LEGRAND Evolution ATCFF, Evolution 6STC, Evolution, Evolution 6CFFTC, Evolution 15FFHA Installation Instructions Manual

...Page 1

Wiremold electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Wiremold electrical products may

bear the mark as UL Listed and/or Classified and should

be installed in conformance with current local and/or the National

Electrical Code.

Evolution™Series

6" Furniture Feed Poke-Thru Devices

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 007 155 R2 – Updated May 2010

Products Covered: 6ATCFF, 6STC, 6CFFTC, 15FFHA, 152CHA, CE6ATCFF

CAUTION DO NOT operate tile stripper, cleaning, or resurfacing equipment over top of covers. This may result in

damage to the surface finish of the product.

Suitable for use in air handling spaces in accordance with Sec. 300-22 (C) of the National Electrical Code.

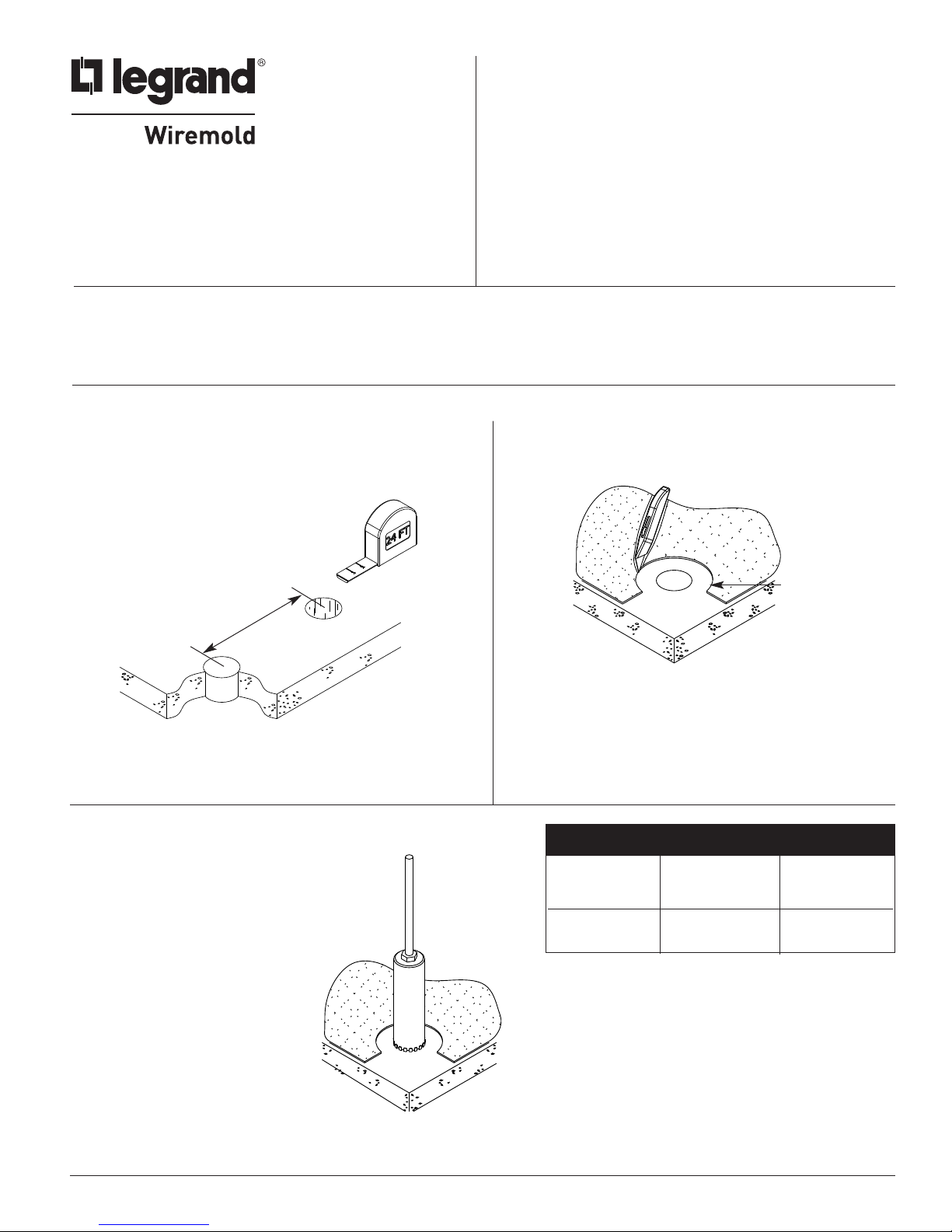

FLOOR PREPARATIONS

Step 1 Layout and locate position of hole(s).

CAUTION: Minimum spacing of 2ft on center and not more than

one device per each 65 square feet of floor area in

each span.

IMPORTANT: Please read all instructions

before beginning.

Step 2 Remove 7 1/4" dia. [166mm] section from

carpet or tile. Use template provided.

24" [610mm] Min

Center – Center

CAUTION: Be certain to locate hole at least 6" [152mm] from any wall or

pillar to leave enough room for Poke-Thru cover assembly.

Step 3 Create core hole according to the

dimensions provided in the chart.

7 1/4"

[166mm]

FLOOR CORE CORE

TYPE SIZE (Min.) SIZE (Max.)

Covered Floors 6" [152mm] 6 1/8" [156mm]

(Carpet, Tile or

Wood)

Bare Concrete 6 1/16" [154mm] 6 1/8" [156mm]

or Terrazzo

1

Page 2

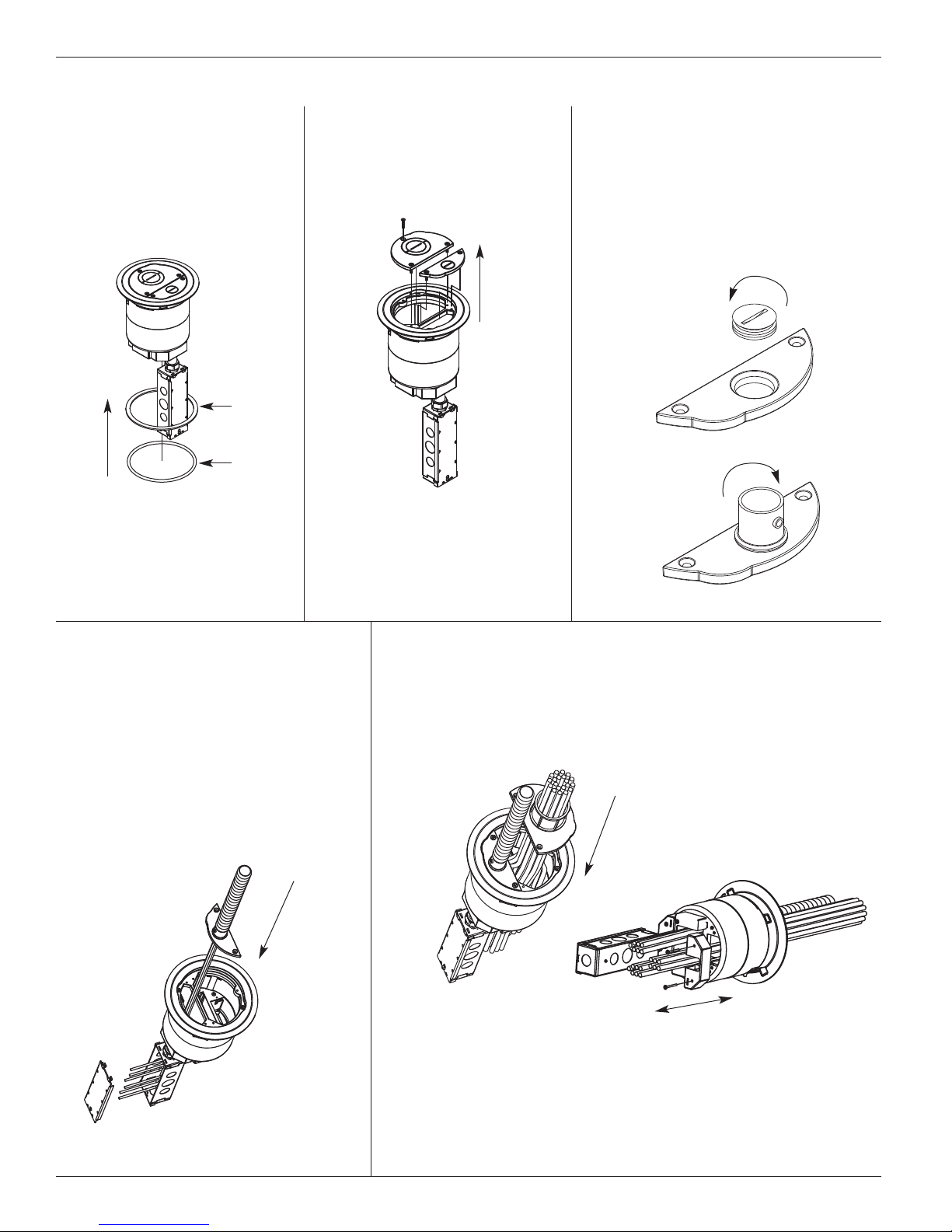

NSTALLING COMPLETE ASSEMBLY

I

Step 1 Place appropriate gasket

around Poke Thru and

slide under flange. Use

flat foam gasket for tile

pplications or use round

a

neoprene gasket for

carpet applications.

ile Gasket

T

Carpet

asket

G

Step 2 Remove cover plates by

removing (5) 8-32 screws.

Step 3 Remove 3/4" plug from small

cover plate by rotating counterclockwise using a large straight

lade screwdriver. Install 3/4"

b

conduit fitting (provided) into

opening on large cover. Repeat

procedure for 2" conduit fitting,

on large cover plate. (provided)

Step 4 Feed 3/4" inch flexible conduit

into 3/4" conduit fitting on cover

plate. Feed power wires through

small compartment and into the

junction box. Make wiring connections in the junction box.

Refer to copper cross section

chart to determine quantity of

wires to pass through each opening. Attach cover to the flange

using (2) 8-32 x 3/8" screws.

Step 5 Feed data wires through larger compartment and through

2" conduit fitting on cover plate. Refer to copper cross

section chart to determine quantity of cables to pass

through each opening. Attach cover to the flange using

(3) 8-32 x 3/8" screws.

NOTE: Splices must be made in junction box.

NOTE: If necessary remove Feed Plates to pull communications wires through

Poke-Thru device. Replace Feed Plates when finished pulling wires.

CAUTION: To maintain fire classification, Feed Plates must be installed.

2

Page 3

Step 6 Orient Poke Thru so that the three channels span across the corrugations of the deck.

Push Poke-Thru into floor.

B BA A

Device openings must

span across deck

CAUTION: Cover must be removed to rotate Poke Thru once it has been installed in the floor.

Step 7 Installation complete.

3

Page 4

NSTALLING STEM ASSEMBLY AND SEPARATE COVER

I

Step 1 Orient Stem Assembly such that the three channels span across the corrugations of the deck.

nsert Stem Assembly into core hole.

I

A A B B

Device openings must

span across deck

CAUTION: Cover must be removed to rotate Poke Thru once it has been installed in the floor.

Step 2 Remove disposable plate and (2) plate clips by removing the 8-32 screws. Install Flange using the

(2) 8-32 x 1/2" Cap Head screws provided with the cover assembly.

4

Page 5

CONFIGURING FEED PLATES

Step 1 Remove cover assembly from Poke Thru by

emoving (2) 8-32 screws and lifting cover off.

r

tep 2 Remove Poke Thru from floor by bending

S

tabs inward and pulling unit up.

Step 3 Remove (4) 8-32 screws and pull off

feed housings.

Step 4 Use (4) 8-32 screws to install new feed plate

or housing.

CAUTION: To maintain fire classification, Feed Plates

must be installed.

5

Page 6

Evolution Series Poke-Thru Devices are UL Listed and Classified to U.S. and Canadian safety standards to the

following conditions:

The 6STC Poke-Thru Stem with the 6CFFTC Service Head Fitting, and the 6ATCFF factory assembled Poke-Thru device are

for use with 1-, 1 1/2 -, or 2- hour rated unprotected reinforced concrete floors and 1-, 1 1/2 -, or 2- hour rated floors employing

unprotected steel floor units and concrete topping (D900 Series Designs), or concrete floors with suspended ceilings. (Fire resistive

esigns with suspended ceilings should have provisions for accessibility in the ceiling area below the Poke-Thru fittings).

d

The assembled Poke-Thru stem and service fitting will not reduce the ratings of the floor assembly when the thickness and type

of concrete (required for the specific rating) are within the specified limits and the fittings are installed as specified:

1. Spacing – Minimum of 2' [610mm] OC and not more than one unit per 65 sq. ft. [6 m

2

] of floor area in each span.

2. Concrete – Minimum thickness of structural concrete topping of 2 1/4" [57mm] over metal deck or a minimum 3" [76mm]

thick reinforced concrete slab. Unit weight of concrete to be 110 to 155 pcf.

3. Installation – Mounted in a 6" [152mm] diameter hole in concrete per installation instructions accompanying

the fittings. For use with power circuits, data and/or audio/visual cables as tabulated below:

COPPER CROSS-SECTION

POWER DATA CHANNEL DATA CHANNEL

CHANNEL (CENTER) (OUTSIDE)

Max Copper .0815 sq. in. .0686 sq. in. .0187 sq. in.

X-Section [52.6mm2] [44.3mm2] [12.1mm2]

Max # (10) 10 AWG (176) 23 AWG (48) 23 AWG

Conductors

NOTE: When using conductor sizes other than listed above, the aggregate cross-sectional area of

the copper conductors shall not exceed the cross-sectional areas listed.

The “TC” suffix letters indicate that the device may be installed on tile or carpet covered concrete floors.

Copper Cross Sectional Area

of Commonly Used Conductors

Size Solid

#24 .00032 sq. in. [.20645mm2]

#22 .00050 sq. in. [.32258mm2]

#14 .00323 sq. in. [2.08386mm2]

#12 .00512 sq. in. [3.30321mm2]

#10 .00815 sq. in. [5.25805mm2]

#8 .01296 sq. in. [8.36127mm2]

NOTE: Use above values for solid or stranded conductors.

6

Page 7

7

Page 8

Carpet Cutout Template

arpet Cutout

C

1/2" [166mm]

6

(See chart below for

Core Hole dimensions.)

Core Hole

CAUTION: When printing copies of this

template please be sure template

is scaled correctly and is the

correct size once it is printed.

© Copyright 2009 Wiremold All Rights Reserved

FLOOR CORE CORE

TYPE SIZE (Min.) SIZE (Max.)

Covered Floors 6" [152mm] 6 1/8" [156mm]

(Carpet, Tile or

Wood)

Bare Concrete 6 1/16" [154mm] 6 1/8" [156mm]

or Terrazzo

WIREMOLD

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

1 007 155 R1 0709

Loading...

Loading...