Page 1

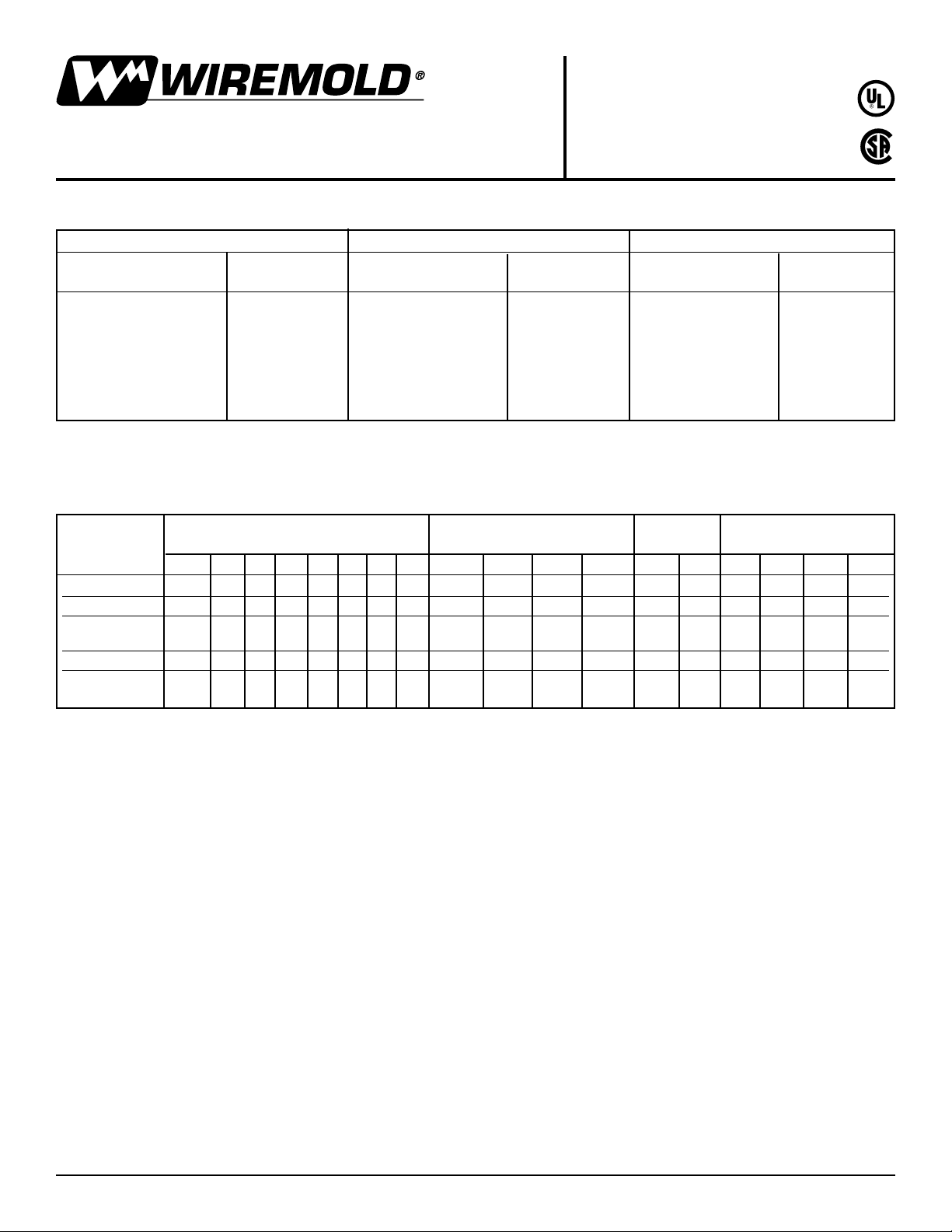

TELEPHONE CABLE-TYPE CM/CMR 24 AWG COAXIAL IBM CABLING

NUMBER OF PAIRS RG62A/U RG6/U RG59/U RG58A/U SYSTEM SIGNAL WIRE

CABLE TYPE 100 75 50 25 6 4 3 2 22 Gage 18 Gage 20 Gage 20 Gage Type 1 Type 2 18AWG 20 AWG 22 AWG 24 AWG

Nominal O.D. Inches 0.68 0.60 0.50 0.38 0.22 0.18 0.14 0.12 0.26 0.275 0.242 0.195 0.43 0.51 0.066 0.057 0.05 0.044

Capacity @ 30% XSA 6 8 11 20 59 88 146 199 42 38 49 75 16 11 658 882 1146 1480

Capacity of Divided

@ 30% XSA 3 4 6 10 29 44 72 98 21 19 24 37 8 5 325 435 566 730

Capacity @ 60% XSA 12 16 23 40 118 177 292 398 85 76 98 151 31 22 1316 1764 2293 2961

Capacity of Divided

@ 60% XSA 6 8 11 20 58 87 144 196 42 37 48 74 15 11 649 870 1131 1461

Installation

Instructions

S4000 Raceway Wire Fill Capacities for Power

POWER WIRING WITHOUT DEVICES WITH DEVICES

Wire Size (AWG) Non-Divided Divided Non-Divided Divided

(THHN/THWN) O.D. 40% Fill 40% Fill 40% Fill 40% Fill

2 0.388 25 13 12 5

4 0.328 35 18 16 7

6 0.257 58 29 26 11

8 0.218 80 40 37 15

10 0.153 163 81 74 30

12 0.122 257 127 117 48

14 0.105 347 171 158 64

S4000 Data/Communication Wire Fill Capacities

NOTES: 1) XSA = Cross Sectional Area of S4000 Surface Raceway.

2) Capacity range is calculated at 30% to 60% of raceway area as stated in the Commercial Building Standard for

Telecommunications Pathways and Spaces, EIA/TIA-569.

3) Reduce wirefill by 20% when fittings are to be used in installation.

All Wiremold electrical products, unless specifically noted, are listed by Underwriters’Laboratories, Inc.and conform to U.S.

Federal Specification W-C-582.They comply with the National Electrical Code. Products designed primarily for use in telephone or communications wiring and tools normally do not require U.L.Listing or CSA certification.Most products are CSA

certified in compliance with the Canadian Electrical Code. All products must be installed in a manner consistent with applicable electrical codes. Wiremold S4000 Stainless Steel Surface Raceway is CSA certified (File No. LR350) and listed by

Underwriters’ Laboratories (File Nos. E4376 [Raceway] and E41751 [Fittings]). This product is in compliance with the

National Electrical Code and the Canadian Electrical Code.

See typical basic system (illustrated on back) for installation details. In general, the following procedure for installing S4000

is recommended.

1. Starting at feed connection, install S4000 Base sections over entire run. Butt ends of sections and install couplings as

shown on back of this sheet. Cut base sections to length as required for connection of bases of fittings. Custom precut base and cover lengths are available and recommended to ensure an expeditious installation.

2. Assemble device brackets in S4000 Base.

3. Install wiring in base and wire devices.

4. Assemble devices and device covers in S4000 Base.

5. Cut S4000 Cover sections to length as necessary and snap onto base. It is recommended that covers overlap base

joint.

6. Tighten all fitting locking screws securely.

S4000 Stainless Steel Raceway

NOTES: 1) % Fill is based on use of Surge/GFCI style devices, mounted perpendicular in raceway.

2) Reduce wirefill by 20% when fittings are to be used in installation.

Page 2

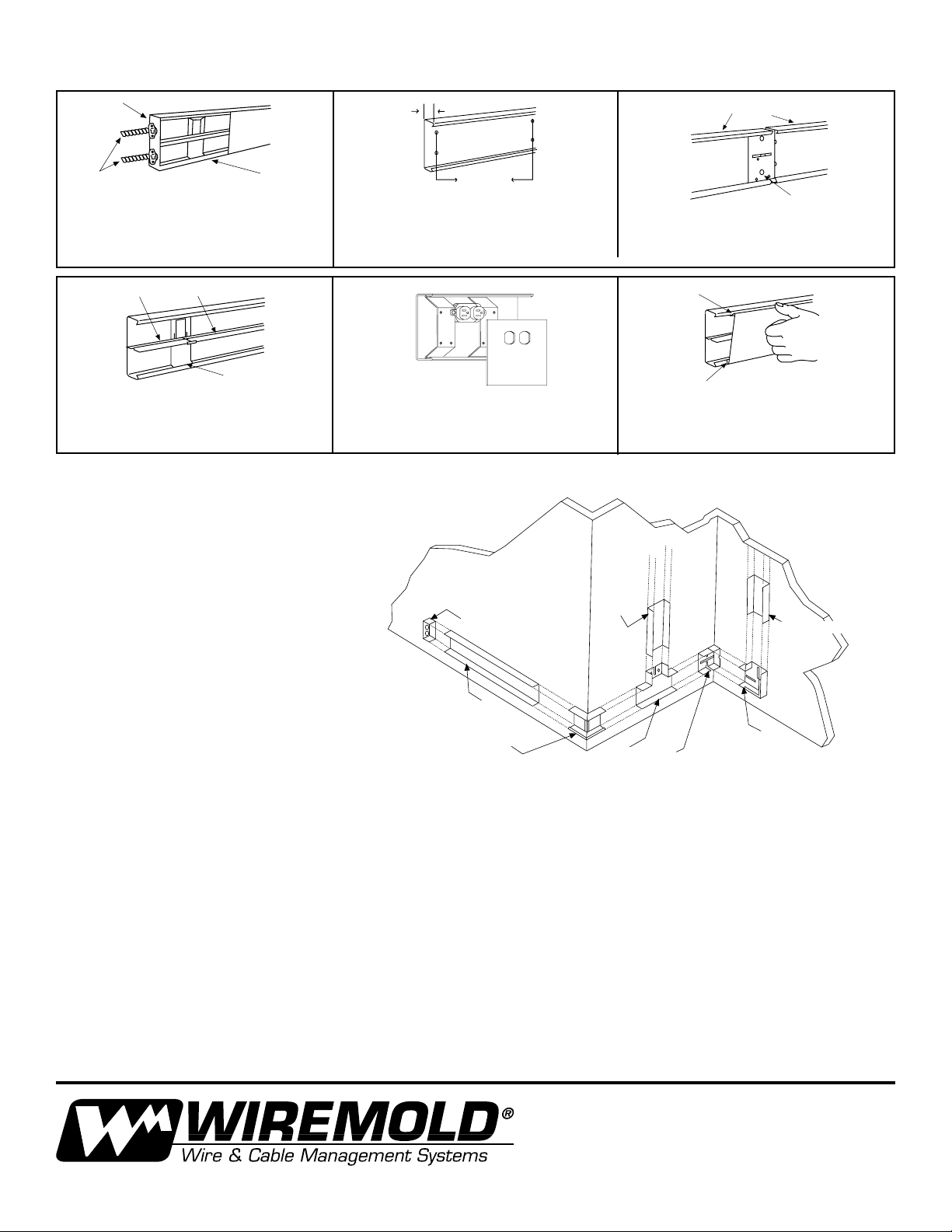

1. Deter mine the method of feeding raceway:

S4000B for back feed, S4010B1 or S4010B2

for end feed.

2.To mount S4000 base to surface, remove

mounting screw KO’s (approx. 18" centers along

base) as required. Mount base with No. 8 flat

head fasteners.

3.To couple lengths of S4000B, inser t the

G4001 coupling into one base section (centered on joint). Slide other length of base onto

coupling.Tighten locking screws.

4. For divided installations, snap G4001D

divider clip into base at 30" intervals. Snap

G4000D divider into place.

The Wiremold Company

In U.S.:

60 Woodlawn St. • W. Hartford, CT 06133-2500

1-800-621-0049 • FAX 203-232-2062

In Canada:

850 Gartshore St. • Fergus, Ontario N1M 2W8

1-800-741-7957 • FAX 519-843-5980

©1995 The Wiremold Company

INS00002 695

S4000 Stainless Steel Raceway Typical Basic System:

5.To install device covers, snap device straps in

base as shown.Wire device and assemble to

straps. Snap device plate over base and device.

6. Cut S4000C cover to fit between device

plates. Snap in place as shown. Continue along

entire run.

A. End Blank

At end of S4000 Base run install an End

Blank. May use S4010B0 (no knockouts),

S4010B1 (1 knockout — for non-divided

installations) or S4010B2 (2 knockouts —

shown). Knockouts provided are 1/2" 3/4" concentric style.

B. External Elbow

At 90° outside corner: Insert S4018

External Elbow onto G4001 Coupling on

S4000 Base section.Slide next base section onto G4001 Coupling with S4018.

After wiring system, snap S4018 Cover

onto elbow and butt against S4000

Cover. Couplings are not fur nished.

C.Tee

For S4000 T-branch run on same surf ace:

Use S4015 Tee fitting (shown) or S4015D

Tee fitting (for divided installations).

Couple to base sections with G4001 Couplings (not furnished). After wiring system, snap S4015 Cover into place and butt

against adjoining S4000 Covers.

D. Internal Elbow

At 90° inside cor ners: Insert S4017 Internal Elbow in end of S4000 Base section and mount section. Assemble next Base

section on S4017.After wiring system, butt S4000 Cover sections together over S4017 Base to enclose the wiring.No couplings are required.

E. Flat Elbow

At 90° turn on same surface: Inser t S4011 Flat Elbow into S4000 Base section and fasten screws. Assemble next Base

section on S4011. After wiring system, screw S4011 Cover onto elbow. Butt adjoining S4000 Covers. No couplings are

required.

S4010B2

1/2" Flexible

Metal Conduit

4000 Base

G4000D Sections

G4001D as Divider Clip

1 3/4"

18"

Approx.

Base Sections

G4001

Snap cover onto base

Engage one leg of cover on base

S4010B2 End Blank

S4000B Base

S4000B Base

S4000B

Base

S4018 External Elbow

S4015 Tee

S4017 Internal

Elbow

S4011 Flat

Elbow

A

B

C

D

E

Loading...

Loading...