Powered by Harley Davidson

2009-2013

H-D TOURING MODELS

INSTALLATION

INSTRUCTIONS

*FLHX AND FLTR MODELS REQUIRE ADDITIONAL HARDWARE

December 2013

Rev. 8

FOREWARD

This manual is designed for use by authorized Lehman Trikes

manual may be printed for internal use in your shop. This manual is for use in a properly equipped shop

and should remain available for reference in the shop area.

Some procedures outlined in this manual require sound knowledge of mechanical theory, tool use, and

shop procedures in order to perform work safely and correctly. Illustrations in this manual may show a

trike body or other component removed for clarity. These illustrations are for photographic purposes

only and may or may not indicate removing such components.

Read the text and become familiar with the procedures before starting any work. Some procedures require the use of special tools. Use only the proper tools as specified. If you have any doubt as to your

ability to perform any of the procedures outlined in this manual, please contact Lehman Trikes

you start work at 1-888-394-3357.

®

dealer technicians. Online copies of this

®

before

© 2010. All rights reserved.

Lehman Trikes

taken in the preparation of this manual, Lehman Trikes

damages resulting from the use of the information contained herein. Lehman Trikes

as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

Lehman Trikes

holders. Printed in the United States of America.

®

provides this publication as is without warranty of any kind, either expressed or implied. While every precaution has been

®

is a registered trademark. All other brands and product names are trademarks or registered trademarks of their respective

2009-2013 FLH RENEGADE

®

assumes no responsibility for errors or omissions. Neither is any liability assumed for

®

reserves the right to revise and improve its products

2

SAFETY INFORMATION

UNDERSTANDING SAFETY LABELS & INSTRUCTIONS

READ AND BECOME FAMILIAR WITH ALL WARNING, CAUTION SYMBOLS AND STAT EMENTS

LISTED BELOW AND IN THE TEXT OF THIS MANUAL BEFORE YOU BEGIN WORK.

DANGER, WARNINGS & CAUTION SYMBOLS

Throughout these instructions “Front” or “Forward” refers to the front of the bike. The front of any component is the end which faces toward the front of the bike. The “Left” and “Right” hand sides refer to the

position of the parts as viewed by a rider sitting on the seat, facing forward.

NOTE: The symbol HD refers to Harley Davidson. The symbol LH refers to left-hand side while seated

on the bike. The symbol RH refers to the right-hand side while seated on the bike.

These instructions do not include information, specifications, or procedures relating to the motorcycle

itself. For this information, refer to the factory service manual.

The information in these instructions is provided to Lehman Trike dealers. It is proprietary to Lehman

Trikes, Inc. and provided solely for use by dealers. Any unauthorized duplication or distribution is a violation of international copyright law.

This is the safety alert symbol. When you see this

symbol on your machine or in this manual, be alert

to the potential for personal injury. Your safety is

involved!

SAFETY ALERT WARNING indicates a potential hazard

that may result in severe injury or death to the operator, bystander or person (s) inspecting or servicing the vehicle.

Indicates a potential hazard that may result in minor personal injury or damage to the vehicle.

CAUTION indicates special precautions that must be taken

to avoid vehicle damage or property damage.

NOTE provides key information by clarifying instructions.

IMPORTANT provides key reminders during disassembly,

assembly and inspection of components.

WARNING

CAUTION

CAUTION

NOTE:

IMPORTANT:

2009-2013 FLH RENEGADE

3

SECTION BREAKOUT

UNPACKING THE KIT

PREPARING THE MOTORCYCLE

REMOVING HD SWINGARM

INSTALLING LEHMAN SWINGARM

TOP MOTOR MOUNT LINK

CARRIER/PULLEY

DIFFERENTIAL-LEFT HALF

DIFFERENTIAL-RIGHT HALF

BELT TENSIONING/TRACKING

BRAKE SYSTEMS

FRAME/SUSPENSION

EXHAUST

ELECTRICAL

BODY

REPLACEMENT PARTS

TORQUE SPECIFICATIONS

FINAL TRIKE INSPECTION

HARDWARE DESCRIPTION/BOLT BAG BREAKDOWN

*Notes before starting conversion

*For 2009+ FLHX (Street Glide) and FLTR (Road Glide) installations, the following parts will need

to be ordered from H-D for antenna and turn signal installation:

HD P/N

76252-86 Base, antenna 1

76253-86 Reinforcement plate 1

76255-86 Gasket, base 1

11486 Grommet 1

68713-94A Lamp, rear signal 2

**Dakota Digital offers a hidden antenna kit as an alternative. Part # ANT-2000

*For 2010+ Models, the following parts are required.

HD P/N

73108-96BK Pin Housing 1

73190-96 Terminal Pin 8

*For 2010+ FLTR Models, the following parts are required.

HD P/N

65846-09 Muffler 1

LP1351 Exhaust Extension 1 (Lehman Part)

**ABS Models– Disabling the ABS light will also disable the cruise control light.

Description Qty.

Description Qty.

Description Qty.

2009-2013 FLH RENEGADE

4

GENERAL INFORMATION

General Safety Information

This kit is designed to be installed by a competent technician. Improper installation can affect

the safe operation of your trike, which could also result in serious injury or death. Make sure

you have a complete understanding of the work to be preformed. Unqualified installers are

urged to have the unit installed by a trained technician.

• Always protect yourself when the vehicle is in the air. Make sure the vehicle is properly supported

anytime you use a hoist or jack.

• Always use the proper tools.

• Protect your eyes by using proper safety glasses or goggles.

• Read through the installation instructions before you begin. Make sure you have all the proper

tools, parts and skill set to perform the installation safely and completely.

NOTE: Compliance with national (DOT-USA, MOT-Canada), State, Provincial, and local vehicle is

standards is the responsibility of the installer. Installation of the parking brake and grab handles is necessary to achieve compliance with DOT/MOT.

ARB Label Confirmation– California Kits

1. See Fig. 1. California Air Resource Board (ARB) certification label must be affixed on all swin-

garms for kits sold into California.

2. Label should be placed on left side of swingarm 1/2” from rear

weld.

3. Make sure label correlates with correct model year.

Fig. 1

2009-2013 FLH RENEGADE

5

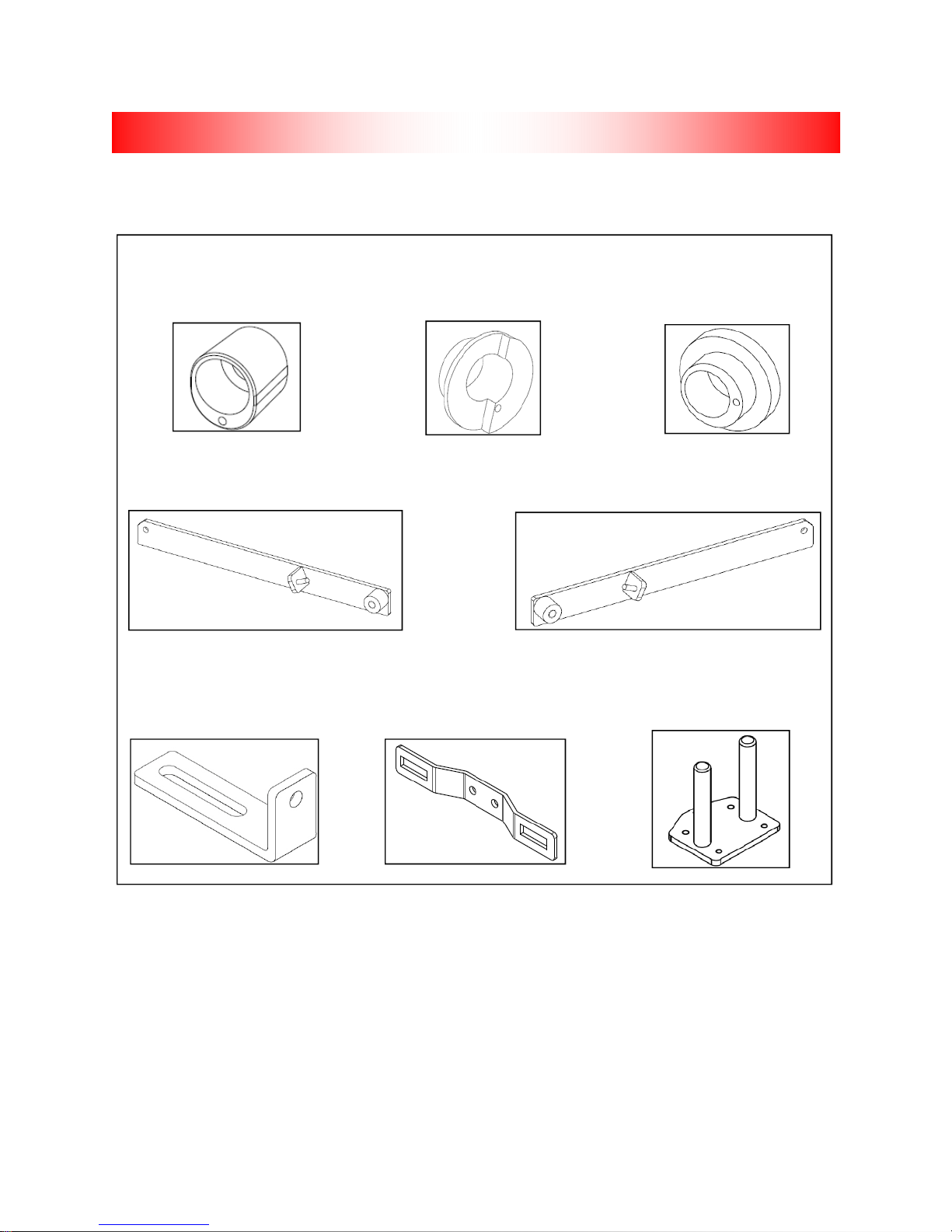

ILLUSTRATIONS

SWINGARM BUSHING-

S001315 (09-10 MODELS)

FRAME BRACE-S001266 FRAME BRACE-S001268

BODY BRACE-LB1235 LICENSE PLATE BRACKET-LB1207 ADAPTER PLATE-LP1038

SWINGARM BUSHING-LT-

S001346

SWINGARM BUSHING-RT-

S001347

2009-2013 FLH RENEGADE

6

ILLUSTRATIONS CONTINUED

MODULAR DIFFERENTIAL

LS2013-2002+ SWINGARM

GM0142 MOTOR MOUNT LINK

S001271-FRAME

2009-2013 FLH RENEGADE

7

PREPARING THE MOTORCYCLE

The following instructions are a guide to preparing the motorcycle to accept the Lehman Trike Conversion Kit. This will assist you in removing the necessary parts to install the kit. Refer to H-D service manual for detailed procedures on motorcycle disassembly.

1. Locate motorcycle year, model and serial number, as well as Lehman serial number, located inside

body, on left-side of swingarm and on warranty registration form in owner’s manual.

2. Make sure motorcycle is standing straight up and handlebars are centered. Support motorcycle under rear of transmission so it is straight up and down and handlebars are straight. The front forks or

handlebars should be anchored to hold bike.

NOTE: Use a small spirit level on rear wheel or disc brake to stand bike straight up. Any

movement of handlebars will move bike off level. Locate reference point on bike frame that

is level and check it frequently.

3. Remove seat and save mounting screw.

4. Disconnect battery.

CAUTION: Always disconnect negative battery cable first. If positive cable should conta ct a

grounded object while negative cable is installed, resulting sparks may cause an explosion.

5. Remove tour pack.

6. Raise motorcycle lift to working height.

7. Remove side stand mounting bolt and separate side stand from bracket.

8. Remove passenger footboards. Save boards and hardware for re-installation.

9. Remove side covers; they will be re-used.

10. Remove saddlebags (if equipped).

11. Remove mufflers and saddlebag mounts. Keep all muffler mounting hardware including rubber isolators located in saddlebag mounts. These parts will be re-used.

12. Support bike on center stand.

13. Disconnect airlines from shocks and remove shocks. Stand shocks upright to prevent oil leaks.

Save air valve plate and discard original shock mounting bolts.

14. Remove rear fender and save turn signal lights.

15. Remove brake line from caliper and remove caliper.

16. Remove retaining clip from rear axle and remove axle nut with 36mm socket. Axle can now be removed.

17. Remove rear wheel assembly.

18. Support transmission from below with jack and padded block.

2009-2013 FLH RENEGADE

8

REMOVING HD SWINGARM

2009-2010 MODELS

1. See Fig. 1. Remove (2) bolts to free swingarm

fork bracket from left side of motorcycle frame.

2. Release rear brake line hose and rear wheel speed

sensor (if ABS equipped) from cable clips on right

side of swingarm.

3. Remove decorative chrome plug from right side.

NOTE: For best results, use an air impact

wrench to remove right-side nut. Applying heat

to right-side nut may also improve removal. If

left-side nut loosens first, remove left-side nut

and use double nuts to hold pivot shaft while

removing right-side nut.

4. See Fig. 2. Hold left-side nut and remove right

side nut from end of pivot shaft. Remove and

discard cup washer.

5. Using a suitable punch, tap pivot shaft toward

left side of motorcycle.

6. See Fig. 1. Pull pivot shaft assembly with nut,

cup washer, rubber mount and outer spacer out

of transmission mount and left side fork. Hold

shaft in padded vise and remove LH nut. Discard LH cup washer.

7. Remove outer spacer from right side of swingarm.

8. Remove rubber mount from right side.

2011+ MODELS

1. See Fig. 1. Remove (2) bolts to free swingarm fork bracket from left side of motorcycle frame.

2. Release rear brake line hose and rear wheel speed sensor (if ABS equipped) from cable clips on

right side of swingarm. Remove black plastic plug from right side.

NOTE: For best results, use an air impact wrench to remove right-side bolt. Applying heat to

right-side bolt may also improve removal. If left-side bolt loosens first, use a ¾” socke t to

hold LH pivot shaft outer spacer while removing right-side bolt.

3. See Fig. 2. Hold left-side bolt and remove right side bolt from end of pivot shaft.

4. Using a suitable punch, tap pivot shaft toward left side of motorcycle.

5. See Fig. 1. Pull pivot shaft assembly with outer spacer and rubber mount out of transmission mount

and left side fork. Hold shaft in padded vise and remove LH bolt.

6. Remove outer spacer from right side of swingarm. Remove rubber mount from right side.

Pivot shaft nut

Right-side mount

Fig. 1

LH Fork bracket bolts

Fig. 2

2009-2013 FLH RENEGADE

9

REMOVING H-D SWINGARM

TRIMMING EXHAUST

NOTE: Trimming rear head pipes is more

convenient while swingarm is removed

from frame.

1. Remove LH and RH rear heat shields.

2. See Fig. 4. Using an appropriate cutting tool,

cut 1 5/8” from end of both rear head pipes.

3. Reinstall LH heat shield after cut. Shield will

be placed 1/4” to 1/2” forward to gain clearance for extension pipe installation.

4. Install RH heat shield.

Fig. 4

2009-2013 FLH RENEGADE

10

INSTALLING LEHMAN SWINGARM

NOTE: Swingarm pivot shaft components are different between

2009-10 and 2011+ models. Be sure to use the correct procedu re

for your specific model year. See Fig. 1. Swingarm pivot shaft

bushings for 2011 models (S001661) will have a larger inside diameter.

Fig. 1

2009-2010 Models

NOTE: If all original components of H-D swingarm are in good

working order, they may be re-used.

1. Press bearing assemblies out of HD swingarm using appropriate

press collar. Refer to HD service manual.

NOTE: Make sure swingarm bore is clean where bearing w ill

be pressed in.

2. Press bearings into Lehman swingarm following H-D service man

ual procedure (H-D tool # HD-45327). H-D tool will set bearings at

correct location in Lehman swingarm collar.

3. See Fig. 1 & Fig 2. OEM cup washers will be replaced by new

swingarm reinforcement bushings (S001346-LH, S001347-RH &

S001315).

4. See Fig. 3. Install RH swingarm reinforcement bushings (S001347 & S001315) into original rubber mounts. Be

sure to align offset in mount and bushings.

5. Install Lehman swingarm with word “TOP” (stamped into swingarm collar) facing upward.

6. See Fig. 3. Assemble parts for LH side (S001346 & S001315) as shown.

7. See Fig. 3. Re-install LH swingarm fork bracket. Apply Loctite 242 and torque bolts to 55 ft.-lbs.

8. Apply Loctite 242 to pivot shaft nuts and install. Torque swingarm pivot shaft nuts to 55 ft.-lbs and

reinstall chrome caps.

NOTE: Refer to HD service manual for swingarm installation procedures and torque specifications for specific model of motorcycle.

Verify swingarm assembly moves freely with no side to side play. Light resistance when moving up

9.

and down is normal.

Fig. 3

Fig. 2

2009-2013 FLH RENEGADE

11

INSTALLING LEHMAN SWINGARM

2011+ Models

NOTE: If all original components of H-D swingarm are in good working order, they may be re used.

1. Press bearing assemblies out of HD swingarm using appropriate press collar. Refer to HD service

manual.

NOTE: Make sure swingarm bore is clean where bearing will be pressed in.

2. Press bearings into Lehman swingarm following H-D service manual procedure (H-D tool # HD-

45327). H-D tool will set bearings at correct location in Lehman swingarm collar.

3. See Fig. 1 & Fig 2 on previous page. Swingarm reinforcement bushings (S001346-LH, S001347-

RH & S001661).

4. See Fig. 4. Install RH swingarm reinforcement bushings (S001347 & S001661) into original rubber

mounts. Be sure to align offset in mount and bushings.

5. Install Lehman swingarm with word “TOP” (stamped into swingarm collar) facing upward.

6. See Fig. 4. Assemble parts for LH side (S001346 & S001661) as shown.

7. See Fig. 4. Re-install LH swingarm fork bracket. Apply Loctite 242 and torque bolts to 55 ft.-lbs.

8. Apply Loctite 242 to pivot shaft bolts and install. Torque swingarm pivot shaft bolts to 55 ft.-lbs.

9. See Fig. 4. Discard OEM black plastic pivot shaft plugs and replace with S001662 chrome caps.

NOTE: Refer to H-D service manual for swingarm installation procedures and torque specifi

cations for specific model of motorcycle.

10. Verify swingarm assembly moves freely with no side to side play. Light resistance when moving up

and down is normal.

Fig. 4

2009-2013 FLH RENEGADE

12

Top Motor Mount Link Removal: 2009+ Models

NOTE: For 2009+ models, do not disturb

OEM head bolts or lower engine mount bolt.

MOTOR MOUNT LINKS

1. See Fig. 1. OEM top motor mount link will be

replaced with Lehman Motor Mount Link.

2. See Fig. 2. Remove OEM motor mount link.

3. Save all mounting hardware.

Lehman Motor Mount Link

NOTE: Refer to H-D service manual for

proper removal and installation procedures

for all motor mounts.

4. Adjust Lehman motor mount link to same distance from center of hole to center of hole as

OEM motor mount link.

• (1) Upper Engine Stabilizer Link– GM0142

NOTE: Locate position of eyelet holes and

alignment of OEM link. Lehman link must be

adjusted same as OEM link; when link is adjusted, use Loctite 262 and secure lock nuts

in place.

5. Install Lehman link using existing OEM bolts,

blue Loctite 242 and supplied motor mount link

shims. Reinstall OEM washer below link on RH

side.

NOTE: Be sure to shim both sides of link ends.

6. Torque OEM bolts to 33 ft. lbs.

Fig. 1

Lehman motor mount link

OEM Top motor mount link

Fig. 2

Lehman link installed

2009-2013 FLH RENEGADE

13

DIFFERENTIAL

Differential Installation

1. See Fig. 1. Attach LH adapter plate (LP1038) to

swingarm as shown. Leave hardware loose.

2. See Fig. 2. Attach RH adapter plate to swin-

garm as shown with park brake bracket mounted

to lower holes. Leave hardware loose.

3. See Fig. 1 and 2. Install 3/8” nut to adjuster bolt

and thread into adapter plate from backside. Run

bolt completely into adapter plate.

Fig. 1

Fig. 2

2009-2013 FLH RENEGADE

14

DIFFERENTIAL CONTINUED

4. See Fig. 3 and 4. Loosely install hardware to

pinch blocks before installing differential to

swingarm.

NOTE: Shock plate orientation is different

on 09+ models. Make sure shock mount

hole on rear of plate is towards the top.

Fig. 3

Hole towards top

Fig. 4

Hole

towards

top

2009-2013 FLH RENEGADE

15

DIFFERENTIAL CONTINUED

5. Support swingarm with jack stands.

6. See Fig. 5. With differential assembly on lift,

slide belt over LH axle tube and against center

housing.

7. See Fig. 5. Set differential assembly on swin-

garm adapter plates. Slide differential as far

forward as possible. Set jack stands under

axle tubes.

8. Tighten pinch block hardware just enough to

allow differential to slide on swingarm adapter

plates.

9. See Fig. 5. Remove upper, lower and rear

housing plates.

10. See Fig. 6. Carefully slide belt over pulley.

11. Reinstall housing plates with original hardware

using Loctite 242. Install all hardware before

tightening. Torque hardware to 17 ft. lbs.

Fig. 5

Remove plates

Fig. 6

Install belt

2009-2013 FLH RENEGADE

16

DIFFERENTIAL CONTINUED

12. See Fig. 10. Remove RH front plate hardware

and install tapered washers (S001784) into

holes on RH side before installing brace.

13. Bolt rear half of differential brace to housing

using bolts (CB1939).

14. See Fig. 11. Bolt front half of differential brace

to top of swingarm gusset with a 3/8” x 1” bolt,

flat washers and lock nut.

Note: Do not bolt down brace until belt tensioning is completed.

15. Tighten bolts in following order:

a. Front half of brace to swingarm gusset.

Torque bolts to 35 ft. lbs.

b. Rear half of brace to differential housing.

Torque bolt to 25 ft. lbs.

c. Torque LH front plate bolts to 17 ft. lbs.

Fig. 7

Tapered washers

Fig. 8

2009-2013 FLH RENEGADE

17

BELT TENSIONING AND TRACKING

1. Center differential to motorcycle frame– this is critical for proper body and seat pan alignment.

Make sure distance is within 1/16” from side to side.

2. Level swingarm to motorcycle frame. This will help achieve proper ride height and is critical for

proper belt tensioning.

3. See Fig. 1. Using adjusters, push differential assembly back until belt has about 3/8” slack with 10

lbs. pressure at midpoint of bottom run. Measure between adapter plates and pinch blocks to en-

sure that distances are equal.

4. Rotate pulleys forward for at least 3 revolutions of rear pulley by pulling

backwards on bottom run of belt. Pull belt

straight back to get an accurate reading. Check

that belt is running about 0.030” from flange on

rear pulley. Belt may ride next to flange as long

as it’s not trying to climb.

5. Tighten socket head screws (8) that hold adapter

plates to swingarm and torque to 35 ft. lbs.

6. Once tracking is obtained, re-check belt tension.

Raise and lower differential assembly slowly with a jack while checking belt tension. When tightest

position is located, apply 10 lbs. force at midpoint of lower strand of belt. Correct deflection for

various models is as follows:

Fig. 1

MODEL INCHES MILLIMETERS

FLHX 1/4-5/16 6.4-7.9

All other FLH models 3/8-7/16 9.5-11.1

7. Increase or reduce belt deflection by turning adjuster screw on each side in or out an equal number

of turns.

8. Look along top of belt to check belt alignment on front pulley. There should be about 0.030” clearance between pulley flange and belt. Check rear alignment and belt tension again if adjustment is

required.

NOTE: If necessary, apply chalk to edge of belt to aid in getting proper clearance be tween

belt and pulley flanges. If visible clearance cannot be obtained, be sure belt is not climbing

up the side of pulleys or squeaking as belt is rotated.

9. After all adjustments are made, tighten adjuster lock nuts and tighten pinch block bolts. Tighten

pinch blocks in a criss-cross pattern. Go over both sides at least 2 times to seat blocks over pins.

Torque bolts to 25 ft. lbs.

2009-2013 FLH RENEGADE

18

BRAKE SYSTEMS

Disc Brakes

CAUTION: Brakes are a critical safety component of the trike. Verify all brake components

have been properly installed before test riding.

Improper brake operation could result in death

or serious injury. Do not allow dirt or debris to

enter master cylinder reservoir. New brake

pads and rotors will have a break-in period before optimum brake operation is achieved.

Note: FOR ABS DISABLE, SEE PAGE 21

Brake System

1. See Fig. 1. Attach brass tee to differential

brace using the following hardware.

• (1) Brass Tee– CF5105

• (1) Spacer– S001530

• (2) 1/4” x 1-3/4” Hex Bolt– CB1100

• (2) 1/4” Flat Washers– CW2005

• (2) 1/4” Lock Nut– CN3042

2. See Fig. 1. Install original brake line from

master cyclinder and rear braided lines to

brass tee using the following hardware. Torque

banjo bolt to 16 ft. lbs.

• (1) Banjo Bolt– S002022

• (2) Banjo Washers- GC6002

• (2) 45” M10 Braided Line– S001976

3. See Fig. 2. Install (2) braided brake lines to

rear calipers as shown. Torque bolts to 16 ft.

lbs.

• (2) M10 Banjo Bolt– CB6001

• (4) M10 Banjo Washers- GC6002

4. Secure brake lines to swingarm with cable ties.

Fig. 1

OEM line

Spacer

Fig. 2

Install brake lines to LH/RH calipers

2009-2013 FLH RENEGADE

19

BRAKE SYSTEMS CONTINUED

Note: Be sure you have correct model year reservoir extension pack before proceeding

(Reminder: packs are labeled 1997-2007 and

2008+).

5. See Fig. 3. Remove original master cylinder

reservoir cap screws and discard. Install extension to master cylinder with new extension

screws. Do not over tighten extension

screws.

Note: Verify all brake lines and hardware are

tight before bleeding system.

6. Add brake fluid (refer to OEM reservoir cap for

brake fluid requirements) to brake system and

work brakes to fill lines.

7. Remove rubber caps on bleeder valves. Install

clear brake bleeder hose over bleeder valve on

caliper.

8. Pump brake pedal to build hydraulic pressure.

9. While holding the brake pedal, open bleeder

valve to release pressure and remove air from

system. Repeat bleeding on both calipers until

fluid is solid without bubbles in bleeder hose.

10. Tighten bleeder valves and check for leaks.

11. Install master cylinder reservoir cap with new

screws. Do not over tighten cap screws.

Park Brake Assembly

1. See Fig. 4. Install park brake cable to caliper

brackets. Secure cable to bracket with cir-clip

provided on cables.

Fig. 3

Supplied cover screws

Extension screws (2008+ pack)

Fig. 4

Secure to bracket

Attach cable

2009-2013 FLH RENEGADE

20

BRAKE SYSTEMS CONTINUED

5. See Fig. 7. Remove snap ring from one side of large

clevis pin on brake lever. Hold park brake lever on its

side and push release button at end of park brake lever

to allow clevis pin to slide out.

6. See Fig. 7.Place park brake lever within park brake

bracket, ensuring ratchet is secure on cross brace. Attach with large clevis pin.

7. See Fig. 7. Attach park brake cable pulling bracket

(LB1294) to brake lever using small clevis pin (CC3106)

and cotter pin (CC4017).

8. See Fig. 8. Route left park brake cable above differen-

tial and under motorcycle frame, attaching cable ties to

cable and frame, and install in left hole in handle mount.

9. See Fig. 9. Route right park brake cable up around axle

and forward to right hole in handle mount.

10. See Fig. 9. Secure both cables to upper rear pinch block

with clamp (GC0108).

11. See Fig. 10. Secure cable retaining nuts to handle

mount with 7/8” wrench.

12. Check for tire clearance.

13. See Fig. 10. Thread one 5/16” NF nut onto each brake

cable. Place threaded end of brake cables through

holes in cable bracket. Thread second nut onto each

brake cable.

14. Adjust park brake cables at handle to engage at 3–4

clicks.

Note: Take up slack in cables before tightening ends to

ensure good adjustment range with threaded end of

brake cables.

Fig. 7

Fig. 8

Left park brake cable

Fig. 9

Cable routing

Attach clamp

Fig. 10

Cable retaining nuts

Adjuster nuts

2009-2013 FLH RENEGADE

21

BRAKE SYSTEMS-ABS MODELS

ABS Systems

1. See Fig. 1. Disconnect OEM rear brake line (black)

from ABS unit “MR”. Route brake line along lower

frame tube and above swingarm. This line will be

used for the rear brake system.

2. See Fig. 2. Re-install banjo bolt with spacer

(S001067) in ABS unit “MR” and tighten.

3. See Fig. 1. Disconnect OEM rear brake line (silver)

from ABS unit “R” and discard (brake line was disconnected from rear caliper during motorcycle disassembly).

4. See Fig. 2. Re-install banjo bolt with spacer

(S001067) in ABS unit “R” and tighten.

5. See Fig 3. Locate ABS front wheel sensor plug un-

der left side of fairing and disconnect. Secure longer

sensor plug to fairing wire bundle with cable tie

(CT1026).

6. See Fig. 4. Locate ABS rear wheel sensor plug (left

side of ABS unit). Disconnect plug, remove sensor

from right-side axle and discard.

7. Place ABS warning label above warning light indicators on fairing.

Fig. 1

From ABS to caliper (silver)

From Mas. Cyl. to ABS (black)

R

MR

Fig. 2

R

MR

Banjo bolt spacer (S001067)

Fig. 3

ABS front wheel sensor plug

2009-2013 FLH RENEGADE

Fig. 4

ABS rear wheel sensor plug

22

BRAKE SYSTEMS-ABS MODELS CONTINUED

Note: Items 7-11 can be performed during Neck Race

Preload check.

7. Remove outer fairing (refer to HD service manual).

Caution: Disabling ABS light will also disable cruise

control light.

8. See Fig. 5. Disable ABS warning light by cutting orange wire with white stripe.

9. See Fig. 6. Install 2” heat-shrink to each end of cut

wire.

10. Re-install fairing.

11. See Fig. 7. Place ABS warning label above warning

light indicators on fairing.

Fig. 5

Fig. 6

Apply heat shrink to ends of wires

Fig. 7

Place “ABS Disabled” sticker here

2009-2013 FLH RENEGADE

23

FRAME AND SUSPENSION

1. The holes in front of Lehman frame line up with

HD shock mount holes.

2. Position Lehman frame above differential and

inside motorcycle frame, lining up mounting

holes.

3. See Fig. 1. Install the following hardware in the

front frame mounting holes. Torque bolts to 75

ft.-lbs.

• (2) 1/2” X 2” bolts- CB1406

• (2) 1/2” Lock Washers– CW2061

• (2) 1/2” Flat Washers– CW2025

4. See Fig. 2. Install the following hardware in the

rear frame mounting holes. Torque bolts to 18

ft.-lbs.

• (4) 5/16” x 1” Bolts– CB1161

• (4) 5/16” Lock Washers– CW2047

• (4) 5/16” Flat Washers– CW2010

5. See Fig. 3. Install LH and RH frame straps to

upper holes in motorcycle frame using the fol-

lowing hardware. Torque bolts to 18 ft.-lbs.

• (1) LH Frame Strap– S001266

• (1) RH Frame Strap– S001268

• (2) 5/16” x 1” Bolts– CB1161

• (2) 5/16” Lock Washers– CW2047

• (2) 5/16: Flat Washers– CW2010

6. See Fig. 3. Lower frame strap mounting holes

will use the following hardware. Torque bolts to

52 ft.-lbs.

• (2) 7/16” x 1” Bolts– CB1287

• (2) 7/16” Lock Washers– CW2022

• (2) 7/16” Flat Washers– CW2053

Fig. 1

LH and RH front holes

Fig. 2

LH and RH rear holes

Fig. 3

Frame strap top mounting holes

2009-2013 FLH RENEGADE

Frame strap bottom mounting holes

24

FRAME AND SUSPENSION

7. Use original cross-over airline to connect “tee” to air

valve. Use new air line to connect two shocks together.

8. See Fig. 4. Air valve plate for front and rear shocks

must be removed and relocated. Recommended location is on right side of trike behind air deflector in location shown.

9. See Fig. 5. Air valve plate will be fastened with

stainless nuts on both sides of deflector.

10. Route airlines along bottom side of upper frame tube

and back to rear shocks.

11. Secure airline to frame with cable ties as needed.

12. Charge system with air to 20 psi and check for leaks.

13. See Fig. 6. Install Shock to lower threaded shock

plate. Torque bolt to 40 ft.-lbs. Secure bolt with lock

nut.

• (2) 1/2” X 2 x 1/4” Bolts– CB1411

• (2) 1/2” Flat Washer– CW2025

• (2) 1/2” Lock Nut

14. See Fig. 6. Raise differential and install top of shock

To frame using the following hardware. Shock should

run parallel to frame tube when viewed from rear.

Torque shock bolts to 40 ft.-lbs.

• (2) 1/2” X 2 x 1/4” Bolts– CB1411

• (2) 1/2” Lock Washer– CW2060

• (2) 1/2” Flat Washer– CW2025

Fig. 6

Fig. 4

Relocate air valve plate

Fig. 5

Air valve plate

mounting hardware

2009-2013 FLH RENEGADE

25

EXHAUST

NOTE: Exhaust pipes are marked “L” and “R.”

1. See Fig. 1. Install exhaust clamp (GC1016) on front end of LH extension pipe (S001309) and slide

onto LH OEM pipe.

2. Install exhaust clamp (GC1016) on front end of RH extension pipe (S001273) and slide onto RH

OEM pipe.

3. Install rubber mount into Lehman frame.

4. Slide OEM muffler mounting bracket through rubber mount.

5. Slide mufflers with clamps in place over Lehman extension pipes.

6. Ensure mufflers are even on both sides.

7. Torque exhaust clamps to 40 ft.-lbs.

8. Use OEM mounting hardware to secure muffler to mounting bracket on Lehman frame. Torque bolts

to 144 in.-lbs.

Fig. 1

ITEM PART # QTY. DESCRIPTION

0 OEM PARTS

1 S001273 1 PIPE, EXT., RIGHT-HAND

2 S001309 1 PIPE, EXT., LEFT-HAND

3 GC1016 2 CLAMP, EXHAUST

2009-2013 FLH RENEGADE

26

LIGHTS AND WIRING

Lights and Wiring

Caution: Use care with painted surfaces

1. See Fig. 1. Drill 15/16” hole for turn signal on flat

below taillight. Center turn signal with inside edge

of taillights. Mount H-D turn signals using original

bolts with supplied washers (CW2001).

NOTE: Do not over tighten taillight mounting hardware. Damage to housing may occur.

2. See Fig 2. Mount taillight assemblies to body with

gaskets. Attach ground wire to stud with flange nut

after taillight mounting hardware is installed.

• (2) Taillight Assembly-S002204

• (2) Gaskets– BG0200

• (4) 1/4” Flat Washer– CW2006

• (4) Lock washer– Provided with light

• (4) Nut– Provided with light

• (2) 1/4” Flange Nut– CN3007

3. See Fig’s 3 & 4. If required- Install female terminals

and male connectors to taillight wiring Use appropriate

tool for crimping terminals to wires. (Mac Tools–

TCT1028).

4. See Fig’s 3 & 4. Inspect crimps before installing into

connector. Distortion should be minimal.

Fig. 1

Mount signal

to body

Fig. 2

Attach ground wire to stud

Fig. 3

Female Terminal

Insulation crimp

2009-2013 FLH RENEGADE

Wire core crimp

Fig. 4

1

2

3

27

LIGHTS AND WIRING

5. See Fig. 5. Install license plate bracket to door

with 1/4” x 1” bolts, washers, lock nuts and rubber

washers. Use rubber washers between bracket

and door. Install U-nuts to bracket

• (2) 1/4” x 1” Button head bolt (CB1086)

• (2) 1/4” Rubber washer (FG1002)

• (2) 1/4” Flat washer (CW2005)

• (2) 1/4” Lock nut (CN3040)

• (2) 1/4” U-nut (CN3301)

6. See Fig. 6. Install license plate light and support

plate to bracket using (2) 1/4” x 1 bolts.

See Fig. 5. Run wiring through lower hole in door .

• (1) License plate light (S001469)

• (1) Support plate (S001601)

• (2) 1/4” x 1 Button head bolt (CB1086)

• (2) M6 Flat washer- CW2175

7. See Fig. 6. Install lower license plate mounting

hardware into place on support bracket using 1/4”

x .50” bolts and (2) lock nuts

Fig. 5

Install rubber washers

between bracket and door

U-nut

Install wire through lower hole

Fig. 6

• (2) 1/4” x .50 Button head bolt (CS4032)

• (2) 1/4” Lock nut (CN3040)

8. Solder and heat shrink light wiring to trunk wiring

harness. Attach wire as follows-

• Black wire on light to Black wire on

trunk harness

• Red wire on light to Red wire on trunk

harness

9. Seal wiring through door with silicone (Ultra

Black).

2009-2013 FLH RENEGADE

28

Renegade Wiring Harness

1. See Fig.’s 1-2. Attach wiring harness to body

clips on underside of body. The Purple turn signal wire will go to the LH side. The Brown turn

signal wire will go to the RH side.

2. Connect 8 position connector on wiring harness

(Fig. 3) to OEM harness, located under rider

seat at rear of OEM frame.

Body clip

LIGHTS AND WIRING CONTINUED

Fig. 2

Fig. 1

Taillight connector

Light bar

connector

on RH side

Body clips

Fig. 3

8-position connector on wiring harness-main

License plate connector

6-position connector on wiring harness for trailer

3. See Fig.’s 4-5. Before connecting license plate and light bar (optional) to harness, terminals and

connectors will need to be installed to each before connecting to wiring harness. Use appropriate

tool for crimping terminals to wires. (Mac Tools– TCT1028, Blue Point– PWC47 or H-D 41609).

4. See Fig. 5. Inspect crimps before installing into connector. Distortion should be minimal.

Fig. 4

Male terminal

Fig. 5

Insulation crimp

Wire core crimp

Female terminal

2009-2013 FLH RENEGADE

29

LIGHTS AND WIRING CONTINUED

6 position connector for

trailer-GH0023-2

8 position connector

under seat-GH0023-1

Included in bag

Fig. 8

Left brake

light-GH0023-4

Left turn signalGH0023-4

License plate connectorGH0023-3

Right brake

light-GH0023-3

Right turn signalGH0023-4

Light barGH0023-5

Wiring Diagram

Red/White

Tracer

Purple

Blue

Fig. 9

Orange/White

Tracer

Brown

Black

Orange/White

Tracer

2009-2013 FLH RENEGADE

Black

30

SIDE COVER MODIFICATION

1. See Fig. 1. Place side cover template

(S001324) as shown with a 90° bend at center;

make sure template rests firmly against mounting peg.

2. See Fig. 2. Mark grommet access hole and

side-cover cut-out as shown.

3. Using 1/8” drill bit, make a starter hole for grommet access hole.

4. Using a 7/16” drill bit, drill a 7/16” hole for grommet access hole.

5. Install rubber grommet (S001323) in grommet

access hole. Secure with glue if necessary.

6. Using appropriate cutting tool, cut side-cover

along template mark.

7. See Fig. 3. Trim upper, rear mounting peg

leaving 1/4” remaining.

8. Repeat steps 1-7 for other side.

Fig. 1

Set template firmly against peg

Template should be at 90°

Fig. 2

Mark side-cover cut-out

Mark grommet access hole

Fig. 3

Trim mounting peg to 1/4”

2009-2013 FLH RENEGADE

31

BODY

WARNING: To meet DOT and MOT requirements one of the following must be installed

on all Lehman Trikes: stock grab handles,

stock grab strap or Lehman-supplied grab

handles. Please contact Lehman Trikes if

you require replacement grab handles.

1. Place body on trike frame.

2. Route emergency trunk release cable along H-D

frame and secure behind LH side cover.

3. Install (1) rubber body washer (CW2097) between body and frame mounting tabs.

4. Place a thin strip of weather seal around seat

shell.

• (1) Weather Seal– CW2505

• (1) 09+ Seat Shell– S001317

5. Insert (2) studs with Red Loctite (262) into seat

shell inserts.

• (2) 1/4” x 1” Studs– S001343

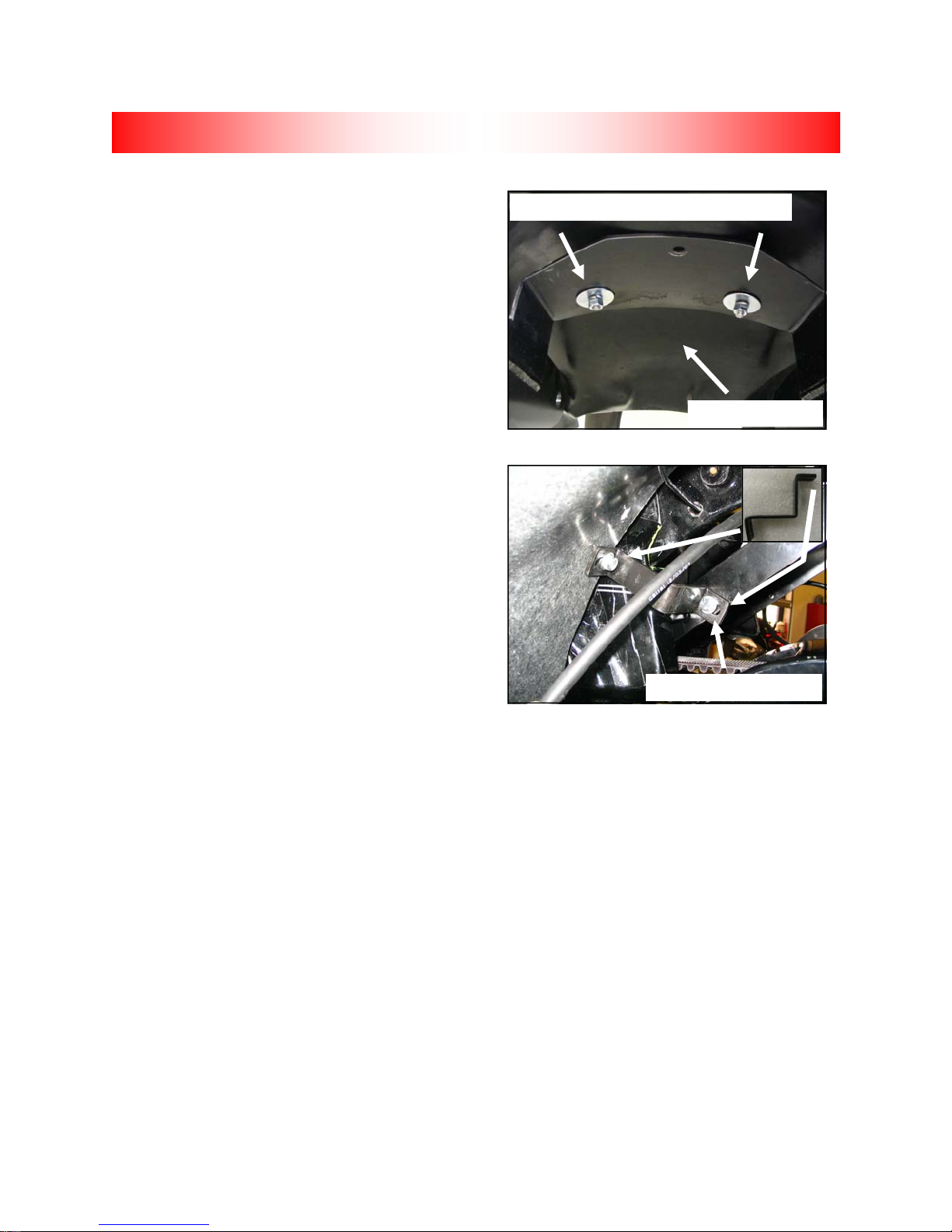

6. See Fig. 1. Install seat shell to support on frame

using the following hardware. Leave bolts loose.

• (2) 1/4” Fender Washers– CW2108

• (2) 1/4” Lock Washers– CW2040

• (2) 1/4” Lock Nuts– CN3041

7. See Fig. 2. Install left and right body support

brackets with 90° bend against frame strap; attach front of body mount bracket into seat shell inserting rubber washer between bracket and body. Attach brackets with the following hardware. Leave

bolts loose.

• (2) Rubber Washer– CW2096

• (2) 1/4” 1” Bolts– CB1085

• (2) 1/4” Lock Washers– CW2040

• (2) 1/4” Flat Washers– CW2005

8. Attach rear of body mount bracket to frame strap using the following hardware. Leave bolts loose.

• (2) 1/4” x 3/4” Bolts– CB1081

• (2) 1/4” Lock Washers– CW2040

• (2) 1/4” Flat Washers– CW2005

Underside of frame-seat shell hardware

Fig. 1

Seat shell support

Fig. 2

90° bend to frame strap

2009-2013 FLH RENEGADE

32

BODY CONTINUED

9. See Fig. 3. Center body to differential from side

to side until equal measurements are achieved on

both sides.

10. See Fig. 4. Center body front to back measuring

from rear axle flange to front of fender until equal

measurements are achieved on both sides.

11. Allow at least 1/2” gap between front of seat shell

and side cover for side cover removal.

12. Tighten hardware in this order: seat shell bolts,

front body mount bolts into seat shell; torque front

body mount bolts to 6 ft-lbs.

13. From underside of body, drill a 1/4” hole in body

through each of four mounting tabs. Keep hole

centered in slots on frame.

14. Fasten body to Lehman frame as follows: Head

of bolt will be inside trunk.

• (4) 1/4” x 1-1/2” Button Head Bolts- CS4031

• (4) 1/4” x 1 1/4” Fender Washers- CW2108

• (4) Foam Sealing Washers- FG1002

• (4) 1/4” Flat Washers- CW2007

• (4) 1/4” Lock Nuts- CN3041

15. Recheck body alignment; adjust accordingly.

16. Tighten body mount brackets to frame straps.

Torque bolts to 8 ft.-lbs.

17. See Fig. 5. Install upper body braces (LB1235)

by attaching slotted side on top of Lehman frame using the following hardware. Leave hardware loose.

• (2) Body Brace– LB1235

• (2) 5/16” x 1” Bolts– CB1161

• (2) 5/16” Lock Washers– CW2047

• (2) 5/16” Flat Washers– CW2010

18. Slide bracket against trunk, mark and drill 1/4” hole.

19. Attach bracket to body using the following hardware.

• (2) 1/4” x 1-1/2” button head bolts- CS4031

• (2) 1/4” x 1 1/4” fender washers CW2108

• (2) Foam Sealing Washers FG1002

• (2) 1/4” Flat Washers- CW2007

• (2) 1/4” Lock Nuts- CN3041

20. Tighten 5/16” hardware into place on trike frame.

21. Verify all body mounting hardware is tight.

Fig. 3

Equal measurements on both sides

Fig. 4

Equal measurements on both sides

Fig. 5

Body brace attached

to frame

2009-2013 FLH RENEGADE

33

TOUR PACK

NOTE: See Fig. 1. Adapter plate (S001307)

angled ears determine rearward position and

straight and 90° edges determine forward

position.

1. Install tour pack adapter plate to base plate us-

ing button head bolts. Torque bolts to 8 ft.-lbs.

• (1) Adapter Plate- S001307

• (1) Base Plate– S001090

• (4) 1/4” x 5/8” Button Head Bolts– CS4089

2. See Fig. 1. Set base assembly on bench and

place tour pack on base assembly.

3. See Fig. 2. Open tour pack lid and temporarily

fasten tour pack to base assembly using (2) of

the (4) 1/4” x 7/8” button head bolts (CS4094).

4. Set tour pack and assembly on body.

5. Center tour pack to body, seat and grab handle.

6. Mark holes in body with scribe or equivalent.

7. Remove tour pack and assembly from body.

8. Drill holes in body with 5/16” drill bit and drill.

9. Remove tour pack from base assembly.

10. See Fig. 3. Place rubber gaskets on body and

install base assembly using the following hardware.

• (4) 5/16” x 1-1/4” Button Head Bolts– CB1163

• (4) 5/16” Lock Washers– CW2046

• (4) 5/16” Flat Washers– CW2009

11. Install tour pack support brackets inside trunk

body and fasten plates to assembly hardware.

Torque bolts to 17 ft.-lbs.

• (1) Tour Pack Support Brackets- S001091

12. Reinstall tour pack and fasten tour pack with all

hardware. Torque bolts to 8 ft.-lbs.

13. Reinstall all tour pack wiring in proper locations.

14.NOTE: Tour pack ground strap will need

to be relocated to proper ground.

14. Reinstall tour pack liner.

Fig. 1

Rearward

Adaptor plate-S001307

Fig. 2

Temporarily fasten tour pack with hardware

Fig. 3

Base assembly on body

Forward

2009-2013 FLH RENEGADE

34

TRUNK DOOR

Trunk Door Installation

Note: Lip on weather seal will face away

from door opening; top of seal is flush with

top of door.

1. See Fig. 1. Install door seal around edge of

body, starting at center on bottom and following trunk opening. Trim seal ends straight

with scissors; glue ends together when finished.

• (6’) Door Seal– CW2536

2. See Fig. 2. Insert lanyard through top bend

on cable stop bracket. Make a small loop in

the end of lanyard and crimp using aluminum clip (see inset in Fig. 2). There should be

7-1/2” between the crimp and pre-made end of

lanyard. Verify both lanyards match before

crimping.

• (2) Door Lanyard– S001686

• (2) Cable Bracket– FB1036

• (2) Aluminum Crimp– CC1900

3. Apply masking tape to body just below hinge

mounting holes to prevent scratching of paint by

hinges.

Fig. 1

Top of seal is flush with door opening

Lip on weather seal

Fig. 2

Insert through bracket

Loop and crimp

4. See Fig. 3.Install door hinges and stop cable

brackets to body with hinge gaskets underneath

hinge using 10/32” x 1” screws and plated star

nuts.

• (2) Door Hinge– GH0903

• (2) Hinge Gaskets– FG1003

• (4) 10/32” x 1” Phillips Screws– CS4024-0

• (4) Plated Star Lock Nuts– CN1898

5. Fasten door to hinges using 10/32” x 3/8”

screws.

• (4) 10/32 x 3/8” Phillips Screws– CS4024-1

6. Attach lanyard to door using shoulder screws

with M6 flat washer under cable end.

• (2) 1/4” x .438 Shoulder Screws– CB1151

• (2) M6 Flat Washer– CW2172

7. See Fig. 3.Torque shoulder screws to 6 ft-lbs us-

ing 5/32” Allen socket.

2009-2013 FLH RENEGADE

35

Shoulder Screw

Washer under

cable end

Fig. 3

TRUNK DOOR CONTINUED

8. See Fig. 4 Install key switch through body.

9. See Fig. 4 Install latch cable bracket onto key

switch.

10. See Fig. 4 Install large nut to rear door key

switch using 7/8” wrench and adjust bracket in

an upright position.

11. See Fig. 4.Attach cable to key mechanism while

key is in vertical position with head of screw from

cable facing out.

12. See Fig. 5. Install striker pin to striker bracket

using 5/16” lock nut .

• (1) Striker Pin– GL2041

• (1) Striker Bracket– LB1297

• (1) 5/16” Lock Nut– CN3045

13. Attach striker pin bracket to door using 1/4”

lock washers and 1/4” bolts .

• (2) 1/4” x 1/2” Bolts– CB1075

• (2) 1/4” Lock Washers– CW2040

14. Install Renegade badge to bottom right side

of door. Install Lehman badge GB1320 to

bottom left side of door.

• (1) Renegade Badge– GB1324

• (1) Lehman Badge– GB1320

15. Cut license plate wire from body to length to

reach body wiring as needed.

16. Install shrink tubing over license plate wires.

17. Strip and solder ends of license plate wires from the body and door together.

18. Slide shrink tubing over soldered connections and heat.

19. Solder and heat shrink light wiring to trunk wiring harness. Attach wire as follows-

Cable bracket

Fig. 4

Fig. 5

Key switch

Striker pin

and bracket

• White wire on light to Black wire on trunk harness

• Gray wire on light to Red wire on trunk harness

20. Secure wiring to trunk door.

2009-2013 FLH RENEGADE

36

DOOR ADJUSTMENT

Fig. 1

2009-2013 FLH RENEGADE

37

DOOR ADJUSTMENT CONTINUED

Fig. 2

Fig. 18

2009-2013 FLH RENEGADE

38

FINAL ASSEMBLY

Final Assembly

1. Install grab handle to seat shell using the following hardware. Torque bolts to 8 ft.-lbs.

• (1) Grab Handle– LH1026

• (2) 1/4” x 3/4” Bolts– CB1081

• (2) 1/4” Lock Washers– CW2040

• (2) 1/4” Flat Washers– CW2005

2. Install seat to fender using original H-D mounting hardware.

Note: Make sure insert in fender is free of paint before installing screw.

3. Install wheels. Torque wire wheel lug nuts to 75 ft.-lbs. and aluminum wheel lug nuts to 85 ft.-lbs.

Install center caps (if applicable).

Caution: Do not use an impact wrench when installing lug nuts.

4. Reflectors can be installed to body. See Fig. 1. Install rear reflectors 3” below taillights on body.

See Fig. 2. Install side reflectors using wheel center caps as a reference, 1/4” above wheel opening

on body.

Fig. 1 Fig. 2

2009-2013 FLH RENEGADE

39

STEERING NECK

Neck Race Preload,

Steering head should be approximately twice as tight as factory specifications for a trike conversion.

Refer to H-D service manual for adjustment procedure.

Caution: Do not tighten bolts past factory specifications. Only bearing adjustment collar should

be tightened past factory settings.

2009-2013 FLH RENEGADE

40

TORQUE SPECIFICATIONS

Swingarm pivot shaft (09+ models) 55 ft. lbs.

LH fork bracket 55 ft. lbs.

Park brake bracket 35 ft. lbs.

Pinch block bolts 25 ft. lbs.

LP1038 Adapter Plate 35 ft. lbs.

Banjo bolts 16 ft. lbs.

Torque link to engine/frame 33 ft.-lbs.

Lehman frame, front 75 ft. lbs.

Rear frame bolts 18 ft. lbs.

Frame brace, top 18 ft. lbs.

Frame brace, lower 52 ft. lbs.

Shock bolts 40 ft. lbs.

Wheels/aluminum 85 ft. lbs.

Wheels/wire 75 ft. lbs.

Caliper to bracket bolts 38 ft. lbs.

Caliper bracket to axle flange bolts 38ft. lbs.

Differential bearing bridge bolts 38ft. lbs.

Axle flange bolts 38 ft. lbs.

2009-2013 FLH RENEGADE

41

FINAL TRIKE INSPECTION

1. Reflectors Installed

2. Lights and horn work

3. Park brake operation

4. Engine/Transmission oil levels

5. Belt tension 3/8”-7/16”

6. Wheel torque 85 ft. lbs. (75 ft. lbs.-wire)

7. Rear tire pressure 26 psi

8. Front tire pressure 36 psi

9. Trunk clean and dry

10. Trunk door seals and operates smoothly

11. Rear shocks set @ 20 psi

12. Heat shields, side covers

13. Renegade/Lehman badge installed

14. Accessories (if applicable)

15. No paint defects

16. Warranty/owner’s manual included

Good Rework

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

□ □

2009-2013 FLH RENEGADE

42

Loading...

Loading...