Page 1

Leica T-Scan Collect

Reference Manual

Version 10.35

English

Page 2

1 Introduction

1.1 Purchase

Congratulations on the purchase of the Leica Geosystems T-Scan Collect software.

This manual contains instruction for setting up the product and operating it. Read carefully through

the User Manual before you use the product.

These are original instructions and part of the software. Keep for future reference and pass on to

subsequent holders/users of the hardware or software. This User Manual contains information

protected by copyright and subject to change without notice. No part of this User Manual may be

reproduced in any form without prior and written consent from Leica Geosystems AG.

Leica Geosystems shall not be responsible for technical or editorial errors or omissions.

© Leica Geosystems AG

1.2 Trademarks

Product Names are trademarks or registered trademarks of their respective owners.

1.3 Validity of this Manual

This manual applies to the Leica Geosystems T-Scan Collect software.

1.4 Feedback

Your feedback is important as we strive to improve the quality of our documentation. We request

you to make specific comments as to where you envisage scope for improvement. Please use the

following E-mail address to send your suggestions:

support.tracker@hexagon.com

1.5 Contact

Leica Geosystems AG

Metrology Division

Moenchmattweg 5

5035 Unterentfelden

Switzerland

Phone +41-62-737 67 67

Fax +41-62-723 07 34

www.leica-geosystems.com/metrology

Page 3

2 Contents

1 Introduction ........................................................................................................ 1

1.1 Purchase ................................................................................................ ....... 1

1.2 Trademarks ................................................................................................... 1

1.3 Validity of this Manual ................................................................................... 1

1.4 Feedback ...................................................................................................... 1

1.5 Contact .......................................................................................................... 1

2 Contents .............................................................................................................. 2

3 Revisions ............................................................................................................ 6

4 T-Scan Collect - Software – Introduction ......................................................... 7

4.1 Installation and Program Start ....................................................................... 7

4.2 Licensing ................................................................................................ ....... 7

5 Working with Viewers ........................................................................................ 8

5.1 3D Viewer ..................................................................................................... 8

5.2 Status Indicators ......................................................................................... 12

5.3 Additional Coordinate Axes ......................................................................... 13

5.4 Data Explorer ................................................................ .............................. 13

6 Customizing the User Interface ...................................................................... 20

7 Measurement .................................................................................................... 24

7.1 Selection of Measurement Mode ................................................................ 24

7.2 Measurement Settings ................................................................................ 24

7.2.1 General ................................................................................................ 25

7.2.2 Line Scanner ........................................................................................ 25

7.2.3 Surface Mode....................................................................................... 27

7.2.4 3D Point Mode ..................................................................................... 31

7.2.5 Static Polyline Mode ............................................................................ 32

7.2.6 Dynamic Polyline Mode ....................................................................... 34

7.3 Starting a Measurement .............................................................................. 34

7.3.1 Surface Mode....................................................................................... 34

7.3.2 3D Point Mode ..................................................................................... 35

7.3.3 Static Polyline Mode ............................................................................ 36

7.3.4 Dynamic Polyline Mode ....................................................................... 37

7.4 Stopping a Measurement ............................................................................ 38

8 Interactive Tools ............................................................................................... 39

8.1 Selection Mode ........................................................................................... 40

8.2 Interactive Clipping...................................................................................... 40

8.3 Check Accuracy .......................................................................................... 40

8.4 Cross Sections ............................................................................................ 43

8.5 Create Reference Points ............................................................................. 44

8.6 Fill Holes (Triangle Mesh) ........................................................................... 45

8.7 Create Bridges (Triangle Mesh) .................................................................. 46

Page 4

8.8 Smoothing (Triangle Mesh) ......................................................................... 47

8.9 Decimate Mesh (Triangle Mesh) ................................................................. 48

8.10 Sharpen Edges (Triangle Mesh) ................................................................. 49

8.11 Alignment Calibration .................................................................................. 49

9 Calibration ........................................................................................................ 50

9.1 Calibrate measurement range ..................................................................... 50

9.1.1 Preparation .......................................................................................... 50

9.1.2 Procedure ............................................................................................ 50

9.2 Alignment Calibration .................................................................................. 53

9.2.1 Requirements for an Alignment Sphere ............................................... 53

9.2.2 Measurement Strategy ......................................................................... 53

9.2.3 Step-by-Step Guide ............................................................................. 56

10 Working with Files ........................................................................................ 59

10.1 Create New Project ..................................................................................... 59

10.2 Open Existing Project .................................................................................. 59

10.3 Save Project ................................................................................................ 59

10.4 Save Project Under New Name .................................................................. 59

10.5 Import Data ................................................................................................. 59

10.5.1 Using the File Menu ............................................................................. 60

10.5.2 Using the Data Explorer ....................................................................... 60

10.5.3 Using Drag and Drop ........................................................................... 60

10.6 Export Data ................................................................................................. 60

10.6.1 Using the File Menu ............................................................................. 60

10.6.2 Using the Data Explorer ................................ ................................ ....... 61

11 Processing of Data Sets ............................................................................... 62

11.1 Transform Data ........................................................................................... 62

11.1.1 Transform ............................................................................................ 62

11.1.2 Transform to Nominal Points................................................................ 63

11.1.3 3 Planes Alignment .............................................................................. 69

11.1.4 3-2-1 Alignment .................................................................................... 72

11.1.5 Scale ................................ ................................ ................................ .... 76

11.1.6 Mirror ................................................................................................... 76

11.2 Optimize Data ............................................................................................. 76

11.2.1 Smoothing ............................................................................................ 76

11.2.2 Decimating ........................................................................................... 77

11.3 Matching ..................................................................................................... 77

11.3.1 Global Matching ................................................................................... 77

11.3.2 Tolerance Based Matching .................................................................. 82

11.4 Optimize Triangle Meshes .......................................................................... 85

11.4.1 Remove Unassociated Areas............................................................... 85

11.4.2 Remove Outliers .................................................................................. 86

11.4.3 Noise Reduction ................................................................................... 86

11.4.4 Curvature Based Decimation ............................................................... 87

11.4.5 Smoothing ............................................................................................ 87

11.5 Interactive Tools .......................................................................................... 87

Page 5

12 Post-Processing ........................................................................................... 88

13 Calculation of Feature Lines ........................................................................ 92

13.1 Calculation of Feature Lines ....................................................................... 93

13.2 Calculation of V-Lines ................................................................................. 95

13.3 Interactive Generation of Polylines.............................................................. 96

13.4 Processing of Polylines and Triangle Meshes ............................................. 97

13.5 3D Viewer Control ....................................................................................... 99

14 Service ......................................................................................................... 100

15 Tracking System ......................................................................................... 101

15.1 Initialize ..................................................................................................... 101

15.2 Disconnect/Connect .................................................................................. 101

15.3 Environmental Parameters ........................................................................ 101

15.4 Laser Control ............................................................................................ 102

15.5 Reflectors ................................ ................................ ................................ .. 102

15.6 Information ................................................................................................ 102

15.7 Go Birdbath ............................................................................................... 103

15.8 Go Zero Position ....................................................................................... 103

15.9 Move Station ............................................................................................. 103

15.9.1 Measuring the Pass Points ................................................................ 104

15.9.2 Selection of Pass Points .................................................................... 105

15.9.3 Moving the Station ............................................................................. 106

15.9.4 Measuring the Pass Points ................................................................ 106

15.9.5 Transformation Results ...................................................................... 107

15.9.6 Invoking Move Station again .............................................................. 108

15.10 Release Motors ..................................................................................... 109

16 Digitize ......................................................................................................... 110

16.1 Start .......................................................................................................... 110

16.2 Stop ........................................................................................................... 110

16.3 Information ................................................................................................ 110

17 Settings ....................................................................................................... 112

17.1 Cross Sections .......................................................................................... 112

17.2 Matching ................................................................................................... 113

17.3 3D Viewer ................................................................................................. 115

17.3.1 General Settings ................................................................................ 115

17.3.2 Lines .................................................................................................. 115

17.3.3 Surfaces ............................................................................................. 116

17.3.4 Other Settings .................................................................................... 117

17.4 Dynamic Camera ...................................................................................... 118

17.5 Coordinate Axes........................................................................................ 119

17.6 Accuracy Check ........................................................................................ 119

17.7 Measuring Mode ....................................................................................... 119

17.8 Measurement ................................................................ ............................ 120

17.9 Acoustic Feedback .................................................................................... 120

17.10 Materials ................................................................................................ 121

Page 6

17.11 Adjust Size Automatically ...................................................................... 122

17.12 Display Scanner .................................................................................... 122

17.13 Display T-Probe ..................................................................................... 123

17.14 Display T-Probe Coordinates ................................................................ 123

17.15 Keep On Top ......................................................................................... 124

18 Extras ........................................................................................................... 125

18.1 Execute Macro .......................................................................................... 125

19 Help .............................................................................................................. 126

19.1 About T-Scan Collect ................................................................................ 126

20 Appendix ..................................................................................................... 128

20.1 DCOM Configuration ................................................................................. 128

20.2 T-Scan Collect vs. T-Scan Interface .......................................................... 131

21 Index ............................................................................................................ 135

Page 7

3 Revisions

Rev.

Date

Changes

Author

Released

1.0

04/2001

FP

3.0

01/2003

Adjustments for version 3.0

FP

BK

4.0

10/2003

Adjustments for version 4.0

FP

MPo/AB

4.2

4/2004

Adjustments for version 4.2

FP

BK

5.0

12/2004

Adjustments for version 5.0

FP

5.01

5/2005

Adjustments for version 5.01

FP

6.0

4/2006

Adjustments for version 6.0

FP

SG/AB

7.0

7/2007

Adjustments for version 7.0

FP

BK/SG

8.0

5/2009

Adjustments for version 8.0

FP/FS

FS/BK

9.0

8/2010

Adjustments for version 9.0

FP/FS

10.11

10/2013

Adjustments for version 10.11

FP

10.2

9/2014

Adjustments for version 10.20

MBN

AFU

10.3

12/2014

Adjustments for version 10.30

BK/MBN

AFU

10.32

12/2015

Adjustments for version 10.32

BK/MBN

AFU

10.34

07/2016

Adjustments for version 10.34

BK

AFU

10.35

08/2017

Adjustments for version 10.35

BK

AFU

Page 8

4 T-Scan Collect - Software – Introduction

4.1 Installation and Program Start

Installation of T-Scan Collect

T-Scan Collect has been pre-installed on your system. If you want to install it again, please use the

Product USB Stick. Please note that T-Scan Collect is a 64-bit application and will only run on 64bit operating systems.

Start of T-Scan Collect

Use the Windows start menu or the shortcuts on your desktop to start the application.

If you only want to use T-Scan Collect for viewing, processing or evaluating data (i.e. you do not

want to measure), select the NoSensor shortcut which can be used without digitizing hardware.

4.2 Licensing

The T-Scan Collect software is protected by a CODEMeter dongle. The driver for the

CODEMeter dongle is automatically installed with the software. If you would like to upgrade

the software, please verify that the dongle is valid for the new software version. If you are

unsure, please contact support.tracker@hexagonmetrology.com and request the required

license file for upgrading the CODEMeter dongle to the new version. For more information, see

chapter 19.1.

Page 9

5 Working with Viewers

5.1 3D Viewer

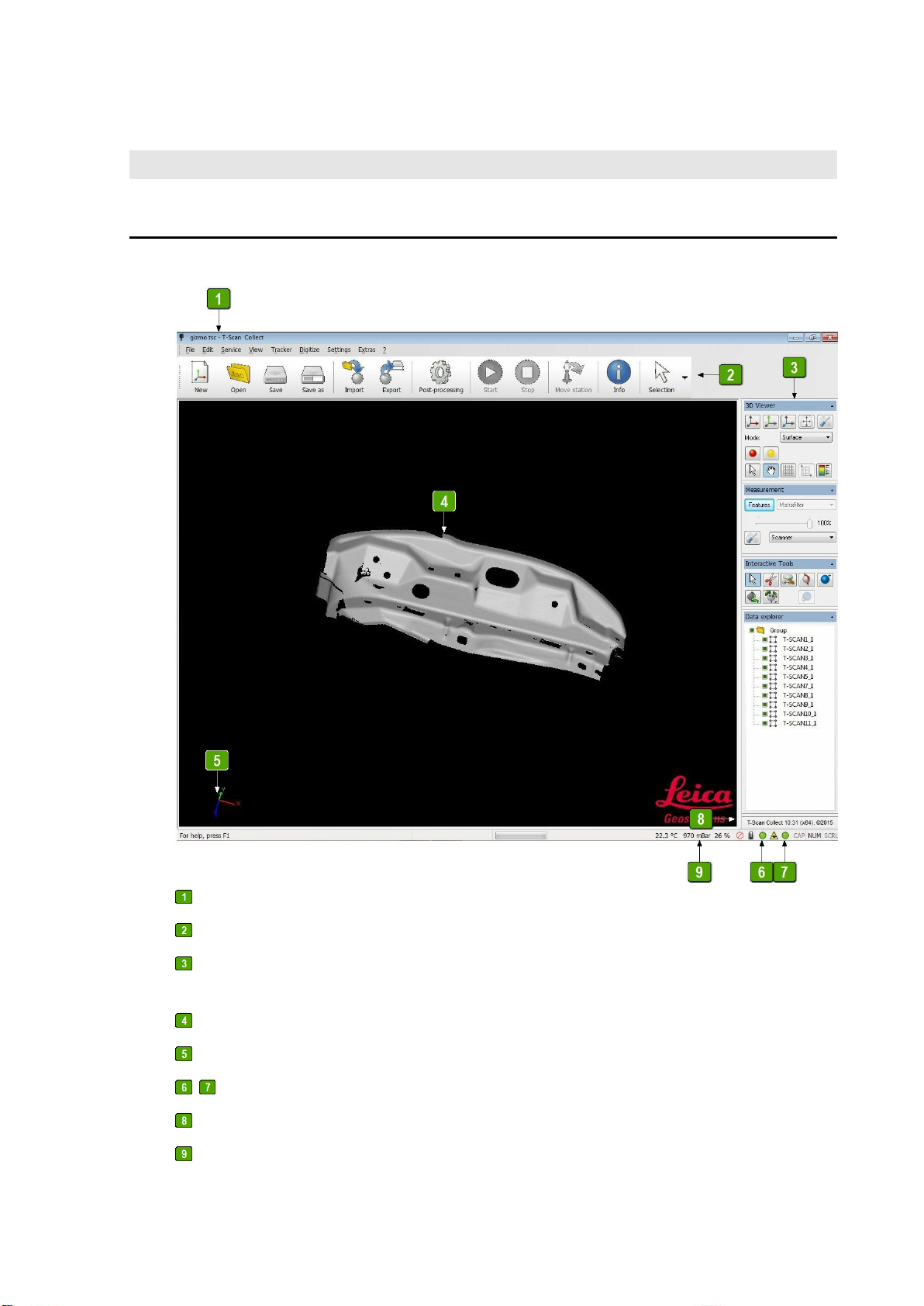

After the program start the user interface shows up:

Title bar, contains the name of current project

Toolbar with icons for frequently used functions

Several toolboxes. To save space, you can minimize/restore the toolboxes by clicking on the

corresponding button in their upper right corner

3D viewer with visualized data

Coordinate axes

, Status indicators for tracking system and controller, see chapter 5.2

Version information

Information from Weather Station

Page 10

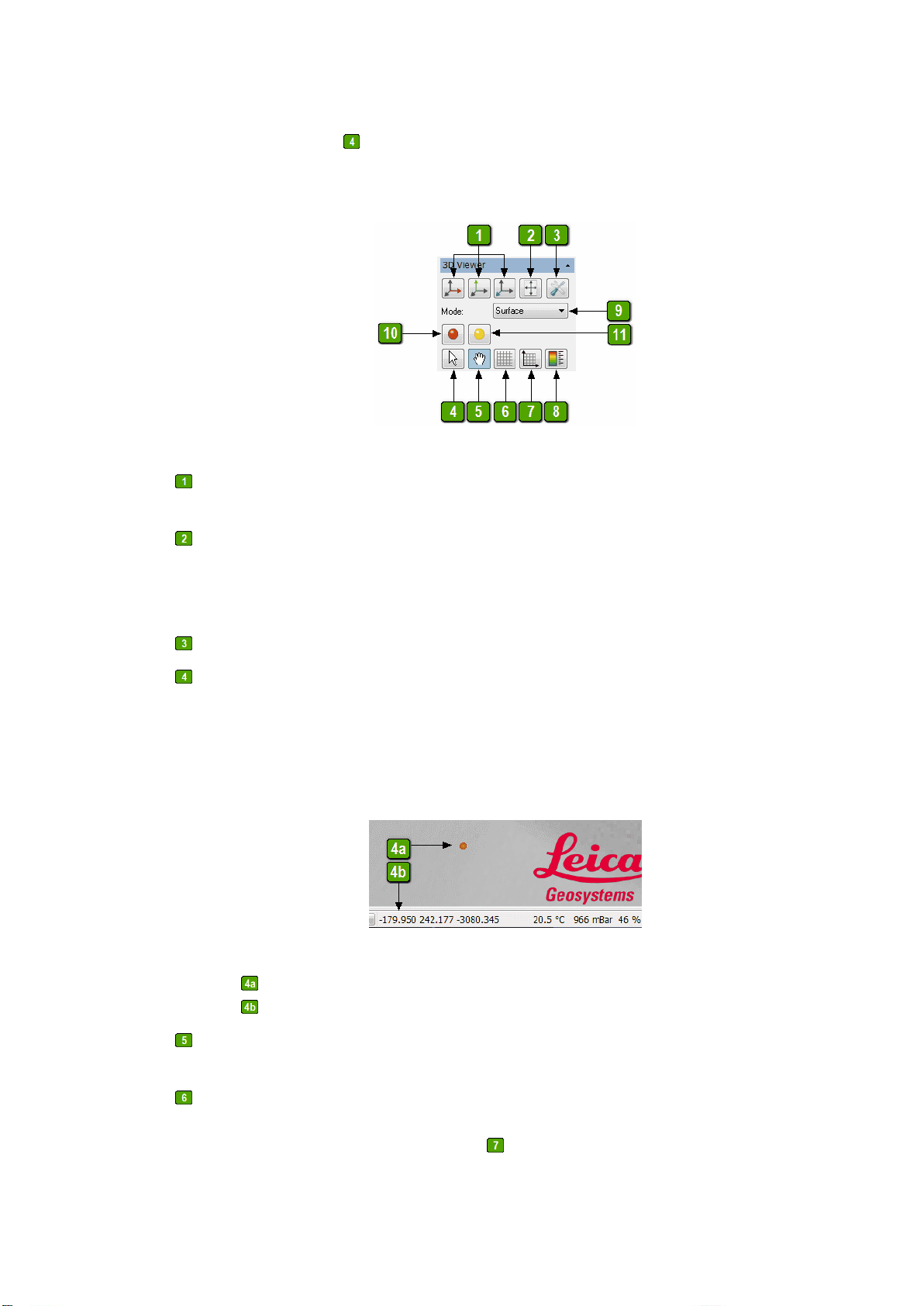

The area marked with in the above image shows the actual 3D viewer. The 3D Viewer

toolbox provides access to frequently used display functions:

Selection of viewing direction along the positive X, Y or Z coordinate axis. If you hold the

<Shift> key while clicking, the viewing direction is along the negative coordinate axis.

View all: If you use this button the zoom factor and the viewing position are adjusted so

that all visible data is shown. You can also achieve this by pressing the middle mouse button

while the cursor is over data or by holding down the <Shift> key and clicking with the left

mouse button in the 3D viewer.

Opens the dialog for the 3D Viewer Settings (see chapter 17.3).

Selection mode: By left clicking a data set in the 3D viewer, this data set is displayed in the

assigned selection color (see chapter 17.3.4) and marked red in the Data Explorer toolbox.

By right-clicking on a data point, the point is marked and its coordinates are displayed

(picking).

: Selected data point

: Point coordinates

Activation of viewing mode for interactive adjustment of the viewing direction, the position,

and the zoom factor.

Toggles a grid in the 3D viewer which can be used to quickly estimate distances or sizes. The

current distance between two major grid lines is displayed in the lower left corner. This

function cannot be used at the same time as .

Page 11

Show coodinate axes: This option is only available if the viewing direction is along a

coordinate axis (see ). The displayed coordinate axes are labeled. This function cannot be

used at the same time as . If you rotate the scene in the 3D viewer, the coordinate axis are

automatically hidden.

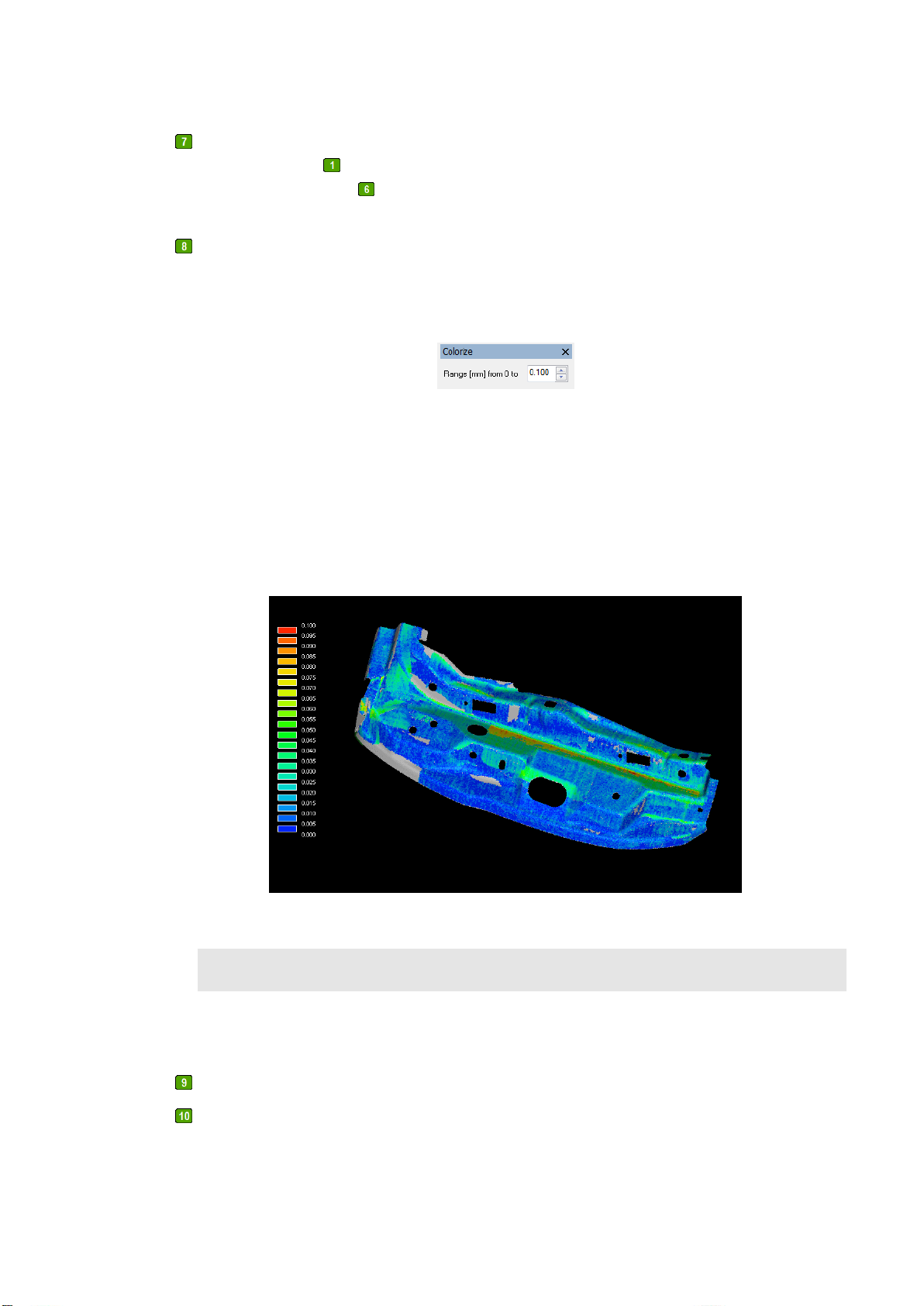

Colorize: This option is available as soon as two or more rasterized data sets are displayed.

When activated, overlapping areas of the data sets will be colorized according to the distance

of related points; a color lookup table indicates which color represents which distance.

The following toolbox opens:

Here you can enter the maximum distance that should still be colorized. This allows a quick

examination of the data quality and thus of the quality of the calibration. If large gaps occur

between the rasterized data, a tolerance-based matching (see chapter 11.3.2) or, if necessary,

a calibration (see chapter 9) should be performed. If deviations in data sets exceed the entered

value, they are displayed in the default color like scans that do not overlap.

Note

Colorizing large data sets may take a few seconds.

Viewing mode: The available settings are described in chapter 17.3.3.

Show/hide reference points: Toggles visualization of all nominal points created with the

Transform to Nominal Points wizard (see chapter 11.1.2).

Page 12

Show/hide tie points: Toggles visualization of all tie points created with the Move Station

wizard (see chapter 15.9).

The viewing direction, position and zoom factor in the 3D viewer can be interactively

controlled with the mouse. Activate the viewing mode or use <Space Bar> (as long as the

cursor is in the 3D viewer). In viewing mode, the following options are available:

Orientation:

Press the left mouse button, keep it pressed and move the cursor. The visualized object area is

shown using the dynamic display settings and is rotated according to the mouse movements.

When you release the left mouse button, the object is shown using the static displays settings

again.

Position:

Press the right mouse button, keep it pressed and move the cursor. The visualized object area

is shown using the dynamic display settings and is moved according to the mouse movements.

When you release the mouse button, the object is shown using the static display settings

again.

Zoom factor:

Press the middle mouse button, keep it pressed and move the cursor up and down. The

visualized object area is shown using the dynamic display settings and is zoomed according to

the mouse movements. When you release the mouse button, the object is shown using the

static display settings again.

You can also use the mouse wheel to change the zoom factor.

Zoom window:

Press the <Shift> key; the mouse cursor changes to an arrow with a rectangle. Press the left

mouse button while holding down the <Shift> key and move the cursor. As long as the left

mouse button is pressed, you can define a rectangular area. When you release the left mouse

button, the selected area is zoomed to fit the 3D viewer.

Defining the center of rotation:

To define the center of rotation, briefly press the <S> key. The cursor changes to an arrow with

a dot. With the left mouse button, click a point to define the center of rotation on the object’s

surface. The object is moved in such a way that the new center of rotation is in the center of

the 3D viewer.

Page 13

Note

Scanner: A symbol next to this graphic indicates whether a connection to the scanner

has been established.

If this symbol is green, a connection has been successfully established. If it is red, the

application has either been started in NoSensor mode or there is no connection to the

sensor via the controller. In this case, switch off the controller and check all connections

to the controller and to the sensor. Then switch the controller back on and wait until

the symbol turns green.

Tracking system: A symbol next to this graphic indicates whether a connection to the

tracking system has been established.

If this symbol is green, a connection has been successfully established. If it is red, the

application has either been started in NoSensor mode or there is no connection to the

tracker via the controller. In this case, switch off the controller and check all

connections to the controller and to the tracking system. Then switch the controller

back on and wait until the symbol turns green. The symbol for the tracking system is

yellow during measurement.

Probe: This icon show the probe that is currently tracked:

Scanner, left side (side 1)

Scanner, right side (side 4)

Scanner, top side (side 2)

Scanner, rear side (side 3)

By default, the center of rotation is in the center of gravity of the virtual box, which encloses

the whole object. However, you can freely determine the center of rotation as described above.

To set the center of rotation back to default, use the tool .

Axis rotation:

Press the <Alt> key and then press the left mouse button. Keep both pressed and move the

mouse cursor. A line from the center of rotation to the mouse cursor is drawn to help you

control the rotation. The view is rotated according to the mouse movements.

Illumination:

Press the <L> key and then press the left mouse button. Keep both pressed and move the

mouse cursor. The scene is illuminated according to the mouse movements.

5.2 Status Indicators

The status indicators are provided in the lower right area and can contain the following

symbols:

Page 14

T-Probe

Reflector

No Probe

Online Transformation: This symbol indicates that an online transformation is active

(see chapter 11.1.1).

5.3 Additional Coordinate Axes

By selecting Settings

arbitrary positions within the 3D viewer. The following dialog appears:

No additional coordinate axes

The additional axes will not be displayed.

Localize additional coordinate axes by picking

The positions of the additional coordinate axes can be defined by picking, as described in

chapter 5.1, item . The additional coordinate axes are positioned at the selected points.

Localize additional coordinate axes by selectable coordinates

The entries for the X, Y and Z coordinates contain the last defined positions of the coordinate

axes, regardless of whether they have been defined by picking or entered manually.

Coordinate axes, you can display additional coordinate axes at

New values take effect as soon as you click OK.

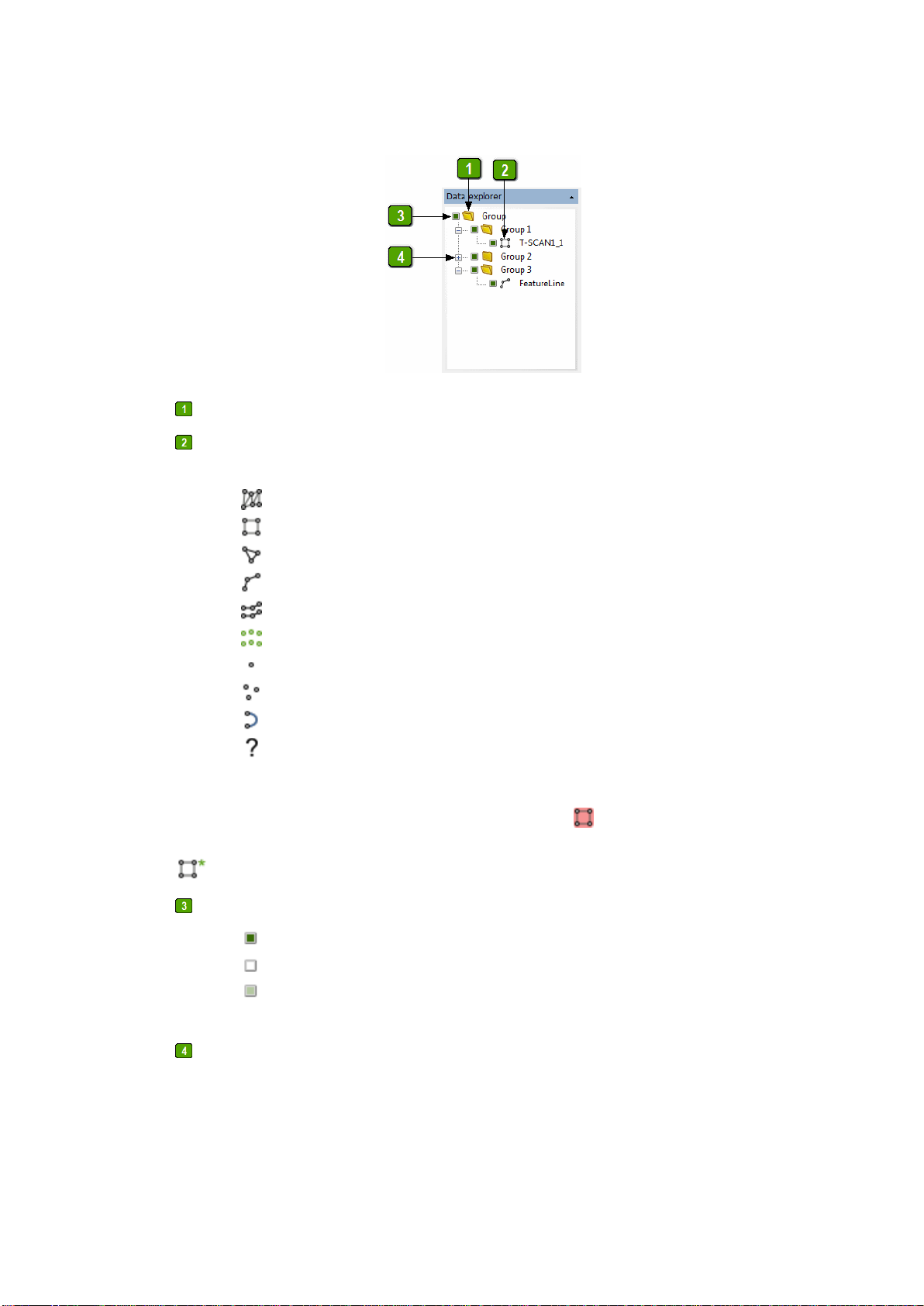

5.4 Data Explorer

This toolbox provides tools for grouping, editing and selecting data sets, and for the

customization of display characteristics.

Page 15

Group: The folder symbol represents a group, which may contain data or other groups.

Object name, data type and state: The object name is assigned automatically, but can be

changed. The symbol depends on the data type and can look like this:

Non-rasterized scan data

Rasterized scan data

Triangle mesh

Polyline

Polyline set

Alignment data

3D point

Unstructured point cloud

NURBS curve

Unknown data type

Symbols of selected data sets are highlighted in red, e.g. for a selected, rasterized data set.

If the data set is shown with customized display options, its symbol is marked with an asterisk:

.

Object visibility: This symbol can look like this:

for data: data is visible; for groups: all group entries are visible

for data: data is hidden; for groups: all group entries are hidden

only for groups: some group entries are visible, some are hidden

By clicking “+” or “-” you can expand or collapse groups.

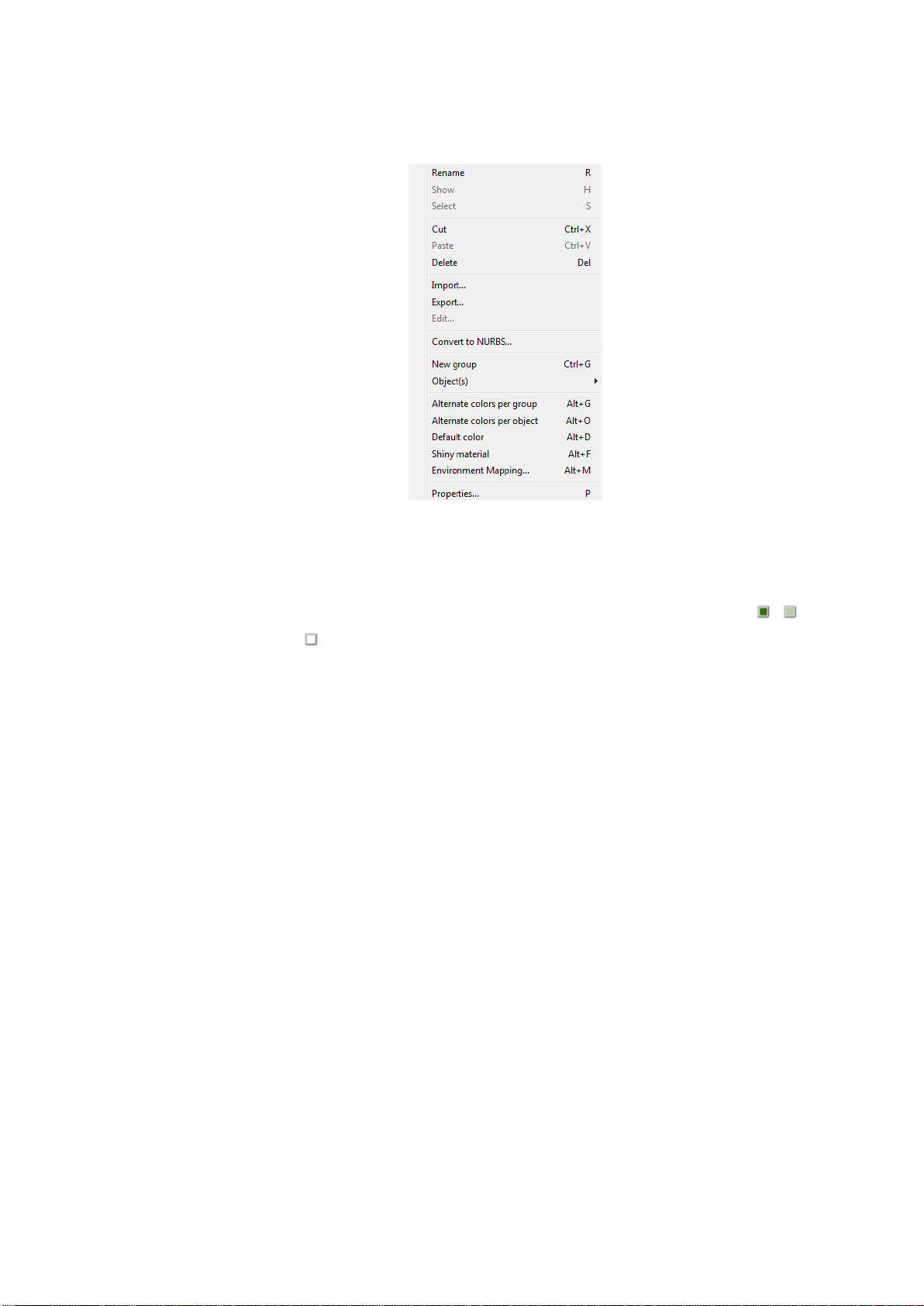

When at least one object is selected in the data explorer, you can open a context menu with

the following commands by clicking the right mouse button:

Page 16

Rename

Renames the selected object. You can also achieve this by pressing <F2> or

clicking on the selected object.

Show / Hide

Shows or hides object(s). You can also achieve this by clicking the , and

symbols.

Select /

Deselect

Selects or deselects object(s)

Cut

Removes the selected objects and adds them to an internal clipboard

Paste

Adds objects from the internal clipboard to the selected group

Delete

Deletes the selected objects; this action cannot be undone!

Import

Imports data to the current group

Export

Exports selected data to a file

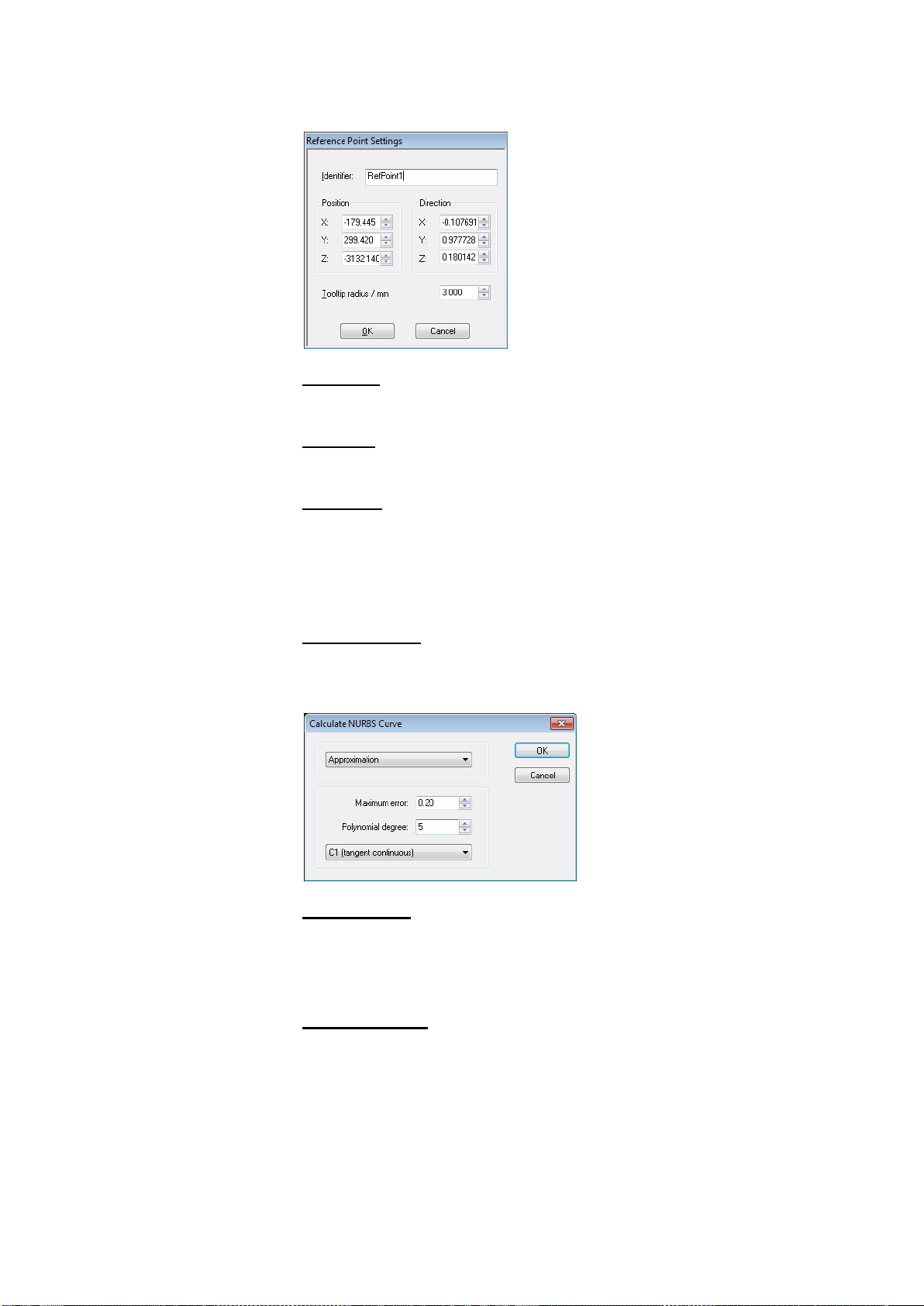

Edit

Only available for reference points; the following dialog appears:

Page 17

Identifier:

Displays the name of the reference point and allows renaming it

Position:

Displays the position of the current point

Direction:

If available: Direction from which the reference point was measured; the

length of the direction vector is normalized to 1 and the point is shown in

green. If no direction information is available, the fields display (0, 0, 0) and

the point is shown in blue.

Tooltip radius:

Displays the radius of the T-Probe’s tip with which the point was acquired.

Convert to

NURBS

Only applicable to lines; the following dialog appears:

Interpolation:

The NURBS curve passes exactly through the measurement points. By

adjusting the Polynomial degree and choosing the method, you can define

how the NURBS curve will be created.

Approximation:

The NURBS curve is approximated to the measurement points and will not

deviate by more than the specified maximum error at the control points. By

adjusting the Polynomial degree and choosing the method, you can define

how the NURBS curve will be created.

Three methods are available:

Page 18

C0 (discontinuous): Neither the tangent nor the curvature of the created

NURBS curve will be continuous

C1 (tangent continuous): The tangent of the created NURBS curve will be

continuous

C2 (curvature continuous): The curvature of the created NURBS curve will

be continuous

Note

Depending on the data and the settings you choose it might happen that the

NURBS curve cannot be calculated. In this case, adjust the parameters and

recalculate the curve.

New group

Adds a new subgroup to the selected group

Object(s)

Opens the submenu for other object settings

Alternate

colors per

group

Assigns a different color to each group

Alternate

colors per

object

Assigns a different color to each object

Default color

Assigns the default color to each object

Shiny material

Assigns a shiny color and material to each object

Environment

Mapping

Opens a dialog where you can select an image that is projected onto the

objects and helps to identify faults in the surface. For best results select

Smooth shading in the 3D viewer settings.

Properties

Displays the characteristics of the object

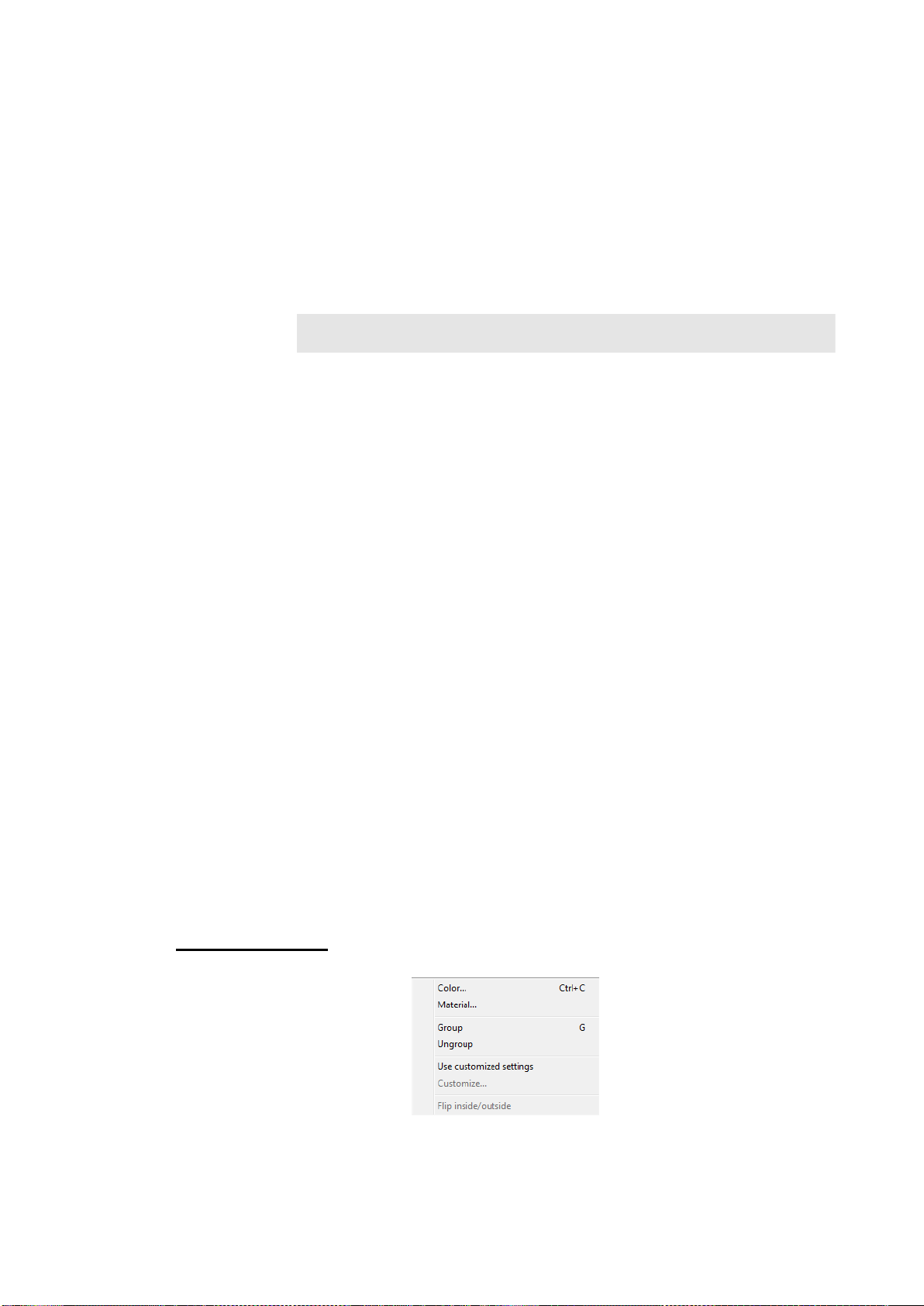

Object(s) submenu:

Page 19

Color

Opens a dialog where you can choose a color for the selected objects

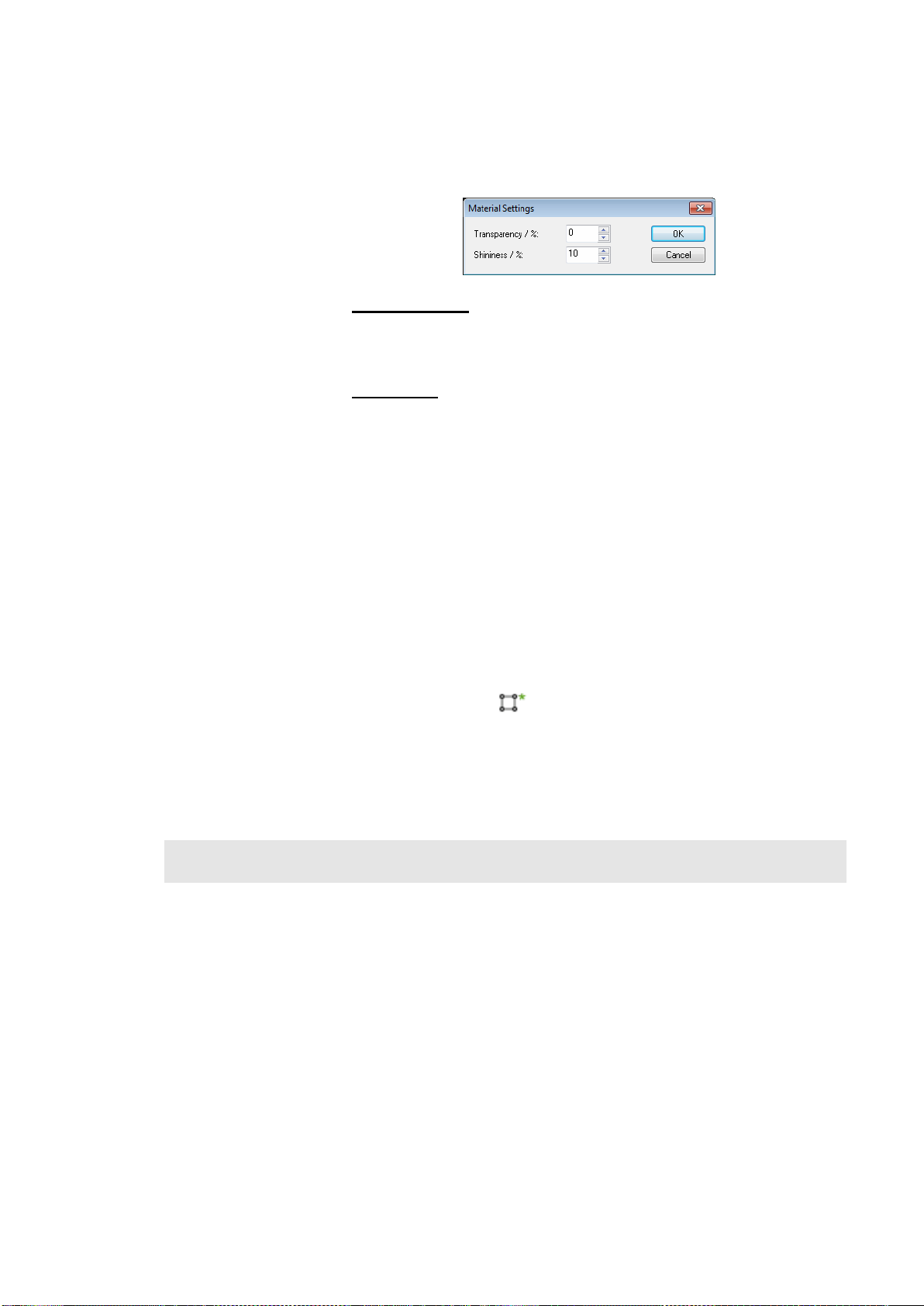

Material

The following dialog appears:

Transparency:

Enter the transparency of the object (in percent). 0% means the

object is opaque, 100% means it is translucent.

Shininess:

Enter the shininess of the object (in percent). 0% means the object is

not shiny, 100% means the object is very shiny.

Group

Combines all selected data sets (also those in a selected group) into a

new group. The name of the new group is the name of the first data

set in the group, followed by the number of data sets in the group (if

the group contains more than one data set).

Ungroup

Moves all selected data sets (also those in a selected group) to root

and then deletes all selected groups.

Use customized

settings

The selected objects are either displayed with the global settings for

the 3D viewer (see chapter 17.3) or with customized display settings.

The symbols of objects with customized display settings are marked

with an asterisk, e.g.: .

Customize

Opens a dialog for customizing the display settings for the selected

objects (see also chapter 17.3)

Flip inside/outside

Flips the inside and outside of a triangle mesh

Note

Please note that some commands are only available if a single object is selected, while other

commands are also available if multiple objects are selected.

You can select multiple objects in different ways:

1. Click the first object, then move the cursor to the last object. Press and hold the <Shift> key

2. Click the first object, then press and hold the <Ctrl> key and click other objects. Clicking an

and click the last object. All objects in-between are selected.

already selected object deselects it.

3. You can combine the two methods described above.

Page 20

4. You can also use the shortcuts <Shift> + <PageUp> / <PageDown> / <Home> / <End > to

select multiple objects.

Please keep in mind that any changes you make are also saved in the project. The next time you

open the project, all settings that were in effect the last time you saved the project will be

active again.

Shortcuts, cursor keys and drag and drop are easy ways to increase efficiency. When using

shortcuts, make sure that the data explorer has the focus.

Page 21

6 Customizing the User Interface

The T-Scan Collect user interface can be customized. You can define your own shortcuts,

menus and toolbars. Choose View Toolbars or right-click a toolbar to open the context

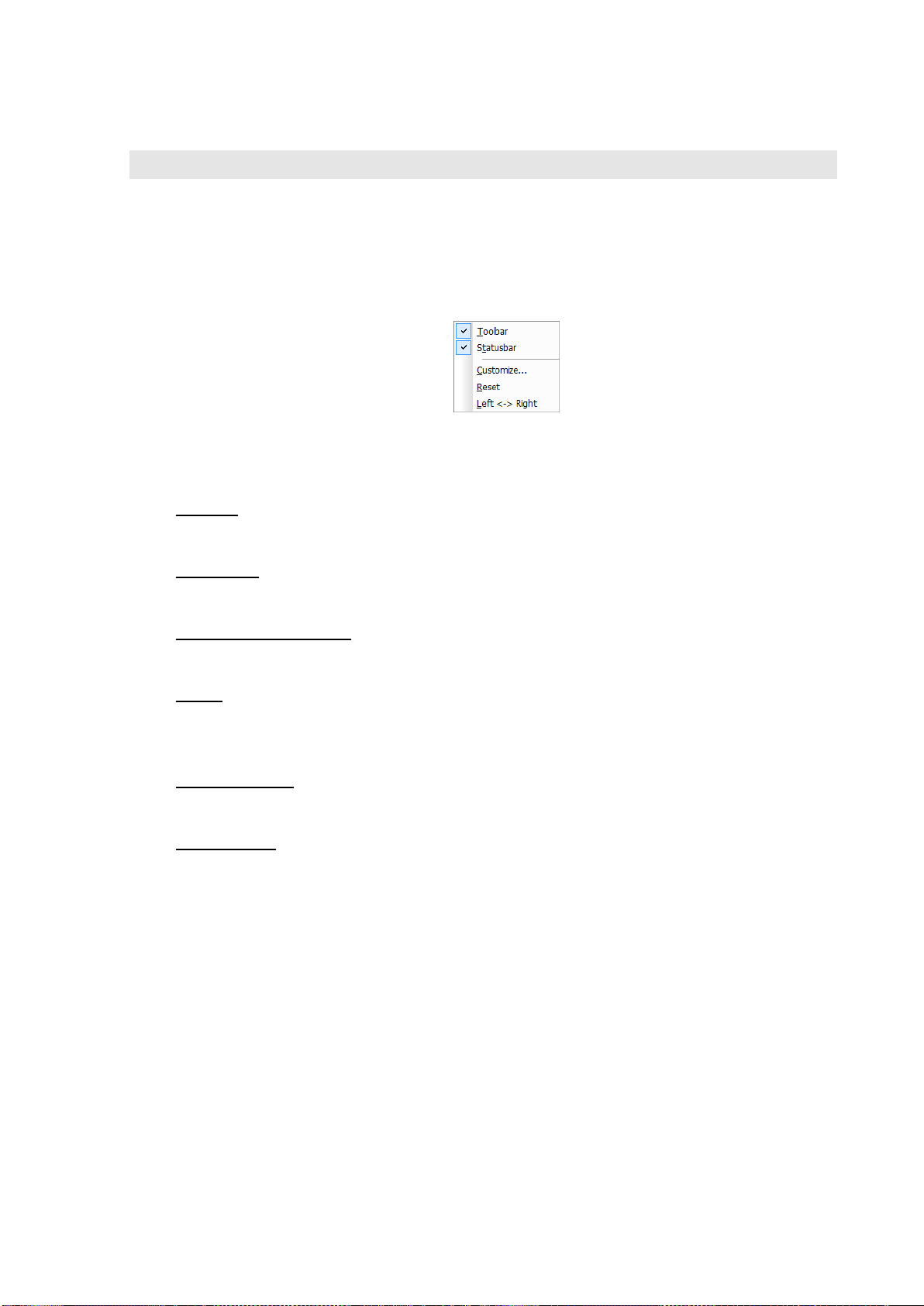

menu.

The context menu provides the following functions:

Toolbar

Shows or hides the standard toolbar

Status bar

Shows or hides the status bar

User defined toolbars

If you defined your own toolbars, you can choose which to show or hide

Reset

Resets all shortcuts, menus and toolbars to the default settings of T-Scan Collect. All userdefined changes will be lost. This action cannot be undone!

Left Right

Swaps the positions of the toolbars

Customize...

Opens a dialog where you can define and change shortcuts, menus and toolbars. As soon as

the dialog is open, you can drag and drop buttons onto or off toolbars to move, add or delete

buttons.

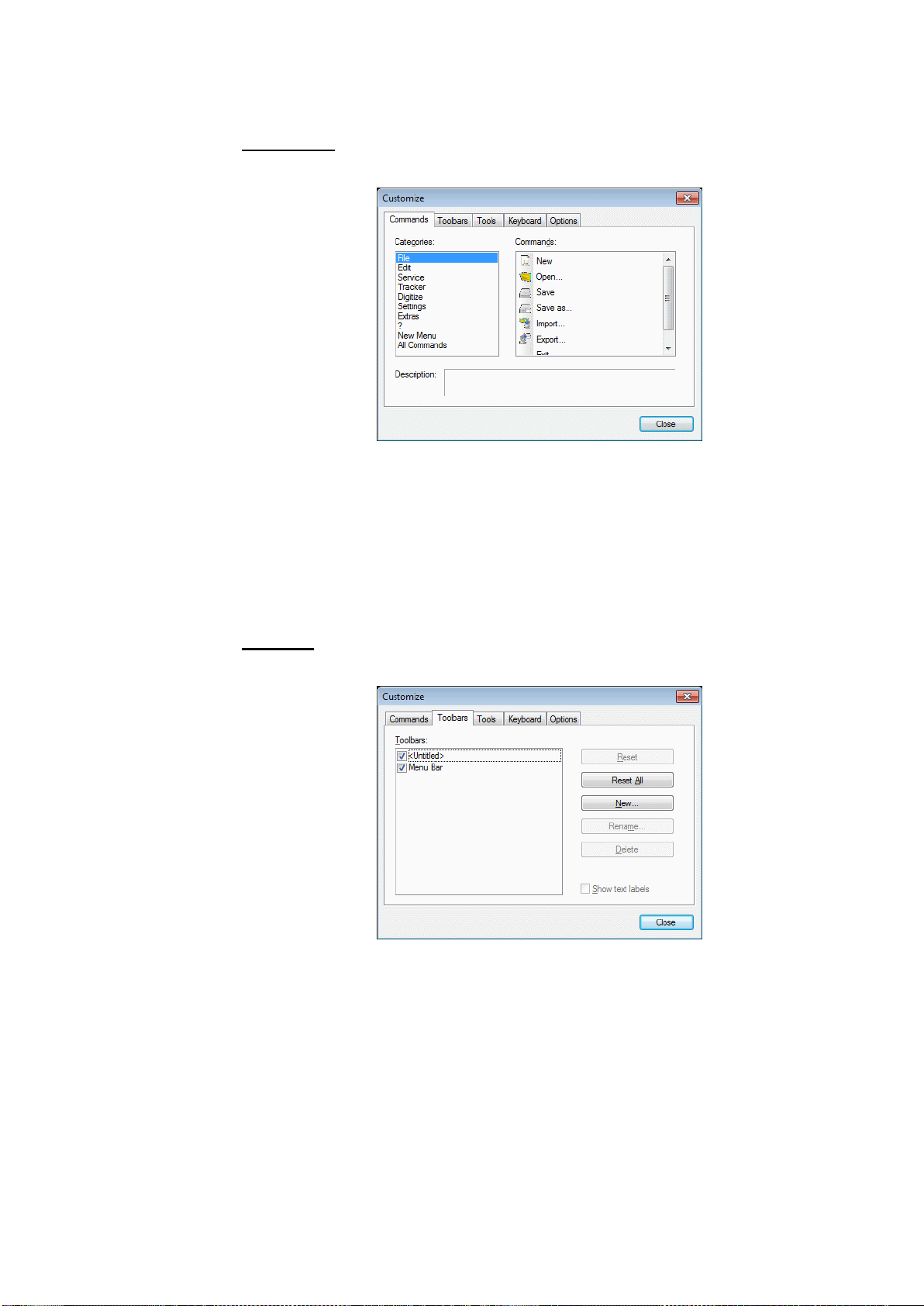

The dialog contains various tabs:

Page 22

Commands

You can add all listed commands to a toolbar. Left-click a command and drag it onto a

toolbar while holding the mouse button down. When you release the mouse button,

the command is added to the toolbar.

You can also remove a command from a toolbar: Click the icon and drag it off the

toolbar while holding the left mouse button down.

Toolbars

A list shows the available toolbars. By selecting or deselecting the checkboxes in the

list, you can show or hide the toolbars.

To create a new toolbar, click New.... A dialog box appears where you can enter a

name for the new toolbar.

To delete a toolbar, select it and click Delete.

Page 23

Click Rename… to rename the selected toolbar. A dialog box appears where you can

enter a new name for the toolbar.

You can reset the standard toolbar to the default settings of T-Scan Collect by clicking

Reset. This action cannot be undone!

To reset all toolbars to the default settings of T-Scan Collect, click Reset All; userdefined toolbars will be lost. This action cannot be undone!

You can choose whether to show or hide the text labels of the icons by selecting or

deselecting the Show text labels checkbox.

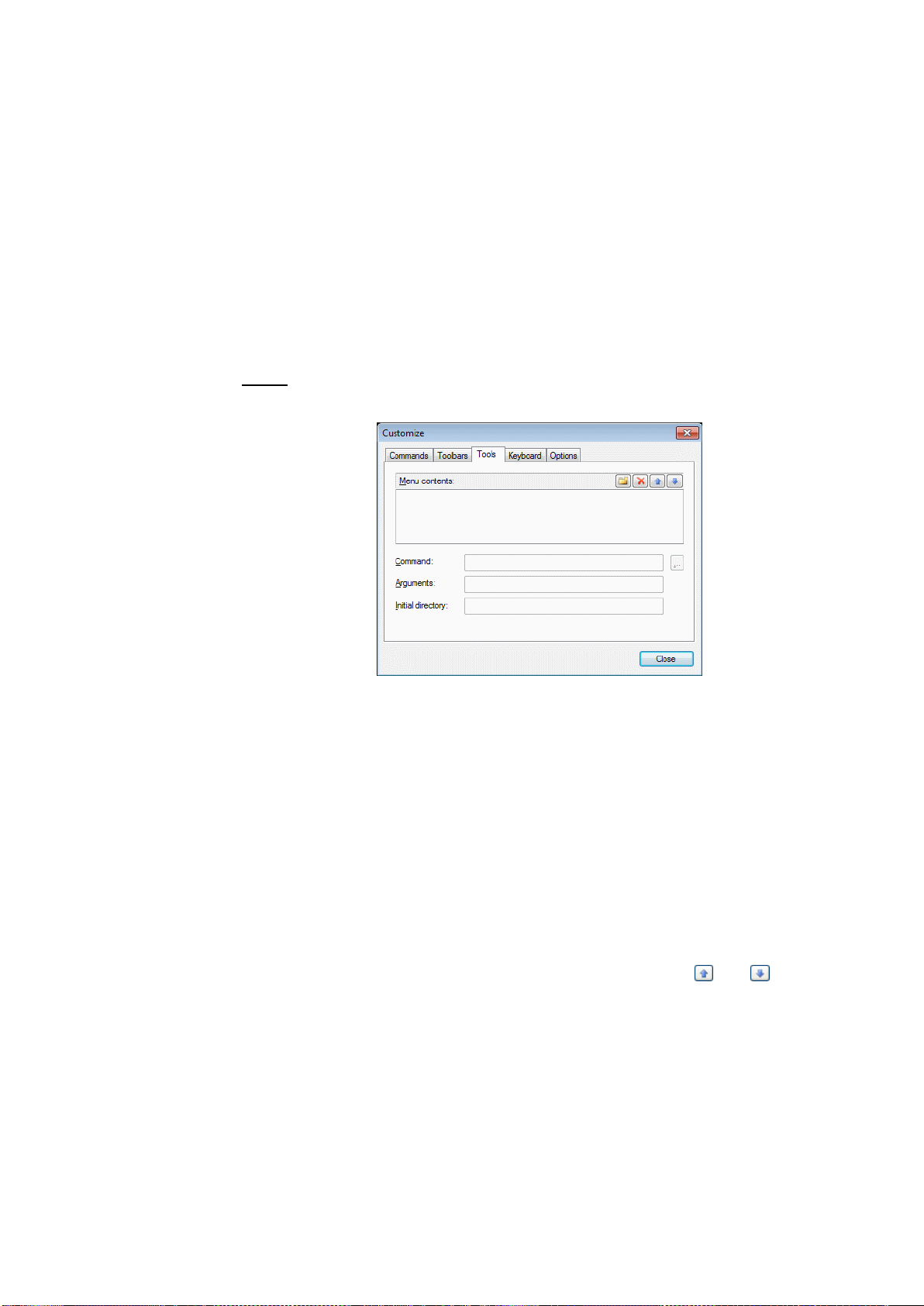

Tools

With this tab, you can manage the commands provided in the Extras menu.

By pressing the <Ins> key or clicking the New icon, you can create a new menu entry.

An input line appears where you can enter a name for the menu entry, e. g. “Start

COMET Inspect”. In the Command line, define the application that will be started

when the entry is selected; e. g. D:\Program Files\Steinbichler\INSPECTplus 5.23\

INSPECTplus.exe. If you want to pass arguments to the application, enter those in the

Arguments line. Initial Directory defines the directory in which the command will be

executed.

By pressing <Del> or clicking the Delete icon, you can delete the selected entry.

By pressing <Alt> and <Up> or <Alt> and <Down> or the icons and , you can

change the position of the selected entry within the menu.

Page 24

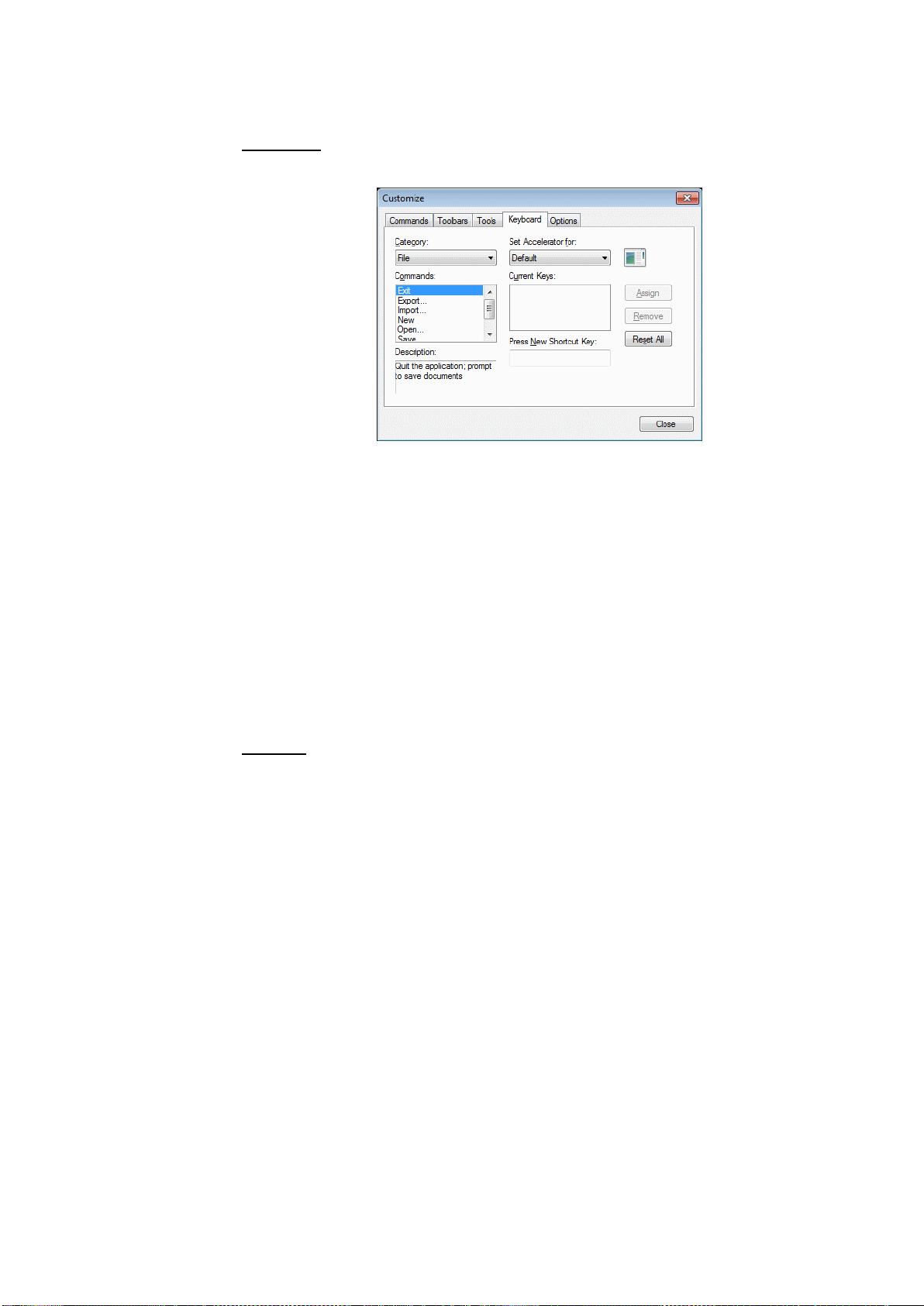

Keyboard

Here you can define shortcuts for all menu commands. In the Category list, select the

menu that contains the command. The Commands list then shows all the

commands of this category. Select the command for which you want to change the

shortcut. The current shortcut (if available) is displayed in the Current Keys box.

Select the input line for Press New Shortcut Key and press the key combination for

the new shortcut. Then click Assign.

To remove the shortcut for a command, select the command and click Remove.

To reset all shortcuts to the default settings of T-Scan Collect, click Reset All. This

action cannot be undone!

Options

Select or deselect Show ScreenTips on toolbars and Show Shortcut keys in

ScreenTips according to your preferences. It is recommended to select both options.

The Large Icons function is currently not supported.

Page 25

7 Measurement

7.1 Selection of Measurement Mode

To select a measurement mode, choose Settings Measurement… or use the Measurement

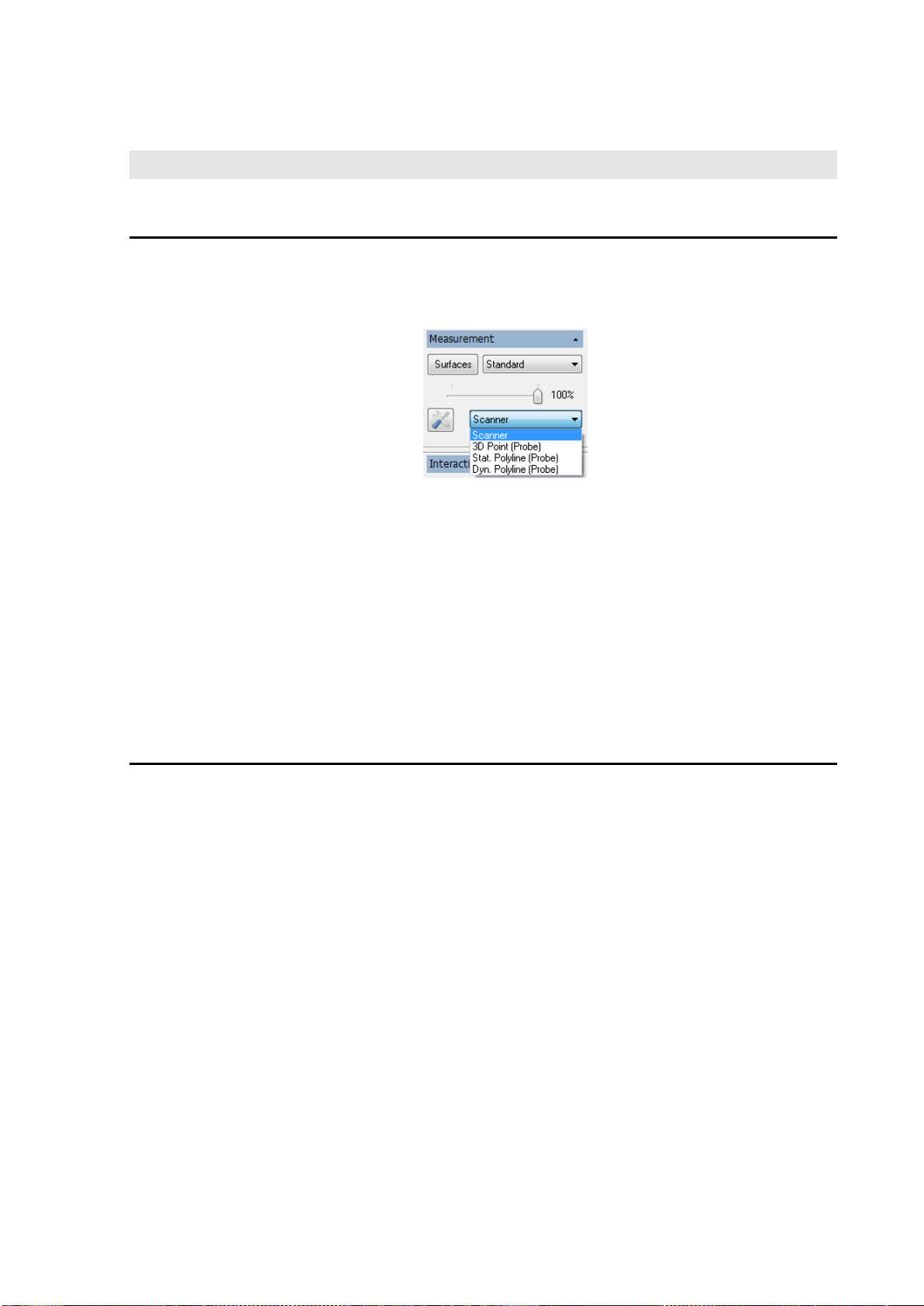

toolbox:

In Surface mode, object surfaces can be digitized. This mode is activated after the

program start by default

In 3D Point mode, single points will be measured with the T-Probe (Probe)

In Static Polyline mode, lines will be measured with the T-Probe (Probe) where each point

of the line has to be measured explicitly

In Dynamic Polyline mode, lines are measured with the T-Probe (Probe) where the points

of the line will be measured automatically according to the chosen settings

7.2 Measurement Settings

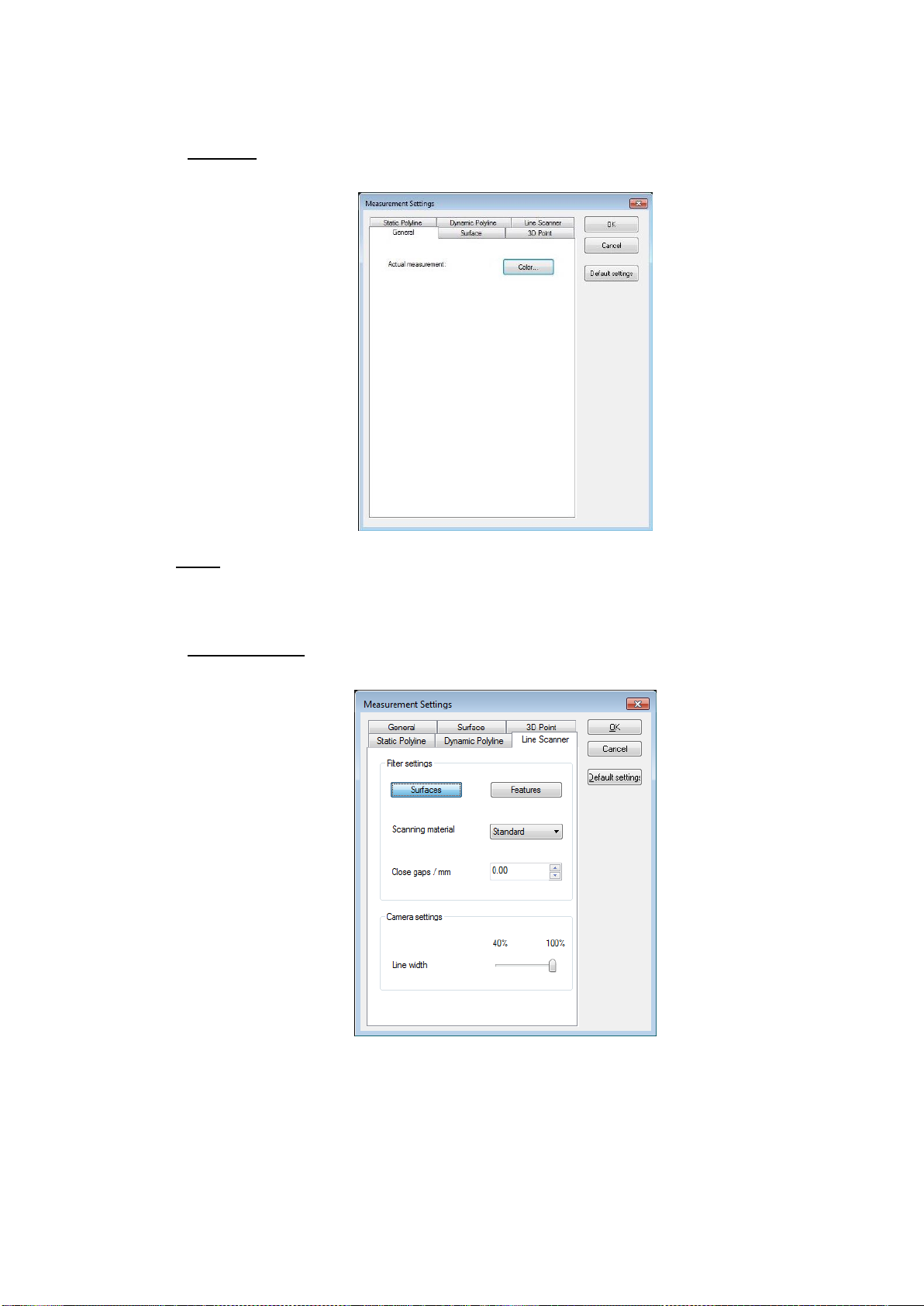

The settings can be adjusted separately for almost every measurement mode. To do this,

choose Settings Measurement…. A dialog appears where you can select the tab for the

measurement mode you want to adjust. You can also open the dialog from the measurement

toolbox by clicking the Measurement parameter settings icon.

Page 26

7.2.1 General

Color

This button opens a dialog where you can specify a color for the last measurement data you

acquired.

7.2.2 Line Scanner

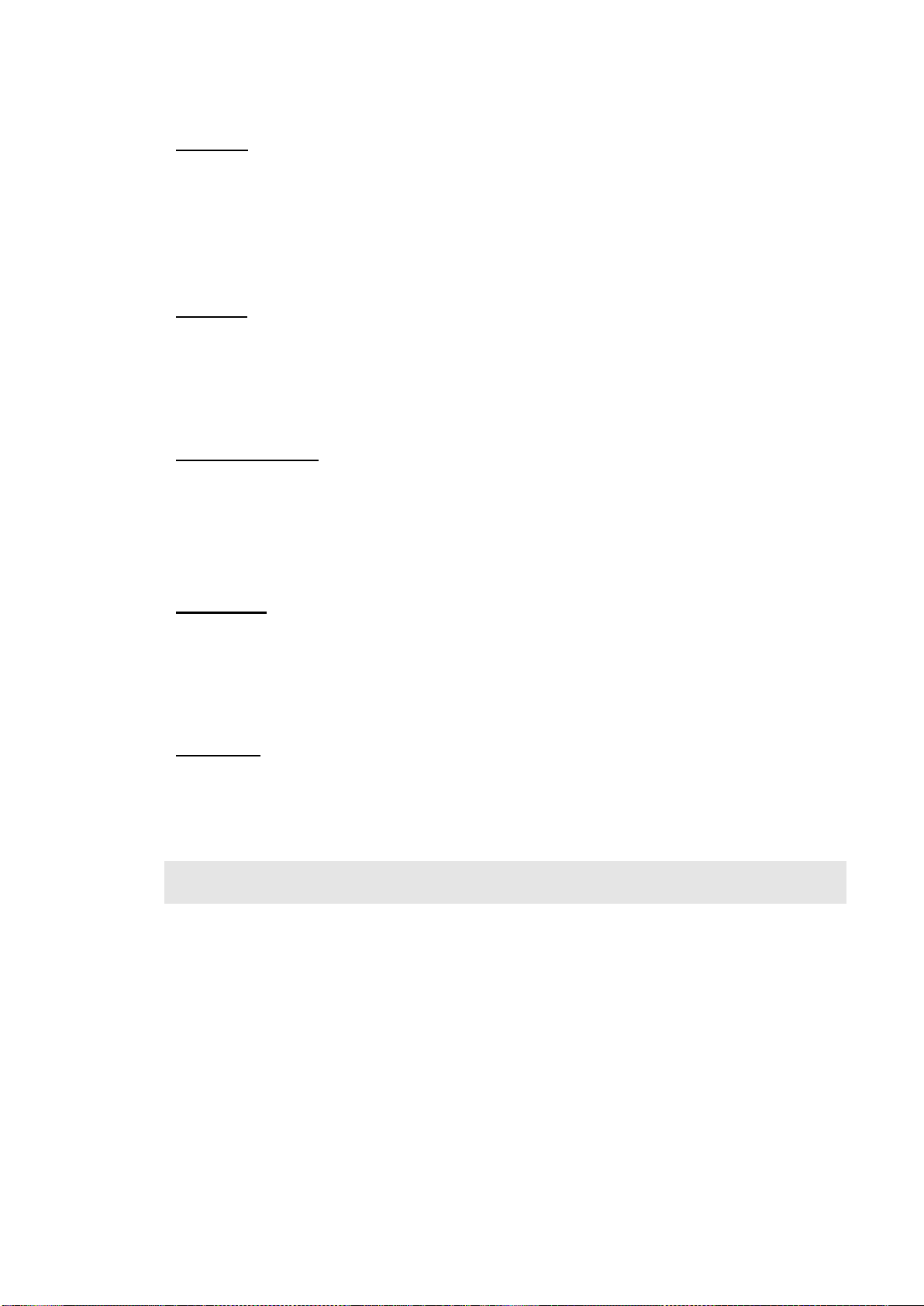

This dialog provides settings for adjusting the line scanner. If inappropriate settings are made

here, however, you might not be able to acquire any measurement data. If you would like to

restore the default values, click the Default Settings button.

Page 27

Surfaces

Press Surfaces if you want to measure surfaces. In this mode, measured data are rasterized

immediately after acquisition using the selected settings (see chapter 7.2.3). Besides, the value

for Close gaps will be used as well as the reflection filter defined in the materials editor (see

chapter 17.10).

Optionally you can select Surfaces in the Measurement toolbox by hitting Surfaces/Features.

Features

Press Features if you want to measure features like e.g. gaps or boundaries. In this mode,

measured data are not rasterized, but visualized as a point cloud. Close gaps will be

deactivated.

Optionally you can select Features in the Measurement toolbox by hitting Surfaces/Features.

Material selection

From the list of materials, select the one which resembles your object’s properties the most.

By default, the following materials are available: Standard, Shiny bright, Dark and Shiny dark.

You can add, modify or delete further materials using the Material Editor (see chapter 17.10).

Optionally you can select a material in the Measurement toolbox.

Close gaps

If gaps appear within a scan line, they can be filled automatically by means of interpolation.

Specify a value for the maximum gap size up to which a gap will be closed automatically.

This setting is useful when measuring surfaces like fabrics, felt, foam material or similar, and a

complete surface is required.

Line width

With this slider, you can reduce the width of the line to be scanned down to 40% of the

maximum width. By choosing a smaller line width, you can increase the line frequency.

Optionally you can modify the line width in the Measurement toolbox.

Note

Please note that the visible width of the laser line is not influenced by this setting.

Page 28

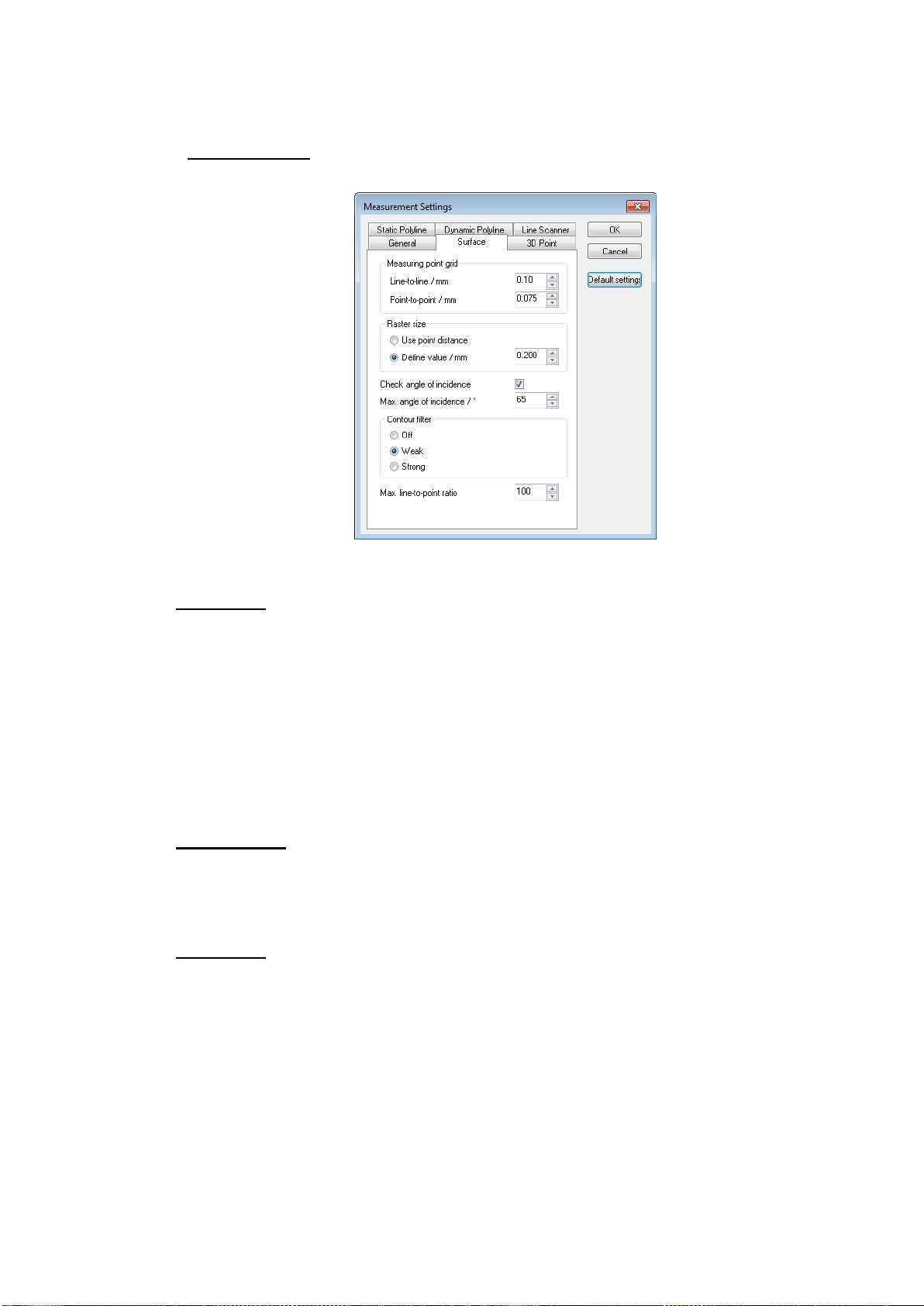

7.2.3 Surface Mode

Line to line

This value defines the minimum distance between two scan lines. The minimum distance

prevents the acquisition of too dense data if the scanner is moved very slowly or not at all. The

software checks if the scanner moved more than the entered Line to line value. If it did not,

the current scan line is rejected.

The absolute distance between the scanner positions is calculated, i.e. spatial movement in the

scan line direction also increases the distance. Only the distance to the previous scan line is

calculated. If the scanner is repeatedly moved over the same point, data is acquired with each

new movement.

Point to point

This value determines the average point distance on the scan line. It refers to the center of the

scanner’s measurement range and changes with increasing or decreasing distance to the

object. The value can only be changed in 0.075 mm steps.

Raster size

If the Use point distance radio button is selected, the raster width is set according to the point

to point distance.

If you want to use a different raster width, select Define value and specify the raster width.

Bear in mind that a raster width of less than 0.1 mm will dramatically increase the amount of

data generated.

Page 29

Note

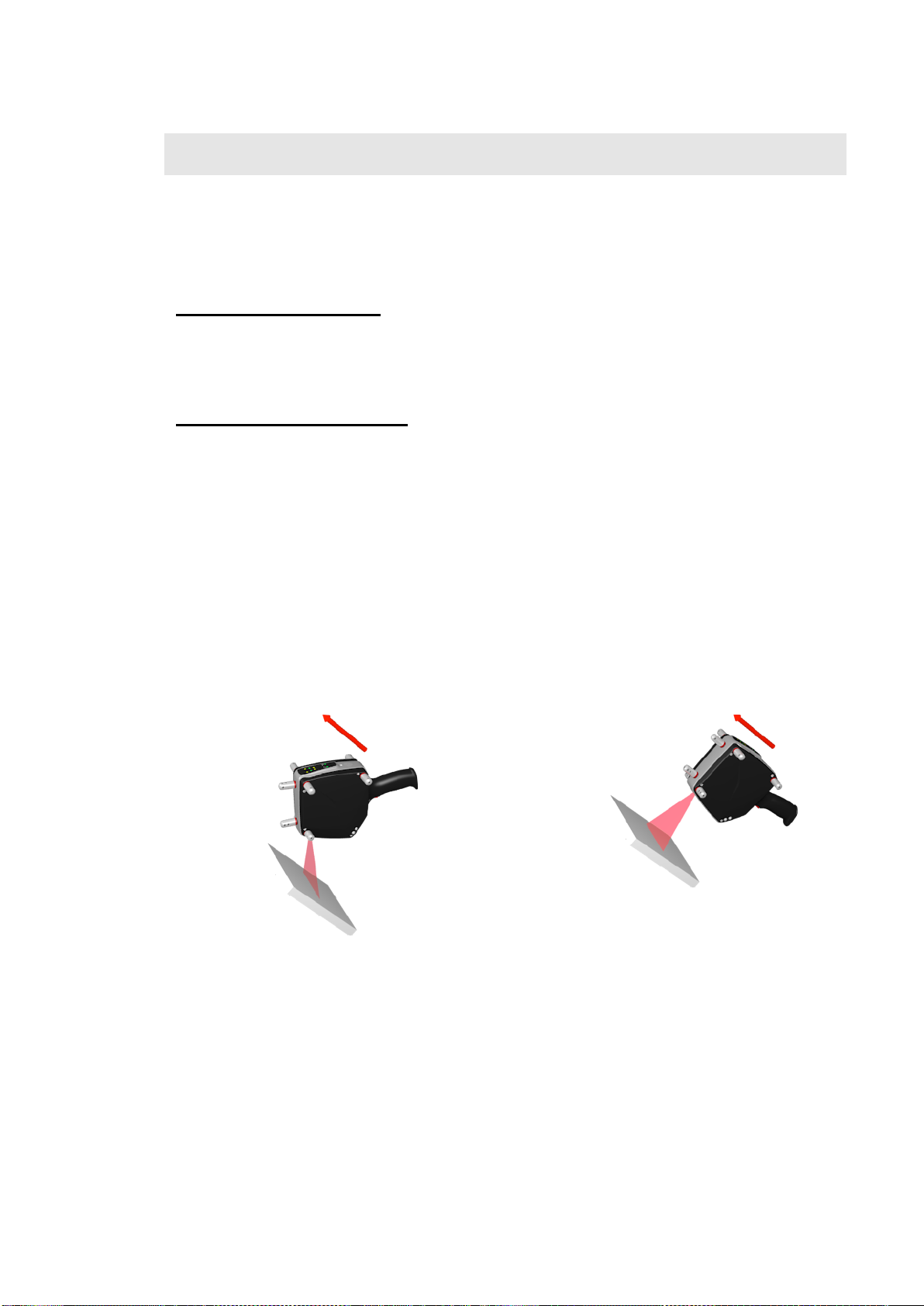

Angle treatment when moving in the direction of motion

The angle between the laser plane and the

object exceeds the entered threshold: No

measurement data will be acquired.

Measuring correctly: The angle between the laser

plane and the object is almost perpendicular.

A rasterization process is started when

- the Measurement Settings for the Line Scanner is set to Surfaces (see chapter 7.2.2) or

- post-processing is started and the scene contains non-rasterized scanner data.

Check angle of incidence

If this checkbox is selected, a filter is applied to the data. The filter removes points measured

with an angle of incidence that exceeds the specified maximum value. How this filter works is

described in more detail below.

Maximum angle of incidence

Measured points for which the angle of incidence between the laser beam and the surface

exceeds the entered value are rejected. The smaller the value, the less data you will acquire,

but the higher the data quality will be.

The angle is initially checked within each scan line. If the Measurement Settings for the Line

Scanner is set to Surfaces (see chapter 7.2.2), the angle is additionally checked in the direction

of motion of the scanner.

The following illustrations demonstrate the principle of the filter. The arrow indicates the

direction of motion of the scanner.

Page 30

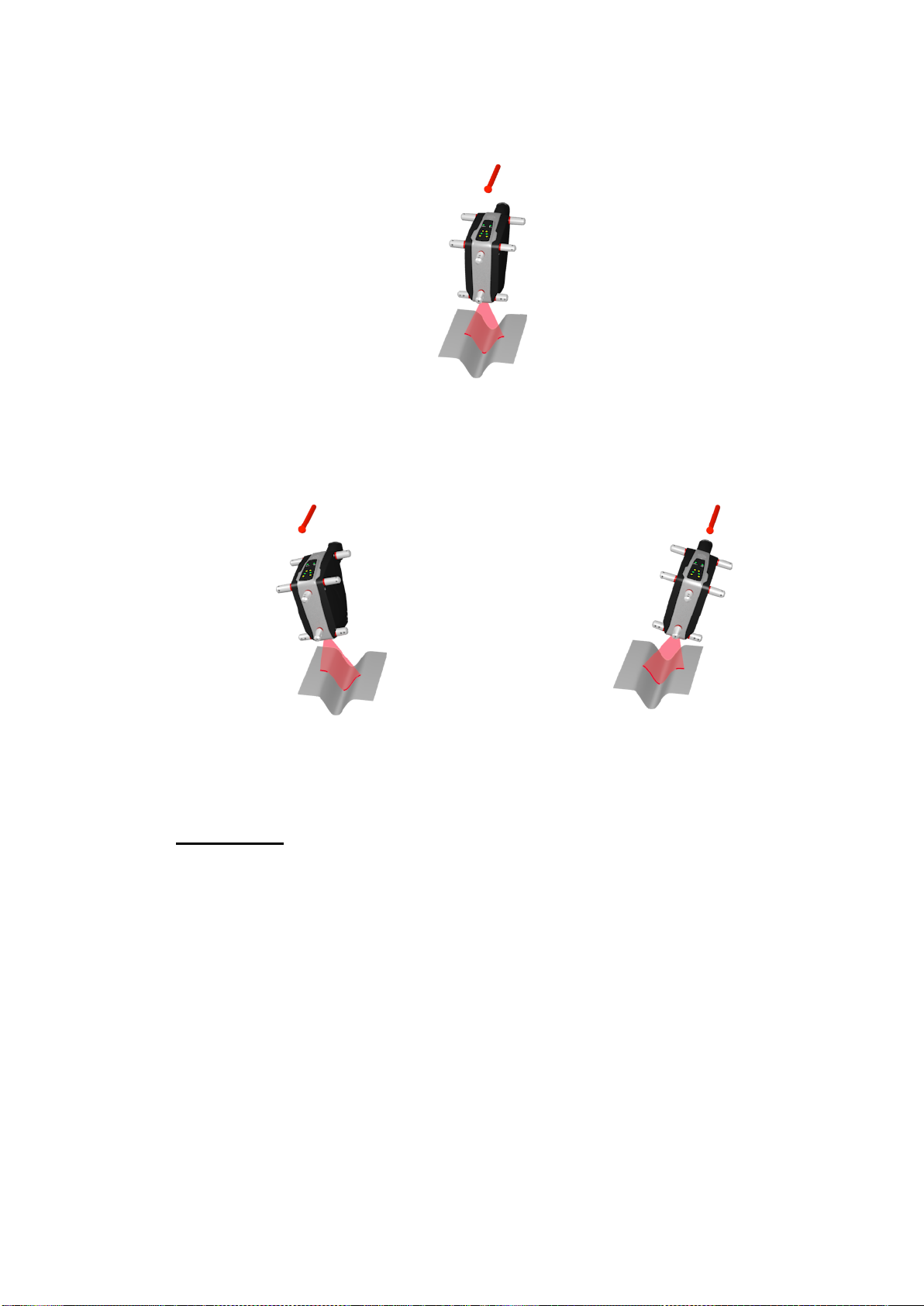

Angle treatment within a scan line

No measurement data is acquired if the angle between

the laser beam and the surface exceeds the entered

value.

To measure the surface completely, do two

scans. Tilt the scanner first in one direction...

...and then in the other direction.

Contour filter

This filter is only applied if the measurement settings for the Line Scanner is set to Surfaces

(see chapter 7.2.2). It can improve the data quality of the scan data when measuring

contoured objects using an inappropriate measurement strategy.

Page 31

Inappropriate measurement strategy: the

scanner is moved too fast and the scan line is

almost parallel to the object’s contour. The

contour filter will remove data.

If the scanner is moved too fast relative to the selected point-to-point distance and the scan

line is almost parallel to the object’s contour (see illustration), surface elements that do not lie

completely on the object surface might be created between neighboring scan lines. The

object’s contour will then look ‘blurred’.

The contour filter analyzes the points of neighboring scan lines and prevents the points from

being connected to a continuous surface if an inappropriate measurement strategy is used.

Therefore, gaps in the data may occur, providing a visual indication to the user that this area

should be measured again using a more suitable strategy.

The filter strength can be adjusted to achieve optimal data quality. If the filter is set to strong,

more data will be rejected. If the filter is set to weak, less data will be rejected; however, data

might then be retained that does not actually lie on the object’s surface. You can also disable

the filter if you want to keep the data in any case.

The measurement strategy described above should generally be avoided. Instead, you should

always try to measure perpendicularly to the object’s contours (see illustration below). Even if

the filter is set to strong, the algorithm will detect if an appropriate strategy has been used and

will retain all data.

Page 32

Appropriate measurement strategy: The scanner

is moved perpendicularly to the object’s contour. The contour filter will retain all data.

Max. line-to-point ratio

If the speed the scanner is moved over a measurement object is too fast relative to the

selected point-to-point distance, widely spaced scan lines will be created. When this data is

then rasterized, the point-to-point distance used is taken as the basis for rasterization. As a

result, the “gaps” between the scan lines may be filled (interpolated) with many points, which

excessively increase the data volume without improving the data quality.

Ideally, the scanner is moved fast enough so that the distances between points on a scan line

are approximately equal to the distances between neighboring scan lines.

If the ratio of “distance between scan lines” to “point distance within a scan line” exceeds the

specified value, these scan lines are not connected to create a continuous surface, but gaps are

left. This can help the user to optimize the measurement strategy and avoid unnecessarily

large data volumes.

7.2.4 3D Point Mode

Page 33

For this measurement mode, data is acquired and averaged internally. The averaged value is

output as a measurement point.

Measuring priority

This setting controls the method how a 3D point is measured. By default, the following options

are available: Precise, Standard and Fast.

Next ID

This field is only available in the settings for 3D points and defines the name for the next point

to be measured. If the ID does not end with a digit, a sequential number – beginning with “1” –

is automatically appended to the name.

7.2.5 Static Polyline Mode

The settings for these two modes are identical.

Page 34

For this measurement mode, data is acquired and averaged internally. The averaged value is

output as a measured point.

Measuring priority

This setting controls the method how a 3D point is measured. By default, the following options

are available: Precise, Standard and Fast.

Page 35

7.2.6 Dynamic Polyline Mode

Point frequency

The points will be acquired with the entered frequency.

Point-to-point distance

This value defines the minimum distance between two successive points. The minimum

distance prevents a too dense data recording if the T-Probe is not moved or moved very

slowly. The software checks if the T-Probe moved more than the Point-to-point distance value.

If not, the current point will be rejected.

7.3 Starting a Measurement

When you click the Start icon in the standard toolbar or choose Digitize Start, the scanner or

the T-Probe is activated in the selected measurement mode (Surface, 3D Point, Static Polyline).

The Start icon is disabled and the Stop icon is enabled.

7.3.1 Surface Mode

In Surface Mode, 3D points on the object’s surface can be measured with the T-SCAN scanner.

Page 36

The measurement itself is started as soon as you use the trigger button on the scanner handle.

T-Scan Collect automatically becomes the active application – depending on the settings (see

chapter 17.15) – if another application was active. You can make as many measurements as

required.

During measurement, 3D coordinates are calculated and the newly measured data is shown in

the selected color (typically red, see chapter 7.2.1).

If the measurement setting for the line scanner is set to Surfaces (see chapter 7.2.2), the data

is displayed in the default color immediately after it has been rasterized.

A new entry is created in the data explorer toolbox. If the measurement setting for the line

scanner is set to Features (see chapter 7.2.2), the entry is named “T-SCAN[sequential

number]”. The number is incremented with each scan.

If the measurement setting for the line scanner is set to Surfaces, a scan might be split up into

several parts. This happens if the scanner orientation changes significantly during a scan, thus

influencing the rasterization direction. In the data explorer, splitted scans are named “T-SCAN

[sequential number]_[sub number]”, where [sub number] always starts with 1.

7.3.2 3D Point Mode

In 3D Point Mode, single 3D points can be measured with the T-Probe. Depending on the

selected settings (see chapters 17.13 and 17.14), the T-Probe coordinates window and/or the

wireframe of the T-Probe will show up as soon as the measurement starts.

Page 37

To acquire a measurement point, press the trigger button on the T-Probe or press the <M>

key. As soon as the measurement was successfully completed, the measurement point is

displayed in green color. You can acquire as many measurement points as are required.

Note

Every measured point is stored in a separate data set and named according to the settings you

made (see chapter 7.3.2). If a data set of the same name already exists, another data set is

created using the next free number.

By pressing the <D> key, you can delete the points in the reverse order in which they were

acquired.

7.3.3 Static Polyline Mode

In Static Polyline Mode, single 3D points are measured with the T-Probe and automatically

connected to create line segments. This way, you can acquire polylines. Depending on the

selected settings (see chapters 17.13 and 17.14), the T-Probe coordinates window and/or the

wireframe of the T-Probe will show up as soon as the measurement starts.

To acquire a measurement point, press the trigger button on the T-Probe or press the <M>

key. As soon as the measurement was successfully completed, the measured point is visualized

Page 38

and connected to the previous point by a line. You can adjust the point size and line size (see

chapter 17.3) to optimize the visualization. A polyline may contain any number of points.

You can start a new polyline by pressing the <N> key. The last active polyline is closed and

displayed in blue.

Note

Polylines are saved in data sets named “Polyline[X]”, where [X] is a sequential number. If you

rename such a data set, it will not be treated as a polyline anymore.

Pressing <D> deletes points from the “Polyline[Y]” data set, where [Y] is the highest existing

number. If the last point of a polyline is deleted, the polyline itself will also be deleted. The next

delete action will open the data set with the now highest number and delete the last measured

point from that line.

7.3.4 Dynamic Polyline Mode

In Dynamic Polyline Mode 3D points can be measured continuously with the T-Probe. The

points will be connected automatically to form line segments. According to the settings (see

Page 39

chapters 17.13 and 17.14) the T-Probe coordinate window and/or the wire frame model of the

T-Probe will be displayed as soon as the measurement starts.

As long as the right mouse button or the button of the T-Probe is pressed, points will

continuously be acquired with the chosen settings (see chapter 7.2.6). By releasing the button,

the polyline will be completed. Pressing the button anew will create a new poly line.

Remarks

Lines will be stored in data sets named „Polyline[X]“ where [X] is a running number. If you

rename such a data set it will not be treated as a poly line anymore.

7.4 Stopping a Measurement

To stop a measurement, click the Stop icon in the standard toolbar or choose Digitize Stop.

The infrared LEDs are switched off and the scanner goes into sleep mode. The Start and Stop

icons change their states accordingly.

You can continue the measurement at any time. All you need to do is restart the

measurement. The measured data is added to the existing data.

Page 40

8 Interactive Tools

There are several interactive tools you can use for editing existing data sets. These tools are

provided in the ‘Interactive Tools’ toolbox and can also be accessed by selecting Edit

Interactive Tools or the drop down menu in the toolbar.

The toolbox contains the following tools:

Selection mode (“No Tool”)

Interactive clipping

Check accuracy

Cross sections

Create reference points

Fill holes / tools for editing triangle meshes

Alignment calibration

The Data Analysis tool is currently not used and therefore is not available

The tools and have a small arrow in the bottom right corner. The arrows indicate that a

submenu can be opened when clicking the icons and keeping the mouse button pressed.

The functions of these icons can be modified by selecting a menu item.

The tool currently in use is shown in the toolbar. A blue background indicates whether the tool

is active (“tool mode”) or inactive (“view mode”). By pressing <Space Bar> in the 3D viewer,

you can switch between these modes.

Page 41

8.1 Selection Mode

This icon activates the selection mode. When you click a data set in the 3D viewer, it is

displayed in the assigned selection color and shown in red in the data explorer (see chapter

5.4).

8.2 Interactive Clipping

This tool allows you to clip data of any type. If all data of an object or entire objects are

clipped, the corresponding entry is removed from the data explorer.

The toolbox offers the following options:

Choose whether the clipping action will apply to All faces, only Front faces or only Back

faces. This option is only effective for objects that have back and front faces.

If this option is enabled (symbolized by a “normal” eye), no data will be deleted that is

currently invisible, e.g. because it lies outside the 3D viewer or is hidden by other data. If the

option is disabled (“X-ray eye”), all the data within the selection will be deleted.

If this option is enabled, data within the selected area will be retained and all data outside

the selection will be deleted. The selected area will then be shown in green instead of red.

Move the mouse cursor over the area containing the data you want to edit. If view mode is

currently active, change to tool mode by pressing <Space Bar> in the 3D viewer.

Define the area to clip with the left mouse button. By left-clicking, you can define a straight

line. If you keep the left mouse button pressed, you can draw a continuous line. Close the area

by double clicking with the left mouse button or pressing the right mouse button. You can also

select multiple areas in this way.

Press or the <Enter> or <Del> key to clip the selected areas. Press to undo the last action

or actions you made.

8.3 Check Accuracy

With this tool, you can check the measurement accuracy of the T-SCAN system.

Page 42

1. Before running an accuracy check, it is advisable to review the nominal values in the

settings dialog :

1. If you are using a barbell, enter the sphere radii into the corresponding fields. Sphere 1

corresponds to the red, Sphere 2 to the blue sphere displayed in the toolbox. The

correct Distance between the two spheres also needs to be specified.

If you are using a single sphere, you are free to choose which field to use for the

nominal radius. Take care to select the correct sphere (red/blue) later in the

evaluation.

2. If Fit with free radius is disabled when you perform the accuracy check, the software

will try to fit a sphere with the given radius into the data. This may lead to an error

message if it is not possible to calculate a reasonable result, e.g. because the given

radius differs significantly from the actual data.

3. In the Remove outliers fields, you can specify how many of the worst fitting points will

be removed before sphere fit and plane fit. A setting of 1 Sigma will eliminate

approximately 32%, 2 Sigma approximately 5% and 3 Sigma approximately 3 ‰ of the

most off-size points.

4. For the sphere fit, Visible points only is disabled by default because, in most cases, you

will want to check the entire sphere, including the rear side.

For the plane fit, Visible points only is enabled by default because usually only the

Page 43

selected points are part of the plane, whereas surfaces or data sets located behind the

plane are to be left unconsidered.

2. Now use the lasso in the 3D viewer to select the first or the only sphere/plane you want

to check. Make sure that the correct sphere or plane is selected in the toolbox (red/blue).

Then start the evaluation by pressing <Enter> or clicking .

3. The following result dialog appears:

Example

for one sphere: for two spheres:

The results can be saved to a text file which can be imported into third party software (e.g.

Microsoft Excel).

Note

If you click the currently selected button ( , , , ) in the toolbox once more, the

result dialog is reopened and you can again view or save the available results. The values

remain stored even after the toolbox is closed, but will be deleted when you exit the

application.

4. Fitted objects (spheres or planes) are displayed in the 3D viewer. Their colors help to

identify their correspondences to the first fit (red) or the second fit (blue).

These objects are removed when the toolbox is deactivated or closed, or when switching

from sphere fit to plane fit (or vice versa).

5. If you want to check a second sphere or plane, select the correct icon in the toolbox (for

spheres normally , for planes normally ) and repeat step 2.

On completion of a calculation for spheres, a line connecting the two sphere centers in the

Page 44

3D viewer displays the determined distance.

Repeating a calculation will overwrite existing results.

6. The icon clears all results of the sphere and plane fits as well as the objects created in

the 3D viewer.

7. By default, the lasso is selected for creating the set of points for the fit. However, it is

also possible to create single points that will be used as the basis for the calculation. To do

so, switch to point mode .

You can now select points by left-clicking on the data. These points are displayed as small

spheres. As soon as at least four valid points have been selected, a preview object (sphere

or plane) is created and displayed in the 3D viewer. Every time you add a new point, the

preview is recalculated to make the changes visible. The final calculation is carried out

when you press <Enter> or click in the toolbox.

8.4 Cross Sections

When the cross sections toolbox is active, the following tools for creating cross sections are

available:

Page 45

The cross sections toolbox provides access to manipulation functionality for the cross

section plane . The cross section plane and, if activated, the auxiliary planes for multiple

sections, are visualized.

Selection of the cross section plane direction (along the coordinate axes)

Position of the cross section plane along the selected coordinate axis

Center the cross section plane in the data set

Open the dialog with the cross section settings; see chapter 17.1

Create multiple sections. If this mode is active, the step width field defines the distance

between multiple sections. Two auxiliary planes are displayed at the specified distance to the

main plane in the 3D viewer, providing a preview of the settings.

Calculate and display cross sections

Note

The following display settings will be used:

o Red, semitransparent: cross section plane

o White: bounding box

o Green: center lines of the cross section plane as well as the start and end points and

the intersection point of these lines.

8.5 Create Reference Points

With this tool, you can use sphere fits to create reference points from measurement data. The

following toolbox appears:

Page 46

1. Before creating a reference point, it is advisable to review the settings. Click on the

Settings button to open the dialog:

If Fit with free radius is disabled, the software will try to fit a sphere with the

given radius into the data. This may lead to an error message if it is not

possible to calculate a reasonable result, e.g. because the given radius differs

significantly from the actual data.

In the Remove outliers field, you can specify a factor which defines how many

percent of the worst fitting points will be removed in a sphere fit. The default

value is 0.003, meaning 3 ‰.

The Visible points only checkbox is deselected by default because, in most

cases, you will want calculate the fit for the entire sphere, including the rear

side. This checkbox can be selected if required.

2. Now use the lasso in the 3D viewer to select the data you want to use for the sphere

fit and press <Enter> or the toolbox icon .

3. The reference sphere is displayed as a blue sphere in the 3D viewer.

8.6 Fill Holes (Triangle Mesh)

This tool provides options for interactively or automatically filling holes in a triangle mesh. This

functionality is available if a single triangle mesh is loaded. The following toolbox appears:

Page 47

Holes can be selected in two different ways:

Move the mouse cursor over the triangle mesh area you want to edit. If view mode is

currently active, change to tool mode by pressing <Space Bar> in the 3D viewer. Holes

in the data set in the area near the mouse cursor are detected automatically and

shown with a yellow border. When you left-click a detected hole, the hole is filled and

a preview of the result is displayed.

Click the Previous Hole or Next Hole icon to select one hole after the other. The 3D

view can be automatically centered on the selected hole if icon is activated.

With the Density and Noise sliders, you can adjust the data generated for the filled

hole to optimally fit the characteristics of the surrounding measurement data. If multiple holes

are selected and filled, these settings are applied to each of them.

The Mode list box provides the following filling strategies:

flat fills a hole as plane as possible; works very fast

curved incorporates the orientations of the surrounding mesh into the calculations,

delivering excellent results e.g. when filling holes in spheres; calculation takes longer

To accept the generated areas, press the Apply icon or right-click in the 3D viewer. If you

are not satisfied with the result, click Undo to undo the last action or actions you made.

Holes can also be filled automatically. For this, enter the maximum Circumference in mm

and click . All holes up to this size are filled automatically using the specified settings.

The title bar of the toolbox shows information on how many holes have been detected in

the triangle mesh.

8.7 Create Bridges (Triangle Mesh)

This tool provides the possibility to interactively create bridges over gaps in a triangle mesh.

This functionality is available if a single triangle mesh is loaded. The following toolbox appears:

Page 48

Move the mouse over the triangle mesh area you want to edit. If view mode is currently active,

change to tool mode by pressing <Space Bar> in the 3D viewer.

To create bridges, move the mouse over the area to be edited until the area is highlighted in

yellow. Click on it with the left mouse button to define the start edge for the bridge. Then

select the end edge with the left mouse button. A preview bridge with the currently selected

parameters is displayed between the two selected edges.

In the Mode list box , you can choose between the following bridge modes:

Linear

This mode creates a linear data bridge as the shortest connection between the selected edges.

Tangential

This mode creates a data bridge between the selected edges, taking the surface orientation of

the adjacent triangles into account.

Corner

This mode creates two linear data bridges, one from each selected edge. The surface

orientation of the adjacent triangles is taken into account. The edge that is formed where the

two linear bridges meet can then be rounded with the Radius slider .

The selected mode can be changed even after you have selected the start and end edges. This

way you can visually adjust the generated bridge to the surrounding area.

To accept the generated bridge, press the Apply button or right-click in the 3D viewer. If

you are not satisfied with the result, click Undo to undo the last action or actions you made.

8.8 Smoothing (Triangle Mesh)

With this tool, you can interactively smooth areas in a triangle mesh. This functionality is

available if a single triangle mesh is loaded. The following toolbox appears:

Page 49

Move the mouse over the triangle mesh area you want to edit. If view mode is currently active,

change to tool mode by pressing <Space Bar> in the 3D viewer.

A circle is displayed around the mouse cursor showing the radius of effect of the tool (“brush

size”). It can be resized with the mouse wheel or by drag and drop with the middle mouse

button.

To smooth an area, left-click on the beginning of the area and keep the mouse button pressed.

Now drag the cursor over the desired area on the object. The data in this area is smoothed

while you move the cursor. Releasing the mouse button stops the smoothing process.

The smoothing strength can be adjusted with the Strength slider .

If you are not satisfied with the result, click Undo to undo the last action or actions you

made.

Note

Take care to only smooth surfaces that face the user in the 3D viewer. Smoothing transitions

from front side to back side (e.g. on spheres), or on faces which can only be seen under a very

small angle, can lead to artifacts.

8.9 Decimate Mesh (Triangle Mesh)

This tool is used to interactively decimate a triangle mesh. This functionality is available if a

single triangle mesh is loaded. The following toolbox appears:

Move the mouse over the triangle mesh area you want to decimate. If view mode is currently

active, change to tool mode by pressing <Space Bar> in the 3D viewer.

A circle is displayed around the mouse cursor, showing the radius of effect of the tool (“brush

size”). It can be resized with the mouse wheel or by drag and drop with the middle mouse

button.

To decimate an area, left-click on the beginning of the area and keep the mouse button

pressed. Now drag the cursor over the object to mark the area you want to decimate. When

you release the left mouse button, the marked area is automatically decimated.

The Max. error parameter defines the maximum permissible deviation in millimeters; the

Max. edge length parameter defines the size of the resulting triangles in millimeters.

If you are not satisfied with the result, click Undo to undo the last action or actions you

made.

Page 50

8.10 Sharpen Edges (Triangle Mesh)

This tool provides the possibility to sharpen edges of triangle meshes interactively. This

functionality is available if a single triangle mesh is loaded. The following toolbox appears:

Move the mouse over the triangle mesh area you want to edit. If view mode is currently active,

change to tool mode by pressing <Space Bar> in the 3D viewer.

A circle is displayed around the mouse cursor, showing the radius of effect of the tool (“brush

size”). It can be resized with the mouse wheel or by drag and drop with the middle mouse

button.

To sharpen edges, left-click on the beginning of the area and keep the mouse button pressed.

Now drag the cursor over the object to mark the area you want to modify. When you release

the left mouse button, the edges in the marked area are automatically sharpened.

The Min. Angle parameter defines the minimum angle an edge must have in order to be

sharpened. A theoretical value of 0 means that all data is modified, a value of 180 means that

no data is modified.

If you are not satisfied with the result, click Undo to undo the last action or actions you

made.

8.11 Alignment Calibration

How to use this toolbox is described in detail in chapter 0 Calibration.

Page 51

9 Calibration

Environmental influences (such as temperature changes or transport of the system) may lead

to a gradual decrease in data quality.

To increase data quality, T-Scan Collect offers the alignment calibration feature which the user

can – and should – perform on site if:

an upcoming measurement requires highest accuracy

local accuracy has decreased. This can manifest itself, for example, in poor statistics

when calculating a sphere fit

gaps occur in the data

wavy data is measured on actually planar surfaces

9.1 Calibrate measurement range

9.1.1 Preparation

In order to perform the measurement range calibration, you need a planar surface with diffuse

reflection.

Not suited are surfaces containing scratches, bumps, dents or similar faults. In general, a table

board should suffice the requirements. However, it is recommended to use a specified plane

which is optionally available.

9.1.2 Procedure

Open the Measurement range toolbox. The measuring mode Alignment will automatically be

activated. When opening the toolbox the status – symbolized by the traffic light – will be set to

red by default, indicating that no action has been performed yet.

To perform the calibration, two measurements have to be made. Take care to account for the

following:

The distance between scanner and plane has to be as constant as possible

The laser should hit the plane perpendicularly

The markers of the used scanner face should point as directly as possible towards the

camera

The orientation of the scanner must not change during measurement

Each measurement must contain at least 5000 points

For both measurements, the same scanner face must be used

Both measurements must be made on the same area of the plane

Page 52

First measurement: keep scanner distance

constant (Close End*)

Second measurement: keep scanner distance

constant (Far End*)

*: For the definitions of these terms, see graphics in chapter 17.12.

Avoid measurements where the laser does not

hit the surface perpendicularly

Avoid measurements where the laser does not

hit the surface perpendicularly

Avoid tilting the scanner, so the markers do not

point directly towards the camera

Avoid changing the distance of the

scanner to the surface

The above sketches are drawn from the camera’s perspective.

Page 53

Now measure the plane one time using the Close End of the scanner and another time using

the Far End of the scanner (“Calibration measurement”).

In the 3D viewer, select the two data sets using the lasso. Take care not to select points which

do not lie on the plane. If other data (e. g. from previous measurements) is located at the same

area, hide or delete it in the Data Explorer toolbox prior to using the lasso.

Press Verify. If the data does not suffice the requirements an adequate message box will open.

In this case, repeat the measurement. Otherwise the status indicator will show you the status

of the measurement range calibration:

Green state: The scanner is calibrated optimally. No further steps are necessary and

you may close the toolbox.

Yellow state: The scanner calibration has been optimized using the measured data. To

make sure that the optimization improved the calibration it is necessary to measure

the plane again (in the same way as described above) one time using the Close End of

the scanner and another time

Red state: The scanner calibration has not been started yet or the Undo button was

pressed.

Page 54

If the Verification measurement confirms an improvement, the status indicator will switch

to green. In this case, save the new calibration by pressing Apply.

Otherwise the status indicator will remain yellow. You now have the possibility of either

repeating the verification measurement or undoing the calibration measurement by

pressing Undo.

If you are not able to reach the green status, you can close the toolbox. All changes will be

undone after a confirmation message box is displayed.

When closing the toolbox, the measuring mode which has been active before will be restored.

9.2 Alignment Calibration

9.2.1 Requirements for an Alignment Sphere

To do an alignment calibration, a high-precision calibration sphere is needed. It is