Page 1

Leica Rugby 410/420 DG

User Manual

Version 1.0

English

Page 2

Introduction

Purchase Congratulations on the purchase of a Rugby instrument.

This manual contains important safety directions as well as instructions

for setting up the product and operating it. Refer to "9 Safety Directions"

for further information.

Read carefully through the User Manual before you switch on the

product.

Trademarks XBeePro is a registered trademark of Digi International. All other trade-

marks are the property of their respective owner.

Product identification

Symbols The symbols used in this manual have the following meanings:

The model and the serial number of your product are indicated on the

type plate.

Enter the model and serial number in your manual and always refer to

this information when you need to contact your agency or Leica Geosystems authorized service workshop.

Type-Serial No.: 410-_______________

Date of purchase: ____________________

Type Description

Danger Indicates an imminently hazardous situation which,

Warning Indicates a potentially hazardous situation or an

Caution Indicates a potentially hazardous situation or an

)

420-_______________

if not avoided, will result in death or serious injury.

unintended use which, if not avoided, could result in

death or serious injury.

unintended use which, if not avoided, may result in

minor or moderate injury and/or appreciable material, financial and environmental damage.

Important paragraphs which must be adhered to in

practice as they enable the product to be used in a

technically correct and efficient manner.

Rugby 410/420 DG2

Page 3

Table of Contents

1Introduction 4

2 Features and Functions 5

3Operation 6

4Setup 13

5 Checking Level Accuracy 18

6 Accessories 20

7 Troubleshooting 25

8 Care and Transport 28

9Safety Directions 30

10 Technical Data 41

3.1 Entering Grade 6

3.2 Identification of the Axes 8

3.3 Slope - Percent of Grade 8

3.4 Alignment of the Axes 8

3.5 Precise Alignment of the Axes 9

3.6 Axis Alignment Application 10

4.1 General Setup 13

4.2 Setup Options 13

4.3 Additional Setup Options 17

5.1 Checking Level Accuracy 18

5.2 Adjusting Level Accuracy 19

6.1 Batteries 20

6.2 The Sighting Scope 21

6.3 Remote Control 22

7.1 Display Screen Explanations 25

7.2 Troubleshooting Suggestions 27

8.1 Transport 28

8.2 Storage 28

8.3 Cleaning and Drying 29

9.1 General 30

9.2 Intended Use 30

9.3 Limits of Use 31

9.4 Warranty 31

9.5 Responsibilities 31

9.6 Hazards of Use 32

9.7 Laser Classification 35

9.8 Electromagnetic Compatibility (EMC) 37

9.9 FCC Statement, Applicable in U.S. 38

Rugby 410/420 DG 3

Page 4

1 Introduction

The Rugby Grade laser is designed to serve your needs in a wide variety

of applications.

It is a proven tool for increased production with substantial reduction of

labor, time and material costs. It can be used to accurately control land

leveling, sloped or level grading, trenching, open cut mining, dredging,

contouring of levees, general construction and excavation.

This manual contains operating and set-up procedures for common

applications. Its purpose is to describe the features of the Rugby and

how the Rugby operates. The manual is not intended to describe specific

applications. Contact your local dealer or Leica Geosystems for information specific to your jobsite requirements.

The Rugby Grade lasers are rugged, accurate and fully electronic with an

operating range (diameter) of up to:

• Rugby 410DG: 2600 feet (800 meters)

• Rugby 420DG: 3600 feet (1100 meters)

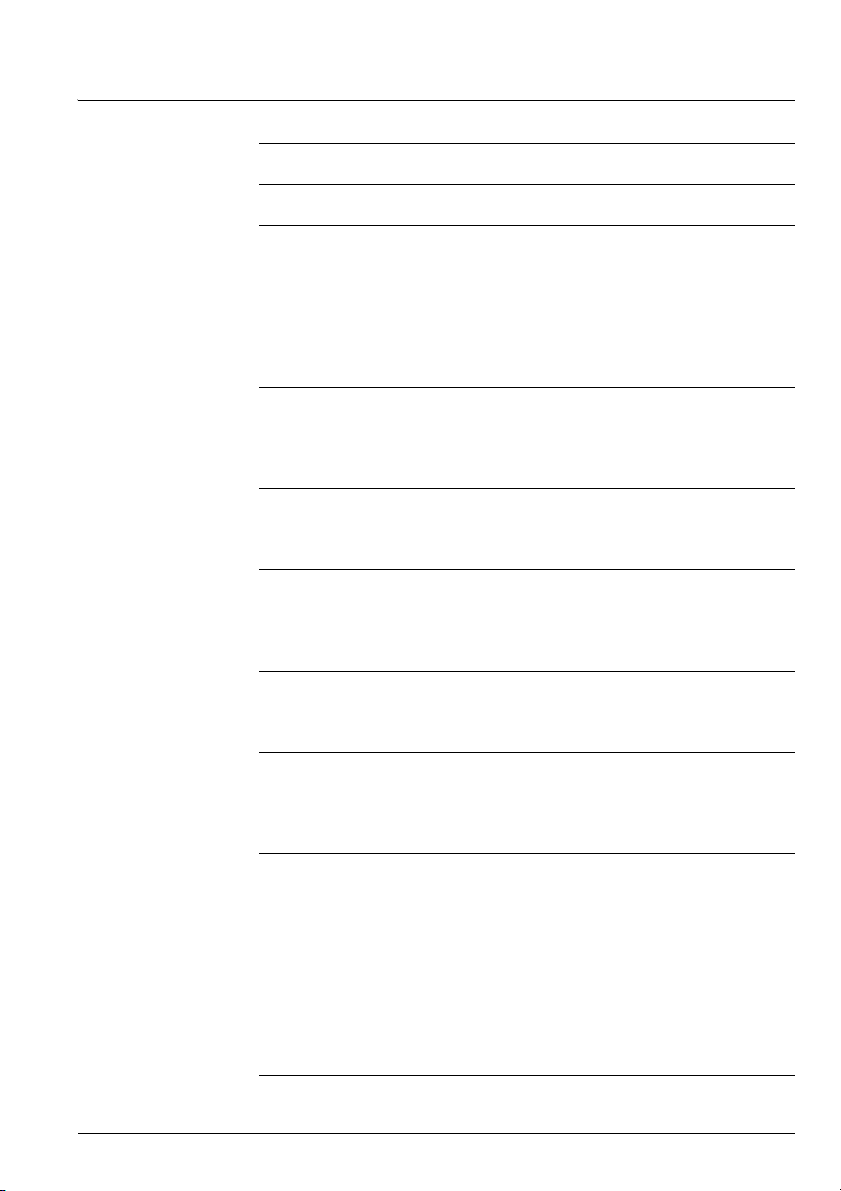

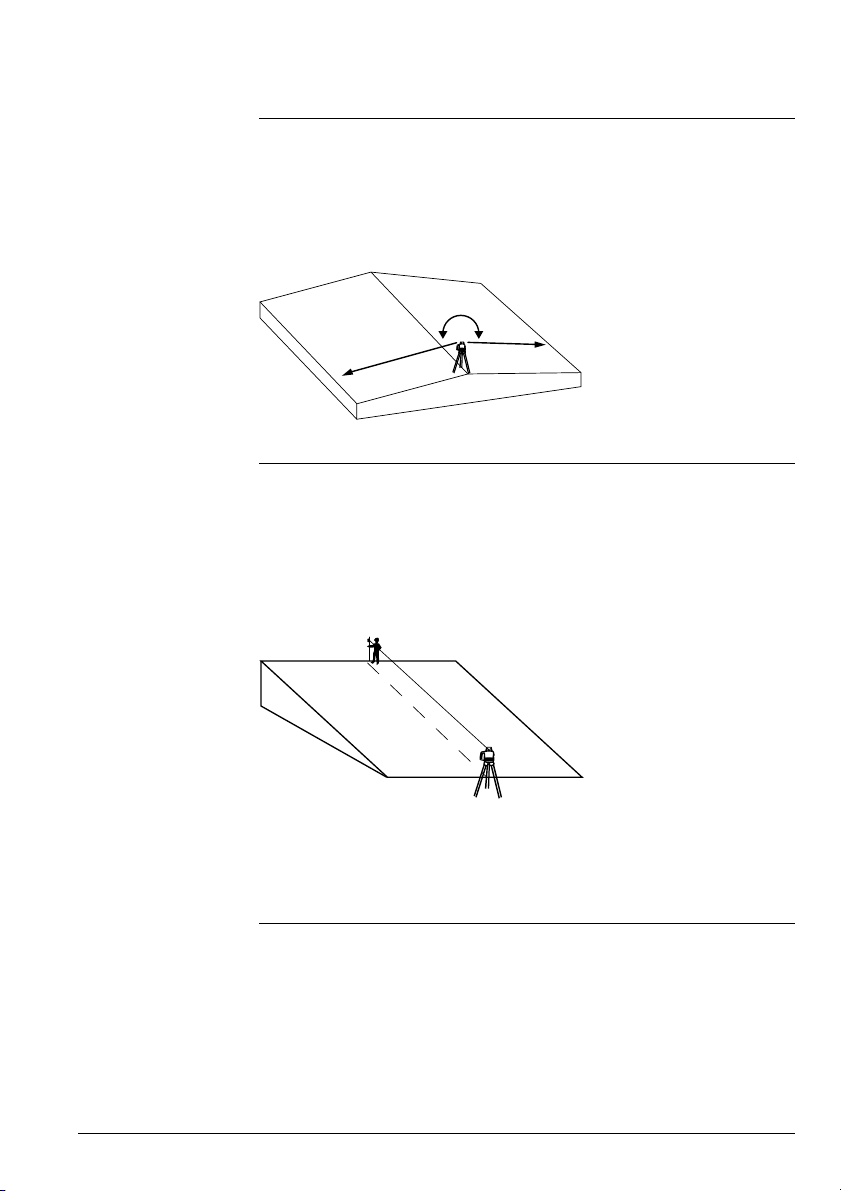

The Rugby 410/420 DG is a dual grade laser and is capable of producing

an accurate plane of laser light for applications that are level (1), single

grade (2) or dual grade (3).

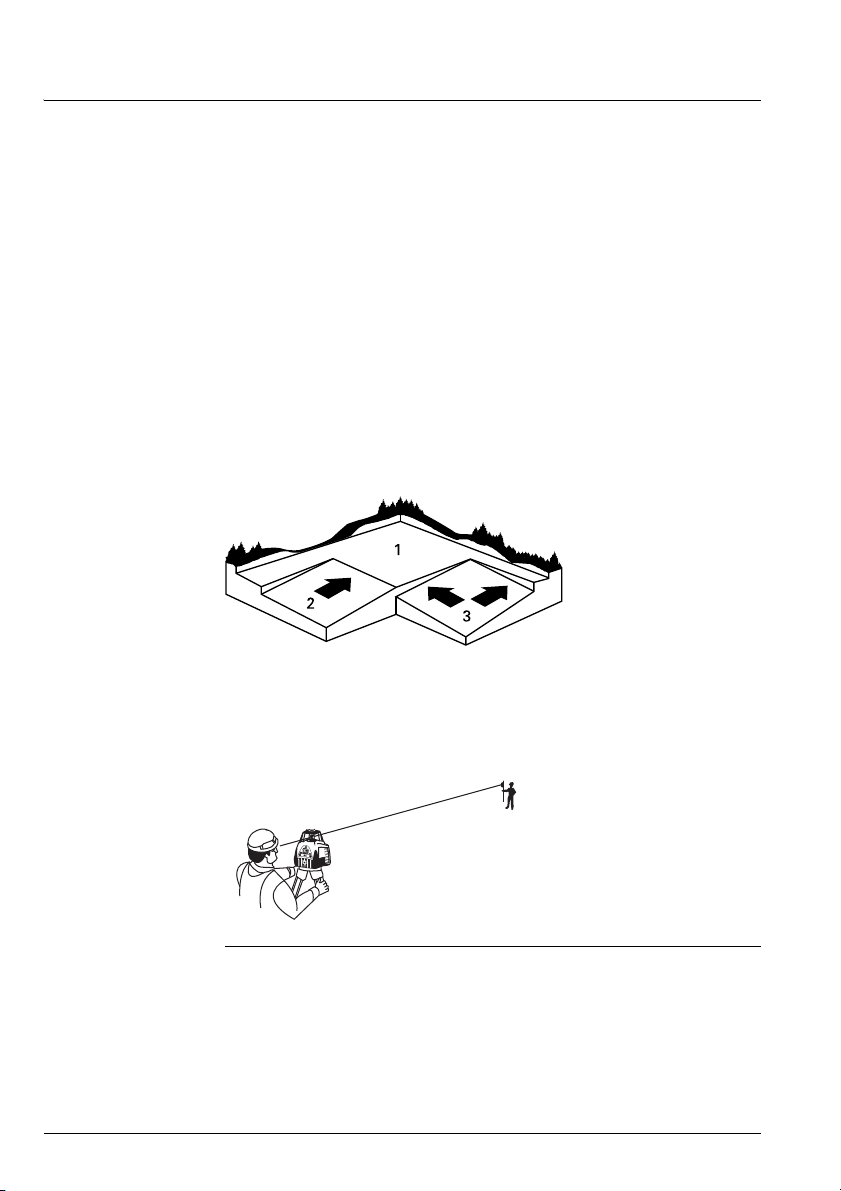

Alignment is as easy as sighting over the top of the Rugby to your control

point using the integrated alignment sights or the optional sighting

scope assembly. For increased accuracy, follow the procedure for "3.5

Precise Alignment of the Axes". For highest accuracy refer to the

Axis Alignment application.

Rugby 410/420 DG Introduction4

Page 5

2 Features and Functions

a)

i)

j)

a)

l)

g)

e)

f)

k)

h)

d)

c)

b)

a) POWER Button – Powers the Rugby on and off.

b) LCD Display – Shows the grade setting for the X axis. The display

shows also Beam Masking, Battery status, H.I. and Head Speed.

c) X/Y Button – Press to set grade in the X- and Y-axis.

d) UP Arrow Button – After pressing X/Y, press to increase the grade

shown.

e) STAR Button – Press to enter setup screens and the grade entry by

digit screen.

f) DOWN Arrow Button – After pressing X/Y, press to decrease the

grade shown.

g) Circular Level Vial – For initial setup reference.

h) 12-volt input – Charge the batteries or run the Rugby directly from

12-volts.

i) Dual Batteries – The Rugby will run with one or two sets of

batteries for maximum flexibility and battery life.

j) Raised alignment sights and mounting plate for the optional

sighting scope.

k) Easy grip handle for carrying and setup.

l) Tripod mount for attachment to a 5/8”-11 tripod.

Rugby 410/420 DG 5Features and Functions

Page 6

3 Operation

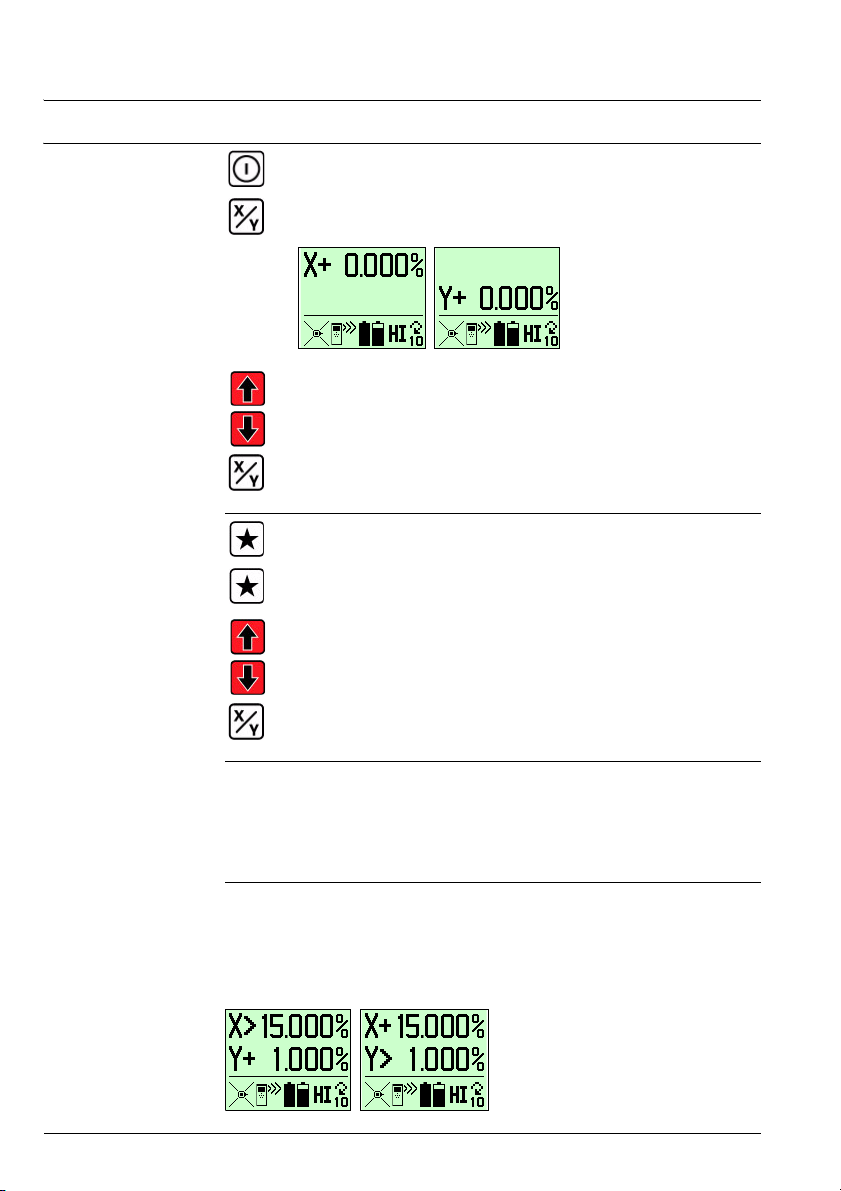

3.1 Entering Grade

Direct Grade Entry

Press POWER to turn the Rugby on.

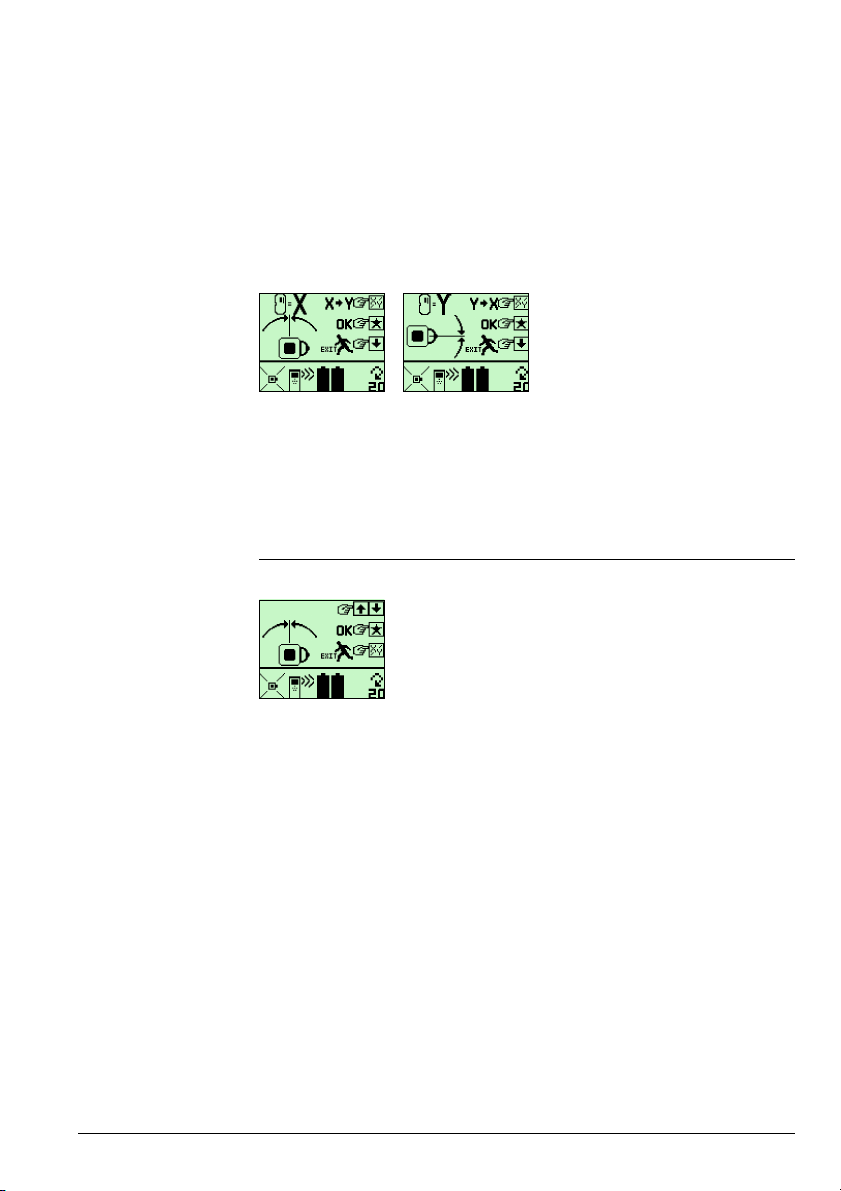

Press X/Y once to enter X-axis grade. Press X/Y again to enter

Y-axis grade.The display will show the grade entry screens.

Use the UP or DOWN buttons to set the desired grade.

Press X/Y to exit.

Grade Entry by

Digit

Grade Zero The grade in either axis can quickly be set to zero by pressing both the

Up and Down buttons simultaneously while in either grade entry mode.

When changing grade using the direct entry method, the counter will

always stop at zero. Release the button and press again to continue

counting beyond zero.

Grade Capability The Rugby 410/420 DG can have up to 15% grade simultaneously in both

axes, or up to 25% in one axis.

Grades above 15% in one axis require that the cross axis grade be ±1%

or lower. In this situation, if attempting to enter grades greater than 1%

or 15%, a notice will appear on the screen when the button is pressed.

While in the grade entry screens, press the STAR button and a

cursor will appear on the +/- sign.

Press the STAR button to move the cursor to the right.

Press the UP or DOWN buttons to change the sign or the digit

that is highlighted.

Press X/Y to exit.

Rugby 410/420 DG Operation6

Page 7

)

Grade Swap The grade in the X and Y axes can easily be swapped from positive to

Grade Matching In Direct Grade Entry mode the movement of the leveling mechanism

If no button is pressed, the display will revert to the main display after

ten seconds.

negative in the Grade Entry by Digit screen.

A typical application for this feature is road building. For example, with

the Rugby setup on the crown of the road and with one axis aligned to

the center line, the cross axis grade can be made to fall to the right or

lefthand side simply by changing the +/- sign on the display.

moves at the same speed as the grade counters.

To match an existing slope, set up the laser over the known gradebreak

(base) of the slope, and align the laser to the end of the slope with both

control points parallel to the direction of grade.

Adjust the Rod-Eye receiver on your grade rod for the elevation of the

laser at the gradebreak next to the laser.

Move the grade rod to a point on the slope that is too be matched. Then,

dial grade into the laser until the Rod-Eye indicates an on-grade reading.

The percent of grade in the display is now equal to the grade being

matched.

Rugby 410/420 DG 7Operation

Page 8

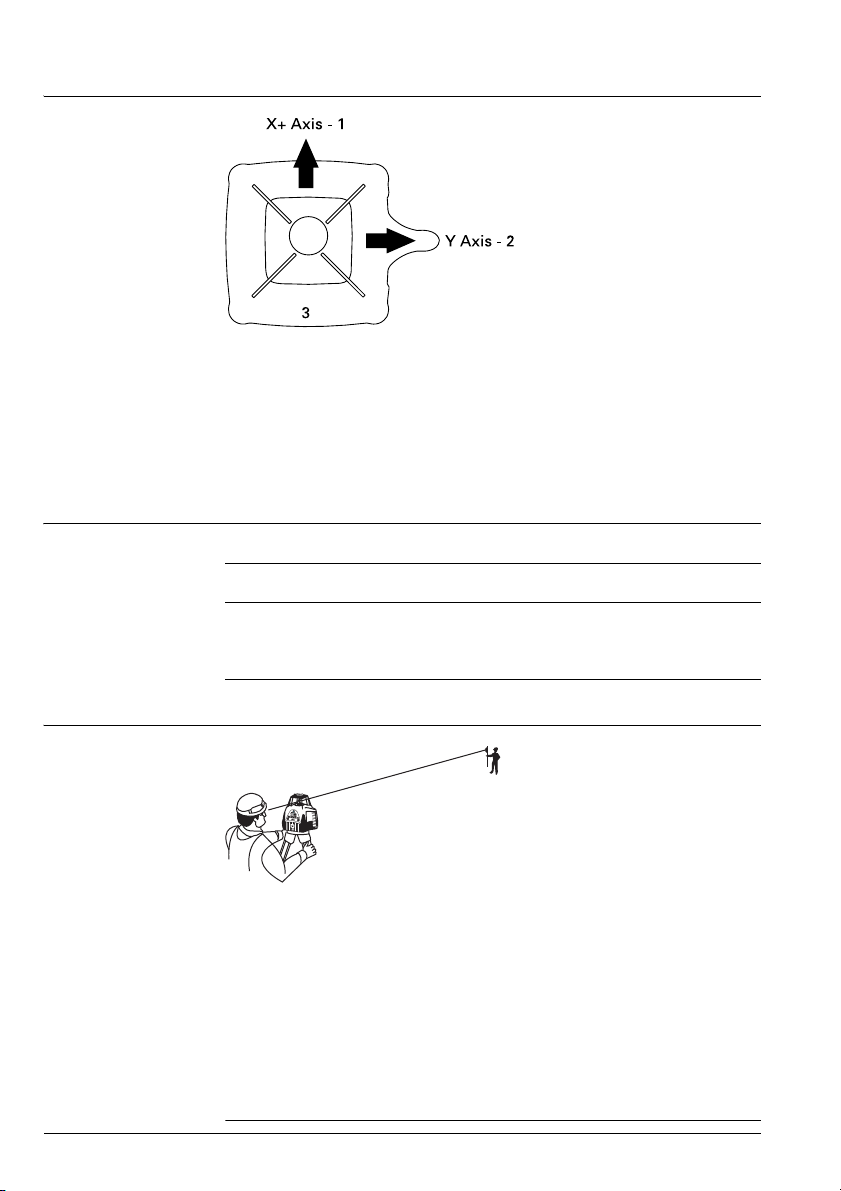

3.2 Identification of the Axes

1. X+ Axis – When positive grade is entered in the X-axis, grade will

increase in this direction.

2. Y+ Axis – When positive grade is entered in the Y-axis, grade will

increase in this direction.

3. Front of Rugby – See also axis labeling on the side of the laser and

inside the top windows.

3.3 Slope - Percent of Grade

Slope The change in elevation per unit of measure (foot, meter, etc.)

Percent of Grade The change in elevation per 100 units of measure (feet, meters, etc.)

Calculating Percent

of Grade from the

Slope

Slope = 0.0059

Conversion = 0.0059 x 100

Percent of Grade = 0.590%

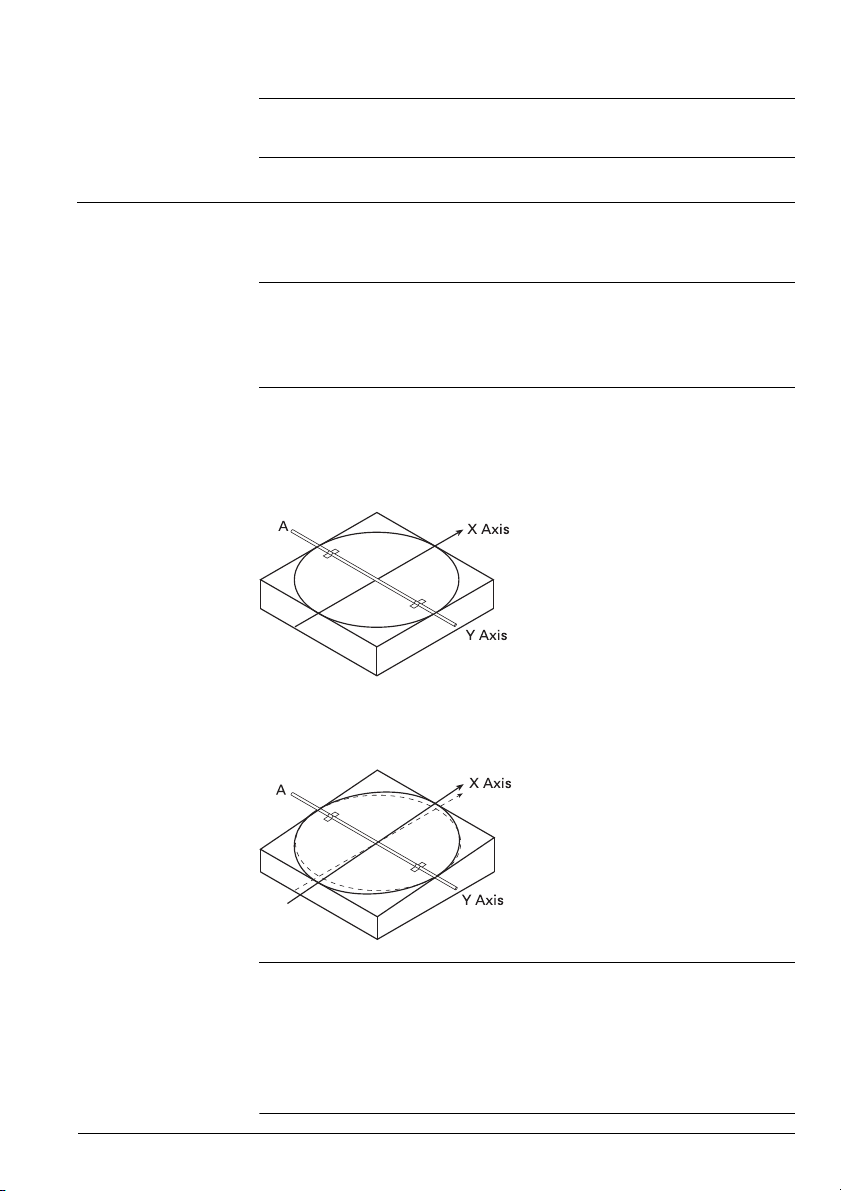

3.4 Alignment of the Axes

When the desired grade is correctly set in the display, it is necessary to

align the X and Y axes to the jobsite.

Ensure the circular level vial is positioned near the center of the circle for

maximum self-leveling capability.

Ensure the Rugby is properly positioned over a control point.

As shown, the direction of the X-axis is seen from the front of the Rugby,

sighting over the top of the Rugby.

Rotate the Rugby slightly until the sights are aligned with your second

control point.

Once aligned, work can begin.

Rugby 410/420 DG Operation8

Page 9

)

)

An optional sighting scope is also available.

For very accurate alignment, refer to the steps for Precise Alignment of

the Axes.

3.5 Precise Alignment of the Axes

Under most conditions, the raised alignment marks on the top of the

Rugby are adequate for alignment of the axes. However, for more

precise alignment, use the following procedure.

Objective • To establish Point A on the Y-axis as a reference and take an eleva-

tion reading.

• To dial grade into the X-axis and then adjust the position of the laser

until the original elevation at Point A is again found.

Procedure 1. With 0.000% grade in both axes, set up the Rugby directly over a

grade stake and rough align the Y-axis to a second grade stake that

we will call Point A.

2. Take an elevation reading at Point A using a Rod-Eye Receiver and a

survey rod.

3. Enter +5.000% grade into the X-axis. When grade is entered in the

X-axis, the Y-axis acts like a hinge or fulcrum.

4. With 5.000% in the X-axis, take a second reading at Point A.

Alignment • If the second reading is equal to the first reading, the X-axis is

aligned correctly.

• If the second reading is greater than the first reading, rotate the

Rugby clockwise (to the right) until the two readings are the same.

• If the second reading is less than the first reading, rotate the Rugby

counter-clockwise (to the left) until the two readings are the same.

Rugby 410/420 DG 9Operation

Page 10

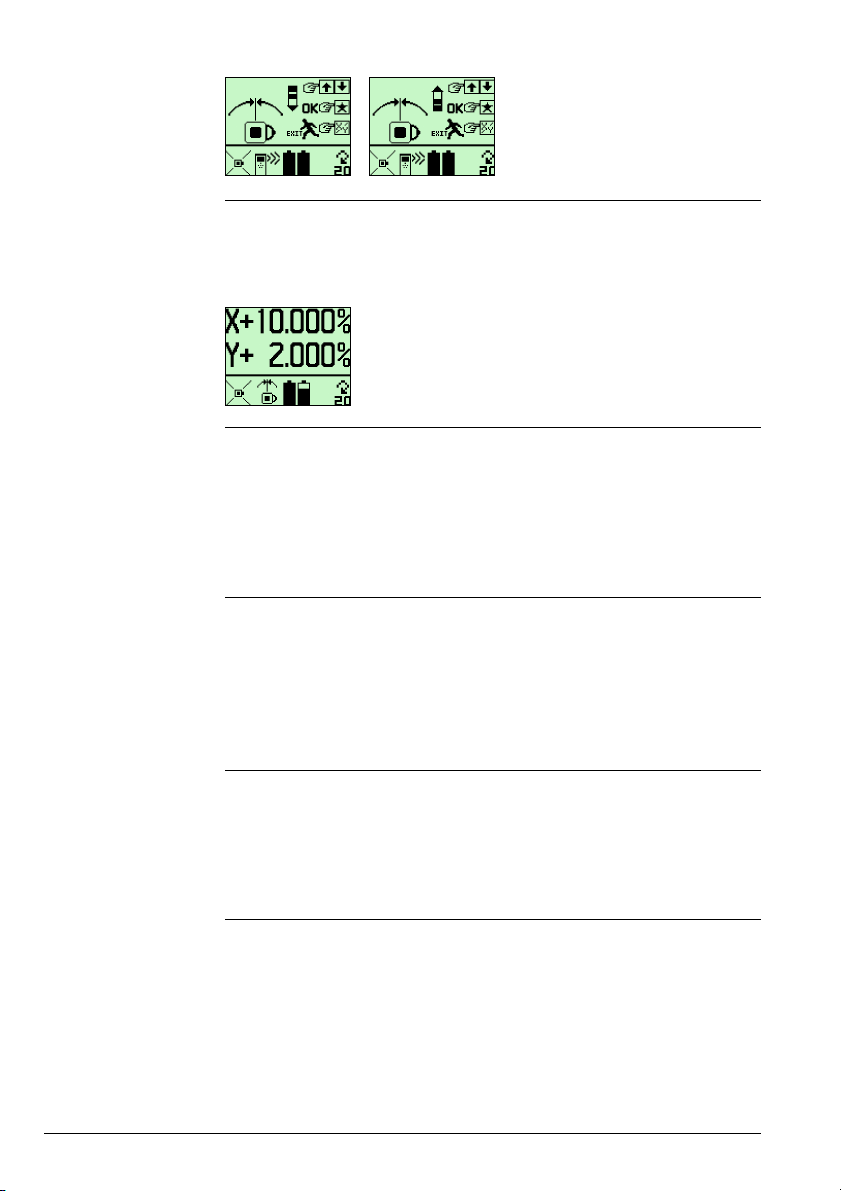

3.6 Axis Alignment Application

The Axis Alignment Application is designed to precisely align the axis

when grade accuracy is extremely important. For most applications, the

traditional sighting method (using the sights on the laser, or using the

optional sighting scope) is sufficient, but when precise grades are critical, it is important to have the axes accurately aligned. This Axis Alignment Application is only available on the Rugby 410/420 DG.

How to use the Axis Alignment Application:

Preparation Power up the laser and enter the desired grade.

(For Example: X=+10.000% and Y=+2.000%).

To establish a proper laser position, make use of the sights on the top

of the laser (or the optional scope) and adjust the laser on the tripod so

that the axis you intend to precisely align is aimed at your second control

point. We recommend using the X-axis when possible.

Using the optional remote control, the Axis Alignment procedure can be

a one person operation. With-out the remote control, two people are

needed to complete the set-up.

Be sure the remote control is 'enabled' if you intend to use it for this setup. Refer to page 17 of this manual.

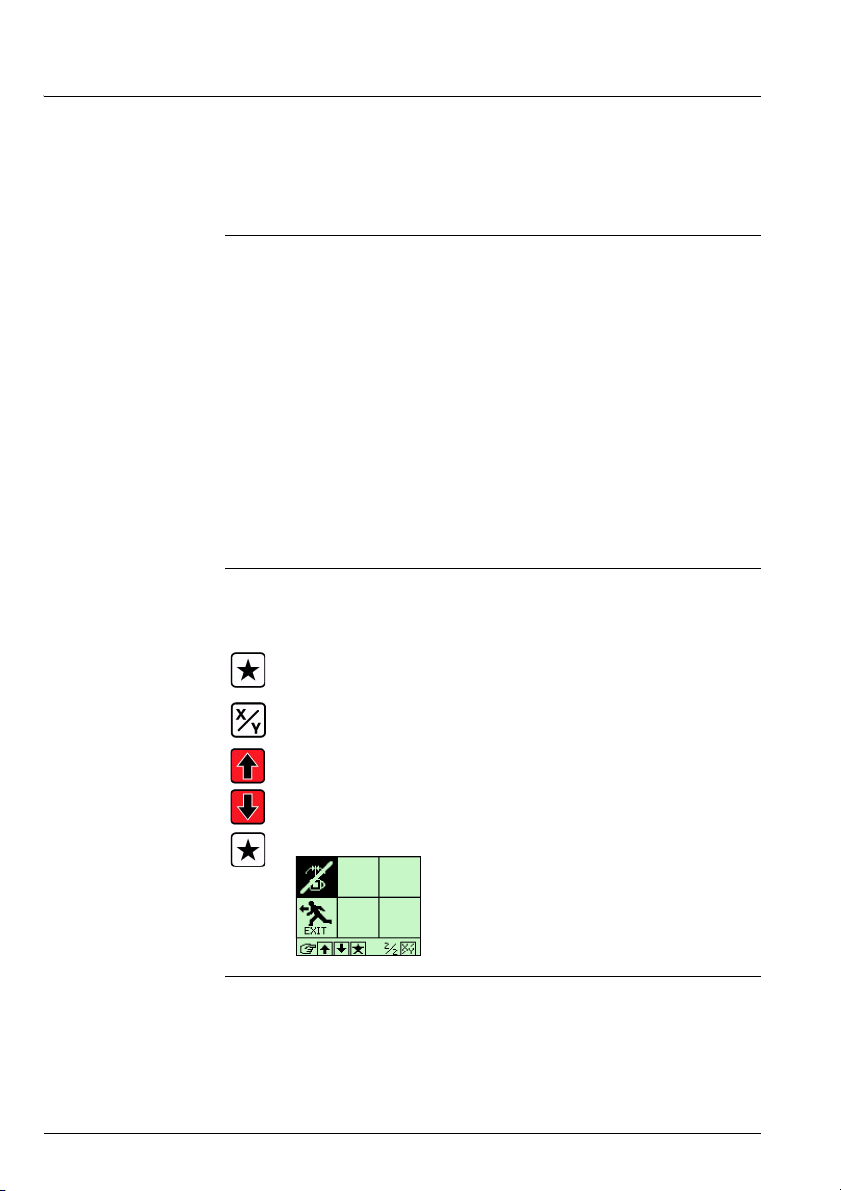

Step 1 Access the Axis Alignment Application (directly from the laser or via the

remote control).

From the main operation screen:

Press the STAR button once.

Press the X/Y button once.

Use the UP / DOWN buttons to toggle to the Axis Alignment

Application.

Press the STAR button once to start the application.

Rugby 410/420 DG Operation10

Page 11

Step 2 • The X-Axis is automatically pre-selected as the axis to be precisely

Step 3 Carefully watch the arrows (laser beam) on the receiver.

aligned. Press the X/Y button to change to the Y-axis if desired.

During this process the cross-axis is automatically reset to 0.000%

grade.

• The cross axis is at 0.000% grade when 'OK' is shown on the display.

• On the second control point adjust the Rod-Eye receiver on the grade

rod and make sure it is located in the on-grade position on the axis

selected (solid bar or solid tone). This part of step 2 is very

important.

• When you're done press STAR to continue.

Once STAR is pressed, the cross axis grade will change from 0.000% to

+5.000%.

As a result the laser beam signal on the receiver will most likely change

the elevation indication from the 'on-grade' position to either a 'high or

low' position. This is because the Rugby is not mechanically aligned and

the laser will no longer be giving an on grade signal. This is where the

electronic Axis Alignment is used.

•Use the UP / DOWN buttons to move the laser beam once again on

the center.

• Select between Speed 1, 2 or 3 which is available in both directions.

• One push will start moving the beam in slow speed.

• A second push will move the beam at medium speed.

• A third push will move the beam at highest speed.

• During this process an arrow symbol is shown.

If the arrow symbol stops flashing the maximum limit is reached

and the laser beam does not move anymore. (If the laser beam did

not pass the 'on-grade' position on the receiver please consider

re-orientating the laser instrument).

• To stop the laser beam movement press STAR.

• If the Rod-Eye receiver shows an UP arrow displayed, use the

DOWN arrow on the remote control to return to 'on-grade'.

• If the Rod-Eye receiver shows a DOWN arrow, then use the UP

arrow on the remote control to return to 'on-grade'.

Rugby 410/420 DG 11Operation

Page 12

Step 4 • Hold the receiver steady and watch the laser beam. When the on-

grade signal is achieved, the laser is precisely aligned.

•Press the STAR button to apply the axis correction, to quit the application and return to the main menu.

Notes • The X and Y-axis return now to the previously entered grade values.

Important • In order to reset the axis alignment correction, select the axis align-

Limits and Exceptions

The alignment is electronically compensated; therefore the mechanical alignment of the laser may not be in alignment with the axes.

• In order to indicate that axis alignment is active, the axis alignment

icon appears on the display instead of the remote icon.

• As a control watch the laser beam on your receiver, insure that it is

still centered.

ment dialog and press STAR.

• The axis alignment icon is not shown if the axis alignment correction

is off.

• By turning off the instrument the axis alignment correction is turned

off as well.

• HI alert is disabled during the axis alignment procedure.

• The X- or Y-axis must have less than -3.500% or 13.500% grade.

• The maximum angle of miss-orientation allowed is 5 degrees.

(This represents an offside of 8.7m at 100m).

• The maximum working distance for axis alignment is limited to the

operation of the remote control when used, or the sensor's ability to

receive the laser signal when the remote is not used.

Rugby 410/420 DG Operation12

Page 13

4 Setup

4.1 General Setup

Location Make sure the location is clear of possible obstructions that may block

or reflect the laser beam.

Make the most efficient use of the Rugby’s operating radius. The Rugby

can be placed in the center of the working area or to one side.

Make sure the ground is stable. Ground vibration and extremely windy

conditions can affect the operation of the Rugby.

If working in very dusty conditions, place the Rugby up-wind. The dirt and

will then be blown away from the Rugby and reduce interference.

Recommended

Head Speeds

Tripod Setup Attach the Rugby securely to a tripod or laser trailer, or mount on a

For surveying and manual machine control applications the typical head

speed is 10 rps (600 rpm).

For automatic machine control applications it is recommended to use the

highest head speed, 20 rps, to increase the frequency of updates.

When working at extended distances, decreasing the head speed

(increasing the pulse time on the receiver) or changing the band width

of the receiver to wide band can improve distance and performance.

stable level surface.

Always check the tripod or trailer before beginning work.

Make sure all screws, bolts, and nuts are tight.

If your tripod has chains, they should be slightly loose to allow for

thermal expansion during the day.

On extremely windy days, secure the tripod. Placing a sandbag on each

leg can do this. (See also adjustment for setting the wind sensitivity of

the Rugby.)

If using a tripod with a quick disconnect adapter, point the control lever

into the wind. This places the locking mechanism also into the wind, and

will provide better stability.

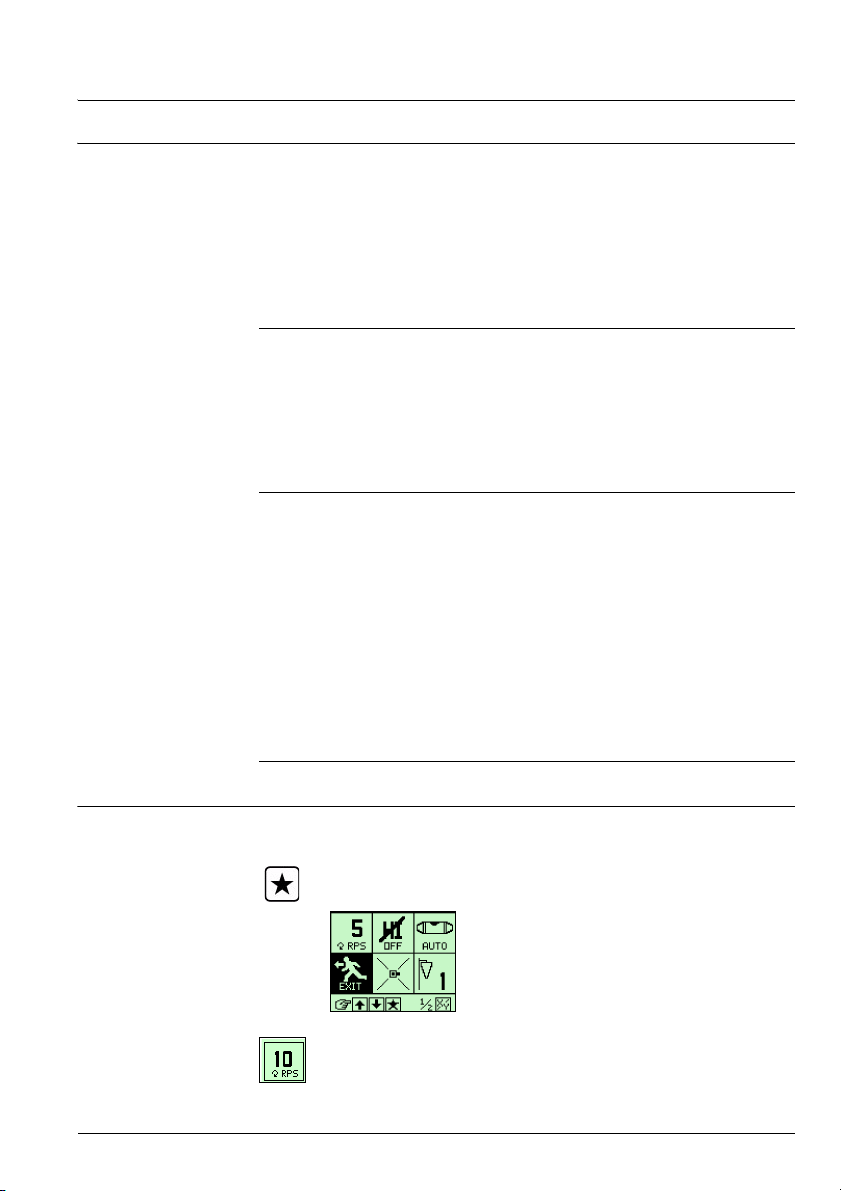

4.2 Setup Options

The Rugby has several setup options that are easily accessed and

changed in the first setup screen.

From the main operating screen, Press STAR to access the

setup screen.

Head Speed Selections –

5, 10, 15, 20 rps.

Rugby 410/420 DG 13Setup

Page 14

HI Function – Turns the H.I. function on and off.

Automatic, Manual or Manual with Grade.

Wind Sensitivity (1-5) – (1) for calm days, (3) for normal days,

(5) for extremely windy days.

Beam Masking – Turns the beam off in the selected quadrants.

Changing the Setup

Options

When entering the setup screen, the EXIT window will be highlighted.

To change the setup options in this window the buttons are used in the

following way:

Use the STAR button to select or deselect the setup parameters and exit the setup screen.

Use the UP and DOWN buttons to move the cursor or change

the selected parameter.

Press the Star button and the cursor will become a thick border around

the selected parameter. Once selected, use the Up and Down buttons to

change the parameter.

Use the X/Y button to switch between the first and second

page of the setup screen.

Beam masking requires using also the X/Y button.

With the beam masking option selected, press the X/Y button

to turn the beam on or off in the selected quadrant.

Use the Up and Down buttons to move around the quadrants.

The quadrant will become solid and dark when selected for the

beam to be masked (off) in the quadrant.

Select the EXIT window, then press the Star button to exit and

return to the main display.

)

Head Speeds The Rugby can be set to any of four different head speeds – 5, 10 , 15,

If no button is pressed, the display will revert to the main display after

ten seconds.

or 20 rps. (300, 600, 900, 1200 rpm)

Select the head speed that provides the best performance for your appli-

cation. The selected head speed is shown on the bottom, right corner of

the main display screen.

Rugby 410/420 DG Setup14

Page 15

H.I. (Height of

Instrument)

The H.I. function is used to prevent elevation changes caused by movement of the tripod.

When the H.I. Alert function is activated, the self-leveling accuracy

remains the same, but the self-leveling range of the Rugby is reduced.

Movement of the Rugby beyond its self-leveling range will cause an “alert

condition”. The Rugby will stop rotating and the following screen will

appear on the display:

Stop t he “ale rt co nditio n” by p ressin g the Star o r Powe r but ton and rese t

the function.

Check carefully the setup and elevation of the unit to determine what

has caused the alert condition. Adjust as required to the correct elevation.

The H.I. function can be turned on or off in the first setup screen.

When the H.I. function is turned on, the letters “HI” will appear in the

bottom, right part of the display.

The H.I. function becomes active 30 seconds after the unit has

completely leveled and the head starts rotating.

The H.I. function can be made to turn on automatically at

power-up. This can be enabled in the second setup screen.

Automatic and

Manual Mode

)

The Rugby will always turn on in automatic mode and will continuously

self-level to maintain grade accuracy.

In manual mode the self-leveling function is turned off.

The display screen will show the following:

The X-axis slope can be changed using the X/Y and arrow buttons, but

the amount of change is not shown in the display.

Rugby 410/420 DG 15Setup

Page 16

Manual Mode with

Grade

In Manual Mode with Grade, the display will alternately show the grade

entered for the X- and Y-axis and the crossed out level vial as shown

here:

In this mode, grade can be entered into either axis. The Rugby will selflevel to the grade input in the unit, then will lock into manual mode at

this grade.

)

Wind Sensitivity The Wind Sensitivity setting allows the Rugby to operate in adverse envi-

Beam Masking Electronic Beam Masking allows the operator to turn off the laser beam

Once locked in manual mode the self-leveling function is turned off.

If it is desired to change the manual grade shown, a new grade can be

entered (same as in automatic mode) and the Rugby will level to this new

grade, then lock in manual mode.

ronmental and windy conditions, while still ensuring maximum accuracy.

The sensitivity numbers can be set from 1 to 5. Select “1”

for calm conditions. Select “5” for very windy conditions.

Use the lowest setting for conditions present.

in specific quadrants to prevent interference with other operations on

the job.

Using the setup menu, the beam can be turned off in up to three

selected quadrants.

When a quadrant is turned off, the space will appear dark.

The quadrants selected can be either diagonals of

corners of the Rugby. This selection is made in the

second setup screen.

The settings for beam masking are normally not saved

when the Rugby is turned off. The Rugby can be made to

save the mask settings in the second setup screen.

Rugby 410/420 DG Setup16

Page 17

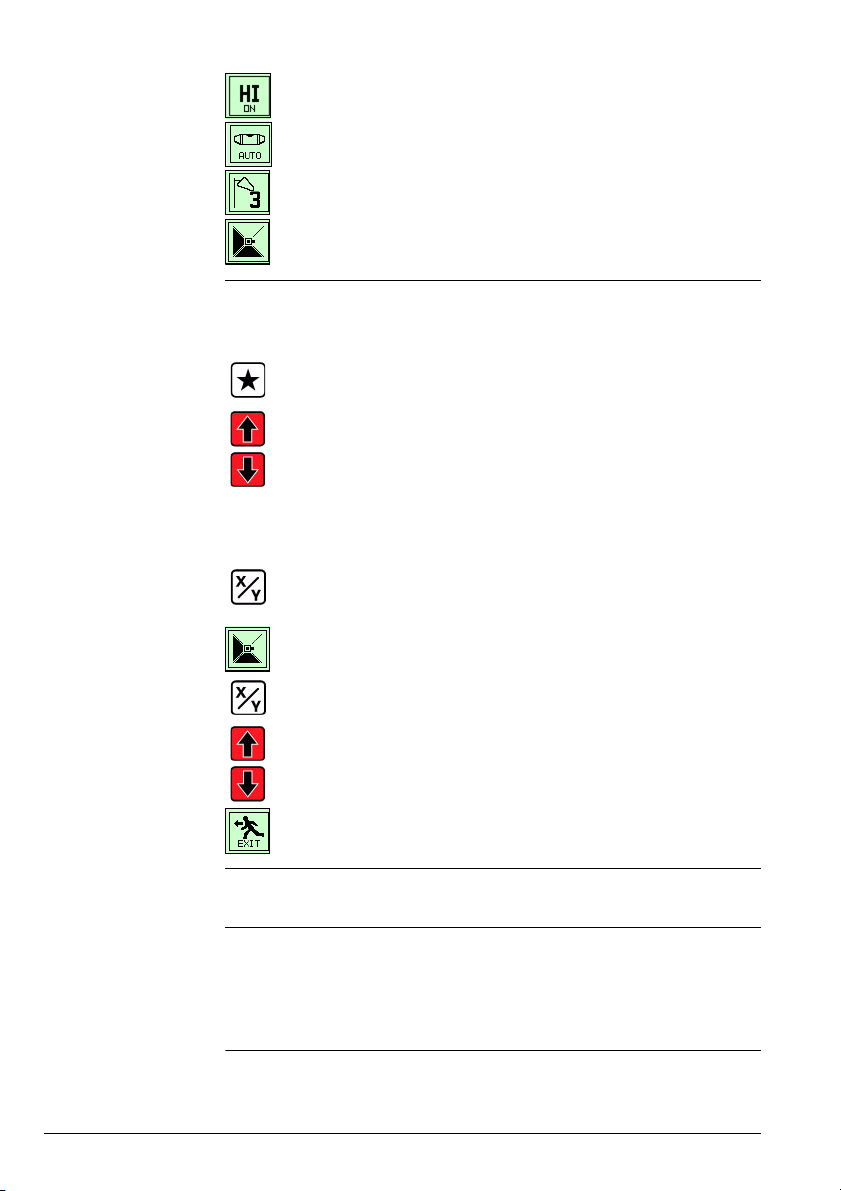

4.3 Additional Setup Options

Additional setup options may be accessed in a second setup screen.

+

From the main operating screen, Press and hold the UP

button, then press the STAR button to access the

second level setup screen.

Selects beam masking at the diagonals or at the corners.

Allows the Rugby to always start up with no beam

masking, or to save and start up with the last beam mask

setting used.

Allows the Rugby to start up with the H.I. Alert automatically turned on, or turned off.

Allows the operator to disable the negative grade function of the Rugby. When disabled, negative grade cannot

be entered in the grade displays.

The remote control is enabled only when a remote is to

be used with the Rugby. It is normally off to conserve

battery power.

Changing the Setup

Options

)

When entering the setup screen, the EXIT window be highlighted.

To change the setup options in this window the buttons are used in the

following way:

The STAR button is used to se lect or deselect the setup parameters.

The UP and DOWN buttons are used to move the cursor and

change the parameters.

Press the STAR button and the cursor will become a thick border around

the selected parameter. Once selected, use the UP and DOWN buttons

to change the parameter.

Select the EXIT window, then press the STAR button to exit and

return to the main display.

If no button is pressed, the display will revert to the main display after

ten seconds.

Rugby 410/420 DG 17Setup

Page 18

5 Checking Level Accuracy

1

2

)

)

)

It is the respon sibili t y of th e user t o follo w opera ting in struct ions, a nd to

periodically check the accuracy of the instrument and work as it

progresses.

The Rugby is adjusted to the defined accuracy specification at the

factory. It is recommended to check your laser for accuracy upon receipt

and periodically thereafter to ensure accuracy is maintained. If your laser

requires adjustment, contact your nearest authorized service center or

adjust the laser using the following procedure.

Do not enter this mode or attempt adjustment unless you plan to change

the accuracy. Accuracy adjustment should be performed only by a qualified individual that understands basic adjustment principles.

5.1 Checking Level Accuracy

To check level accuracy of your Rugby, place the unit on a flat, level

surface or tripod approximately 100 feet (30 meters) from a wall.

Checking the X-Axis Align the X-axis so that it is square to the wall. Allow the unit to self-level

completely (approximately one minute after the unit begins to rotate),

and then, using your Rod-Eye receiver, mark the position of the beam

(Position 1).

Rotate the Rugby 180°, allow it to self-level and then mark the opposite

side of the X-axis (Position 2).

Mark the position half-way between the two marks. The X-axis is within

its accuracy specification if the two marks are within ± 1/16” (± 1.5 mm)

from center.

Rugby 410/420 DG Checking Level Accuracy18

Page 19

Checking the Y-Axis Align the Y-axis by rotating the Rugby 90° so that the Y-axis is now

square to the wall. Allow the unit to self-level completely, then check the

Y-axis in the same way as above.

5.2 Adjusting Level Accuracy

To Enter Adjustment Mode

X-Axis Accuracy

Adjustment

Y-Axis Accuracy

Adjustment

With the unit turned off, press and hold both the Up and Down buttons,

then press the Power button to put the unit in adjustment mode.

If entered correctly, the X-axis adjustment screen will appear.

When entering the adjustment screen, a small hour glass will appear.

Wait until the hour glass disappears before checking and changing the

adjustment numbers.

Use the Up and Down arrows to change the number and move the beam

to the half-way point between the positions marked for the X-Axis. Five

counts in the display are equal to approximately 1/16” at 100 feet

(1.5 mm at 30 meters).

Press the Star button to accept this position and accept the number in

the display for the X-Axis.

Press the Star button again to move to the Y-Axis adjustment screen.

If entered correctly, the Y-axis adjustment screen will appear.

Wait until the hour glass disappears before checking and changing the

adjustment numbers.

Use the Up and Down arrows to change the number and move the beam

to the half-way point between the positions marked for the Y-Axis.

Press the Star button to accept this position and accept the number in

the display for the Y-Axis.

Press the Star button again to accept, save, store the adjustment

activity, and to return to the main display screen.

)

)

)

After adjustment, always check your work.

Always check accuracy prior to critical applications. Repeated activation

of the grade mechanism may result in accuracy variations up to ± 20 arc

seconds.

Pressing the power button at any time before completing the procedure

will revert the accuracy to previously saved information.

Rugby 410/420 DG 19Checking Level Accuracy

Page 20

6 Accessories

6.1 Batteries

The unique battery solution in the Rugby has two independent battery

compartments that will accept various combinations of NiMH packs or

individual D-cell batteries (2).

The battery status is displayed on power-up and as small icons on the

main operating screen.

Install the NiMH batteries (1) as shown on the label of the pack.

Install individual D-cell batteries (2) as shown on the battery door cover.

The charge jack (3) is located on the laser above the locking knob of the

battery door (4).

Charge time is approximately 4-5 hours.

The Rugby can also be run directly from a 12-volt source through the

charge jack.

Charging / First

Time Use

Operation/

Discharging

• The batteries must be charged prior to using it for the first time

because it is delivered with an energy content as low as possible.

• The permissible temperature range for charging is between +32°F to

+104°F (0°C to +40°C). For optimal charging we recommend charging

the batteries at a low ambient temperature of +32°F to +68°F (0°C

to +20°C) if possible.

• It is normal for the battery to become warm during charging. Using

the chargers recommended by Leica Geosystems, it is not possible to

charge the battery if the temperature is too high.

• For new batteries or batteries that have been stored for a long time

(> three months), it is effectual to make 3 - 5 charge/discharge cycle.

• The batteries can be operated from -4°F to +122°F (-20°C to +50°C).

• Low operating temperatures reduce the capacity that can be drawn;

very high operating temperatures reduce the service life of the battery.

Rugby 410/420 DG Accessories20

Page 21

6.2 The Sighting Scope

A

A sighting scope (739870) is available as an optional accessory for

alignment of the axes and second day setups.

The scope is magnetically mounted to the top of the housing and once

aligned has a repeatable accuracy of approximately ± 0.2°.

Alignment of the

crosshairs

If using the scope for reference or second day setup, use the raised

sights on the top of the laser to align your Rugby to a second control

point.

The scope is roughly aligned at the factory. If a more precise alignment

is desired, first align the Rugby to a second control point using the procedure for Precise Alignment of the Axes found in this manual.

A = Vertical crosshair alignment

Rugby 410/420 DG 21Accessories

Page 22

6.3 Remote Control

The Rugby LR Remote Control (765668) is a full functioning, twoway remote control.

The LCD display and the grade and star buttons on the remote are the

same as on the Rugby.

The Power button turns on only the remote. When pressed it

will communicate with the Rugby to receive current information.

Once communication is established, the remote can be used to

change grade and setup parameters on the laser.

If the remote is not within range or otherwise loses communication, the

lost communication screen will be displayed.

It is important, to achieve specified distances, that the remote be used

within the “line of sight” of the Rugby.

Press and hold the power button for 1.5 seconds to turn the remote off.

The Standby button will cause the Rugby to go into standby

mode for up to 16 hours. After this time the Rugby will shut off

and can only be turned on again at the laser.

When in standby mode the display will show only a sleeping Rugby.

Pressing any button (except power) while the unit is in standby mode will

cause the laser to return to normal operation.

Automatic Shut Off - To conserve battery power, the remote will automatically shut off after two minutes of non-use.

Rugby 410/420 DG Accessories22

Page 23

Low Battery – The remote will display a low battery screen when the

batteries have reached a voltage where the remote can no longer

communicate with the laser.

To replace the batteries, remove the bottom cover of the housing. Install

as indicated on the side of the housing.

Before you can use the remote it is necessary to enable the remote

capability on the laser.

To do this follow the instructions for entering and changing the setup in

the second setup screen (page 17).

Change the remote symbol in the setup screen so that it

no longer has a line through it.

When enabled, the remote symbol will appear on the bottom of the main

display.

Programing the remote – To program the remote for your laser press

and hold the STAR button, then press the POWER button.

The remote will search the immediate area for Rugby units with remote

capability, and will identify these in the display.

To select your laser highlight the serial number and press the STAR

button. The remote will connect to the selected laser.

To exit this screen without changing settings, highlight EXIT - NO

CHANGE and press the X/Y button.

Rugby 410/420 DG 23Accessories

Page 24

Remote Notes Setting the shut-off timer – The remote is set from the factory to shut

off after two minutes of not being used.

To change this shut-off time, enter the remote programming screen (just

described) by pressing and holding the STAR button, then pressing the

POWER button.

When the Rugby select screen is shown, press and hold the

STAND-BY button for 1.5 seconds. The shut-off time will change

between 120, 60, or 30 seconds each time the button is held.

Backlighting – The LCD backlighting is normally off to conserve battery

power.

To backlight the display on the remote, press the power button a

second time after the remote has been turned on.

Remote reception – The remote is an RF (radio frequency)

device with an internal antenna. Always ensure that the remote is within

the “line of sight” of the Rugby.

If the remote loses communication, hold the remote at a different angle

to improve reception.

Rugby 410/420 DG Accessories24

Page 25

7 Troubleshooting

7.1 Display Screen Explanations

Leica Start-up Screen

• Can be programmed to display customer’s name and

address.

Battery Status Screen

• Displays on power-up

• Displays also when batteries are empty.

Automatic Mode

• Main Display Screen

• Unit automatically self-levels.

Manual Mode

• Unit will not self-level

• Grade can be changed with the grade/arrow buttons.

Manual Mode with Grade

• Unit will self-level to grades input, then lock in

manual mode.

• Grade can be changed with the grade/arrow buttons.

Stand-by Mode

• Controlled by the stand-by button on the remote.

• Press the power button on the Rugby to turn off.

H.I. Alert Warning

• Unit has moved and elevation may have changed.

• Press Power or Star to reset H.I. function.

• Check unit’s elevation and adjust if required.

Servo Limit Warning

• Unit is not level

• Check setup and circular level vial.

Tilt Warning

• Unit is tilted more than 30°.

Temperature Warning

• Unit is too hot or cold to operate properly.

• Shade unit if too hot.

• Warm unit before continuing if too cold.

Rugby 410/420 DG 25Troubleshooting

Page 26

Negative Grade Disabled

• The ability to enter negative grade has been disabled

in the second setup screen.

Grade greater than 15%

• If attempting to enter grades greater than 15%, the

cross axis grade is limited to 1%.

• Four similar screens are possible.

Lost Communication

• The remote is out of range. Move closer.

• The remote is not in the line if sight of the laser.

Rugby 410/420 DG Tro u b l e shoot ing26

Page 27

7.2 Troubleshooting Suggestions

Whenever there are questions regarding your laser, check the basics first.

• Mode of operation - automatic, manual, manual with grade.

• Battery status

• Warning Screens - H.I., servo limit, temperature, adjustment.

• Head speed setting

• Beam mask setting

Symptom Possible Causes and Solutions

No beam • The Rugby beam is infrared (Rugby 410 DG

only) and invisible to the human eye.

• Check with a receiver to verify.

No self-leveling • Check the basics above.

Cannot change

grade

Loss of distance • Check the window surfaces.

Head rotates slowly • Check the basics above.

Grade stakes do not

match the laser

Beam masking not

saved when laser is

turned off

Remote will not turn on• Check and replace the batteries.

• Check the basics above.

•Check the other axis.

• Check operation in manual mode.

• Check if at grade limit.

• Check with a different receiver.

• At extended distances, decreasing the head

speed may improve performance.

• In low battery mode the Rugby will rotate

slowly (7 RPS) to trigger the laser low battery

function on the RE Pro.

• Check for proper alignment of the axes.

• Check level accuracy of the laser.

• Check the grade stakes to verify their accu-

racy or to determine if they have moved.

• Set up this preference in the second set-up

screen.

)

Remote will not

communicate with

the laser.

If none of the above suggestions results in a solution, contact your local

dealer or nearest authorized service center.

• Check that remote capability is enabled on the

laser. (see small icon on the main display)

•Check remote battery status.

• Reduce distance and try again.

• At longer distances, ensure the remote is in

“line of sight” of the laser.

• Reposition the remote at a different angle to

improve the internal antenna reception.

Rugby 410/420 DG 27Troubleshooting

Page 28

8 Care and Transport

8.1 Transport

Transport in the

field

Transport in a road

vehicle

Shipping When transporting the product by rail, air or sea, always use the

Shipping, transport of batteries

Field Adjustment After transport inspect the field adjustment parameters given in this user

When transporting the product in the field, always make sure that you:

• Either carry the instrument in its original transport case

• Or carry the tripod with its legs splayed across your shoulder,

keeping the attached instrument upright.

Never carry the instrument loose in a road vehicle. It can be affected by

shock and vibration. Always carry the product in its transport container

and secure it.

complete original Leica Geosystems packaging transport container and

cardboard box, or its equivalent, to protect against shock and vibration.

When transporting or shipping batteries, the person in charge of the

product must ensure that the applicable national and international rules

and regulations are observed. Before transportation or shipping, contact

your local passenger or freight transport company.

manual before using the product.

8.2 Storage

Product Respect the temperature limits when storing the product, particularly in

Field Adjustment After long periods of storage inspect the field adjustment parameters

summer if the instrument is inside a vehicle. Refer to “Technical Data”

for information about temperature limits.

given in this user manual before using the product.

Nickel-Metal

Hydride and D-Cell

Batteries

• Refer to "10 Technical Data" for information about storage temperature range.

• Fully charged NiMH batteries can be stored for a maximum of 180

days. NiMH batteries must then be recharged again.

• Remove the batteries from the product for storage.

• After storage, recharge the batteries before use.

• Protect batteries from damp and wetness. Wet or damp batteries

must be dried before storing or use.

Rugby 410/420 DG Care and Transport28

Page 29

8.3 Cleaning and Drying

Product and Accessories

Damp Products • Dry the product, the transport container, the foam inserts and the

Cables and Plugs • Keep plugs clean and dry.

Connectors with

Dust Cap

• Blow dust off optical parts.

• Never touch the glass with your fingers.

• Use only a clean, soft, lint-free cloth for cleaning. If necessary,

moisten the cloth with water or pure alcohol.

• Do not use other liquids; these may attack the polymer components.

accessories at a temperature not greater than 104°F / 40°C and

clean them.

• Do not repack until everything is completely dry.

• Always close the transport container when using in the field.

• Blow away any dirt lodged in the plugs of the connecting cables

• Wet connectors must be completely dry before attaching the dust

cap.

Rugby 410/420 DG 29Care and Transport

Page 30

9 Safety Directions

9.1 General

The following directions should enable the person responsible for the

product, and the person who actually uses the equipment, to anticipate

and avoid operational hazards.

The person responsible for the product must ensure that all users understand these directions and adhere to them.

9.2 Intended Use

Permitted use • The product casts a horizontal laser plane or a laser beam for the

purposes of alignment.

• The product can be set up on its own baseplate or on a tripod.

• The laser beam can be detected by means of a laser detector.

• Remote control of product.

• Data communication with external appliances.

Adverse use • Use of the product without instruction.

• Use outside of the intended limits.

• Disabling safety systems.

• Removal of hazard notices.

• Opening the product using tools, for example screwdriver, unless this

is specifically permitted for certain functions.

• Modification or conversion of the product.

• Use after misappropriation.

• Use of products with obviously recognizable damages or defects.

• Use with accessories from other manufacturers without the prior

explicit approval of Leica Geosystems.

• Inadequate safeguards at the construction site (e.g. when using on

or near roads).

• Deliberate dazzling of third parties.

• Controlling of machines, moving objects or similar monitoring application without additional control and safety installations.

Warning Adverse use can lead to injury, malfunction, and material damage.

It is the task of the person responsible for the equipment to inform the

user about hazards and how to counteract them. The product is not to

be used until the user has been instructed how to work with it.

Rugby 410/420 DG Safety Directions30

Page 31

9.3 Limits of Use

Environment Suitable for use in an atmosphere appropriate for permanent human

habitation: not suitable for use in aggressive or explosive environments.

Charger Suitable for use in dry environment only and not under adverse conditions.

Danger Local safety authorities and safety experts must be contacted before

working in hazardous areas, or in close proximity to electrical installations or similar situations by the person in charge of the product.

9.4 Warranty

International

Limited Warranty

This product is subject to the terms and conditions set out in the International Limited Warranty which you can download from the Leica

Geosystems home page at http://www.leica-geosystems.com/internationalwarranty or collect from your Leica Geosystems distributor.

The foregoing warranty is exclusive and is in lieu of all other warranties,

terms or conditions, express or implied, either in fact or by operation of

law, statutory or otherwise, including warranties, terms or conditions of

merchantability, fitness for a particular purpose, satisfactory quality and

non-infringement, all of which are expressly disclaimed.

9.5 Responsibilities

Manufacturer of

the product

Manufacturers of

non-Leica Geosystems accessories

Person in charge of

the product

Leica Geosystems AG, CH-9435 Heerbrugg, hereinafter referred to as

Leica Geosystems, is responsible for supplying the product, including the

user manual and original accessories, in a completely-safe condition.

The manufacturers of non Leica Geosystems accessories for the product

are responsible for developing, implementing and communicating safety

concepts for their products, and are also responsible for the effectiveness of those safety concepts in combination with the Leica Geosystems

product.

The person in charge of the instrument has the following duties:

• To understand the safety instructions on the product and the

instructions in the user manual;

• To be familiar with local regulations relating to accident prevention;

• To inform Leica Geosystems immediately if the product and the

application becomes unsafe.

• To ensure that the national laws, regulations and conditions for the

operation of radio transmitters are respected.

Warning The person responsible for the product must ensure that it is used in

accordance with the instructions. This person is also accountable for the

training and the deployment of personnel who use the product and for

the safety of the equipment in use.

Rugby 410/420 DG 31Safety Directions

Page 32

9.6 Hazards of Use

Warning The absence of instruction, or the inadequate imparting of instruction,

Caution Watch out for erroneous measurements if the product has been dropped

Danger Because of the risk of electrocution, it is very dangerous to use grade

can lead to incorrect or adverse use, and can give rise to accidents with

far-reaching human, material, financial, and environmental consequences.

Precautions:

All users must follow the safety directions given by the manufacturer and

the directions of the person responsible for the product.

or has been misused, modified, stored for long periods or transported.

Precautions:

Periodically carry out test measurements and perform the field adjustments indicated in the user manual, particularly after the instrument has

been subjected to abnormal use and before and after important measurements.

rods and staffs in the vicinity of electrical installations such as power

cables or electrical railways.

Precautions:

Keep at a safe distance from electrical installations. If it is essential to

work in this environment, first contact the safety authorities responsible

for the electrical installations and follow their instructions.

Warning If the product is used with accessories, for example masts, staffs, poles,

Warning Inadequate securing of the work site can lead to dangerous situations,

Caution If the accessories used with the product are not properly secured and the

you may increase the risk of being struck by lightning.

Precautions:

Do not use the product in a thunderstorm.

for example in traffic, on building sites, and at industrial installations.

Precautions:

Always ensure that the work site is adequately secured. Adhere to the

regulations governing accident prevention and road traffic.

product is subjected to mechanical shock, for example blows or falling,

the product may be damaged or people may sustain injury.

Precautions:

When setting-up the product, make sure that the accessories, for

example tripod, tribrach, connecting cables, are correctly adapted, fitted,

secured, and locked in position.

Avoid subjecting the equipment to mechanical stress.

Rugby 410/420 DG Safety Directions32

Page 33

Caution: During the transport, shipping or disposal of batteries it is possible for

Warning During dynamic applications, there is a danger of accidents occurring

Danger The product is not designed for use under wet and severe conditions.

inappropriate mechanical influences to constitute a fire hazard.

Precautions:

Before shipping the product or disposing of it, discharge the batteries

by running the product until they are flat.

When transporting or shipping batteries, the person in charge of the

product must ensure that the applicable national and international

rules and regulations are observed. Before transportation or shipping

contact your local passenger or freight transport company.

if the user does not pay attention to the environmental conditions

around, for example obstacles, excavations or traffic.

Precautions:

The person responsible for the product must make all users fully aware

of the existing dangers.

Operation of Charger:

If unit becomes wet it may cause you to receive an electric shock.

Precautions:

Use the product only in dry environments, for example in buildings or

vehicles. Protect the product against humidity. If the product becomes

humid, it must not be used!

Operation of Charger:

Warning If you open the product, either of the following actions may cause you

Warning Batteries not recommended by Leica Geosystems may be damaged if

Warning If the product is improperly disposed of, the following can happen:

to receive an electric shock

•Touching live components

• Using the product after incorrect attempts were made to carry out

repairs.

Precautions:

Do not open the product. Only Leica Geosystems authorized service

workshops are entitled to repair these products.

Inserting and Removing the Batteries:

charged or discharged. They may burn and explode.

Precautions:

Only charge and discharge batteries recomended by Leica Geosystems.

• If polymer parts are burnt, poisonous gases are produced which

may impair health.

Rugby 410/420 DG 33Safety Directions

Page 34

• If batteries are damaged or are heated strongly, they can explode

and cause poisoning, burning, corrosion or environmental contamination.

• By disposing of the product irresponsibly you may enable unauthorized persons to use it in contravention of the regulations,

exposing themselves and third parties to the risk of severe injury

and rendering the environment liable to contamination.

Precautions:

The product must not be disposed with household waste.

Dispose of the product appropriately in accordance with

the national regulations in force in your country.

Always prevent access to the product by unauthorized

personnel.

Product specific treatment and waste management information can be

downloaded from the Leica Geosystems home page at

http://www.leica-geosystems.com/treatment or received from your

Leica Geosystems dealer.

Warning Only Leica Geosystems authorized service workshops are entitled to

Warning Using a battery charger not recommended by Leica Geosystems can

Warning High mechanical stress, high ambient temperatures or immersion into

repair these products.

destroy the batteries. This can cause fire or explosions.

Precautions:

Only use chargers recommended by Leica Geosystems to charge the

batteries.

fluids can cause leakage, fire or explosions of the batteries.

Precautions:

Protect the batteries from mechanical influences and high ambient

temperatures. Do not drop or immerse batteries into fluids.

Warning Short circuited battery terminals can overheat and cause injury or fire,

for example by storing or transporting in pockets if battery terminals

come in contact with jewelry, keys, metallized paper or other metals.

Precautions:

Make sure that the battery terminals do not come into contact with

metallic objects.

Rugby 410/420 DG Safety Directions34

Page 35

9.7 Laser Classification

General The following directions (in accordance with the statement of the art

- international standard IEC 60825-1 (2001-08; 2007-03) and IEC TR

60825-14 (2004-02) provide instruction and training information to

the person responsible for the product and the person who actually

uses the equipment, to anticipate and avoid operational hazards.

The person responsible for the product must ensure that all users

understand these directions and adhere to them.

)

)

Rugby 410 DG The rotating laser produces an infrared laser beam which emerges

Class 1 laser

products

Product classified as laser class 1, class 2 and class 3R do not require:

• Laser safety officer involvement

• Protective clothes and eyewear

• Special warning signs in the laser working area

If used and operated as defined in this user manual due to the low eye

hazard level.

Products classified as laser class 2 or 3R may cause dazzle, flash-blindness and afterimages, particularly under low ambient light conditions.

from the rotating head.

The laser product described in this section, is classified as laser class

1 in accordance with:

• IEC 60825-1 (2001-08): "Safety of laser products"

• EN 60825-1: 1994 + A11:1996 + A2:2001: "Safety of laser products"

These products are safe under reasonable foreseeable conditions of

operation and are not harmful to eyes provided that the products are

used and maintained in accordance with this user manual.

Description Value

Maximum radiant power (Rotating mode) 1.7 mW

Maximum radiant power per pulse N/A

Pulse duration (effective) N/A

Pulse repetition frequency N/A

Beam divergence 0.2 mrad

Measurement uncertainty +/- 5%

Rugby 410/420 DG 35Safety Directions

Page 36

Labeling Class 1

LEICA GEOSYSTEMS AG

CH-9435 Heerbrugg Switzerland

Type-Serial No. 410- Manufactured 2008

Art. No. 766298 Made in Singapore

Power: 6 VDC = nominal 280 mA max.

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two condition

(1) This device may not cause harmful interference

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

This device contains a transmitter:

FCC ID: OUR-XBEEPRO

IC ID: 4214A-XBEEPRO

ERP: <100mW

Complies with 21 CFR 1040.10 and

1040.11 except for deviations

pursuant to Laser Notice No 50,

dated July 26, 2001.

Class 1 Laser Product

according to IEC 60825-1

(2001 - 08)

A = Laser Beam

Rugby 420 DG The rotating laser produces a visible red laser beam which emerges

from the rotating head.

The laser product described in this section, is classified as laser class

2 in accordance with:

• IEC 60825-1 (2007-03): "Safety of laser products"

• EN 60825-1 (2007-10): "Safety of laser products"

Class 2 laser

products

Warning From a safety perspective class 2 laser products are not inherently

These products are safe for momentary exposures but can be

hazardous for deliberate staring into the beam.

Description Value

Maximum peak radiant power < 2.7 mW c.w.

Pulse duration (effective) 2.2, 1.1, 0.74, 0.56 ms

Pulse repetition frequency 5, 10, 15, 20 rps

Wavelength 620 - 690 nm

safe for the eyes.

Precautions:

Avoid staring into the beam or pointing the beam at other people.

Rugby 410/420 DG Safety Directions36

Page 37

Labeling Class 2

LEICA GEOSYSTEMS AG

CH-9435 Heerbrugg Switzerland

Type-Serial No. 420- Manufactured 2008

Art. No. 766362 Made in Singapore

Power: 6 VDC = nominal 280 mA max.

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

This device contains a transmitter:

FCC ID: OUR-XBEEPRO

IC ID: 4214A-XBEEPRO

ERP: <100mW

Complies with 21 CFR 1040.10 and

1040.11 except for deviations

pursuant to Laser Notice No 50,

dated July 26, 2001.

Laser Radiation

Do not stare into beam

Class 2 Laser Product

according to IEC 60825-1

(2007 - 03)

Po 2.7mW

= 620 - 690mW

A = Laser Beam

9.8 Electromagnetic Compatibility (EMC)

Description The term Electromagnetic Compatibility" is taken to mean the capa-

bility of the product to function smoothly in an environment where

electromagnetic radiation and electrostatic discharges are present,

and without causing electromagnetic disturbances to other equipment.

Warning Electromagnetic radiation can cause disturbances in other equipment.

Caution There is a risk that disturbances may be caused in other equipment if

Caution Disturbances caused by electromagnetic radiation can result in error-

Although the product meets the strict regulations and standards which

are in force in this respect, Leica Geosystems cannot completely

exclude the possibility that other equipment may be disturbed.

the product is used in conjunction with accessories from other manufacturers, for example field computers, personal computers, two-way

radios, non-standard cables or external batteries.

Precautions:

Use only the equipment and accessories recommended by Leica

Geosystems. When combined with the product, they meet the strict

requirements stipulated by the guidelines and standards. When using

computers and two-way radios, pay attention to the information

about electromagnetic compatibility provided by the manufacturer.

neous measurements.

Rugby 410/420 DG 37Safety Directions

Page 38

Although the product meets the strict regulations and standards which

are in force in this respect, Leica Geosystems cannot completely

exclude the possibility that the product may be disturbed by very

intense electromagnetic radiation, for example near radio transmitters, two-way radios or diesel generators.

Precautions:

Check the plausibility of results obtained under these conditions.

Warning If the product is operated with connecting cables attached at only one

Warning Electromagnetic radiation can cause disturbances in other equipment,

of their two ends, for example external supply cables, interface cables,

the permitted level of electromagnetic radiation may be exceeded and

the correct functioning of other products may be impaired.

Precautions:

While the product is in use, connecting cables, for example product to

external battery, product to computer, must be connected at both

ends.

Use of product with radio devices:

in installations (e.g. medical ones such as pacemakers or hearing aids)

and in aircraft. It can also affect humans and animals.

Precautions:

Although the product meets the strict regulations and standards which

are in force in this respect, Leica Geosystems cannot completely

exclude the possibility that other equipment may be disturbed or that

humans or animals may be affected.

• Do not operate the product in the vicinity of filling stations or

chemical installations, or in other areas where an explosion hazard

exists.

• Do not operate the product near to medical equipment.

• Do not operate the product in aircraft.

• Do not operate the product for long periods with it immediately

next to your body.

9.9 FCC Statement, Applicable in U.S.

Warning Changes or modifications not expressly approved by Leica Geosystems

Warning This equipment has been tested and found to comply with the limits

for compliance could void the user's authority to operate the equipment.

for a Class B digital device, pursuant to part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

This equipment generates, uses and can radiate frequency energy and,

if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation.

Rugby 410/420 DG Safety Directions38

Page 39

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Labeling Rugby

410/420 DG and LR

Remote Control

Rugby 410/420 DG 39Safety Directions

Page 40

Conformity to

National Regulations

• FCC Part 15 (applicable in US)

• Hereby, Leica Geosystems AG, declares that the product Rugby

410/420 DG and LR Remote control is in compliance with the essential requirements and other relevant provisions of the applicable

Europe Directive. The declaration of conformity may be consulted at

http://www.leica-geosystems.com/ce.

Class 2 equipment according European Directive

1999/5/EC (R&TTE) for which following EU

Member States apply restrictions on the placing

on the market or on the putting into service or

require authorization for use:

• France

• Italy

• Norway (if used in the geographical area within

a radius of 20km from the centre of Ny-Ålesund)

• The conformity for countries with other national regulations not

covered by the FCC part 15 or European directive 1999/5/EC has to

be approved prior to use and operation.

Frequency range: 2405-2480 MHz

Transmission power: < 100 mW (e.i.r.p.)

Antenna

Specific Absorption

Rate (SAR)

Rugby 410/420 DG: Whip Antenna

Remote: Chip Antenna

The product meets the limits for the maximum permissible exposure of

the guidelines and standards, which are force in this respect. The

product must be used with the recommended antenna. A separation

distance of at least 20 centimeters should be kept between the antenna

and the body of the user or nearby person within the intended application.

Rugby 410/420 DG Safety Directions40

Page 41

10 Technical Data

Rugby 410/420 DG

Rugby 410 DG

specific

Self-leveling accuracy* ±1/16” at 100’ (1.5 mm at 30 meters)

Self-leveling range ± 5°

Grade Capability -5% to +15% in either axis simultaneously

up to +25% with up to ±1% in the cross axis

Head Speeds 5, 10, 15, 20 RPS

Operating Temperature -4° to +122°F (-20° to +50°C)

Storage Temperature

(without batteries)

Storage Temperature

(with batteries)

Battery Life** 65 hours (4-alkaline), 130 hours (8-alka-

Charging time 4.5 hours (approximate)

Dimensions (HWD) 10.4 x 10.2 x 7.92” (265 x 260 x 200 mm)

Weight without batteries 11.1 lbs. (5 kg)

Water resistance Waterproof to IP57 Standard

Operating range 1300 ft (400 meters) radius

Laser Diode Type 780 nm (invisible)

Laser Classification Class 1 IEC60825-1

-40° to +158°F (-40° to +70°C)

+32° to +68°F (0° to +20°C)

line)

50 hours (1-NiMH pack), 100 hours (2-

NiMH packs)

Rugby 420 DG

specific

Rugby LR Remote

Operating range 1800 ft (550 meters) radius

Laser Diode Type 635 nm (visible red laser)

Laser Classification Class 2 IEC60825-1

Distance 750 ft (225 meters) typical radius

Battery type Four AAA-alkaline batteries

Size 6.1 x 2.8 x 1.8” (155 x 70 x 45 mm)

Weight 14.4 oz. (410g)

* Accuracy defined at 77°F / 25°C.

** Battery life is dependent on many variables.

Rugby 410/420 DG 41Technical Data

Page 42

Rugby 410/420 DG Technical Data42

Page 43

Rugby 410/420 DG 43Technical Data

Page 44

Total Quality Management: Our commitment to total customer satisfaction.

Leica Geosystems AG, Heerbrugg, Switzerland, has been

certified as being equipped with a quality system which

meets the International Standards of Quality Management

and Quality Systems (ISO standard 9001) and Environmental

Management Systems (ISO standard 14001).

Ask your local Leica Geosystems dealer for more information about our TQM

program.

766323-1.0.0en Original text

Printed in Switzerland © 2008 Leica Geosystems AG, Heerbrugg, Switzerland

Leica Geosystems AG

Heinrich-Wild-Strasse

CH-9435 Heerbrugg

Switzerland

Phone +41 71 727 31 31

www.leica-geosystems.com

Loading...

Loading...