LEGRAND Keor MOD 25, Keor MOD 100, Keor MOD 150, Keor MOD 125, Keor MOD 175 Installation And Maintenance Manual

...Page 1

Keor MOD

Installation and maintenance manual

Part. LE11406AB-04/19-01 GF

Page 2

Keor MOD

ENGLISH 3

EN

2

Page 3

Keor MOD

Table of Contents

1 Introduction 5

1.1 Purpose of the manual 5

1.2 Symbols in the manual 5

1.3 Where and how to keep the manual 5

1.4 Update of the manual 6

1.5 Manufacturer’s liability and guarantee 6

1.5.1 Guarantee terms 6

1.5.2 Extension of the guarantee and maintenance contracts 7

1.6 Copyright 7

2. Regulatory and safety requirements 8

2.1 General notes 8

2.2 Denitions of “Skilled Technician” and “Operator” 8

2.2.1 Skilled Technician 8

2.2.2 Operator 8

2.3 Personal Protective Equipment 8

2.4 Hazard signs in the workplace 9

2.5 Signs on the equipment 9

2.6 General warnings 10

2.7 How to proceed in an emergency 11

2.7.1 First-aid procedures 11

2.7.2 Fire procedures 11

Installation and maintenance manual

3. Transportation and placement 12

3.1 Visual check 12

3.2 Equipment check 12

3.3 Transportation 13

3.4 Unpacking 14

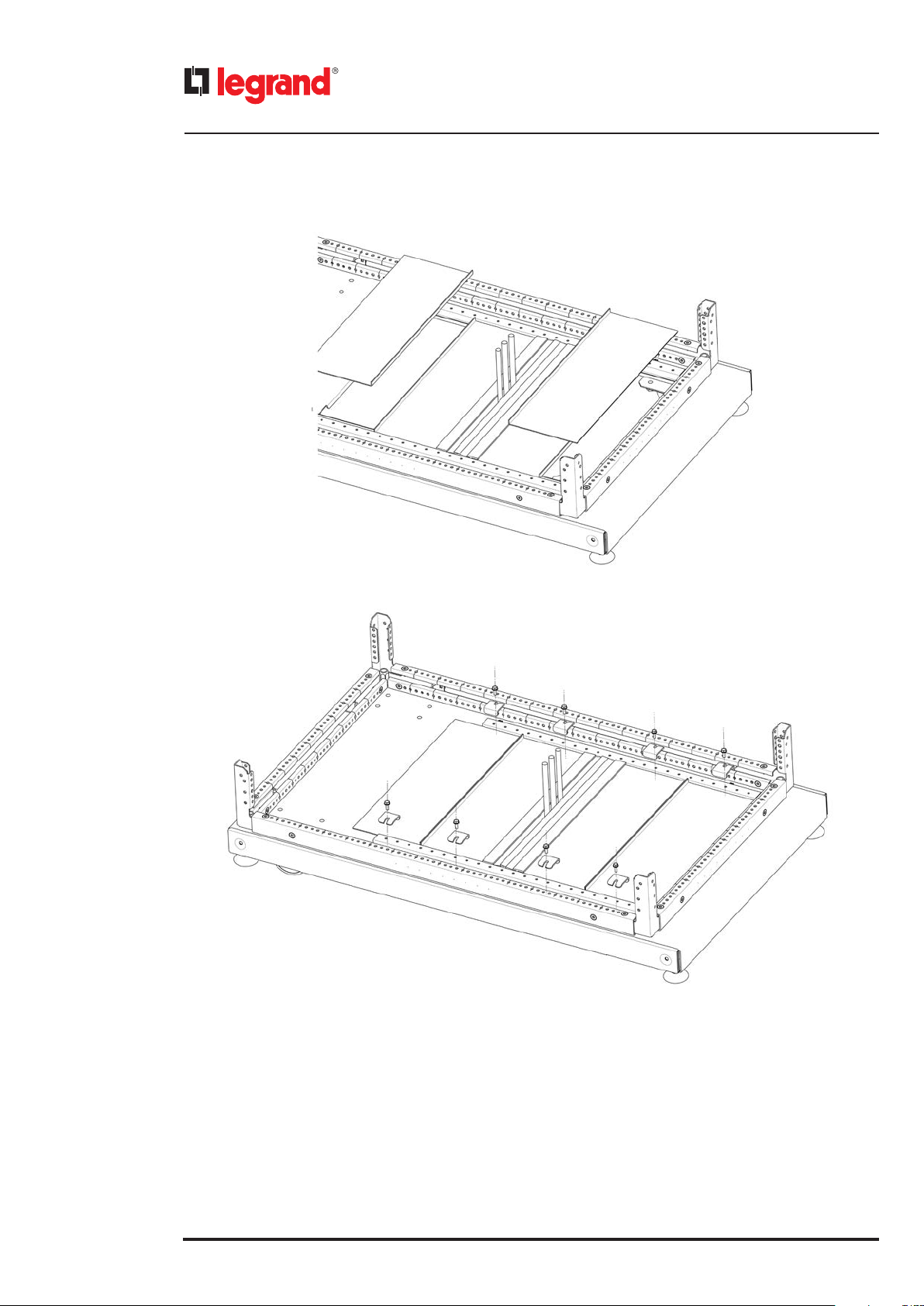

3.5 Placement 15

4. Installation 17

4.1 Safety regulations 17

4.2 Electrical connections 17

4.2.1 Protective devices 18

4.2.2 Disassembly of the distribution panel 18

4.2.3 Earthing connection 23

4.2.4 Cable fastening 25

4.2.5 Backfeed protection 34

4.2.6 Input cables installation 35

4.2.7 Bypass cables installation 41

4.2.8 Output cables installation 45

4.2.9 Battery cables installation 49

4.3 Power modules installation 58

4.4 Battery drawers installation 60

4.5 SSS interface 66

4.5.1 Emergency Power O (EPO) 67

3

Page 4

Table of Contents

5. Configuration and start-up 68

5.1 Pre-start-up checks 68

5.2 Start-up procedure 68

5.3 Switching o the UPS 70

6. Maintenance 71

6.1 Preventive maintenance 71

6.2 Periodical checks 71

6.3 Ordinary maintenance 72

6.3.1 Hot-swap procedure for the replacement of power modules 72

6.3.2 Installation/replacement of power modules with the UPS in maintenance bypass mode 76

6.3.2.1 Setting the UPS in maintenance bypass mode 76

6.3.2.2 Installation/replacement of power modules 76

6.3.2.3 Exit the UPS from the maintenance bypass mode 78

6.3.3 Removal of the SSS drawer 79

6.4 Battery drawers replacement 80

6.4.1 Installation/replacement of battery drawers with UPS in on-line mode 80

6.4.2 Installation/replacement of battery drawers with UPS in maintenance manual bypass 81

6.5 Replacing the fuses and surge arrester (DIN rail) 82

6.6 Extraordinary maintenance 83

7. Warehousing 84

7.1 UPS 84

7.2 Batteries 84

8. Dismantling 85

8.1 Battery disposal 85

8.2 UPS dismantling 85

8.3 Electronic component dismantling 85

9. Mechanical characteristics 86

9.1 Cabinets 86

9.2 Power module PM25 91

9.3 Battery drawer 92

9.4 Battery block 93

10. Technical data 94

11. Tables 98

4

Page 5

1. Introduction

INDICATION

The instructions in this manual are intended for a SKILLED TECHNICIAN (paragraph 2.2.1)

Keor MOD

1.1 Purpose of the manual

The purpose of this manual is to provide the skilled technician (see paragraph 2.2.1) with instructions for safely installing

the Keor MOD UPS, also called “equipment” in the rest of the manual and carry out ordinary maintenance procedures.

Extraordinary maintenance operations are not dealt with because they are the sole preserve of the LEGRAND Technical

Support Service.

The reading of this manual is essential but does not substitute the skill of technical personnel who must have received

adequate preliminary training.

The intended use and configurations envisaged for the equipment as shown in this manual are the only ones allowed by

the Manufacturer.

Any other use or configuration must be previously agreed with the Manufacturer in writing and, in this case, the written

agreement will be attached to the installation and user manuals.

This manual also refers to laws, directives and standards that the skilled technician is required to be aware of and consult.

The original text of this publication, drafted in English, is the only reference for the resolution of disputes of interpretation

linked to translations into other languages.

1.2 Symbols in the manual

Some operations are shown in graphic symbols that draw the attention of the reader to the danger or the importance

they imply:

DANGER

This indication shows a danger entailing a high degree of risk that, if not avoided, will lead to death or serious injury or

considerable damage to the equipment and things around it.

Installation and maintenance manual

WARNING

This indication shows a danger entailing a medium degree of risk that, if not avoided, could lead to death or serious injury

or considerable damage to the equipment and the things around it.

CAUTION

This indication shows a danger entailing a low level of risk that, if not avoided, could lead to minor or moderate injury or

material damage to the equipment and the things around it.

INDICATION

This symbol indicates important information which should be read carefully.

1.3 Where and how to keep the manual

This manual must be kept in a safe, dry place and must always be available for consultation exclusively by the skilled

technician.

It is recommended to make a copy of it and file it away.

If information is exchanged with the Manufacturer or the authorized assistance personnel, it is essential to refer to the

equipment’s rating plate data and serial number.

INDICATION

The manuals provided with the equipment are an integral part of it and must therefore be kept for its entire lifetime. In

case of need (for example in case of damage that even partially compromises its consultation) the skilled technician is

required to get a new copy from the Manufacturer, quoting the publication code on the cover.

5

Page 6

1. Introduction

1.4 Update of the manual

The manual reflects the state of the art when the equipment was put onto the market. The publication conforms to the

directives current on that date. The manual cannot be considered inadequate when new standards come into force or

modifications are made to the equipment.

Any addition to the manual the Manufacturer considers appropriate to send to the users, must be kept together with the

manual of which they will become an integral part.

The version of the manual updated to its latest release is available on the Internet at http://www.ups.legrand.com

1.5 Manufacturer’s liability and guarantee

The skilled technician and the operator shall scrupulously comply with the precautions and installation instructions indicated in the manuals. They must:

- always work within the operating limits of the equipment;

- always carry out constant and careful maintenance through a skilled technician who complies with all the procedures

indicated in the installation and maintenance manual.

The Manufacturer declines all indirect or direct responsibility arising from:

- assembly and cabling made by personnel not qualified and authorized by LEGRAND and not fully qualified according to

national standards to work on equipment presenting electrical hazards;

- assembly and cabling made without using safety equipment and tools required by national safety standards;

- failure to observe the installation and maintenance instructions and use of the equipment which differs from the specifications in the manuals;

- use by personnel who have not read and thoroughly understood the content of the user manual;

- use that does not comply with the specific standards used in the country where the equipment is installed;

- modifications made to the equipment, software, functioning logic unless they have been authorized by the Manufacturer in writing;

- repairs that have not been authorized by the LEGRAND Technical Support Service;

- damage caused intentionally, through negligence, by acts of God, natural phenomena, fire or liquid infiltration;

- damage caused by the use of batteries and protections not specified in the manuals;

- damage caused by improper unloading and transportation after delivery of the equipment;

- accidents caused by a wrong assembly of the safety protections or due to the lack of application of the safety labels

specified in the installation manual.

The transfer of the equipment to others also requires to hand over all the manuals. Failure to do it will automatically nullify

any right of the buyer, including the terms of the guarantee where applicable.

If the equipment is sold to a third party in a country where a different language is spoken, the original owner shall be responsible for providing a faithful translation of this manual in the language of the country where the equipment will be used.

1.5.1 Guarantee terms

The guarantee terms may vary depending on the country where the UPS is sold. Check the validity and duration with

LEGRAND’s local sale representative.

If there should be a fault in the product, contact the LEGRAND Technical Support Service which will provide all the instructions on what to do.

Do not send anything back without LEGRAND’s prior authorization.

The guarantee becomes void if the UPS has not been brought into service by a properly trained skilled technician qualified and authorized by LEGRAND (see paragraph 2.2.1).

If during the guarantee period the UPS does not conform to the characteristics and performance laid down in this manual, LEGRAND at its discretion will repair or replace the UPS and relative parts.

All the repaired or replaced parts will remain LEGRAND’s property.

LEGRAND is not responsible for costs such as:

- losses of profits or earnings;

- losses of equipment, data or software;

- claims by third parties;

- any damage to persons or things due to improper use, unauthorized technical alterations or modifications;

- any damage to persons or things due to installations where the full compliance with the standard regulating the specific

usage applications have not been guaranteed.

6

Page 7

Keor MOD

1.5.2 Extension of the guarantee and maintenance contracts

The standard guarantee can be consolidated in a single extension contract (maintenance contract).

Once the guarantee period has passed, LEGRAND is available for giving a technical assistance service able to meet all

requirements, maintenance agreements, 24/7 availability and monitoring.

Please, contact the LEGRAND Technical Support Service for further information.

1.6 Copyright

The information contained in this manual cannot be disclosed to any third party. Any partial or total duplication of the

manual by photocopying or other systems, including electronic scanning, which is not authorized in writing by the Manufacturer, violates copyright conditions and may lead to prosecution.

LEGRAND reserves the copyright of this publication and prohibits its reproduction wholly or in part without previous

written authorization.

Installation and maintenance manual

7

Page 8

2. Regulatory and safety requirements

DANGER

Before carrying out any operation on the equipment, it is necessary to read the entire manual carefully, especially

this chapter.

Look after this manual carefully and consult it repeatedly during installation and maintenance by a skilled technician.

2.1 General notes

The equipment has been made for the applications given in the manual. It may not be used for purposes other than those

for which it has been designed, or differently from those specified in this manual.

The various operations must be carried out according to the criteria and the chronology described in this manual.

2.2 Definitions of “Skilled Technician” and “Operator”

2.2.1 Skilled Technician

The figure that will carry out the installation, start up and ordinary maintenance is called “Skilled Technician”.

This definition refers to people qualified by LEGRAND who have the specific technical qualification and are aware of the

method of installing, assembling, repairing, bringing online and using the equipment safely.

In addition to the requirements listed in the section below for a general operator, the Skilled Technician is qualified

according to national safety standards to work under dangerous electrical voltage and uses the personal protective

equipment required by national safety standards for all the operations indicated in this manual (see the examples

listed in paragraph 2.3).

INDICATION

The safety manager is responsible for protection and company risks prevention according to what is indicated in European directives 2007/30/EC and 89/391/EEC regarding safety in the workplace.

The safety manager must ensure that all the people working on the equipment have received all the instructions concerning them in the manual, especially those contained in this chapter.

2.2.2 Operator

The figure assigned to the equipment for normal use is called “Operator”.

This definition refers to people who know how to operate the equipment defined in the user manual and have the following requisites:

1. technical education, which enables them to operate according to safety standards in relation to the dangers linked to

the presence of electric current;

2. training on the use of personal protective equipment and basic first aid interventions.

The company safety manager, in choosing the person (operator) who uses the equipment, must consider

- the person’s work fitness according to the laws in force;

- the physical aspect (not disabled in any way);

- the psychological aspect (mental stability, sense of responsibility);

- the educational background, training and experience;

- the knowledge of the standards, regulations and measures for accident prevention.

He shall also provide training in such a way as to provide thorough knowledge of the equipment and its component parts.

Some typical activities the operator is expected to carry out are:

- the use of the equipment in its normal functioning state and the restore of the functioning after it shuts down;

- the adoption of the necessary provisions for maintaining the quality performance of the UPS;

- the cleaning of the equipment;

- cooperation with personnel responsible for ordinary maintenance activities (Skilled Technicians).

2.3 Personal Protective Equipment

DANGER

The UPS poses a considerable risk of electric shocks and a high short circuit current. During installation, use and maintenance operations, the equipment mentioned in this section must be used.

People responsible for operating this equipment and/or passing close to it must not wear garments with flowing sleeves,

nor may laces, belts, bracelets or other metal pieces that might cause a danger.

8

Page 9

Keor MOD

The following list sum up the minimum Personal Protective Equipment to wear always. Additional requirements may be

needed according to national safety standards.

Anti-accident and non-sparking shoes with rubber

sole and reinforced toe

Protective gloves for handling operations

Isolated rubber gloves for operations of connection

and work under hazardous voltage

Protective garments for electrical work

Protective face and head shield

Isolated tools

INDICATION

The skilled technician must work on electrical insulated carpet and he must not wear any kind of metal objects like watches, bracelets, etc.

2.4 Hazard signs in the workplace

The following signs must be exhibited at all points of access to the room where the equipment is installed:

Installation and maintenance manual

Electric current

This sign indicates the electrical live parts.

How to proceed in an emergency

Do not use water to quench fires but just the extinguishers specially designed for putting out fires in electrical

equipment.

No smoking

This sign indicates that smoking is not allowed.

2.5 Signs on the equipment

Displayed on the UPS are explanatory plates that can vary depending on the country the equipment is intended for and

constructional standards applied.

Make sure the instructions are adhered to. Removing these plates and working in a way that differs from what written

there, is strictly prohibited.

The plates must always be clearly read and they must be cleaned periodically.

If a plate deteriorates and/or it is no longer legible, even partially, the Manufacturer must be contacted for another one.

CAUTION

The plates must not be removed or covered. Signs in different languages are provided along with the equipment to

replace those in English. No other plates may be affixed to the equipment without the Manufacturer’s prior written authorisation

9

Page 10

2. Regulatory and safety requirements

WARNING

Potential risks can be drastically reduced by wearing the Personal Protective Equipment listed in this chapter, which are

indispensable. Always operate with due care around dangerous areas marked by the appropriate warning notices on the

equipment.

2.6 General warnings

DANGER

The UPS works with dangerous voltages. Only skilled technicians qualified and authorized by LEGRAND must perform the

installation and ordinary maintenance operations. No part of the UPS can be repaired by the operator.

Extraordinary maintenance operations must be carried out by LEGRAND Technical Support Service personnel.

DANGER

Before beginning any installation and/or maintenance operation, make sure that all the DC and AC power sources are

disconnected.

The UPS and the external battery cabinet, if present, must be installed with an earth connection to avoid high leakage

currents. First connect the earthing cable.

Check during each installation and/or maintenance operation the continuity of the earthing system.

DANGER

The UPS is powered by its own DC energy source (batteries). The output terminals may have a dangerous voltage even if

the UPS is not connected to the AC power network.

Disconnect all battery drawers and external battery cabinets before performing any installation and/or maintenance

operation.

WARNING

A battery can present a risk of electrical shock and burns by high short-circuit circuit current. Failed batteries can reach

temperatures that exceed the burn thresholds for touchable surfaces. The following precautions should be observed

when working on batteries:

a) remove watches, rings or other metal objects.

b) use tools with insulated handles.

c) wear rubber gloves and boots.

d) do not lay tools or metal parts on top of batteries.

e) disconnect the charging source prior to connecting or disconnecting battery terminals.

f) determine if battery is inadvertently grounded. If inadvertently grounded, remove source from ground.

Contact with any part of a grounded battery can result in electrical shock. The likelihood of such shock can be reduced

if such grounds are removed during installation and maintenance (applicable to equipment and remote battery sup-

plies not having a grounded supply circuit).

g) never leave live cable terminals without an insulated protection.

h) When replacing batteries, replace with the same type and number of batteries or battery packs. There is the risk of

explosion if batteries are replaced by an incorrect type.

Do not dispose of batteries in a fire. The batteries may explode.

Do not open or mutilate batteries. Released electrolyte is harmful to the skin and eyes. It may be toxic. The batteries

installed inside the cabinet must be disposed of correctly. For the disposal requirements refer to local laws and relevant

standards.

INDICATION

The UPS functions with TT, IT, TN-C and TN-S systems. Input and output neutral are referenced to the same neutral potential: the output neutral status is the same as the input neutral status.

When the output load needs a different neutral status, it is necessary to place downstream of the UPS a suitably scaled

isolation transformer that must be protected in compliance with the standards in force.

10

CAUTION

Do not open the battery fuse holders while the UPS is powering the loads in battery mode.

Page 11

Keor MOD

WARNING

To reduce the risk of fire or electric shock, the UPS must work in closed, clean environments with controlled temperature

and humidity. It must be kept away from inflammable liquids and corrosive substances. The room temperature must not

be above +40°C (+104°F) and the relative humidity must be a maximum of 95% not condensing.

WARNING

Keor MOD is a category C3 UPS according to the standard EN62040-2.

The UPS is a product for commercial and industrial application in the second environment – installation restrictions or

additional measures may be needed to prevent disturbances.

INDICATION

When the UPS is used for special applications such as life support systems or any other application where a product failure

is likely to cause substantial harm to people, it is mandatory to contact LEGRAND to confirm the possibility of the equipment to meet the requested level of safety, performance, reliability and compliance with applicable laws, regulations and

specifications.

Installation and maintenance manual

CAUTION

- While maintenance operations are being carried out, “Maintenance work in progress” signs must be affixed in the de-

partment in such a way that they can be easily seen from any access area.

- The connection of the equipment (and of any accessory devices) signs must always be perfectly grounded to discharge

short-circuit currents and electrostatic voltages. The input voltage must correspond with the value shown on the rating

plate. Current adapters must not be used under any circumstances. Pay attention to polarity when connecting.

- Any intervention on the equipment must be done only after it has been disconnected from the power supply network

by means of a switch disconnector and must be locked with an appropriate padlock.

- The UPS must not be turned on if liquid is leaking from the batteries.

- Depositing flammable material near the equipment is strictly forbidden. The equipment should always be locked, and

only specifically trained personnel are allowed access to it.

- Do not disable any safety, notification or warning device and do not ignore any alarm, warning message or notice, no

matter whether they are generated automatically or represented by plates fixed to the equipment.

- Do not run the equipment with fixed protections not installed (panels etc.).

- In case of breaking, buckling or malfunctioning of the equipment or parts of it, repair or replace immediately.

- When replacing fuses, only use ones of the same type.

- The replacement of the batteries is an operation intended to be carried out by a skilled technician.

- Keep a register in which to enter the date, time, type, performer’s name and any other useful information about each

and any routine and extraordinary maintenance operation.

- Do not use oils or chemical products for cleaning because they could scratch, corrode or damage certain parts of the

equipment.

- The equipment and workplace must be kept completely clean.

- Upon completion of the maintenance operations, before connecting the power supply, carefully check that no tools

and/or material of any kind have been left next to the equipment.

INDICATION

The skilled technician must not leave at the disposal of the operator:

- the keys for opening the UPS door;

- the installation and maintenance manual.

2.7 How to proceed in an emergency

The following information are general. For the specific interventions consult the regulations in force in the country where

the equipment is installed.

2.7.1 First-aid procedures

When administering first aid, adhere to the company rules and the usual procedures.

2.7.2 Fire procedures

Do not use water to quench fires but just the extinguishers specially designed for putting out fires on electrical equipment.

11

Page 12

3. Transportation and placement

3.1 Visual check

On delivery of the UPS, carefully inspect the packaging and the equipment for any damage that might have occurred

during transport. Check there is no damage to the indicator on the outer label reading “Shock Watch”.

If there is possible or ascertained damage, immediately inform:

- the transporter;

- the LEGRAND Technical Support Service.

Check that the equipment corresponds with the items indicated in the delivery documentation.

If the UPS must be stored, follow the instructions of Chapter 7.

3.2 Equipment check

The equipment and the relative supplied accessories must be in perfect conditions.

Check that:

- the shipping data (address of the recipient, no. of packages, order no, etc.) correspond to what is contained in the deliv-

ery documentation;

- the technical rating plate data on the label applied to the UPS correspond with the material described in the delivery

documentation;

- the documentation accompanying the equipment includes the installation and user manuals.

In case of discrepancy, immediately inform the LEGRAND Technical Support Service before commissioning the equipment.

The content of the supply is subject to thorough checking before the shipment. Nonetheless it is always advisable to

check that it is complete and in order on receiving the material.

The following list is general:

- 1 UPS (empty cabinet) with keys to close the doors;

- 1 accessory box;

- user manual;

- installation and maintenance manual.

In case of defects and/or missing items, immediately inform the LEGRAND Technical Support Service before commissioning the equipment.

INDICATION

The installation manual must be used and consulted only by Skilled Technicians.

INDICATION

Power modules and battery drawers to be installed must be bought separately.

12

Page 13

Keor MOD

3.3 Transportation

WARNING

The UPS must be placed and stand in a vertical position throughout the transportation. It shall also be packed properly.

Move the UPS very carefully, lifting it as little as possible and avoiding dangerous swings or falls.

Follow always the directions indicated in the symbols present on the packaging.

The equipment must always be handled by trained and instructed personnel. Comply with the safety regulations in force

in your country relative to the usage of lifting equipment and/or accessories.

For any lifting, use a forklift or a transpallet with an adequate carrying capacity, placing the forks in the specific spaces of

the base and making sure they come out on the other side by at least twenty centimetres.

Installation and maintenance manual

Keor MOD UPS has four wheels at the bottom of the cabinet. Before installations and while it is still empty, it can be moved

by hand by at least two people.

CAUTION

Do not move the UPS after the installation or following the insertion of the power modules.

13

Page 14

3. Unpacking and moving

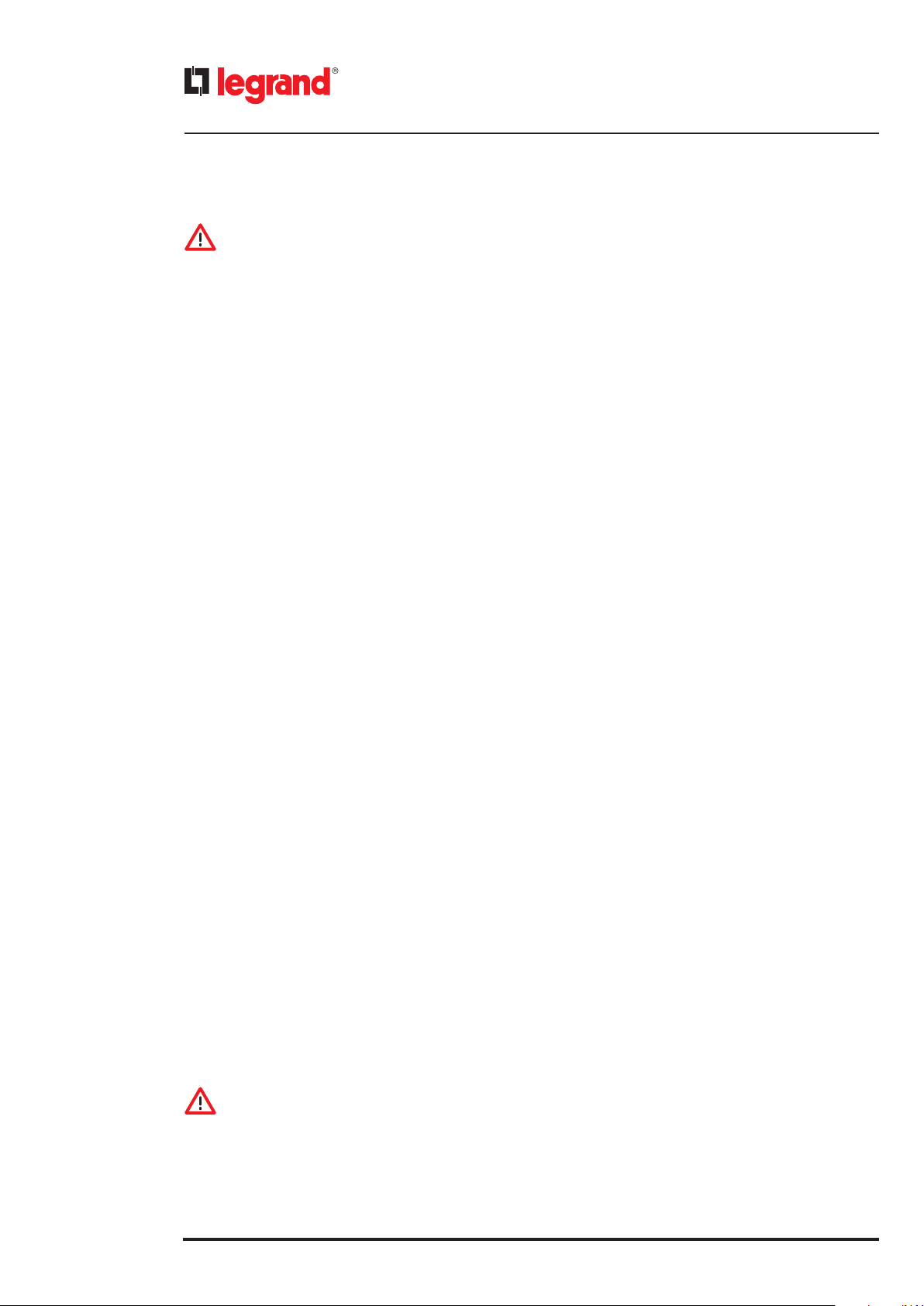

3.4 Unpacking

To remove the packaging material, two people are required and they must comply comply with the following procedure:

- bring the UPS to the installation site using a forklift and/or a transpallet with suitable characteristics (see fig. 1);

- remove the plastic film and cardboards protecting the UPS;

- bring down the wooden chute attached to the pallet (see fig. 2)

- loose the screws of the brackets that fix the equipment on the pallet (see fig. 3);

- gently slide by hand the equipment along the chute using the wheels (see fig. 4).

1

3

2

4

14

Page 15

Keor MOD

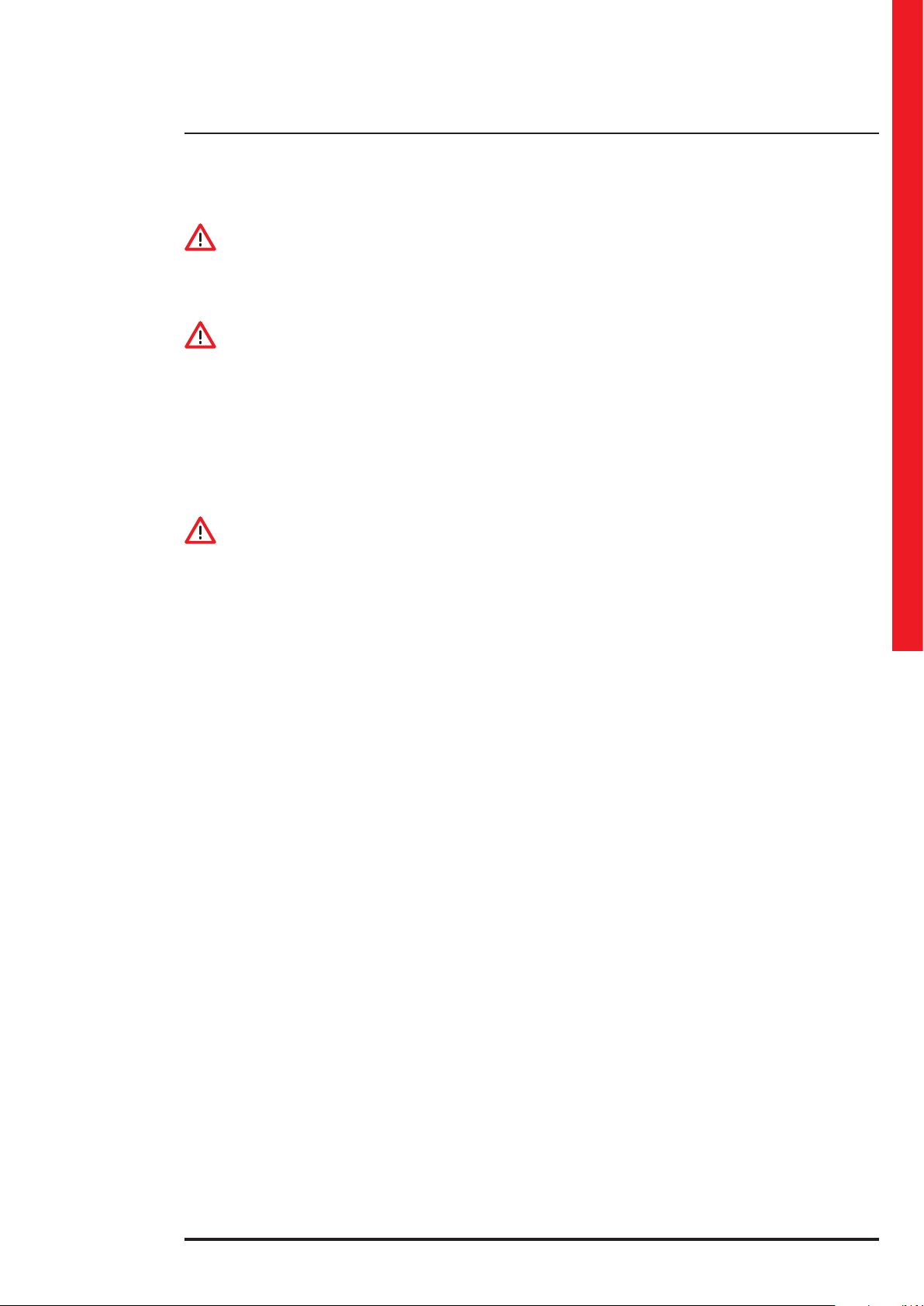

3.5 Placement

When the UPS is in the final position for the installation, unscrew counterclockwise the feet on the front and rear of the

cabinet to position it.

Make sure that all the wheels and feet adhere to the floor.

Installation and maintenance manual

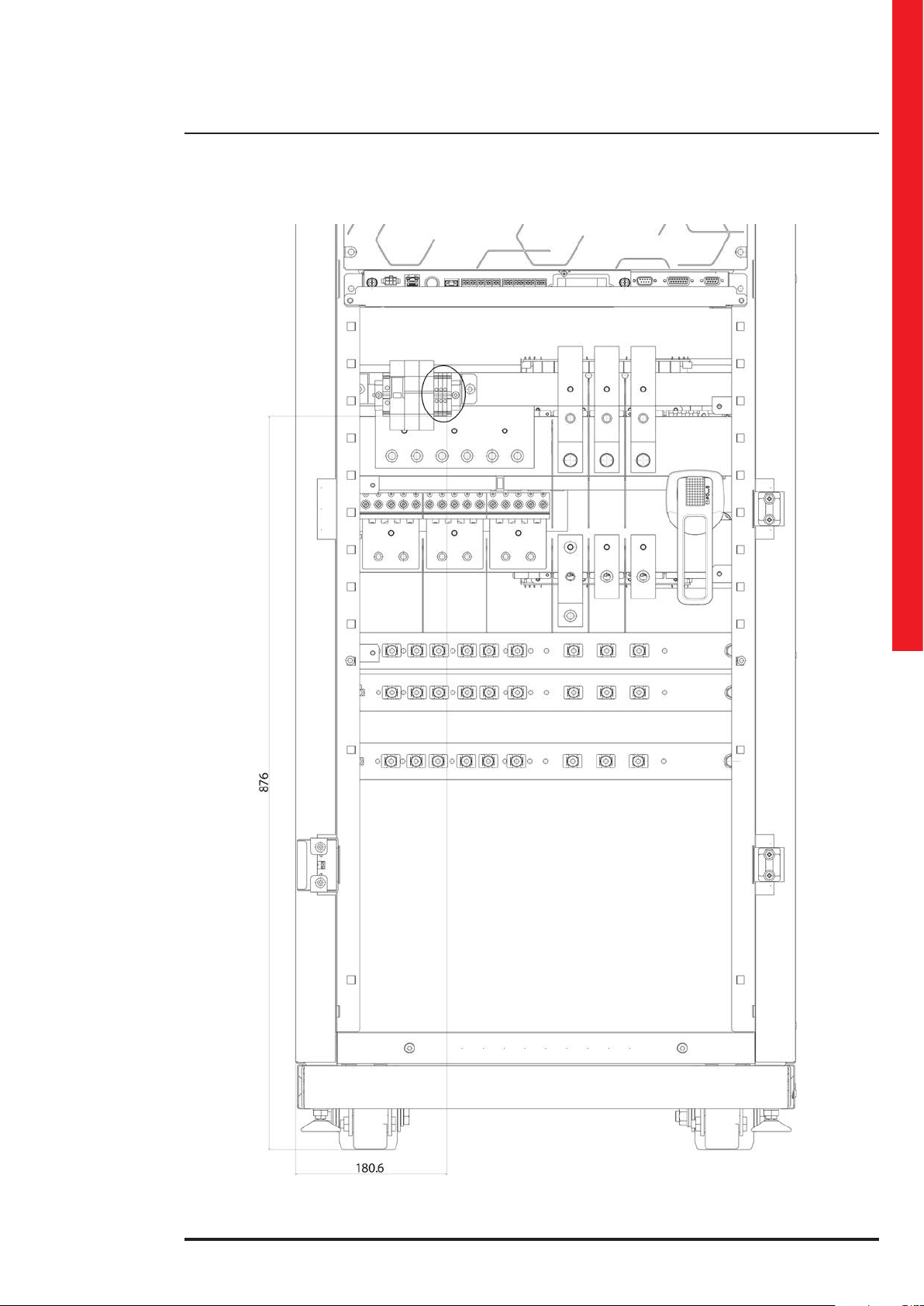

(all the dimensions are in mm)

15

Page 16

3. Unpacking and moving

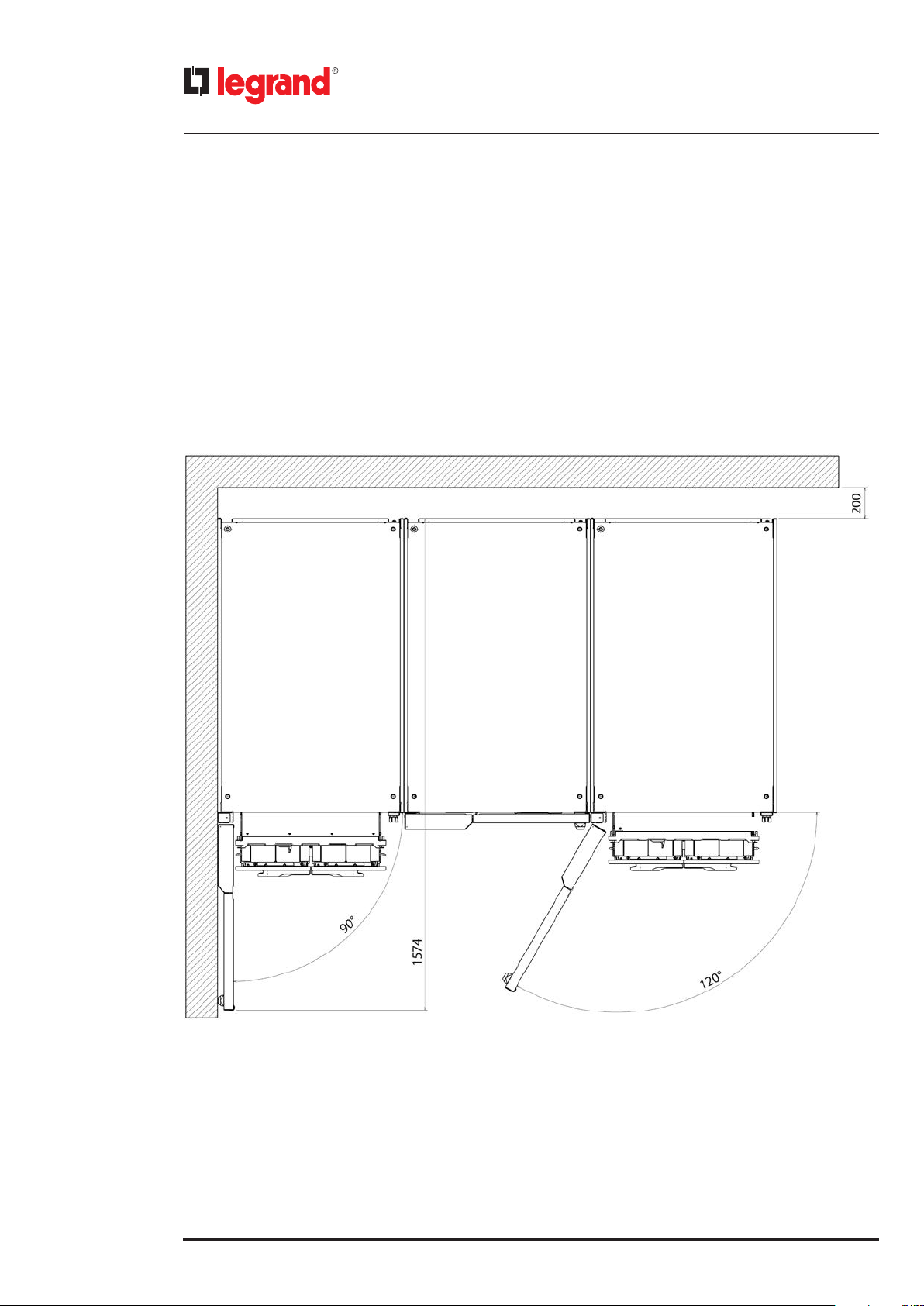

The UPS must be positioned respecting the following conditions:

- do not cover the cooling vents of the power modules and keep a clearance of 20 cm beyond the cabinets real panels;

- keep a clearance of 160 cm on the front to allow the opening of the door;

- temperature and humidity must be within permitted limits;

- fire regulations must be respected;

- the wiring must be simply made;

- front and rear accessibility must be available for assistance or periodic servicing;

- the cooling flow of air must be guaranteed;

- the air conditioning system must be adequately sized;

- dust, corrosive and explosive atmospheres must be absent;

- the installation site must be free of vibration;

- the support surface must be sized for the weight necessary to support the equipment:

- regulate the equipment feet to have perfect perpendicularity and level of the UPS compare with the floor.

16

POWER MODULE EXTRACTION

BATTERY DRAWERS EXTRACTION

POWER MODULE EXTRACTION

BATTERY DRAWERS EXTRACTION

To safeguard the batteries as well as possible it is necessary to bear in mind that their average lifetime is strongly influenced by the operating room temperature. Position the UPS in an environment with a temperature range between +20°C

(+68°F) and +25°C (+77°F) to guarantee the optimum life of the batteries.

Before proceeding with the installation operations, make sure that there is enough lighting to clearly see every detail.

Provide artificial lighting if the natural lighting does not satisfy this requirement.

In case of maintenance operations in places that are not sufficiently well lit, portable lighting systems must be used,

avoiding shadows that prevent or reduce visibility on the point where you intend to work or on the surrounding areas.

Page 17

Keor MOD

4. Installation

DANGER

All UPS installation operations must be carried out exclusively by a SKILLED TECHNICIAN qualified and authorized

by LEGRAND (paragraph 2.2.1).

4.1 Safety regulations

DANGER

Before carrying out any installation operation you must read and apply the following:

- The UPS has a high leakage current. The earthing connection must be connected before cabling the UPS input. The

switchgear must have a safe connection with the earthing and an adequate protection as required by the installation

standards.

- The UPS must only be installed in a fixed way with a thermal-magnetic circuit breaker placed upstream of it. Connection

to the mains via traditional type plug is not allowed.

- A circuit to protect from voltage backfeed made as in the diagrams shown in paragraph 4.2.5 must be provided outside

the UPS.

- The switchgear or the disconnector switch must be installed near the equipment and must be easily accessible.

- A warning label must be placed on all the mains disconnector switches installed away from the area of the UPS to remind the

assistance personnel of the fact that the circuit is connected to a UPS. The label must contain the following or equivalent text:

Installation and maintenance manual

Before working on this circuit

- Isolate Uninterruptible Power System (UPS)

- Then check for the presence of Hazardous Voltage

between all terminals including the protective earth

Risk of Voltage Backfeed

- Do not carry out the installation in presence of water or humidity.

- Open only the UPS panels necessary for the electrical connections. After that, close and fix them.

- Check there is no mains voltage on the equipment.

- Check that the loads are off and disconnected from the UPS.

- Check that the UPS is off and no voltage is present.

- Check that the fuse breakers on the external battery cabinets (if present) are open.

- Check that all battery drawers (if present) are not fully inserted in the UPS cabinet.

- Check that the mains input voltage and frequency correspond with the values indicated in the technical data on the

UPS rating plate.

- Check that the earthing has been carried out in compliance with IEC (International Electrotechnical Commission) stand-

ards or local regulations.

- Check that the electrical system has been fitted with the necessary differential and thermal-magnetic protections up-

stream of the UPS.

- The energy quality of the electrical network should comply with the individual voltage harmonics compatibility levels

defined by EN 61000-2-2. For more severe conditions, a power quality audit is required during the UPS commissioning

by the LEGRAND Technical Support Service in orded to check the compatibility.

4.2 Electrical connections

The electrical hook-up of the UPS to the switchgear or to the external battery cabinets is part of the installation that is not

normally performed by the UPS manufacturer. For this reason, the indications that follow are to be considered approximate and it is recommended that the electrical connections are based on local installation standards.

After removing the UPS from the packaging and positioning it in its definitive place, the Skilled Technician can begin to

make the electrical connections.

WARNING

The choice of cables type and their cross sections depending on the rated current and their installations must be made as

indicated by the local installation standards and it is a responsibility of the Skilled Technician.

The input current and the output power of the UPS are indicated in chapter 10 and the battery current in table 4 of chapter 11.

INDICATION

Chapter 11 includes tables with the recommended cables, fuses, automatic and differential breakers.

17

Page 18

4. Installation

4.2.1 Protective devices

To ensure proper protection from overloads, output short-circuits or electrical shocks, it is necessary to install adequate

automatic residual-current and thermal-magnetic breakers upstream of the UPS on the input line. In case there is a separate bypass line, the residual current earth leakage protection system must be common for the AC input and bypass lines

and must be installed upstream.

The protective devices must be selected according to the indications in the tables shown in chapter 11.

CAUTION

The equipment can cause a d.c. current in the PE conductor. Where a residual current-operated protective device (RCD) is

used for protection against electrical shock, only an RCD of Type B is allowed on the supply side of this product.

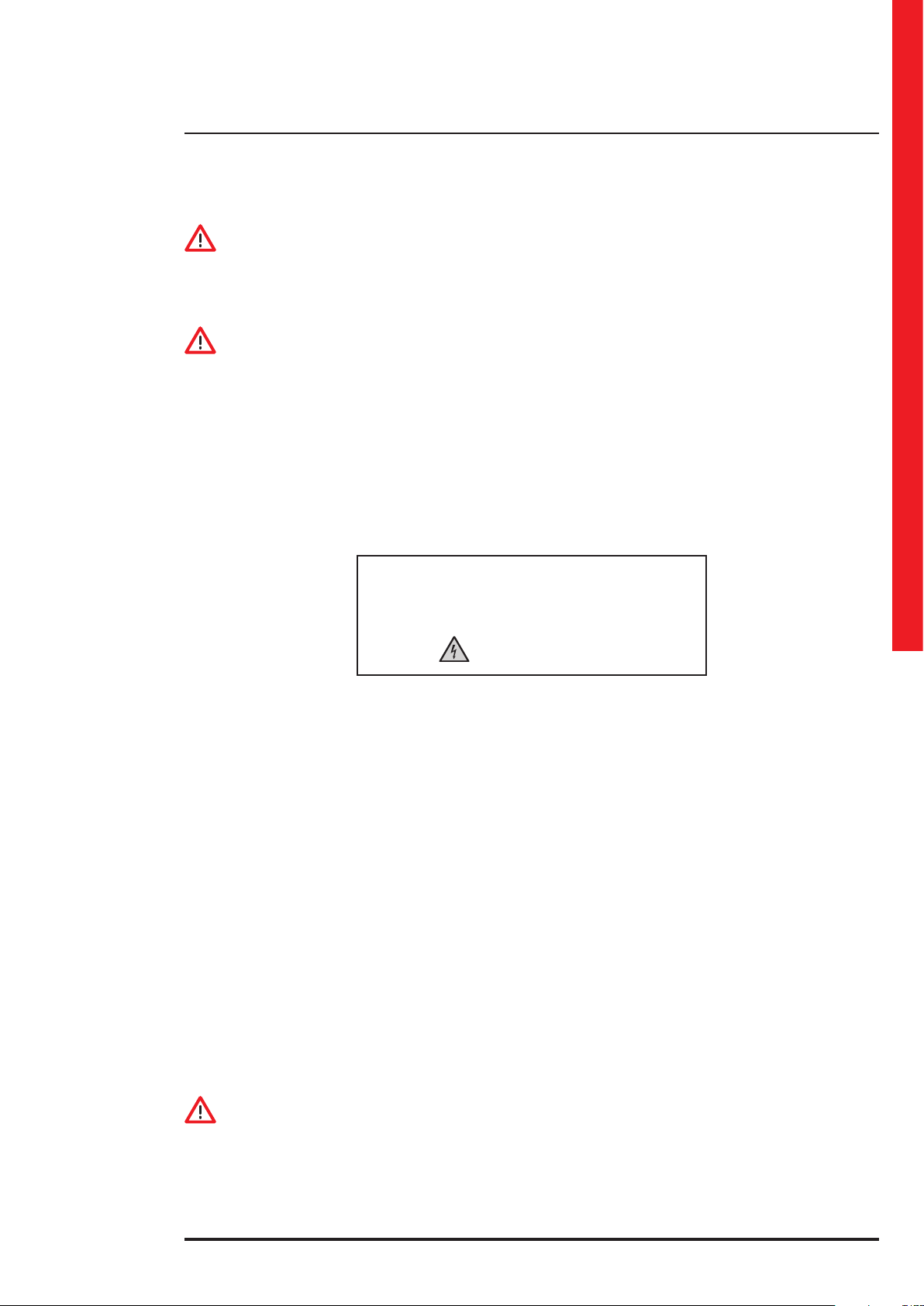

4.2.2 Disassembly of the distribution panel

To carry out all the electrical connection operations, it is necessary to unscrew the screws that fix the distribution panel

to the cabinet. The screws must be saved to close the distribution panel at the end of the installation (hex socket M6x20

screws along with M6 toothed washers).

Unscrew also the screws that fix the plexiglass protection panel and save them to close the panel and the end of the

installation (Phillips pan head M4x10 screws).

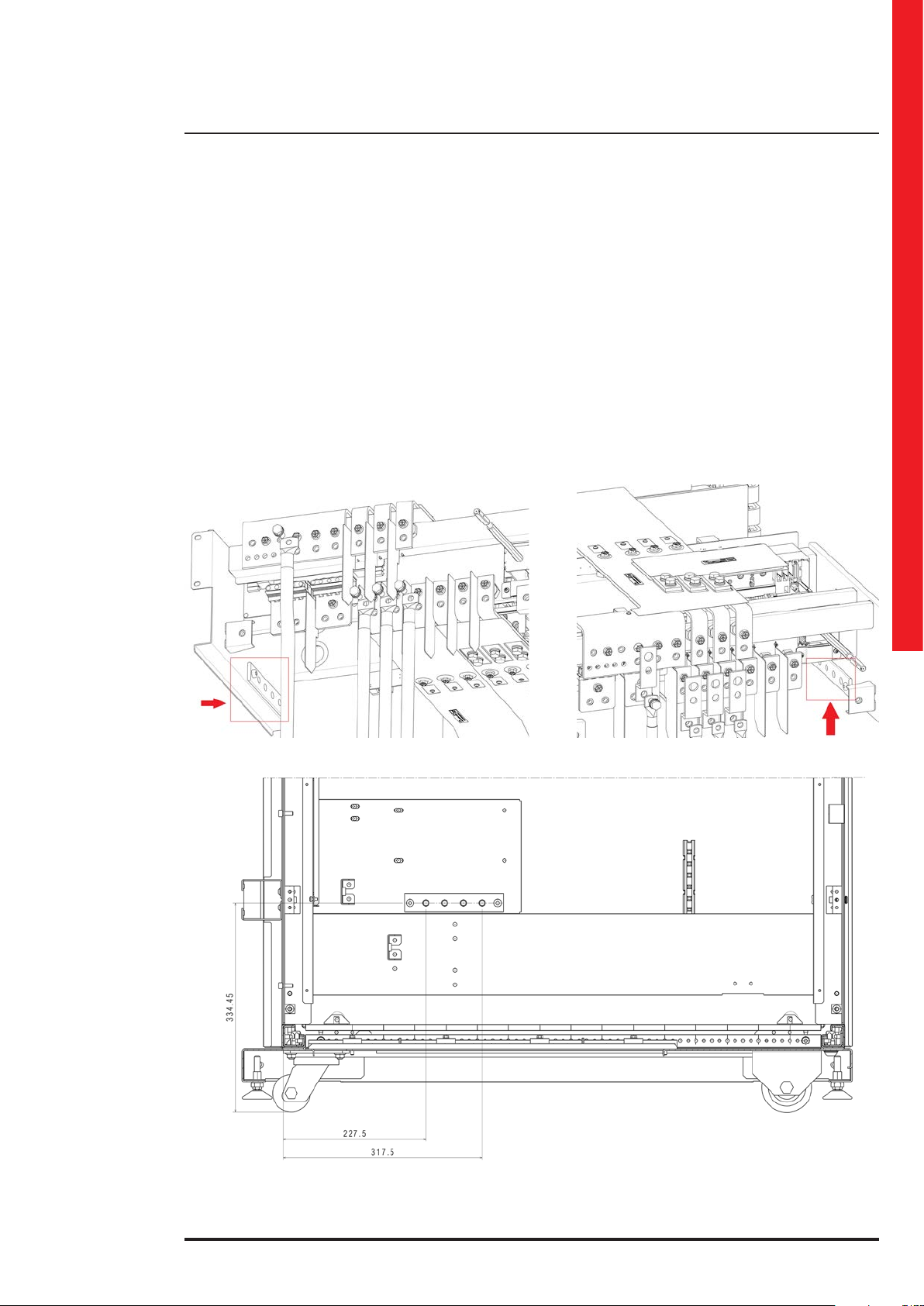

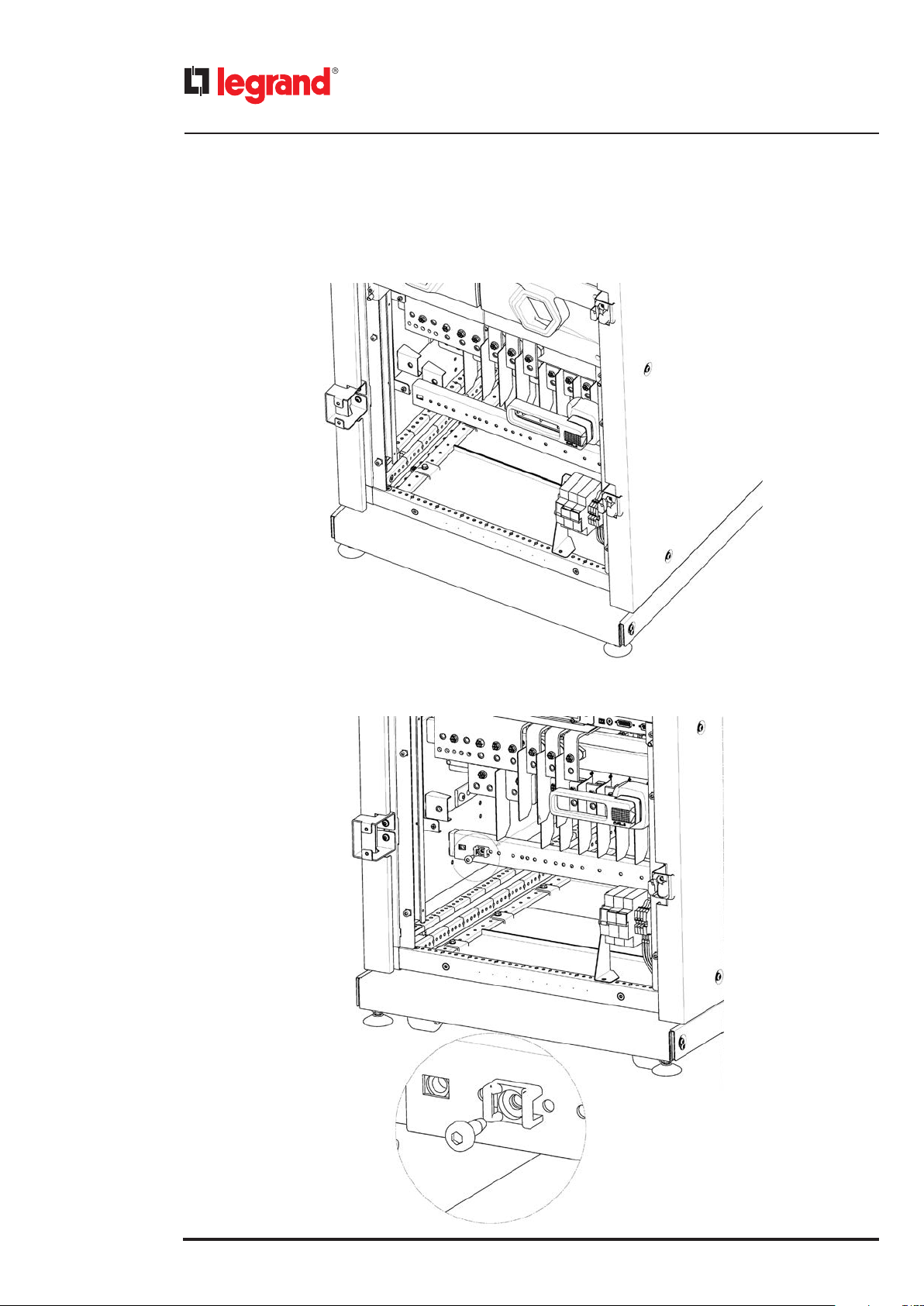

The following pictures show how to disassemble the panels:

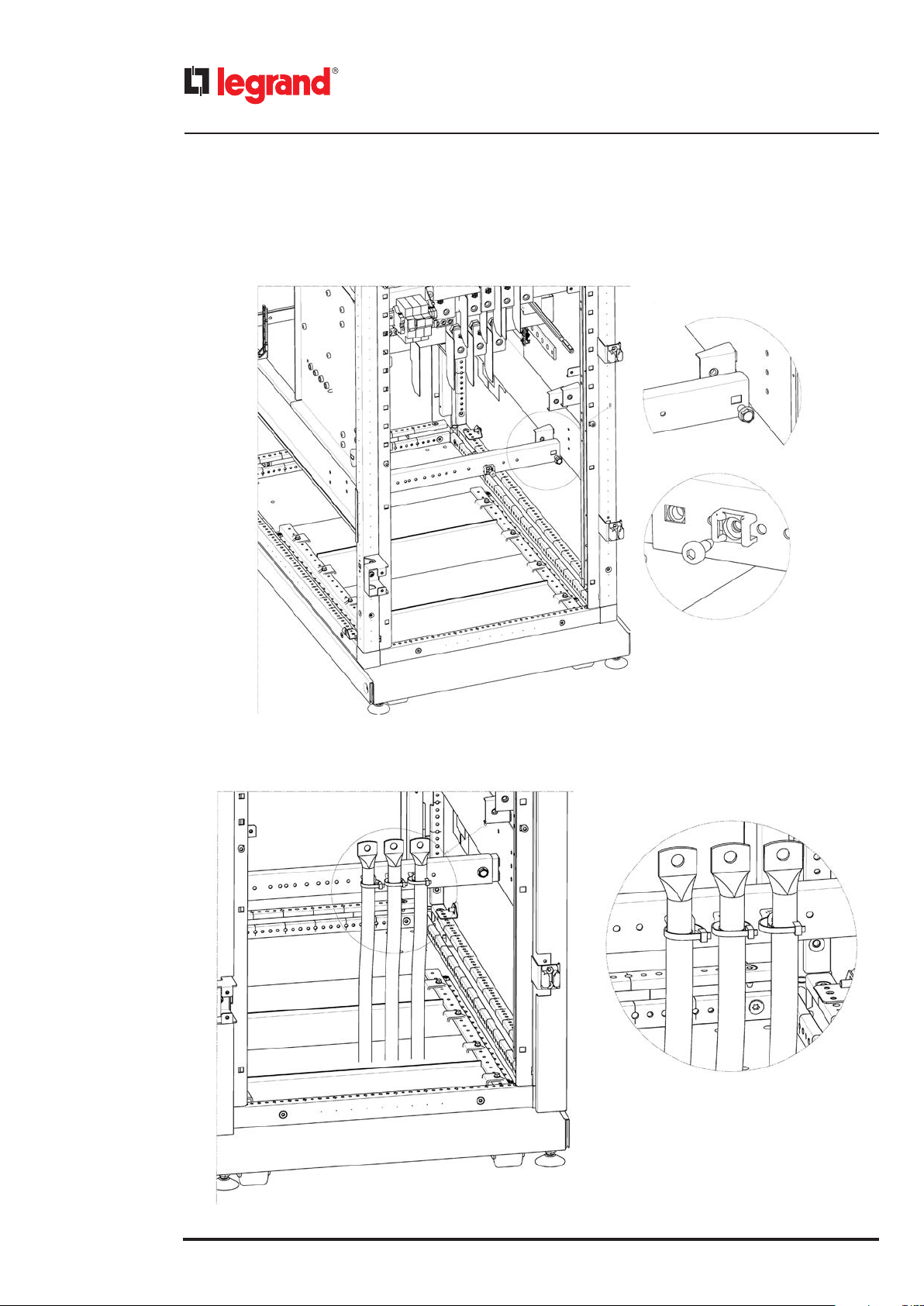

KEOR MOD 125

KEOR MOD 250

18

Page 19

Keor MOD

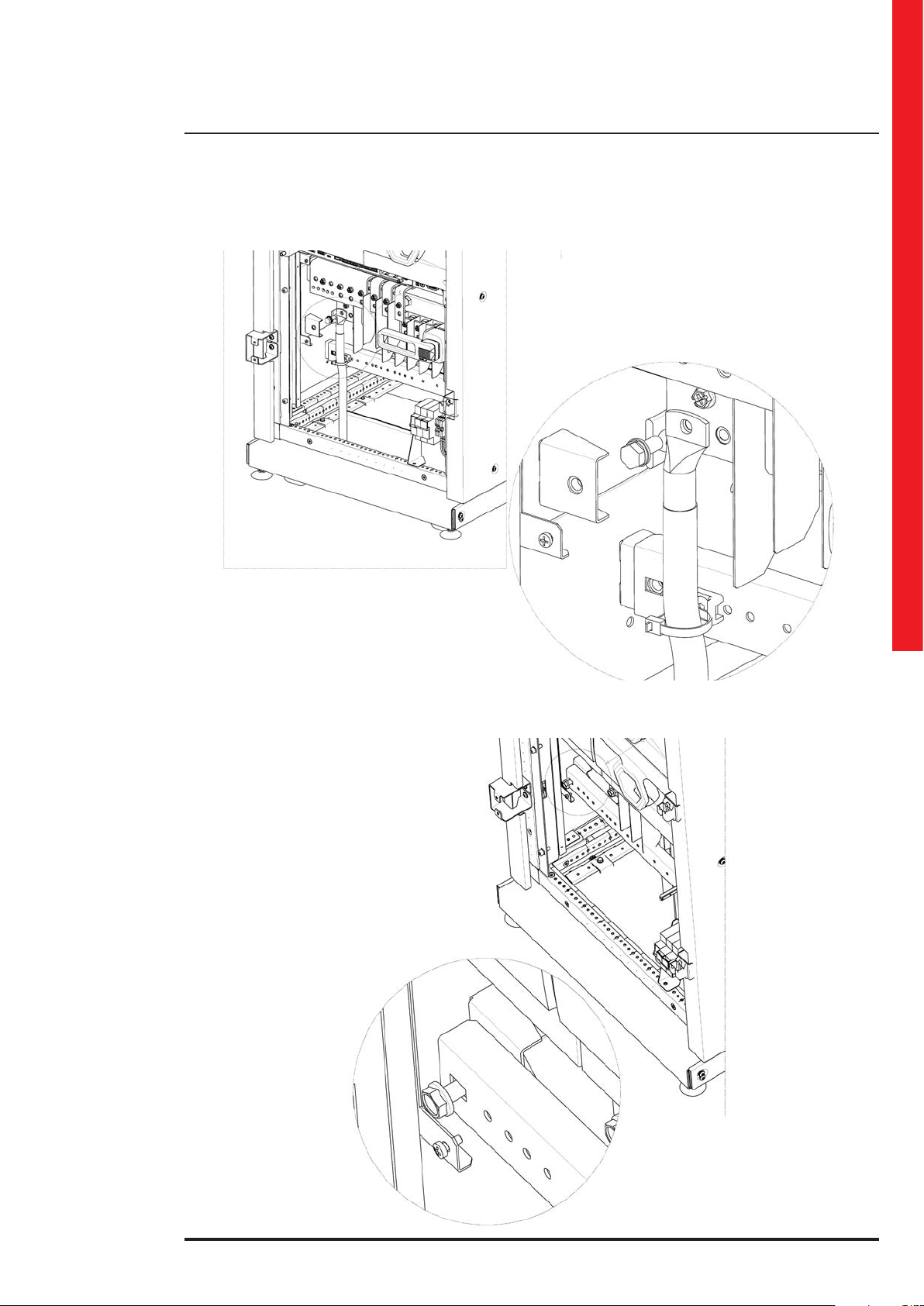

To insert the cables in the cabinet, it is necessary to remove the panels at the bottom of the cabinet according to the

following sequence:

1

2

Installation and maintenance manual

19

Page 20

4. Installation

3

4

20

5

Page 21

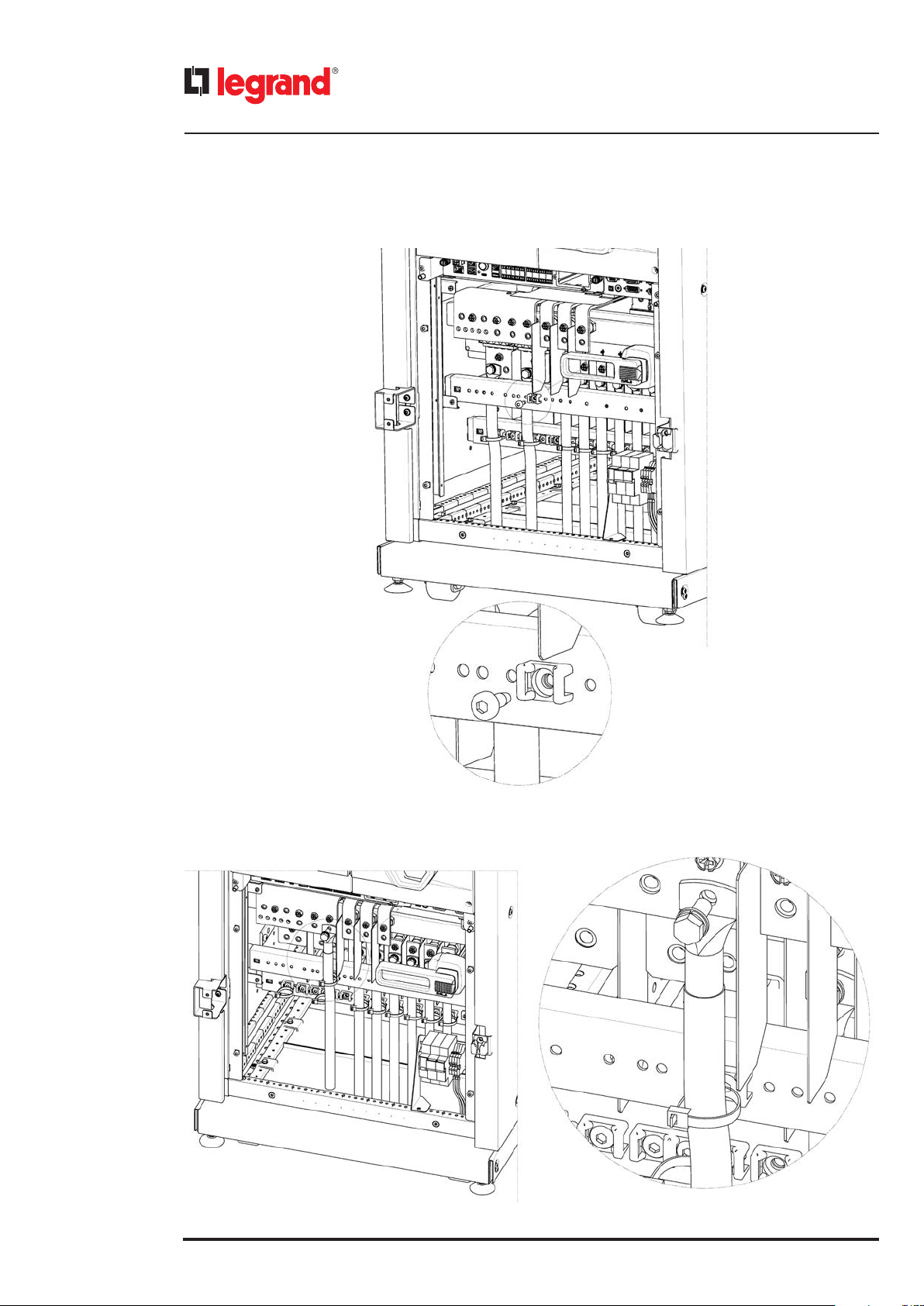

Insert the cable and add the panels according to the following sequence:

6

Keor MOD

Installation and maintenance manual

7

8

21

Page 22

4. Installation

9

10

22

Page 23

Keor MOD

4.2.3 Earthing connection

Before carrying out any other installation operation, connect the earthing wiring coming from the low voltage switchgear

to one of the earthing bars located on the left and right side of the busbars connection system.

The minimum cross-sectional area of the earthing conductor must be chosen according to the following criteria:

• if the cross-sectional area S of the phase conductors is S ≤ 16 mm2, the minimum cross-sectional area of the earthing

conductor must be the same as the phase conductors;

• if the cross-sectional area S of the phase conductors is 16 mm2 < S ≤ 35 mm2, the minimum cross-sectional area of the

earthing conductor must be16 mm

• if the cross-sectional area S of the phase conductors is S > 35 mm2, the minimum cross-sectional area of the earthing

conductor must be S/2 mm

Each earthing cable must be crimped with M8 eyelets and fixed to the earthing metal bar using hex M8x20 screws along

with M8 flat washers and M8 grower washer.

The grower washer must be put on the top of the flat washer.

2

;

2

.

Installation and maintenance manual

KEOR MOD 125 – earthing bars

23

Page 24

4. Installation

24

KEOR MOD 250 – earthing bars

Page 25

Keor MOD

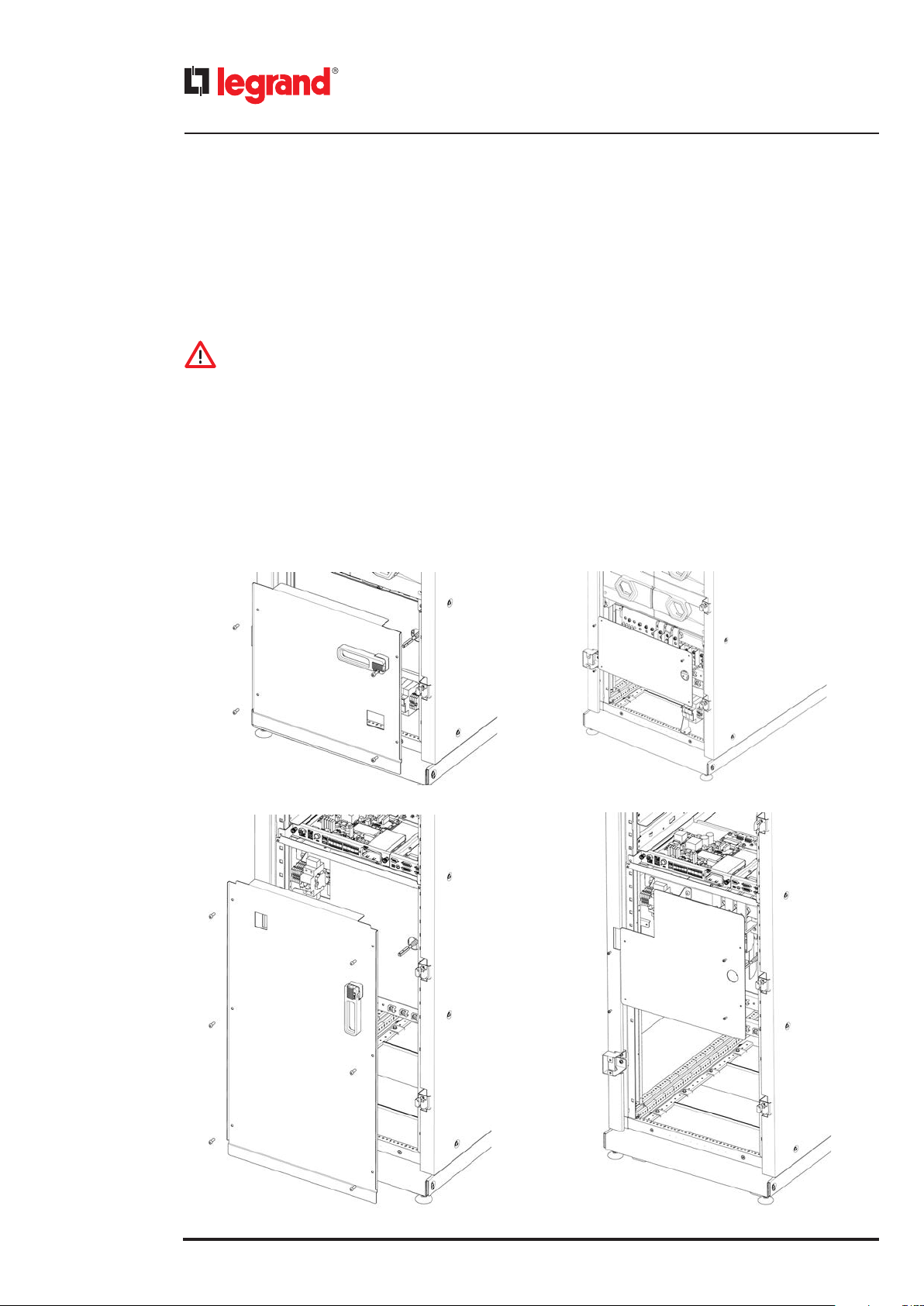

4.2.4 Cable fastening

In the accessory box there are two metal bars for Keor MOD 125 and three metal bars for Keor MOD 250. They are used

along with the plastic supports for cable ties to fasten the installation cables.

Each bar must be fixed to the cabinet using two hex M8x14 screws.

The plastic supports for the cable ties must be fixed on the bar using the M6 torx pan head screws.

Installation and maintenance manual

(all the dimensions are in mm)

KEOR MOD 125 – view of the two metal bars for cable fastening

25

Page 26

4. Installation

The fastening of the battery, input and output cables on Keor MOD 125 must be done according to the following steps:

1) Fix the first metal bar to the cabinet, behind the surge arrester and the fuse holders, using two hex M8x14 screws.

2) Fix the plastic supports for cable ties using M6 torx pan head screws.

26

Page 27

3) Fix the cables with cable ties.

Keor MOD

Installation and maintenance manual

The fastening of the neutral and output cables on Keor MOD 125 must be done according to the following steps:

1) Fix the second metal bar to the cabinet, close to the maintenance manual bypass switch, using two hex M8x14 screws.

27

Page 28

4. Installation

2) Fix the plastic support for cable ties using M6 torx pan head screws.

28

3) Fix the cables with cable ties.

Page 29

Keor MOD

Installation and maintenance manual

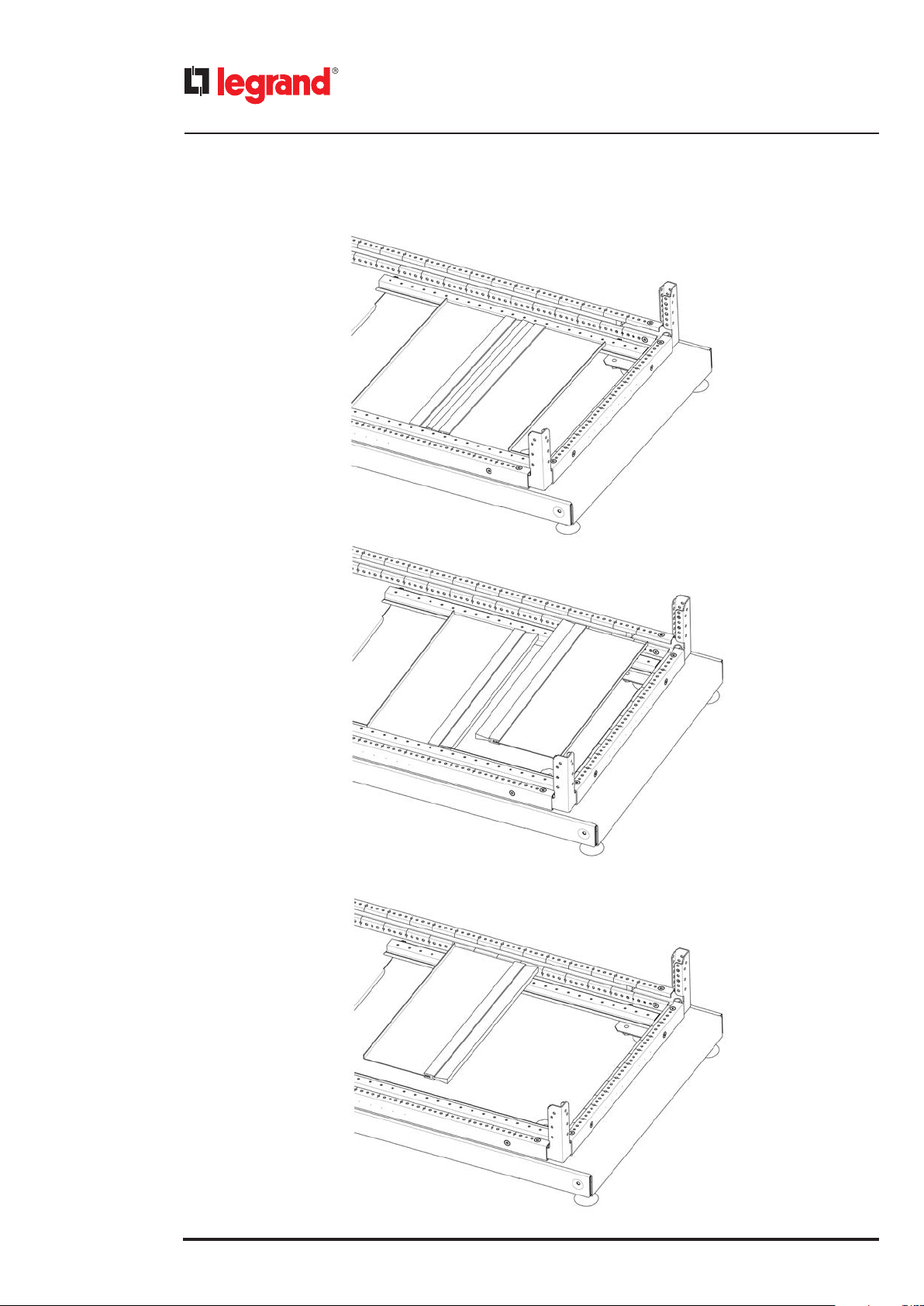

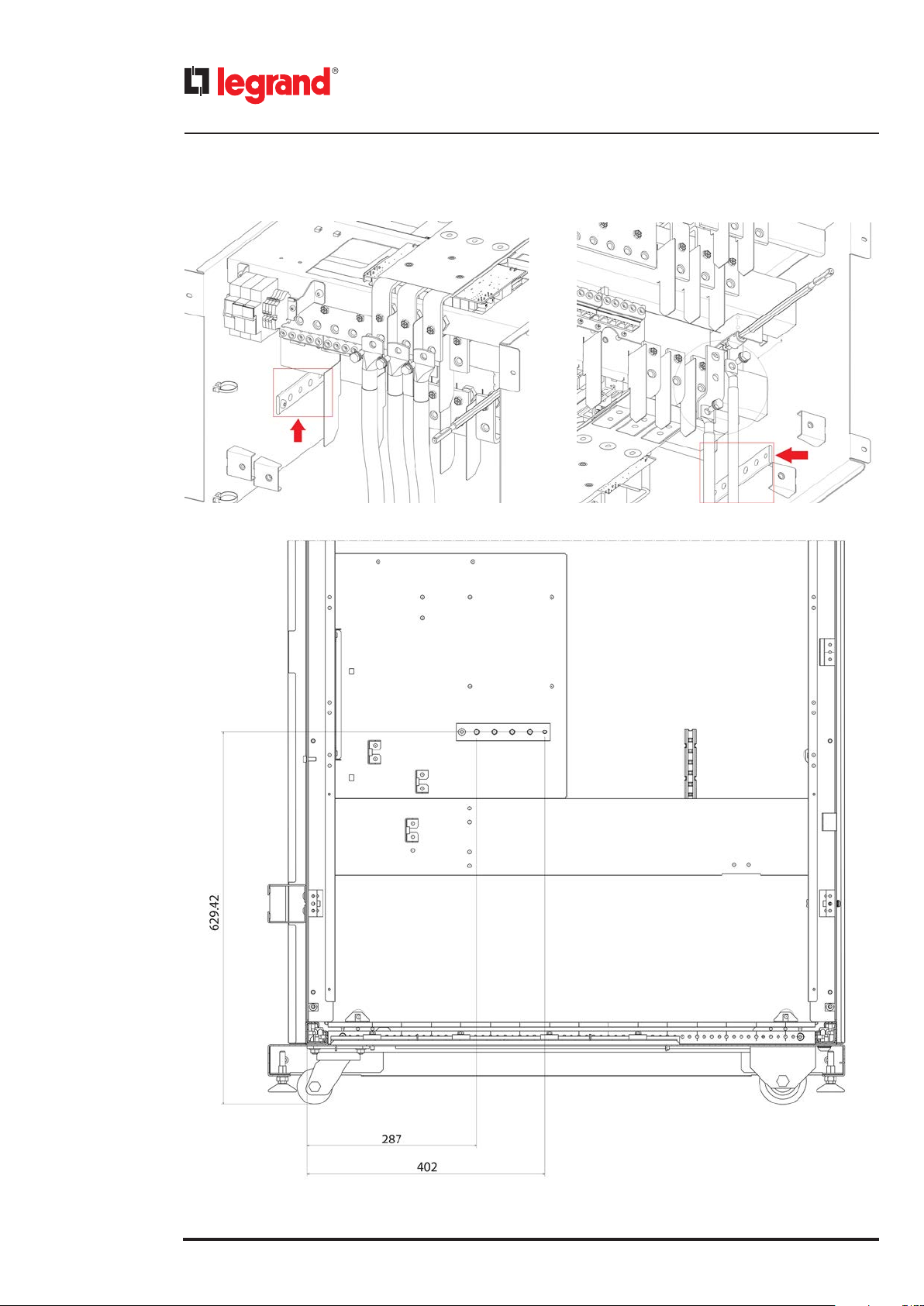

(all the dimensions are in mm)

KEOR MOD 250 – view of the three metal bars for cable fastening

29

Page 30

4. Installation

The fastening of the battery and output cables on Keor MOD 250 must be done according to the following steps:

1) Fix the first metal bar at the bottom of the cabinet using two hex M8x14 screws. Then fix the plastic support for the

cable ties using M6 torx pan head screws.

2) Fix the cable with cable ties.

30

Page 31

Keor MOD

The fastening of the neutral and bypass cables on Keor MOD 250 must be done according to the following steps:

1) Fix the second metal bar above the first bar using two hex M8x14 screws. Then fix the plastic support for the cable ties

using M6 torx pan head screws.

Installation and maintenance manual

2) Fix the cable with cable ties.

31

Page 32

4. Installation

The fastening of the input cables on Keor MOD 250 must be done according to the following steps:

1) Fix the third metal bar above the second bar using two hex M8x14 screws. Then fix the plastic support for the cable

ties using M6 torx pan head screws.

2) Fix the cable with cable ties.

32

Page 33

The tightening torque values for the cables are the following:

- M8 screws: 24 Nm

- M6 nuts: 15 Nm

- M10 nuts: 35 Nm

Keor MOD

Installation and maintenance manual

KEOR MOD 125

KEOR MOD 250

33

Page 34

4. Installation

4.2.5 Backfeed protection

An external protection against voltage backfeed must be provided according to the following diagrams:

34

Page 35

Keor MOD

4.2.6 Input cables installation

The default configuration has the input line in common with the bypass line through a metal jumper.

Before the installation of the input cables, check the following:

- the mains line must be able to provide an input voltage of 400 V + 15% - 20%;

- the available mains power must be at least the same of the UPS nominal power;

- the cables to connect to the UPS must be isolated upstream and no voltage must be present;

- the earthing cable from the low voltage switchgear must be properly connected (see paragraph 4.2.3).

WARNING

The neutral input cable must always be connected.

KEOR MOD 125

The default configuration has the input line in common with the bypass line through a metal jumper.

If no change is required, follow these steps:

- unscrew the three hex M8x25 screws that fix the jumper to the bypass terminal of the busbar;

- crimp the input and neutral cables with M8 eyelets;

- connect the input cables L1, L2, L3 to the metal jumper of the terminals BYP L1, BYP L2, BYP L3 of the bypass busbar

using the three screws removed previously along with M8 flat washers and M8 grower washers. The grower washer must

always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the input neutral cable to the neutral busbar with a hex M8x20 screw along with a M8 flat washer and a M8

grower washer. The grower washer must always be put on top of the flat washer.

Installation and maintenance manual

35

Page 36

4. Installation

36

KEOR MOD 125 – input cables installation with input line in common with bypass line

In case the input line is separated from the bypass line, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the input and neutral cables with M8 eyelets;

- connect the input cables L1, L2, L3 to the terminals IN L1, IN L2, IN L3 of the input busbar using three hex M8x20 screws

along with M8 flat washers and M8 grower washers. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the input neutral cable to the neutral busbar with a hex M8x20 screw along with a M8 flat washer and a M8

grower washer. The grower washer must always be put on top of the flat washer.

Page 37

Keor MOD

Installation and maintenance manual

KEOR MOD 125 – input cables installation with input line separated from the bypass line

When the input line is separated from the bypass line, it is also possible to install an accessory for double cable. In this way

it is possible for each terminal to use two cables with a smaller cross section than the one of a single cable.

For this installation, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the input and neutral cables with M8 eyelets;

- connect the first three input cables L1, L2, L3 to the hole at the bottom of the accessory for double cable using three hex M8x20

screws along with M8 flat washers and M8 grower washers. The grower washer must always be put on top of the flat washer;

- connect the other three input cables L1, L2, L3 to the hole at the top of the accessory for double cable using three hex

M8x25 screws along with M8 flat washers and M8 grower washers. Through these screws, fix the accessories to the terminals IN L1, IN L2, IN L3 of the input busbar. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the first neutral cable to the hole at the bottom of the accessory for double cable using a hex M8x20 screw

along with a M8 flat washer and a M8 grower washer. The grower washer must always be put on top of the flat washer;

- connect the second neutral cable to the hole at the top of the accessory for double cable using a hex M8x25 screw along

with M8 flat washer and M8 grower washer. Through this screw, fix the accessory to the terminal of the neutral busbar. The

grower washer must always be put on top of the flat washer.

KEOR MOD 125 – input cables installation with accessories for double cable and input line separated from the bypass line

37

Page 38

4. Installation

KEOR MOD 250

The default configuration has the input line in common with the bypass line through a metal jumper.

If no change is required, follow these steps:

- unscrew the three hex M10x35 screws that fix the jumper to the input terminal of the busbar;

- crimp the input and neutral cables with M10 eyelets;

- connect the input cables L1, L2, L3 to the metal jumper of the terminals IN L1, IN L2, IN L3 of the input busbar using the

three screws removed previously along with M10 flat washers and M10 grower washers. The grower washer must always

be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the input neutral cable to the neutral busbar with a hex M10x30 screw along with a M10 flat washer and a M10

grower washer. The grower washer must always be put on top of the flat washer.

38

KEOR MOD 250 – input cables installation with input line in common with bypass line

Page 39

Keor MOD

In case the input line is separated from the bypass line, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the input and neutral cables with M10 eyelets;

- connect the input cables L1, L2, L3 to the terminals IN L1, IN L2, IN L3 of the input busbar using three hex M10x30 screws

along with M10 flat washers and M10 grower washers. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the input neutral cable to the neutral busbar with a hex M10x30 screw along with a M10 flat washer and a M10

grower washer. The grower washer must always be put on top of the flat washer.

Installation and maintenance manual

KEOR MOD 250 – input cables installation with input line separated from the bypass line

39

Page 40

4. Installation

When the input line is separated from the bypass line, it is also possible to install an accessory for double cable. In this way

it is possible for each terminal to use two cables with a smaller cross section than the one of a single cable.

For this installation, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the input and neutral cables with M10 eyelets;

- connect the first three input cables L1, L2, L3 to the hole at the bottom of the accessory for double cable using three hex

M10x30 screws along with M10 flat washers and M10 grower washers. The grower washer must always be put on top

of the flat washer;

- connect the other three input cables L1, L2, L3 to the hole at the top of the accessory for double cable using three hex

M10x35 screws along with M10 flat washers and M10 grower washers. Through these screws, fix the accessories to the

terminals IN L1, IN L2, IN L3 of the input busbar. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the first input neutral cable to the hole at the bottom of the accessory for double cable using a hex M10x30

screw along with a M10 flat washer and a M10 grower washer. The grower washer must always be put on top of the flat

washer;

- connect the second input neutral cable to the hole at the top of the accessory for double cable using a hex M10x35

screw along with M10 flat washer and M10 grower washer. Through this screw, fix the accessory to the terminal of the

neutral busbar. The grower washer must always be put on top of the flat washer.

40

KEOR MOD 250 – input cables installation with accessories for double cable

and input line separated from the bypass line

Page 41

4.2.7 Bypass cables installation

The default configuration has the input line in common with the bypass line through a metal jumper.

If no change is required, follow the steps indicated in the previous paragraph.

Keor MOD

To perform a dual input installation with a separate bypass line, the following requirements must be met:

- the two lines must be supplied by the same MV/LV transformer source (same electrical potential). If this is not the case,

an insulation transformer should be added in the bypass line upstream the UPS;

- separate protective devices are required for each line.

The UPS does not modify the neutral configuration of the system. The mains, bypass and output neutral are connected

internally to each other.

Before the installation of the bypass cables, check the following:

- the bypass line must be able to provide a voltage of 400 V + 15% - 20%;

- the available bypass power must be at least the same of the UPS nominal power;

- the cables to connect to the UPS must be isolated upstream and no voltage must be present;

- the earthing cable from the low voltage switchgear must be properly connected (see paragraph 4.2.3).

WARNING

The neutral bypass cable must always be connected.

KEOR MOD 125

In case the bypass line is separated from the input line, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the bypass and neutral cables with M8 eyelets;

- connect the bypass cables L1, L2, L3 to the terminals BYP L1, BYP L2, BYP L3 of the bypass busbar using three hex M8x20

screws along with M8 flat washers and M8 grower washers. The grower washer must always be put on top of the flat

washer;

- do not change the phase sequence (L1, L2, L3);

- connect the bypass neutral cable to the neutral busbar with a hex M8x20 screw along with a M8 flat washer and a M8

grower washer. The grower washer must always be put on top of the flat washer.

Installation and maintenance manual

KEOR MOD 125 – bypass cables installation with input line separated from the bypass line

41

Page 42

4. Installation

When the input line is separated from the bypass line, it is also possible to install an accessory for double cable. In this way

it is possible for each terminal to use two cables with a smaller cross section than the one of a single cable.

For this installation, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the bypass and neutral cables with M8 eyelets;

- connect the first three bypass cables L1, L2, L3 to the hole at the bottom of the accessory for double cable using three

hex M8x20 screws along with M8 flat washers and M8 grower washers. The grower washer must always be put on top

of the flat washer;

- connect the other three bypass cables L1, L2, L3 to the hole at the top of the accessory for double cable using three

hex M8x25 screws along with M8 flat washers and M8 grower washers. Through these screws, fix the accessories to the

terminals BYP L1, BYP L2, BYP L3 of the input busbar. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the first bypass neutral cable to the hole at the bottom of the accessory for double cable using a hex M8x20

screw along with a M8 flat washer and a M8 grower washer. The grower washer must always be put on top of the flat

washer;

- connect the second bypass neutral cable to the hole at the top of the accessory for double cable using a hex M8x25

screw along with M8 flat washer and M8 grower washer. Through this screw, fix the accessory to the terminal of the

neutral busbar. The grower washer must always be put on top of the flat washer.

42

KEOR MOD 125 – bypass cables installation with accessories for double cable

and input line separated from the bypass line

KEOR MOD 250

In case the bypass line is separate from the bypass line, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the bypass and neutral cables with M10 eyelets;

- connect the bypass cables L1, L2, L3 to the terminals BYP L1, BYP L2, BYP L3 of the bypass busbar using three hex M10x30

screws along with M10 flat washers and M10 grower washers. The grower washer must always be put on top of the flat

washer;

- do not change the phase sequence (L1, L2, L3);

- connect the bypass neutral cable to the neutral busbar with a hex M10x30 screw along with a M10 flat washer and a M10

grower washer. The grower washer must always be put on top of the flat washer.

Page 43

Keor MOD

Installation and maintenance manual

KEOR MOD 250 – bypass cables installation with input line separated from the bypass line

43

Page 44

4. Installation

When the bypass line is separated from the input line, it is also possible to install an accessory for double cable. In this way

it is possible for each terminal to use two cables with a smaller cross section than the one of a single cable.

For this installation, follow these steps:

- remove the metal jumper that connects the input line with the bypass line;

- crimp the bypass and neutral cables with M10 eyelets;

- connect the first three bypass cables L1, L2, L3 to the hole at the bottom of the accessory for double cable using three

hex M10x30 screws along with M10 flat washers and M10 grower washers. The grower washer must always be put on

top of the flat washer;

- connect the other three bypass cables L1, L2, L3 to the hole at the top of the accessory for double cable using three hex

M10x35 screws along with M10 flat washers and M10 grower washers. Through these screws, fix the accessories to the

terminals BYP L1, BYP L2, BYP L3 of the bypass busbar. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the first bypass neutral cable to the hole at the bottom of the accessory for double cable using a hex M10x30

screw along with a M10 flat washer and a M10 grower washer. The grower washer must always be put on top of the flat

washer;

- connect the second bypass neutral cable to the hole at the top of the accessory for double cable using a hex M10x35

screw along with M10 flat washer and M10 grower washer. Through this screw, fix the accessory to the terminal of the

neutral busbar. The grower washer must always be put on top of the flat washer.

44

Page 45

Keor MOD

Installation and maintenance manual

KEOR MOD 250 – bypass cables installation with accessories for double cable

and input line separated from the bypass line

4.2.8 Output cables installation

Before the installation of the output cables, check the following:

- the nominal power of the UPS must be at least the same of the nominal power of the load;

- the cables to connect to the UPS must be isolated upstream and no voltage must be present;

- the earthing cable from the low voltage switchgear must be properly connected (see paragraph 4.2.3).

INDICATION

Provide a separate switchgear for the load.

The following information must be indicated on the system switchgear by means of stickers or similar:

- maximum nominal power of the load;

- maximum nominal power of the load at the load outlets;

- if a common switchgear is used (mains and UPS power outlets), make sure that there is an indication of the power source

on every power outlet (“Mains” or “UPS”).

WARNING

The neutral output cable must always be connected.

KEOR MOD 125

Follow these steps:

- crimp the output and neutral cables with M8 eyelets;

- connect the output cables L1, L2, L3 to the terminals OUT L1, OUT L2, OUT L3 of the output busbar using three hex

M8x20 screws along with M8 flat washers and M8 grower washers. The grower washer must always be put on top of the

flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the output neutral cable to the neutral busbar with a hex M8x20 screw along with a M8 flat washer and a M8

grower washer. The grower washer must always be put on top of the flat washer.

45

Page 46

4. Installation

KEOR MOD 125 – output cables installation

It is also possible to install an accessory for double cable. In this way it is possible for each terminal to use two cables with

a smaller cross section than the one of a single cable.

For this installation, follow these steps:

- crimp the output and neutral cables with M8 eyelets;

- connect the first three output cables L1, L2, L3 to the hole at the bottom of the accessory for double cable using three hex M8x20

screws along with M8 flat washers and M8 grower washers. The grower washer must always be put on top of the flat washer;

- connect the other three output cables L1, L2, L3 to the hole at the top of the accessory for double cable using three hex

M8x25 screws along with M8 flat washers and M8 grower washers. Through these screws, fix the accessories to the terminals OUT L1, OUT L2, OUT L3 of the input busbar. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the first output neutral cable to the hole at the bottom of the accessory for double cable using a hex M8x20 screw

along with a M8 flat washer and a M8 grower washer. The grower washer must always be put on top of the flat washer;

- connect the second output neutral cable to the hole at the top of the accessory for double cable using a hex M8x25 screw

along with M8 flat washer and M8 grower washer. Through this screw, fix the accessory to the terminal of the neutral busbar. The grower washer must always be put on top of the flat washer.

46

KEOR MOD 125 – output cables installation with accessories for double cable

Page 47

Keor MOD

KEOR MOD 250

Follow these steps:

- crimp the output and neutral cables with M10 eyelets;

- connect the output cables L1, L2, L3 to the terminals OUT L1, OUT L2, OUT L3 of the output busbar using three hex M10x30

screws along with M10 flat washers and M10 grower washers. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the output neutral cable to the neutral busbar with a hex M10x30 screw along with a M10 flat washer and a M10

grower washer. The grower washer must always be put on top of the flat washer.

Installation and maintenance manual

KEOR MOD 250 – output cables installation

47

Page 48

4. Installation

It is also possible to install an accessory for double cable. In this way it is possible for each terminal to use two cables with

a smaller cross section than the one of a single cable.

For this installation, follow these steps:

- crimp the output and neutral cables with M10 eyelets;

- connect the first three output cables L1, L2, L3 to the hole at the bottom of the accessory for double cable using three hex M10x30

screws along with M10 flat washers and M10 grower washers. The grower washer must always be put on top of the flat washer;

- connect the other three output cables L1, L2, L3 to the hole at the top of the accessory for double cable using three hex

M10x35 screws along with M10 flat washers and M10 grower washers. Through these screws, fix the accessories to the

terminals OUT L1, OUT L2, OUT L3 of the output busbar. The grower washer must always be put on top of the flat washer;

- do not change the phase sequence (L1, L2, L3);

- connect the first output neutral cable to the hole at the bottom of the accessory for double cable using a hex M10x30 screw

along with a M10 flat washer and a M10 grower washer. The grower washer must always be put on top of the flat washer;

- connect the second output neutral cable to the hole at the top of the accessory for double cable using a hex M10x35

screw along with M10 flat washer and M10 grower washer. Through this screw, fix the accessory to the terminal of the

neutral busbar. The grower washer must always be put on top of the flat washer.

48

Page 49

Keor MOD

Installation and maintenance manual

KEOR MOD 250 – output cables installation with accessories for double cable

4.2.9 Battery cables installation

The default configuration has the strings of batteries in common.

Before the installation of the input cables, check the following:

- the fuse breakers of all the external battery cabinets must be open;

- the cables to connect to the UPS must be isolated upstream and no voltage must be present;

- the earthing cable from the low voltage switchgear must be properly connected (see paragraph 4.2.3).

WARNING

The neutral battery cable must always be connected.

49

Page 50

4. Installation

KEOR MOD 125

The default configuration has the strings of batteries in common.

KEOR MOD 125 – battery terminals

If no change is required, follow these steps:

- crimp the positive, negative and neutral battery cables with M8 eyelets;

- connect the positive cable of the battery cabinet to the + BATT terminal using a hex M8x20 screw along with M8 flat

washer and M8 grower washer. The grower washer must always be put on top of the flat washer;

- connect the negative cable of the battery cabinet to the - BATT terminal using a hex M8x20 screw along with M8 flat

washer and M8 grower washer. The grower washer must always be put on top of the flat washer;

- connect the neutral cable of the battery cabinet to the neutral busbar using a hex M8x20 screw along with M8 flat wa-

sher and M8 grower washer. The grower washer must always be put on top of the flat washer.

50

KEOR MOD 125 – battery cables installation with strings of batteries in common

Page 51

Keor MOD

In case there is the need to use a double cable for each terminal in order to use a smaller cross section for each cable,

follow the previous procedure but install two cables for each terminal.

Installation and maintenance manual

KEOR MOD 125 – battery cables installation with strings of batteries in common (double cable)

It is also possible to install independent string of batteries. In this case, each power module is associated to a unique string.

The following picture shows the association between the power modules and the relative battery strings:

51

Page 52

4. Installation

In case of installation of independent strings of batterie, follow these steps:

- remove the metal jumpers inserted in the positive and negative battery terminals.

- remove the supports for the metal jumpers.

52

- insert the positive battery cables of the battery cabinets in the positive battery terminal and the negative battery cables

of the battery cabinets in the negative battery terminal.

The maximum cross section accepted by the terminals is 16 mm2.

Connect the battery cables on the terminals according to the string:

BATT1: +1 ; -1

BATT2: +2 ; -2

BATT3: +3 ; -3

BATT4: +4 ; -4

BATT5: +5 ; -5

Page 53

Keor MOD

Installation and maintenance manual

- take from the accessory box the metal support for the neutral battery cables and install it in the relative position on the

neutral busbar.

53

Page 54

4. Installation

- crimp the neutral battery cables with M5 eyelets;

- connect the neutral cables of the battery cabinets to the metal support of the neutral busbar using hex M5 nuts along

with M5 flat washer and M5 grower washers present in the accessory box. The grower washer must always be put on

top of the flat washer.

54

Page 55

KEOR MOD 250

The default configuration has the strings of batteries in common.

Keor MOD

Installation and maintenance manual

KEOR MOD 250 – battery terminals

If no change is required, follow these steps:

- crimp the positive, negative and neutral battery cables with M8 eyelets;

- connect the positive cable of the battery cabinet to the + BATT terminal using a hex M8x20 screw along with M8 flat

washer and M8 grower washer. The grower washer must always be put on top of the flat washer;

- connect the negative cable of the battery cabinet to the - BATT terminal using a hex M8x20 screw along with M8 flat

washer and M8 grower washer. The grower washer must always be put on top of the flat washer;

- connect the neutral cable of the battery cabinet to the N BATT terminal using a hex M8x20 screw along with M8 flat

washer and M8 grower washer. The grower washer must always be put on top of the flat washer.

KEOR MOD 250 – battery cables installation with strings of batteries in common

55

Page 56

4. Installation

In case there is the need to use a double cable for each terminal in order to use a smaller cross section for each cable,

follow the previous procedure but install two cables for each terminal.

KEOR MOD 250 – battery cables installation with strings of batteries in common (double cable)

It is also possible to install independent string of batteries. In this case, each power module is associated to a unique string.

The following picture shows the association between the power modules and the relative battery strings:

56

Page 57

In case of installation of independent strings of batterie, follow these steps:

- remove the metal jumpers inserted in the battery terminals.

Keor MOD

Installation and maintenance manual

- insert the positive battery cables of the battery cabinets in the positive battery terminal, the negative battery cables of

the battery cabinets in the negative battery terminal and the neutral battery cables of the battery cabinets in the neutral

battery terminal.

The maximum cross section accepted by the terminals is 35 mm2.

Connect the battery cables on the terminals according to the string:

BATT1: +1 ; -1

BATT2: +2 ; -2

BATT3: +3 ; -3

BATT4: +4 ; -4

BATT5: +5 ; -5

57

Page 58

4. Installation

4.3 Power modules installation

Once all the electrical connections have been made, close the distribution panels and fix them by screwing all the hex

socket M6x16 screws along with M6 toothed washers.

It is then possible to move onto the insertion of the power modules into the UPS.

During the installation it is necessary to use the appropriate Personal Protective Equipment like protective gloves and

anti-accident shoes (see paragraph 2.3).

INDICATION

To guarantee the stability of the Keor MOD 125 cabinet, first install the power modules and only later the battery drawers.

Insert the power modules one at a time starting from the top of the cabinet.

Unscrew the four screws that fix the slot cover where the power module must be installed and save them.

58

Handle the power module from his sides and never from the front.

Page 59

Insert the power module in the free slot, making sure that its switch in the front is open.

Keor MOD

Installation and maintenance manual

Make sure that the power module is abut and then close its front switch. Fix the module to the cabinet with the four

screws that were previously saved.

59

Page 60

4. Installation

4.4 Battery drawers installation

The cabinet for Keor MOD 125 may include two to ten internal battery drawers. Each battery string is made up of two

drawers, therefore it is necessary to install them two by two.

The battery drawers have a specific order in the cabinet that must be kept, especially if the UPS has to work in a configuration with indipendent strings of batteries.

During the installation it is necessary to use the appropriate Personal Protective Equipment (see paragraph 2.3).

60

Page 61

Keor MOD

Starting from the top of the cabinet, unscrew the four screws that fix the slot cover where the battery drawers must be

installed and save them.

Installation and maintenance manual

Insert the empty battery drawers in the free slots and push them till the ‘click’ of the safety block is heard.

The battery blocks must be added to the drawers only after the activation of the safety block.

61

Page 62

4. Installation

Remove the terminal covers of the batteries at the extremes.

Add two battery blocks on a drawer and connect in series the two blocks using the cable provided and respecting the

polarity (connect a positive terminal to a negative terminal).

62

Page 63

Keor MOD

Once the connection is done, insert the terminal covers on the two batteries and push the blocks at the bottom of the

drawer.

Installation and maintenance manual

Add other two battery blocks on the drawer

63

Page 64

4. Installation

Connect in series the two new blocks to the ones already in the drawer using the cable provided and respecting the polarity (connect a positive terminal to a negative terminal).

Connect the free terminals of the two batteries located close to the handle of the drawer to the cables that go to the back

of the drawer. Check the correct polarity of the whole cabling.

Insert the remaining terminal covers on the batteries.

64

Page 65

Keor MOD

Fill the second drawer in the same way.

After the two drawers are ready, push them inside the UPS cabinet till they are abut and fix them with the four screws that

were previously saved.

Installation and maintenance manual

65

Page 66

4. Installation

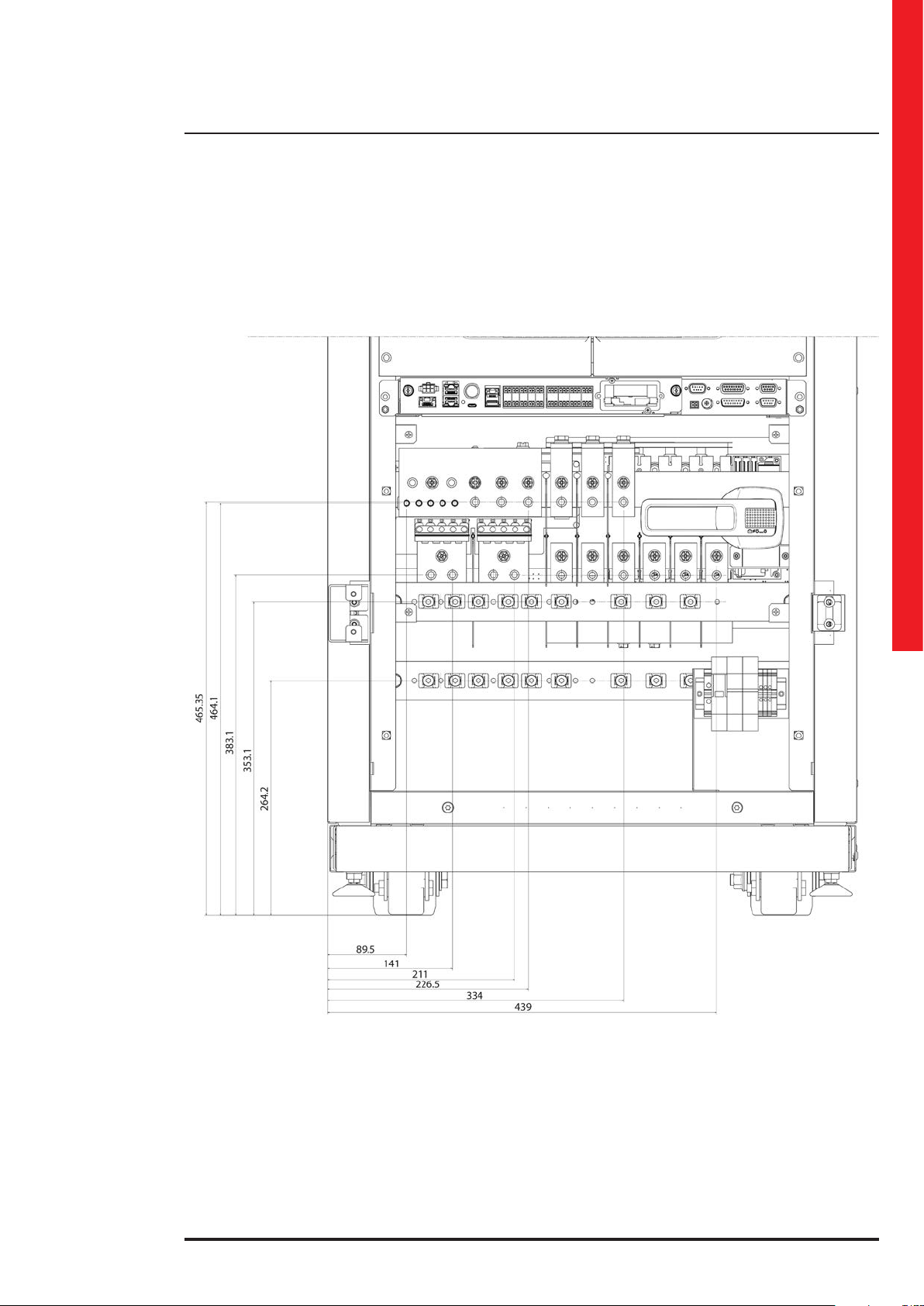

4.5 SSS interface

TERMINAL PINS FUNCTION

Analogic

floating

inputs

Digital

floating

inputs

Output

contacts

N16

N15

N14

N13

N12

N11

N10

N9

1-2 CONFIGURABLE CONTACT 3 Maximum input voltage: 15V

3-4 CONFIGURABLE CONTACT 4

1-2 CONFIGURABLE CONTACT 1

3-4 CONFIGURABLE CONTACT 2

1-2

3-4

1-2 EPO

3-4 EXTERNAL OUTPUT SWITCH

1-2

3-4 EXTERNAL BATTERY SWITCH

4-5-6 CONFIGURABLE CONTACT 3 NC/NO contacts

1-2-3 CONFIGURABLE CONTACT 2

4-5-6 CONFIGURABLE CONTACT 1

1-2-3 BYPASS STATUS

4-5-6 ALARM

1-2-3 OVERLOAD

EXTERNAL MAINTENANCE

BYPASS SWITCH

EXTERNAL TEMPERATURE

Maximum Input Voltage: 5V

(not available at the moment)

GENSET

It allows the UPS to know if

there is an external generator.

If the contact is closed, the

generator is present.

125 Vac - 0,5 A (resistive load).

15 kΩ pull-up

Maximum input voltage: 5V

1 kΩ pull-up

30 Vdc -1 A

66

N8

N6 1-2

CONNECTOR TERMINAL

N3B

4-5-6 BATTERY AUTONOMY RESERVE

1-2-3 MAINS/BATTERY STATUS

bypass mode through this NO contact

USB HOST

Port used for FW updates

AUXILIARY REMOTE BYPASS

CONTAC T

It is possible to enable the forced

Page 67

Keor MOD

4.5.1 Emergency Power Off (EPO)

The UPS has a contact that can be used to activate the immediate stop of the equipment. It can be set as normally closed

(NC) or normally open (NO) from the user interface. The default configuration is NC.

The EPO terminal is found on pins 1 and 2 of contact N13 of the SSS interface.

Use a voltage-free contact to connect the epo externally.

INDICATION

It is not possible to connect in parallel the EPO circuits of several UPS. If necessary, use contacts on the EPO emergency

pushbutton isolated from each other.

The electric characteristics of the EPO interface are:

- voltage between terminals 1 and 2 of contact N13 with open circuit: 5 Vdc

- current between terminals 1and 2 of contact N13 with closed circuit: 5 mA

Installation and maintenance manual

67

Page 68

5. Conguration and start-up

DANGER

All the configurations and start-up operations must be carried out exclusively by a SKILLED TECHNICIAN (paragraph 2.2.1).

5.1 Pre-start-up checks

Before powering the equipment, carry out the following checks:

1. Close all the distribution panels on the UPS cabinet.

2. Check that the external mains input disconnector is open (OFF position).

3. Check that the external bypass input disconnector (if present) is open (OFF position).

4. Check that the external output disconnector is open (OFF position).

5. Check that the battery disconnectors of the external battery cabinets (if present) are open.

6. Check that the maintenance bypass disconnector and the output disconnectors of the UPS are open (OFF position).

7. Check that the input and output wiring has been done and that all the connections have been tightened up properly.

8. Check the correct phase sequence of the input and bypass line (if separate).

9. Check that the parameters (voltage and frequency) of the mains input are compatible with those shown on the UPS

rating plate.

10. Check that all the power modules are inserted properly and that the fixing screws are screwed up to abut the relative

slots (use hex socket M6x16 screws along with M6 toothed washers).

11. Check that all the battery drawers (if present) are inserted properly and that the fixing screws are screwed up to abut

the relative slots (use hex socket M6x16 screws along with M6 toothed washers).

12. Check the presence of the EPO terminal according to the setting (see paragraph 4.5.1)

5.2 Start-up procedure

1. Insert the battery fuses into the appropriate fuse breakers of the external battery cabinets (if present).

2. Press for at least 5 seconds the COLD START button of the SSS interface. The display turns on and the UPS boot starts.

3. The UPS boot ends when the LEDs on the power modules turn to steady blue. Tap on the Setting icon of the menu bar

at the bottom of the display

4. Choose the desired language in the tab “General” by tapping on the pencil icon on the item “Language”.

5. Set the correct day/time in the tab “General” by tapping on the pencil icon on the item “Date and Time”.

68

Page 69

Keor MOD

Installation and maintenance manual

6. Set the desired voltage and frequency output in the tab “System” by tapping on the pencil icon on the items “Voltage”

and “Frequency”.

7. Set the correct number of KB (Battery Kits) installed in the tab “System”

69

Page 70

5. Conguration and start-up

INDICATION

1 KB (Battery Kit) represents a string of 48 batteries in series.

In case of models with internal battery drawers, 1 KB is made up of 2 drawers.

8. Set the correct battery capacity in Ah of the single KB in the tab “System”

INDICATION

The UPS calculates the total battery capacity as produced by the total KB * Capacity.

9. Provide the mains supply to the UPS by closing the external mains input/bypass input disconnectors (ON position).

10. Tap on the tab “System” and select ON on the item “System Power” to turn ON the UPS. Ensure that the EPO is connect-

ed to the SSS interface (the default setting is NC).

11. The LEDs on the power modules turn to steady yellow while they are powered from the batteries. When they are

powered from the mains and the UPS is on-line, the LEDs turn to steady green.

12. Check that the output voltage and frequency values set correspond with the requirements of the load. If not, turn off

the UPS and set the correct values (see step 6).

13. Provide the power supply to the load by closing the external output disconnector (ON position).