Page 1

LEHNER

SuperVario

®

Operating instructions with

replacement parts list

Control unit LAS 3

Software from version 2.5 onwards

Status: April 2012

Serial number: .................................................................

Software version: ...............................................................

Translation of the original operating manual

Page 2

Operating manual

LEHNER Agrar GmbH

Häuslesäcker 5-9

D-89198 Westerstetten

Tel.: +49 7348 959 622

Fax: +49 7348 959 640

www.lehner.eu

info@lehner.eu

It is not permitted for this document to be distributed or reproduced, or for

its content to be utilised and disseminated unless these activities have been

expressly allowed.

Contraventions shall result in an obligation to provide compensation for

damages. All rights reserved with regard to patent claims or submission of

design or utility patents.

2

Page 3

Operating manualTable of contents

Table of contents

1. What you should know .......................................................5

1.1 Foreword .................................................................................... 5

1.2 About this operating manual ....................................................... 5

1.3 Intended use ............................................................................... 6

1.4 Warranty ..................................................................................... 6

1.5 About your safety ....................................................................... 7

2. Commissioning the SuperVario® .......................................8

2.1 Mounting the frame .................................................................... 8

2.2 Electrical connection .................................................................. 8

2.3 Mounting the SuperVario

2.4 Mounting the control panel ....................................................... 10

®....................................................................................................... 9

3. Operating the SuperVario® ...............................................12

3.1 Controls on the control panel ................................................... 12

3.2 The display ...............................................................................13

3.3 Switching on / off ...................................................................... 14

3.4 Setting the speed ..................................................................... 15

3.5 Setting the slide opening .......................................................... 16

3.6 Opening/closing the slide .........................................................16

3.7 Performing the slide reference run ........................................... 16

3.8 Setting the spreading width ...................................................... 17

3.9 Setting the agitator ...................................................................18

3.10 Empty indicator .........................................................................18

3.11 Adapting the empty indicator to the motor output ..................... 19

3

Page 4

Operating manual Table of contents

4. Settings and displays .......................................................21

4.1 Making settings ........................................................................ 21

4.2 Language ................................................................................. 21

4.3 Selecting the empty indicator ...................................................22

4.4 Setting the EHR signal .............................................................22

4.5 Setting the EHR cycle .............................................................. 23

4.6 Setting the empty indicator ....................................................... 23

4.7 Displaying the spreader type .................................................... 24

4.8 Spreader number ..................................................................... 24

4.9 Displaying the motor ................................................................. 24

4.10 Headland manager (optional accessory) .................................. 24

4.11 Checks ..................................................................................... 26

4.12 Spreading width and turning procedure ................................... 26

4.13 Setting the auto-dose (optional accessory) .............................. 28

®

4.14 Operating SuperVario

in automatic mode ...............................30

5. Maintenance and cleaning ...............................................33

5.1 Service ..................................................................................... 33

5.2 Cleaning ................................................................................... 34

6. Appendix ...........................................................................35

6.1 EC Declaration of conformity .................................................... 35

6.2 Identifi cation ............................................................................. 37

6.3 Distribution box reference list ................................................... 38

6.4 Troubleshooting ........................................................................ 39

6.5 Replacement parts ................................................................... 40

6.6 Spreading charts ...................................................................... 42

4

Page 5

Operating manual What you should know

1. What you should know

1.1 Foreword

Congratulations on your decision to purchase this product. We are grateful

that you have placed your trust in us. With the SuperVario®, you have acquired

a high-quality and innovative product.

Thanks to its advanced design, meticulous material selection, state-of-the art

manufacturing techniques and the conscientious work of our employees, this

equipment meets all effi ciency, quality, reliability and value requirements.

Maintaining and servicing in accordance with the operating manual ensures

the safety of the device and maintains the value of your SuperVario

®

.

1.2 About this operating manual

This operating manual forms part of the SuperVario® and must always be

readily available. All persons who work with the SuperVario® must read and

follow the operating manual.

They will learn about the technical details and how to control the machine and

optimise its performance.

Warning notices

Warning notices in this operating manual are identifi ed as follows:

Danger!

Warning of immediate danger. Non-observance of

appropriate measures may result in death and severe

personal injury or serious damage to property.

Warning!

Warning of possible danger. Death, severe personal

injury or serious damage to property are possible.

Caution!

Warning of possible dangerous situations. Slight

personal injury or damage to property are possible.

5

Page 6

Operating manual What you should know

1.3 Intended use

The SuperVario

®

is used exclusively for spreading granules and seeds.

1.4 Warranty

We offer a 24 month warranty on the SuperVario

Caution!

Faulty or incorrectly sized plugs and cables can lead

to malfunctions. Only use original plugs and cables, or

ones approved by the manufacturer.

Any changes to cable or plug connections without factory approval automatically will automatically invalidate the warranty. Motors may not be opened or

dismantled.

Warranty repairs must be coordinated with the manufacturer before any work

is started.

For replacement parts, additional expenses are automatically charged for any

changes made to cables and plugs by the customer. Replacement parts are to

be returned carriage paid.

Rusted bearings are not subject to the manufacturer's warranty.

Prior to assembly:

Check your SuperVario

®

upon receipt for any damage caused in transit. Such

damage must be reported to the manufacturer within 24 hours of receipt.

®

.

6

Page 7

Operating manual What you should know

1.5 About your safety

• Read this operating manual through carefully before use and follow the

instructions. Always keep these instructions at the point of use.

• Observe the accident prevention regulations, safety and operating

regulations and the regulations for environmental protection.

• Observe all applicable standards and guidelines.

• When travelling on public roads and streets, follow the legal rules of the

road.

• Observe the safety instructions.

• Immediately resolve any safety-related defi ciencies.

• Keep out of the spreading zone. Make sure that no other persons enter

in the spreading zone.

• Do not reach into the hopper during operation.

• Follow the safety guidelines on the package insert when spreading

granules.

• Wear protective closing, in particular universal protective gloves, fi lling

with slug pellets or baits. Only fi ll as many pellets or baits as needed in

the short term. Return any remaining product to the original packaging.

Ensure that the product does not enter the environment in an

uncontrolled manner.

• Observe the following points when spreading slug pellets:

The device should only be mounted on the front of carrier vehicles with

a closed cabin.

Windows should remain closed.

Care should be taken that air intake into the cabin is always fi ltered. The

operator must check that the fi lter is working.

• Do not undertake any repairs, maintenance or cleaning procedures on

the SuperVario

• Comply with the regulations of the spreading material manufacturer.

• It is essential to comply with the instructions of the spreading material

manufacturer in question.

• LEHNER Agrar GmbH does not accept any liability for storage and use

of the spreading material.

®

when the mains plug is connected.

7

Page 8

Operating manual Commissioning the SuperVario®

2. Commissioning the SuperVario

®

2.1 Mounting the frame

The SuperVario

used.

Mounting holes have been provided on the back of the frame.

Please refer to the spreading charts for the delivery height (1.00 - 1.30 m).

The SuperVario

vehicle, ATV or soil cultivation implement. Because a full hopper makes the

SuperVario

brackets is to be checked.

®

can be screwed on directly or an auxiliary bracket can be

®

can be attached on the front or rear of a tractor, off-road

®

considerably heavier, the load capacity of side walls and other

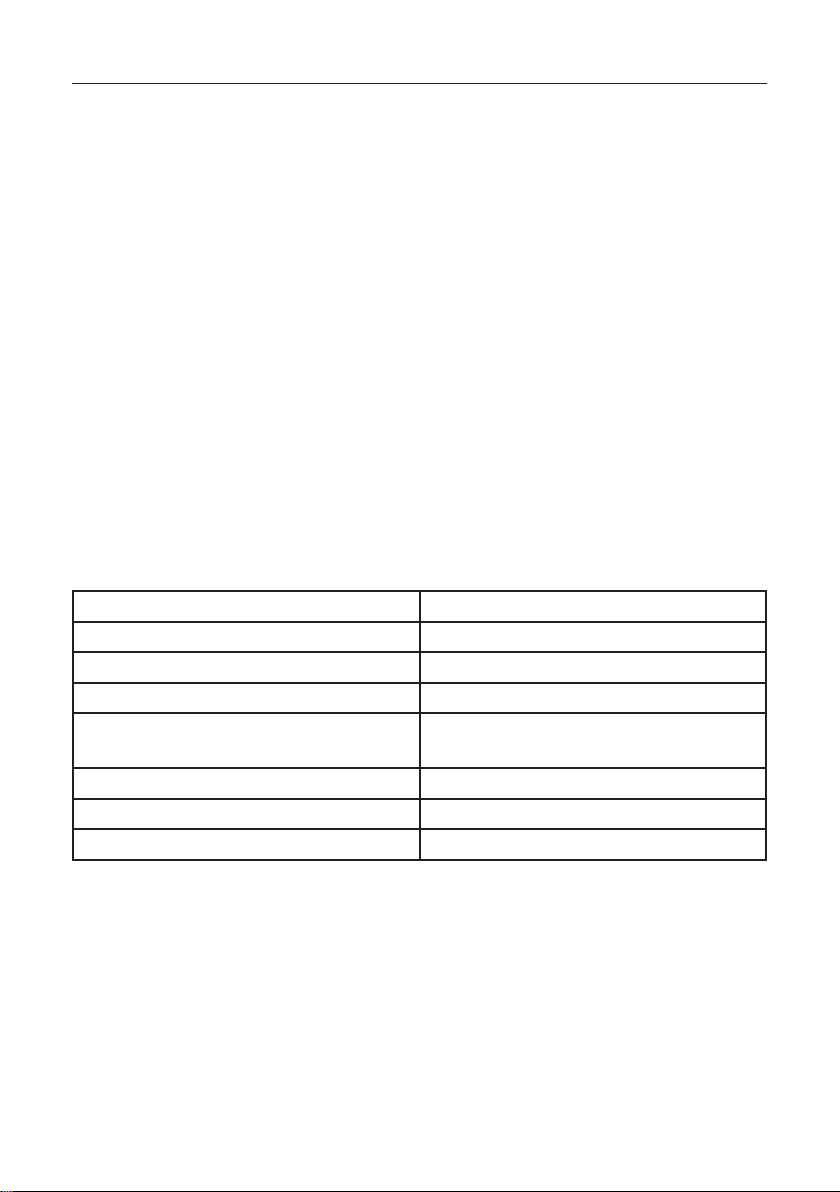

2.2 Electrical connection

Technical data

Operating voltage 12 to 15 V

Fuse 25 A

Motor output 180 W

Speed range 200 to 3000 rpm

Current draw

Bosch motor

Operating temperature -10 to +70 °C

Storage temperature -30 to +70 °C

Weight of SuperVario

®

70/110/170 31.5/33/35 kg

Start up to 25 A, normal operation

up to 18 A

Any changes to cable or plug connections without factory approval will

automatically invalidate the entire warranty. Changes to cables are are

automatically charged in the event of repair.

You must consult with the manufacturer before carrying out any cable

extensions.

Power loss must be taken into account when extending cables. A poor power

supply may prevent you from achieving the desired speed. This could also

lead to intermittent complete failure.

8

Page 9

Operating manual Commissioning the SuperVario®

2.3 Mounting the SuperVario

®

1. Check whether the hopper fi ts well in the hopper platform.

2. Using screws, attach the included baffl e plate (arrow) perpendicular to

the spreader.

3. Check that the SuperVario

®

is securely attached.

9

Page 10

Operating manual Commissioning the SuperVario®

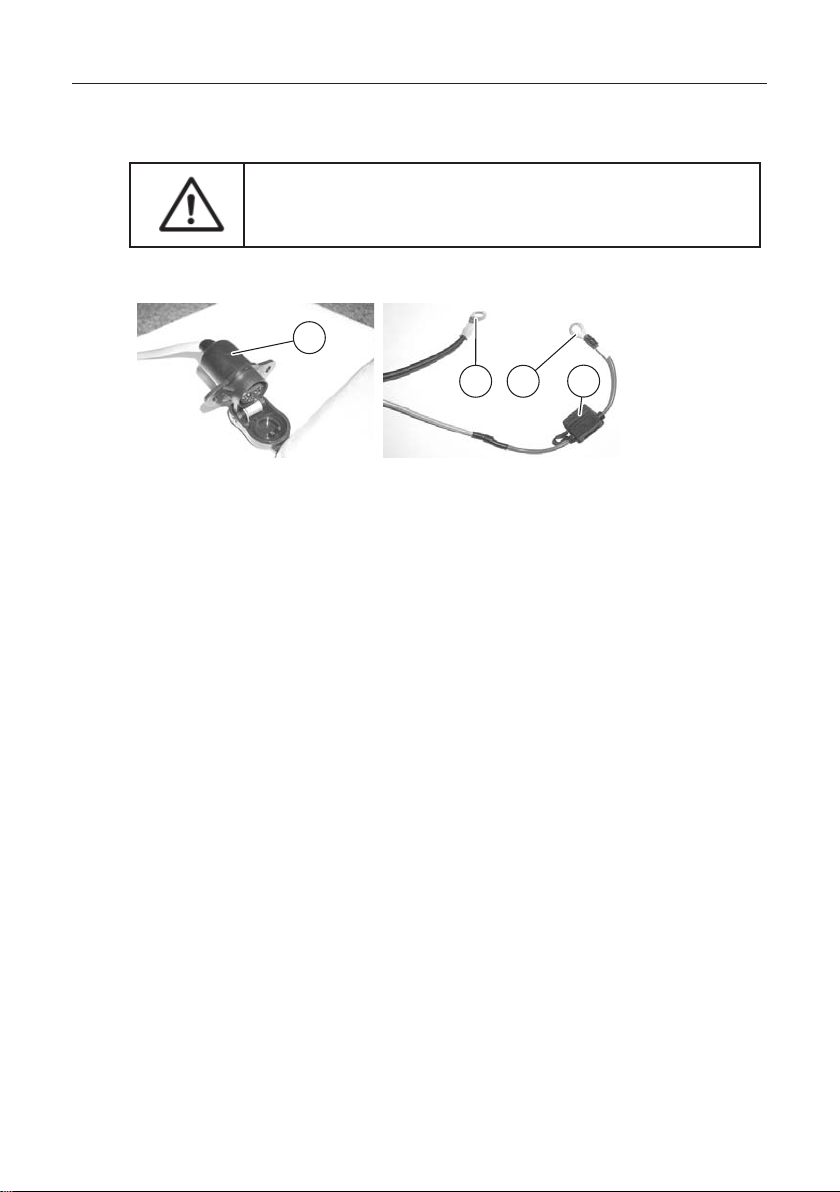

2.4 Mounting the control panel

Caution!

Ensure that the cable is not routed over any sharp

edges.

1

2 3

1. Mount the support for the control panel in the vehicle cabin.

2. Always use the supplied battery cable even if there is a socket, because

our battery cable is 4 mm².

Connect connection 2 to the negative terminal of the battery (not to

the bodywork).

Connect connection 3 (with fuse 4) to the positive terminal of the

battery. Place the cable end with socket into the carrier vehicle.

3. Plug the spreader cable into the 16-pin socket of the control panel.

Your device is now ready to operate.

4

10

Page 11

Operating manual Operating the SuperVario®

3. Operating the SuperVario

3.1 Controls on the control panel

®

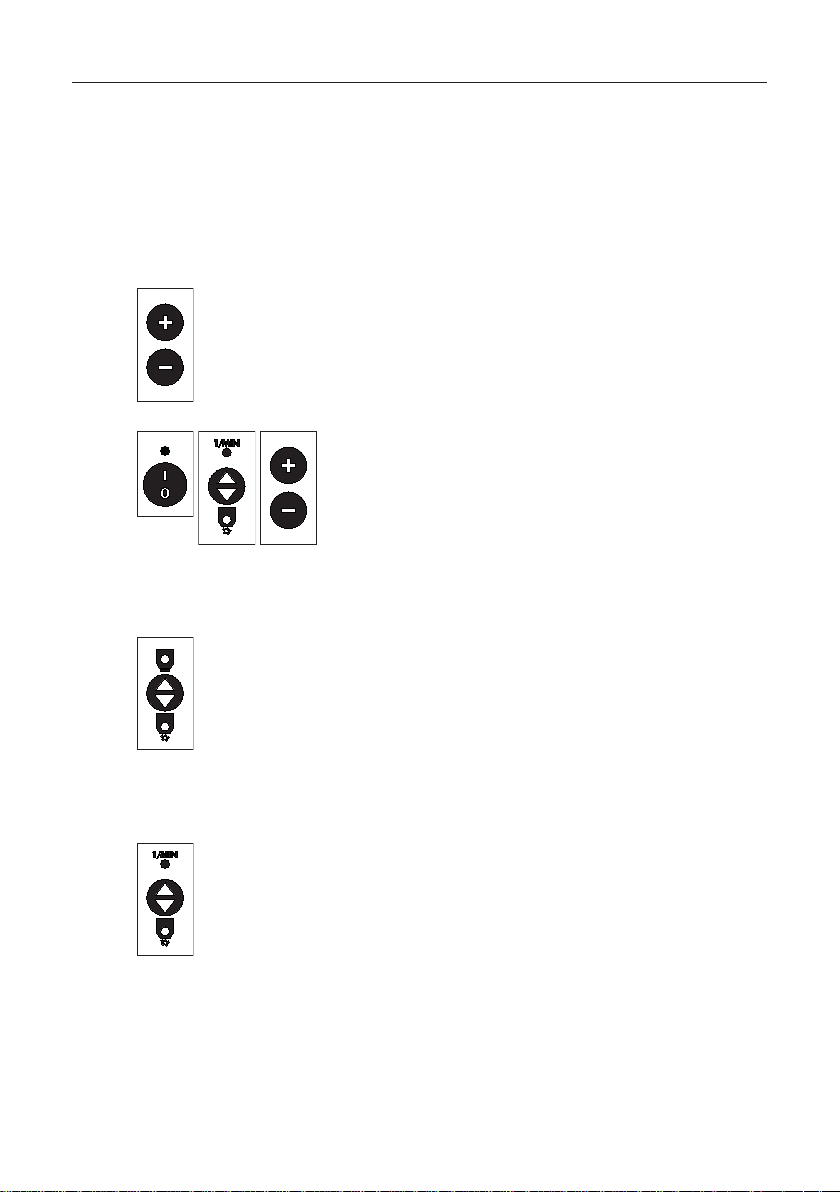

1. On/off switch

2. Display

3. Open and close slide

Slide open: green LED lights up

Slide closed: yellow LED lights up

4. Empty indicator

5. Switch to change between speed and slide

6. Adjusting the speed or slide

7. Preparation of headland manager (VGM)

12

Page 12

3.2 The display

1 2

1. Arrow denotes the active line

2. Spreading disc speed

3. OK symbol for open slide

4. Slide opening

Disc blockage

Slide not open

Operating manual Operating the SuperVario®

34

Error messages, see also chapter "6.4 Troubleshooting" on page 39.

13

Page 13

Operating manual Operating the SuperVario®

3.3 Switching on / off

Danger!

The drive motor starts immediately when switching

on. Make sure that no-one is in the danger area when

switching on.

Press the button.

The spreading disc speed and slide

opening are displayed. The slide is

> RPM 200

Slide 29

always closed when switching on the

drive motor.

If this message is displayed, a cable is damaged

or a plug disconnected.

> RPM 200

Spr. connection

Low temperatures can cause the empty indicator to respond slowly.

Checking the setting:

1. Allow the spreader to run for about 1 minute with the slide closed.

2. If the slide is now opened, the empty indicator must respond after about

5 seconds.

3. If this is not the case, adjust the empty indicator by 5% in the negative

range, see chapter "4.6 Setting the empty indicator" on page 23.

Autostart

If the motor is diffi cult to start due to heavy loads, start the motor up to

10 times in alternating motor directions. If the agitator does not break free

as a result, the motor is automatically switched off. The following message

is shown in the display: Disc blockage.

14

Danger!

Never open the hopper and never touch the spreading

disc when the drive motor is running.

Switch off the drive motor and make sure that the motor

has stopped before you open the hopper or touch the

spreading disc.

Page 14

Clearing the blockage:

1. Switch off the motor.

2. Manually turn the spreading disc or empty the hopper.

3.4 Setting the speed

Operating manual Operating the SuperVario®

Press the button if necessary to select

the speed,

the arrow points to the fi rst line in the

> RPM 200

Slide 29

display.

Press the + or - button to set the speed.

The speed can be infi nitely varied from 200 - 3000 rpm.

Refer to the spreading charts for the required speed.

The display shows the set speed for 10 seconds; only then

is the actual speed displayed.

15

Page 15

Operating manual Operating the SuperVario®

3.5 Setting the slide opening

If necessary, press the button to select

the slide; the arrow points to the second

line in the display.

Press the + or - button to set the slide

opening.

Refer to the spreading charts for the

required slide opening.

Speed 200

> Slide 29

3.6 Opening/closing the slide

Press the button to open or close the

slide.

Slide open: green LED lights up

Slide closed: yellow LED lights up

> RPM 200

Slide 29 ok

Slide monitoring

If the slide does not reach the specifi ed position within 10 seconds, the

spreader switches off.

The following message is shown in the display:

Slide not open or Slide not closed. 5 warning signals also sound.

For troubleshooting, see chapter "6.4 Troubleshooting" on page 39.

3.7 Performing the slide reference run

The slide motor and control panel are adjusted to one another at the factory.

The setting can be lost over time or when replacing the control panel.

16

Page 16

Operating manual Operating the SuperVario®

Switch off the machine.

Press and hold the button for switching

between speed and slide and the + button to

The slide performs its reference run.

The display shows the upper value as approx. 240 and the lower value as

approx. 40. Switch machine off at the main switch so that the values are

stored. If a slide reference run cannot be performed, the following message

fl ashes on the display: Slide not calib.

Check the mechanical clearance of the slide and attempt the reference run

again.

switch the machine on.

Keep all three buttons pressed for

about 3 seconds.

3.8 Setting the spreading width

The spreading width depends on the nature of the spreading material and

the speed of the spreading disc. The more coarse the spreading material, the

larger the possible spreading width.

1. Set the speed according to the spreading chart.

2. Set the casting shovels according to the spreading chart.

17

Page 17

Operating manual Operating the SuperVario®

3.9 Setting the agitator

Because grasses, in contrast to seeds with a grain structure, have very poor

fl ow properties, the agitator must be adjusted accordingly.

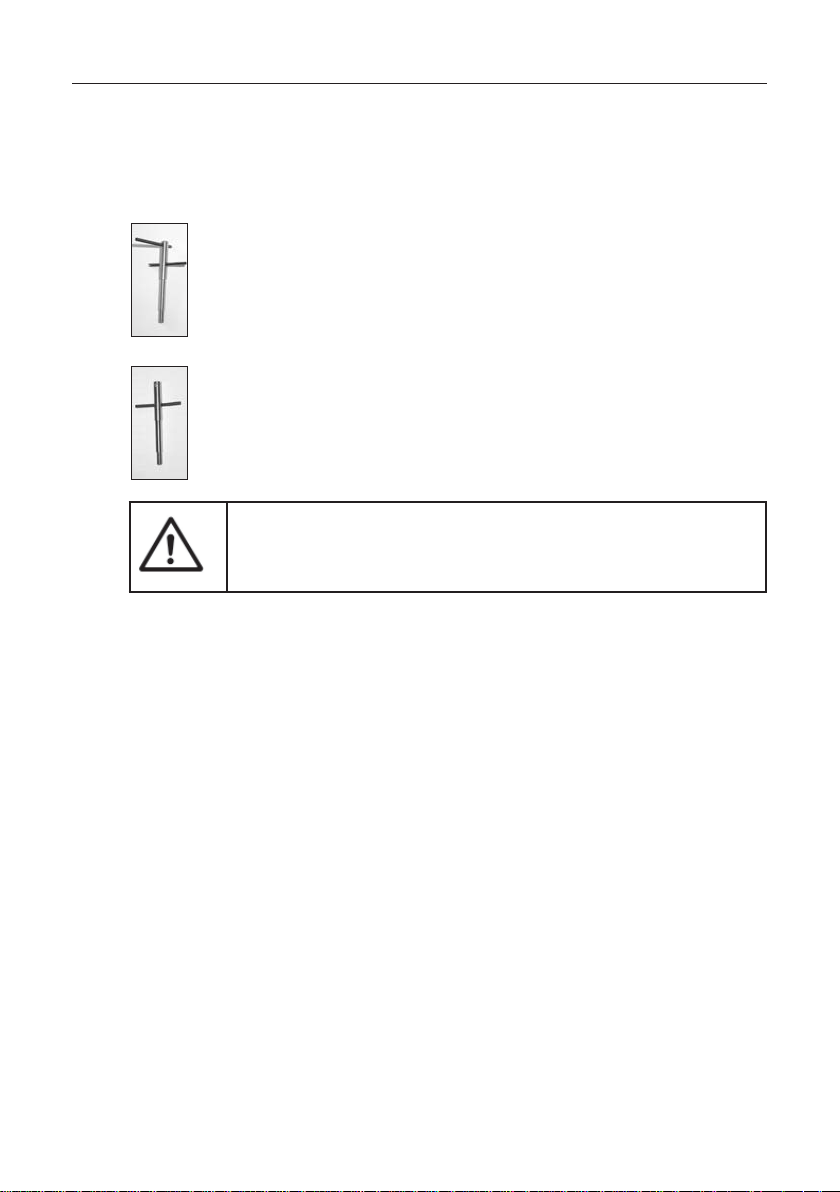

Setting for grasses:

Upper stirring shaft on one side

Lower stirring shaft at a ratio of 2/3 t 1/3

Setting for remaining products:

Upper stirring shaft removed

Lower stirring shaft at a ratio of 1 to 1

Danger!

Do not adjust the stirring shafts if the agitator is installed,

which otherwise could lead to bearing failure on the motor.

1. Remove the hopper.

2. Firmly hold the spreading disc and loosen the agitator by turning to the

right.

Important: Left-hand thread!

3. Install the stirring shaft appropriately.

3.10 Empty indicator

The empty indicator shows when the spreading material in the hopper drops

below a particular fi ll level.

The "Hopper empty" message fl ashes for about 5 seconds on the display.

At the same time, 8 warning signals sound and the red LED on the empty

indicator fl ashes.

To switch off the empty indicator again, briefl y close the slide or switch off the

spreader.

18

Page 18

Operating manual Operating the SuperVario®

3.11 Adapting the empty indicator to the motor output

Note:

Only make adjustments if the empty indicator setting was unsuccessful, see

"4.6 Setting the empty indicator" on page 23.

Empty the hopper.

Then, in the main menu, use the + and - buttons to set the

empty indicator to zero.

Press and hold down the button for switching

between speed and slide and the - button to

switch the machine on.

Set the spreading disc motor to 2400 rpm.

Keep the Open/close button pressed for about 5

seconds.

The display now changes to the Bosch disc motor (TLB).

Press the button for changing between speed

and slide (1x). The display shows the actual idling

speed output (LL) and idling speed output table

(LLT) values.

Press the - button 1x to reset the stored values.

Press the + button 1x to transfer the LL value to the

LLT.

This means the empty indicator has been

readjusted.

19

Page 19

Operating manual Operating the SuperVario®

Press the + button to confi rm; the actual idling

speed output (LL) is transferred to the idling speed

output table (LLT) in three numbers.

This means the empty indicator has been

readjusted.

20

Page 20

Operating manual Settings and displays

4. Settings and displays

The control element can be used to make the following settings:

Language

Empty indicator selection

EHR signal

EHR cycle

Empty indicator setting

Spreader type

Spreader number

Motor selection

4.1 Making settings

Switch off the machine.

4.2 Language

Press the + and - buttons at the

same time and hold them until

the machine switches on.

Keep all three buttons pressed

for about 3 seconds.

The language selection is

displayed.

Press the + or - button to set the

language.

Press toggle switch: Setting saved,

next menu item or press main switch:

Setting saved and machine switches

off.

Language 0

English

Language 0

English

21

Page 21

Operating manual Settings and displays

4.3 Selecting the empty indicator

Press the + or - button to select the

empty indicator.

From spreading disc resistance

Empty indicator 1

One disc

via agitator motor with soft agitator

and external empty indicator - not

programmed or empty indicator

switched off.

Press toggle switch: Setting saved,

next menu item or press main switch:

Setting saved and machine switched

off.

4.4 Setting the EHR signal

When the spreader is equipped with the headland manager accessory, the

hydraulic signal of the tractor can be detected. This signal is output when

lifting or lowering.

The spreader factory setting is for the signal to be output when lifting. If the

tractor outputs the signal when lowering, you can adjust the spreader.

Press the + or - button to set the

EHR signal.

EHR signal for lifting:

EHR signal 0

High active

22

High active is displayed.

EHR signal for lowering: Low active

is displayed.

Press toggle switch: Setting saved,

next menu item or press main switch:

Setting saved and machine switches

off.

Page 22

Operating manual Settings and displays

4.5 Setting the EHR cycle

In the headland manager (optional accessory), you can set how often the slide

should open and close depending on the lifting and lowering of the hydraulics.

The EHR cycle can be set to max. 10 times.

4.6 Setting the empty indicator

Depending on the requirement and spreading material, the empty indicator

can be set to respond earlier or later.

Each of the values can be set between -50 and +50.

Note:

Depending on the spreading material or material humidity, the remainder level

may vary somewhat.

Press the + or - button to set the

corresponding value.

Factory setting is 0.

+ values: Switching on and off if the fi ll

level is relatively high.

- values: Switching on and off if the fi ll

level is relatively low.

Press toggle switch: Setting saved,

next menu item or press main switch:

Setting saved and machine switches

off.

Setting 0

Empty indicator ON

23

Page 23

Operating manual Settings and displays

4.7 Displaying the spreader type

The control unit is intended for a variety of spreaders.

The SuperVario

can be operated with this control panel.

®

is programmed at the factory. Various LEHNER spreaders

Press toggle switch: Setting saved,

next menu item or press main switch:

Setting saved and machine switches

Spreader type 0

SuperVario

off.

4.8 Spreader number

This option is only activated in the duo control unit (optional accessory).

4.9 Displaying the motor

The SuperVario

The control unit is programmed at the factory and adjusted to the installed

motor. Thi setting cannot be changed.

®

can be equipped with 2 different drive motors.

4.10 Headland manager (optional accessory)

If the headland manager is connected, an * is

displayed at the end of the second line.

The headland manager automatically opens the slide when the hydraulics are

lowered, and automatically closes it when the hydraulics are lifted.

Speed 200*

Slide 29

The slide can be opened and closed manually at any time using the control

panel.

When starting work with the headland manager, the slide must fi rst be

opened manually.

The signal can be detected by a 7-pin socket or a sensor signal.

24

Page 24

Operating manual Settings and displays

7-pin socket

1. Connect the connecting cable of the control panel to the 7-pin signal

socket of the tractor.

2. Set the EHR signal of the spreader depending on whether the tractor

emits the hydraulic signal when lifting or lowering.

Sensor signal

1

1

1. Mount the sensor in the joint section of the lower link.

2. Mount the magnetic encoder to the lower link.

3. Set the position of the sensor and the magnetic encoder.

Maximum distance 10 mm.

Hydraulics lowered:

Sensor not in fi eld of magnetic encoder.

Hydraulics at the height where the slide should close or open:

Sensor just reaches fi eld of magnetic encoder.

Hydraulics lifted:

Sensor must still be in fi eld of magnetic encoder.

When the hydraulics are lifted, the sensor must not leave the fi eld of

the magnetic encoder, as otherwise the slide will open again.

Please note that the contact surfaces 1 of the sensor are only located on the

left and right sides.

25

Page 25

Operating manual Settings and displays

4.11 Checks

Voltage check

In order to check the operating voltage (in V), the spreader must be on and the

hopper fi lled.

Press the button for 5 seconds.

The operating voltage is displayed for

8 seconds.

Factory recommendation min. 12.6 V.

Performance check

The motor is adjusted at the factory. No changes are permitted, since otherwise

the drive and control parameters would no longer match.

To check the performance data, the spreader must be on.

V oltage 14.0 V

Keep the button pressed.

The following information is displayed:

TLB 23.4W 201

91R 3.4V 6.9A

Line 1: Current drive motor,

power consumption in watts and

precise speed.

Line 2: R value for factory-internal

data, the motor voltage in volts, the

current consumption of the motor in

ampere.

4.12 Spreading width and turning procedure

Reference values for the spreading widths of individual spreading materials

can be found in the attached spreading charts.

If you turn the spreader, please note that spreading material continues to

roll on fi rm surfaces, while on the fi eld it falls directly into the surface soil.

In addition, the fl ow quantities differ from the testing values due to different

vibrations during fi eld use.

26

Page 26

Operating manual Settings and displays

Turning

1. Put the spreader in the box or put the box over the spreader to catch

the spreading material.

2. Set the speed of the spreading disc, the speed must be the speed used

in practice, due to the suction effect.

3. Weigh out the ejected spreading material at various slide positions until

the suitable slide position is determined.

Determining the spreading width

1. Spread on a fi rm surface.

2. Sweep up and weigh the spreading material.

Formulae

Output rate in kg/min x 600

= Speed in km/h

Output amount in kg/ha x spreading width in m

Output rate in kg/min x 600

Speed in km/h x spreading width in m

Output amount in kg/ha x speed in km/h x spreading width in m

600

= Output amount in kg/ha

= Output rate in kg/min

27

Page 27

Operating manual Settings and displays

4.13 Setting the auto-dose (optional accessory)

AUTO

Press the buttons.

The speed of the spreading disc and

the slide opening are displayed.

> Speed 200

Slide 29

The slide is always closed when

switching on the drive motor.

Press the button.

The spreading material, the spreading width and the output

kg/ha are displayed.

Press the button, the spreading material designation

"fl ashes".

Press the + or - button to change spreading material (e.g.

from yellow mustard to Metarex).

While the 7-pin plug or GPS receiver are not plugged in, the

full spreading material name is displayed.

Press the button to confi rm the choice of spreading material.

28

Spreading width "fl ashes".

Press the + or - button to set the spreading width.

Page 28

Operating manual Settings and displays

Press the button to confi rm the choice of spreading width.

Output kg/ha "fl ashes".

Press the + or - button to set the output amount.

Press the button to confi rm the output kg/ha.

The control panel is programmed for automatic operation.

The set spreading material, the spreading width and the

output kg/ha are displayed.

AUTO

Hold the button down for at least 5 sec.

The quantity adaptation is displayed in %.

Here, you can change the output amount yourself if you fi nd

there is too much or too little.

Press the button.

Speed impulse - - - 1/m is displayed.

Press the + or - button to set the impulses per metre that are

emitted by the tractor (further information can be found in

the tractor's operating manual).

29

Page 29

Operating manual Settings and displays

Press the button.

The quantity adaptation is displayed in %.

AUTO

The set spreading material, the spreading width and the

output kg/ha are displayed.

The speed impulses per metre are set.

The control unit is ready to start.

In GPS mode, no impulse setting is required.

The spreading value stored in the spreading chart can be changed

temporarily.

Set the quantity adaptation.

Press the button.

AUTO

Press the button for around 5

seconds.

Quantity adaptation

0%

Press the + button to increase the

spreading value by up to 50%

Press the - button to decrease the

spreading value by up to 50%

AUTO

Press the button to return to operating

mode.

Press the button.

AUTO

The quantity adaptation has been stored. The quantity

adaptation remains stored until the spreading material is

switched or changed in the display.

4.14 Operating SuperVario® in automatic mode

Connect the speed signal (GPS receiver or 7-pin signal socket).

The stored table value continues to appear in the display. The quantity

adaptation in % is executed automatically from the control panel.

30

Page 30

Operating manual Settings and displays

AUTO

Press the button.

The speed of the 'spreading disc and

the slide opening ar displayed.

> Speed 200

Slide 29

The slide is always closed when

switching on the drive motor.

Press the button.

The set spreading material, the spreading width and the

output kg/ha are displayed.

If a speed signal is connected, the speed travelled at is also

displayed along with the spreading material.

Press the button to open the slide.

With the vehicle stationary, set off within 5 seconds,

otherwise the message "Slide not open" appears.

If the slide is open, the message

"Open" and the relevant slide opening,

e.g. "Open 46" appear; the speed

OPEN 46 5.9km/h

15.0 m 25.0 kg/ha

travelled at is also displayed.

If the speed travelled at is higher than

the value stored in the spreading

chart in the control unit, the message

"Too fast" appears in the display.

Only the maximum speed stored in

the spreading chart is included in the

calculation, not the speed actually

being travelled at.

OPEN 120 33.2km/h

T oo fast

31

Page 31

Operating manual Settings and displays

If the speed travelled at is lower than

the value stored in the spreading

chart in the control unit, the message

Yellow mustard 2 km

T oo slow

"Too slow" appears in the display.

The minimum speed stored in the

spreading chart is included in the

calculation, not the speed actually

being travelled at.

At a travel speed of less than 3 km/h,

the software does not work and the

message "Slide not open" appears.

Slide not open

Once the vehicle stops and sets off

again, the button "Slide open" must be

pressed again to make the slide open.

When working with the headland

manager (VGM), this operation is not

required.

At the present time, our spreading charts are designed for

a maximum speed of 44 km/h, depending on the spreading

material. At speeds faster than 44 km/h, the error message

"Too fast" appears, depending on the spreading material.

32

Note

A total of 12 spreading charts can be stored in the control

panel. This setting can only be made at the factory.

Spreading charts can of course be exchanged

(see section "6.6 Spreading charts" on page 42).

Page 32

Operating manual Maintenance and cleaning

5. Maintenance and cleaning

5.1 Service

The dosing device and slide should be inspected and cleaned from time to

time.

In particular, spreading material with a high dust content can cause the slide

unit to clog.

3

3

1. Remove screws 1 on the right and left.

2. Remove the hopper 2.

3. Remove screws 3.

4. Remove the cover plate 6.

5. Firmly hold the spreading disc and loosen the agitator 5 by turning to

the right.

Important: Left-hand thread!

6. Remove nuts 4.

7. Dismantle the hopper platform and pull the dosage slide out from the top.

8. Clean the slide unit with a broom or compressed air.

For corrosive spreading material such as silage, regularly remove and clean

the motor, and fi ll the shaft end with grease or copper compound.

33

Page 33

Operating manual Maintenance and cleaning

5.2 Cleaning

The hopper can be almost completely emptied by means of the residue

discharge.

1. Unscrew the hopper.

2. Clean spreader and hopper with a broom.

34

Page 34

6. Appendix

6.1 EC Declaration of conformity

EC Declaration of conformity

in accordance with the EC Machinery Directive 2006/42/EC, app. II,

Manufacturer:

LEHNER Agrar GmbH

Häuslesäcker 5-9

89198 Westerstetten

Person resident in the Community who is entitled to assemble the

relevant technical documents:

Jürgen Beck-Graf

LEHNER Agrar GmbH

Häuslesäcker 5-9

89198 Westerstetten

Description and identifi cation of the machine:

®

Product: SuperVario

Type: 70/110/170

Function: The SuperVario

seeds for grasses and intermediate crops such as mustard, phacelia,

fodder radish and turnip rape. It is produced in three sizes. These differ

in the hopper capacity; 70, 110 and 170 litres. There is a stirring shaft on

the spreading disc that projects into the hopper. This keeps the spreading

material mobile in the area of the application opening. The application

rate and the rotation speed of the spreading disc are infi nitely variably

controlled from the operator's cabin via the control panel. Optionally, a

separate motor drives a slowly rotating agitator which can

be installed horizontally (soft agitator).

®

is a spreader for spreading slug pellets and

Operating manual Appendix

1.A

35

Page 35

Operating manual Appendix

It is expressly declared that the machine is in accordance with all

relevant provisions of the following EC Directives:

2006/42/EC

2004/108/EC

Source of the harmonised standard applied acc. to Article 7, para. 2:

EN ISO 12100-2:2003-11

EN ISO 14121-1:2007

EN 50498:2010

EN ISO 14982:2009

Source of the other technical standards and specifi cations applied:

EN ISO 12100-1:2003-11 Safety of Machinery – Basic concepts;

EC Machinery Directive 2006/42/EC

(Electromagnetic Compatibility) Directive

2004/108/EC of the European Parliament

and Council dated 15

December 2004 on the harmonisation of

legal regulations in the member states

regarding electromagnetic compatibility

and replacing Directive 89/336/EEC

Safety of Machinery – Basic concepts;

general principles for design – Part 2

Technical principles

Safety of Machinery – Risk assessment –

Part 1: Principles (ISO14121-1:2007)

Electromagnetic compatibility - Product

family standard for electronic

equipment subsequently installed in

vehicles

Electromagnetic compatibility - Agricultural

and forestry machinery

general principles for design – Part 1:

Basic terminology, methodology

36

Westerstetten, 12.04.2009

Place, date

Signature

Helmut Lehner

CEO

Page 36

6.2 Identifi cation

The serial number of the spreader is

applied to the rear of the frame.

Note the serial number in this operating

manual so that it is readily available for

inquiries.

Operating manual Appendix

The hardware and software versions are

briefl y displayed when the control panel

is switched on.

Note the software version in this

operating manual so that it is readily

available for inquiries.

LEHNER GmbH

LAS3 V2.5

SuperVario

37

Page 37

Operating manual Appendix

6.3 Distribution box reference list

38

Page 38

6.4 Troubleshooting

r

Operating manual Appendix

Status: 04/2012

Dismantle upper stirring shaft

Upper stirring shaft installed / power supply Place lower stirring shaft in centre

Check the agitator, check the stirring shaft, see the "Setting the agitator" chapter

Check the electrical power supply, see the "Mounting the control panel" chapte

Clean the slide, see the "Cleaning" chapter

Very strong vibrations and resulting settling Order and install "load relief roof" accessory

of the material

Foreign bodies in the agitator, load too great or

power supply too weak

Spreading material or dirt is jammed between the slide plates

Check slide for contamination, or perform reference

Check the agitator, check the stirring shaft, see the "Setting the agitator" chapter

Material may be excessively compacted Possibly restart spreader

See the "Performing the slide reference run" chapter

run; see Slide reference run,

Cable not plugged in, motor defective

Adjust the empty indicator, see chapter "4.6 Adjusting the empty indicator" on page 23.

If this does not resolve the problem, please carry out the procedure described in point

"3.11 Adapting the empty indicator to the motor output" on page 19.

Control panel plug not connected to spreader Check plug connections, cables, socket and pins

or cable damage/voltage dip

Check plug connections, cables, socket and pins.

Distance from sensor to magnetic encoder too great Check the left/right distance from the sensor, max. 10 mm

connected to the slide motor.

Troubleshooting LEHNER SuperVario®

Problem Cause Resolution

Nothing appears on the display after switching on Polarity reversed or fuse has blown Check connections and fuses

The following information should help you resolve minor problems yourself. You are welcome to call us as needed. We are glad to help.

Spreading disc does not reach set speed

Agitator does not turn over Foreign bodies in the agitator Empty hopper and check for foreign bodies

Slide jams

Display shows: Slide not open Slide could not reach correct position when opening

Display shows: Slide not closed Slide could not reach correct position when closing Check slide mechanism for foreign bodies or perform the reference run

Slide does not open although no error Mechanical damage to slide mechanism Check slide motor and transfer mechanism

Display shows: Disc blockage Spreading disc does not turn; switches off after 10 attempts

message is displayed.

Display shows: Spr. Connection

Empty indicator does not respond Empty indicator is set too low

Headland manager closes the slide when draining Signal incorrectly applied Rotate the signal, see the "Setting the EHR signal" chapter

the hydraulics and opens when lifting

Display shows 8888 or letters Control panel fault Control panel must be replaced

Headland manager does not always close

Slide fault Plug from control panel not connected to spreader. Plug not

39

Page 39

Operating manual Appendix

6.5 Replacement parts

40

Page 40

A

r

A

c

A

c

c

r

t

Status 04/2012

Operating manual Appendix

Designation Quantity

Steel frame

1

Dosage slide, bottom "white"

2

U disc

3

djusting washe

4

Slide

5

Double spherical bearings with ball stud

6

Slide motor

7

Fixing bracket for slide motor

8

Dosage slide, top in V

9

Hopper platform

10

Hopper seal

11

Hopper bracket

12

Star-knob screw M8x14 mm

13

Bosch drive motor

14

Motor mounts

15

Hexagon socket set screw

16

Spreading dis

17

Casting shovel

18

Stirring shaft

19

gitator with left-hand thread

20

Sealing dis

21

Stabilisation dis

22

Edge guard without padding

23

Edge guard with padding

24

Cover plate

25

Edge guard with padding for hoppe

26

Discharge cover

27

Hopper 70 / 110 / 170 litres

28

Sealing cap

29

Star grip nut M6

30

Base plate

31

Baffle plate

32

Battery cable with bracke

33

Cable set 6 m (no diagram)

34

Control panel (no diagram)

35

Operating manual with spreading charts

36

LEHNER

1 80356

1 80281

3

1

1

1

1

1

1

1

1

1

4

1

3

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

Article no.

-

80234

73213

80379

81393

81394

80265

81395

80342

73214

80177

-

80472

81396

80376

73215

80268

-

81397

80393

81075 / 81076 / 81077

80107

73216

80606

81398

72154

80658

80645

80174

41

Page 41

Operating manual Appendix

1820221921252124272227

t

8

k

/h

2629332730383035423141

20

kg/ha

2629332730383035423141

600 RPM

980 RPM 600

RPM

980

RPM

RPM RPM

g

5

8

3

3139

3438

8

573

10

kg/ha

2528312731393438573247

the

universal

spreader

the

slide

setting

up

to

50

is

the

same

and

only

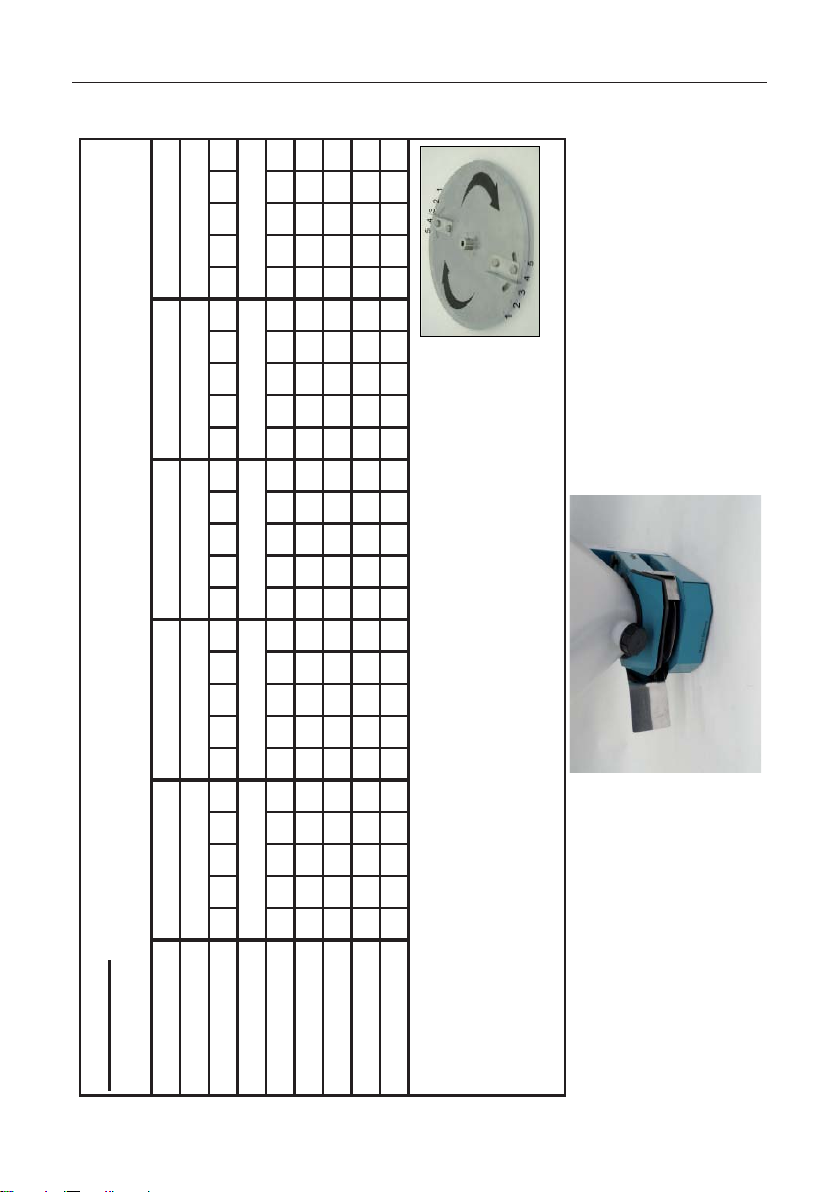

6.6 Spreading charts

47

2

LEHNER SuperVario®

4

427

1

Status: 08/2005 Check settings with field samples.

2.5 m 3.00 m 4.00 m 4.70 m

300 RPM 350 RPM 400 RPM 460 RPM

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

18 20 22 24 19 21 23 25 21 24 26 27 22 25 27 28

19 22 24 26 20 24 26 27 23 26 28 30 24 27 29 31

21 24 26 28 22 26 27 29 25 28 30 32 26 29 31 35

23 26 28 31 25 27 29 32 27 30 33 37 28 31 35 39

6.00 m 9.00 m 12.00 m 15.00 m

28 33 37 40 29 35 39 42 32 39 44 48 35 41 47 51

a

g

Spreading chart, yellow mustard

Delivery height: 1.00 m

Spreading width

RPM

km/h

Slide opening:

a

at 10 kg/ha

at 12 kg/ha

at 15 kg/ha

at 25 kg/ha

Spreading width

2

6 8 10 12 6 8 10 12 8 10 15 20 8 10 15 20

2

23 26 28 29 25 28 31 35 30 34 43 50 29 32 41 49

/ha

km/h

Slide opening:

at 8 kg/ha

at 10 k

27 30 35 37 29 34 39 43 38 43 53 65 36 40 54 67

30 34 38 43 33 39 44 48 43 48 62 76 40 47 63 82

34 40 45 49 39 45 54 58 50 59 76 91 49 58 82

at 12 kg/ha

at 15 kg/ha

at 20 kg/ha

38 45 50 54 44 50 60 66 59 67 87 58 70 100

at 25 kg/ha

LEHNER

,

,

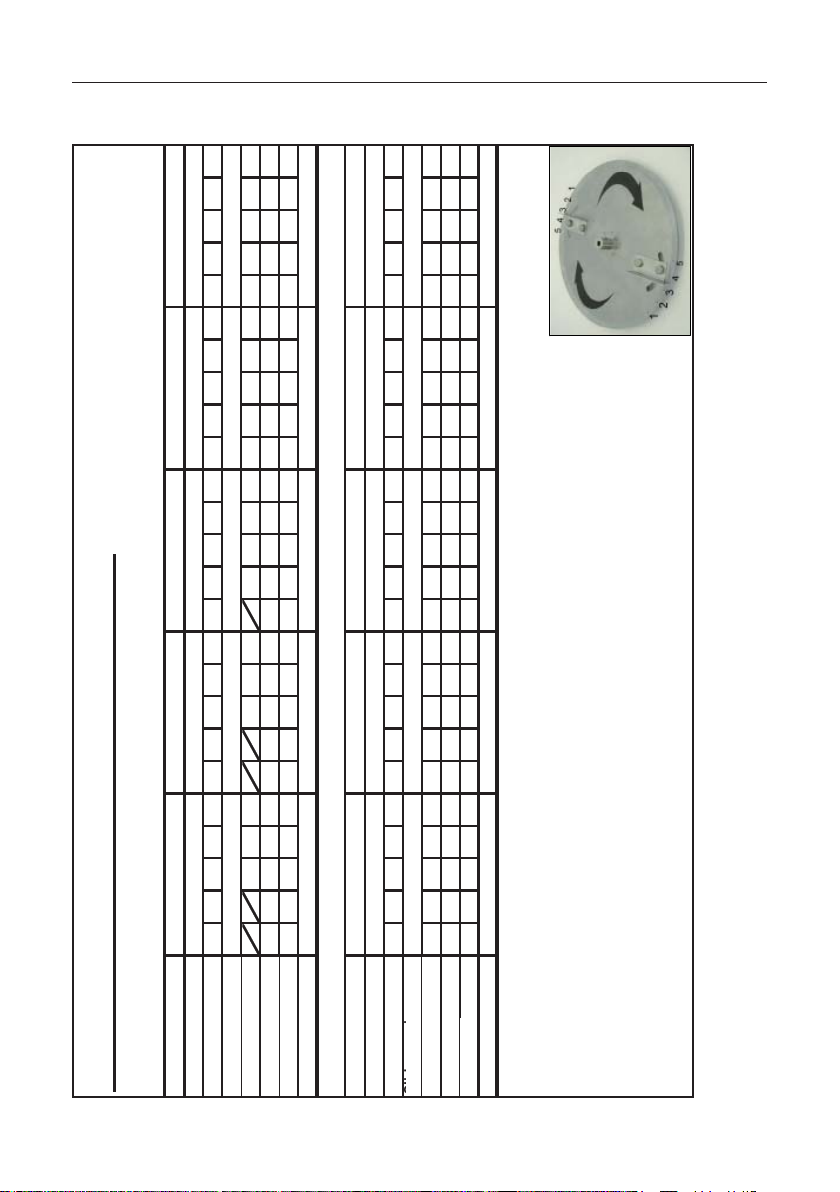

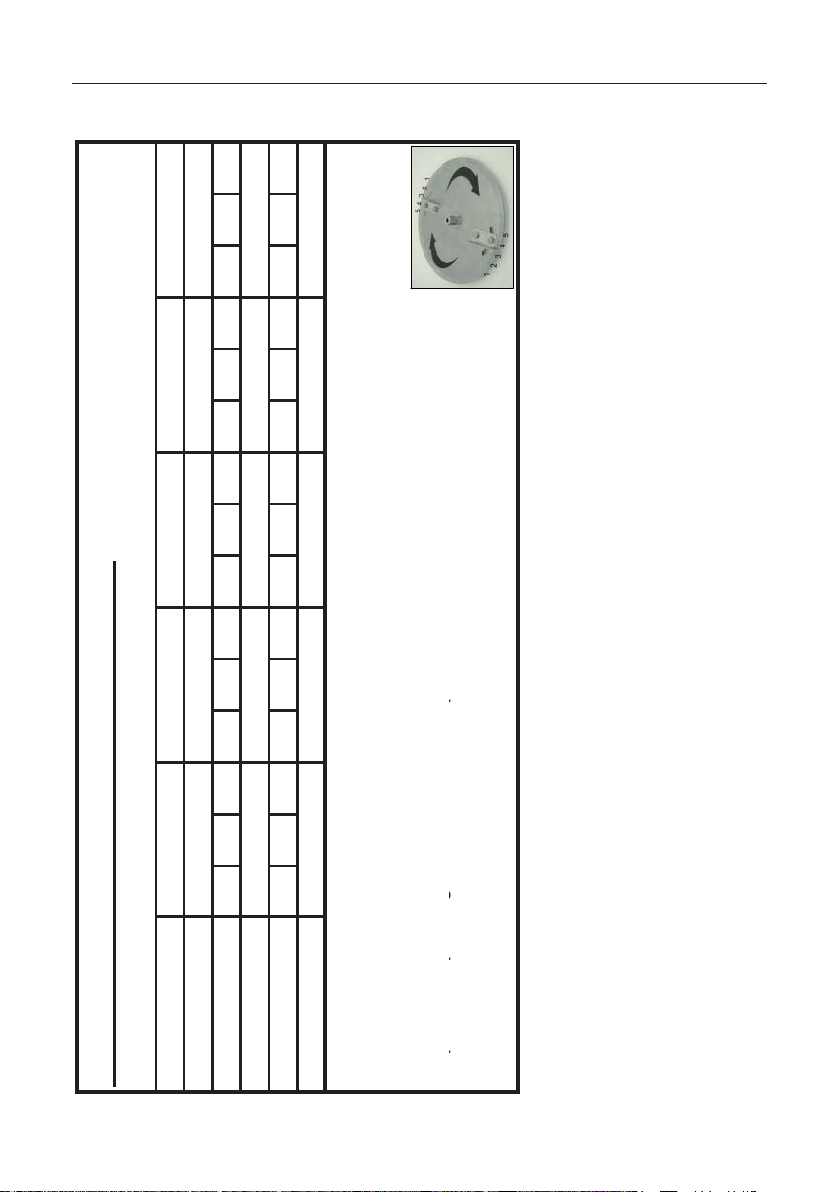

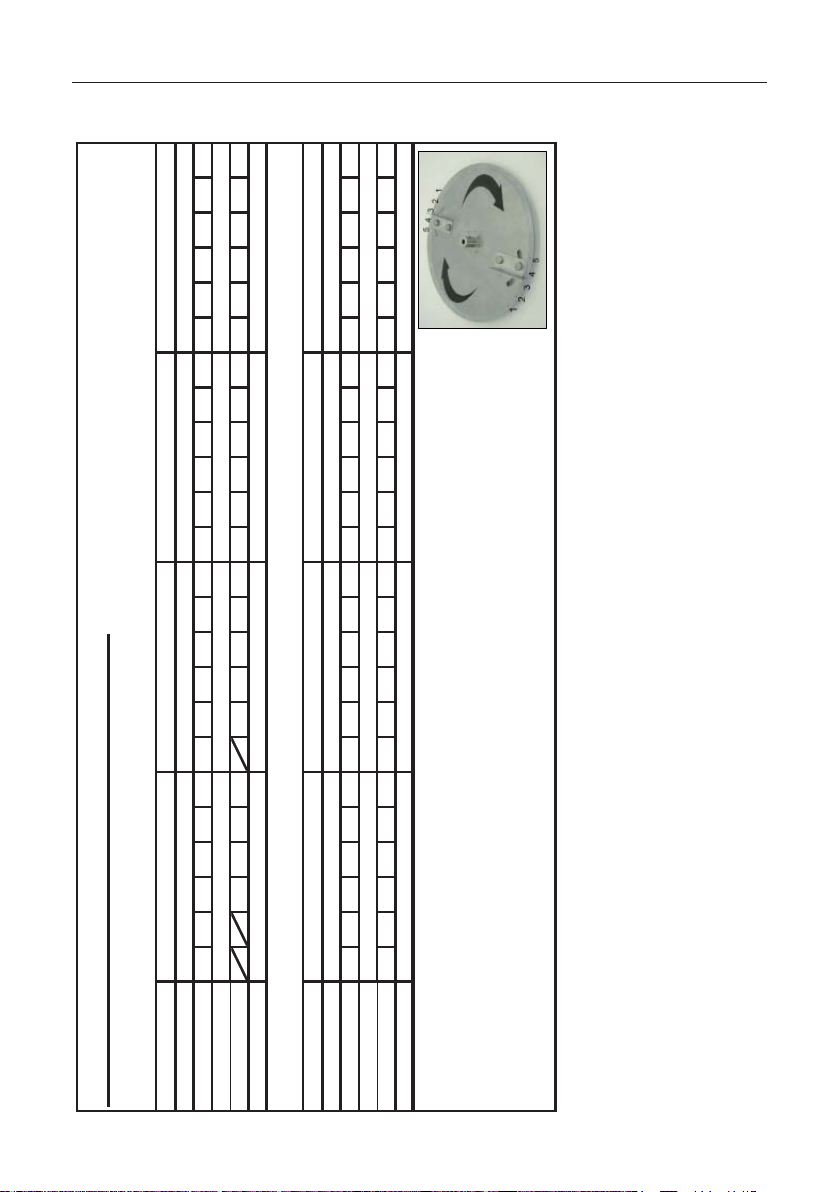

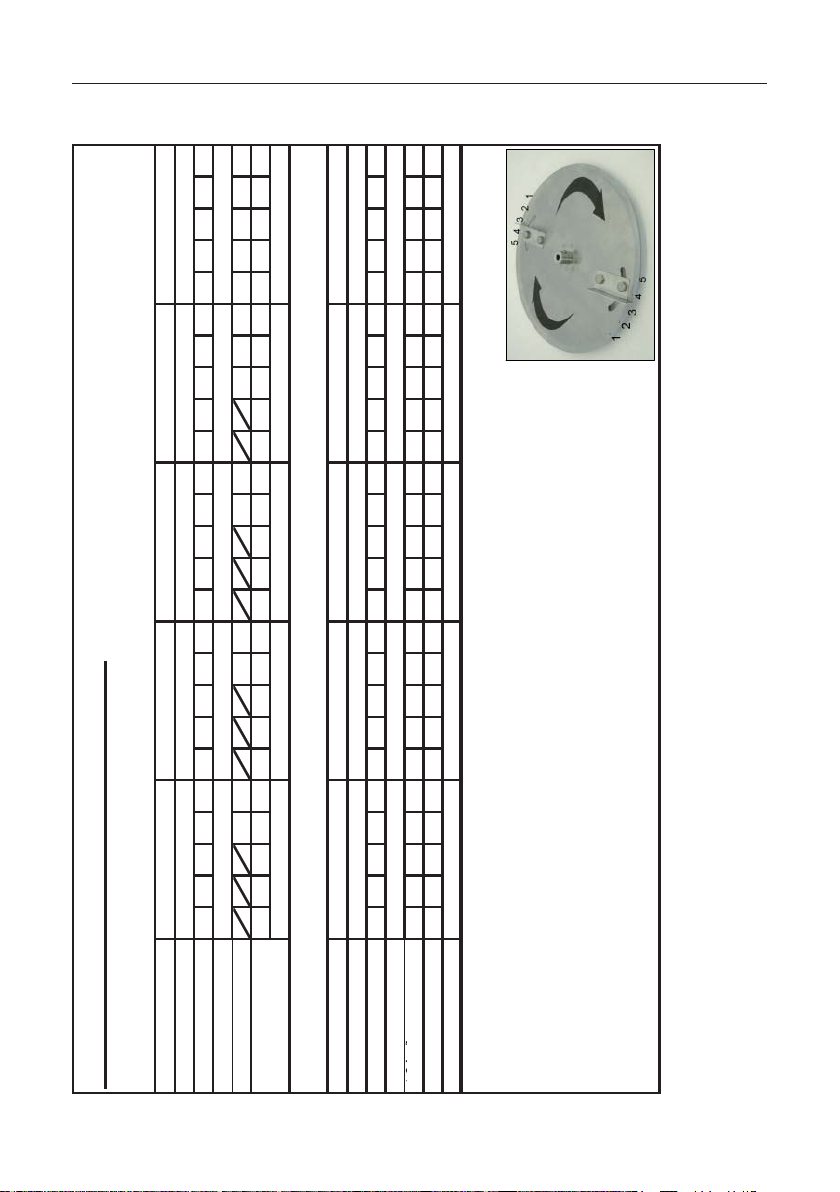

Position of casting shovels: Hole 5

At low delivery heights, the speed of the disc must be increased.

The pull of the spreading disc increases as the speed increases.

needs to be shifted by one decimal place. E.g. 41 is changed to 4.1

From 50 onwards, the slide unit of the SuperVario is somewhat larger, because it is pear-shaped.

42

Page 42

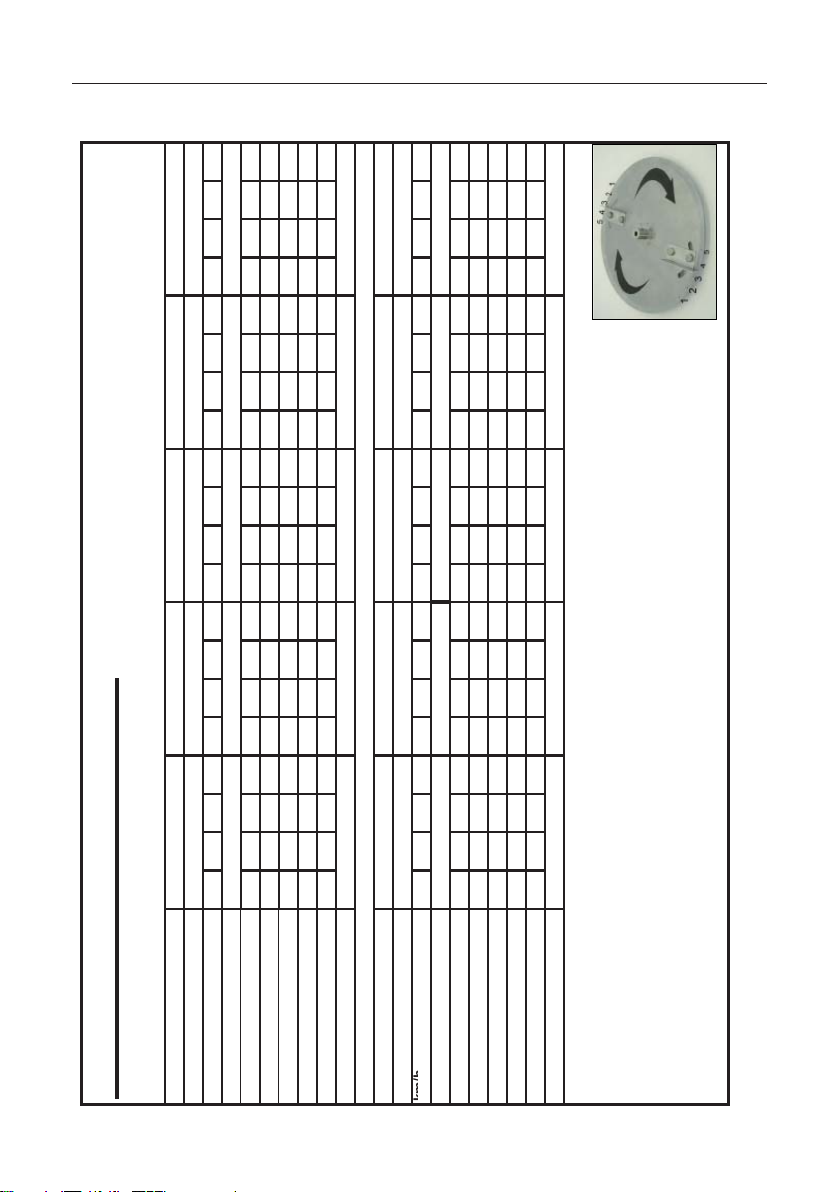

Spreading width

3m4m5m

Spreading

width

Slide opening:

3

m

5

m

m

4

m

5

m

Slide

opening

at 12 kg/ha

131521231616231519231820262127

30

t

12

k

/h

131521231616231519231820262127

30

Status: 07/2002

Position of casting shovels: Hole 5

Status:

07/2002

I th i l d th lid tti i th d l

Position

of

casting

shovels:

Hole

5

g

y

©LEHNER

2500 RPM

2300 RPM

LEHNER SuperVario®

2000 RPM

Operating manual Appendix

.

1700 RPM

is the same, and onl

1400 RPM

9 101215171011121618111214171914161820221719212325

:

One-sided spreading chart, yellow mustard ©

RPM

Delivery height: 1.00 m

km/h 4 6 8 10 12 4 6 8 10 12 4 6 8 10 12 4 6 8 10 12 4 6 8 10 12

a

g

at 8 kg/ha

at 10 kg/ha 11 12 14 18 20 11 13 15 19 21 12 14 16 20 22 16 18 20 22 24 19 22 24 27 28

a

at 15 kg/ha 16 17 20 24 26 17 18 22 25 27 18 21 23 26 29 20 22 24 26 28 23 26 30 33 35

at 20 kg/ha 18 21 23 26 28 19 22 24 27 29 24 24 25 29 32 22 24 26 28 30 25 28 33 36 38

It is essential to check the lateral distribution with a field test.

Mount the boundary spreading device so that spreading takes place in the direction of rotation of the spreading disc.

Not the other way around!

In the universal spreader, the slide settin

Note: A special adjustable deflector plate "ploughing right" is required for this! Article 72181

needs to be shifted by one decimal place. E.g. 45 is changed to 4.5

43

Page 43

Operating manual Appendix

/

6810126810126

12

LEHNER SuperVario®

Status: 08/2005 Check settings with field samples.

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

23 25 26 28 24 26 28 30 25 27 29 31 26 28 31 35

24 26 28 30 25 28 30 33 26 29 32 35 27 30 35 37

26 28 30 33 27 30 34 37 28 31 36 39 30 35 38 41

28 31 35 38 30 34 38 42 31 37 40 44 34 39 43 47

30 35 38 42 34 38 42 46 36 40 45 48 38 43 47 51

Spreading chart, fodder radish

Delivery height: 1.00 m

Spreading width 2.5 m 3 m 3.4 m 4.00 m

RPM 200 RPM 250 RPM 300 RPM 340 RPM

km/h

Slide opening:

at 10 kg/ha

at 12 kg/ha

at 15 kg/ha

at 20 kg/ha

at 25 kg/ha

Spreading width 5.00 m 6.00 m 12.00 m 17.00 m

RPM 370 RPM 460 RPM 930 RPM 2300 RPM

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

28 31 34 37 29 32 35 38 35 42 46 50 32 38 43 47

30 33 37 40 31 34 38 45 40 45 50 55 36 42 47 51

Slide opening:

at 10 kg/ha

km/h

at 12 kg/ha

32 37 41 45 34 38 45 48 44 50 57 60 40 47 53 59

38 43 47 51 39 46 50 56 50 58 69 75 47 56 66 74

41 47 53 59 45 50 57 66 56 69 78 87 54 66 80 90

at 15 kg/ha

at 20 kg/ha

at 25 kg/ha

Position of casting shovels: Hole 5

The pull of the spreading disc increases as the speed increases. © LEHNER

At low delivery heights, the speed of the disc must be increased.

In the universal spreader, the slide setting up to 50 is the same, and only

needs to be shifted by one decimal place. E.g. 41 is changed to 4.1

From 50 onwards, the slide unit of the SuperVario is somewhat larger, because it is pear-shaped.

44

Page 44

Operating manual Appendix

lateral

distribution

is

uneven

adjust

casting

shovels

5

10.0 m

LEHNER SuperVario®

© LEHNER

.

,

2.5 m 3.0 m 4.0 m 5.0 m 6.0 m

450 RPM 500 RPM 600 RPM 700 RPM 850 RPM 2500 RPM

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12 8 10 15 20

Spreading chart, phacelia

Delivery height: 1 m

RPM

Spreading width

km/h

Slide opening:

17 20 22 24 17 20 22 24 20 23 26 31 24 26 31 37 26 29 35 44 30 32 38 55

at 10 kg/ha

At low delivery heights, the speed of the disc must be increased.

Please note that the spreading widths of 5.00 and 6.00 metres have not been tested.

These values have been calculated mathematically.

Please check the settings with a field test.

Important: A special phacelia spreading disc is required for this! Article 8057

45

Page 45

Operating manual Appendix

10126812681081012610

12

/h

©

®

Hole 4Hole 4.5 Hole 4.5 Hole 4.5 Hole 4

LEHNER SuperVario

Recommended output: 20 kg/ha Check settings with field samples.

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

14 19 21 22 18 21 22 26 22 23 26 28 23 26 27 30 24 27 29 32

21 22 23 25 22 24 25 28 24 26 28 30 25 28 30 32 26 30 32 35

23 24 26 28 24 27 29 30 26 28 31 33 27 30 33 36 30 33 36 39

26 27 28 30 27 28 32 33 29 31 34 37 31 34 38 41 33 36 41 44

28 29 30 33 30 31 34 35 32 34 37 41 33 37 42 45 34 39 45 47

Spreading chart, red clover

Delivery height: 1.00 m

Spreading width 2.5 m 3 m 4 m 5 m 6 m

RPM 250 RPM 300 RPM 400 RPM 500 RPM 700 RPM

km/h

Slide opening:

at 10 kg/ha

at 12 kg/ha

at 15 kg/ha

at 20 kg/ha

at 25 kg/ha

Position of casting shovels

Spreading width 7 m 8 m 9 m 12 m 15 m

RPM 1300 RPM 1500 RPM 1700 RPM 2300 RPM 2500 RPM

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

22 25 27 30 23 26 28 32 24 27 30 34 25 28 33 36 26 32 34 38

24 28 30 33 25 29 32 35 26 31 34 36 27 33 36 39 31 34 38 42

m

Slide opening:

at 10 kg/ha

at 12 kg/ha

28 30 32 37 29 31 34 37 30 33 36 42 32 36 40 45 34 38 45 48

at 15 kg/ha

Hole 3.5 Hole 3 Hole 3 Hole 3 Hole 3

31 34 39 44 33 36 42 46 35 38 44 51 36 41 46 52 38 45 49 57

33 39 44 47 34 41 46 50 37 44 51 54 40 45 53 57 45 49 57 69

At lower delivery heights, the speed of the disc must be increased.

at 20 kg/ha

at 25 kg/ha

Position of casting shovels

If lateral distribution is uneven, adjust casting shovels. In the universal spreader, the slide setting

up to 50 is the same, and only needs to be shifted by one decimal place. E.g. 41 is changed to 4.1.

LEHNER Status: 08/2005

The opening is larger in the SuperVario® from opening 50 onwards.

The speed may decrease at the upper spreading width. Please shorten stirring shaft by half.

46

Page 46

LEHNER SuperVario®

Check settings with field samples.

©LEHNER

Operating manual Appendix

2.5 m 3.0 m 6.0 m 12.0 m

500 RPM 600 RPM 1000 RPM 2100 RPM

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

Spreading chart, white clover

Spreading width

RPM

Delivery height: 1.00 m

km/h

10 12 14 16 12 14 16 18 13 15 18 20 16 19 21 23

at 10 kg/ha

Slide opening:

Position of casting shovels: Hole 5

At lower delivery heights, the speed of the disc must be increased.

If lateral distribution is uneven, adjust casting shovels.

In the universal spreader, the slide setting is the same, and only needs to be

shifted by one decimal place. E.g. 41 is changed to 4.1

47

Page 47

Operating manual Appendix

®

v

v

f

©

R

Hole 5

LEHNER SuperVario

LEHNE

2.00 m 2.50 m 3.00 m

300 RPM 400 RPM 800 RPM

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15

Hole 5 Hole 5

4.00 m 5.00 m 6.00 m

1200 RPM 1650 RPM 2000 RPM

56 58 59 61 63 57 59 61 62 64 46 50 52 54 56

58 60 62 64 67 60 62 63 65 68 50 53 55 57 59

61 64 67 69 72 62 64 67 70 72 54 56 59 61 62

65 69 72 74 76 65 70 72 74 77 58 61 63 65 68

69 72 75 76 78 71 73 75 78 80 61 64 67 70 71

72 75 77 78 80 72 75 78 81 83 63 66 70 72 74

76 78 80 85 88 74 81 84 87 89 69 72 75 77 81

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15

43 46 50 52 55 37 39 42 44 48 34 35 37 39 44

47 51 54 56 59 40 43 46 51 53 39 40 42 44 50

51 55 59 63 67 44 49 53 56 68 45 46 50 52 57

57 62 67 71 76 51 56 67 72 75 52 53 58 62 66

63 68 75 77 79 56 70 73 77 81 60 61 65 68 76

Hole 4 Hole 4 Hole 3

67 75 77 79 84 68 73 77 81 84 65 66 69 76 80

77 80 86 98 76 82 85 100 77 78 82 87

the spreading disc increases as the speed increases.

Spreading chart, grassland mixture

Spreading width

RPM

km/h

Slide opening:

5 kg/ha

7 kg/ha

10 kg/ha

15 kg/ha

20 kg/ha

25 kg/ha

40 kg/ha

Spreading width

RPM

km/h

Slide opening:

5 kg/ha

7 kg/ha

10 kg/ha

15 kg/ha

20 kg/ha

25 kg/ha

30% ryegrass, 18% timothy, 21% meadow fescue, 9% orchard grass, 13% Kentucky bluegrass , 9% white clover

Position of casting sho

40 kg/ha

Position of casting sho

48

Delivery height: 1.00 m Status: 03/2005

Check settings with field samples.

If lateral distribution is uneven, adjust casting shovels.

The flow properties of grass seed are greatly affected by external

influences such as water content - humidity. Please note!

The pull o

Page 48

LEHNER SuperVario®

Check settings with field samples.

Operating manual Appendix

© LEHNER

LEHNER SuperVario®

6 8 10 12 6 8 10 12 6 8 10 12

48 52 56 59 38 40 43 45 44 45 46 48

53 57 60 62 45 56 60 65 55 56 57 58

Spreading chart, Welsh ryegrass

Spreading width 2.50 m 4.00 m 6.00 m

RPM 500 RPM 1200 RPM 2000 RPM

km/h

at 15 kg/ha

Delivery height: 1.00 m

at 25 kg/ha

Slide opening:

Position of casting shovels: Hole 5

The flow properties of grass seed are greatly affected by external

influences such as water content - humidity. Please note!

The pull of the spreading disc increases as the speed increases.

In the universal spreader, the slide setting is the same, and only needs to be

shifted by one decimal place. E.g. 41 is changed to 4.1

© LEHNER

Check settings with field samples.

6 8 10 12 6 8 10 12 6 8 10

48 51 57 59 39 43 52 55 38 40 45

52 55 70 82 50 53 66 72 60 75 82

Spreading chart, German ryegrass

Spreading width 2.50 m 4.00 m 6.00 m

RPM 500 RPM 1200 RPM 2000 RPM

km/h

at 15 kg/ha

Delivery height: 1.00 m

at 25 kg/ha

Slide opening:

Position of casting shovels: Hole 5

The flow properties of grass seed are greatly affected by external

influences such as water content - humidity. Please note!

The pull of the spreading disc increases as the speed increases.

In the universal spreader, the slide setting is the same, and only needs to be

shifted by one decimal place. E.g. 41 is changed to 4.1

49

Page 49

Operating manual Appendix

,

p

g

,

p

p

From

50

onwards,

the

slide

unit

of

the

SuperVario

is

somewhat

larger,

because

it

is

pear shaped.

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

RPM 200 RPM 250 RPM 300 RPM 850 RPM

km/h

Slide opening:

40 41 39 40 41 43

40 41 40 41 43 41 43 44 46

5 kg/ha

7 kg/ha

40 41 41 43 40 42 45 46 43 46 47 49

40 43 45 42 45 47 43 46 48 50 46 48 50 53

40 43 46 48 42 46 49 51 46 49 52 56 48 51 55 59

10 kg/ha

15 kg/ha

20 kg/ha

43 46 48 51 45 48 52 56 48 52 58 63 50 55 59 65

48 52 59 66 51 57 65 72 57 65 75 82 58 67 74 85

25 kg/ha

40 kg/ha

Position of casting shovels Hole 3 Hole 3.5 Hole 3.5 Hole 4.5

LEHNER SuperVario®

Status: 08/2005 Check settings with field samples.

MG 500 coated seed

Delivery height: 1.00 m

Spreading width 2.5 m 3 m 4 m 5 m

Spreading width 6 m 8 m 9 m 10 m

RPM 1600 RPM 2000 RPM 2250 RPM 2500 RPM

6 8 10 12 6 8 10 12 6 8 10 12 6 8 10 12

39 40 42 44 38 42 46 47 39 45 50 52 38 45 47 49

km/h

Slide opening:

5 kg/ha

7 kg/ha

43 44 45 47 43 47 49 52 46 51 53 55 45 48 51 60

45 46 48 50 48 51 54 61 52 55 59 62 50 56 61 63

10 kg/ha

48 50 51 56 52 62 65 71 56 63 69 74 60 63 70 76

53 57 60 62 61 69 73 78 63 71 80 83 63 73 78 84

58 59 64 68 66 73 80 88 69 80 84 85 70 78 85 88

15 kg/ha

20 kg/ha

25 kg/ha

ed.

ear-sha

because it is

er

erVario is somewhat lar

69 70 77 87 77 90 94 98 83 91 96 99 84 89 98

40 kg/ha

Position of casting shovels Hole 5 Hole 4.5 Hole 4.5 Hole 4

If lateral distribution is uneven, adjust casting shovels.

The flow properties of grass seed are greatly affected by external © LEHNER

influences such as water content - humidity. Please note!

the slide unit of the Su

The pull of the spreading disc increases as the speed increases.

In the universal spreader, the slide setting up to 50 is the same, and only

needs to be shifted by one decimal place. E.g. 41 is changed to 4.1

From 50 onwards

50

Page 50

LEHNER SuperVario®

Position of casting shovels: Hole 5

Position

of

casting

shovels:

Hole

5

Check settings with field samples.

Operating manual Appendix

2.50 m 4.00 m 6.00 m

500 RPM 1200 RPM 2100 RPM

6 8 10 12 6 8 10 12 6 8 10

Spreading chart, annual ryegrass

Spreading width

RPM

Delivery height: 1.00 m

km/h

41 46 50 53 43 48 50 61 47 49 52

47 53 56 59 49 56 62 72 58 60 68

at 15 kg/ha

Slide opening:

at 25 kg/ha

The pull of the spreading disc increases as the speed increases.

In the universal spreader, the slide setting is the same, and only needs to be

The flow properties of grass seed are greatly affected by external

influences such as water content - humidity. Please note!

shifted by one decimal place. E.g. 41 is changed to 4.1

51

Page 51

Operating manual Appendix

©

R

LEHNE

Status: 07/2006

68106810

49 53 56 40 41 43

56 67 67 46 49 55

70 74 78 62 69 77

Spreading chart, grass DSV G5 Permanent pasture © LEHNER SuperVario®

52

Spreading width 2 m 5 m Note

RPM 450 RPM 1600 RPM

km/h

at 5 kg/ha

at 10 kg/ha

Check settings with field samples.

Slide opening:

at 25 kg/ha

Delivery height: 1.00 m

Position of casting shovels: Hole 5

If lateral distribution is uneven, adjust casting shovels.

The flow properties of grass seed are greatly affected by external

influences such as water content - humidity. Please note!

Please note that when a spreading width of 2 m is selected, the grass seed does not run on well due to the pull.

The pull of the spreading disc increases as the speed increases.

Page 52

LEHNER SuperVario®

s

3 kg/ha

192022242023251819

24

3

kg/ha

192022242023251819

24

s

Operating manual Appendix

© LEHNER

17 17 18 17 18 19

4.00 m 6.00 m 8.00 m

magnesium carbonate, 0.2% Se selenium

200 RPM 420 RPM 550 RPM

3

17 18 19 17 18 20 21 17 18 19 21 23

Hole 3 Hole 3 Hole 3

9.00 m 12.00 m 15.00 m

650 RPM 800 RPM 1150 RPM

17 18 19 21 17 18 20 21 23 18 19 21 23 25

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15

calcium carbonate, 5% Mg CO

3

Spreading chart, Dino Selenium

Spreading width

RPM

km/h

Slide opening:

70% Ca CO

2 kg/ha

3 kg/ha

4 kg/ha

17 18 19 21 23 18 20 21 23 25 19 22 23 25 27

18 19 22 24 25 21 23 24 26 28 23 24 27 28 32

5 kg/ha

7 kg/ha

Position of casting shovel

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15

Spreading width

RPM

km/h

Slide opening:

17 18 19 20 17 18 19 20 21 17 19 20 21

2 kg/ha

Hole 3 Hole 3 Hole 3

19 20 22 24 26 20 21 23 25 27 20 23 25 26 29

20 23 24 26 28 21 24 26 27 30 22 25 28 29 32

24 25 28 29 33 25 27 29 32 36 25 27 31 35 39

4 kg/ha

5 kg/ha

7 kg/ha

Delivery height: 1.00 m Status: 01/2006

Position of casting shovel

Check settings with field samples.

If lateral distribution is uneven, adjust casting shovels.

The flow properties of the product are greatly affected by external

influences such as water content - humidity. Please note!

Position of stirring shafts: Do not install the upper stirring shaft, lower at 2/3 to 1/3

53

Page 53

Operating manual Appendix

©LEHNER

Status: 05/2002

LEHNER SuperVario®

23462346

Spreading chart

Bonsilage Schaumann

Spreading width 1.7 m 3.70 m

RPM 300 RPM 2200 RPM

km/h

54

85 85 85 85 85 85 85 85

215 145 108 72 100 67 50 34

Slide opening:

gr/m²

Delivery height: 1.00 m

Position of casting shovels: Hole 5

Special feature: Boundary spreading device is required as additional equipment, otherwise one-sided spreading pattern. (too much material in direction of rotation)

in the driving direction with front mounting causes even lateral distribution with this material.

Boundary spreading device mounted on the right

Important: After each use, thoroughly clean the spreader with water, and regularly grease the drive motor at the shaft output.

In the universal spreader, the slide setting up to 50 is the same, and only needs to be shifted by one decimal place E.g. 85 is changed to 8.5.

From 50 onwards, the flow rate in the SuperVario® is greater.

Page 54

LEHNER SuperVario®

©

Operating manual Appendix

LEHNER

1.50m 2 m 4 m

300 RPM 650 RPM 2600 RPM

234623462346

Spreading chart

Eurosil maize microgranulate (Timac)

Spreading width

RPM

km/h

85 85 85 85 85 85 85 85 85 85 85 85

180 120 90 60 130 90 65 45 65 45 32 22

Space for

gr/m²

own values:

Slide opening:

in the driving direction with front mounting causes even lateral distribution with this material.

Delivery height: 1.00 m

Position of casting shovels: Hole 5

Important: Thoroughly clean the spreader with water after each use. Regularly remove the motor and grease it at the shaft output.

Special feature: "Eurosil baffle plate" is required as an additional device, otherwise one-sided spreading pattern. (too much material in direction of rotation)

Status: 05/2002

Plate mounted on the right

55

Page 55

Operating manual Appendix

)

y

LEHNER

Status: 05/2002

LEHNER SuperVario®

234623462346

85 85 85 85 85 85 85 85 85 85 85 85

180 120 90 60 142 95 71 47 80 52 40 105

Spreading chart

Eurosil 70 microgranulate (Timac)

Spreading width 1.50m 2 m 4 m

RPM 300 RPM 500 RPM 2200 RPM

56

km/h

Space for

Slide opening:

own values:

gr/m²

Delivery height: 1.00 m

Feature: "Eurosil baffle plate" is required as an additional device, otherwise one-sided spreading pattern. (too much material in direction of rotation

Plate mounted on the right in the driving direction with front mounting, causes even lateral distribution with this material.

Position of casting shovels: Hole 5

Important: After each use, thoroughly clean the spreader with water, and regularly grease the shaft output.

In the universal spreader, the slide setting is the same, and onl

needs to be shifted by one decimal place. E.g. 85 is changed to 8.5

Page 56

®

6810152010152010

15

/h

g

g

g

y

g

g

g

y

g

y

y

g

g

g

Operating manual Appendix

LEHNER SuperVario

©LEHNER

.

Check settings with field samples.

Status: 08/2005

out of the midpoint

htl

er, because it is pear-shaped.

ed to 4.1

. 41 is chan

3 m4 m6 m9 m10 m

30 31 32 33 28 31 32 33 34 29 32 33 34 35 30 33 35 36 38 32 34 36 40 46

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 15 20

30 33 35 37 38 31 34 36 39 42 33 35 37 41 43 35 39 41 44 49 36 41 44 52 60

32 37 38 39 41 35 40 42 44 46 38 41 44 46 48 42 44 48 51 54 44 47 51 59 71

35 39 40 42 43 38 43 45 47 49 42 45 47 49 53 45 49 50 53 58 48 53 55 63 81

41 45 49 53 59 48 53 58 63 70 56 57 61 66 73 63 71 79 86 97 65 75 82 100

Hole 5 Hole 5 Hole 4 Hole 5 Hole 5

12 m 15 m 18 m 21 m 24 m

Hole 5 Hole 5 Hole 4 Hole 5 Hole 5

6 8 10 15 20 6 8 10 15 20 6 8 10 15 20 6 8 10 15 20 6 8 10 15 20

33 35 37 42 47 34 36 38 43 48 35 37 39 44 49 36 38 41 45 50 37 39 44 47 51

37 42 46 54 62 38 43 48 55 63 40 44 49 57 65 41 45 50 58 66 43 47 51 59

45 50 54 64 75 46 51 55 67 78 47 52 57 70 81 48 53 58 71 83 49 55 63

49 56 59 68 85 50 57 63 74 88 51 59 65 79 93 52 60 66 84 55 63

68 79 86 69 81 90 74 86 97 59 68 75 61 71

hts, the speed of the disc must be increased.

widths, wind speed should be noted to avoid incorrect spreadin

hei

up to 50 is the same, and onl

disc, 2 means sli

one decimal place. E.

e spreadin

Spreading chart, Ratron rodenticide

Delivery height: 1.30 m

Spreading width

Speed 250 RPM 300 RPM 500 RPM 850 RPM 1000 RPM

km/h

Slide opening:

at 3 kg/ha

at 6 kg/ha

at 9 kg/ha

at 12 kg/ha

at 25 kg/ha

Position of casting shovels

m

Spreading width

Speed 1200 RPM 1700 RPM 1900 RPM 2400 RPM 2650 RPM

Slide opening:

at 3 kg/ha

at 6 kg/ha

at 9 kg/ha

at 12 kg/ha

If lateral distribution is uneven, adjust casting shovels.

For lar

If there is no scale on the spreadin

at 25 kg/ha

Position of casting shovels

At lower deliver

From 50 onwards, the slide unit of the SuperVario is somewhat lar

needs to be shifted b

in the direction of rotation. 3 means the middle of the slot.

In the universal spreader, the slide settin

57

Page 57

Operating manual Appendix

e

at 3 kg/ha23242629333034232528302831362425

29

36

t

3

k

/h

e

©

®

LEHNER SuperVario

Check settings with field samples.

Mesurol

Hole 2.5Hole 2.5 Hole 2.5 Hole 2.5 Hole 2.5

LEHNER

Status: 08/2003

Hole 3 Hole 3 Hole 3 Hole 3 Hole 3

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 8 10 12 15 20

Speed 300 RPM 400 RPM 500 RPM 750 RPM 850 RPM

km/h

Slide opening:

21 23 25 27 20 22 24 26 28 20 23 24 27 28 21 23 24 26 28 22 23 25 28 33

21 23 25 27 29 21 23 26 28 29 21 24 27 28 30 22 24 27 30 31 25 26 28 31 36

at 3 kg/ha

at 5 kg/ha

Position of casting shov

12 m 15 m 18 m 21 m 24 m

8 10121520 8 10121520 8 10121520 8 10121520 8 10121520

23 24 26 29 33 23 25 28 30 34 23 25 28 30 35 23 25 28 31 36 24 25 29 32 36

a

g

Speed 1000 RPM 1800 RPM 2300 RPM 2500 RPM 2700 RPM

km/h

Slide opening:

a

Spreading width

26 27 28 31 39 27 30 32 37 41 28 31 34 39 42 28 32 36 41 43 30 33 37 44 45

For large spreading widths, note wind speed to avoid incorrect spreading.

At lower delivery heights, the speed of the disc must be increased.

If lateral distribution is uneven, adjust casting shovels.

If there is no scale on the spreading disc, 2 means slightly out of the midpoint

in the direction of rotation. 3 means the middle of the slot.

In the universal spreader, the slide setting is the same, and only

needs to be shifted by one decimal place. E.g. 41 is changed to 4.1

at 5 kg/ha

Position of casting shov

The speed may decrease at the upper spreading width. Please shorten stirring shaft by half.

3 m4 m6 m9 m10 m

Spreading chart, Mesurol slug pellets

Delivery height: 1.30 m

Spreading width

58

Page 58

Operating manual Appendix

e

t3k /h

2531342629323530333630323630323438

3

/

e

g

g

g

y

g

g

g

y

g

y

y

g

g

g

®

Hole 2.5Hole 2.5 Hole 2.5 Hole 2.5 Hole 2.5

40 43 51 35 38 42 45 53

LEHNER SuperVario

Check settings with field samples.

22 24 26 23 24 27 22 24 25 28 22 23 25 26 29 24 26 27 30 31

3 m4 m6 m9 m10 m

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 8 10 12 15 20

23 24 25 27 29 24 25 26 28 30 25 26 27 28 31 26 27 28 29 32 27 28 29 33 34

25 26 27 29 31 26 27 28 31 33 27 28 29 32 34 28 29 30 32 35 30 31 34 36 37

12 m 15 m 18 m 21 m 24 m

8 10 12 15 20 8 10 12 15 20 8 10 12 15 20 8 10 12 15 20 8 10 12 15 20

25 27 28 31 34 26 28 29 32 35 27 29 30 33 36 28 30 32 36 38 30 32 34 38 41

28 29 32 33 36 28 30 33 34 38 30 31 35 36 39 31 32 36 37 42 33 34 38 42 45

.

out of the midpoint

LEHNER

er, because it is pear-shaped

Status: 11/2004

ed to 4.1

htl

. 41 is chan

up to 50 is the same, and onl

disc, 2 means sli

Hole 2 Hole 2 Hole 2 Hole 2 Hole 2

31 32 35 40 42 32 33 37 41 43 33 34 39 42 46 34 35

hts, the speed of the disc must be increased. ©

widths, wind speed should be noted to avoid incorrect spreadin

one decimal place. E.

hei

e spreadin

For lar

If lateral distribution is uneven, adjust casting shovels.

If there is no scale on the spreadin

at 7 kg/ha

At lower deliver

Position of casting shov

needs to be shifted b

in the direction of rotation. 3 means the middle of the slot.

In the universal spreader, the slide settin

From 50 onwards, the slide unit of the SuperVario is somewhat lar

59

Speed 1000 RPM 1700 RPM 2500 RPM 2650 RPM 2800 RPM

km/h

Slide opening:

ha

kg

at

at 5 kg/ha

Spreading chart, METAREX slug pellets

Delivery height: 1.30 m

Spreading width

Speed 250 RPM 350 RPM 400 RPM 600 RPM 750 RPM

km/h

Slide opening:

at 3 kg/ha

at 5 kg/ha

at 7 kg/ha

Spreading width

Position of casting shov

Page 59

Operating manual Appendix

s

k/h6102068101581520610206810

15

/

s

g

g

g

y

g

5

g

g

y

g

y

y

g

g

g

®

Hole 5Hole 5 Hole 5 Hole 4 Hole 5

LEHNER SuperVario

©LEHNER

.

Check settings with field samples.

Status: 08/200

out of the midpoint

er, because it is pear-shaped.

ed to 4.1

htl

. 41 is chan

up to 50 is the same, and onl

disc, 2 means sli

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 15 20

30 31 32 33 28 31 32 33 34 29 32 33 34 35 30 33 35 36 38 32 34 36 40 46

30 33 35 37 38 31 34 36 39 42 33 35 37 41 43 35 39 41 44 49 36 41 44 52 60

32 37 38 39 41 35 40 42 44 46 38 41 44 46 48 42 44 48 51 54 44 47 51 59 71

35 39 40 42 43 38 43 45 47 49 42 45 47 49 53 45 49 50 53 58 48 53 55 63 81

41 45 49 53 59 48 53 58 63 70 56 57 61 66 73 63 71 79 86 97 65 75 82 100

3 m4 m6 m9 m10 m

12 m 15 m 18 m 21 m 24 m

6 8 10 15 20 6 8 10 15 20 6 8 10 15 20 6 8 10 15 20 6 8 10 15 20

33 35 37 42 47 34 36 38 43 48 35 37 39 44 49 36 38 41 45 50 37 39 44 47 51

37 42 46 54 62 38 43 48 55 63 40 44 49 57 65 41 45 50 58 66 43 47 51 59

45 50 54 64 75 46 51 55 67 78 47 52 57 70 81 48 53 58 71 83 49 55 63

49 56 59 68 85 50 57 63 74 88 51 59 65 79 93 52 60 66 84 55 63

Hole 5 Hole 5 Hole 4 Hole 5 Hole 5

68 79 86 69 81 90 74 86 97 59 68 75 61 71

hts, the speed of the disc must be increased.

widths, wind speed should be noted to avoid incorrect spreadin

one decimal place. E.

hei

Spreading chart, Ferramol slug pellets

Delivery height: 1.30 m

Spreading width

Speed 250 RPM 300 RPM 500 RPM 850 RPM 1000 RPM

km/h

Slide opening:

at 3 kg/ha

at 6 kg/ha

at 9 kg/ha

at 12 kg/ha

at 25 kg/ha

Position of casting shovel

h

Spreading width

Speed 1200 RPM 1700 RPM 1900 RPM 2400 RPM 2650 RPM

km

Slide opening:

at 3 kg/ha

at 6 kg/ha

at 9 kg/ha

at 12 kg/ha

e spreadin

in the direction of rotation. 3 means the middle of the slot.

At lower deliver

If lateral distribution is uneven, adjust casting shovels.

For lar

at 25 kg/ha

Position of casting shovel

If there is no scale on the spreadin

In the universal spreader, the slide settin

From 50 onwards, the slide unit of the SuperVario is somewhat lar

needs to be shifted b

60

Page 60

Operating manual Appendix

v

i

v

®

LEHNER SuperVario

Check settings with field samples.

Hole 2.5Hole 2.5 Hole 2.5 Hole 2.5 Hole 2.5

46 49 57 41 44 48 51 59

LEHNER

Status: 08/2005

23 24 26 24 25 28 24 26 27 30 25 26 28 29 32 28 30 31 34 35

3 m 4 m 6 m 9 m 10 m

6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 12 15 6 8 10 12 15

23 24 25 27 29 25 26 27 29 31 27 28 29 30 33 29 30 31 32 35 31 32 33 37 38

25 26 27 29 31 27 28 29 32 34 29 30 31 34 36 31 32 33 35 38 34 35 38 40 41

Spreading chart, Clartex blue slug pellets

Delivery height: 1.30 m

Spreading width

Speed 250 RPM 350 RPM 400 RPM 600 RPM 750 RPM

km/h

Slide opening:

at 3 kg/ha

at 5 kg/ha

at 7 kg/ha

12 m 15 m 18 m 21 m 24 m

8 10 12 15 20 8 10 12 15 20 8 10 12 15 20 8 10 12 15 20 8 10 12 15 20

ng:

e open

Spreading width

Speed 1000 RPM 1700 RPM 2500 RPM 2650 RPM 2800 RPM

Position of casting sho

km/h

Hole 2 Hole 2 Hole 2 Hole 2 Hole 2

29 31 32 35 38 30 32 33 36 39 31 33 34 37 40 34 36 38 42 44 36 38 40 44 47

32 33 36 37 40 33 34 37 38 42 34 35 39 40 43 37 38 42 43 48 39 40 44 48 51

35 36 39 44 46 36 37 41 45 48 37 38 43 46 50 40 41

at 3 kg/ha

at 5 kg/ha

at 7 kg/ha

Position of casting sho

For large spreading widths, wind speed should be noted to avoid incorrect spreading.

At lower delivery heights, the speed of the disc must be increased.

If lateral distribution is uneven, adjust casting shovels.