LEGRAND Wattstopper LMRC-101 User Manual

Wattstopper

Daylighting

Sensor

J-Box

Digital Lighting Management Single Relay Room Controller

Gestion numérique de l’éclairage Contrôleur de pièce à relais unique

No: 22893 – 11/17 rev. 2

Catalog Number • Numéro de Catalogue • Número de Catálogo: LMRC-101

Country of Origin: Made in China • Pays d’origine: Fabriqué en Chine • País de origen: Hecho en China

This unit is pre-set for Plug n’ Go™ operation, adjustment is optional.

For full operational details, adjustment and more features of the product, see the

DLM System Installation Guide provided with Wattstopper room controllers, and also

available at www.legrand.us/wattstopper.

Installation shall be in accordance with all applicable regulations, local and NEC

codes. Wire connections shall be rated suitable for the wire size (lead and building

wiring) employed.

For Class 2 DLM devices and device wiring: To be connected to a Class 2 power

source only. Do not reclassify and install as Class 1, or Power and Lighting Wiring.

WARNING: Do not install to cover a junction box having Class 1, 3 or Power and

Lighting Circuits.

Control de la iluminación digital Controlador de habitación de relé simple

Quick Start Guide • Guide de démarrage rapide • Guía de inicio rápido

Input Voltage ....... Single Phase 120/230/240/277VAC, 50/60Hz

Load Requirements

Incandescent ........................................20A @ 120VAC

Ballast ...........................................20A @ 120/277VAC

Motor ............................................ 1Hp @ 120/240VAC

Output ....................................................... 150mA @ 24VDC

DLM Local Network Characteristics:

Provides low voltage power over Cat 5e cable (LMRJ).

Supports up to 24 communicating devices, including 4

LMRC‑10x or LMPL‑101 max per each DLM Local Network.

Free topology up to 1,000ft of low voltage cable.

Environment:

Operating Temperature .........32° to 104°F (0° to 40°C)

Storage Temperature ...........23° to 176°F (‑5° to 80°C)

Relative Humidity ...............5 to 95% (non condensing)

Patent Pending

®

SPECIFICATIONS

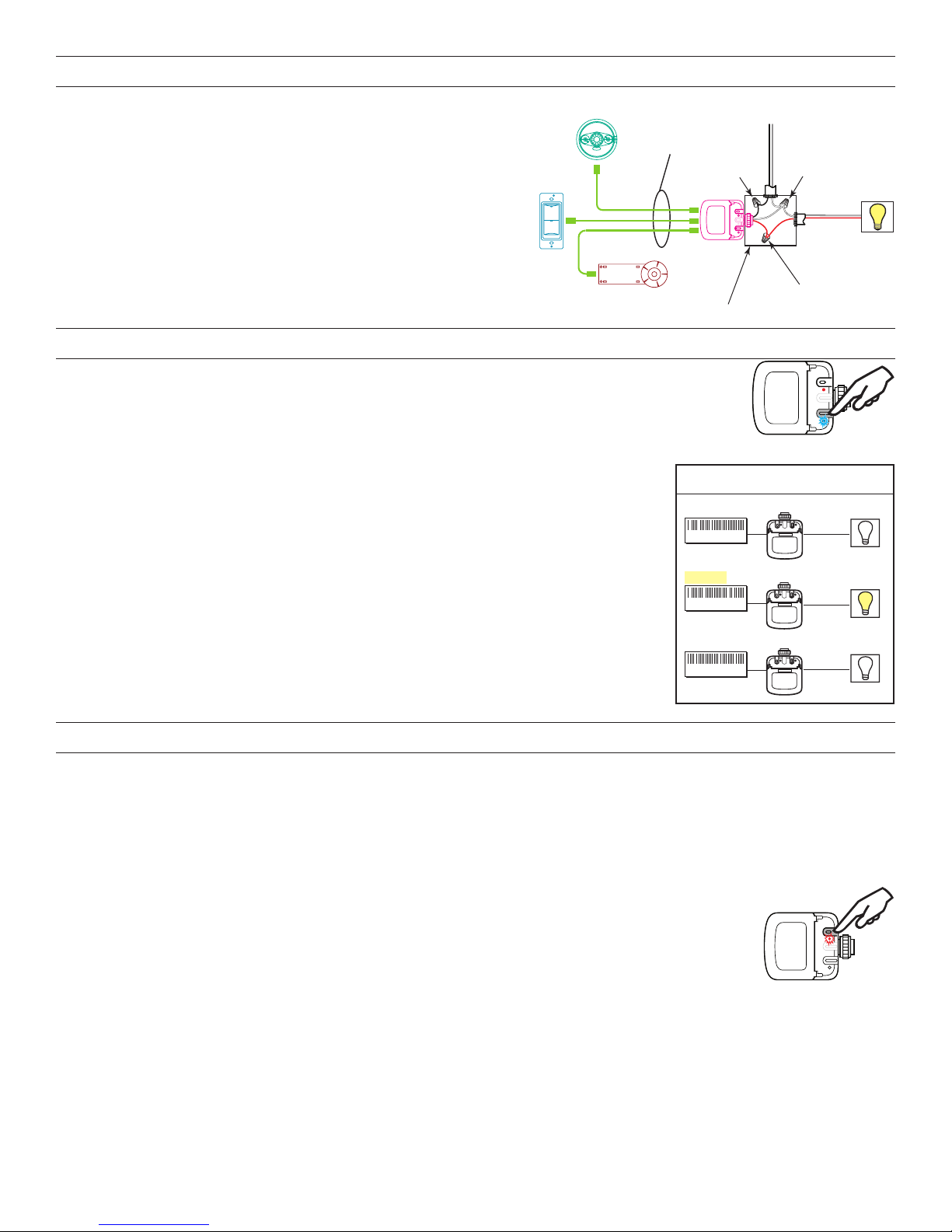

PLACEMENT EXAMPLE

DLM Local Network

(low voltage, Class 2)

Corner Mount

Occupancy

Sensor

J Box

To

Load

Ceiling Mount

Occupancy

Sensor

Room

Controller

LMRJ cables

Switch

MOUNTING THE CONTROLLER

The LMRC‑101 room controller can be mounted external to either

a 4”x 4” or 4‑11/16 x 4‑11/16 junction box, placing it in the plenum

space or mounted directly inside a 4‑11/16 x 4‑11/16 junction box.

Line

Load

Line

Load

J-Boxes

WARNING: TURN THE

POWER OFF AT THE CIRCUIT

BREAKER BEFORE WIRING.

CAUTION: TO CONNECT A COMPUTER TO THE

DLM LOCAL NETWORK USE THE LMCI-100. NEVER

CONNECT THE DLM LOCAL NETWORK

TO AN ETHERNET PORT – IT MAY DAMAGE

COMPUTERS AND OTHER CONNECTED EQUIPMENT.

ATTACHING CABLES

Outside a 4” x 4” or

4 11/16 x 4‑11/16 box

Inside a 4 11/16 x 4‑11/16 box

Remove rubber jack covers if using all 3 RJ45 receptacles.

Leave covers in place for all unused receptacles.

CONNECTIVITY

J-Box

Switch

Ceiling Mount

The LMRC‑101 communicates to all other DLM devices connected to the

DLM Local Network. Connection drawings are for example only. The low

voltage LMRJ cables can connect to any DLM device with an open RJ45

receptacle.

Sensor

DLM Local Network

Low Voltage

LMRJ Cables

All line voltage wiring is #12 AWG.

Daylight Sensor

PLUG N’ GO OPERATION (PNG)

Plug n’ Go supports the most energy efficient control strategy. For example, if one load,

one switch and one occupancy sensor are connected to the DLM local network, the system

operates the load as Manual‑On, Automatic‑Off.

See DLM device Quick Start Guides to determine how each device affects the PNG

operation of the LMRC‑101.

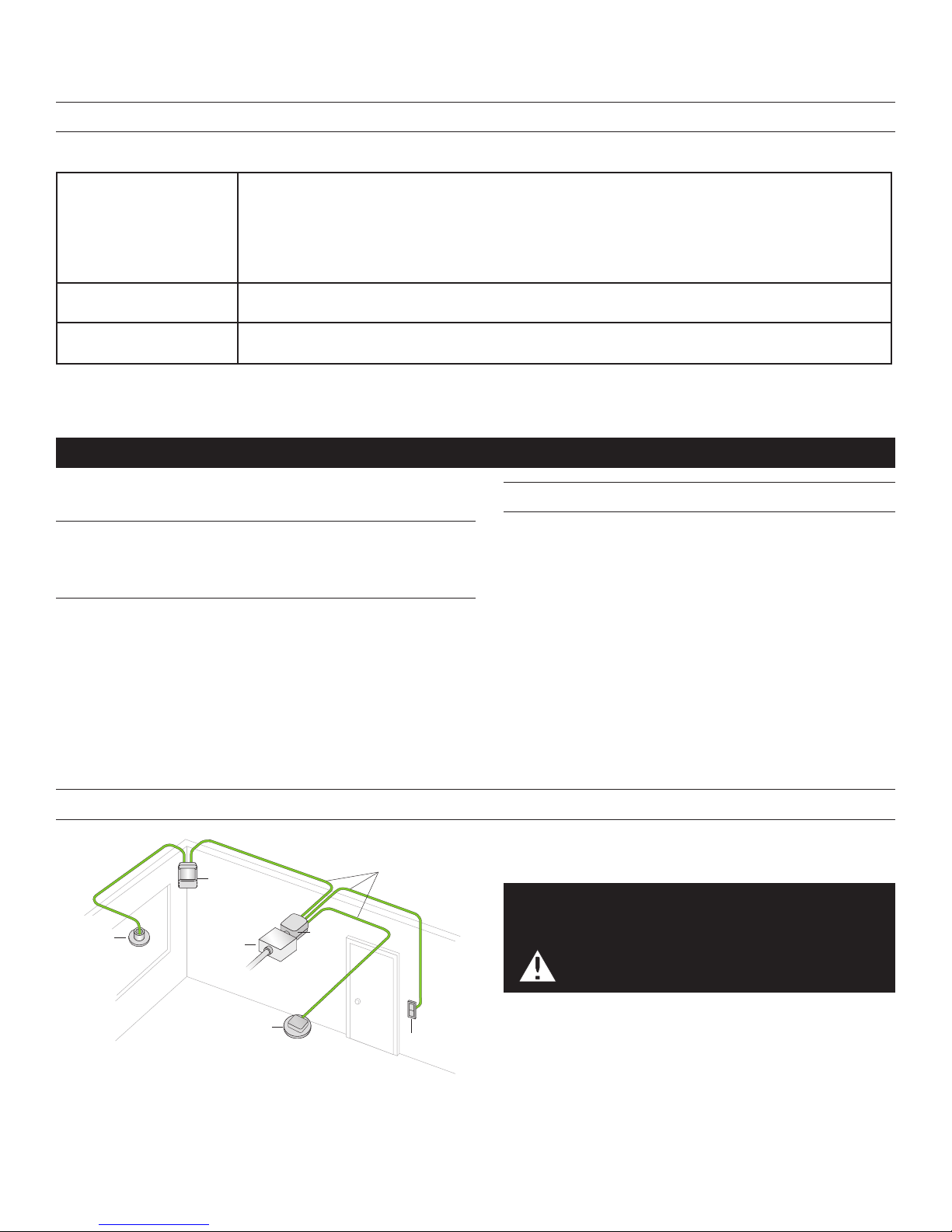

Load Control Arbitration

To take full advantage of automatic PnG configuration, review these simple rules about load control

arbitration.

After the room controllers are connected to the DLM Local Network and powered up they

automatically negotiate to determine which controller becomes the Master, as well as the load

numbers for each relay on the DLM Local Network.

The Master is the controller with the most load relays. If more than one controller has the most

relays, the one with the highest serial number becomes the Master.

The LMRC‑101 has only one load . In a DLM local network with only LMRC‑101 room controllers,

the LMRC‑101 with the highest serial number is the Master, carrying Load 1 and Load 2. The next

highest serial number would have Load 3 and Load 4, and so forth.

Load ON/OFF button

Blue LED ON when

load is ON

Line/Hot

Black wire

LMRC

101

Room

Controller

Serial

Number

0458356155

Master

0458356679

0458356133

Line

Voltage

White wire

Room

Controller

LMRC-101

0458356155

LMRC-101

0458356679

LMRC-101

0458356133

Neutral

Red wire

to Load

Load

Load

Control

2

1

3

OPTIONAL UNIT ADJUSTMENT - PUSH N’ LEARN (PNL)

Load Selection Procedure

A configuration button (Config) allows access to our patented Push n’ Learn™ technology to change binding relationships between

sensors, switches and loads.

Step 1 Enter Push n’ Learn

Press and hold the Config button (on any DLM device) for 3 seconds.

The red LED on the LMRC‑101 begins to blink as does the red LED on ALL other communicating devices connected to the DLM Local

Network.

The red LEDs continue to blink until you exit PnL mode.

All loads in the room turn OFF immediately after entering PnL, then one load will turn ON. This is Load #1, which

is bound to switch button #1 and occupancy sensors as part of the Plug n’ Go factory default setting.

All switch buttons and sensors that are bound to this load have their blue LED solid ON.

Step 2 Load selection

Press and release the Config button to step through the loads connected to the DLM Local Network. As each load

turns ON note the devices (switch buttons and sensors) that are showing a bright solid blue LED. These devices

are currently bound to the load that is ON. The blue LED on the room controller or plug load controller connected to the load is also lit.

• To unbind a switch button from a load, press the switch button while its blue LED is ON bright. The blue LED goes dim to indicate

the button no longer controls the load that is currently ON.

• To unbind an occupancy sensor, press the up () or down () adjustment button while its blue LED is ON. The blue LED turns

OFF to indicate the sensor no longer controls the load that is currently ON.

Pressing the switch or up () or down () button again while the load is ON rebinds the load to the button or sensor and the blue LED

illuminates brightly.

2

Cong button &

red LED

Step 3 Exit Push n’ Learn

Luminosit

Press and hold the Config button until the red LED turns OFF, approximately 3 seconds.

TROUBLESHOOTING

Loads do not operate as expected.

LEDs on a switch or

sensor don’t light

1. Check to see that the the device is connected to the DLM Local Network.

2. Check for 24VDC input to the device: Plug in a different DLM device at the device location. If the

device does not power up, 24VDC is not present.

• Check the high voltage connections to the room controller and/or plug load controller(s).

• If high voltage connections are good and high voltage is present, recheck DLM Local Network

connections between the device and the room controller and/or plug load controller(s).

The wrong lights and

plug loads are controlled

LEDs turn ON and OFF

but load doesn’t switch

1. Configure the switch buttons and sensors to control the desired loads using the Push n’ Learn

adjustment procedure.

1. Make sure the DLM local network is not in PnL.

2. Check load connections to room controllers and/or plug load controllers.

INSTRUCTIONS EN FRANÇAIS

Cet appareil est préréglé pour un fonctionnement Plug n’ GoMC

et son réglage est optionnel.

Pour connaître tous les détails opérationnels, les réglages et les fonctions

supplémentaires du produit, consulter le guide d'installation du système

DLM fourni avec Wattstopper contrôleurs de pièce et aussi disponible au

www.legrand.us/wattstopper.

L'installation doit être effectuée conformément à tous les règlements

ainsi qu'aux codes locaux et de la NEC en vigueur.Les raccordements

de fils doivent être classés comme pouvant convenir au calibre du fil (fil de

sortie et de bâtiment) utilisé.

Pour les dispositifs DLM de classe 2 et le câblage du dispositif:

Doit être connecté à une source d'alimentation de classe 2 seulement.

Ne pas reclasser et installer en tant que classe 1 ou en tant que fil

d'alimentation ou d'éclairage.

MISE EN GARDE: Ne pas installer avec une boîte de jonction dotée de

circuits de classe 1, 3, d'alimentation ou d'éclairage.

SPÉCIFICATIONS

Tension d’entrée .......... Monophasé 120/230/240/277 VCA, 50/60 Hz

Exigences pour la charge

Incandescence ...................................................20 A à 120 VCA

Ballast .........................................................20 A à 120/277 VCA

Moteur ........................................................ 1 Hp à 120/240 VCA

Sortie ...................................................................... 150 mA à 24 VCC

Caractéristiques du réseau local DLM :

Fournit une puissance à basse tension pour le câble Cat 5e (LMRJ).

Prend en charge jusqu’à 24 dispositifs communicants, y compris 4

LMRC‑10x ou LMPL‑101 max par réseau local DLM. Topologie gratuite

allant jusqu’à 305 m (1 000 pi) de câble à basse tension.

Environnement :

Température de fonctionnement .......0 ° à 40 °C (32 ° à 104 °F)

Température d’entreposage .............‑5 ° à 80 °C (23 ° à 176 °F)

Humidité relative .............................. 5 à 95 % (non condensée)

Détecteur de

Mouvement

en coin

Capteur

é

Boîte de

jonction

Vers

charge

Détecteur de présence

monté au plafond

Contrôleur

de pièce

EXEMPLE DE DISPOSITION

Réseau Local DLM

(câblage basse tension

Classe 2, câble LMRJ)

ATTENTION : POUR CONNECTER UN ORDINATEUR

AU RÉSEAU LOCAL DLM, UTILISER LE LMCI-100.

NE JAMAIS CONNECTER LE RÉSEAU LOCAL

Interrupteur

3

DLM À UN PORT ETHERNET – CELA

POURRAIT ENDOMMAGER LES ORDINATEURS

AINSI QUE LE MATÉRIEL CONNECTÉ.

Loading...

Loading...