Page 1

User’s Manual 2008

Power Commander IQ

Network Controlled

SPDU8-1U, SPDU16-2U, SPDU20-0U

Wiremold/Legrand®electrical systems conform to and should be properly grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities. All electrical products may present a possible shock or fire hazard if improperly

installed or used. Wiremold/Legrand electrical products may bear the mark as UL Listed and/or Classified and should be installed in

conformance with current local and/or the National Electrical Code.

1 007 627 0408

© Copyright 2008 Wiremold / Legrand All Rights Reserved

Page 2

Copyright Notice

Copyright

©

2008 by Wiremold/Legrand. The material discussed

in this manual is the proprietary property of Wiremold/Legrand.

AII retains all rights to reproduction and distribution of this

document.

FCC Warning

The Federal Communications Commission has set limits for

emitted radio interference. The Wiremold / Legrand. systems

are constructed with this electromagnetic interference (EMI)

limitation in mind. The systems are classified under FCC

Regulations as a Class A and Class B device. A Class A device

may be used in commercial environments and not in residential

areas, while a Class B device may be used in commercial

environments residential areas. The Power Commender IQ

series devices has been tested and shown to comply with

the following FCC rule: Part 15 Subpart J and ICES-003.

UL Safety Standards Compliance

Power Commender IQ Series products have been tested and

found to be accordance with the following listed test

requirements:

UL-60950-1: 2003, R7.06

CAN/CSA-C22.2 No. 60950-1-03

Warranty Information:

The warranty period on this product (parts and labor) is one

(2) year from the date of purchase. Please contact Wiremold /

Legrand at 1-800-621-0049 or visit our website at

www.wiremold.com for information regarding repairs and/or

returns. A return authorization number is required for all

repairs/returns. See Appendix A for more information.

Changes:

The material in this guide is for information only and is subject to

change without notice. Wiremold / Legrand

reserves the rights to make changes in the product design

without reservation and without notification to its users.

Wiremold / Legrand

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 •

Outside U.S. 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

Page 3

1 SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Products comparison chart: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 What you can do with the system: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Front and back panel: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2 IMPORTANT SAFETY PRECAUTIONS FOR HARDWARE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3 ACCESS TO THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.1 Factory default settings: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.2 User privileges and port reservations: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.3 Local master port access: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.4 External modem access: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.5 Telnet access: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.6 Web access: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.7 Email access: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.8 SNMP information: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.9 AutoPing and power reboot: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4 USING CONTROL COMMAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 USING CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5.1 Starting configuration menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5.2 System main menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5.3 System access setup menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.4 TCP/IP network configuration menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.5 More about emailing access: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.5.1 Sending Control command to the system: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.6 Serial console port configuration menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.7 Power outlet setup menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.8 User account management menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.9 Viewing and changing operation status with a web page: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

APPENDIX A WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

APPENDIX B SERIAL CONSOLE PORT INTERFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

APPENDIX C RS-232 TO RJ45 CONVERSION CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

TABLE OF CONTENTS

Page 4

1

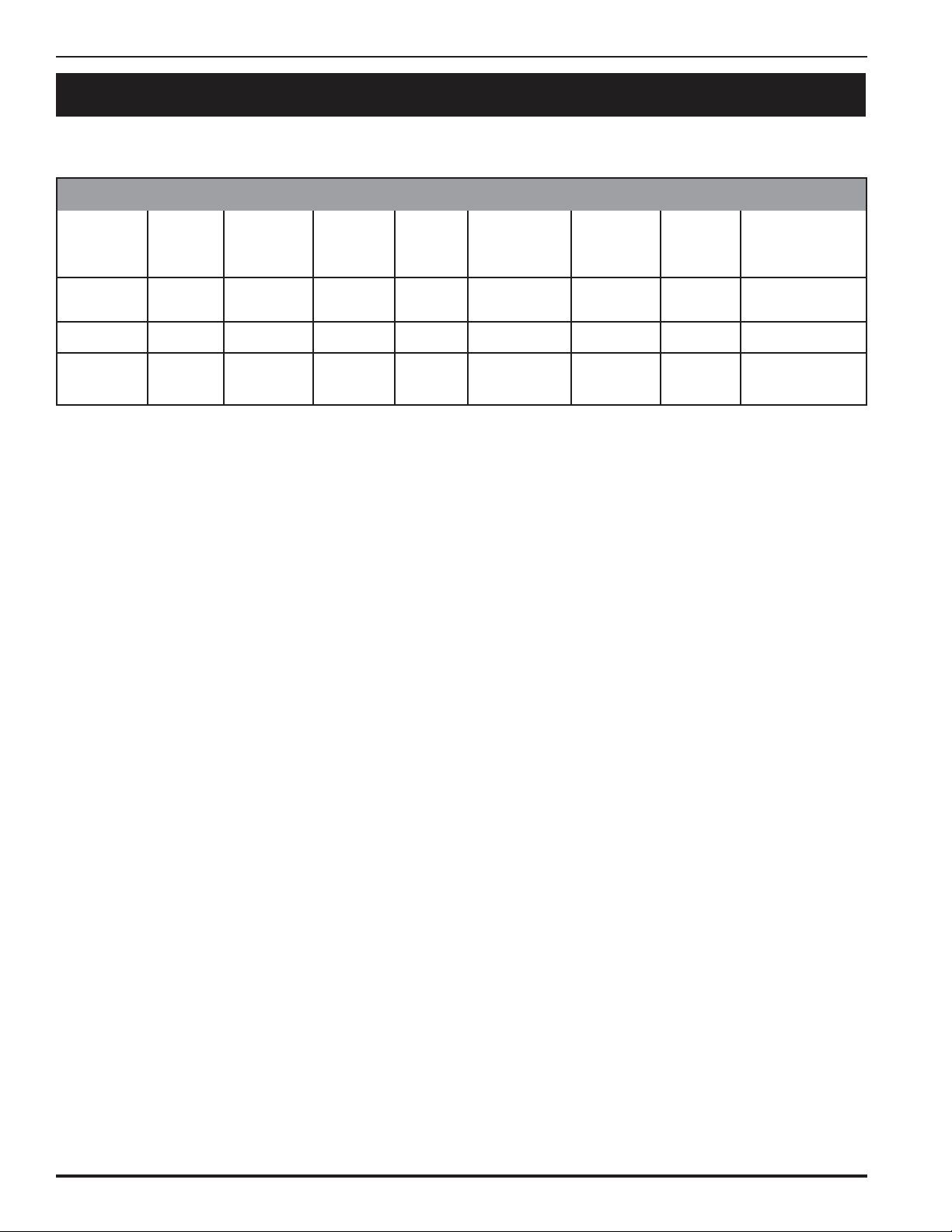

1.1 Products Comparison Chart:

1 SYSTEM DESCRIPTION

The above listed systems provide secure and versatile power

reboot management access for communication equipment such

as routers, switches, and network devices. They are also the

ideal assistant devices for engineering development and test

applications. Key features include:

• Local Master Port access: offers data rates from 2400 to

115200 bits/second and optional hardware handshaking

(CTS/RTS). There are two operation modes for the port:

Console Transparent Mode and System Control Mode.

• Three user privilege login levels: The Administration level

manages system configuration and unconditional access to

all power outlets and all serial ports. The User level allows

each user to reserve and manage his/her own ports, as well as

to change most of system configuration settings. Anonymous

users are able to view all settings and operate unreserved

power outlets and serial console ports.

• User name and password for each port: Each port is user

name and password protected.

• Line commands or menu configuration controls: Menu

table operation offers user-friendly operation methods that are

used for changing system configurations, viewing run time

statuses, and issuing controls. Line commands provide quick

and easy operations.

• Telnet access: Remote access the system over a TCP/IP

network for configuration and control of the systems.

• Out of band Modem access interfacing: Control and

configure the system via a telephone line. Optional custom

Modem AT command string to the Modem.

• HTTP web access: Embedded web server provides secured

user name and password authentication. The operations are

easy and friendly, utilizing tables and graphical icons.

Download SNMP MIB files for convenience, or view an online

help manual.

• SNMP MIB capability: An SNMP (Simple Network

Management Protocol) agent is integrated in the system for

an exchange of management information between the system

and network devices.

• POP/SMTP Emailing with SMTP Authentication capability:

A user can send control commands such as reboot power

outlet via emails. Command execution reports are replied for

each command email received. SMTP user name and

password are protected through authentication process.

• SNMP Trap for sending logging message: The Trap is used

to asynchronously report events to the NMS. It forwards

power reboot command execution information to the remote

Trap logging receiver.

1.2 What you can do with the system:

• Remote equipment power source management over

TCP/IP networks, including rebooting user equipment, and

permanently turning on/off user power source. Schedule

power reboots or power source on/off events monthly, weekly,

daily or at any time an application requires. Reboot power

source to equipment when a network connection is lost.

• Monitoring AC Power Consumptions and sending warning

messages when the aggregated AC draw from a system is

crossed predefined threshold.

• Remote control anywhere by emailing. Via emails, you are

able to manage the systems or user communication

equipment power sources when LAN access is impossible. Via

emails, you can send user data to the NP control commands

such as rebooting user power source. Reply emails are sent

after the system intercepts incoming emails so that you are

informed with the operation status.

• AutoPing and reboot user equipment. Connect your

system to a power outlet and assign the system network

IP address or URL. The NP system will ping the user

equipment periodically (in every 15 seconds). If the user

Figure 1 - Product Comparison Chart

POWER COMMANDER IQ

Model Chassis # of # of Input Total AC Input Power AC Current Network Regulatory

Outlets Power Current Cord Plug Monotoring Port ULSafety

Cords Output Type (Ethernet) & EMI

(Inlet) Amps

SPDU8 1-U 8 1 15 NEMA 5-15P Y Y UL60950-1/FCC

Class A

SPDU16 2-U 16 2 30 NEMA 5-15P Y Y UL/FCC Class A

SPDU20 0-U 20 1 20 NEMA L5-20P Y Y UL/FCC Class A

Vertical

Page 5

2

equipment stops responding the ping request, the equipment

will be power rebooted.

• Scheduling AC outlet power cycling periodically or per

weekly planner. Each outlet can be programmed with it’s

own timer.

1.3 Front and Back Panel:

Figure 3 - SPDU8-1U Front and Back Panel Illustration

Figure 4 - SPDU8-1U Detail of

Connections

Figure 5 - SPDU16-2U Front and Back Panel Illustration

Figure 5A - SPDU20-0U Front and Back Panel Illustration

Page 6

3

1. Power Outlet status LEDs: Visual indication of user power

outlet On/Off status.

2. NP system power On/Off status LED: Indication of

system power On/Off status.

3. Ethernet Link status LED: When the LED is illuminated,

Ethernet port and a LAN connection are established.

4. Ethernet Active data status LED: When there is data traffic

on the LAN, the LED is illuminated.

5. Factory Default Reset switch: Allow a user to reset the

system to factory default settings. The switch is located

behind the small front panel opening.

6. Power Outlet sockets: Power outlets for user

applications.

7. Local Master Port (DCE, 9 pin DB, female, or RJ-45 socket):

This is also a service port for the user to

configure and change system operation settings.

8. Ethernet Port (RJ45, 10 base-T): 10 based-T Ethernet port

for connection to LAN.

9. Manual Switch: Outlet power output switch. Momentarily

pressing down the button to index to the desired outlet.

Pressing down for 3 seconds to toggle the outlet power state.

This switch is equipped on NP08 and NP-16 systems.

10. Audio Alarm Off Switch: To temporarily turn off the audio

alarm when aggregated AC current draw crosses over the

defined threshold. This control switch is equipped on NPB20 system.

2.1 Safety Precautions

It is important that you read this section before attempting any

of the hardware installation and maintenance procedures in

this guide.

The following instructions are important for your safety and for

the functioning of the unit. Read the instructions carefully before

attempting the installation

WARNING! To reduce the risk of fire or electrical shock,

never remove the cover of the unit. No user serviceable

parts inside. Repair should be done by authorized service

personnel only.

The unit should be installed in indoor with ambient temperature

and sufficient airflow.

WARNING! Ensure that the hardware you are working with

is disconnected from the power supply during installation.

This means that the unit’s power cable and network cables

must remain disconnected until you are instructed to make

the connections. Follow the instructions in the procedures

carefully.

This equipment is disconnected from the power supply

by removing the power cord(s) from the power outlet. It is

therefore important to locate the unit close to a power outlet

that is easily accessible.

WARNING! When connecting a hardware unit to a power

supply, for your safety you must always connect it to a

grounded wall outlet.

2.2 Battery Replacement

A 3.0V Lithium battery is installed in the unit for internal RealTime Clock and system data retention. The battery should last

at least 10 years. If the battery needs to be replaced, please ask

qualified personnel for the service. Here is the instruction for the

replacement:

A) Use CR2032 type, 3.0V Lithium battery.

B) Remove the old battery from the battery holder,

C) Insert the new replacement to the holder with “+” facing up.

3.1 Factory Default Settings:

The system is shipped with Factory Default settings. The default

settings for the Local Master serial port are: 9600, 8 data bits,

no parity, 1 stop bit, and no hardware handshaking (Flow

Control). The default Administrator’s login name “admin” and

the default password is “admin”. All existing user accounts are

erased if the system is recovered to the default settings. The

default SNMP Community string for public, private and Trap

access is “public”.

There are two ways to restore the system to the Factory Default

settings. The first method is to press a push-button switch

located on the front panel for 1 second. The second method

is to select "Reload Factory Defaults" from the Main Menu. The

Main Menu can be viewed by running a terminal emulation

program such as Window’s Hyper Terminal or Telnet.

Upon the system startup, the terminal screen displays the

following screen, as shown in the Figure 6.

If you do not see the screen as shown in the Figure 6, it is

likely that the system is not in the default state. Otherwise,

your connection to the Local Master port is established.

2 IMPORTANT SAFETY PRECAUTIONS FOR HARDWARE INSTALLATION

3 ACCESS TO THE SYSTEM

Page 7

4

3.2 User Privileges and Port Reservations:

All user levels, including anonymous (visitor), are able to access

the system via a serial connection from your work station to the

Local Master port, or via a Telnet session from your work

station.

• Administration Login: There is only one Administration

account on the system. The default name is “admin” and

default password is also “admin”. The default name and

password may be changed. If you login at Administration level,

you are able to remove or change existing user accounts, take

over power outlets or user serial console ports and change

system settings.

• User Login: At user login level, you are able to reserve power

or console ports for your applications if they are “open”, as

well as make system configuration changes. At this login level,

you are not able to change power outlet operation status for

other reserved power outlets.

• Anonymous(Visitor) Access: If you have no account

established on the system (as an anonymous user), you are

only able to view the system configuration settings and

operate unreserved power outlets.

3.3 Local Master Port Access:

To access and configure the system from the master port, you

need to connect a RS232 port from your work station to the

Local Master Serial Port. Then run a terminal emulation program

(such as Window’s Hyper Terminal) on your computer.

1) Connect the system’s Local Master Port (DCE) with a straight

DB-9 type cable, if your work station is equipped with a DTE

part.

2) Connect the system’s Ethernet port to your LAN, if you intend

to use the network port.

3) Turn the system power on.

4) At the terminal emulation program, type the “setup”

command to start the system setup process. Type “help” for

help information.

5) The system has DHCP enabled, as a default setting. Network

connectivity parameters are displayed at the startup screen. If

the system does not get a DHCP offer, the system falls back

to default static network settings. You can alter the default

network settings to fit your need.

6) Use the command “ping” to verify your connection. If a

network connection is established, you are able to use Telnet,

Web Browsing, Emailing and SMNP.

3.4 External Modem Access:

With this access method, an RS232 port on an external Modem

device is connected to the Local Master Port. Typically, a

Modem device is equipped with a DCE (Data Communication

Equipment) terminal connector. Since the system’s Local Master

Port and Modem device ports are not complementary (both are

DCE ports); you need to use a NULL Modem cable with both

male connectors.

3.5 Telnet Access:

Operation of on a Telnet terminal is almost identical to the

access method via Local Master Serial Port. You need to make

sure that Telnet access is enabled, as a default setting. If the

access is not enabled, please refer to Section “Using

Configuration Menu” to change the setting.

Before you start the Telnet application, you need to obtain the

actual IP address for the system. The system displays network

connectivity information at system startup terminal when your

workstation is connected to the system’s Local Master Serial

Port. Please refer to “TCP/IP Network Configuration” section of

this document for information on how to setup the network

parameters.

Once the network connection is established, at your workstation

prompt, you need to enter:

telnet ip_addr

You need to set a Telnet session on your workstation to Local

Echo Off mode.

Telnet session permits an anonymous user who may only to

view the system settings and operate unreserved power outlets

and user serial console ports. Please refer to section 2.2 “User

privileges and Port Reservations” for further information.

• Only one Telnet session may be active at the time. Telnet

sessions will be refused by the system if it already has a Telnet

session active.

• A Telnet session remains active for 10 minutes if it is in idle

state.

• Telnet access methods can be enabled or disabled using the

System Access Setup Menu.

• To terminate an active Telnet session, use the command

“logout” at the terminal. If you are at a serial port terminal and

notice that the terminal is disabled because it is taken over by

a remote Telnet session, use the command “telnetend” at the

serial console terminal to terminate the Telnet if you need to

do so.

Page 8

5

3.6 Web Access:

You need to obtain the system IP address before starting web

access to the system. Please refer to the Telnet Access section

for methods to get the system IP address. You also need to

make sure that web access is enabled, as a default setting. If

the access is not enabled, please refer to Section “Using

Configuration Menu” to change the setting. Start a Web

browsing application program such as Window’s Explorer and

enter “http://ip_address“in the address field.

You must have an account on the system in order to access the

system via this method. Without a valid account, you are only

able to view the following web page and get a copy of the Help

text message.

Upon clicking the Login button, a secured login table is

displayed at your work station, shown as in the Figure 10.

Factory default setting for user name is “admin”. The default

pasword is “admin”.

3.7 Email Access:

To establish this access method, the system’s network

connection is already established. With the email access

method, you are able to execute the NP system controlling

commands. The NP system periodically checks incoming mails

from a designated POP mail server. The system sends a reply

email with command process status if an email is intercepted.

See Section 4.4 for more information about how to setup email

accounts.

3.8 SNMP Information:

Applications such as an NMS (Network Management System) or

an SNMP browser can exchange information with the NP

systems. SNMP is disabled with the default setting.

The information managed by an SNMP daemon on the system

can be obtained using SNMP requests from a remote work

station. An SNMP Get/Get Next request fetches the value of

a single variable or a set of variables. An SNMP Set request

modifies the value of a variable.

You need to know the name of a variable before your can

fetch or modify a variable’s value. A variable’s symbolic

name is mapped to a numeric name, which is referred as OID.

The MIB (Management Information Base) is a text file

describing the internal objects the SNMP agent can

display, monitor, and/or modify. Each MIB object is the system

variable that has name and an OID, as shown in Figure 12. You

need the MIB file to properly configure the SNMP client

("manager") for server monitoring. To get a copy of the MIB file,

please use a web browser to access the NP systems. Open the

TCP/IP Network Configuration Menu and then click the button

“Get SNMP MIB File” to download the MIB file that is stored in

the system’s memory.

Figure 10 - Web Access Login Entry Table

Figure 9 - Web Access Startup Page (NP-08)

Page 9

6

Figure 12 - Implemented MIB Description, List of MIB object

DEFINITION OID RETURNED MESSAGE

systemModel .1.1 System Model number. Read only.

systemName .1.2 The system name or site name. Read only.

powerOutletNum .1.3 Number of power outlets on the system. Read only.

serialPortNum .1.4 Number of console ports on the system. Read only.

systemUpTime .1.5 Seconds since the system in operation.

swVersion .1.6 Firmware version

Outlet Sequence

outletIndex .2.1 Index for the outlet table

outletName .2.2 Outlet socket name. Read/Write.

outletStatus .2.3 Outlet socket ON/OFF status. Read only.

outletAction .3.4 Change outlet state to ON, OFF or Reboot.

Write only.

powerOutlet4OpStatus .3.2.5.0 Read/Write. Applicable to NPC/NP systems.

Envro/Current Sequence

enviroIndex .3.1 Index for the table

currentAlarmThreshold .3.2 Aggregated AC current draw threshold for each power inlet (or power cord).

currentDrawStatus1 .3.3 First AC current monitoring reading. For a system equipped with single power

cord, this the valid current reading. For dual power corded system, this is the

first part of the AC current reading.

CurrentDrawStatus2 .3.4 For dual power corded system, this is the AC current reading for the second

power inlet (or power cord).

currentDrawMax1 .3.5 Maximum aggregated AC current draw value was captured for the first power

inlet (or power cord). For a system equipped with single power cord, this is

the valid current reading. For dual power corded system, this is the first part

of the AC current reading.

CurrentDrawMax2 .3.5 Maximum aggregated AC current draw value was captured for the 2nd power

inlet (or power cord).

temperatureThreshold .3.6 Environment temperature threshold in F.

temperatureReading .3.7 Temperature reading in F. Value is zero when the temperature probe is not

installed.

Event Notifications

opEvents .100.1 Explicit operation events. Last TRAP/Notification sent. The messages include

outlet power status changes, AutoPing/Reboot events, system power on

event, user login/logout event,

CurrentThresholdCross-Event .100.2 Current draw (Amps) crosses the defined threshold for inlet 1 or 2."

temperatureThresholdCrossEvent .100.3 Environment temperature reading (in F) crosses predefined threshold.

ENTERPRISE OID: 1.3.6.1.4.1.21728.2.4.1

Page 10

7

3.9 AutoPing and Power Reboot:

Each power outlet has optional settings that a NP system uses

to ping network equipment. The pinged equipment is attached

to a specific power outlet. It reboots user equipment power

source if a network connection is not detected any more.

However, user equipment never gets power reboot if the

equipment never replies ping reply to a NP system.

A power outlet has the optional settings (Power Outlet Setup

Menu) that specify the destination IP address that the system

will ping periodically, and maximum network downtime allowed.

In addition, to avoid unwanted reboots, a NP system also pings

the gateway IP address (as default) to make sure a NP system

has a network connection that is still active. Otherwise,

AutoPing will be in off mode if a NP system lost network

connection. To change the default gateway IP address as ping

destination, use TCP/IP Configuration Menu to enter your

desired destination address.

A NP system provides command line options for viewing

or changing system configuration and operation status. In

addition, by using the control command option, users are

able to create script files for automation of equipment test

and control.

Control commands are applicable to the connections between

your work station and Local Master Serial Port or a Telnet

session.

Some of the control commands are also applicable to emails.

See related sections for more detailed information about how to

setup email accounts.

Once the system starts or a Telnet session is open, you

are ready to send control command to the system. Type

command “help” to have a complete list of available

commands, as shown in Figure 13.

All login levels including anonymous users are able to use

the command line option. However, the actual command

executions are based on your login level. For example, if

you are an anonymous user, you are not able to reserve or

un-reserve serial console ports or power outlets. If you login

at Administration level, you are able to operate any serial ports

and power outlets, reserve or unreserved any ports or outlets

even if they are reserved by other users. See Section 2.2 for

a complete description of user privileges.

4 USING CONTROL COMMAND

************************************************************

* *

*

*

* Help Menu *

* *

*

*

************************************************************

>

>

apVbs n Displays AutoPing ru n -time info(0 -disabl e, 1 - enable)

cs n Displays AC current draw Status(1 -display, 0 -erase max value).

date Displays

current date

emailvbs n Displays emailing run time info(0 -disable,1 - basic,2 - detailed)

emailget Starts email reading immediately

emails end Sends a test email message immediately

ecmd Sets email command delimitor(Select: &, - ,+,~,$,*,>,|,<, or ?)

ftpget ip id pwd fileName - Get system data file from a FTP server.

ftpput ip id pwd fileName - Put system data file to a FTP serve r.

login *Enters user login

logout

*Exits current login

datalog Executes data logging(0 -logging off; 1- on; 2 - read; 3 - clear)

mac Displays Ethernet port Mac address

nwset Restarts Ethernet network interface

nwshow Displays network Status

ping *Pings a host. E.g.: ping 192.168.0.1, or ping yahoo.com

prsv n *Reserves power outlet #n for current login user

pset n v

*Sets power outlet #n to v(value 1 -on, 0 -off)

psetd n v s *Sets power outlet n to v(value 1 -on, 0 - off) with delay s sec.

ps v Sets all power outlets to v(value 1 -on, 0 -off)

pshow *Displays power outlet status

pTmshow Displays power outlet timer information

punrsv n *Unreserves power outlet n from current l ogin user

rb n *Reboots power outlet n

rbd n s *Reboots power outlet n with delay s seconds.

rbt s *Sets reboot duration to s seconds (s > 0).

setup Starts system configuration menu

sshow Displays console ports config uration status

sysshow Displays system information

time Displays current time

usershow Displays all users

whoami

Displays current login user

ver Displays hardware and software versions

! Repeats previous com mand

***Note - if Restricted Access Mode is on, non -Admin users are limited

to use commands marked with "*"

.

>

Figure 13 - Control Command Help Menu

Page 11

8

5.1 Starting Configuration Menu:

There are four ways to start the Configuration Menu:

1) Local Master Port access method. Run a terminal program

from a work station via serial connections between a serial

port from your work station and the Local Master Port of

the system.

2) External Modem device access method. Run a terminal

program from a remote work state and establish the

connection via a telephone line.

3) Telnet access method. Your workstation and the system are

connected to LAN.

4) Web access method. Your workstation and the system are

connected to LAN.

If you have already logged on to the system, enter the

command “setup” and you will see “Main Menu” table as shown

in Figure 15. Without login to the system, if you enter command

“setup” you will see the following screen:

Menu selection 1: When you enter the system as an

anonymous user, you can start operate serial console ports or

power outlets as far as they are not reserved by other users.

However, you can only view system configuration parameters

and are not able to make system configuration changes.

Menu selection 2: If you already have accounts established

and want to start configuring the system or to change serial

console port and power outlet operation status, choose this

menu option.

Menu selection 3: If you do not have an account on the system

or if you have an account already and want to modify your

account or delete an account, select option 3.

Menu selection 4: Lists help information.

Menu selection 5: Exit menu operation.

5.2 System Main Menu:

This is a top level system main configuration menu, as shown in

Figure 15 and 16.

5 USING CONFIGURATION MENU

************************************************************

* *

*

*

* Login Menu *

*

*

* *

***************** *******************************************

>

> 1) Anonymous (Visitor) login

2)

Login

3) Help

4) Quit

>Enter your selection:

Figure 14 – Menu Configuration – Login Menu

************************************************************

* *

* *

* Main Menu

*

* *

* *

************************************************************

>

> 1) Reboot Power Outlet

2) Setup System

3) Setup TCP/IP Network

4) Configure Serial Console Port

5) Configure Power Outlet

6) Setup New or Existing Accounts

7) Reload Factory Defaults

8) Save Settings

9) Quit

>Please enter your selection

:

Figure 15 - System Main Menu (Terminal Program Screen)

Page 12

9

From Figure 15, System Main Menu (Terminal Screen):

Option 1 - Reboot a power outlet: Reboots a power outlet.

Rebooting executes if the outlet is unreserved

(“open”) or it is reserved under your account.

However, if you logged in at Administration level; you

are able to operate any power outlets even if they

are reserved by other users.

Helpful info: control command “rb n” executes the same function

as the option 1.

Option 2 – Setup System: Enters System Access Setup

submenu.

Helpful info: control command “sysshow” displays system

access configuration settings.

Option 3 – Setup TCP/IP Network: Enters TCP/IP Network

Configuration submenu.

Helpful info: control command “nwshow” displays network

connectivity information.

Option 4 – Configure Serial Console Port: Enters Serial

Console Port Configuration submenu.

Helpful info: control command “sshow” displays all serial

console port settings.

Option 5 – Configure Power Outlet: Enters Power Outlet Setup

submenu.

Helpful info: control command “pshow” displays all power

outlet current status.

control command “ptmshow” displays all power outlet

timer settings.

Option 6 – Setup new or existing accounts: Enters User

Account Setup submenu. Select this option if you

need to create new account, change existing

account, and delete existing account and reserve

power outlets and serial

console ports.

Helpful info: control command “userlist” displays all account

names.

Option 7 – Reload Factory Defaults: Reloads to factory default

settings. You must login at Administration level.

Option 8 – Save Settings: Save current system configuration

parameters.

Option 9 – Quit: Returns to previous menu.

Figure 16 - System Main Menu (Web Page)

Page 13

10

5.3 System Access Setup Menu

• System(Device) name: Assign a system name, sometimes

referred as site or device name.

• Date and Time: Enter calendar date and real-time clock.

• Serial Port Mode: Configure the Local Master Port to

interface type: either to a serial RS-232 port on your work

station or an external Modem device. An external Modem

device is typically equipped with a DCE (Data Communication

Equipment) terminal connector. Since the system's Local

Master Port and Modem device ports are not complementary,

you need to use a NULL Modem cable with both male

connectors. For information about connecter pin assignment,

please see Appendix A.

• Modem Startup String: Define an external Modem control

command string that is sent from the system to an external

modem device periodically (in every 15 minutes). If you do not

need to define the control string, leave the entry field empty.

• Web Access: Enable or disable web access to the system.

Default to enable.

• Telnet Access: Enable or disable Telnet access to the system.

Default to enable. Only one active Telnet session is

permissible.

• Enable Telnet Anonymous User: Enable or disable an

anonymous user's access to Telnet port.

• Control command via Emails: Enable or disable this access

method. When it is enabled, you need to make sure you also

have completed POP/SMTP server and email receiving and

sending addresses. See “TCP/IP Network Configuration”

setup menu for detailed information how to setup email

accounts. Default to disable.

• SNMP Agent Enabling: Enable or disable SNMP agent

on the system. If the system SNMP Agent is enabled, it

collects and stores management information and makes

this information available to NMS using SNMP. Please see

Section 2.5 for a list available MIB objects that the system

supports. Default to disable.

• SNMP Trap Enabling: Enable or disable Trap sending. If this

option is enabled, Traps are sent if there is a power reboot

command execution on the system. Default to disable.

Note: You must enable the above SNMP Agent setting.

Otherwise, enabling Trap setting will not take effect.

• SNMP Trap Receiver IP Address: Enter Trap Monitoring

receiver IP address.

• SNMP Community String: To specify SNMP MIB/Trap

community string. The default string is “public”. This

string is used for public, private and Trap.

• Current Alarm Threshold: To defined AC current draw

alarm threshold. The unit is Amps.

• Alarm Email Notification: Enable or disable Email alarm

sending method.

• Alarm Notification Interval (Minute): Define alarm notification

sending interval.

• Save and Quit: Save current configuration data and return to

previous configuration menu.

************************************************************

* *

*

*

* System Access Setup *

*

*

* *

**************** ********************************************

>

> 1) System(Device) name...............Undefined

2) Date(mm/dd/yyyy)..................03/07/2007

4) Serial port mode............. .....Console

5) MODEM startup string..............ATE0M0Q1&C0&D0S0=1

6) Non - Admin user restriction*(Y/N)..N

7) Web access (Y/N)..................Y

8) TELNET enable (Y/N)...............Y

9) TELNET timeout(max 655 35 minutes).10

10) TELNET anonymous user (Y/N).......Y

11) Command control via email(Y/N)....N

12) SNMP agent enable(Y/N)............N

13) SNMP Community String ............******

14) SNMP Trap (1 - on 0 -off).......... ..0

15) SNMP Trap Receiver IP Address.....

s) Save.

q) Quit.

***Note for 6): for controlling non -Admin user's access to system

data.

>Please enter your selection:

Figure 17 - System Access Setup Menu (Terminal Screen)

Figure 18 - System Access Control Menu (Web Page)

Page 14

11

5.4 TCP/IP Network Configuration Menu:

This is a submenu of System Main Menu.

• Obtain IP using DHCP: Enable or disable DHCP. The

purpose of using DHCP (Dynamic Host Configuration Protocol)

is to assign dynamic IP addresses to a computer or a network

device on a network. There must be a DHCP server on a

network running and the server must permit an assigned

computer or network device to be on the LAN. If

this option is disabled on the NP systems, the system will not

send DHCP requests to a network.

• Fallback to static IP (if DHCP server no offer): Define a

static IP address. If DHCP is disabled on the system, there

is no DHCP server running on a network, or a DHCP server

refuses IP offering, you have the option to whether either allow

the system to use a static IP address or not.

• Static IP Address: A static IP Address is an IP address

that never changes. This IP address will be used if a DHCP

server IP has no IP offered or DHCP automatic IP address

is disabled.

• Subnet Mask: Defines a static subnet mask that is a part of

your static network address settings. This entry is for your IP

network class, which is distinguished by using a subnet mask.

• Gateway IP address: Specifies a gateway IP address that is a

part of your static network address settings. This is your

router's IP address.

• HTTP Port Number: Specifies a HTTP port number. Default

value is 80.

• Telnet Port Number: Specifies a Telnet port number. Default

value is 23.

• POP3 Email Server: Specifies POP (incoming Email)

server address. The system supports POP3 Internet Email

Protocols, not web based Email services. “mail.wiremold.com”

and “pop.tom.com” are examples of POP Email servers. Make

sure that the POP server you use does not require log on

secure password authentication.

• SMTP Email Server: Specifies SMTP (outgoing Email)

server address. This server will be used for you to send

outgoing (reply) Emails. “mail.wiremold.com” and

“smtp.tom.com” are examples of SMTP Email servers. NP

supports SMTP log on secure password authentication option.

Helpful Info: Use the command “emailget” to immediately

check incoming emails.

• Incoming Email Account Name: Specifies email address that

the system receives. This email account name is also used for

outgoing (replying) emails.

• Incoming Email Account Password: The Email account

password is specified in this entry. This password is also used

for outgoing (replying) emails.

• 2nd Outgoing (Replying) Email Address: This is an

additional outgoing reply email address. The system always

send replying email to the sender. There is no limitation of

types of destination email servers, whether a web based

emailing system or SMTP. Examples of destination addresses

are myMail@hotmail.com

and yourMail@aol.com.

Helpful Info: Use the command “emailsend” to immediately

send an outgoing test email.

• Reply (Outgoing) Email Authentication: If an SMTP

(outgoing) email requires a user name and password

authentication, enter “Y” for this entry.

Helpful Info: Use command “emailget” to immediately

check incoming emails.

• Check Email Interval: This entry specifies how often the

system checks incoming emails. The minimum interval is one

minute.

• Access Control List (ACL) Enable: Enable or disable for

controlling client IP addresses to access the system.

• Network Connection Check Using This IP: This entry

specifies an IP address or a URL site that the NP system will

ping periodically for verification of network connectivity. If the

network connection is down or inactive, AutoPing is in off

mode. If this entry leaves blank, network gateway IP address

will be used.

Figure 20 - TCP/IP Network Configuration Menu (Web Page)

************************************************************

* *

* Network Configuration Menu *

*

*

************************************************************

>1) Obtain IP using DHCP...................Y

2) Fallback to static IP(if DHCP failed)..Y

3) Static IP Address......................192.168.1.100

4) Subnet Mask............................255.255.255.0

5) Gateway IP Address.....................192.168.1.1

6) Set DNS Server IP Manually (Y/N).......N

7) Primary DNS IP Address.................0.0.0.0

8) Secondary DNS IP Address...............0.0.0.0

9) HTTP Port number(default 80, see note).80

10) Telnet Port Number(default 23).........23

11) POP3 Port

Number(default 110)..........110

12) SMTP Port Number(default 25)...........25

13) POP3 Email Server......................Undefined

14) SMTP Email S er ver......................Undefined

15) Incoming Email Account Name............Undefined

16) Incoming Email Password................******

17) 2nd outgoing(replying) Email Address...

18) Outgoing Email Authentication..........Y

19) Checking Email Interval(M inute)........2

20) Access Control List(ACL) Enable (Y/N)..N

21) Network Connection Check Using This IP..

[Leave 21) blank if Gateway IP is used. Applicable to AutoPing Mode.]

s) Save.

q) Quit.

Note - Requires system reboot, if the parameter changes .

Please enter your selection:

Figure 19 - Network Configuration Menu (Terminal Screen)

Page 15

12

5.5 More about Emailing Access:

5.5.1 Sending Control command to the system:

A control command is placed in the email subject field. It has

the following format:

&SysName&userName&password&Command&,

where “&” is a command delimiter; “SystemName” is a user

defined system or device name; “username” and “password”

are valid user account name and password; and “command” is

the actual system control command.

Command delimiters are special characters or spaces that

identify the beginning or end of a group of characters in a

command. Delimiters are used to separate a character string

into the individual parts that form a command: command label,

command name, parameter keywords, and parameter values.

The default delimiter character is “&” symbol. To change it, use

command “eCmd X” at terminal program or telnet session. Use

command “/Help” is view available command delimiter symbols.

For example, sending email subject

“&mySite3&johnW&123456&rb 2&” will reboot power outlet 2 on

the NP system, named as “mySite3”. The user name is “johnW”

and password is “123456”.

Before a command is executed, a confirmation reply email is

sent. The destination of the replying email address is already

defined in the Network Configuration Table. Figure 22 shows

a reply email is received and displayed at “hotmail” web site.

A control command is not executed if the system name does

not match, user name does not exists, or the name does not

have the privilege to operate the designated serial console port

or power outlet port, or if there is a command syntax error. If this

happens, a reply email is sent to indicate the problem of the

command, as shown in the Figure 23.

Helpful Info:

• Use the command “emailvbs x” to set to mail verbose mode.

In verbose mode, the system displays detailed information

while sending and receiving emails. It is helpful while you are

setting up your email accounts.

“emailvbs 0” turns the verbose mode off.

“emailvbs 1” sets the system to level 1 verbose mode, in which

high level emailing activities are displayed.

“emailvbs 2” sets to the system to level 2 verbose mode, in

which detailed emailing activities are displayed.

• Use command “emailget” to check incoming emails

immediately.

• Use command “emailsend” to send a test mail immediately.

5.6 Serial Console Port Configuration Menu:

This section describes serial console port configuration and

operating settings.

Serial Console Port configuration starts with the following menu:

************************************************************

* *

*

*

* "Master" Port Configuration Menu *

*

*

* *

************* ***********************************************

>

> aud rate..................................9600

Data bits:(7 or 8).........................8

Stop bits(1 or 2)..........................1

4) Parity(1 - Even,2 -Odd,3- None)................3

5) Flow control(1 -hardware,2 -None)............2

rt name..................................Master

7) Save:

8) Quit:

>Please select a parameter to change:

Figure 24 - Serial Port Parameter Entry Table

Figure 25 - Serial Port Setup Menu (Web Page)

Page 16

• Baud Rate: The system supports the following baud rates:

2400, 4800, 9600, 19200, 38400, 57600 and 115200. It is

strongly recommended that Master port and a user serial port

have the same data rate while exchanging data between

them so that data loss is eliminated. If you must run both

ports using different baud rates, Flow Control (hardware

handshaking) should be enabled on all connected serial

console ports.

Please also note that when Telnet access is used for

exchanging data between the system’s Ethernet interface

port and user communication equipment, without enabling

flow control, you might experience data loss when data

exchange rate is high. This is because data flow from the

system’s Ethernet port is subject to the congestion condition

of LAN traffic.

• Data Bit: Supports 7 or 8 bits.

• Stop Bits: Supports 1 or 2 bits.

• Parity Bits: Supports Even, Odd or None.

• Flow Control: Flow Control is hardware handshaking using

CTS/RTS signals on the connectors. Please see Appendix A

for information about RS232 connector pin assignments.

• Port Name: Assign a name for the port. Always assigned to

the name “Master”.

5.7 Power Outlet Setup Menu:

This section describes:

1) Manual Power Outlet Set Swith Operation.

2) Power Outlet Configuration

3) AutoPing Functions

4) Timer Usages.

Manual Power Outlet Set Switch Operation:

1) Press the switch for more than 0.5 seconds (but less than

3 seconds) and then release the switch. You will see a LED

on the front panel blinking. Continue the procedure until the

desired LED/power outlet number is selected.

2) Once the desired LED (power outlet number) is blinking,

holding down the switch for 3 seconds. Then you will

observe the LED is changed to solid On or Off state. The

power outlet power status is changed accordingly.

3) Repeat the procedure 1) and 2) for change the next power

outlet state.

If you run a terminal program, power outlet setup starts with the

following menu:

• Change Power Port Parameters: Enter power outlet

configuration submenu.

• Change Power Reboot Duration: Enter power reboot

duration value. When the reboot process starts, the system

flips current power outlet status from On to Off, or Off to On

for the number of seconds that this parameter defines. The

default value is 5 seconds. This is parameter applies to all

power outlets.

• List of All Power Port Status: Display all power ports

current statuses, as shown in Figure 30.

Helpful Info: Use command “pshow” to display all power

outlet status.

Figure 28 and 29 show the power outlet entry table. This is an

example of the power outlet in Timer off mode. In Figure 29, to

enable the Timer, select option 3. Once a timer is enabled, the

entry table is extended including all timer parameters as shown

in Figure 33.

13

Figure 26 - Power Outlet Setup Menu (Terminal Screen)

Figure 27 - List of Power Outlet Status (Terminal Screen)

Page 17

14

• Power Outlet Name: Define a name for the power outlet.

• Power Outlet: Set the power outlet to power on or off state.

• Power Outlet Timer: Enable or disable the Timer for

the port.

• Enable AutoPing (Power reboot If user equipment’s

network is down): Disable or enable AutoPing power reboot

function. If it is enabled, the system schedules auto pings to

the communication equipment that is connected to the

power outlet. If no response is received in a period of time

(user defined, see below) from the communication

equipment, the system starts the power reboot process for

the power outlet.

Helpful Info: Use the command “/apVbs 1” to displays AutoPing

run-time information.

• Max Network Downtime allowed: Set a value of maximum

network down time, in seconds. If probed communication

equipment does not send ping response messages back to

the system for this period of time, the system will start reboot

processes for the power outlet.

Note: AutoPing starts power reboot process if and only if the fol-

lowing two conditions are met:

1) NPC system is active on the network interface. This enables

AutoPing mode at system operation level.

The active network connection is verified periodically by

pinging a network target IP address (default to network

gateways IP address). If there is no response from the

network target address, AutoPing mode is in off mode.

2) Once AutoPing mode is on, if user communication equipment

stops sending responses back to the NPC system for a

period of time (Max Network Downtime allowed), power

rebooting process begins . If the user equipment has never

sent a ping response back to the system after AutoPing

mode turns on, AutoPing will never trigger the power reboot

process for the power outlet.

• AutoPing (Ping) destination IP address (or URL): Enter an

IP address of the probed communication equipment IP. This

IP address is associated to the power outlet.

Figure 28 - Power Outlet Setup Menu (Web Page)

Figure 29 - Power Outlet Parameter Menu (Timer Off Mode)

Figure 30 - Power Outlet Parameter Menu (Timer On Mode)

Page 18

• Timer Start Time: Specify starting time for the timer. The

starting time is the actual calendar date and real-time clock.

Once a timer reaches this specified Start Time, the power

outlet on/off state will flip. It is in the format of

“month:day:hour:minute:second”. For example, to start

changing the power outlet on/off state at 6:31:2pm, on June

20th, the entry data is 6:20:18:31:02.

• Timer Period: Specify the timer period. It is in the format of

“days:hours:minutes:seconds”, which is not a calendar and

real-time clock entry type. The period setting is used for

applications that require the power outlet to continuously

change on/off in a specific interval. For example, you need to

schedule power reboot for the outlet daily, the period is 24

hours. Your entry will be 00:24:00:00.

• Timer Loop Count: The number of Periods for the Timer is

defined as Loop Count. For example, you schedule the timer

to flip the power outlet states in every 20 seconds and want

to repeat 300 times, your entry will be 300.

Enter “0” for this setting, if you schedule the power outlet

simply change power state from on to off, or from off to on a

specific time and date.

Enter “1” for the setting, if you schedule the power outlet

to be on-off-on, or off-on-off once. For example, the system

executes one power reboot cycle on a specific date and

time.

• Toggle Duration: Specify the duration of the power outlet

state that toggles when a new Timer Period starts. This

parameter is meaningful if the Timer Loop Count is > 0. The

unit for the duration is in seconds. The concept of the

specification can also be viewed as Duty Cycle. The value of

this parameter should be 0 < Toggle Duration < Timer Period.

There are a few examples of applications using the Power Outlet

Timers:

1) Reboot daily: Current Calendar date and time are:

Aug. 10th, 10:00 am.

Requires daily power Reboot at 1:00am.

Reboot duration is 10 seconds.

Timer Start Timer = 8:11:1:0:0

Reboot starts on Aug. 11th, 1:00 am.

Timer Period = 1:0:0:0

Period is 1 day, 0 hour, 0 minute, and 0 second.

Timer Toggle Duration = 10

Power outlet will toggle on/off state for 10 seconds.

Timer Loop Count = 1000

1000 days

2) Toggle Power Outlets for 300 times: Toggling Power outlet

on/off state 300 times in a period of 10 seconds starts

immediately.

Current Calendar date and time are:

Aug. 10th, 10:00 am.

Timer Start Time = 8:10:10:00:20

Start toggling on Aug. 10th, at 10:00:20 am.

Timer Period = 20

Choose 20 seconds and duty cycle 50%.

Note: the period setting is not 10.

Timer Toggle Duration = 10

This results in 10 seconds on and 10 seconds off.

Timer Loop Count = 300

300 periods.

3) Reboot once on a specific date and time:

Current Calendar date and time are:

Aug. 10th, 10:00 am.

To schedule a reboot on Feb 12th, 1:00 am.

Timer Start Time = 2:12:1:00:00

Start the event at 1:00am, on Feb. 12th

Timer Period = 6

6 seconds

Timer Toggle Duration = 5

5 seconds.

Reboot duration is 5 seconds.

Timer Loop Count = 1

Reboot once.

15

Figure 30 - Power Outlet Parameter Menu (Timer On Mode)

Page 19

16

5.8 User Account Management Menu:

User account management includes reserving or un-reserving

each serial console ports and power outlets to a current login

user, as well as adding new user accounts, modifying and

deleting user accounts.

Helpful Info: Use the command “userlist” to view all existing

account

5.9 Viewing and Changing Operation Status

with a Web Page:

Figure 34 shows a web page that lets you to view and change

serial console port and power outlet operation status.

With this web page, you are able to:

• View on/off status for each power outlet. As shown in the

table, Power outlet 1 is power on (illuminated in red) and

outlet 2 is power off (not illuminated, in grey).

• Change power outlet on/off status by clicking “on/off” push

switch button icon.

• Reboot a power outlet by clicking “Reboot” push switch

button icon.

• Get current all ports status by pressing “Refresh View”

button.

Figure 32 - User Account Management Menu (Terminal)

Figure 33 - User Account Management Menu (Web Page)

Figure 34 - Viewing and Changing System Operation Status

Page 20

Wiremold/Legrand warrants, to the original purchaser or owner

only, that any product manufactured and sold by

Wiremold/Legrand will be substantially free from defects in

material and workmanship under normal use and service,

for a period of one year from the date of original installation or

two years from the date of purchase, whichever is sooner. This

limited warranty applies only to products, which have been

installed properly in accordance with Installation Instructions

supplied by Wiremold/Legrand and any applicable codes and

standards.

This limited warranty is void and Wiremold/Legrand shall not be

liable for any damages or held responsible for the quality,

performance or safety of products that have been repaired,

altered or tampered with outside of Wiremold/Legrand facilities

or which have been intermixed (used within a system) with

products or materials not approved by Wiremold/Legrand or

have been subjected to accident, negligence, misuse or abuse.

Wiremold/Legrand’s sole obligation (and the sole and exclusive

remedy of the purchaser or owner of the product) with respect

to any products which are proven to be defective, shall be the

repair or replacement of the defective products, at the sole

option of Wiremold/Legrand. Returned products will not be

accepted unless The Wiremold Company is notified and

authorizes the return, prior to shipment.

Wiremold/Legrand shall not be liable for any damages in excess

of the purchase price of the defective products, and under no

circumstances shall Wiremold/Legrand be liable for incidental,

consequential, special or punitive damages.

Certain products of Wiremold/Legrand may have a specific

limited warranty or limitation of liability which is included with

such products and which differs from that set forth in this

Statement. The terms of any such specific limited warranty or

limitation of liability will supersede that set forth in this

Statement.

Except as set forth in the preceding paragraph, THIS LIMITED

WARRANTY IS EXCLUSIVE AND Wiremold/Legrand MAKES

NO OTHER WARRANTIES WITH RESPECT OF ITS

PRODUCTS, EXPRESSED OR IMPLIED, INCLUDING NO

WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A

PARTICULAR PURPOSE.

17

APPENDIX A LIMITED WARRANTY & LIABILITY STATEMENT

Page 21

RS-232 — DB9 FEMALE RJ45 (8-PIN)

RJ45 (8-PIN)RS-232 — DB9 MALE

18

APPENDIX B SERIAL CONSOLE PORT INTERFACES

PIN # NAME LONG NAME DIRECTION DESCRIPTION

1 DCD Data Carrier Detect <<< Raised when an carrier communication is established.

2 TD Transmitting Data >>> Serial data stream sent to the DTE device.

Same note as above apply.

3 RD Receive Data <<< Receives serial data stream.

4 DSR Open <<< Not connected.

5 GND Signal Ground

6 DTR Terminal Ready >>> Indication of serial port activated.

7 CTS Clear To Send <<< When hardware flow control is enabled, if this signal is

raised, an external device can send data to Local

Master Port.

8 RTS Request To Send >>> When hardware flow control is enabled, this signal is

raised by the Local Master Port when it is ready to

receive new data from an external device.

9 Open Open

6 Open <<< Not connected.

8 CTS Clear To Send <<< When hardware flow control is enabled, if this signal is

raised, an external device can send data to Local

Master Port.

7 RTS Request To Send >>> When hardware flow control is enabled, this signal is

raised by the Local Master Port when it is ready to

receive new data from an external device.

9 Open Open

APPENDIX C RS-232 TO RJ45 CONVERSION CABLES

PIN # SIGNAL

1 DCD

2 TxD

3 RxD

4 DSR

5 GND

6 DTR

7 CTS

8RTS

9–

PIN # SIGNAL

1 DSR

2RTS

3 GND

4 TxD

5 RxD

6 DCD

7 CTS

8 DTR

DB-9 F

RS-232 — RJ45 (8-PIN)

C-RJ45-DB9F-4, RJ-45 to RS232 (Female, DCE) cable, 4’

PIN # SIGNAL

1 DCD

2 RxD

3 TxD

4 DTR

5 GND

6 DSR

7RTS

8 CTS

9–

PIN # SIGNAL

1 DSR

2RTS

3 GND

4 TxD

5 RxD

6 DCD

7 CTS

8 DTR

RS-232 — RJ45 (8-PIN)

C-RJ45-DB9M-4, RJ-45 to RS232 (Male, DTE) cable, 4’

8

8

DB-9 M

Loading...

Loading...