Page 1

Walkercell®/Walkerdeck

Wiremold electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Wiremold electrical products

may bear the mark as UL Listed and/or Classified and should

be installed in conformance with current local and/or the National

Electrical Code.

®

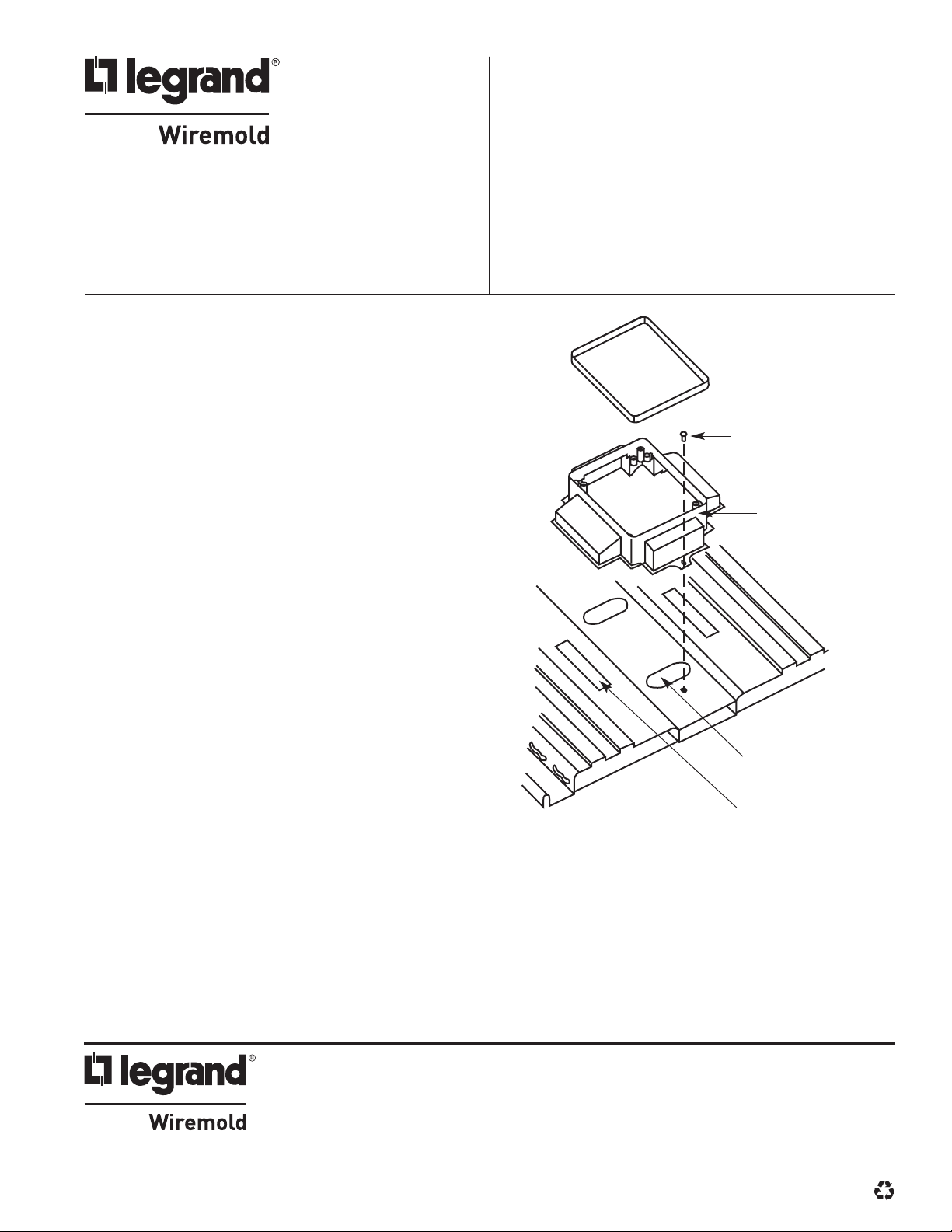

PK Series Preset Insert

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: IP0125R1 – Updated March 2010

reset insert heights (in decimal inches x 100)

P

= 150, 200, 250, 300, and 325.

The PK Series preset insert assembly shown here consists

of a single piece die cast zinc alloy preset and a steel

mudcap. Each unit is shipped fully assembled.

1. Orient the preset insert so the prepunched rivet hole in

the cellular raceway aligns with the rivet hole cast

into preset.

2. Hook the preset insert into the end of the prepunched

data access openings in the cellular raceway utilizing its

two offset flanges.

3. Slide the preset into position toward the hooked end

until the preset insert rivet hole is aligned with the rivet

hole in the cellular raceway and install a 16" [4.8 mm]

diameter steel pop-rivet with a 1/8" [3.2 mm] grip

range (by others).

4. Caulk around preset if necessary and install mudcap

if shipped separately.

5. Final Inspection: A final inspection of all inserts must

be made by the electrical contractor just prior to

concrete placement. Any damaged preset inserts

must be replaced.

CAUTION: The concrete shall be thoroughly worked by the

most practical means, such as tamping or vibrating adjacent

to the sides of the preset insert. The electrical contractor

should assure that this is done during the pour and finishing

of the concrete floor.

6. Fire Classification – Walkerdeck Only: Refer to the

Underwriters’ Laboratories, Inc., Fire Resistance

Directory for information on fireproofing requirements

for the particular Fire Resistance Design Classification

that is required. The Fire Resistance Directory also

specifies the maximum number of presets, spacing

and locations.

IMPORTANT: Please read all instructions

before beginning.

Steel Mudcap

3/16" [4.8 mm]

Diameter Steel

Pop-Rivet

PK Series

Preset Insert

Prepunched Knockouts

for Isolation of High

Potential Wires at

Inactive Preset Inserts

Prepunched

Openings for Low

Potential Access

NOTE: Steel mudcap must be in place prior to concrete placement.

UL Listed and Classified activation kits ordered separately

include snap-in plastic grommets for the power opening

only. If desired, grommeting for the data openings may be

purchased using part number 2897-0034.

© Copyright 2010 Legrand/Wiremold All Rights Reserved

Wiremold

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

IP0125R1 0310

Loading...

Loading...