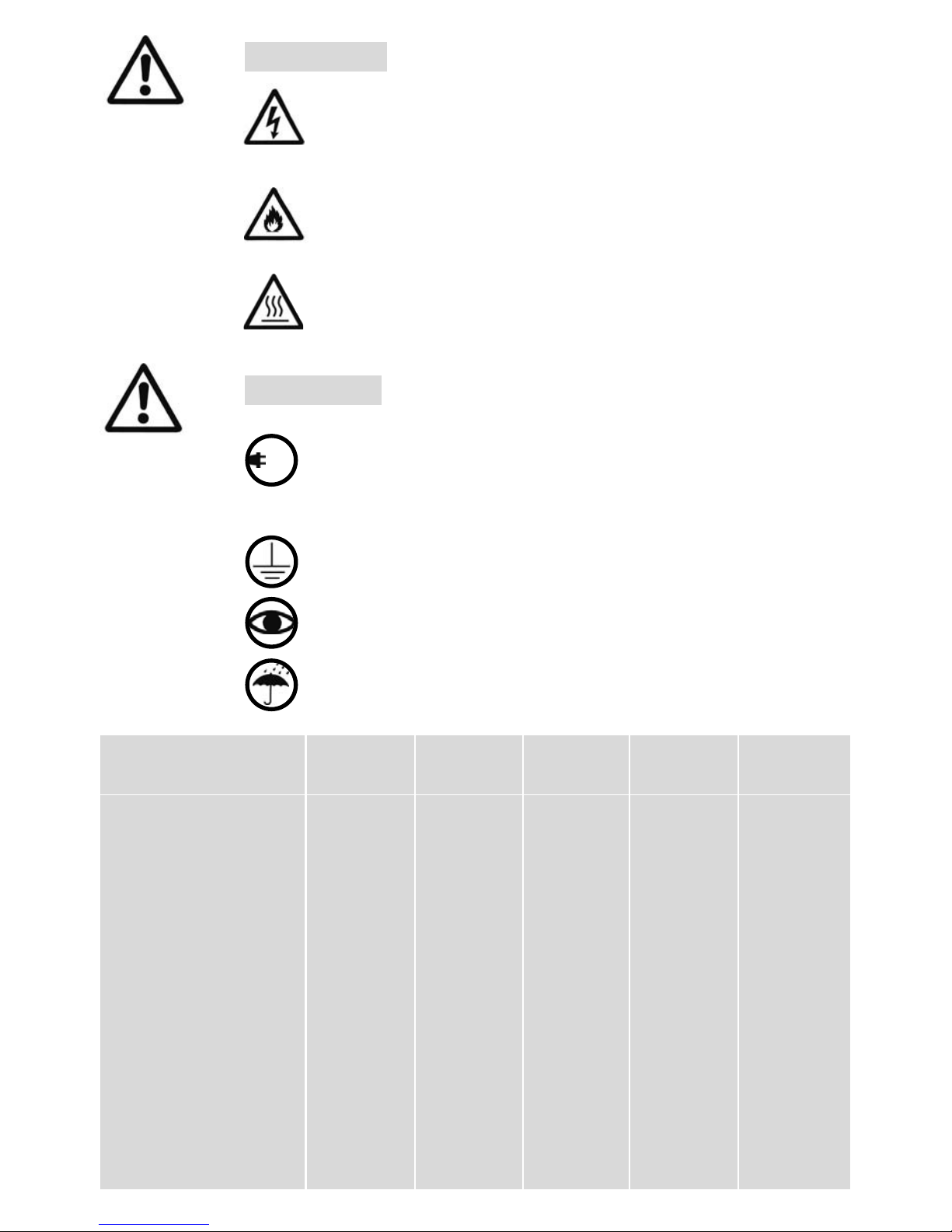

Danger! When opening up the tool, live components and

connections are exposed. The mains plug must be removed

from the main socket before opening up the tool. Caution

separate source voltage.

Incorrect installation and use of air heaters can present

a fire and explosion hazard, particularly in the proximity of

flammable materials and explosive gases.

Do not touch the element housing and nozzle when hot

as they can cause burns. Do not point the hot air flow at

people or animals.

WARNING

The tool must be operated with supervision. Warmth can

reach combustible materials, which are out of sight.

The voltage rating stated on the tool should correspond

to the mains voltage.

IEC/EN 61000-3-11; Z

max

= 0.047

Ω

+ j 0.029Ω. If necessary,

consultate supply authority.

Protect the tool from dampness and wet.

CAUTION

The tool with protection class I should be earthed using a

protective conductor.

100

480

OPERATING Leister LHS CLASSIC

3

Installation

• When installing the tool, ensure that:

- only cold air is supplied

- no (hot air) back pressure develops

- the tool is not subjected to a hot air flow from another tool

• The tool is protected against mechanical vibration and shaking.

• Installation dimensions on pages 5, 6 and 7.

Air supply

• To protect the tool and the heat element, the stipulated minimum air flow must

under no circumstances fall short, and the maximum temperature (measured

at the hotest point 3 mm in front of the element housing) must also not be

exceeded. In the event that the minimum air flow falls short, the power must

immediately be disconnected.

• The air heater should only be supplied with air up to a max. 80°C.

• Pay attention to the direction of the airflow.

• Leister blowers must be used for the air supply (pay attention to the direction of

rotation and the electrical connection).

• For use in a dusty environment the tool should be fitted with a Leister stainless

steel filter on the air intake connection. Where a particularly critical dust problem

exists (eg metal, electrically charged or damp dust) special filters must be used to

avoid short circuiting of the tool.

Operation

• The tool must be connected by a qualified electrician in accordance with the

circuit diagram (Pages 5,6 or 7).

• Fit a nozzle appropriate to the use.

• It should be checked that the hot air can flow out freely, otherwise a back

pressure of hot air may damage the tool (danger of fire!).

• Attention: Keep to the minimum air flow according to the technical details

(Page 2).

• Switch on mains.

• Allow the tool to cool down after use.

Attention: Never operate tool without air supply!

Loading...

Loading...