Leica FSC User Manual

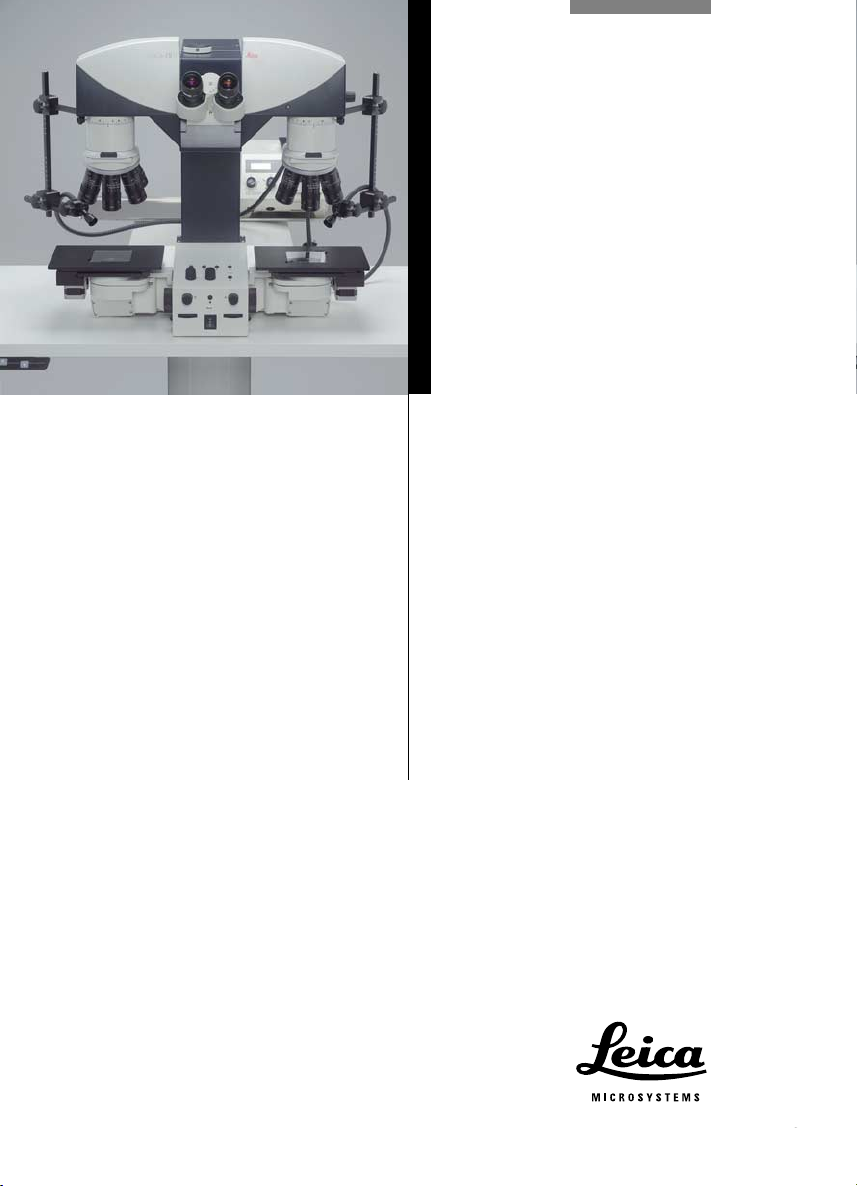

Leica FS C

Operating Manual

Bedienungsanleitung

Manuel d’utilisation

1

Published 2003 by:

Herausgegeben 2003 von:

Publié en 2003 par:

Leica Microsystems Wetzlar GmbH

Ernst-Leitz-Strasse

D-35578 Wetzlar (Germany)

Responsible for contents:

Verantwortlich für den Inhalt:

Responsable du contenu:

Katja Peter, Karin Schwab

Marketing CM, Compound Microscopy, Product Management,

Marketing CM, Compound Microscopy, Productmanagement,

Marketing CM, Compound Microscopy, Product Management ,

In case of questions, please contact:

Bei Fragen wenden Sie sich bitte an:

Pour toute question, contacter:

2

Phone +49 (0) 6441-29 2261

Fax +49 (0)64 41-2922 55

E-Mail MQM-Hotline@leica-microsystems.com

Leica FS C

Operating Manual

3

Copyrights

Copyrights

All rights to this documentation are held by

Leica Microsystems Wetzlar GmbH. Reproduction of text or illustrations (in whole or in part) by

print, photocopy, microfilm or other method (including electronic systems) is not allowed without express written permission from Leica

Microsystems Wetzlar GmbH.

The term “Windows” can be used in the following text without further identification. It is a registered trademark of the Microsoft Corporation.

Otherwise, no inference with regard to the free

usability of product names may be drawn from

the use of those names.

The instructions contained in the following documentation reflect state-of-the-art technology

and knowledge standards. We have compiled

the texts and illustrations as accurately as possible. Nevertheless, no liability of any kind may

be assumed for the accuracy of this manual’s

contents. Still, we are always grateful for comments and suggestions regarding potential mistakes within this documentation.

The information in this manual is subject to modification at any time and without prior notification.

4

Contents

Contents

1. Important Notes about this Manual ...... 6

2. Safety Notes ............................................... 7

2.1. General Safety Notes ............................... 7

2.2. Electrical Safety ........................................ 7

2.3 Weights ....................................................... 7

3. Field of Application .................................. 9

4. Installation Site ......................................... 10

5. Unpacking the Macroscope ................... 11

6. Overview of the Instrument .................... 13

7. Assembly .................................................... 14

7.1 Comparison Bridge ................................... 14

7.2 Illumination ................................................. 14

7.3 Eyepieces .................................................... 18

7.4 Objectives ................................................... 18

7.5 Cabling ......................................................... 19

8. Operation .................................................... 21

8.1 Switching on the Macroscope ............... 21

8.2 Stages .......................................................... 22

8.3 Tube ............................................................ 22

8.4 Eyepieces .................................................... 23

8.5 Brightness Setting..................................... 23

8.6 Focusing ...................................................... 23

8.7 Objectives ................................................... 24

8.8 Magnification Changer............................. 24

8.9 Diaphragm Setting .................................... 24

8.10 The Smart Move Control Panel............... 25

8.11 Adjusting the Height of the Stand .......... 25

8.12 Magnification Calibration ........................ 25

8.13 Oblique Incident Illumination .................. 26

8.14 Coaxial Incident Illumination................... 26

8.15 Transmitted Light Illumination................. 28

8.16 UV Illumination........................................... 29

9. Accessories ............................................... 30

9.1 Motorized Work Table .............................. 30

9.2 Stackable Stages ...................................... 31

9.3 Slide Holder ................................................ 33

9.4 Rotating Mechanism for

Toolmark Examination .............................. 41

9.5 Light Panel .................................................. 41

9.6 Filter for Color Contrast ............................ 42

9.7 Polarization Devices ................................. 43

9.8 Stage Scales

and Calibration Standard ......................... 44

10. Technical Data ......................................... 45

11. Care of the Comparison Macroscope .... 48

11.1 Dust Cover .................................................. 48

11.2 Cleaning....................................................... 48

11.3 Handling Acids and Alkalines ................. 49

12. Wear and Spare Parts .............................. 50

13. EU Declaration of Conformity ................. 51

5

1. Important Notes about this Manual

1. Important Notes about this Manual

Caution!

This operating manual is an essential component of the Leica FS C Comparison Macroscope, and must be read carefully before the

macroscope is put into operation or used.

Text symbols and their meanings:

(1.2)

→ page 20

!

This operating manual contains important instructions and information for the operational

safety and maintenance of the comparison macroscope and accessories. Therefore, it must be

kept and taken care of.

Numbers in parentheses such as (1.2), correspond to illustrations (in the example, Figure 1,

Item 2).

Numbers with pointer arrows (for example

→ page 20), point to a certain page of this manual.

Special safety instructions are indicated

with the triangle symbol shown here, and

have a gray background.

Caution! The macroscope and accessories can

be damaged when operated incorrectly.

Danger due to hot surface.

Explanatory note.

*

6

Item not contained in all configurations.

2. Safety Notes

2. Safety Notes

2.1 General Safety Notes

This safety class 1 device is constructed

and tested in accordance with EN 61010-1/IEC

1010-1, safety regulations for electrical measuring, control, and laboratory devices.

Caution!

In order to maintain this condition and to ensure safe operation, the user must follow the

instructions and warnings contained in this

operating manual.

Caution!

The devices and accessories described in

this operating manual have been tested for

safety and potential hazards.

The responsible Leica affiliate or the main

plant in Wetzlar must be consulted whenever the device is altered, modified or used in

conjunction with non-Leica components that

are outside of the scope of this manual.

2.2. Electrical Safety

General Specifications

For indoor use only.

Supply voltage:

Frequency:

Power input:

Fuse (power supply):

Fuse (power pack):

Ambient temperature:

Relative humidity:

Overvoltage category:

Pollution degree:

2.3 Weights

Comparison bridge:

Macro stand with stage:

Motorized work table:

90-250 V~

50-60 Hz

maximum 125 VA

F 6,3 A L 250 V -ULT 16 A L 250 V

10-36°C

maximum 80% to 30°C

II

2

15 kg

32 kg

50 kg

Unauthorized alterations to the device or

noncompliant use shall void all rights to any

warranty claims!

7

2. Safety Notes

Caution!

The power plug may only be plugged into an

outlet equipped with a grounding contact.

Do not interfere with the grounding function

by using an extension cord without a ground

wire. Any interruption of the ground wire inside or outside of the device, or release of

the ground wire connection, can cause the

device to become hazardous. Intentional

ground interruption is not permitted!

Caution!

By connecting them to ground, ancillary devices providing their own and/or separate

power supplies and which are connected to

the comparison macroscope can be connected to the same ground wire potential.

For connections without a ground connector, Leica Service must be consulted.

Caution!

The comparison macroscope’s electrical

accessory components are not protected

against water. Water can cause electric

shock.

Do not assemble the comparison macroscope and its accessory components in the

immediate vicinity of a water connection or

other areas where the possibility of water

exposure exists.

Caution!

Protect the comparison macroscope from

excessive temperature fluctuations. Such

fluctuations can lead to the accumulation of

condensation, which can damage the electrical and optical components.

Caution!

Never use any fuses as replacements other

than those of the types and the current ratings listed here. Using patched fuses or

bridging the fuse holder is not permitted.

8

Caution!

Before exchanging the fuses or lamps, be

absolutely certain to switch-off the main

power switch and remove the power cable.

3. Field of Application

3. Field of Application

Comparisons of small surfaces or profiles need

to be performed with sufficient precision, if the

objects of comparison can be observed simultaneously.

If only a macroscope with just one image beam

input is available for such comparisons, then,

depending on the interruption of observation by

a change of objective, high demands are made

on the memory of the observer. Therefore, it is

impossible to rule out incorrect interpretation in

the case of objects with very minor differences

in the surface or profile.

The Leica FS C (Forensic Solution Comparison)

Macroscope with two image beam inputs is designed for comparing structures of items such

as those listed below in split images and composite images in forensic laboratories, document printing facilities, mints and banks, and

documenting the results on photographs and

videos:

– Evidence on fired ammunition pieces

– Toolmarks

–Manufacturing traces on adhesive tape

– Playback traces on magnetic tape

– Documents

–Writing samples

– Banknotes

– Stamps

– Coins

– etc.

Illumination equipment are available for incident

light (including UV light) and transmitted light.

9

4. Installation Site

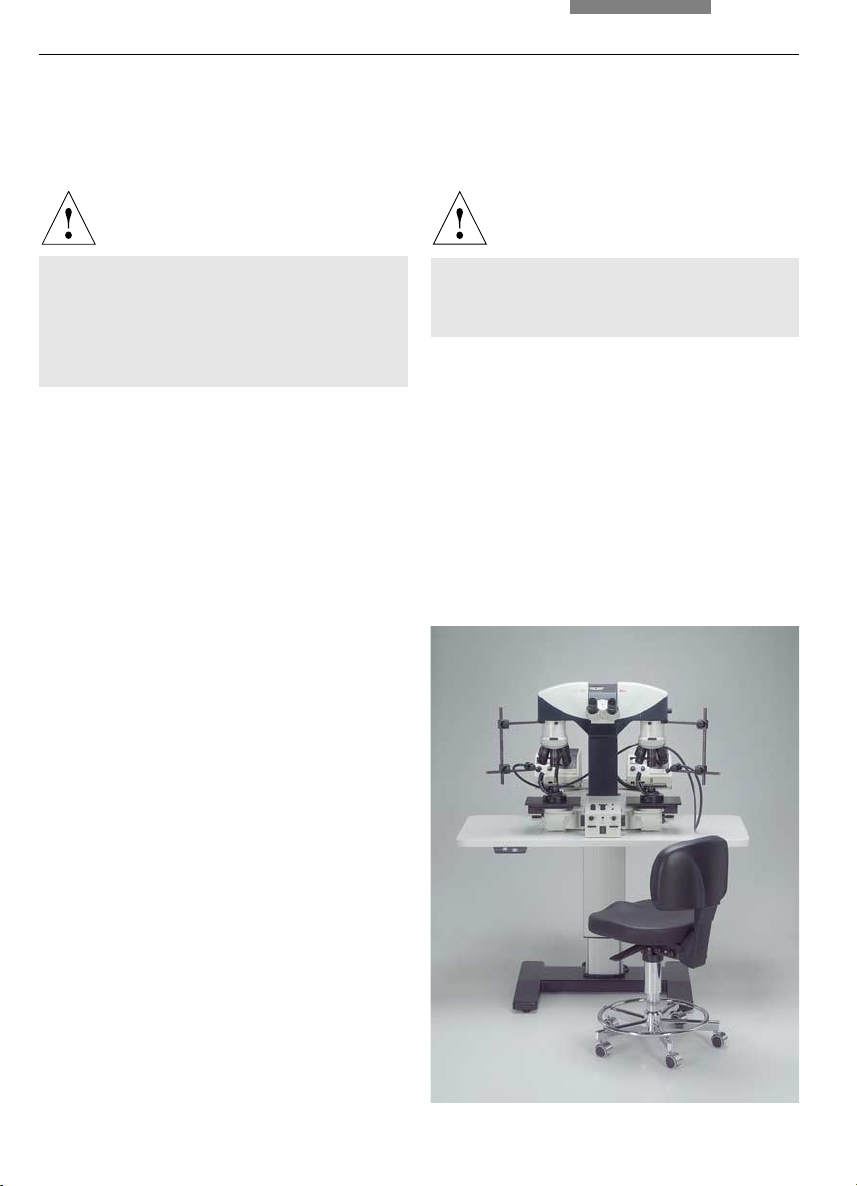

4. Installation Site

Caution:

Ensure that the workplace area is free of oil

and chemical fumes. Vibrations, direct sunlight and strong temperature fluctuations interfere with measurements as well as microphotography and image documentation.

The basic prerequisite is a stable instrument table of optimum height (70–80 cm). Combined

with an ergonomically correct, adjustable chair,

these are the basic requirements for fatiguefree microscopy.

Allowable ambient conditions

Temperature 10–36 °C

Relative humidity max. 80% up to 30°C

Macroscopes in warm and warm-damp climatic

zones require special care in order to prevent

the build up of fungus.

For additional instructions, see the chapter entitled “Care of the Comparison Macroscope”

page 48.

→

Caution:

Electrical components must be assembled at

least 10 cm from the wall and away from

flammable substances.

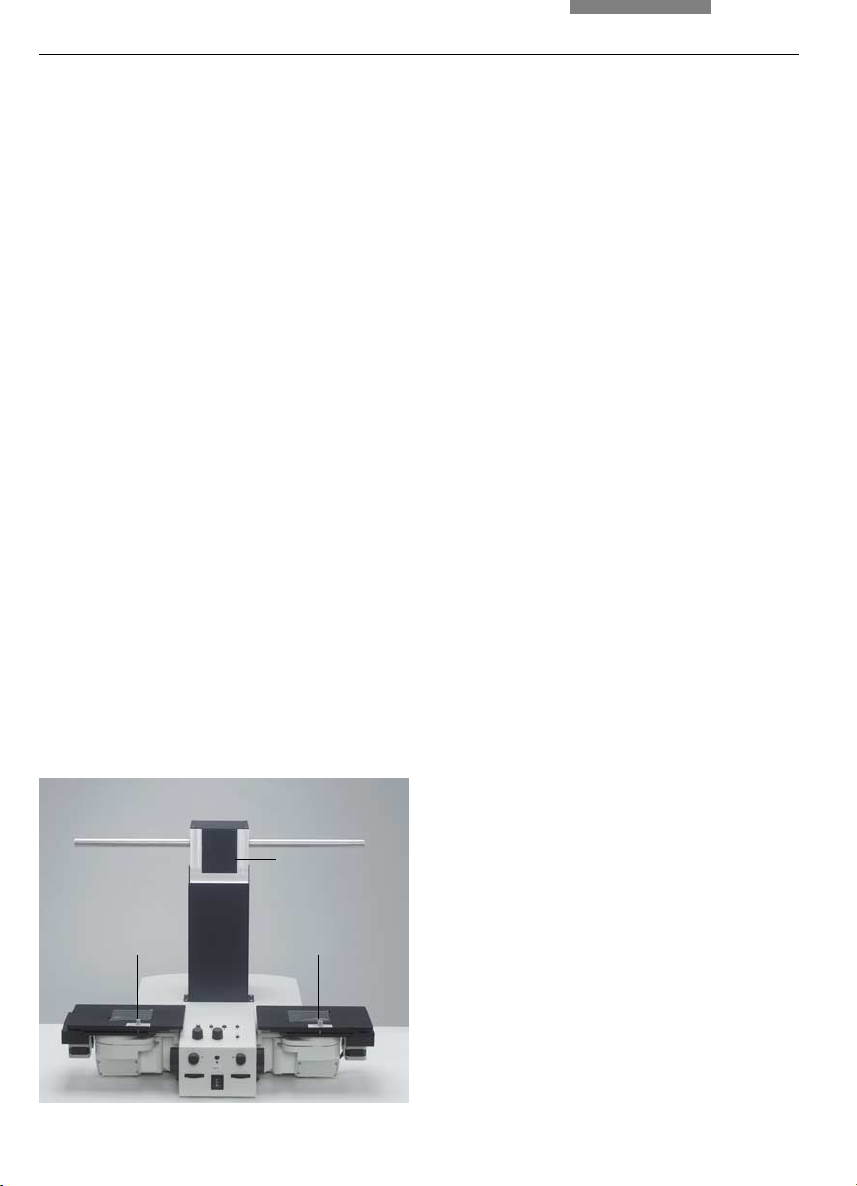

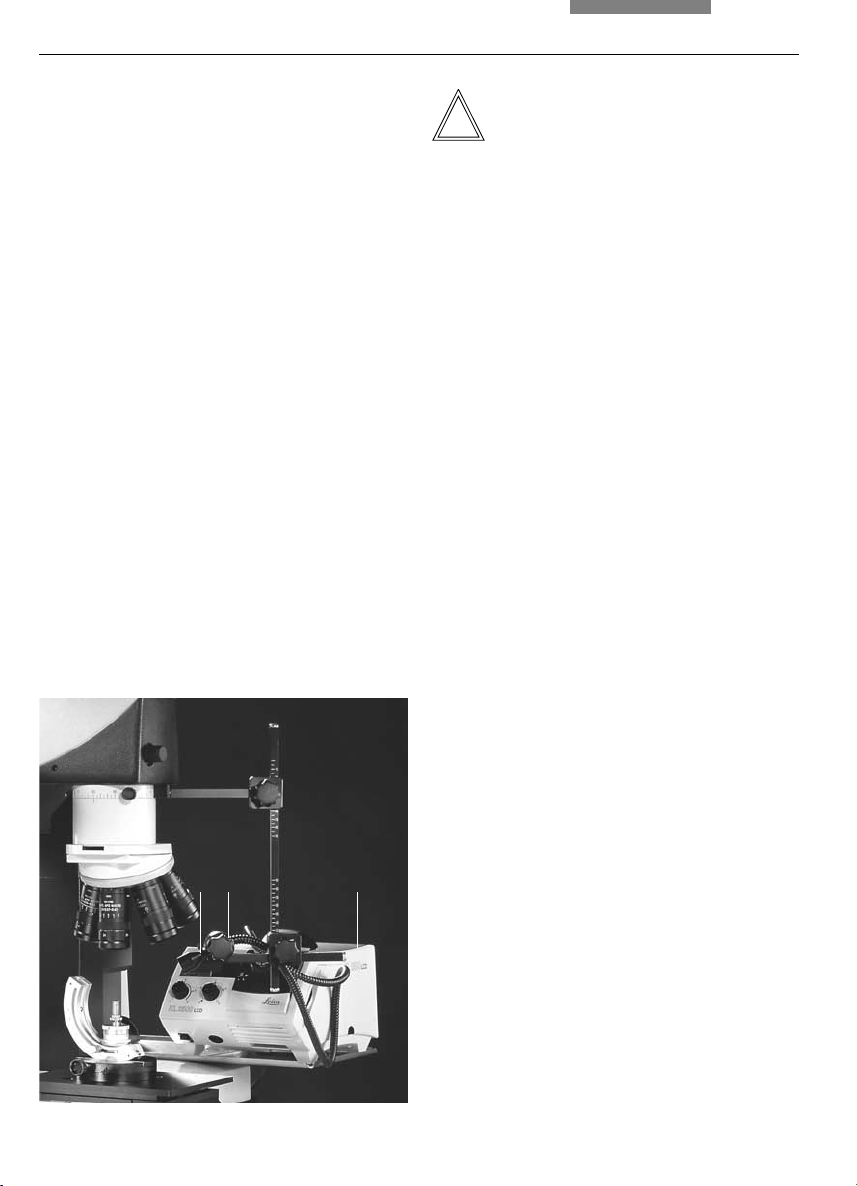

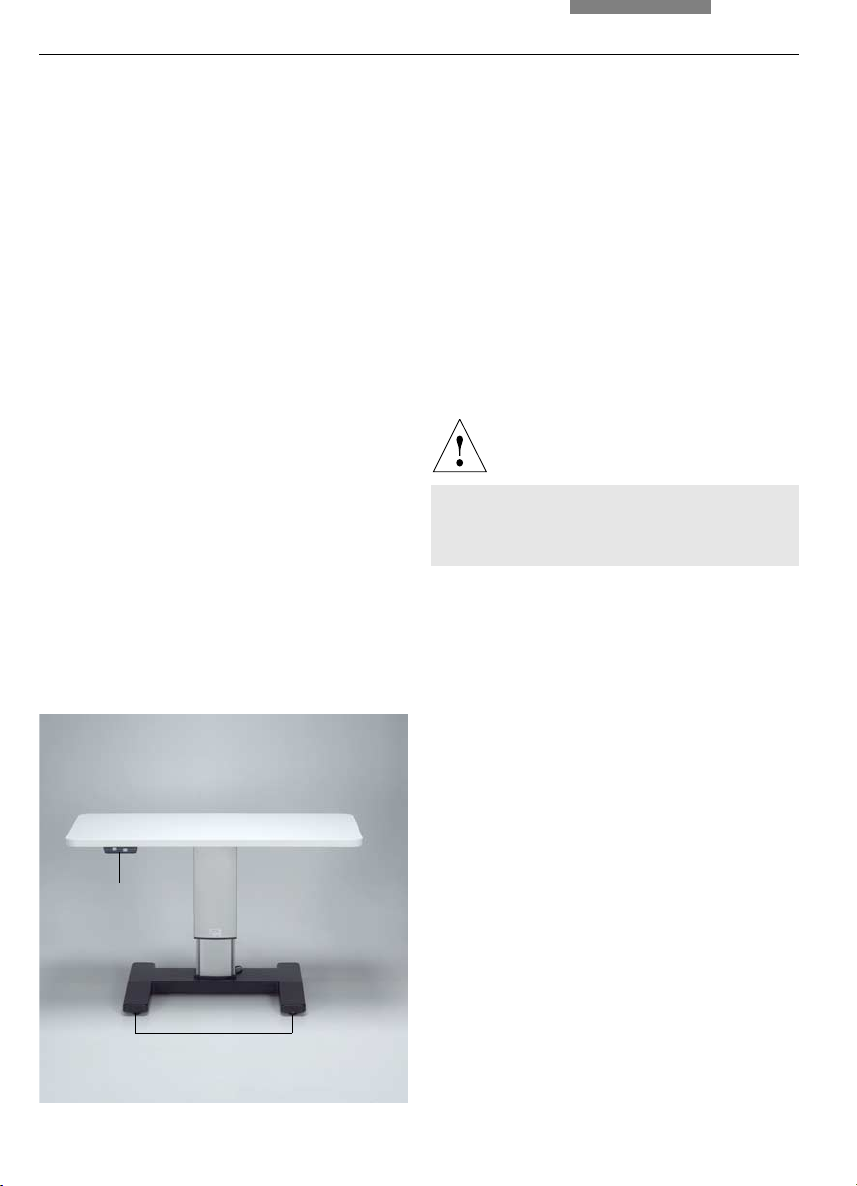

Fig. 1 Leica FS C with adjustable-height work table and

ergonomic working chair

10

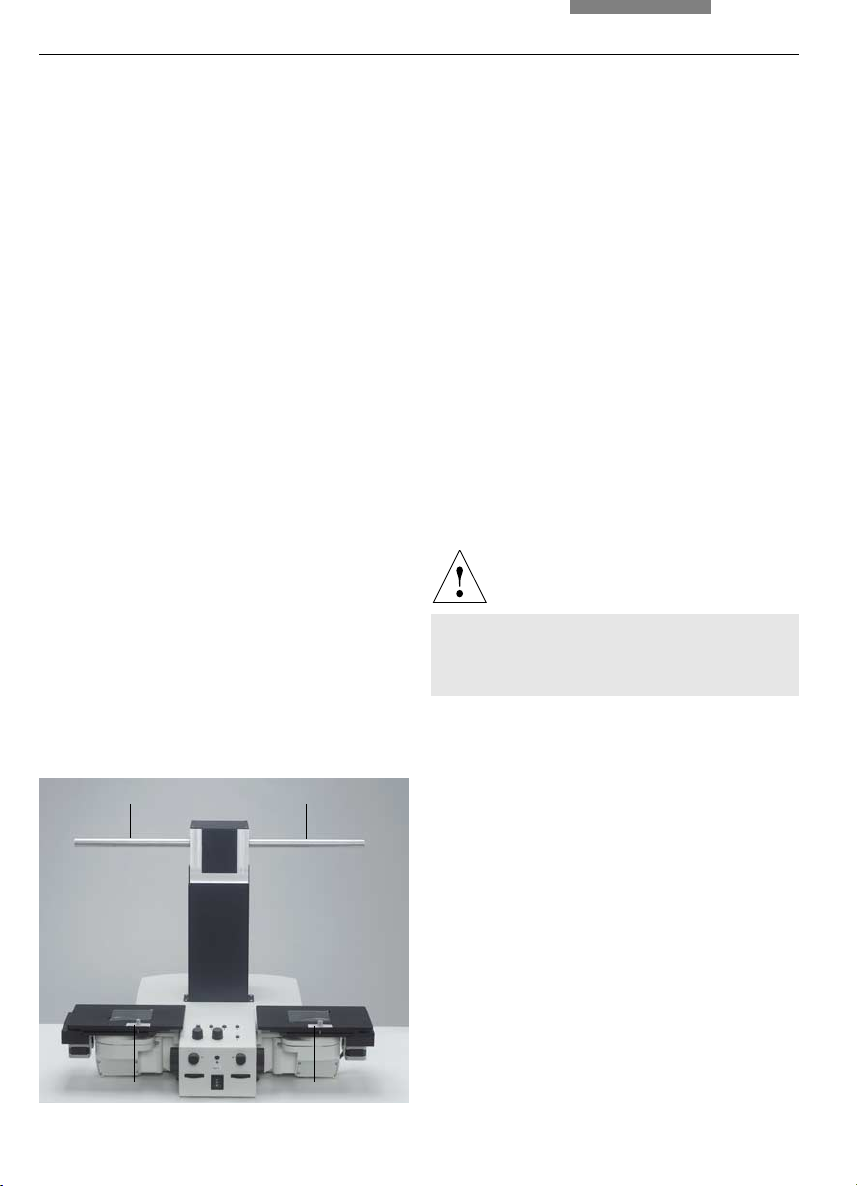

5. Unpacking the Macroscope

5. Unpacking the Macroscope

The stand is delivered in a solid box with packaging inserts.

The delivery includes the following components:

• Stand with base and control panel, as well as

the stages, which are already installed. The

stand is equipped with two carrying handles.

• Comparison bridge with integrated tube

• One or two cold light sources

• Accessory case with slide holder

• Optical accessories

• Oblique incident illuminator

• Optional accessories

Fig. 2 Stand with carrying handles

1 Removable carrying handle

2 Transport anchors

11

When unpacking the equipment, follow these instructions:

• After opening the box, first remove the comparison bridge and then the cardboard boxes,

which hold the accessories.

• Lift the stand out of the carton by its carrying

handles (2.1).

!

Caution!

When lifting the macroscope out of the packaging, and when transporting it to its installation site, carry it by its handles only.

Caution:

Note that the stand weighs approx. 32 kg.

Two people are required to lift it out if its

packaging and carry it to its installation site.

Later, the carrying handles can be unscrewed

and removed from the upper part of the macroscope. Then, seal the threaded holes using

seal plugs.

22

11

5. Unpacking the Macroscope

• Carefully remove all components from the

transportation and packaging materials.

Caution!

!

If at all possible, avoid touching the lens surfaces of the objectives. If fingerprints do appear on the glass surfaces, remove them with

a soft leather or linen cloth. Even small traces

of finger perspiration can damage the surfaces of optical surfaces in a short time. For additional instructions, see the chapter entitled

“Care of the Comparison Macroscope”

page 48.

→

• Check the delivery carefully against the packing list, delivery note or the invoice. We highly

recommend keeping a copy of these documents with the manual in order to have delivery date and delivery package information

available when (for example) placing repeat

orders or making service calls. Please make

sure that no small parts are lost in the packaging materials.

Note:

Keep the packaging materials for storage purposes and transportation of the individual components.

Caution:

Do not yet connect the comparison macroscope and peripherals to the power supply

at this point!

12

6. Overview of the Instrument

9

6. Overview of the Instrument

1

8

7

6

2

3

4

5

Fig. 3 Leica FSC with motorized work table

1 Comparison bridge

2 Special articulated arms for oblique incident illuminator

3 Universal cold light source

4 Motorized work table

5 Control unit

6 Transmitted light illuminator

7 Motorized stage

8 Objective turret with objectives

9 Tube with eyepieces

13

7. Assembly

7. Assembly

For instructions for assembling the stackable

stages and various slide holders, please refer to

Chapter “9. Accessories” →

!

!

Caution!

The stages and slide holders have to be mounted before screwing in the objectives.

Only a few commonly used screwdrivers and

keys are necessary for assembly, which are included in the delivery package.

Caution!

First, remove the transport anchors (4.1).

Fig. 4 Stand with carrying handles

1 Transport anchors

2 Dovetail guide

page 31 ff.

7.1 Comparison Bridge

• From above, set the comparison bridge onto

the dovetail guide (4.2) and push the bridge

downwards until the upper end of the dovetail

guide is tightly fastened.

• Fasten the comparison bridge using the side

clamping screw.

7.2 Illumination

Either one or two cold light sources can be

used. We recommend using the same cold light

source for both sides based on the illumination

method being used. A double-armed, flexible

light line is included for this purpose. The second cold light source should then be used for

another illumination method.

14

2

11

7. Assembly

Oblique Incident Illumination

• Screw the special articulated arms onto the

left and right of the macroscope carrier (5.1).

• Screw the light guide with ø 4.5 mm (Fig. 6)

onto the cold light illuminator (8.1).

• Place the cold light source next to the stand

or onto the shelf that is to be screwed onto

the base of the comparison macroscope (7.1).

• Insert both light guide ends into the left and

right receptacles of the special articulated

arms (5.2) and tighten them using an Allen

wrench.

•Mount and fasten the focusing optics (6.1).

Fig. 5 Special articulated arms for oblique incident illumi-

nation

1 Fastening screws for the articulated arm

2 Receptacle for light guide

Fig. 6 Light guide ø 4.5 mm

1 Focusing optics

1

Fig. 7 Shelf for the cold light illuminator

1 Fastening screws for the shelf

1

1

2

Fig. 8 Cold light illuminator KL2500 LCD

1 Connection for light guide

1

15

7. Assembly

Coaxial incident light

• Remove the cover plates (9.1) to the rear left

and right on the macroscope carriers.

• In their place, screw on the coaxial

illuminator (11.1)

• Screw the light guide with ø 9 mm (Fig. 12)

onto the cold light illuminator (8.1).

• Place the cold light source next to the stand

or onto the shelf that is to be screwed onto

the base of the comparison macroscope (7.1).

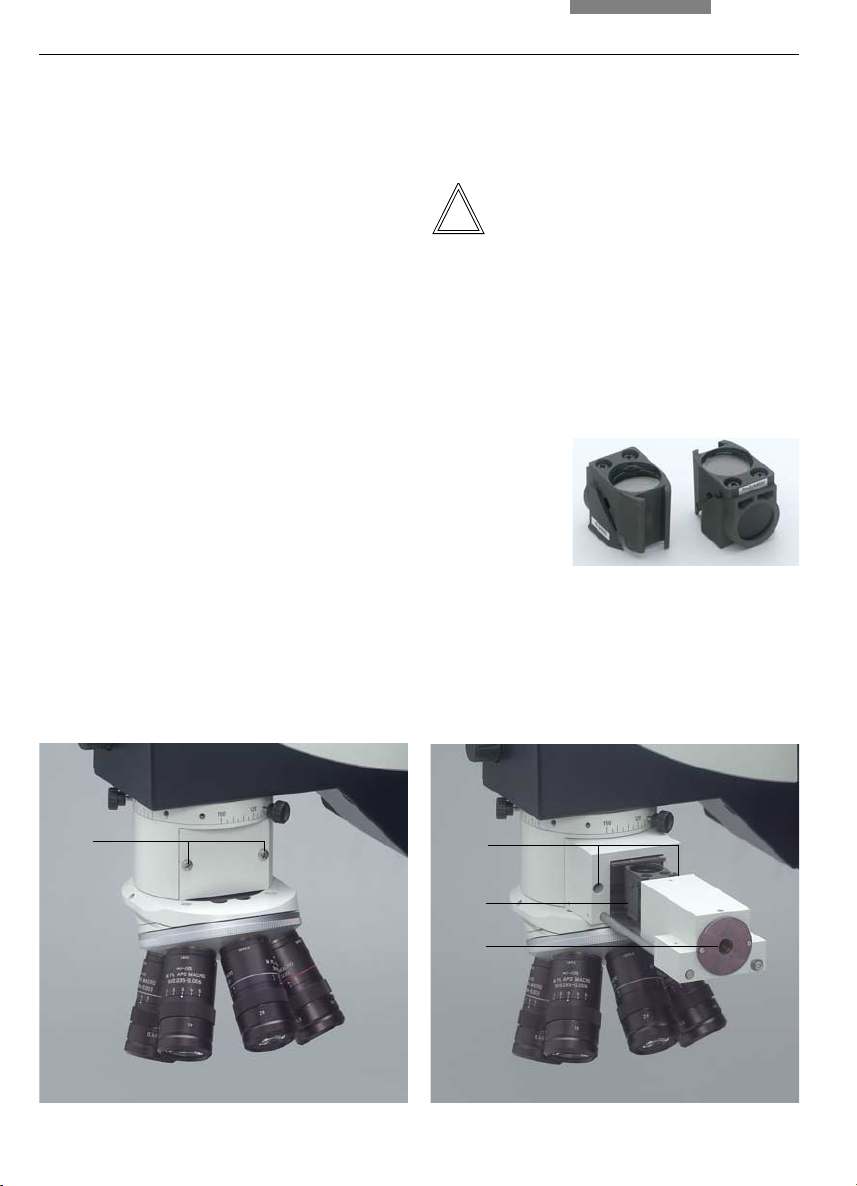

• Insert the polarization filter cube (Fig. 10).

To do so, attach the filter cube onto the side

and push it into the holder (11.2).

Fig. 9 Fastening the coaxial illuminator

1 Fastening screws for the cover plate

• Insert the two light guide ends into the left and

right receptacles on the coaxial illuminator

(11.3).

Note:

If, after installation, point-like objects are appear in the image, the light guide must be pulled

1 to 2 mm out of the coaxial illuminator. The

point-like objects are caused by the fibers of the

light guide.

Fig. 10 Polarizing

filter cube

1 From the rear

2 From the front

Fig. 11 Coaxial illuminator

1 Fastening screws for the coaxial illuminator

2 Filter cube inserted

3 Receptacle for light guide

1

2

16

1

1

2

3

7. Assembly

3

Transmitted Light

The transmitted illuminator is pre-installed in the

factory.

• Screw the light guide with ø 9 mm (Fig. 12)

onto the cold light illuminator (8.1).

• Place the cold light source next to the stand

or onto the shelf that is to be screwed onto

the base of the comparison macroscope (7.1).

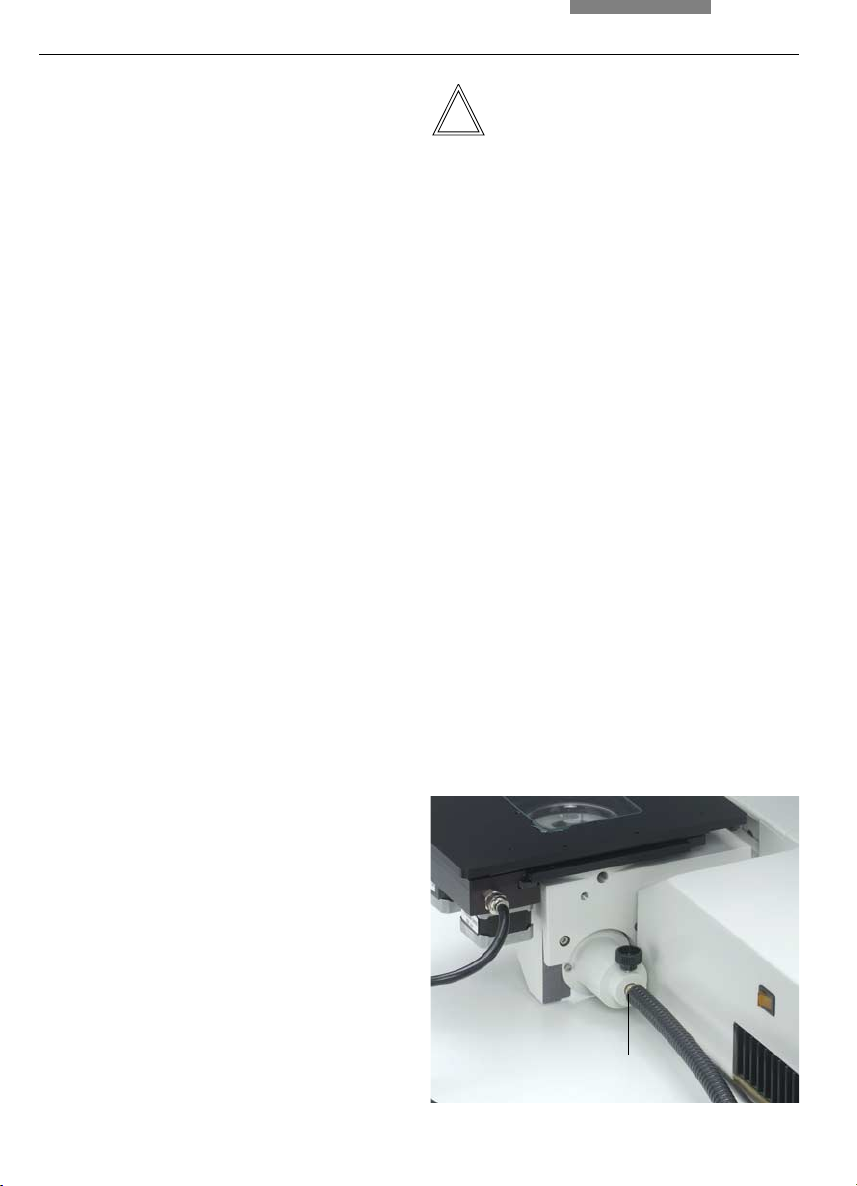

Fig. 12 Light guide ø 9 mm

• Insert the two light guide ends into the left and

right receptacles on the transmitted light illuminator (13.1).

• Connect the cables of the transmitted light illuminator on both sides with the rear side of

the stand (17.2, 17.3).

UV Illumination

• Screw the holder for UV lamps (14.1) onto the

comparison bridge.

• Insert the UV lamps (14.3) into this holder.

Align them with the object and screw them

tight.

Fig. 13 Transmitted light illuminator

1 Connection for light guide

Fig. 14 Assembly of the UV illuminator

1 Holder for UV lamps

2 Rod for fastening a UV lamp

3 UV lamp

2

1

1

17

7. Assembly

7.3 Eyepieces

• The eyepieces are inserted into the eyepiece

tubes on the tube.

7.4 Objectives

The position of the individual objectives is preset at the factory. The object turret eyes are

numbered.

• Screw the objective into the objective turret

(Fig. 15).

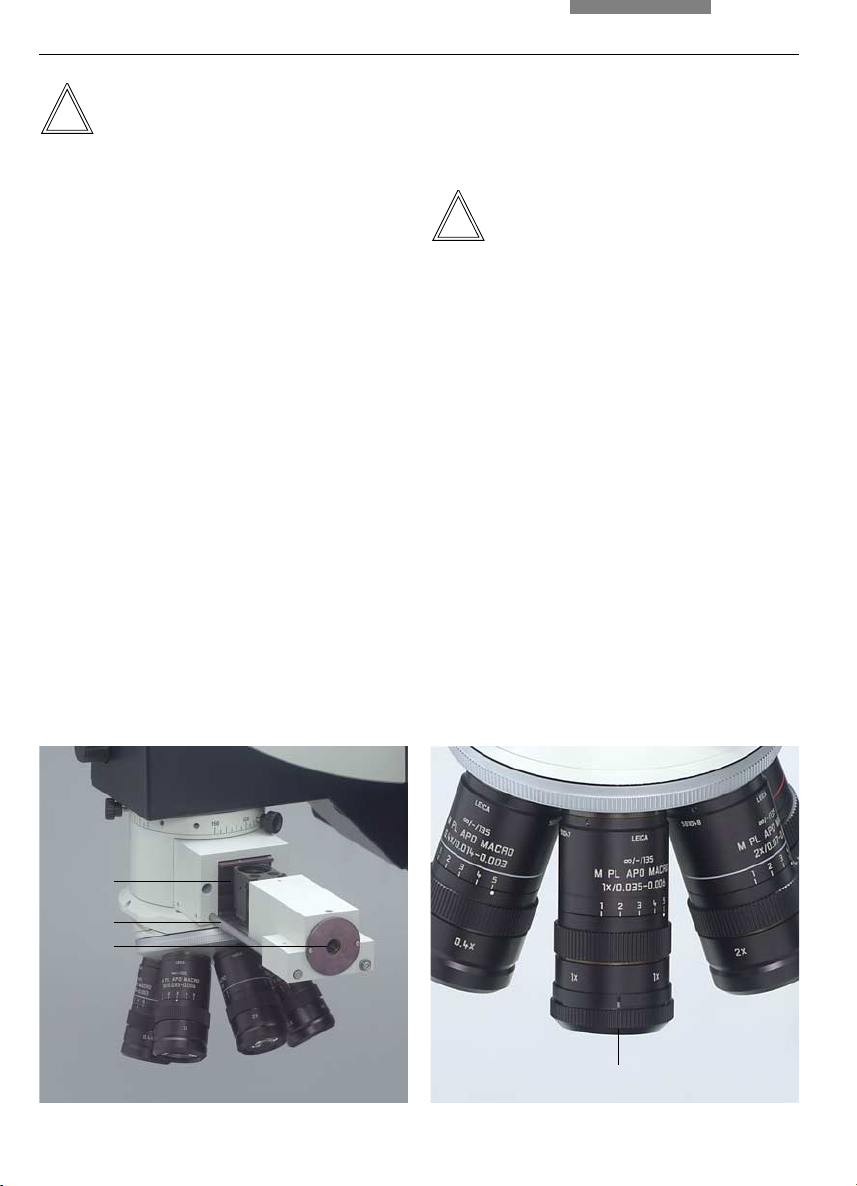

Eye Objective

No. 1 0.4x

No. 2 1x

No. 3 2x

No. 4 4x

Fig. 15 Objective turret from below

Fig. 16 Objective turret with objectives

1 Filter receptacle

18

1

7. Assembly

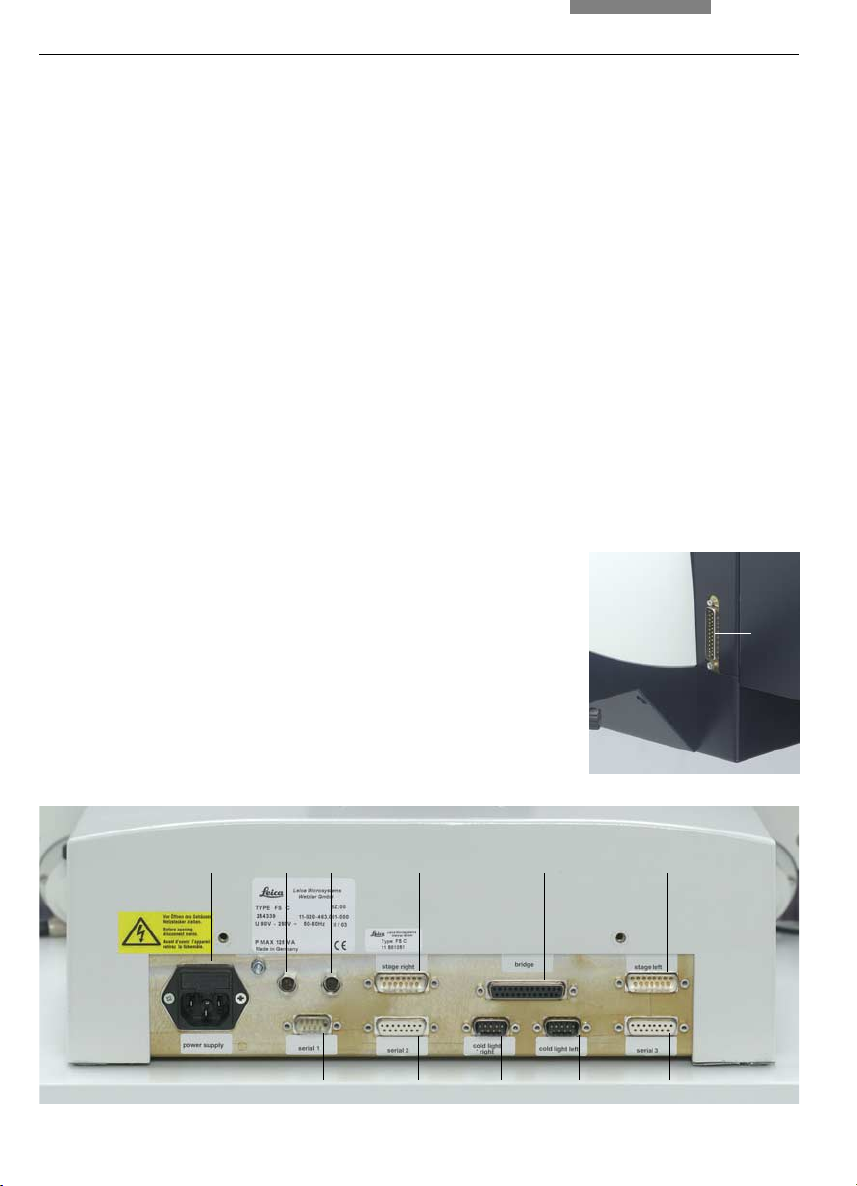

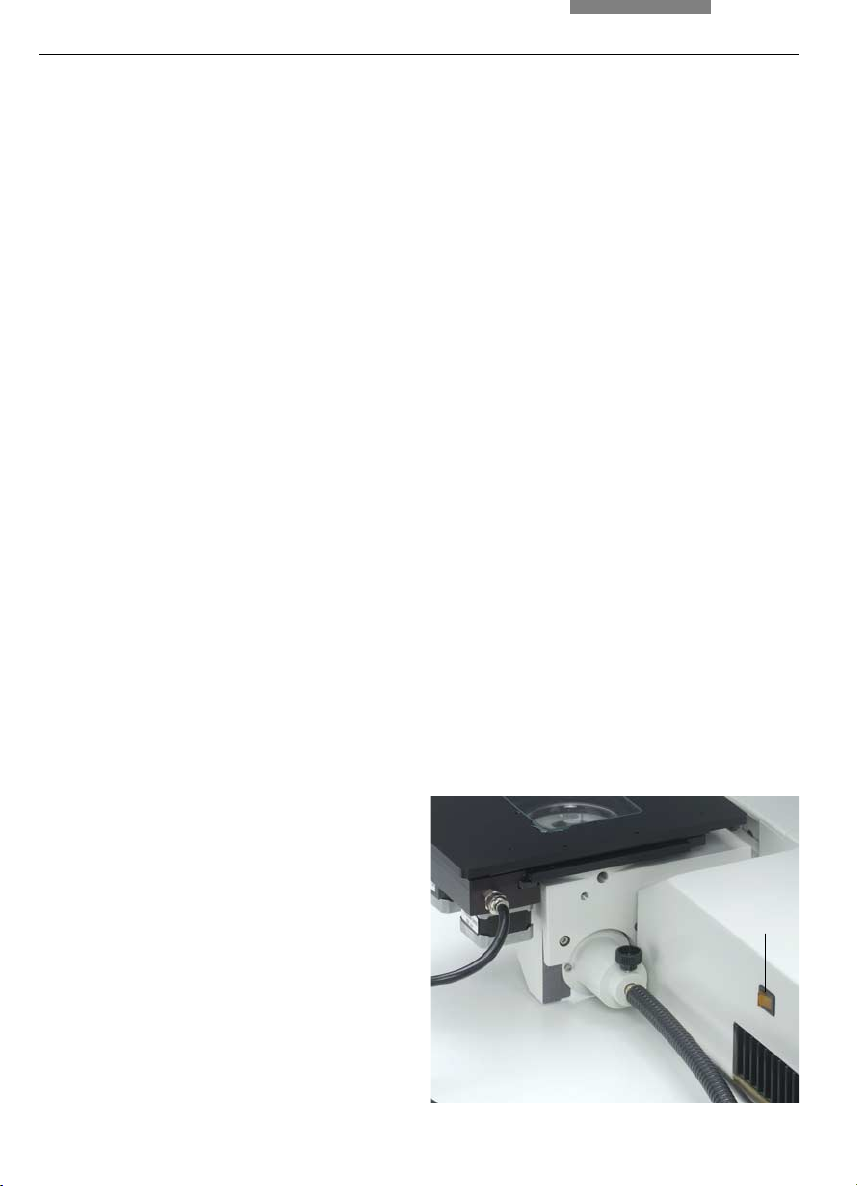

7.5 Cabling

The connector panel is labeled.

• Connect the left and right stage cables to terminals (17.4) and (17.6).

• Terminal (17.5) on the rear of the stand is connected to terminal (18.1) on the rear side of

the comparison bridge. For this purpose, use

the 25-pin bridge cable.

• The remote control cables of the cold light

sources are connected to terminals (17.9) and

(17.10). When using a cold light source, select

the corresponding terminal.

Fig. 17 Stand connector panel

1 Power supply

2 Transmitted light condenser lens, right

3 Transmitted light condenser lens, left

4 Stage, right

5 Comparison bridge

6 Stage, left

7 Serial interface 1 (PC)

8 Serial interface 2

9 Cold light source, right

10 Cold light source, left

11 Serial interface 3 (Smart Move)

• If you have not already done so when installing the transmitted light illuminator, connect

the cables for the transmitted light condenser

to terminal (17.2) and/or (17.3).

• The optional Smart Move control panel is connected to the serial interface 3 (17.11).

• The RS232C interface (17.7) is intended for

connecting a PC.

• Finally, connect the comparison macroscope

and the cold light illuminator to the power

supply using the power cable.

Fig. 18 Rear side

of the comparison bridge

1 Connection

1

123 4 5 6

7891011

19

7. Assembly

• UV illumination:

The UV lamps are rated for a 230 V/50 Hz power supply.

Caution:

If this voltage supply is not available, a pretransformer must be used.

For further details, please refer to the special instructions included with the UV lamps.

Caution:

Wear safety goggles when working with UV

lamps!

20

8. Operation

8. Operation

The Leica FS C Comparison Macroscope offers

the following functions:

• Simultaneous or separate methods for the left

and right stage

• Brightness setting

• Left and right-side focussing

• Left and right-side objective turret

• Height-adjustable stand

Additionally, the comparison bridge contains

•Motorized diaphragms for various imaging

techniques

•A magnification changer

•A magnification calibration with control LED

8.1 Switching on the Macroscope

The switch (19.1) switches on all components integrated into the stand, as well as the cold light

illuminator.

Wait until the initialization of the stages is complete.

Fig. 19 Right stand side

1 On/off switch

1

21

8. Operation

8.2 Stages

The stages on the left and right side can be

moved either independently of each other, or

simultaneously in the X and Y directions.

The right stage is positioned using the setting

wheels on the front right (20.5) in the X direction

and on the right side (20.6) in the Y direction.

For the left stage, the setting wheels are,

respectively, at the front left (20.3) and on the

left side (20.2).

To move both stages simultaneously, press the

button (20.10). The LED underneath the button

lights up to indicate that synchronous adjustment is active. In this case, the setting wheels

for the X and Y directions, as well as the focusing handwheel, have the same function on the

left and right side.

Note:

The travel speed of the stages is adjusted to the

magnification setting. When viewed through the

observation tube, the speed always appears the

same when rotating the setting wheel. In fact,

for lower magnification the stage travels faster.

8.3 Tube

Note:

Close any unused tube openings, as otherwise

stray light can interfere with observation.

Adjusting the viewing distance

• Adjust the viewing distance of the eyepiece

tubes so that a congruent total image is seen.

Fig. 20 Control unit

1 Focus (left stage)

2 Adjust in Y direction (left stage)

3 Adjust in X direction (left stage)

4 Adjusting the height of the stand

5 Adjust in X direction (right stage)

6 Adjust in Y direction (right stage)

7 Focus (right stage)

8 Right cold light source

9 Control LED (right cold light source)

10 Synchronous adjustment in X, Y, Z direction

11 Control LED (left cold light source)

12 Left cold light source

22

12

11 9

37654

1012 8

8. Operation

Adjusting the Angle of Vision

• The viewing angle can be adjusted from 5° to

32° by tilting the binocular eyepiece.

8.4 Eyepieces

Note:

The eyepiece’s aperture protector must be removed during microscopy while wearing eyeglasses, or at least folded back.

Eyeglasses with multifocal lenses (bifocals and

smooth view glasses) must be removed while

operating the macroscope.

Correction for Vision Problems

•With your right eye, look through the right

eyepiece and bring the specimen into sharp

focus.

If both oculars have an adjustable eyelens,

the eyelens of the right ocular can be brought

to the position for normal vision, which is indicated by an encircling line.

When using a graticule in the right eyepiece,

the eyelens must first be focused on the graticule.

• Then, view the same specimen using the left

eye and rotate the eyelens of the left eyepiece until the object appears in sharp focus.

While doing so, do not use the focus dial.

8.5 Brightness Setting

Cold Light Illumination

The control dials (20.8 and 20.12) adjust the first

and (if applicable) the second cold light source.

The function is dependent on the cabling on the

rear side of the stand → page 19.

We recommend using the same cold light

source for both sides based on the illumination

method being used. The second cold light

source should then be used for another illumination method.

Illumination method →

Note:

The LED (20.9) or (20.11) is green if the corresponding lamp is operated in standard mode. If

the LED is red, the bulb life of the lamp is

reduced.

UV Illumination

The UV lamps are equipped with a high-pressure, 180 W quartz radiator and UV filter disks

for a wavelength of 366 nm. They are rated for a

direct 230 V/50 Hz power supply.

For further details →

tions.

8.6 Focusing

page 26ff.

see the special instruc-

You can focus using the handwheels on the left

and right side (20.1 and 20.7).

If the button (20.10) is pressed, i.e. if the synchronous adjustment of the stages is activated,

focusing is also synchronous.

23

8. Operation

Note:

The focus, like the movement of the stages, is

also adjusted to the magnification setting. When

viewed through the observation tube, the speed

always appears the same when rotating the setting wheel.

8.7 Objectives

The desired objectives are swiveled into place

manually.

All objectives have an iris diaphragm. With the

iris diaphragm, the NUM aperture can be adjusted continuously. Five ratchets make it easy to

adjust to identical settings on both sides.

The M macro-objectives can be used for coaxial

incident light. To avoid reflex, ARM caps must

be used in conjunction with the built-in pole filters → page 27ff.

Four diaphragm positions are already predefined and can be selected by pressing the

corresponding button (21.4):

Mix The left and right images are super-

imposed (composite image method).

LR The left and right image appear side-

by-side. A line in the middle of the

field of vision separates the two images (split-image method).

L Only the left image is displayed.

R Only the right image is displayed.

The LEDs below the selector buttons (21.4) are

illuminated if one of the predefined settings has

been selected or set manually. Similarly, the

corresponding LED lights up if the dividing line is

moved.

The dividing line is moved to the left or to the

right by rotating the knob (21.2).

The knob (21.1) is used to change the width of

the dividing line.

8.8 Magnification Changer

Use the button (21.3) to switch the magnification

changer on and off.

When the magnification changer is switched on,

the current magnification of both images is increased by a factor of 1.5x. The LED underneath

the button (21.3) is illuminated.

The magnification changer controls the visual

and photo outputs simultaneously.

8.9 Diaphragm Setting

The motorized diaphragms allow transition from

a superimposed image to the separate view of

the right and left image, as well as the setting of

the dividing line.

24

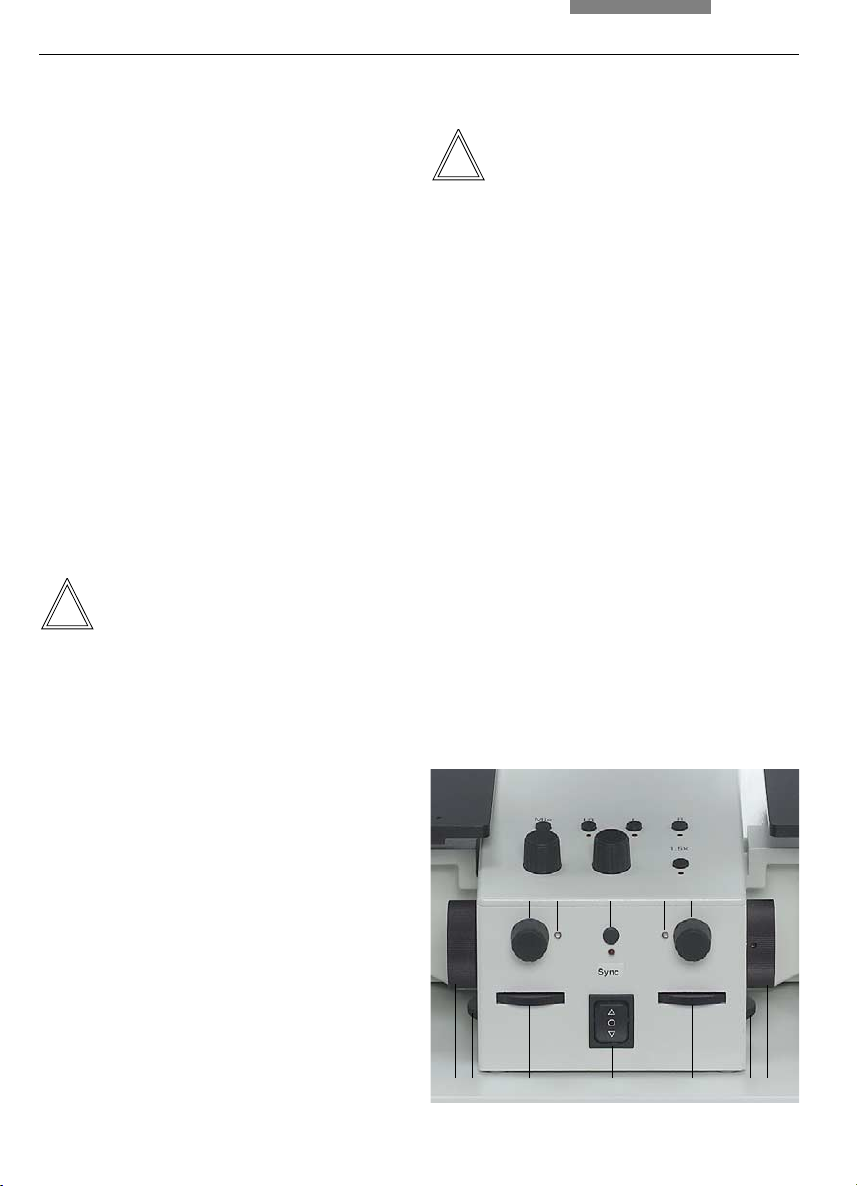

Fig. 21 Control panel

1 Adjusting the width of the dividing line

2 Adjusting the dividing line in x direction

3 Magnification changer on/off

4 Predefined diaphragm settings

5 Adjusting the height of the stand

4

3

21

5

8. Operation

8.10 The Smart Move* Control Panel

Alternatively, you can connect the Smart Move

control panel.

The Smart Move control panel allows control of

the stage (22.1, 22.2), as well as setting the focus

(22.3).

Use the buttons (23.1 and 23.2) to specify whether the settings are to apply to the left or right

stage. The synchronous adjustment is activated

using the buttons (23.3).

Fig. 22 Smart Move control panel

1 Movement in y direction

2 Movement in x direction

3 Focus setting

4 Individual setting of the knob height position

1

8.11 Adjusting the Height of the Stand

The rocker switch (21.5) adjusts the height of the

stand individually. This is provided for aligning

the height of objects or object holders which

vary in height.

8.12 Magnification Calibration

For specialized applications, such as calibrating

thermally modified replicas, the magnification of

the right beam path can be changed in the range

of +/-4% relative to the left beam path.

Use the button (24.1) to make this adjustment. To

prevent the setting from being changed accidentally, the button can only be turned while it is

pressed down.

In neutral position, the LED (24.2) is green, i.e.

magnification calibration is activated. Otherwise, the LED is red.

3

Caution!

2

Fig. 23 Smart Move control panel buttons

1 Left stage

2 Right stage

3 Synchronous stage adjustment

1

3

2

3

The objective magnifications are accurately

4

preset at the factory. It is not necessary to calibrate the magnification calibration for this purpose.

Fig. 24 Magnification calibration

1 Magnification calibration adjusting knob

2 Control LED

21

25

8. Operation

8.13 Oblique Incident Illumination

The light is guided to the incident light object by

the cold light illuminator KL2500 (25.3) and the

double-armed, flexible light guide with 4.5 mm

diameter. Insert the light guide ends into the left

and right receptacles on the special articulated

arm (25.2). If applicable, attach and tighten the

focusing optics (25.1).

The light bundle can be rotated and tilted in every direction. The scales on the movable articulated arms can be used to adjust the illumination

accurately. The cold light source KL2500 is used

for fine adjustment of the light intensity.

It can be adjusted electrically and mechanically.

For electrical light control, the color temperature is changed. For mechanical light control,

the color temperature remains constant.

Fig. 25 Oblique incident illumination

1 Focusing optics

2 Receptacle for light guide with 4.5 mm diameter

3 Cold light illuminator KL 2500

12 3

Note:

The LED (20.9) or (20.11) is green if the corresponding lamp is operated in standard mode. If

the LED is red, the bulb life of the lamp is reduced.

The KL2500 can be controlled using the rotary

knobs (20.8 and 20.12).

Please make sure that the KL2500 is connected

with the included cables on the rear side of the

stand.

The light and shadow effect of the oblique illumination yields very pronounced surface reliefs

of bullet and shell casing traces, toolmarks, as

well as other form, material, and textile texture

traces. For reflection protection, a polarization

filter can be attached to the focusing optics.

8.14 Coaxial Incident Illumination

The coaxial incident illuminator is mounted on

the macroscope carrier. It can be retrofitted at

any time. The light is guided to the incident light

object by the cold light illuminator KL2500 (25.3)

and the double-armed, flexible light guide with

9 mm diameter. Insert the light guide ends into

the left and right receptacles of the coaxial illumination (26.3).

To use the coaxial incident illuminator, it must

be inserted completely. When switching to another illumination method, the coaxial incident

illumination must be pulled out of the beam path

(to the first stop).

26

Note:

If, after installation, point-like objects are appear in the image, the light guide must be pulled

1 to 2 mm out of the coaxial illuminator. The

point-like objects are caused by the fibers of the

light guide.

The specimen is illuminated by the illumination

optics, the reflector and the macro-objectives

1x, 2x and 4x. The 0.4x macro-objective is not intended for the coaxial illumination, because the

object field cannot be illuminated completely.

8. Operation

It can be adjusted electrically and mechanically.

For electrical light control, the color temperature is changed. For mechanical light control,

the color temperature remains constant.

Note:

The LED (20.9) or (20.11) is green if the corresponding lamp is operated in standard mode. If

the LED is red, the bulb life of the lamp is

reduced.

The KL2500 can be controlled using the rotary

knobs (20.8 and 20.12).

The light source is centered and yields a homogenous object field illumination of up to 22

mm field of vision. The cold light source KL2500

is used for fine adjustment of the light intensity.

Fig. 26 Coaxial incident illuminator in assembly position

1 Filter cube inserted

2 Stop rod

3 Receptacles for light guide(s) with 9 mm diameter

1

2

3

Please make sure that the KL2500 is connected

with the included cable on the rear side of the

stand.

For reducing remaining internal reflections, attach the anti-reflex cap (27.1) to the objective

currently being used. Rotate it until ideal image

contrast is achieved. This only works in connec-

Fig. 27

1 Anti-reflex cap

1

27

8. Operation

tion with the reflector with built-in pol filter. For

this purpose, the coaxial illumination unit must

be inserted completely into the beam path.

In particular, traces on smooth, highly reflective

surfaces appear true-to-detail and contrast-rich

using coaxial illumination.

8.15 Transmitted Light Illumination

The transmitted light illuminator is factory preinstalled and must be ordered along with the

stand. It cannot be retrofitted later.

The light is guided to the transparent transmitted light object by the cold light illuminator

KL2500 and the double-armed, flexible light

guide with 9 mm diameter. Insert the light guide

ends into the left and right receptacles of the

transmitted light illumination (28.1).

The specimen is illuminated by the collector

lens, the diffusion filter, the mirror, and condenser system.

The encoded objective turret recognizes the objective currently being used, and the condenser

is automatically adjusted to the current objective magnification.

The light source is centered and yields a

homogeneous object field illumination of up to

55 mm field of vision. The cold light source

KL2500 is used for fine adjustment of the light

intensity.

It can be adjusted electrically and mechanically.

For electrical light control, the color temperature is changed. For mechanical light control,

the color temperature remains constant.

Note:

The LED (20.9) or (20.11) is green if the corresponding lamp is operated in standard mode. If

the LED is red, the bulb life of the lamp is reduced.

The KL2500 can be controlled using the rotary

knobs (20.8 and 20.12).

Please make sure that the KL2500 is connected

with the included cables on the rear side of the

stand.

Likewise, the cable for the condenser lens on

the rear side of the stand must be connected.

Examination with transmitted light illumination is

a valuable tool for detecting evidence of manipulations and forgeries of documents and certificates, as well as for identifying trace evidence

in textile and material textures, foils, adhesive

tape, etc.

Fig. 28 Transmitted light illuminator

1 Receptacle for light guide with 9 mm diameter

28

1

8.16 UV Illumination

The UV lamps are fastened to the comparison

bridge using a special holder (29.1) and are intended for incident illumination of objects with a

large surface area with fluorescent parts (e.g.

documents, currency, securities). They are

equipped with 180W high-pressure quartz radiators and filter cubes for UV light with 366 nm

wavelength.

The UV lamps are rated for a 230 V/50 Hz power

supply.

8. Operation

Caution:

For other voltage supplies, a pre-transformer

must be used!

For further details, please refer to the special instructions included with the UV lamps.

Caution:

Wear safety goggles when working with UV

lamps!

Fig. 29 Assembly of the UV illuminator

1 Holder for UV lamps

2 Rod for fastening a UV lamp

3 UV lamp

2

3

1

29

9. Accessories

9. Accessories

A specially developed work table and correctly

sized work chair allow ergonomically optimized work.

In addition to various optical accessories, such

as filters and stage scales, a number of different

slide holders can be used.

9.1 Motorized Work Table

The work table with motorized height adjustment is designed for optimum ergonomic conditions when working at the comparison macroscope.

Its table surface measures 120 cm x 56 cm and it

is mounted symmetrically on the height-adjustable column.

Fig. 30 Motorized work table

1 Buttons for height adjustment

2 Adjustable-height feet

When setting up the comparison macroscope, make sure that the stand is positioned

exactly over the adjustable-height column.

After the power supply is connected, the work

table can be continuously adjusted within a

range of approx. 62 to 92 cm over floor height.

To do so, use the buttons (30.1).

The lifting speed is approx. 12 mm/sec. The lifting capacity is approx. 2000 N.

Caution:

30

If the floor on which the work table is installed is

not completely level, differences in level can be

compensated for by screwing the feet (30.2) in

or out.

1

2

Loading...

Loading...