LEGRAND Trimod 10 kVA, Trimod 20 kVA, Trimod 15 kVA, Trimod 40 kVA, Trimod 30TM kVA Operating And Maintenance Manual

...Page 1

Trimod®

Operating and Maintenance Manual

®

Part. LE05768AA-07/12-01 GF

Page 2

®

2

EN

ENGLISH 3

Trimod®

Page 3

Trimod®

3

Operating and Maintenance Manual

1 Foreword 6

1.1 Overview 6

1.2 Purpose of the manual 6

1.3 Where nad how to keep the manual 7

1.4 Manual update 7

1.5 Collaboration with the user 7

1.6 Manufacturer 7

1.7 Responsabilities of the manufacturer and guarantee 7

1.8 Copyright 8

2 Technological description 9

2.1 Technology Trimod® 9

2.2 Features 9

2.3 Models 12

2.4 Communications device 20

2.4.1 RS232 serial ports 20

2.4.2 Relay interface 20

2.4.3 Logic Level Interface 21

2.4.4 Communications slot 21

2.4.5 Power module block diagram 22

2.4.6 Interconnection block diagram 22

3 Safety provisions 23

3.1 General notes 23

3.2 Symbols 23

3.3 Definitions of “operator” and “specialized technician” 23

3.3.1 Qualification required to the operator 23

3.3.2 Qualification required to the specialized technician 24

3.4 Individual protective gear 24

3.4.1 Gear to wear 24

3.5 Indications of danger in the work place 25

3.5.1 Indications on board the equipment 25

3.6 Residual risks 25

3.7 General warnings 26

3.8 Emergency interventions 27

3.8.1 First aid intereventions 27

3.8.2 Fire prevention measures 27

Index of contents

Page 4

4

®

4 Unpacking 28

4.1

Visual inspection

28

4.1.1 Checking the equipment and accessories supplied 28

4.2 Unpacking 28

4.3 Checking the contents of the pack 28

4.4 Storing 29

4.4.1 UPS 29

4.4.2 Batteries 29

4.5 Handling 30

4.6 Positioning 30

4.7 Last operations 31

5 Installation 32

5.1 Safety rules and regulations 32

5.1.1 Mains connections for TN systems 33

5.1.2 Mains connections for TT systems 34

5.2 Electrical connections 35

5.2.1 Safety reccomandations 35

5.2.2 Preliminary operations 35

5.2.3 Connectiong the loads 35

5.2.4 Emergency Power Off (Remote E.P.O.) 36

5.2.5 Installing the Trimod® BATTERY 36

5.2.6 Protections 39

5.2.7 Earthing 39

5.2.8 Connectiong the power supply 39

5.2.9 Wiring 40

5.3 Wiring diagrams 40

5.3.1 THREE-PHASE input, THREE-PHASE output 41

5.3.2 THREE-PHASE input, SINGLE-PHASE output output connections 45

5.3.3 SINGLE-PHASE input, SINGLE-PHASE output connections 45

5.3.4 SINGLE-PHASE input, THREE-PHASE output connections 48

5.3.5 SINGLE-PHASE input connections no. 3 separate outputs 49

5.3.6 UPS Trimod® 30TM connections 52

Index of contents

Page 5

Trimod®

Operating and Maintenance Manual

5

6 Configuration and Start-up 53

6.1 Input configuration 53

6.2 Output configuration 53

6.3 Checks prior to switching ON 53

6.4 Starting procedure 53

7 Control panel 56

7.1 “Service Mode” function 57

7.2 Main menu and submenus 57

7.2.1 UPS status 61

7.2.2 UPS settings 64

7.2.3 Power Modules 67

7.2.4 Events 69

7.2.5 Tools 69

7.2.6 Logout 70

7.2.7 Turning the single output phases ON and OFF 70

7.2.8 Shutting down the UPS Trimod® 70

8. Diagnostics 71

8.1 Luminous and acoustic signals 71

8.2 Messagges 73

9. Maintenance 80

9.1 Introduction 80

9.2 Preventive maintenance 80

9.3 Periodical checks 80

9.3.1 Preparing the UPS for maintenance. Forced bypass mode 80

9.4 Adding or replacing a power module or battery drawers 81

9.4.1 Power Module 81

9.4.2 Exit from the maintenance manual bypass 81

9.4.3 Battery drawers 82

10. Dismantling 83

10.1 Disposing of the batteries 83

10.2 Dismantling the UPS 83

10.3 Disposing of the electronic components 83

11. Tables 84

Index of contents

Page 6

6

®

1.1 Overview

Congratulations for having bought a LEGRAND® UPS Trimod® product.

Thanks to UPS Trimod® unit your critical equipment will be protected by a constant and reliable supply of power for years

to come.

LEGRAND® is based in Italy and specializes in designing and producing UPS units. The UPS Trimod® system is unique,

modular and the last generation of three-phase medium power UPS units.

Highly reliable, low running costs and excellent electrical performance are but a few of the great features of this innovative

UPS. Moreover, the criteria and methods that LEGRAND® uses for its design and production comply with the strictest

quality standards. The product is, in fact, produced at an ISO14001 certied factory in full compliance with the eco-design

laws.

The UPS Trimod® system is made in compliance with the existing European Community directives and with the technical

standards that include their requirements as certied by the Declaration of Conformity issued by the Manufacturer and

enclosed with this manual.

This publication, simply dened ‘manual’ herein, contains all the information for the installation, use and maintenance of

the equipment specied in the Declaration of Conformity.

This equipment will be referred to simply as ‘equipment’ or even ‘machine’ in this manual and is manufactured by

LEGRAND®.

The contents of this manual are intended for an operator who has already been instructed on the precautions to be taken

in relation to the presence of electricity.

The persons to whom this publication is addressed, normally dened ‘users’, are all those people who, for their eld of

expertise, have the need and/or obligation to provide instructions or work directly on the equipment.

These people can be the following:

- managers;

- heads of operating areas;

- department heads;

- operators directly concerned with transporting, storing, installing, using and servicing machines from the moment

they are put on the market up to the day they are scrapped;

- direct private users.

The original text of this publication, written in the Italian language, is the only reference for solving any disputes

concerning the interpretation of translations into Community languages.

This publication is to be considered an integral part of the equipment supplied and, as such, must

be kept for future reference up until the equipment is denitively dismantled and scrapped.

1.2 Purpose of the manual

The purpose of this manual is to provide indications for using the equipment safely and to carry out routine maintenance

procedures.

Adjustments and extraordinary maintenance jobs are not dealt with in this manual as they are reserved exclusively to the

assistance technician who must observe to the technical and design characteristics for which the equipment was made

when working on it.

It is essential that this manual is read through but it is not a substitute for the expertise of the technical personnel who

must have had adequate preliminary training.

The intended use and congurations envisaged for the equipment are the only ones allowed by the Manufacturer; do not

attempt to use the equipment in disagreement with the indications given.

1. Foreword

Page 7

Trimod®

Operating and Maintenance Manual

7

Any other use or conguration must be agreed on beforehand with the Manufacturer in writing and, in such a case, will

be an enclosure to the manual.

For its use the user must also comply with the specic laws on work that exist in the country where the equipment is

installed.

Reference is also made in this manual to laws, directives, etc., that the user must know and consult in order to full the

purposes established by the manual.

1.3 Where and how to keep the manual

This manual (and its enclosures) must be kept in a safe, dry place and always be available for consultation.

We suggest making a copy and ling it.

If information is exchanged with the Manufacturer or assistance personnel authorised by the former, please refer to the

equipment’s rating plate data and serial number.

The manual must be kept for the equipment’s useful life cycle and, if necessary (e.g. damage which prevents it being

consulted even partially) the user must ask the Manufacture for a new copy, quoting the publishing code on the cover.

1.4 Manual update

The manual reects the state of the art at the moment the equipment was put on the market, of which it is an integral

part. The publication complies with the directives in force at such a date. The manual cannot be considered inadequate if

updates of standards or changes are made to the equipment.

Any integration to the manual which the Manufacturer deems tting to send to the users, must be kept with the manual,

becoming an integral part of it.

1.5 Collaboration with the user

The Manufacturer is available to its clientele to provide additional information and will take into consideration any

suggestions made to improve this manual to bring it even closer to the requirements for which it was drawn up.

If the equipment is sold, which always includes handing over this operating manual, the primary user must notify the

Manufacturer, giving him the address of the new user so the latter can be reached if there are any communications and/

or updates deemed indispensable.

LEGRAND® reserves the property rights of this publication and forbids the total or partial reproduction of it without prior

written consent.

1.6 Manufacturer

The equipment’s identication data are given on the ID plate.

1.7 Responsibilities of the manufacturer and guarantee

In order to use the guarantee supplied by the Manufacturer the user must scrupulously comply with the precautions

indicated in the manual and in particular:

- to always work within the equipment’s limits of use;

- to always carry out constant and accurate maintenance;

- to have persons use the equipment with proven capabilities and skill and adequately trained for the purpose;

The Manufacturer declines all liabilities, direct and indirect, resulting from:

- disregard for the instructions and if the equipment is used dierently to what is foreseen in the operating manual.

- use by personnel who have not read and understood properly the contents of the manual;

- a use failing to conform to the specic laws existing in the country of installation;

Page 8

8

®

- changes made to the equipment, software, operating logic that were not authorised by the Manufacturer in writing;

- unauthorised repairs;

- exceptional events.

When the equipment is sold to a third party this manual has to go with it; if the manual is not given to the new user then

all purchaser rights are automatically invalidated, including guarantee terms where applicable.

If the equipment is sold to a thirty party in a country of a dierent language it is the responsibility of the original user to

provide a true translation of this manual in the language of the country where the equipment is going to be used.

1.8 Copyright

The information in this manual must not be disclosed to third parties. Any duplication, total or partial, not authorised in

writing by the Manufacturer, obtained by photostatting, duplicating or any other method, even electronically, violates

the copyright conditions and can be persecuted by law.

1. Foreword

Page 9

Trimod®

Operating and Maintenance Manual

9

2.1 Trimod® Technology

Congratulations on your purchase of a UPS Trimod® product from LEGRAND®.

Thanks to the UPS Trimod® your critical equipment will be protected by a constant and reliable supply of power for years

to come.

LEGRAND® has developed a project that is both innovative and unique, creating Trimod®, the UPS with a power range

of 10, 15, 20, 30, 40 and 60 kVA capable of adapting itself at any time to the changing requirements of protected loads:

greater power, longer autonomy, redundancy.

The basic concepts of the Trimod® project are, in fact, modularity, expandability and redundancy which, besides oering

maximum reliability, are also the guarantee of a considerable economic saving.

Trimod® is a modular uninterrupted power supply unit with individually programmable basic modules so you can have

the input/output conguration you want. In this way it is possible to control three- and single-phase voltage in input and

output to have, as preferred the classical three/three, three/single, single/three and single/single lines but it is not limited

to just this: you can also have single- and three-phase lines in output simultaneously or two or more single-phase lines

also of dierent powers (on request).

And then, for each conguration it is possible to obtain redundancy, both complete and partial by which we mean that,

for example, a normal (or redundant) threephase line plus a redundant (or normal) single-phase line can coexist in output.

A microcontroller mounted in each basic module is capable of monitoring the main functions of each single power unit,

monitoring its correct operation and signalling any malfunctions.

The modularity philosophy has also been used for the batteries which are supplied in single pull-out boxes. THDi = 3% Power Factor > 0.99 – High Yield – High Reliability – Easy to install and service.

2.2 Features

Redundant modular architecture

Redundant modular architecture is the best way to protect a company’s critical points.

Advantages:

- There is just one control of the devices powered

- Modular Expandability

- Module redundancy

- Easy to service

- Low running cost

- Compact size

Yield

The UPS units of the Trimod® line place particular attention on the energy taken from the mains and that supplied to the

user points. High Yield (>94%), PFC in Input >0.99, THDi 3%.

Advantages:

- Increasing the yield means reducing the part of power absorbed by the UPS but not supplied at the load and transmitted

to the environment in the form of heat.

- Les s heat dispersed in the environment means reducing the use of aeratin g or conditioning systems on the installation premises.

- PFC in input means no rephasing costs and consequently no increased rates.

- No need to oversize a generator (if used) upstream from the UPS

Expandability

The majority of UPS units on the market is neither modular nor expandable and therefore initial oversizing of the system

is necessary to ensure future expansions (which might not even happen).

Advantages:

- The modular and expandable Trimod® systems allow optimisation of the investments made in UPS units, adapting

them to actual requirements without preventing future expansions and avoiding an unnecessary waste of energy.

- System yield is increased thanks to correct sizing

Reliability

To have a redundancy level with traditional UPS units it is necessary to put at least 2 in parallel, thus doubling the power

bought, the space taken up and the electricity consumed. Instead Trimod®’s modular architecture allows redundant

congurations inside just one single cabinet.

2. Technological description

Page 10

10

®

Advantages:

- A UPS with a modular redundant architecture can be congured as an N+X system redundant in power; even in the

case of a failing module the equipment carries on working and there is no stop in work.

- Clear indications and a large display speed up troubleshooting.

- The modular architecture makes short work of repairing a failure by simply replacing the module in question without

interrupting service.

- A high resolution percentage of failures at the rst assistance intervention.

Power module

The basic module, available in three power sizes, 3,400 VA, 5,000 VA and 6,700 VA, is basically made up of the following

functional blocks: command and control logic (microprocessor controlled), rectier/PFCr, inverter, booster, battery

charger, automatic bypass.

The power unit is the Plug & Play type to facilitate power expansion and all maintenance works. Each module is paralleled

with other identical ones until the UPS power is reached.

The power modules are separate from each other and can work even if one malfunctions. A LED on the front of the

module, with a trac-light code, quickly shows the operating state of the electronic unit.

Prescription forms for PM4, PM6 and PM7 only on the related cabinets: UPS Trimod® electrical distribution equipment

is sized for its nominal power and must be used only with power modules originally installed.

Each cabinet must use only the provided power modules, described in table "Mechanical properties" on page 18 of this

manual. It is not possible to use power modules other than those indicated, nor mix with other models and/or replace

the type of modules.

• The model, the power rating and the type of power module to be installed in the UPS cabinet UPS Trimod® are indicated

on the user manual and on the label inside the door of the UPS.

• The type and power rating of the power module are indicated on the label axed to the bottom of the power module

for proper identication.

It is recommended to use only provided UPS Trimod® Power Modules.

Battery drawers

The battery modules are designed for easy insertion in the cabinet with no work needed to connect them; they are easy

to handle thanks to their light weight, likewise any maintenance or replacing.

A box holds 5 12V, 7.2 Ah or 9 Ah batteries connected in series and, thanks to the Plug & Play connection can be easily

pulled out and put inside the cabinet. In order to guarantee maximum safety, especially during maintenance, the voltage

of each box is adequately disconnected into two 24 and 36V branches and restored only when the box is placed right

inside its housing. This conforms to the CEI-EN 60950 standard on electrical safety which establishes that adequate

safeguards must be used and particular attention where there are dangerous voltages higher than 50 Vdc with the

possibility of direct contact.

Autonomy can be increased further still by adding other battery ‘boxes’ in multiples of four,

exploiting the space inside the UPS and the space in the additional ‘modular cabinets

Digital display and displaying alarms

Trimod® is controlled by a microprocessor and has a backlit alphanumerical liquid crystal display (LCD) with 20 characters

on 4 lines built into the front of the UPS where there is also a highly luminous operating status indicator which, by means

of a trac-light code, indicates the operating status and any alarm conditions.

Four simple push buttons near the display allow the user to: see operating data, set operating parameters, analyse the

state of each single power module, select the language in which to see the messages and execute a set of functional tests.

BCM (Battery Charger Module)

It works together with internal PM chargers, with the same intelligent management of the charging cycle. For each BCM

installed the maximum batteries recharging current is increased of 15Adc: 1 BCM has a charging current equivalent to

that of 6 (internal to the charger) PMs. This guarantees to reduce charging time in installations that require long backup

time UPS and increases the availability of the UPS system after a power failure (blackout).

During operation, the module draws current from the phase input (slot) in which it is installed. If at least n°1 PM is present,

it is possible to install any number of BCM.

2. Technological description

Page 11

Trimod®

Operating and Maintenance Manual

11

All informations about BCM are indicated by LED on the front of the module and described on the display menu.

The module is controlled by a microprocessor to optimize performance and reliability, we recommend the use in

combination with higher than 60Ah capacity batteries.

Input voltage 230V +15% -20%, rated output power 4kW, maximum rated current 15Adc, maintenance voltage 13.75Vdc/

battery. Operating status through the UPS front panel LEDs and multi-colored, adjustable fan speed versus power output,

overtemperature protection.

Intelligent charging cycle with four stages to maximize battery life (constant current, nal charge, maintenance and

stand-by).

O-Line Mode

The UPS Trimod® ® provides a mode of operation o-line that allows to save power while still providing the protection of

the continuity of power supply to the connected load. During the operation O-Line, the load is powered directly by the

mains through the automatic internal bypass circuit in power modules.

This means that the voltage and the output frequency are the same as the network input, and the UPS Trimod can not

control these variables. The benet that you get in the O-Line mode is greater electrical eciency since UPS doesn’t

work. If the output voltage goes out of tolerance range (± 15% of the set voltage output) or is lacking, the UPS activates

its stage inverter powering the load with the energy stored in the batteries.

The runtime during battery operation depends on the conguration of the UPS (full load, battery capacity) and the

percentage of applied load. When AC input is within the parameters of tolerance, the UPS automatically returns to the

O-Line mode. And it is possible to change the operating mode between On-Line and O-Line (and vice versa) when the

UPS is ON or OFF (entering Service Mode).

• To activate the O-Line, enter the Main Menu -> Settings UPS -> Bypass -> O-Line Mode and select Enabled, conrm

the selection with the Enter button.

• To activate the On-Line, enter the Main Menu -> Settings UPS -> Bypass -> O-Line Mode and select Disabled, conrm

the selection with the Enter button.

WARNING!

If the load needs to be fed without any interruption or with a regulated voltage amplitude and/or frequence it is

recommended to use the UPS Trimod® mode On-Line double conversion.

Page 12

12

®

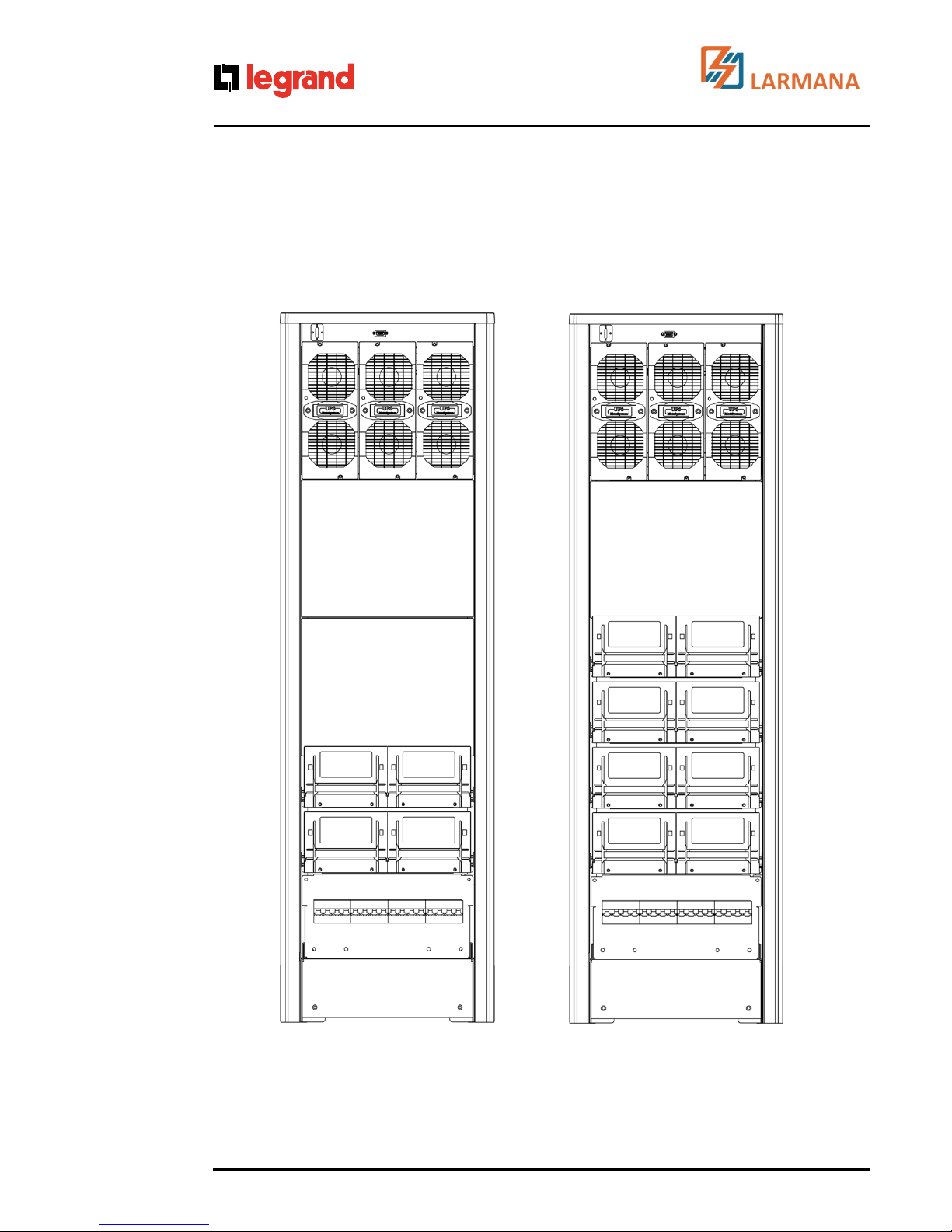

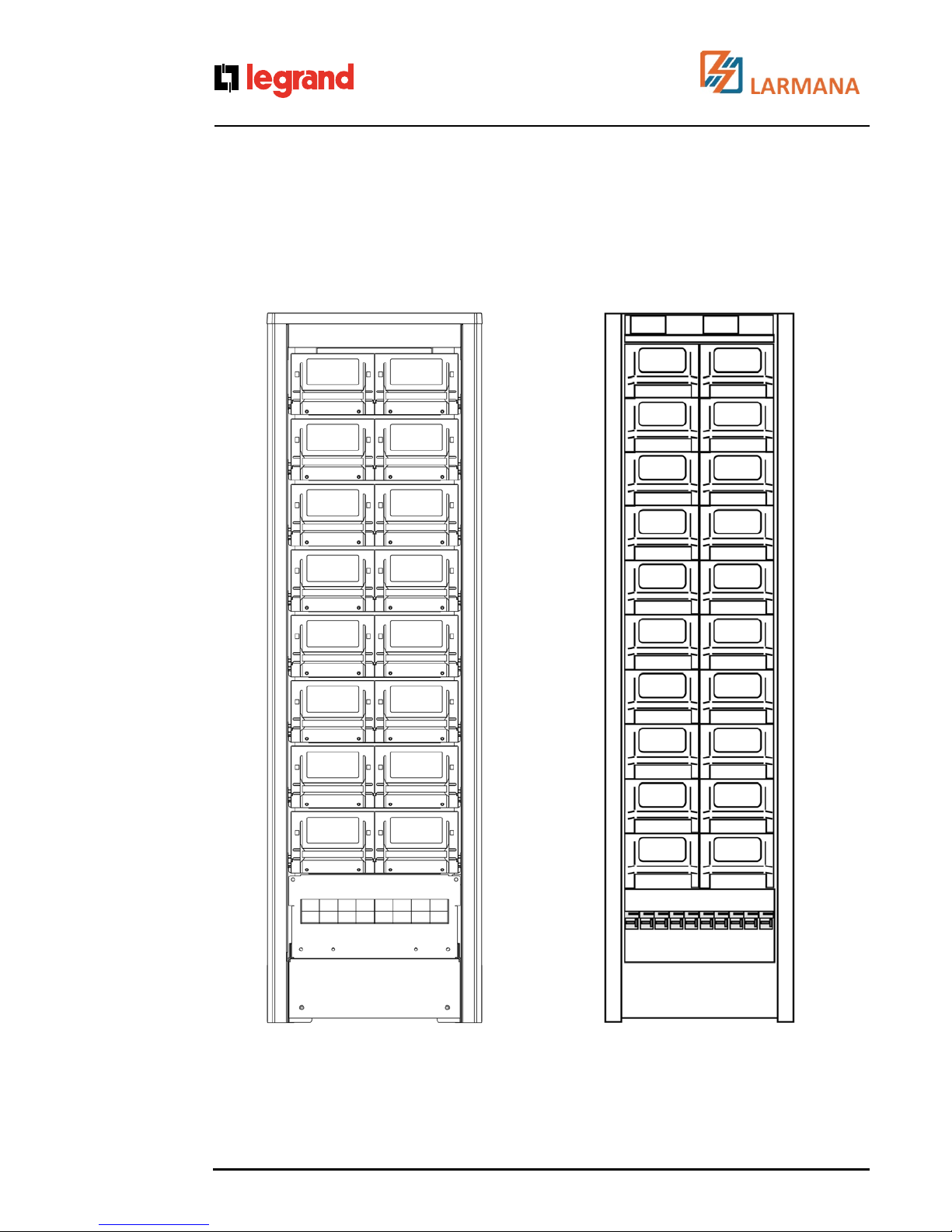

UPS Trim od® 10 UPS Trim od® 10/15/20

2.3 Models

2. Technological description

Page 13

Trimod®

Operating and Maintenance Manual

13

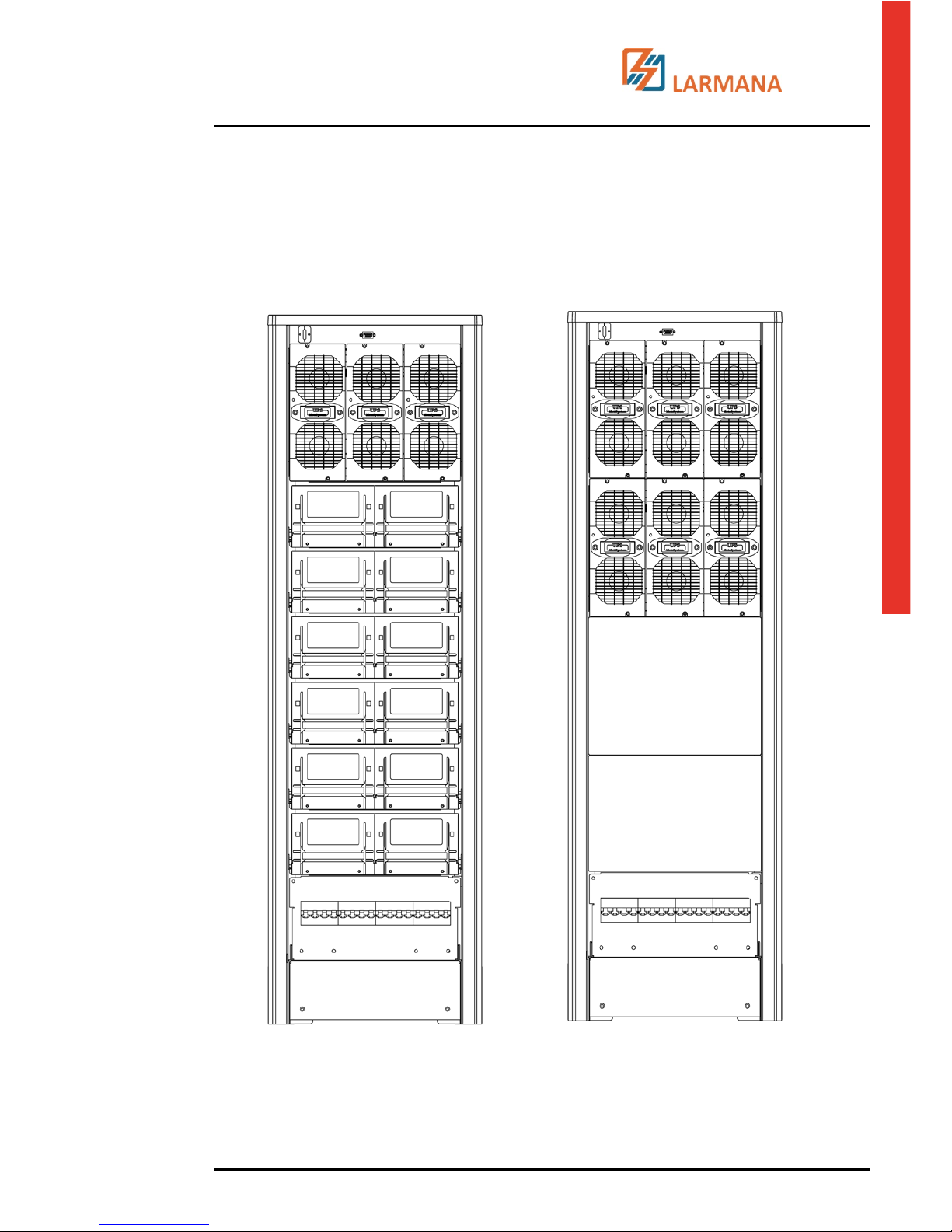

UPS Trim od® 10/15/20 UPS Trim od® 30 TT

Page 14

14

®

UPS Trim od® 30 TM UPS Trim od® 40

2. Technological description

Page 15

Trimod®

Operating and Maintenance Manual

15

UPS Trim od® 60

Page 16

16

®

2. Technological description

UPS Trim od® BATTERY UPS Trim od® BATTERY/2

Page 17

Trimod®

Operating and Maintenance Manual

17

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

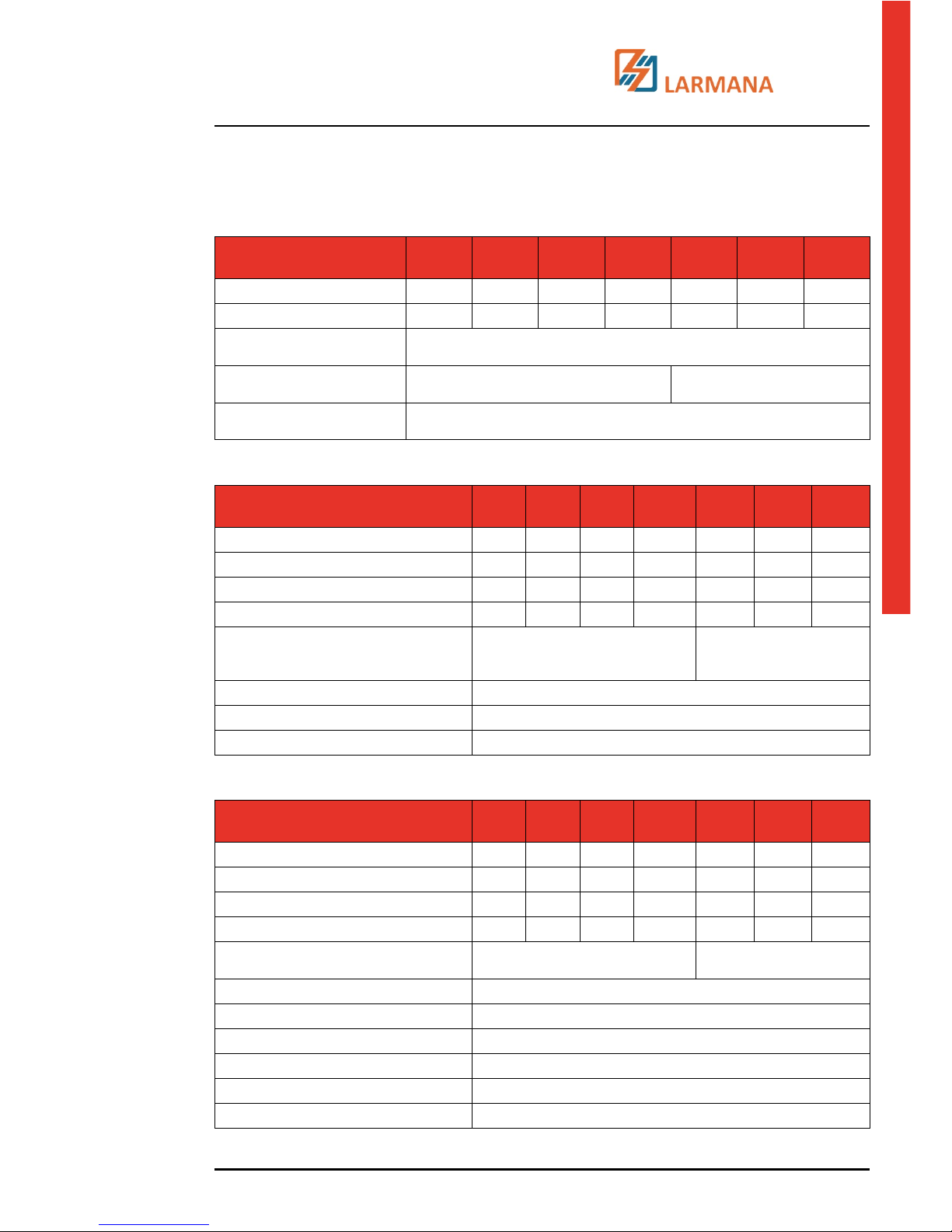

Rated Power 10 kVA 15 kVA 20 kVA 30 kVA 30 kVA 40 kVA 60 kVA

Active Power 9 kW 13.5 kW 18 kW 27 kW 27 kW 36 kW 54 kW

Technology

On Line, double conversion

IEC 62040-3 VF I – S S - 111

IN/OUT configuration

Single / Single – Single / Tri – Tri /

Single – Tri /Tri (can be configured by user)

Tri / Tri

UPS architecture

Modular with 3400 VA - 5000VA - 6700VA power modules housed in a single cabinet

Expendable, Redundant N+X (except for Trimod® 30 kVA TM and Trimod® 60 kVA).

General charateristics

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

Maximum current (Three-phase - Three-phase) 18.5 A 27.8 A 37 A 55.5 A 55.5 A 74 A 111 A

Maximum current (Three-phase - Single-phase) 18.5 A 27.8 A 37 A 55.5 A - - -

Maximum current (Single-phase - Three-phase) 55.5 A 83.3 A 111 A 166.5 A - - -

Maximum current (Single-phase - Single-phase) 55.5 A 83.3 A 111 A 166.5 A - - -

Input voltage

230 V + 15% - 20% (Single-phase)

400 V + 15% - 20% (Three-phase)

(Neutral line is essential)

400 V + 15% - 20%

(Three-phase)

(Neutral line is essential)

Input frequency 50 / 60 Hz

Power factor on the input > 0.99

THD input current < 3%

Input

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

Maximum current (Three-phase - Three-phase) 14.50 A 21.7 A 29 A 43.5 A 43.5 A 58 A 87 A

Maximum current (Three-phase - Single-phase) 43.5 A 65.2 A 87 A 130.5 A - - -

Maximum current (Single-phase - Three-phase) 14.50 A 21.7 A 29 A 43.5 A - - -

Maximum current (Single-phase - Single-phase) 43.5 A 65.2 A 87 A 130.5 A - - -

Output voltage

230 V ± 1% (Single-phase)

400 V ± 1% (Three-phase)

400 V ± 1% (Three-phase)

Static tolerance of output voltage 1%

Output frequency 50 / 60 Hz synchronized

Wave shape Sinusoidal

Mains efficiency (AC/AC on line) 94% max

Mains efficiency (AC/AC eco mode) 99% max

Tolerated overload 125% per 10 min – 150% per 60 s

Output

Page 18

18

®

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

Type of batteries 12V 7.2Ah or 12V 9Ah maintenance-free sealed lead batteries

Tolerated overload 125% per 2 min – 150% per 30 s

Batteries

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

Bypass

Automatic (static and electromechanical)

Manual (for maintenance)

Signals and alarms

Large alphanumerical display with 4 lines,

multicolored status indicator, buzzer

Communication ports Two RS 232 ports, 1 relay interface, 1 contact port

Software Can be downloaded free of charge from the web site www.ups.legrand.com

Protections

Electronic against overloads, short-circuits and excessive battery discharging.

Functions blocks if autonomy ends.

Powering surge limiter.

E.P.O. contact (total shutdown in an emergency) BackFeed Protection.

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

Net weight UPS (without batteries) 110 Kg 130 Kg 154 Kg

Dimensions UPS (L x H x D) (mm) 414 x 1367 x 628

3400VA Power modules installed 3

5000VA Power modules installed 3 6 6

6700VA Power modules installed 3 6 9

Power modules - Net weight 8 Kg

Battery drawing - Net Weight 14 Kg

3 104 36

10 kVA

3 104 37

15 kVA

3 104 37

20 kVA

3 104 39

30 kVA TM

3 104 38

30 kVA TT

3 104 40

40 kVA

3 104 41

60 kVA

Operating temperature 0°C ÷ 40°C

Relative humidity 20% ÷ 80% non-condensing

Noise level at 1m 58 ÷ 62 dBA

Grade of protection IP 21

Accessories

Mechanical characteristics

Environmental conditions

2. Technological description

Page 19

Trimod®

Operating and Maintenance Manual

19

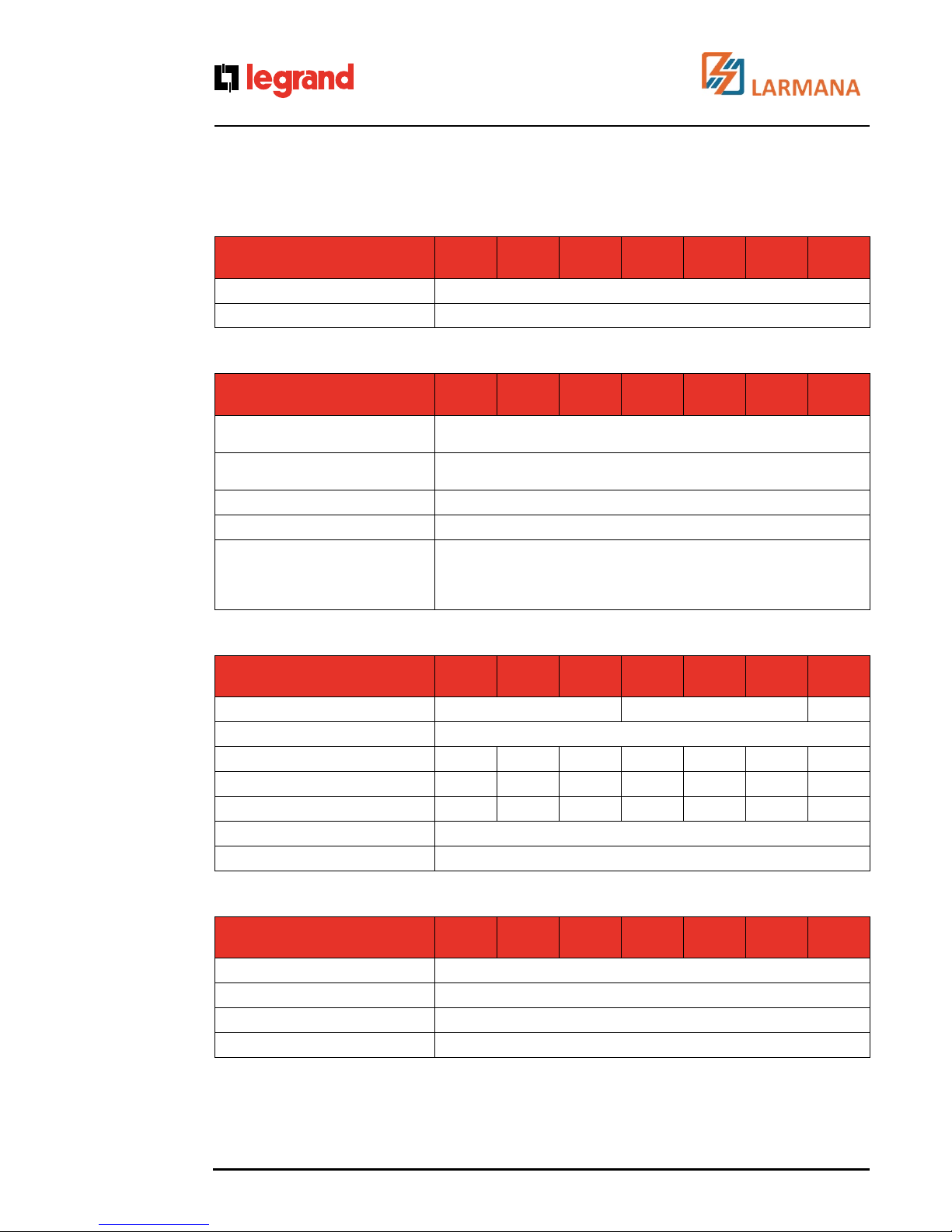

INPUT

Rated voltage and tolerance 230 Vac +15% -20%

Rated current 19.3 Arms

Power Factor PF > 0.99

Input current THD THDi < 3%

ENVIRONMENTAL CONDITIONS

Operating temperature 0°C ÷ 40°C

Relative humidity 20% ÷ 80% non-condensing

Noise level at 1m 42 ÷ 46 dBA

Grade of protection IP 20 (IEC 529)

OUTPUT

Maintenance voltage 13.75 Vdc/battery

Rated current (max) 15 Adc

AC/DC Efficiency >93% at max rated current

INDICATIONS

Operating mode

(multi-color LED on the module

and display menu information

on the UPS)

Yellow LED, Fast intermittent: f1 recharge fase.

Green LED, Slow intermittent: f2 recharge fase and maintenance.

Green LED, fi xed: stand-by

Red LED: Fault mode

STANDARD

EN 62040-1, EN 62040-2, EN 62040-3

Bcm technical specifications

Page 20

20

®

2.4 Communication devices

The uninterrupted power supplies of the UPS Trimod® family have 2 RS 232 serial ports, 1 relay interface and 1 output

on a 9-pole male tray-shaped connector, logic level SELV. insulated.

AT T EN T ION

To en su re o pe ra to r sa fe ty it i s ma nd at or y fo r th e in te r fa ce s to b e co nn ec te d so t ha t:

- the maximum voltage between any two conductors connected to the interface and between either of these two

conductors and earth is less than a peak 42V or less than 60Vdc;

- the insulation voltage between any conductor connected to the interface and earth is at least 1500Vac

2.4.1 RS232 serial ports

The rst of the two RS232 serial ports used on the uninterrupted power supply unit and called “maintenance interface”

is located at the top behind the front door. It is dedicated exclusively to diagnostic functions and updating machine

rmware.

The second, called “user interface”, is at the top at the back of the UPS. Thanks to this port that, with either a computer

or specic network card, it is possible to access UPS operating data and to control the unattended turning o of the

operating system.

2.4.2 Relay interface/E.P.O.

The default setting of the relay interface contacts is Normally Open (NO) but can be congured as Normally Closed (NC)

via the UPS display. Inoltre è presente l’ingresso per la funzione E.P.O.

The indications available with this interface are:

• running on battery

• autonomy reserve

• generic alarm

• overload

• UPS running on bypass

Electrical specications/contact interface

The technical specications of the relay interface contacts are the following:

• V

MAX

= 250VAC - 30VDC, I

MAX

= 5A

E.P.O. input

Voltage with open contacts 12VDC, current with closed contacts 5mA.

The indications available with this interface are the following:

2. Technological description

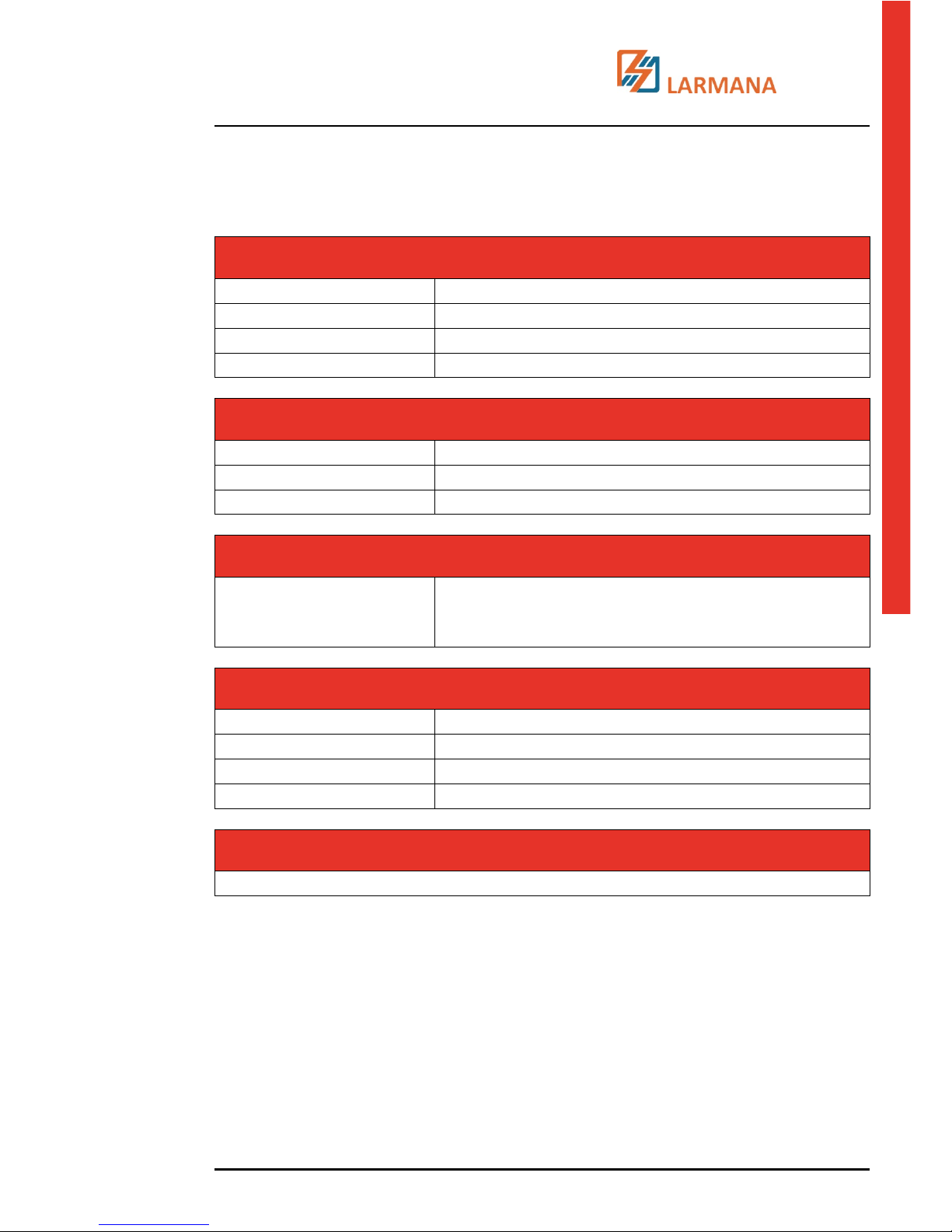

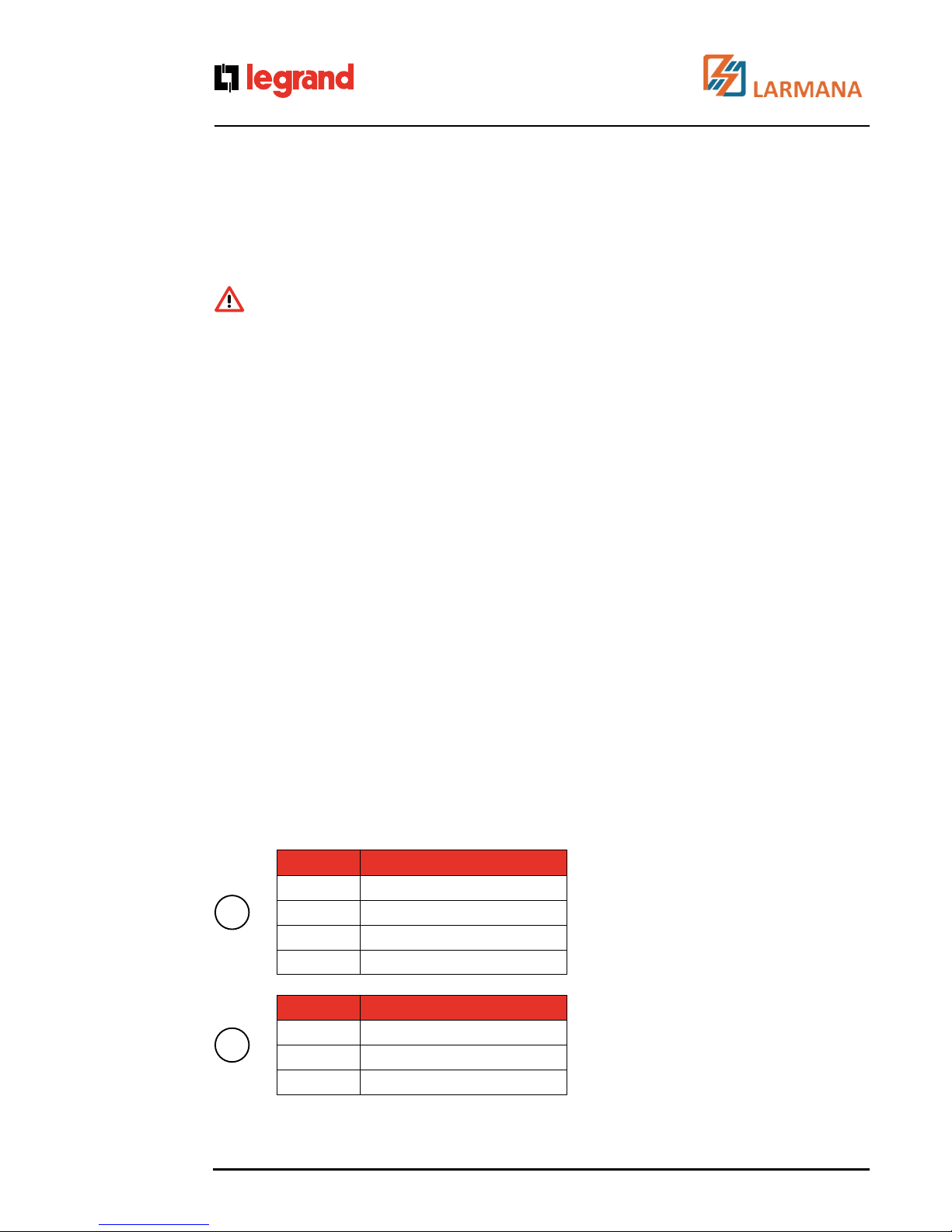

PIN FUNCTION

1 -2 Running on battery

3 - 4 Autonomy Reserve

5 - 6 Generic alarm

7 - 8 Overload

PIN FUNCTION

1 -2 Running on Bypass

3 - 4 E.P.O.

5 - 6 -

Page 21

Trimod®

Operating and Maintenance Manual

21

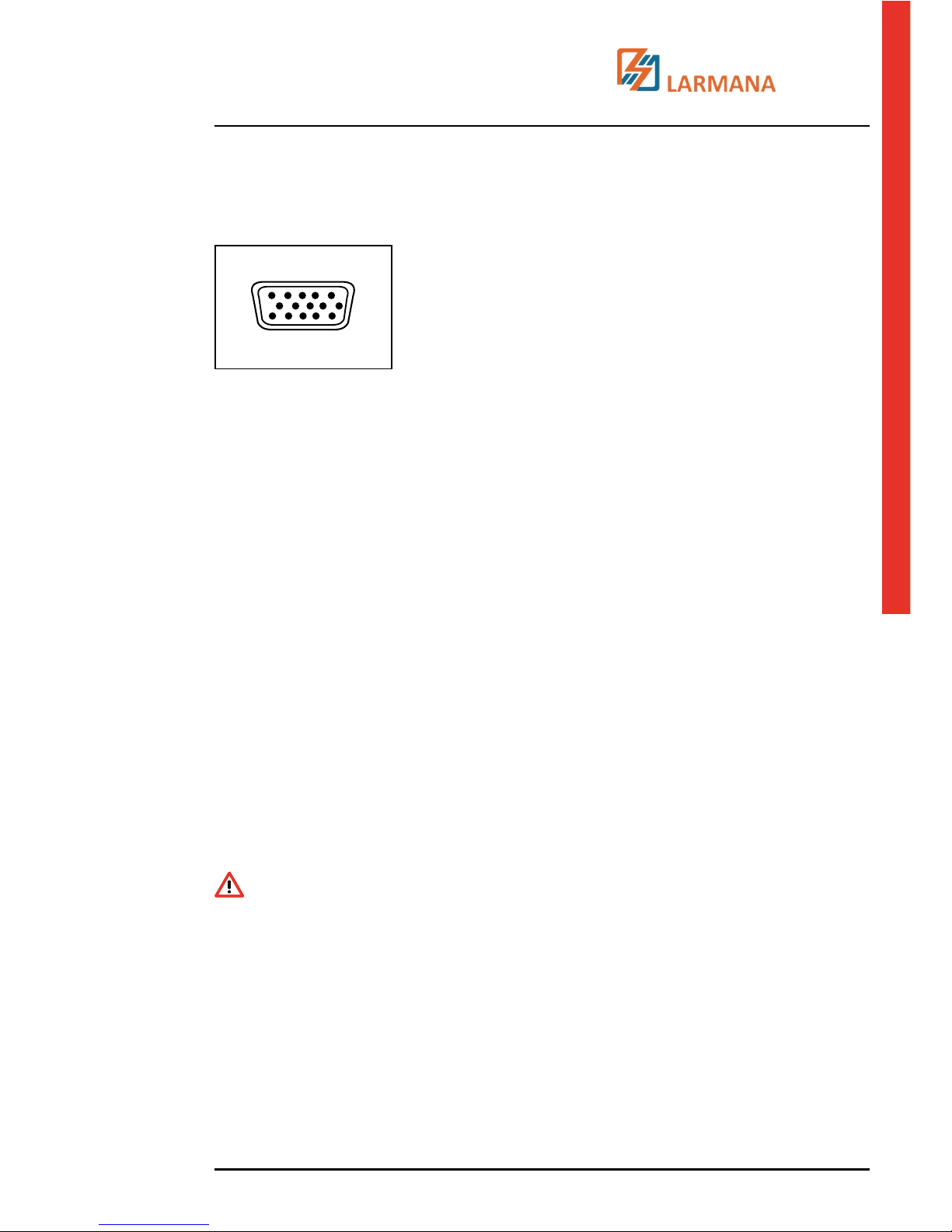

2.4.3 Logic level interface

Logic level interface is available on connector DB15 (F) and it allows the UPS to be connected to a remote system for

monitoring its operating status, making available the following indications and controls:

• Mains/battery operated;

• Autonomy reserve

• UPS fault

• Overload

• UPS on bypass

• ON/OFF input

The functions of the interface pins are:

• Pin 1: GND;

• Pin 2: Mains/Battery (output, active high);

• Pin 3: Autonomy Reserve (output, active high);

• Pin 4: RS232 power supply;

• Pin 6: do not connect

• Pin 7: Overload (open collector, active low);

• Pin 12: UPS on Battery (open collector, active low);

• Pin 13: UPS on Bypass (open collector, active low);

• Pin 14: Autonomy Reserve (open collector, active low);

• Pin 15: Alarm (open collector, active low)..

Electrical specifications

Logic output: 12V

DC

max., output impedance 2.2kΩ in series.

RS232 power supply: 12VDC 700mA max., not adjusted.

Open collector outputs (all): 30VDC, 100mA max

2.4.4 Communication slot

In the rear part of UPS Trimod® an SNMP Slot is available for SNMP Adapter (Optional).

ATTENTION

The maximum current taken from pin4 of connector DB15 “RS232 power supply” and from the SNMP slot for the

network board to work must be, in total, less than 700mA.

Page 22

22

®

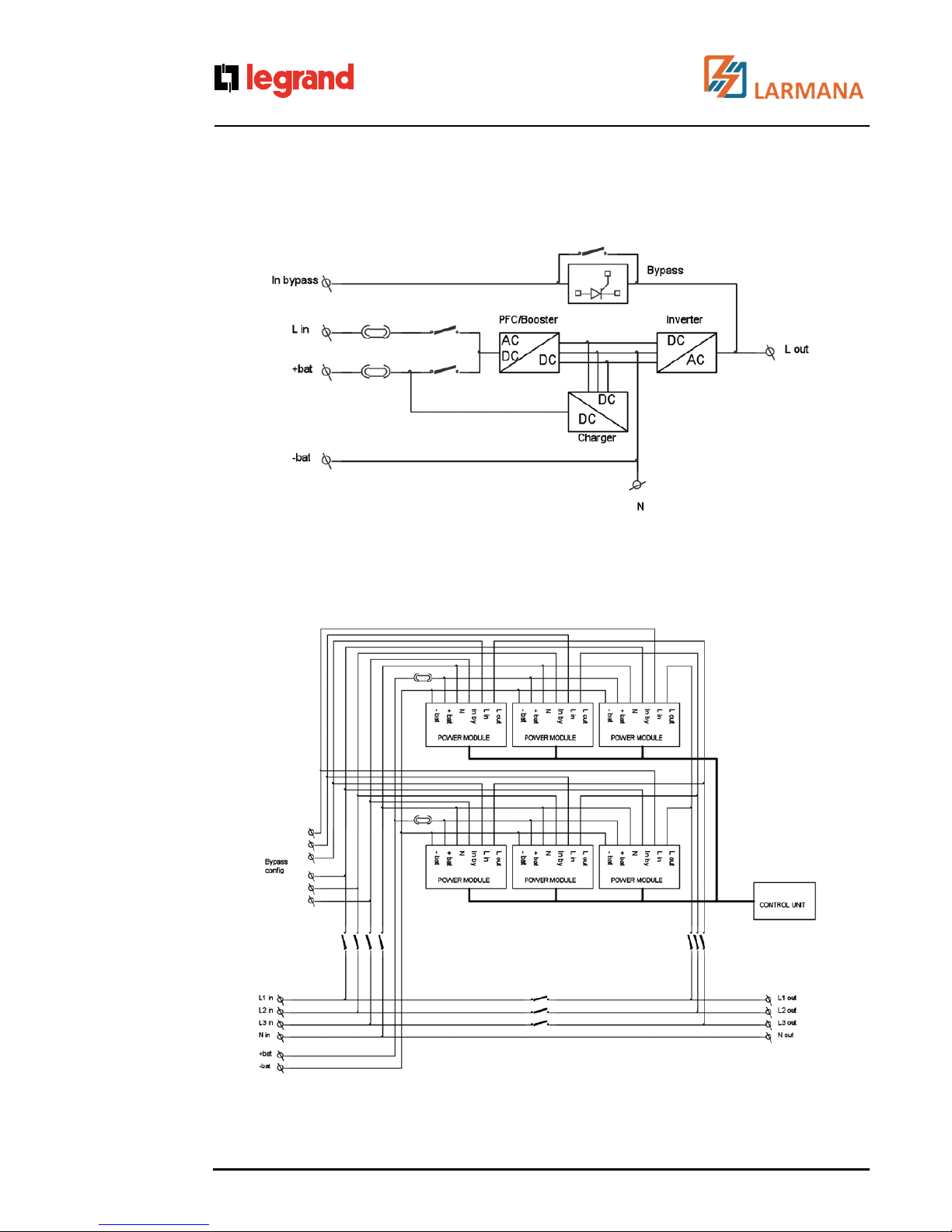

2.4.5 Power module block diagram

2.4.6 Trimod® 30KVA TM Interconnection block diagram

All UPS Trimod® models have a similar block diagram.

2. Technological description

Page 23

Trimod®

Operating and Maintenance Manual

23

3.1 General notes

WARNING

Before doing any operation on the equipment, it is necessary to read through the whole manual carefully, paying

attention to this chapter in particular.

The equipment has been built for the application specified in the declaration of conformity enclosed with this manual.

For no reason whatsoever it is allowed to use it for purposes other than those for which it has been designed, nor in ways

different to those explained in the manual.

The various interventions must be carried out following the criteria and chronology described in this manual.

3.2 Symbols

In this manual some operations are highlighted by graphical symbols that call the attention of the reader to the

dangerousness of the operations. The graphics are as follows:

WARNING

This means the possibility of an event happening that could lead to serious injury or great damage to the equipment

if adequate precautions are not taken.

ATTENTION

This means the possibility of an event happening that could lead to slight injury or material damage if adequate

precautions are not taken.

INDICATION

This means important information that must be read paying maximum attention.

3.3 Definitions of ‘Operator’ and ‘Specialized Technician’

The professional figure that is going to access the equipment for normal use is defined by the term “operator”.

With this definition we mean personnel who know how to use and service the equipment and have the following

requirements:

1. Specific training that authorises them to work according to the safety standards in relation to the dangers that the

presence of electricity can bring about.

2. Training on how to use the Individual Protective Devices and on the basic first aid interventions.

When the company person in charge of safety chooses the operator who is to use the equipment – who must be suitable

for work in accordance with the existing laws – he must consider the physical aspect (no impairment), the psychological

aspect (mental equilibrium, sense of responsibility) and personal education, training, experience and knowledge of the

standards, prescriptions and provisions for the prevention of accidents.

Based on the skill and capacity found, he shall also see to the operator’s training in order to give him full knowledge of the

equipment and of the parts it is made of.

To conclude, the operator must be made aware of the contents of this manual.

3.3.1 Qualification required to the operator

The operator must follow the instructions given to ensure maximum safety for himself and for the others. In particular he

must comply with all the requirements contained in this manual throughout all the operating phases.

Typical activities envisaged:

- using the equipment when it is working normally and resetting subsequent to a stop;

- taking the necessary measures to maintain performance quality;

- cleaning the equipment

- collaborating with personnel who are to see to extraordinary maintenance work (“specialized technician”).

3. Safety Provisions

Page 24

24

®

3.3.2 Qualification required to the specialized technician

The professional person who has to look after installation, starting and extraordinary maintenance is defined by the term

“specialized technician”.

With such a definition we mean people with knowledge of the procedures for installing, assembling,

repairing and servicing the equipment and who have specific technical qualification. Besides the requirements listed for

a generic operator, the specialized technician must have had technical training or specific training for the procedures

needed to use and service the equipment in complete safety.

Broadly speaking, the specialized technician will be a person selected among the professional people in the department

and who has proven experience and capacities and specific technical expertise in relation to the type of work to be done.

WARNING

The person in charge of safety is responsible for the protection against and prevention of company risks in

accordance with the European Directive 89/391 EEC (safety at the work place), in ITALY it is part of the Law Decree

dated 12/11/1994.

The person in charge of safety must ensure that all people working on the machine have received all the relevant

instructions of this manual, included start-up and commissioning, and with particular reference to the contents of

this chapter.

3.4 Individual protective gear

WARNING

There is a high risk of electrical shock with the equipment as well as a considerable short circuit current. When

using and servicing the equipment it is absolutely forbidden to work without the protective gear mentioned in this

paragraph.

The personnel who are going to work and/or transit near the equipment must not wear clothes with baggy sleeves or

laces, belts, bracelets or other metal items that could be a hazard source.

3.4.1 Gear to wear

The following indications summarise the protective gear to wear.

Accident and spark proof footwear with rubber sole and reinforced toe

Use: always

Waterproof rubber gloves

Use: always

Protective gear

Use: always

Protective glasses

Use: always

3. Safety Provisions

Page 25

Trimod®

Operating and Maintenance Manual

25

3.5 Indications of danger in the work place

The following signs must be placed in all points of access to the premises where the equipment is installed.

Electric current

It indicates the presence of live parts.

Emergency interventions

Do not use water to extinguish a fire but only the extinguishers designed specifically

for putting fires out on electronic equipment.

No smoking

This indication explains that it is forbidden to smoke in the area where the sign is affixed.

3.5.1 Indications on board the equipment

The explanatory plates on the equipment can vary according to the country of destination and to the relative applicable

construction laws.

Strictly comply with what is required. It is strictly forbidden to remove these plates or to work in a way different from what

is indicated on them.

All the data on the plates must always be readable and cleaned periodically.

If a plate is ruined and/or is no longer legible, even only in part, ask for a new one from the Manufacturer who is bound

to supply a substitute.

WARNING

The plates must be neither removed nor covered; it is forbidden to affix others on the equipment without the prior

written authorisation from the Manufacturer.

3.6 Residual risks

‘Residual’ risks are risks that were impossible to eliminate at the design phase and, as such, are potentially present on the

equipment.

These risks are found with a specific analysis as prescribed by the standards of the sector. The documentation relative to

the analysis is included in the Technical File of the machine filed

by the Manufacturer.

In the case of the UPS Trimod® there are no residual risks provided that all the indications and provisions in this manual

are scrupulously complied with.

WARNING

The risk can be drastically reduced by wearing the Individual Protective Gear listed in this chapter, considered

indispensable. Always work with due caution when near the dangerous areas indicated by the signs on board the

equipment.

Page 26

26

®

3.7 General warnings

ATTENTION

The equipment generates, uses and can radiate energy and radio frequencies. If not installed and used in agreement

with the indications given in this manual, it can interfere with radio communications.

- The equipment must be kept and used in accordance with the instructions given herein and as suggested from time to

time.

- The department manager must instruct the operating and maintenance personnel on how to use and service the

equipment in complete safety.

- Only specialized and specifically instructed personnel must be allowed to access the equipment for maintenance work.

All the time such maintenance work is being done, ‘Work underway’ signs must be affixed in the department that can

be seen from all access points.

- Connection of the equipment (and of any accessory devices) must include standard earthing to discharge short circuit

current and electrostatic voltages. Mains voltage must correspond to the value on the ID plate. Use of current adapters

is not allowed. When connecting pay attention to polarities.

- Any work on the equipment must be done only after it has been disconnected from the supply mains via the switch

which must be padlocked.

- When the equipment is received, or prior to switching on each time, DO NOT switch the UPS on if the batteries are

leaking.

- Tools used for maintenance (pliers, screwdrivers, etc.) must be the electrically insulated type.

- It is strictly forbidden to deposit combustible materials near the equipment. It must always be kept locked and access

allowed only to specifically trained personnel.

- Do not deactivate the safety devices or delude the indications, alarms and warnings, whether they are communicated

automatically or by means of plates on the installation.

- Do not turn the machine on without the fixed protections in place (panels, etc.).

- In the case of breakages, deformation or malfunctions of the equipment or parts of it, repair or replace immediately,

avoiding “emergency” repairs.

- It is not allowed, for any reason, to modify, manipulate or in any way alter the structure of the equipment, the devices

mounted on it, operating sequence, etc., without having first consulted the Manufacturer.

- If the fuses have to be changed, always and only use ones of the same type.

- Changing the batteries is a job for a specialized technician. Bear in mind that the electrolyte can cause irreparable

injury to skin, mucous membranes, and eyes and is toxic if inhaled or swallowed. Always work with the most suitable

Individual Protective Gear. Do not forget that the batteries must be disposed of according to the laws existing in the

country where the equipment is installed as they are toxic waste. Under no circumstances can a battery be burnt as it

would cause an explosion!

- All maintenance work, routine and extraordinary, must be recorded in a register, noting the date, time, type of job,

name of the operator and all useful information. If necessary use the pages added at the end of the “Maintenance

“chapter.

- Do not use oils or chemicals to clean with as they can corrode or damage parts of the equipment.

- Both the equipment and the work place must be kept perfectly clean.

- When maintenance is finished check carefully that no tools and/or materials have been left near the equipment before

turning the electricity back on.

3. Safety Provisions

Page 27

Trimod®

Operating and Maintenance Manual

27

3.8 Emergency interventions

The following information is of a general nature. For specific interventions please consult the laws existing in the country

where the equipment is installed.

3.8.1 First aid interventions

If any first aid intervention is required, comply with company rules and traditional procedures.

3.8.2 Fire-prevention measures

- Do not use water to extinguish fire but only the extinguishers designed specifically for putting fires out on electronic

equipment.

Page 28

28

®

4.1 Visual inspection

When the UPS is delivered, examine the packaging and product carefully to see if any damage was done during transport.

In particular check the integrity of the indicator on the external “Shock Watch” label.

If either possible or ascertained damage is found report it immediately to:

- the carrier;

- the LEGRAND® Technical Assistance Centre

Make sure that the unit received corresponds to the material specified on the delivery document.

The UPS Trimod® packaging protects the equipment against mechanical and environmental damages.

For greater protection it is also wrapped in a transparent film.

4.1.1 Checking the equipment and accessories supplied

The equipment and relative accessories supplied (as agreed with the manufacturer) must be in perfect condition. Before

it is shipped the equipment is checked carefully; however, it is always advisable to check it is complete and in order when

receiving it.

Make sure that:

- The shipping data (consignee’s address, number of packs, order number, etc.) are the same

as those written on the accompanying documents;

- The technical-legal documentation that comes with the equipment includes the user manual

for the specific type of UPS to install together with the CE Declaration of Conformity.

In the case of defects and/or material missing, send a report immediately to the Manufacturer and wait for his instructions

before commissioning the equipment.

4.2 Unpacking

To remove the packing material observes the ‘ARROW’ on

the outside box. To remove the UPS from the packaging

follow these steps:

1. cut the wrapping and open the plastic safety straps;

2. open the top of the cardboard box;

3. remove the top protection;

4. remove the four corner protections;

5. remove the packaging container, pulling it upwards;

6. remove the pallet and front/rear bracket from the

UPS, loosening the 4 securing screws;

7. inspect the UPS to see if it has been damaged in any

way. Notify the carrier and supplier immediately if any

apparent damage is found;.

Keep the packaging material in case the UPS has to be

shipped in the future. The packaging materials are 100%

recyclable; if you want to dispose of them please comply

with the existing laws.

4.3 Checking the contents of the pack

Below is a list of the materials supplied. The list is general. Please refer to the packing list for

shipment details.

4. Unpacking

Page 29

Trimod®

Operating and Maintenance Manual

29

Trimod® INVERTER

- No. 1 UPS Trimod® unit;

- No. 1 bag of accessories with a set of screws for installing the unit correctly;

- No. 1 front closing panel;

- No. 2 base strips for side closing;

- Operating and maintenance manual

- International guarantee.

Trimod® BATTERY

- No. 1 Trimod® BATTERY cabinet;

- Operating and maintenance manual

- No. 1 multicore cable for connecting to the UPS Trimod® inverter;

- No. 1 bag containing fuses and keys for the front door.

Trimod®/2 BATTERY

- No. 1 Trimod® BATTERY/2 cabinet;

- Operating and maintenance manual

- No. 2 multicore cables for connecting to the UPS Trimod® inverter;

- No. 1 bag containing fuses and keys for the front door.

Check that the UPS Trimod® technical data on the plate on the sticker affixed on the inside panel of the door, inside the

hatch of the UPS, correspond to the material bought, described on the delivery document.

4.4 Storing

4.4.1 UPS

If the UPS is going to be stored prior to installation, regardless of whether or not it is still packed, it must be on dry, clean

and fresh premises where the ambient temperature is between 0°C and +50°C (32-122°F) and with humidity below 90%

(not condensing).

4.4.2 Batteries

The standard batteries of the UPS Trimod® are sealed lead-acid, they are maintenance-free and installed internally.

Lead is a dangerous substance for the environment if it is not recycled by specialized companies. If the batteries are not

charged they cannot be kept for more than 6 months at 20°C (68°F) or more than 3 months at 30°C (86°F) or more than 2

months at 35°C (95°F).

ATTENTION:

sealed batteries must never be stored if they are partly or totally flat.

To charge the batteries before and after storing, simply connect the input power supply to the UPS, plug in battery fuses

(F B+ and F B-) and then close the switches. When the unit detects the input voltage it automatically proposes starting a

battery charging cycle. After about 1 minute charging starts automatically and the time left to finish charging is shown

on the display. The charging cycle can be stopped at any time by pressing the ‘ESC’ key.

If the UPS is delivered without batteries, LEGRAND® is not liable for any damage or bad operation caused to it by an

incorrect wiring of the batteries.

Page 30

30

®

4.5 Handling

WARNING

Handle with great care, lifting it only to the extent necessary, keep it well balanced and avoid swinging which could

be dangerous.

If it weighs less than 30 kg (check on the transport document) the equipment can be moved around by hand as it has

two wheels.

Do not forget that the equipment must always be handled by trained personnel, equipped with the Individual Protective

Gear as specified in Chapter 3.

If the equipment needs to be lifted, use a forklift truck or transpallet of a suitable capacity, inserting the forks in the

wooden base, making sure they come through on the opposite side by at least twenty centimetres.

4.6 Positioning

The UPS must be placed observing the following conditions:

- humidity and temperature must be within the prescribed limits;

- the fire protection regulations must be observed;

- wiring must be of easy execution;

- the front and rear must be accessible for assistance or routine maintenance;

- the flow of cooling air must be guaranteed;

- the air conditioned system must be adequately sized

- there must be no corrosive/explosive gases

- the premises must be free from vibrations;

- the clearance at the back and sides must guarantee adequate circulation of the cooling air.

Bear in mind that the average life of the batteries is strongly influenced by the environmental operating temperature.

Place the unit on premises where the temperature ranges between +18°C (64.4°F) and +23°C

(73.4°F) which will guarantee a very long battery life.

4. Unpacking

Minimum clearances

recomm ended f or

the UPS

X=100 mm / Y=200

mm

Minimum clearances

recomm ended f or

the UPS Trimod® +

Tri mod ® BAT TE RY

X=100 mm / Y=200

mm

Cabinet

Battery

Page 31

Trimod®

Operating and Maintenance Manual

31

Before commencing installation, make sure there is enough lighting on the equipment so that each single detail can be

seen easily. Use artificial lighting if natural lighting is not enough for the aforementioned requirements.

If maintenance work has to be done on parts that are insufficiently illuminated, it is compulsory to use portable lighting,

being careful not to create shadows that will prevent or reduce visibility on the point you are working on or on the

surrounding areas.

4.7 Last operations

Once positioned correctly, fit the two side base strips and the front one supplied in the accessory kit.

Page 32

32

®

WA RNING

The instructions in this chapter are not addressed to a normal operator but to a specialized technician, authorised

to work only if he uses the Individual Protective Gear mentioned in Chapter 3.

5.1 Safety rules and regulations

Prima di eseguire qualsiasi operazione di installazione, leggere e applicare quanto di seguito riportato:

1. Warning: device with high leakage current, it is essential to ensure ground protection before connecting power. It is

necessary to check that the distribution panel, which connects the UPS, has a secure connection to the circuit ground

and adequate protection, as required by law.

2. The installation of the UPS Trimod® units must be provided with a fixed type circuit breaker. There shall be no

connection to the mains through a plug of the traditional type.

3. The framework of power supply or disconnection device, must be installed near the equipment and be easily

accessible.

4. A circuit protection against return voltage must be provided externally to the UPS (backfeed protection). See diagrams

on the next page.

5. You will have to affix a “warning” label on all power disconnects the power supply placed away from the UPS in order

to alert the service personnel that the circuit is connected to a UPS. The label must contain the following text (or

equivalent):

Before working on this circuit

- Isolate Uninterruptible Power System (UPS)

- Then check for Hazardous Voltage between all terminals

including the protective earth

Risk of Voltage Backfeed

The UPS Trimod® is equipped with an auxiliary contact for enabling the external circuit backfeed protection. The auxiliary

contact is made with a relay C / NC / NO and is available on the terminal pole “BACKFEED PROTECTION” in the terminal

box of the UPS.

If the UPS detects a condition of return voltage, the relay is energized and changes state, enabling the cutting of input

lines that must be realized externally as indicated in the schematic below.

The characteristics of relay contacts are:

• Maximum switching voltage: 250Vac.

• Applicable current: 5A, PF = 1.

5. Installation

Page 33

Trimod®

Operating and Maintenance Manual

33

Single-Phase/Single-Phase

Configuration

Single-Phase/Three-Phase

Configuration

5.1.1 Mains connection and Backfeed protection drawings for TN systems

In the diagrams:

“S1” is the circuit breaker required.

“S3” is bypass line breaker contact

“S4” are backfeed protection circuit contacts.

Three-Phase/Three-Phase

Configuration

Three-Phase/Single-Phase

Configuration

Page 34

34

®

5.1.2 Mains connection and Backfeed protection drawings for TT systems

In the diagrams:

“S1” is the circuit breaker required.

“S3” is input line breaker contact

“S4” are backfeed protection circuit contacts.

WARNING

In case of Backfeed Protection warning, please contact Technical Support.

Single-Phase/Single-Phase

Configuration

Single-Phase/Three-Phase

Configuration

Three-Phase/Three-Phase

Configuration

Three-Phase/Single-Phase

Configuration

5. Installation

Page 35

Trimod®

Operating and Maintenance Manual

35

5.2 Electrical connections

The electrical connection of the UPS to the switchboard is part of the installation and is usually done by the user and not

by the UPS manufacturer; therefore the following indications are purely an example and the actual electrical connections

must be done in accordance with local standards.

Once the UPS has been removed from the packaging and positioned in its final place of installation, the authorised

technician can start its installation.

5.2.1 Safety recommendations

WARNING

Before starting please read and apply the following with attention. It is strictly forbidden to proceed with installation

if one or more of the following conditions have not been checked.

1. Do not proceed with installation if there is water or moisture.

2. Remember that opening or removing the panels from the UPS you risk exposure to high and dangerous voltages.

3. Check there is no mains voltage on the equipment.

4. Check that the loads are off and disconnected from the UPS;

5. Check that the UPS is off and not live.

All the electrical connection operations are done working on the distribution box. The fuse carriers, output switch and

manual bypass switch are on the outside of the box while inside you will find the terminal block on which to do the

connections.

5.2.2 Preliminary operations

Before connecting the UPS make sure that:

1. Mains voltage (volt V in input) and frequency correspond to the values on the UPS rating plate;

2. Earthing complies with the IEC standards (International Electronic Commission) or local regulations;

3. The electrical system is equipped with all the necessary differential protections and thermal circuit breakers upstream

from the UPS input.

5.2.3 Connecting the loads

Before actually starting to connect the loads make sure the rated power of the UPS (OUTPUT POWER) indicated on its

rating plate is equivalent to or greater than the total sum of the load powers.

INDICATION

The loads wiring diagram is in the DIAGRAMS chapter.

The characteristics of the output cables must conform to the sections of the cables indicated in table 5 of the TABLES

chapter

A separate switchboard must be supplied for the load. It is a good idea to use isolating switches or thermal circuit breakers

conforming to the IEC standards to protect the lines leading from the electrical panel.

Use adhesive labels or some similar way to indicate the following values on the system’s general panel:

- maximum rated power of the total load;

- maximum rated power of the load at power intakes;

- if an ordinary switchboard is used (outlets for mains voltage and for the UPS), make certain that there is an indication

of the voltage applied on each outlet (‘Mains’”or “UPS”).

Page 36

36

®

5.2.4 Emergency Power Off (Remote E.P.O.)

In accordance with the standards, the UPS is fitted with an emergency device that uses a normally closed contact (already

installed on the UPS) that can be opened to activate the emergency machine power off.

The E.P.O. terminals are in the UPS’s rear panel on pins 3 and 4 of the 6-pole Combicon connector installed on contact

interface.

To connect the emergency power off device please follow these instructions:

- Use a cable with double insulation, no more than 10 metres in length.

- Check that the switch used is galvanically insulated.

Electrical specifications of the E.P.O. interface:

- Voltage between terminals 3 and 4 (6P Combicon) with open circuit = 12Vdc.

- Current between terminals 3 and 4 (6P Combicon) with closed circuit = 5mA

The following figure shows how the emergency power off device has to be connected.

5.2.5 Installing the Trimod® BATTERY

It is possible to connect external battery units to increase ups autonomy.

If the configuration uses more than one battery it is necessary to position all the Trimod® Battery units on the same side

of the UPS Trimod® and connect them in cascade with each other using the multicore cables supplied.

There are four different external battery cabinets for the Trimod® BATTERY units:

- a modular model consisting of a cabinet with an internal structure that uses battery drawers for up to a maximum of 80

12V 7.2Ah or 12V 9Ah batteries (16 drawers).

- a modular model consisting of a cabinet with an internal structure that uses battery boxes for up to a maximum of 100

12V 7.2Ah or 12V 9Ah batteries (20 drawers).

- a compact, non modular, economical model that uses a shelf architecture instead and on which the batteries are

placed. It can house 60 or 120 12V 7.2Ah or 12V 9Ah batteries.

- a compact, non modular, economical model that uses a shelf architecture instead and on which the batteries are

placed. It can house 20 12V 94Ah batteries.

A Trimod® BATTERY can be connected to several UPS Trimod® units.

WARNING

The following instructions are of a prescriptive nature and it is imperative they be complied with.

Opening or removing the panels from the UPS Trimod® or Trimod® BATTERY you risk exposure to high and dangerous

voltages! To guarantee protection of personnel during installation of the Trimod® BATTERY make sure that the connections

are done under the following conditions:

1. There must be no mains voltage

2. The loads are off and disconnected;

3. The UPS Trimod® is off with no voltage and all fuse carrier isolating switches on the UPS Trimod® and Trimod® BATTERY

are open.

5. Installation

Page 37

Trimod®

Operating and Maintenance Manual

37

To ensure that the UPS Trimod® has stopped completely if you want to add a Trimod® BATTERY in an existing installation,

follow the steps illustrated in the MAINTENANCE chapter.

The connection of a Trimod® BATTERY to the UPS Trimod® must be done according to the following diagram and the steps

listed below:

1. Make sure that all the battery fuse carrier isolating switches are open;

2. Connect the UPS and the additional battery cabinet using the earth cable (yellow-green);

3. Use the wiring supplied with the Trimod® BATTERY to connect the positive and negative terminals of the UPS Trimod®

to those of the Trimod® BATTERY.

UPS

Tri mod

®

BATTERY

UPS

Tri mod

®

BATTERY

UPS

Tri mod

®

Page 38

38

®

The connection of a Trimod® BATTERY to the UPS Trimod® 40 - 60 must be done accoring to the diagram above and the

steps listed below:

1. Make sure that all the battery fuse carrier isolating switches are open;

2. In each Trimod® BATTERY remove the lower front panel;

3. In each Trimod® BATTERY remove the terminal block loosening the 2 securing screws;

4. Connect the UPS and the additional battery cabinet using the earth cable (yellow-green);

5. Use the wirings supplied with the Trimod® BATTERY to connect the positive and negative terminals of the UPS Trimod®

to those of the Trimod® BATTERY.

5. Installation

UPS Trim od® 40/60

Page 39

Trimod®

Operating and Maintenance Manual

39

WARNING

The connection of a Trimod® BATTERY to the UPS Trimod® 40 must be done using BOTH wirings supplied with the

Trimod® BATTERY.

The connection of a Trimod® BATTERY to the UPS Trimod® 60 must be done using BOTH wirings supplied with the

Trimod® BATTERY.

6. In each Trimod® BATTERY insert the terminal block securing it with the 2 screws provided;

7. In each Trimod® BATTERY secure the lower front panel.

5.2.6 Protections

To ensure correct operation of the UPS and its accessories the electrical system must be adequately protected.

Automatic differential switches and thermal circuit breakers are typically used, connected between the mains supply and

the UPS with the purpose of providing additional protection in the event of overloads or short circuits.

INDICATION

Table 6, in the TABLES chapter, gives information about the thermal circuit breakers

5.2.7 Earthing

Connect the earth wire leading from the low voltage switchboard panel to the EARTH terminal on the UPS terminal block.

INDICATION

The wiring diagrams are given in the DIAGRAMS chapter

5.2.8 Connecting the power supply

For safety reasons, connection of the power supply must be the last thing to be done.

Before connecting the power supply cables with input make sure that the maintenance by-pass S1 is open in the OFF

position and arrange fuses and jumpers on the terminal block according to the required input-output configuration.

INDICATION

Tables 1 to 8, in the TABLES chapter, gives information about sizing cables, fuses, circuit breakers and differentials.

The default configuration for the UPS Trimod® units distributed by LEGRAND® is a THREE-PHASE INPUT and a THREEPHASE OUTPUT.

If you are using this type of distribution, the fuses and jumpers are already correctly sized and positioned.

For different configurations please consult the following chapter and wiring diagrams in the 5.3 DIAGRAMS chapter.

Connect the power cable leading from the low voltage switchboard to the UPS terminals as illustrated in the previous

figure (or in the wiring diagram for the type of connection used), taking care to observe the cyclic direction of the

phases (L1, L2 e L3).

Page 40

40

®

WARNING

The neutral conductor cable in input must ALWAYS be connected! If the neutral is not connected the UPS could be

seriously damaged when powered by the mains.

5.2.9 Wiring

The UPS has holes in the base for putting cables through if they are coming from underneath. It also has a pre-punched

metal plate at the back arranged for inserting fairleads of different diameters.

The fairleads are supplied in the accessories kit.

The plate is fixed to the UPS with four screws.

5.3 Wiring diagrams

The electrical configuration can be set up either on the operator panel or on the terminal block of the distribution box,

located inside at the bottom of the front door. To access the distribution terminal block you have to loosen the box

locking screws and pull it outwards.

WARNING

If the factory set configuration is changed (see paragraph 5.2.8) the new configuration must be set correctly via the

instrument panel as described in paragraph 6.4.

5. Installation

Page 41

Trimod®

Operating and Maintenance Manual

41

5.3.1 Factory set configuration: THREE-PHASE input, THREE-PHASE output

The UPS is dispatched with the connections as per the following diagram. To use it with this configuration no interventions

are required. We do however suggest that you check beforehand that the wiring in input, output and the connection of

the modular terminals is correct.

UPS Trim od® 10/15/20

Page 42

42

®

5. Installation

UPS Trim od® 30TM

Page 43

Trimod®

Operating and Maintenance Manual

43

UPS Trim od® 30TT

Page 44

44

®

UPS Trim od® 40/60

5. Installation

Page 45

Trimod®

Operating and Maintenance Manual

45

5.3.2 THREE-PHASE input, SINGLE-PHASE output connection

For this type of connection, besides the wiring shown in the following figure, the software has to be configured via the

instrument panel as illustrated in paragraph 6.4 STARTING PROCEDURE.

AT T E NT ION

If the UPS is used with a single-phase output (available on 10/15/20/30TM models) you will have to plug in all the

‘Back Panel’ cards in the connector supplied in the accessory kit.

The ‘Back Panel’ cards are located inside the machine behind the power modules.

There is only one ‘Back Panel’ card in the Trimod® 10/15/20 models while in the Trimod® 30TM there are two. To

access the ‘Back Panel’ cards and insert the connector, simply extract 3 power modules that are on the same shelf

and refer to the following figure. The connector must be inserted in the position indicated with EC 15 on the card

serigraphy. To extract the power modules please consult the MAINTENANCE chapter.

UPS Trim od® 10/15/20/30TM

Page 46

46

®

5. Installation

Page 47

Trimod®

Operating and Maintenance Manual

47

5.3.3 SINGLE-PHASE input, SINGLE-PHASE output connection

For this type of connection, besides the wiring shown in the following figure, the software has to be configured via the

instrument panel as illustrated in paragraph 6.4 STARTING PROCEDURE.

AT T E NT ION

If the UPS is used with a single-phase output (available on 10/15/20/30TM models) you will have to plug in all the ‘Back

Panel ’ cards i n the connector supplied in the acces sory k it. Follow the instructions given in the previous paragraph.

UPS Trim od® 10/15/20/30TM

Page 48

48

®

5.3.4 SINGLE-PHASE input, THREE-PHASE 120° output connection

For this type of connection, besides the wiring shown in the following figure, the software has to be configured via the

instrument panel as illustrated in paragraph 6.4 STARTING PROCEDURE.

WA RNING

In the Trimod® models 10, 15, 20 and 30TM, in the case of a single-phase input and three-phase output configuration,

the manual by-pass S1 MUST NOT be activated for any reason whatsoever. To this end the relative switch must be

locked in the ‘OFF’ position. For greater safety it is possible to deactivate the by-pass completely by cutting the brown

cable that connects the relative by-pass switch S1 to the MAINS INPUT fuse carrier isolating switch, isolating it. To the

contrary, the cable connecting terminal 8 to the phase fuse carrier isolating switch MUST remain connected.

5. Installation

UPS Trimod® 10/15/20/30TM

Page 49

Trimod®

Operating and Maintenance Manual

49

5.3.5 SINGLE-PHASE input connection, no. 3 separate outputs

For this type of connection, besides the wiring shown in the following figure, the software has to be configured via the

instrument panel as illustrated in paragraph 6.4 STARTING PROCEDURE.

UPS Trim od® 10/15/20/30TM

Page 50

50

®

Take from the packet of accessories one cross-connector and cut it in order to get the required length.

Insert the cross-connector into modular terminals as shown in connection blocks.

Insert the cross-connector into modular terminals as shown in connection blocks.

Secure the cross-connector to modular terminal with all the provided screws.

5. Installation

Page 51

Trimod®

Operating and Maintenance Manual

51

Screw all cross connectors

Remove the plastic cover

Check all cross connectors have been screwed properly

Insert the plastic cover

Page 52

52

®

5.3.6 UPS Trimod® 30TM connections

To properly connect the UPS Trimod® ® 30TM it is necessary to remove both panels illustrated in the following figures.

5. Installation

Page 53

Trimod®

Operating and Maintenance Manual

53

WA RNING

The instructions given in this chapter are not for an ordinary operator but for a specialized, authorised technician

only if he is using the Individual Protective Gear specified in chapter 3.

As illustrated in the previous chapter the default configuration for the Trimod® UPS unitsentails a THREE-PHASE INPUT

and a THREE-PHASE OUTPUT. If this type of connection is used, the equipment requires no additional configuration as it

has already been set in the factory.

On the other hand however, if the connection is changed please refer to the following instructions.

6.1 Input configuration

UPSTrimod® automatically recognises the voltage, frequency and number of phases in input even if the electrical

connection on the terminal block is changed. So once the input wiring to the terminal block has been modifi ed

accordingly, no further confi guration via the display is necessary.

6.2 Output configuration

The UPS Trimod® does not automatically recognise the electrical configuration on the output terminal block. Therefore, it

is ALWAYS necessary to select the load type applied via the display.

The default configuration for the UPSTrimod® units is THREE 120° phases, 400 VAC. For powers of 10 to 30 kVA TM the unit

can be configured to obtain just one single-phase output (230 VAC).

If the unit is configured with a three-phase output, it is possible to select management of the three phases as follows:

- THREE single-phase outputs: this setting is necessary if three separate single-phase lines were created at the UPS

output. In this case, the UPS manages the three outputs separately one from the other.

For example, if an excessive load is applied to one of the three output lines, the bypass will intervene only on the

overloaded line while power is guaranteed on the other two by the UPS.

- THREE 120° phases: this is the default setting and it is normally used if three-phase loads have been applied in output

from the UPS (e.g. three-phase electrical motors) or if three-phase and single-phase loads are being powered by the

UPS. In this case the UPS manages the three output phases, protecting the three-phase load.

For example, if an excessive load is applied to one of the three output lines, the automatic bypass switches all three

output lines.

To select the system output configuration correctly on the display follow the instructions given in paragraph 6.4.

6.3 Checks prior to switching on

Check the following before powering the equipment:

1. Ensure that S3 input breaker is open;

2. Ensure that battery fuse breakers of the UPS (F B+ and F B-) and those of the Trimod® BATTERY (if used) are open;

3. Ensure that the input and output wiring is correct; check correct cycling of the phases in input;

4. Check that the mains input parameters (power voltage and frequency) are compatible with those specified on the

UPS data plate.

5. Check that the maintenance by-pass switch S1 and the UPS output switch S2 are both in the OFF position.

6. Configuration and Start-up

Page 54

54

®

6.4 Starting procedure

1. Insert the battery fuses in the relative isolating switches (F B+ and F B-) and, if applicable, those in the Trimod® BATTERY

cabinets (if they exist).

2. Close UPS Trimod® and Trimod® BATTERY (if they exist) battery breakers.

WARNING

Before switching the unit ON the correct output configuration must be selected (Single-phase/Three-phase 120°/

Three separate phases). To do this, proceed as follows.

3. With the unit off, press the ENTER key on the operator panel to gain access to the Service Mode. See the next chapter

for more information about the SERVICE MODE and panel operation.

4. Follow this path: Config. UPS > Output > Inverter

Select Single-phase /Three-phase 120° / Three separate phases depending on the connection.Use the arrow keys to

move the selection on the display, the Enter key to confirm, the ESC key to cancel.

Note: The configuration of the inverter output that is selected by display (three or single phase) must strictly

correspond to the setup on the output terminals during installation.

WARNING

Wrong connections or output configuration settings can cause injury to people or damage to things!

5. Follow the path: Settings UPS -> Batteries -> Total KB

Check / select the correct number of KB (Battery Kit) installed.

6. Follow the path: Settings UPS -> Batteries -> Capacity

Check/select the correct value of KB battery capacity (Ah).

The KB value represents the total number of 20 batteries (installed in series) strings (installed in parallel).

UPS Trimod® 10/15/20 UPS Trimod® 30TT/40/60

UPS Trimod® 30TM

6. Configuration and Start-up

Page 55

Trimod®

Operating and Maintenance Manual

55

Capacity in Ah to enter is the one of a single string (1KB).

UPS calculates the total capacity of the battery as a product of KB * Total Capacity.

7. Exit the Service Mode by pressing the ON/OFF pushbutton.

8. Provide power to the UPS input and close the switch network UPS;

ATTENTION

When the unit detects the input voltage it automatically proposes starting a battery charging cycle. Press the ‘ESC’

key to proceed to switching the UPS Trimod® ON.

9. Press the ON/OFF pushbutton the switch ON the UPS;

10. Wait until the status indicator on the display is solid green;

11. Verify that the values of voltage and frequency output set corresponds to the needs of the applied load. Otherwise

enter the required values .

12. Close the output switch of the UPS.

At this stage the load is powered and protected by the UPS Trimod®.

WARNING

If, when installing, you think it is necessary to check that the battery-run UPS is working properly, turn the mains

power voltage OFF by means of the switch breaker outside the UPS and NOT by means of the input breakers inside

the UPS distribution drawer.

If the UPS has internal batteries it will instead be necessary to open at least one drawer for each set (one set consists of 4

boxes). This cuts the power voltage off to the terminal block generated by the various sets of batteries. This must be done

for all sets.

Each drawer is fixed with two screws which must be removed beforehand.

Before programming the unit, make sure that all the