Page 1

Wattstopper

36'

20%

Ultrasonic

O

c

e

20%

Ul

Overlap

®

360° Dual Technology • Line Voltage Occupancy Sensor (version 3)

with Light Level feature

Double technologie à 360° • Détecteur de mouvement de tension de ligne (v3)

No: 24038 – 10/17 rev. 3

avec les fonctionnalités de niveau de luminosité

Doble tecnología de 360° • Sensor de ocupación de voltaje de línea (v3)

con nivel de luz

Installation Instructions • Instructions d’Installation • Instrucciones de Instalación

Catalog Number • Numéro de Catalogue • Número de Catálogo: DT-355

Country of Origin: Made in China • Pays d’origine: Fabriqué en Chine • País de origen: Hecho en China

DT-355-U is BAA and TAA compliant (Product produced in the U.S.)

SPECIFICATIONS

Voltages ....................................................................120//230/277/347VAC, 50/60Hz

Load Requirements

@120VAC ..........................................................0-800W Ballast/Tungsten/LED

@230VAC (Single Phase) ................................................0-1200W Ballast/LED

@277VAC ........................................................................0-1200W Ballast/LED

@347VAC ........................................................................0-1500W Ballast/LED

Operating Temperature ...................................................... 32° to 131°F (0° to 55°C)

Terminal Torque Rating ........................................... 4.428 inch pound-force (0.5Nm)

Ballast Operating Temperature ........................................... 32° to 131°F (0° to 55°C)

Light Level One-Step Adjustment ..........................................................10FC–300FC

Time Delay Adjustment ..................................................... 30 seconds to 30 minutes

Walk-Through Mode ............................................ 3 minutes if no activity after 30 sec

Test Mode ......................................................................5 sec. upon DIP switch reset

PIR Coverage (Typical) ................................................................................. 1300 ft2

Sensitivity Adjustment ............................................. High or Low (DIP switch setting)

Ultrasonic Coverage (Typical) ....................................................................... 1300 ft2

Sensitivity Adjustment .............................................................. Min. to Max. (trimpot)

Frequency ........................................................................................................ 40kHz

UNIT DESCRIPTION

The Wattstopper DT-355 360° Dual Technology occupancy sensors combine advanced passive infrared (PIR) and ultrasonic

technologies into one unit. The combination of these technologies helps to eliminate false triggering problems even in difficult

applications.

The DT-355 turns lighting systems on and off based on occupancy and ambient light levels. The light level feature can be used to keep

lights from turning on if the ambient light level is sufficient.

The DT-355 offers numerous operating modes that can be combined to create the ideal custom control. The sensors can be configured

to turn lighting on, and hold it on as long as either or both technologies detect occupancy. After no movement is detected for the userspecified time the lights are switched off. A “walk-through” mode can turn lights off after only 3 minutes, if no activity is detected after 30

seconds of an occupancy detection. The DT-355 operates on 120VAC, 230VAC (1Ø), 277VAC, or 347VAC line voltage.

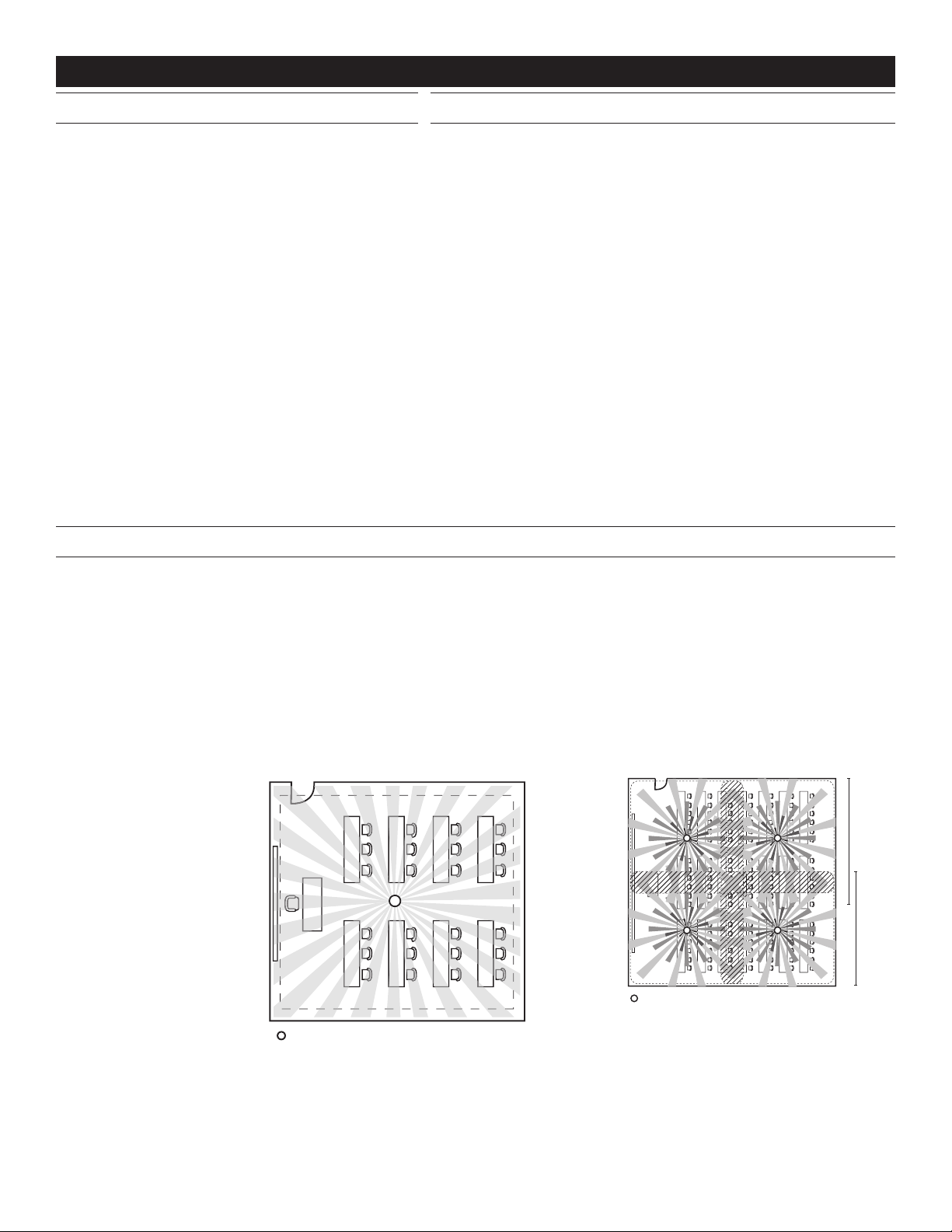

PLACEMENT GUIDELINES

Depending upon obstacles such as furniture or room layout, the area of

coverage may be less or more than the sensing distances shown in the

coverage pattern. This must be considered when planning the number of

sensors and their placement. It is also recommended to place the sensor at

least 4 to 6 feet away from air supply vents.

Mount the sensor to the ceiling. The DT-355 is designed for a ceiling heights of

about 8-12 feet. Mounting above or below this range will significantly affect the

coverage patterns. As a general rule, each occupant should be able to clearly

view the sensor.

Masking the PIR Lens: Opaque adhesive tape is supplied so that sections

of the PIR lens can be masked. This restricts the sensor’s view and allows

you to eliminate PIR coverage in unwanted areas such as hallways outside

of the desired coverage area. Since masking removes bands of coverage,

remember to take this into account when troubleshooting coverage problems.

The Ultrasonic coverage cannot be masked, but you can adjust its sensitivity

to reduce the coverage area.

If the space is larger than 30’ x 30’ it will be necessary to

use more than one sensor to ensure complete coverage.

verlap

36'

PIR

Coverage

36 ft

(10.97m)

Ultrasoni

Coverag

36 ft

(10.97m)

Sensor

trasonic

Page 2

Common application – Classroom: Position the sensor so that the maximum

Sensor

36'

36'

(10.97m x 10.97m)

#12 to #16 AWG

Cu Wire Only

Neutral

Neutral

coverage is achievable. Be sure that the sensor is not pointing out the door. To get

complete coverage in an open office area, install multiple sensors so that there is

approximately 20% overlap with each adjacent sensor’s ultrasonic coverage area.

COVERAGE PATTERN

The DT-355 provides a 360° coverage pattern. The

coverage shown represents walking motion at a mounting

height of 8-12 feet. For building spaces with lower levels

of activity or with obstacles and barriers, coverage size

may decrease. The coverage for PIR ONLY trigger mode

varies with mount height. Refer to pattern below for details.

Ultrasonic coverage is roughly the same for 8-12 foot

mount heights. Refer to PIR and Ultrasonic trigger mode

coverage for details.

Top View

PIR

Coverage

Ultrasonic

Coverage

36 ft x 36 ft

8-12 foot Mounting Height

WIRING DIRECTIONS

8ft

(2.4m)

10ft

(3.0m)

12ft

(3.7m)

0

40ft

(12.2m)

36 ft

(10.97m)

30ft

(9.1m)

Side View

20ft

(6.1m)

10ft

(3.0m)

0

10ft

(3.0m)

20ft

(6.1m)

PIR Only Coverage

* Drawings not to scale, representative of PIR

and Ultrasonic Trigger Mode major motion

coverage

30ft

(9.1m)

40ft

(12.2m)

Multiple Sensors Connected in Parallel

Ground

(Optional)

NOTE: This application does not allow for Load to increase

WARNING: DO NOT INSTALL THE SENSOR IN A SPACE

CONTROLLING A TOTAL LOAD THAT IS HIGHER THAN THE RATING

OF THE DEVICE. EACH SENSOR WILL NEED TO SWITCH THE ENTIRE

LOAD EVEN IF ADDITIONAL SENSORS ARE INSTALLED. RISK OF

OVERLOAD, PRODUCT DAMAGE, SMOKE AND/OR FIRE MAY RESULT.

Load

Load

Line

Neutral

Load

Ground

(Optional)

Line

2

Hot

Neutral

WARNING: TURN THE POWER

OFF AT THE CIRCUIT BREAKER

BEFORE INSTALLING SENSORS.

Single Sensor, Single Load

Load

Load Hot

Ground

(Optional)

Strip Gauge

Neutral

Page 3

*

Cover

Wiremold #V5752 box

Ceiling

MOUNTING THE SENSOR

Using a 4-Inch Square Junction Box

1. Pull the line voltage wires into the J-Box through the conduit

knockout.

2. Run the wires through the CA-1 adapter then connect the

line voltage wires to the appropriate terminals on the sensor.

3. Align the CA-1 and the sensor with the J-Box so that the

mounting screw tabs on the box match the mounting holes

on the sensor’s rear housing and the CA-1.

4. Use two machine screws (included with the sensor) to attach

the sensor to the mounting tabs on the J-Box.

5. Snap the front cover onto the sensor.

Mounting to a 4” Square Wiremold V5752 box or 4”

Square Junction Box with Double-Gang Mudring

4" Square

CA-1 Adapter

Rear Housing

Sensor Flange

Screws

Front Cover

Using an Octagonal J-Box

1. Pull the line voltage wires into the J-Box through the conduit

knockout.

2. Connect the line voltage wires to the appropriate terminals

on the sensor.

3. Loosen the appliance mounting screws attached to the J-Box

4. Align the sensor in the J-Box so that the mounting screws on

the box match the key holes on the sensor’s rear housing.

5. Push the sensor up into the J -Box and twist it so that the

mounting screws are seated in the keyhole slots.

6. Tighten the two screws to secure the sensor to the J-Box.

7. Snap the front cover onto the sensor.

Mounting to an Octagonal Junction Box

4" Octagonal, 2.25" Deep

Junction Box

Ceiling

Sensor

Screws

Front

* The Junction Box must be at least 2.25” deep.

If it is not, an extension ring is required.

SENSOR ADJUSTMENT

NOTE: This unit is pre-set for basic operation as described in this guide.

Adjustment is optional.

The sensors are factory preset to allow for quick installation in most

applications. Verification of proper wiring or coverage, or customizing the

sensor’s settings can be done using the following procedures. To make

adjustments, open the Front Cover with a small screwdriver.

There is a 30 second warm-up period when power is first applied.

Before making adjustments, make sure the office furniture is installed,

lighting circuits are turned on, and the HVAC systems are in the overridden/

on position. VAV systems should be set to their highest airflow. Set the Logic

Configuration and Time Delay to the desired settings. See the DIP switch

Configuration Chart.

To Test Occupancy Sensors

1. Ensure the Time Delay is set for Test Mode* using the “Test Mode/20 minutes” setting. (DIP switches 1, 2, & 3 are OFF).

2. Ensure that the Light Level is at default (maximum). Press and hold the pushbutton for 5 seconds or until the Green LED flashes

rapidly. Wait 10 seconds for the flashing to stop.

3. Ensure that the Ultrasonic Sensitivity trimpot is set to about 70%, clockwise.

4. Remain still. The red and green LEDs should not flash. The lights should turn off after 5 seconds. (If not, see “Troubleshooting”).

5. Move around within the coverage area. The lights should come on. Adjust the Ultrasonic Sensitivity as necessary to provide the

desired coverage (Green LED indicates activation from the ultrasonic sensor).

When testing and adjustment is complete, reset DIP Switches and Light Level to the desired settings, and replace the cover on the

sensor.

• Test Mode is a temporary state that starts when you first set the sensor’s DIP switches for the “Test Mode/20 minutes” (switches 1,

2, 3 OFF). If you need to invoke the Test Mode and the DIP switches are already set for Test Mode/20 minutes, toggle DIP switch 1

ON then back to the OFF position. This provides a 10 minute test period. During the test period, the Time Delay is only 5 seconds.

Ultrasonic

sensitivity

trimpot

DIP switches

Ultrasonic

transducer

cones

Ultrasonic

activity

LED (Green)

Light level pushbutton

ECE

8

7

6

5

4

3

ON

2

1

Keyhole slots

(for mounting to

4" octagonal box)

Double gang

mudring

mounting holes

PIR Activity

LED (Red)

PIR lens

3

Page 4

DIP SWITCH SETTING

= OFF

Switch#

Feature

Time Delay: Switches 1, 2, 3

The sensor will hold the lights ON as long as occupancy is detected. The time delay countdown starts

when no motion is detected. After no motion is detected for the length of the time delay, the sensor will turn

the lights OFF.

Walk-through: Switch 4

Walk-through mode turns the lights OFF three minutes after the area is initially occupied, if no motion is

detected after the first 30 seconds. If motion continues beyond the first 30 seconds, the selected time

delay applies.

PIR Sensitivity: Switch 5

• Minimum forces a reduced detection range for the PIR.

• Maximum causes the DT-355 to monitor the controlled environment and automatically select the

maximum sensitivity that will provide reliable operation without false detection. This setting is

constantly updated.

Occupancy Logic: Switches: 6, 7, 8

The DT-355 has 8 logic configurations for occupancy triggers, set with DIP switches 6, 7 & 8. Determine

the appropriate Occupancy Logic Option using the Trigger matrix, then set the DIP switches accordingly.

Initial Occupancy: The method that activates a change from “Standby” (area unoccupied and loads are

OFF) to “Occupied” (area occupied and loads are ON).

• Both requires detection by PIR and Ultrasonic.

• Either requires detection by only one technology.

• PIR requires detection by the PIR.

• Man. requires activation of the Manual Switch. (See Manual ON functions” for further information).

Maintain Occupancy: The method indicating that the area is still occupied and the lights should remain

ON.

Re-trigger: After the time delay elapses and the lights turn OFF, detection by the selected technology

within the number of seconds indicated turns the lights back ON.

Time Delay

Test Mode/20 min

30 seconds

5 minutes

10 minutes

15 minutes

20 minutes

25 minutes

30 minutes

Walk-Through

Enabled

Disabled

PIR Sensitivity

Minimum

Maximum

Settings

Standard

Option 1

Option 2

Option 3

Option 4

Logic

Option 5

Occupancy

Standard

Standard

Trigger

Standard

Occupancy Logic

Both

Option 1

Option 2

PIR

Both PIR Both(5)

Option 3

Option 4

PIR

Option 5

Either

= Factory Setting

= ON

Initial

Occupancy

Maintain

Occupancy

Either

EitherEither

Either

PIR

PIR

123

4

5

67

Re-trigger

Either(5)

Either(5)

Either(5)

PIR(5)

Either(5)

8

duration)

(seconds

LIGHT LEVEL FEATURE

The Light Level feature holds lights off upon initial occupancy if adequate ambient light exists. It will not turn the lights off if they are on.

The default setting is for maximum, meaning that even the brightest ambient light will not hold the lights off.

Notes on Functionality

• Avoid mounting the sensor close to lighting fixtures.

• Adjust during daylight hours when ambient light in the area is at desired level.

• Light Level cannot be enabled while Test Mode is active. Either wait for Test Mode to expire or select any of the other Time Delay

settings before enabling the Light Level feature.

• Ultrasonic occupancy indicator from LED is disabled when the Light Level feature is enabled. PIR occupancy indicator LED may still

respond when lights are being held off. LEDs will also flash periodically to indicate the sensor has Light Level enabled.

• Light Level settings are only saved in the event of a power loss. Disabling Light Level and then reenabling it will not return it to

previous settings.

• If Test Mode is enabled after Light Level has been set, Light Level functionality will cease to function throughout the duration of Test

Mode. When Test Mode period expires, the Light Level functionality will resume, even if the Dip Switches remain set to Test Mode.

Setting Light Level

1. Make sure Test Mode is not active.

2. Toggle the state of the sensor, by briefly pressing the Light Level button, to include or exclude the lighting load from the light level

calibration. Open the Front Cover and locate the Light Level pusbbutton. See Sensor Adjustment.

3. Press and hold the Light Level button for 2 or more seconds, or until the detection LEDs turn On. Do not exceed 5 seconds.*

The sensor enters setup mode, as indicated by the rapidly flashing LEDs. The LEDs will flash throughout the setup process.

Occupancy indications from the LEDs are disabled during setup.

4. Move away from the sensor to avoid interference with light level detection. The sensor measures the light level for a 10 second

period, then averages the readings and automatically sets the level that will be used as the new setting. The sensor will hold lights

off when the ambient light exceeds this setting.

5. When the two LEDs stop flashing, replace the Front Cover.

4

Page 5

Disabling Light Level

Pressing the pushbutton for 5 seconds or more resets the light to default (maximum).

Press and hold the Light Level button for 5 seconds or until the detection LED(s) turn ON and then OFF. The LEDs flash rapidly for 10

seconds after the setting has changed.

TROUBLESHOOTING

For any unexpected operation

1. Check DIP switch settings. Make sure the switches are set according to the defined settings in the DIP Switch Setting chart.

Lights do not turn on when entering the room.

Neither LED Flashes

1. Check that the circuit breaker has been turned back on.

2. Check all sensor connections.

Red LED does not ash

1. When power is initially applied to the sensor, there is a warm-up period of 30 to 60 seconds before the LED becomes active.

2. Make sure PIR sensitivity is set to 100% (DIP switch #5 is in the “off” position).

Green LED is on steady

Check ultrasonic sensitivity trimpot. Fully counterclockwise position is the override for the sensor. Turn trimpot clockwise until LED

flashes only when movement occurs in the desired coverage area.

Red and Green LEDs ash

1. Check all sensor connections.

2. Check if Light Level is enabled.

• If occupancy indicator LEDs blink together every few seconds, sensor is using Light Level feature.

• If Light Level functionality is not desired, press and hold for 5 seconds to return sensor to the default setting (maximum).

Lights do not turn off automatically.

Green LED ashes

Reduce ultrasonic sensitivity by turning adjustment pot counter-clockwise until it only flashes when movement occurs.

Red LED randomly ashes

Set PIR sensitivity to minimum by turning DIP switch 5 to the “on” position.

Lights do not turn off

Check all sensor andconnections.

SERVICE

To override all sensor functions, set the Ultrasonic Sensitivity trimpot to the fully counterclockwise (Service) position.

This bypasses the occupancy control functions of the sensor.

ORDERING INFORMATION

Catalog # Description

DT-355 360° Dual Technology Occupancy Sensor, Line Voltage, w/light level sensor

CA-1 Cosmetic adapter for ceiling installation with 4” square j-box or Wiremold #V5752 box. All sensors are white.

All sensors are White

5

Page 6

INSTRUCTIONS EN FRANÇAIS

36'

36'

36'

20 %

C

d

Portée des

20 %

C

d

es ultrasons

DESCRIPTION DE L’APPAREIL

Les détecteurs de présence à double technologie 360°

DT-355 de Wattstopper associent les technologies

avancées de l’infrarouge passif (IRP) et des ultrasons

dans une seule unité. L’association de ces technologies

permet de contribuer à éliminer les problèmes de faux

déclenchements même dans les applications difficiles.

Le DT-355 allume et éteint les systèmes d’éclairage en

fonction des niveaux de présence et d’éclairage ambiants.

La fonction de niveau d’éclairage peut être utilisée

pour empêcher les lumières de s’allumer si le niveau

d’éclairage ambiant est suffisant.

Le DT-355 propose différents modes de fonctionnement

qui peuvent être associés pour obtenir une régulation

personnalisée idéale. Les détecteurs peuvent être

configurés pour allumer l’éclairage et le maintenir ainsi

tant que l’une des deux ou les deux technologies détectent

une présence. Sans détection de mouvements durant la

temporisation sélectionnée par l’utilisateur, les lumières

s’éteignent. Le mode « passage » permet d’éteindre

les lumières au bout de 3 minutes seulement si aucun

mouvement n’est détecté 30 secondes après la détection

d’une présence.

Le DT-355 fonctionne sur alimentation secteur 120 VCA,

230 VCA (1Ø), 277 VCA, ou 347 VCA.

INSTRUCTIONS DE PLACEMENT

CARACTÉRISTIQUES

Tensions ............................................................. 120//230/277/347 VCA, 50/60 Hz

Exigences en matière de charge

120 VCA ...............................................................0-800 W Ballast/Tungstène/DEL

à 230 VCA (monophasé) .............................................0-1 200 W Ballast/DEL

à 277 VCA ...................................................................0-1 200 W Ballast/DEL

à 347 VCA ...................................................................0-1 500 W Ballast/DEL

Température de fonctionnement ........................................0 à 55 °C (32 à 131 °F)

Couple nominal des bornes................................................... 4,428 po-lb (0,5 N.m)

Réglage du niveau de luminosité en une étape ...............................10 FC–300 FC

Réglage de la temporisation..........................................30 secondes à 30 minutes

Mode passage ...................................... 3 minutes si aucune activité après 30 sec.

Mode test ............................................ 5 sec. après activation de l’interrupteur DIP

Portée IRP (normale) .............................................................................(1 300 pi2)

Réglage de la sensibilité ............................................ Élevée ou faible (réglage de

l’interrupteur DIP)

Portée ultrasonique (normale) ................................................................ (1 300 pi2)

Réglage de la sensibilité .................................Min. à Max. (potentiomètre d’ajustement)

Fréquence .................................................................................................... 40 kHz

UL & CUL listés pour une utilisation avec les blocs d’alimentation Wattstopper

En fonction des obstacles, tels que des meubles ou la disposition de la pièce, la portée de l’unité peut être réduite ou augmentée par

rapport aux distances de perception illustrées dans le schéma de la portée. Cela doit être pris en compte dans le choix du nombre de

détecteurs et de leur placement. Il est également conseillé de placer le détecteur à une distance de 1,2 à 1,8 mètres (4 à 6 pieds)

minimum des conduits d’aération.

Montez le détecteur sur le plafond. Le DT-355 est conçu pour une hauteur de plafond d’environ 2,44 à 3,66 m (de 8 à 12 pi). Le placer à

une hauteur supérieure ou inférieure à celle recommandée affectera de manière significative la portée de l’appareil. En règle générale,

chaque occupant doit être capable de voir clairement le détecteur.

Obstruction de la lentille IRP: du ruban adhésif opaque est fourni de manière à pouvoir masquer des parties de la lentille IRP. Cela

limite le champ de vision du détecteur et permet d’empêcher la portée de l’IRP dans les zones non désirées, telles que des couloirs

hors de la zone de portée souhaitée. Étant donné que cette obstruction diminue la portée, n’oubliez pas d’en tenir compte en cas de

dépannage des problèmes de portée. La portée des ultrasons ne peut pas être bloquée, mais vous pouvez réglez la sensibilité pour

réduire la zone de portée.

Application habituelle –

Salle de classe Placez le

détecteur de telle sorte que

la portée maximum puisse

36'

Portée

IRP 36 pi

(10,97 m)

être obtenue. Assurezvous que le détecteur n’est

pas dirigé vers la porte.

Pour obtenir une portée de

hevauchement

es ultrasons

détection complète dans

un bureau à aires ouvertes,

installez plusieurs détecteurs

de manière à obtenir un

chevauchement d’environ

20 % entre les zones de

portée de deux détecteurs à

ultrasons adjacents.

Détecteur

double technologie

hevauchement

Si l’espace mesure plus de 9,15 m par 9,15 m (30 pi x

30 pi), il sera nécessaire d’utiliser plus d’un détecteur

ultrasons

36 pi

(10,97 m)

pour assurer une portée sur l’ensemble de l’espace.

6

Page 7

PORTÉE

12.2m

(40pi)

(10.97m)

(10.97m x 10.97m)

#12 à #16 AWG

Câble en cuivre uniquement

Neutre

Neutre

Le DT-355 présente une portée à 360°. La portée indiquée

dans le schéma représente un mouvement de marche

pour une hauteur de montage de 2,44 à 3,66 mètres

(8-12 pi). Pour les bâtiments avec une activité plus faible

ou avec des obstacles et barrières, la zone de portée

risque de diminuer. La portée en mode de déclenchement

par IRP UNIQUEMENT varie selon la hauteur de

montage. Consultez le schéma ci-dessous pour plus de

renseignements. La portée ultrasonique est à peu près la

même lorsque la hauteur de montage se trouve entre 2,44

et 3,66 mètres (8 et 12 pi). Consultez la partie concernant le

mode de déclenchement par IRP et ultrasons pour plus de renseignements.

Vue du haut

IRP

Portée

Ultrasons

Portée

36 pi x 36 pi

2.4m

(8pi)

3.0m

(10pi)

3.7m

(12pi)

0

12.2m

(40pi)

9.1m

(30pi)

Vue latérale

6.1m

(20pi)

3.0m

(10pi)

Portée de l’IRP seul

36 pi

Hauteur de montage de 2,44 à 3,66 m

(de 8 à 12 pi)

0

3.0m

(10pi)

6.1m

(20pi)

9.1m

(30pi)

Les schémas ne sont pas à l’échelle

et représentent la portée principale

du mode de déclenchement des

ultrasons et du système IRP

INSTRUCTIONS DE CÂBLAGE

ATTENTION: NE PAS INSTALLER LE DÉTECTEUR DANS UN

ESPACE CONTRÔLANT UNE CHARGE TOTALE SUPÉRIEURE À

LA VALEUR NOMINALE DE L’APPAREIL. CHAQUE DÉTECTEUR DEVRA

PRENDRE ACTIVER TOUTE LA CHARGE MÊME SI DES DÉTECTEURS

SUPPLÉMENTAIRES SONT INSTALLÉS. RISQUE DE SURCHARGE,

D’ENDOMMAGEMENT DU PRODUIT, DE FUMÉE ET / OU D’INCENDIE.

Plusieurs détecteurs connectés en parallèle

Charge

Sous tension

Charge

Terre

(en option)

Secteur

Neutre

AVERTISSEMENT: Cette application ne permet pas d’augmenter la charge

Charge

Terre

(en option)

Secteur

Neutre

ATTENTION: COUPEZ

L’ALIMENTATION DU DISJONCTEUR

AVANT D’INSTALLER LES DÉTECTEURS.

Détecteur seul, charge seule

Charge

Charge

Sous tension

Terre

(en option)

Gabarit de dénudage

Neutre

7

Page 8

MONTAGE DU DÉTECTEUR

Plafond

Collerette du détecteur

Boîtier de raccordement

e

Potentiomètre

de l’activité

Avec un boîtier de raccordement carré de 10,16 cm de

côté (4 po)

1. Acheminez les fils de tension de ligne dans le boîtier de

raccordement par l’alvéole sectionnable du conduit.

2. Passez les fils dans l’adaptateur CA-1 puis connectez les fils

de tension de ligne aux bornes correspondantes du détecteur.

3. Alignez l’adaptateur CA-1 et le détecteur avec le boîtier de

raccordement de sorte que les pattes de fixation du boîtier

correspondent aux trous de montage de la partie arrière du

boîtier du détecteur et de l’adaptateur CA-1.

4. Utilisez deux vis à métaux (fournies avec le détecteur)

pour fixer le détecteur aux pattes de fixation du boîtier de

raccordement.

5. Clipsez le couvercle frontal sur le détecteur.

Fixation sur un boîtier carré Wiremold V5752 de 10,16 cm de côté

(4 po) ou sur un boîtier de raccordement carré de 10,16 cm de

côté (4 po) avec orices de montage du cadre doubles

10,16 cm (4 po.) carré

10,16cm (4po) carrée

Adaptateur CA-1

Avec un boîtier de raccordement octogonal

1. Acheminez les fils de tension de ligne dans le boîtier

de raccordement par l’alvéole sectionnable du conduit.

2. Raccordez les fils de tension de ligne aux bornes

correspondantes du détecteur.

3. Alignez le détecteur dans le boîtier de raccordement

de sorte que les pattes de fixation du boîtier

correspondent aux fentes en trou de serrure du boîtier

arrière du détecteur.

4. Utilisez deux vis à métaux (fournies avec le boîtier de

raccordement) pour fixer le détecteur aux pattes de

fixation du boîtier de raccordement.

5. Clipsez le couvercle frontal sur le détecteur.

Fixation sur un boîtier de raccordement octogonal

octogonal de 10,16cm

(4po) par 5,72cm

(2,25po) de profondeur*

Plafond

Boîtier arrière

Vis

Couvercle frontal

RÉGLAGE DU DÉTECTEUR

NOTE: L’unité est préréglée pour un fonctionnement de

base, comme décrit dans ce guide. LE RÉGLAGE EST

OPTIONNEL.

Les détecteurs sont préréglés en usine afin de vous permettre de

l’installer rapidement dans la plupart des applications. Pour vérifier que le

câblage ou la portée sont corrects, ou pour personnaliser les réglages du

détecteur, suivez les procédures suivantes. Pour effectuer les réglages,

ouvrez le couvercle frontal en tirant sur les pattes du couvercle.

Lorsque l’unité est mise sous tension pour la première fois, elle passe

tout d’abord par une période de réchauffement de 30 secondes.

Avant d’effectuer des réglages, assurez-vous que les meubles de la zone

de travail sont installés, que les circuits d’éclairage sont allumés et que

les systèmes CVCA sont en position neutralisé/marche. Les systèmes

DAV doivent être réglés sur le débit d’air le plus important. Paramétrez

la configuration logique et la temporisation en adoptant les réglages

souhaités. Consultez le « Tableau des configurations logiques ».

Pour tester les détecteurs de présence

1. Assurez-vous que la temporisation est réglée sur le Mode Test* en utilisant le réglage « Mode test/20 minutes ». (Interrupteurs

DIP 1, 2 et 3 sur ARRÊT).

2. Assurez-vous que le niveau de luminosité est sur son réglage par défaut (maximum). Appuyez sur le bouton poussoir et

maintenez-le enfoncé pendant 5 secondes ou jusqu’à ce que la DEL verte clignote rapidement. Attendez 10 secondes jusqu’à la

fin du clignotement.

3. Assurez-vous que le potentiomètre d’ajustement de la sensibilité aux ultrasons est placé à environ 70 % dans le sens horaire.

4. Restez immobile. Les DEL rouge et verte ne doivent pas clignoter. Les lumières doivent normalement s’éteindre au bout de 5

secondes. (Dans le cas contraire, voir « Dépannage ».)

Détecteur de présenc

Vis

Couvercle

* Le boîtier de raccordement doit avoir une profondeur d’au

moins 5,72 cm (2,25 po) Dans le cas contraire, un anneau de

prolongement est requis.

d’ajustement

de la sensibilité

aux ultrasons

Interrupteurs DIP

Cônes du

transducteur

à ultrasons

DEL de l’activité

ultrasonique (verte)

Bouton-poussoir du

niveau de luminosité

ECE

8

7

6

5

4

3

MARCHE

2

1

Fentes en trou de serrure

[pour le montage sur la boîte

octogonale de 10,16 cm (4 po)]

8

Orifices de montage

du cadre doubles

DEL

IRP (rouge)

Lentille PIR

Page 9

5. Déplacez-vous dans la zone de portée. Les lumières doivent s’allumer. Réglez la sensibilité ultrasonique comme nécessaire pour

= ARRÊT

Paramètre

obtenir la portée désirée (la DEL verte indique l’activation du détecteur d’ultrasons).

Lorsque le test et le réglage sont terminés, paramétrez de nouveau les interrupteurs DIP et le niveau d’éclairage avec les réglages

souhaités et remettez le couvercle sur le détecteur.

• Le Mode Test est un état temporaire qui démarre lorsque vous mettez les interrupteurs DIP du détecteur sur le « Mode test/20

minutes » pour la première fois (interrupteurs 1, 2 et 3 sur ARRÊT). Si vous avez besoin de lancer le Mode test et que les

interrupteurs DIP sont déjà réglés sur le Mode Test/20 minutes, faites basculer l’interrupteur DIP 1 sur MARCHE, puis de nouveau

sur ARRÊT. Cette action fournit une période de test de 10 minutes. Pendant cette période de test, la temporisation n’est que de 5

secondes.

RÉGLAGE DE L’INTERRUPTEUR DIP

Temporisation : Interrupteurs 1, 2, 3

Le détecteur maintient les lumières ALLUMÉES tant qu’une présence est détectée. Le compte à

rebours de temporisation démarre lorsqu’aucun mouvement n’est détecté. En l’absence de mouvement

pendant toute la durée de la temporisation, le détecteur ÉTEINT les lumières.

Mode passage : Interrupteur4

Le mode passage COUPE l’éclairage trois minutes après la première détection de présence, si aucun

mouvement n’est détecté après les 30 premières secondes. Si le mouvement persiste au-delà des 30

premières secondes, la temporisation sélectionnée se déclenche.

Sensibilité IRP Interrupteur 5

• Minimum impose une réduction de la portée de détection de l’IRP.

• Maximum oblige le DT-355 à surveiller l’environnement contrôlé et à choisir automatiquement la

sensibilité maximum qui garantit un fonctionnement fiable sans fausse détection. Ce réglage est

constamment mis à jour.

Logique de présence : Interrupteurs : 6, 7, 8

Le DT-355 a 8 configurations logiques de déclencheurs de présence, correspondant aux interrupteurs

DIP 6, 7 et 8. Déterminez l’option de logique de présence adaptée en vous servant du tableau des

types de déclenchement, puis réglez les interrupteurs DIP en conséquence.

Présence initiale : permet de passer du mode « Veille » (zone non occupée et charges COUPÉES) à «

Occupé » (zone occupée et charges ACTIVÉES).

• Les deux impliquent que la détection s’effectue via IRP et ultrasons.

• L’un ou l’autre implique que la détection s’effectue via l’une des deux technologies.

• IRP indique que la détection s’effectue uniquement par IRP.

• Man. nécessite une activation de l’interrupteur manuel. (Voir « Fonctions de MARCHE manuelle »

pour plus d’informations.)

Maintien de la présence : méthode qui indique que la zone est toujours occupée et que les lumières

doivent rester ALLUMÉES.

Re-déclenchement : après l’expiration de la temporisation et l’EXTINCTION des lumières, la détection

par la technologie choisie avant la fin du délai indiqué en secondes RALLUME les lumières.

Déclencher

Standard

Option 1

Option 2

Option 3

Option 4

Logique de présence

Option 5

Temporisation

Mode test/20 min

30 secondes

5 minutes

10 minutes

15 minutes

20 minutes

25 minutes

30 minutes

Mode passage

Sensibilité IRP

Minimum

Maximum

Activé

Désactivé

Réglages

Standard

Option 1

Option 2

Option 3

Option 4

Option 5

présence

Logique de

Standard

Standard

Maintenir

Présence

Initiale

L’un ou

Les

l’autre

deux

L’un ou

L’un ou

l’autre

l’autre

L'un ou

IRP

l’autre

Les

IRP

deux

IRP

IRP

L’un ou

IRP

l’autre

= Réglage d’usine

= MARCHE

la présence

N° d’interrupteur

123

4

5

67

Re-déclen-

chement

L’un ou

l’autre (5)

L’un ou

l’autre (5)

L’un ou

l’autre (5)

L’un ou

l’autre (5)

IRP (5)

L’un ou

l’autre (5)

8

(durée en

secondes)

FONCTION DU NIVEAU DE LUMINOSITÉ

La fonction de niveau de luminosité laisse les lumières éteintes si un éclairage ambiant suffisant existe au moment de la présence

initiale. Elle n’éteindra pas les lumières si elles sont allumées. Le réglage par défaut est au maximum, ce qui signifie que même en cas

d’environnement extrêmement lumineux, les lumières s’allumeront.

Remarques sur le fonctionnement

• Évitez d’installer le détecteur près des luminaires

• Effectuez le réglage pendant la journée, lorsque la luminosité ambiante est au niveau souhaité dans la zone.

• Le niveau de luminosité ne peut pas être activé lorsque le Mode test est en marche. Avant d’activer la fonction de niveau de

luminosité, attendez la fin du Mode test ou sélectionnez un autre réglage de temporisation.

• La DEL du détecteur de présence à ultrasons est éteinte lorsque la fonction de niveau de luminosité est activée. La DEL

du détecteur de présence à IRP peut toujours réagir lorsque les lumières restent éteintes. Les DEL clignotent également

périodiquement pour indiquer que la fonction de niveau de luminosité du détecteur est activée.

• Les réglages du niveau de luminosité sont uniquement sauvegardés en cas de coupure de l’alimentation. Le fait de désactiver puis

réactiver la fonction de niveau de luminosité ne permettra pas de retrouver les réglages précédents.

9

Page 10

• Si le Mode test est activé après l’activation de la fonction de niveau de luminosité, celle-ci cessera de fonctionner pendant toute la

durée du Mode test. Lorsque le Mode test arrive à sa fin, la fonction de niveau de luminosité se réactive, même si les interrupteurs

DIP restent en Mode test.

Réglage du niveau de luminosité

1. Assurez-vous que le Mode test est désactivé.

2. Basculez l’état du détecteur en appuyant brièvement sur le bouton de niveau de luminosité, pour inclure ou exclure la charge

lumineuse du calibrage du niveau de luminosité. Ouvrez le couvercle frontal et localisez le bouton-poussoir du niveau de

luminosité. Voir Réglage du détecteur.

3. Appuyez sur le bouton de réglage du niveau de luminosité et maintenez-le enfoncé pendant 2 secondes ou plus, ou jusqu’à ce

que les DEL de détection s’allument. Ne pas dépasser 5 secondes.* Le détecteur passe en mode de réglage, indiqué par le

clignotement rapide des DEL. Les DEL clignotent pendant toute la procédure de réglage. Les notifications de présence des DEL

sont désactivées pendant le réglage.

4. Éloignez-vous du détecteur pour éviter toute interférence pendant la détection du niveau de luminosité. Le détecteur mesure le

niveau de luminosité pendant 10 secondes, puis fait la moyenne des relevés et règle automatiquement le niveau à utiliser comme

nouveau réglage. Le détecteur laisse les lumières éteintes lorsque la luminosité ambiante est supérieure à ce réglage.

5. Lorsque les deux DEL ne clignotent plus, replacez le couvercle frontal.

Désactivation du niveau de luminosité

Appuyez sur le bouton-poussoir pendant 5 secondes ou plus pour remettre la fonction du niveau de luminosité au réglage par défaut

(maximum).

Appuyez sur le bouton du niveau de luminosité et maintenez-le enfoncé pendant 5 secondes ou jusqu’à ce que la/les DEL de détection

s’ALLUMENT puis s’ÉTEIGNENT. Les DEL clignotent rapidement pendant 10 secondes après le changement du réglage.

DÉPANNAGE

En cas de fonctionnement inattendu

1. Vérifiez les réglages de l’interrupteur DIP.

2. Assurez-vous que les interrupteurs sont réglés d’après les réglages définis dans le tableau des réglages des interrupteurs DIP.

Les lumières ne s’allument lorsque quelqu’un entre dans la pièce.

Aucune des deux DEL ne clignote

1. Vérifiez que le disjoncteur de circuit a bien été réenclenché.

2. Vérifiez tous les raccordements du détecteur.

La DEL rouge ne clignote pas

1. Lorsque le détecteur est mis sous tension pour la première fois, il passe tout d’abord par une période de réchauffement de 30 à 60

secondes avant que la DEL ne s’active.

2. Vérifiez que la sensibilité de l’IRP est réglée sur 100 % (interrupteur DIP 5 en position « Arrêt »).

La DEL verte est constamment allumée

Vérifiez le potentiomètre d’ajustement de la sensibilité ultrasonique. Lorsqu’il est entièrement tourné dans le sens antihoraire, le

détecteur est neutralisé. Tournez le potentiomètre d’ajustement dans le sens horaire jusqu’à ce que la DEL ne clignote qu’en cas de

mouvements dans la zone de portée souhaitée.

Les DEL rouge et verte clignotent

1. Vérifiez tous les raccordements du détecteur.

2. Vérifiez que la fonction niveau de luminosité est bien activée.

• Si les DEL de présence clignotent en même temps à intervalles de quelques secondes, le détecteur utilise la fonction de niveau

de luminosité.

• Si la fonction de niveau de luminosité ne doit pas être utilisée, appuyez sur le bouton et maintenez-le enfoncé 5 secondes pour

remettre le détecteur au réglage par défaut (maximum).

Les lumières ne s’éteignent pas automatiquement.

La DEL verte clignote

Réduisez la sensibilité ultrasonique en tournant le potentiomètre d’ajustement dans le sens antihoraire jusqu’à ce qu’elle ne clignote

qu’en cas de mouvements.

La DEL rouge clignote brièvement et la DEL verte ne clignote pas

Regardez si le raccordement de l’interrupteur manuel a été utilisé. Ne raccordez rien à cette borne si vous n’utilisez pas d’interrupteur

instantané basse tension entre le détecteur et le bloc d’alimentation.

La DEL rouge clignote de manière aléatoire

Réglez la sensibilité de l’IRP au minimum en plaçant l’interrupteur DIP 5 sur la position « marche ».

Les lumières ne s’éteignent pas

Vérifiez tous les raccordements du détecteur.

10

Page 11

ENTRETIEN

Pour neutraliser toutes les fonctions du détecteur, tournez le potentiomètre d’ajustement de la sensibilité ultrasonique complètement

dans le sens antihoraire (Fonctionnement).

Cette action permet d’outrepasser les fonctions de contrôle de la présence par le détecteur, tout en laissant la possibilité de réguler

manuellement les lumières à l’aide d’un interrupteur d’éclairage, si un tel dispositif a été installé.

INFORMATIONS CONCERNANT LES COMMANDES

N° de référence Description

DT-355 Détecteur de présence avec technologie double à 360°, tension secteur, avec détecteur de niveau de luminosité

CA-1 Adaptateur décoratif pour installation sur plafond avec boîtier de raccordement carré de 10,16 cm de côté (4 po) ou

boîtier Wiremold #V5752.

Tous les détecteurs sont blancs.

11

Page 12

Sensor

36'

36'

36'

S

uperposición ultrasónica

INSTRUCCIONES EN ESPAÑOL

DESCRIPCIÓN DE LA UNIDAD

Los sensores de presencia con doble tecnología de 360°

DT-355 Wattstopper combinan tecnologías infrarrojas

pasivas (PIR) con tecnologías ultrasónicas avanzadas en

una unidad. La combinación de estas tecnologías ayuda

a eliminar las falsas activaciones, incluso en aplicaciones

difíciles.

El sensor DT-355 enciende y apaga los sistemas de

iluminación según la presencia y los niveles de luz

ambiental. La función de nivel de luz se puede utilizar

para evitar que las luces se enciendan si el nivel de luz

ambiente es suficiente.

El sensor DT-355 ofrece muchos modos de funcionamiento

que se pueden combinar para crear el control

personalizado ideal. Los sensores pueden configurarse

para encender la iluminación y mantenerla encendida

hasta que una o ambas tecnologías detecten una

presencia. Luego de no detectar movimiento durante el

tiempo especificado por el usuario, las luces se apagan.

El modo de “recorrido” puede apagar las luces después

de solo 3 minutos si no se detecta actividad después de

30 segundos de que se detecte una presencia.

El sensor DT-355 funciona con voltaje de línea de 120 V

CA, 230 V CA (1Ø), 277 V CA o 347 V CA.

GUÍAS PARA LA COLOCACIÓN

ESPECIFICACIONES

Voltajes: ...........................................................120//230/277/347 V CA, 50/60 Hz

Requerimientos de carga

A 120 V CA ..............................................0 a 800 W balasto/tungsteno/LED

A 230 V CA (monofásica) ...................................... 0 a 1200 W balasto/LED

A 277 V CA ............................................................ 0 a 1200 W balasto/LED

A 347 V CA ............................................................ 0 a 1500 W balasto/LED

Temperatura de funcionamiento ....................................... 0° a 55° (32 °a 131° F)

Capacidad nominal de torsión de la terminal

.......................................................4,428 librafuerza por pulgada. (0,5 Nm)

Ajuste de nivel de luz en un paso ...............................................10 FC a 300 FC

Ajuste de la demora de tiempo................................... 30 segundos a 30 minutos

Modo de recorrido .........3 minutos si no hay actividad después de 30 segundos

Modo de prueba ............................ 5 s en el restablecimiento del interruptor DIP

Cobertura PIR (típica) ............................................................................. 1300 ft2

Ajuste de sensibilidad .................... Alto o bajo(configuración del interruptor DIP)

Cobertura ultrasónica (típica) .................................................................. 1300 ft2

Ajuste de sensibilidad .............................................. Mín. a máx. (potenciómetro)

Frecuencia ................................................................................................. 40 kHz

Calificado por UL y CUL para el uso con paquetes de alimentación Wattstopper

Según los obstáculos como muebles o distribución de la habitación, el área de cobertura puede ser menor o mayor que las distancias de

detección que se muestran en el perfil de cobertura. Esto debe considerarse cuando se planifica el número de sensores y su colocación.

También se recomienda colocar el sensor a 4 a 6 pies como mínimo de distancia de los respiraderos de suministro de aire.

Montaje de sensor en cielo raso. El sensor DT-355 está diseñado para una altura de cielo raso de aproximadamente 8 a 12 pies. El

montaje por encima o por debajo de este rango afectará significativamente los diagramas de cobertura. Como regla general, cada

ocupante debería poder ver el sensor claramente.

Enmascaramiento de la lente PIR: Se proporciona una cinta adhesiva opaca para que se puedan enmascarar secciones de la lente

PIR. Esto restringe la visualización del sensor y permite eliminar la cobertura PIR en áreas no deseadas, como los vestíbulos que se

encuentran fuera del área cubierta deseada. Dado que el enmascaramiento quita franjas de cobertura, recuerde tener esto en cuenta al

resolver problemas de cobertura. La cobertura ultrasónica no puede enmascararse, pero se puede ajustar la sensibilidad de esta para

reducir el área de cobertura.

Aplicación común

– Aula: Posicione el

sensor de manera que se

pueda alcanzar el límite

máximo de cobertura.

36'

Cobertura PIR de

36 pies

(10,97 m)

Asegúrese de que el

sensor no apunte hacia

la puerta. Para obtener

una cobertura completa

en un área abierta de

oficina, instale varios

sensores para que haya

un 20% de superposición

aproximadamente con

el área de cobertura

ultrasónica de cada

sensor adyacente.

20 %

Superposición

ultrasónica

sensor

Cobertura

ultrasónica de 36

pies

(10,97 m)

Si el espacio es superior a 30' x 30', se deberá utilizar

más de un sensor para asegurar una cobertura completa.

12

Page 13

PERFILES DE COBERTURA

12.2m

(10.97m)

(10.97m x 10.97m)

Neutro

Calibre AWG n.° 12 a 16

Cable de cobre únicamente

Neutro

El sensor DT-355 proporciona un perfil de cobertura de 360°.

La cobertura que se muestra representa el movimiento de

recorrido a una altura de montaje de 8 a 12 pies. En las áreas

de edificios con menos nivel de actividad o con obstáculos

y barreras, el alcance de la cobertura puede disminuir. La

cobertura para el modo de activación de PIR SOLAMENTE

varía según la altura del montaje. Consulte el siguiente perfil

para obtener información detallada. La cobertura ultrasónica

es aproximadamente la misma para las alturas de montaje de

8 a 12 pies. Consulte la cobertura del modo de activación PIR

y ultrasónica para obtener información detallada.

Vista superior

PIR

Cobertura

Cobertura

Ultrasonica

2.4m

(8ft)

3.0m

(10ft)

3.7m

(12ft)

Vista lateral

0

12.2m

(40ft)

9.1m

(30ft)

6.1m

(20ft)

3.0m

(10ft)

0

3.0m

(10ft)

6.1m

(20ft)

9.1m

(30ft)

(40ft)

Cobertura PIR solamente

Los diagramas no son a escala y son

representativos de la cobertura de

movimiento principal del modo de

activación PIR y ultrasónica

36 ft

36 ft x 36 ft

Altura de montaje 8 a 12 pies

INSTRUCCIONES DE CABLEADO

PRECAUCIÓN: NO INSTALE EL SENSOR DONDE LA CARGA

TOTAL ES SUPERIOR A LA CAPACIDAD DEL DISPOSITIVO. CADA

SENSOR NECESITARÁ MANEJAR TODA LA CARGA, INCLUSO SI SE

INSTALAN SENSORES ADICIONALES. PUEDE PRODUCIRSE UN RIESGO

DE SOBRECARGA, DAÑOS AL PRODUCTO, HUMO Y / O INCENDIO.

Sensores múltiples conectados en paralelo

Carga

Carga

Tierra

(Opcional)

Línea

Neutro

ADVERTENCIA: Esta aplicación no permite un aumento de carga.

Carga

Tierra

(Opcional)

Línea

Vivo

Neutro

PRECAUCIÓN: DESCONECTE LA

ENERGÍA DEL DISYUNTOR ANTES

DE INSTALAR LOS PAQUETES DE

ALIMENTACIÓN,

LOS INTERRUPTORES O LOS SENSORES.

Un sensor, una carga

Carga

Carga Vivo

A tierra

(opcional)

Calibre guía para

pelar cables

Neutro

13

Page 14

MONTAJE DEL SENSOR

Caja Wiremold #V5752

Cielo raso

Cielo raso

Caja de conexiones

togonal de 4" y 2,25"

Ranuras de orificios tipo

Uso de una caja de conexiones cuadrada de 4 in

1. Pase los cables de voltaje de línea hacia dentro de la caja

de conexiones por el troquel del conducto.

2. Pase los cables por el adaptador CA-1 y conecte los cables

de voltaje de línea con las terminales correspondientes del

sensor.

3. Alinee el adaptador CA-1 y el sensor con la caja de

conexiones de modo que las pestañas de los tornillos de

montaje en la caja de conexiones coincidan con los orificios

de montaje en el alojamiento trasero del sensor y del

adaptador CA-1.

4. Use dos tornillos maquinados (incluidos con el sensor)

para fijar el sensor a las pestañas de montaje de la caja de

conexiones.

5. Encastre la cubierta frontal en el sensor.

Montaje en una caja Wiremold V5752 cuadrada de 4" o una caja

de conexiones cuadrada de 4" con marco empotrable para caja de

cables con salida doble

cuadrada de 4"

Adaptador CA-1

Uso de una caja de conexiones octogonal

1. Pase los cables de de voltaje de línea hacia dentro de la

caja de conexiones por el troquel del conducto.

2. Conecte los cables de de voltaje de línea con las terminales

correspondientes del sensor.

3. Alinee el sensor en la caja de conexiones, de modo que las

pestañas de los tornillos de montaje de la caja coincidan

con los orificios del alojamiento trasero del sensor.

4. Use dos tornillos maquinados (incluidos con la caja de

conexiones) para fijar el sensor a las pestañas de montaje

de la caja de conexiones.

5. Encastre la cubierta frontal en el sensor.

Montaje en una caja de conexiones octogonal

oc

de profundidad*

Alojamiento trasero

Brida del sensor

Tornillos

Cubierta frontal

*La caja de conexiones debe tener una profundidad de 2,25"

Sensor

Tornillos

Cubierta

como mínimo. En caso contrario, se necesita un anillo de

extensión.

AJUSTE DEL SENSOR

NOTE: Esta unidad se preconfigura en fábrica para el funcionamiento básico como se describe en esta guía. El ajuste es

opcional.

Los sensores vienen con ajuste predeterminado de fábrica para

permitir una instalación rápida en la mayoría de las aplicaciones.

Con los siguientes procedimientos, se puede verificar que el

cableado o la cobertura sean adecuados o personalizar los ajustes

del sensor. Para hacer ajustes, abra la cubierta frontal tirando de la

lengüeta de la cubierta.

Hay un período de calentamiento de 30 segundos cuando se

emplea la energía por primera vez.

Antes de hacer ajustes, asegúrese de que los muebles de

oficina estén instalados, de que los circuitos de iluminación estén

encendidos y de que los sistemas de HVAC estén en la posición

de anulación/encendido. Los sistemas VAV deben configurarse

con su máximo caudal de aire. Establezca la configuración lógica y

la demora de tiempo en el valor deseado. Consulte el “Cuadro de

configuración lógica”.

Potenciómetro de

sensibilidad

ultrasónica

Interruptores DIP

Conos de

transductor

ultrasónico

LED de

actividad

ultrasónica

(verde)

Botón de nivel de luz

ECE

8

7

6

5

4

3

Encendido

2

1

bocallave (para montaje

en caja octogonal de 4")

Orificios de montaje

del marco empotrable

para caja de cables

con salida doble

LED de actividad

PIR (roja)

Lente PIR

Para probar los sensores de ocupación

1. Asegúrese de que la demora de tiempo se configure para el modo de prueba* mediante la configuración “Modo de prueba/20

minutos”. (los interruptores DIP 1, 2 y 3 están APAGADOS).

2. Asegúrese de que el nivel de luz esté en el valor predeterminado (máximo). Presione y mantenga presionado el botón durante 5

segundos o hasta que la luz LED verde destelle rápidamente. Espere 10 segundos hasta que la luz deje de destellar.

3. Asegúrese de que el potenciómetro de sensibilidad ultrasónica esté configurado en aproximadamente 70 % en el sentido de las

manecillas del reloj.

14

Page 15

4. No se mueva. Las luces LED roja y verde no deberían destellar. Las luces deberían apagarse luego de 5 segundos. (En caso

= APAGADO

Función

contrario, consulte “Solución de problemas”).

5. Desplácese dentro del área de cobertura. Las luces deberían encenderse. Ajuste de la sensibilidad ultrasónica según sea

necesario para proporcionar la cobertura deseada (la luz LED verde indica activación desde el sensor ultrasónico).

Cuando la prueba y el ajuste se hayan completado, restablezca los interruptores DIP y el nivel de luz a las configuraciones deseadas, y

vuelva a colocar la cubierta en el sensor.

• El modo de prueba es un estado temporal que comienza cuando ajusta por primera vez los interruptores DIP del sensor para el

“Modo de prueba/20 minutos” (interruptores 1, 2, 3 apagados). Si usted necesita iniciar el modo de prueba y los interruptores DIP

ya están configurados para el “Modo de prueba/20 minutos”, mueva el interruptor DIP 1 a la posición de ENCENDIDO y, luego, a la

posición de APAGADO. Esto proporciona un período de prueba de 10 minutos Durante el período de prueba, el tiempo de retardo

es de solo 5 segundos.

CONFIGURACIÓN DEL INTERRUPTOR DIP

Tiempo de demora: Interruptores 1, 2, 3

El sensor mantendrá las luces ENCENDIDAS siempre y cuando se detecte una presencia. La

cuenta regresiva del tiempo de retardo se inicia cuando no se detecta movimiento. Si no se detecta

movimiento durante la duración de la demora de tiempo, el sensor APAGA las luces.

Recorrido: Interruptor 4

El modo de recorrido APAGA las luces tres minutos después de que el área esté ocupada

inicialmente, si no se detecta movimiento después de los primeros 30 segundos. Si el movimiento

continúa más allá de los primeros 30 segundos, se aplica el tiempo de retardo seleccionado.

PIR Sensitivity (Sensibilidad PIR): interruptor 5

• El mínimo obliga un rango de detección reducido para la tecnología PIR.

• El máximo hace que el DT-355 supervise el ambiente controlado y que seleccione

automáticamente la sensibilidad máxima que ofrecerá un funcionamiento confiable sin falsas

detecciones. Esta configuración se actualiza constantemente.

Lógica de presencia: Interruptores: 6, 7, 8

El DT-355 tiene 8 configuraciones lógicas para los activadores de presencia establecidas en los

interruptores DIP 6, 7 y 8. Determine la opción de lógica de presencia adecuada usando la matriz

de activación y, luego, configure los interruptores DIP en consecuencia.

Ocupación inicial: El método que activa un cambio de “Espera” (área sin presencia y cargas

APAGADAS) a “Ocupado” (área con presencia y cargas ENCENDIDAS).

Mantener ocupación: El método que indica que el área aún está ocupada, y las luces deberían

permanecer ENCENDIDAS.

Reinicio: Después de que transcurre la demora de tiempo y las luces se APAGAN, la detección

mediante la tecnología seleccionada dentro de la cantidad de segundos indicados ENCIENDE

nuevamente las luces.

• Ambos requieren una detección mediante tecnologías PIR y ultrasónica.

• Cualquiera requiere detección mediante solo una tecnología.

• PIR requiere detección mediante PIR.

• Man. requiere activación del interruptor manual. (Consulte “Función de encendido manual” para

obtener más información).

Tiempo de retardo

prueba/20 min.

Mínimo

Carga

Configuración

inicial

Activador

Estándar

Opción 1

Opción 2

Opción 3

Opción 4

Lógica de presencia

Opción 5

Presencia

Ambas

Cualquiera

PIR

Ambas

PIR

Cualquiera

= ENCENDIDO

Interruptor n.°

123

Modo de

30 segundos

5 minutos

10 minutos

15 minutos

20 minutos

25 minutos

30 minutos

Recorrido

Habilitado

Desactivado

Sensibilidad

del PIR

4

5

7

6

Estándar

Opción 1

Opción 2

Opción 3

Opción 4

Opción 5

de presencia

Estándar

Estándar

inicial

inicial

Mantener

Cualquiera

Cualquiera

Cualquiera

PIR

PIR

PIR

= Configuración de fábrica

8

Reinicio

segundos)

(duración en

Cualquiera (5)

Cualquiera (5)

Cualquiera (5)

Ambas (5)

PIR (5)

Cualquiera (5)

FUNCIÓN DE NIVEL DE LUZ

La función de nivel de luz mantiene las luces apagadas durante la presencia inicial si hay una luz ambiente adecuada. No apagará las

luces si están encendidas. La configuración predeterminada está ajustada al máximo, lo que significa que aun con la luz ambiente más

brillante no se mantendrán las luces apagadas.

Notas sobre la funcionalidad

• Evite montar el sensor cerca de dispositivos de iluminación.

• Realice los ajustes durante el día cuando la luz ambiente en el área esté en el nivel deseado.

• El nivel de luz no se puede activar mientras esté activo el modo de prueba. Espere a que finalice el modo de prueba o seleccione

cualquiera de las configuraciones adicionales de demora de tiempo antes de activar la función de nivel de luz.

• El indicador de presencia ultrasónico de la LED se desactiva cuando se activa la función de nivel de luz. El indicador LED de

presencia PIR quizás aún responda cuando las luces se mantienen apagadas. Las luces LED también destellarán periódicamente

para indicar que el sensor tiene el nivel de luz activado.

• Las configuraciones de nivel de luz solo se guardan en el caso de una pérdida de energía. Si se desactiva el nivel de luz y, luego,

se lo vuelve a activar, esto no restituirá las configuraciones anteriores.

15

Page 16

• Si se activa el modo de prueba después de haber establecido el nivel de luz, la funcionalidad de nivel de luz dejará de funcionar

durante todo el período de duración del modo de prueba. Cuando expire el período del modo de prueba, se reanudará la

funcionalidad de nivel de luz, aun cuando los interruptores DIP permanezcan configurados en el modo de prueba.

Conguración del nivel de luz

1. Asegúrese de que el modo de prueba no esté activo.

2. Alterne el estado del sensor, pulsando brevemente el botón de nivel de luz, para incluir la carga de iluminación en la calibración

del nivel de luz o excluirla de esta. Abra la cubierta frontal y encuentre el botón de nivel de luz. Consulte Ajuste del sensor.

3. Presione y mantenga presionado el botón de nivel de luz durante 2 o más segundos, o hasta que las luces LED de detección se

enciendan. No supere los 5 segundos.* El sensor ingresa al modo de configuración, como lo indican las luces LED que destellan

rápidamente. Las luces LED destellarán durante todo el proceso de configuración. Los indicios de presencia de las luces LED se

desactivan durante la configuración.

4. Aléjese del sensor para evitar la interferencia con la detección de nivel de luz. El sensor mide el nivel de luz durante un período

de 10 segundos, luego realiza un promedio de las lecturas y establece automáticamente el nivel que se utilizará como la nueva

configuración. El sensor mantendrá las luces apagadas cuando la luz ambiente exceda esta configuración.

5. Cuando las dos luces LED dejen de destellar, vuelva a colocar la cubierta frontal.

Desactivación del nivel de luz

Al presionar el botón durante 5 segundos o más, se restablece la luz al valor predeterminado (máximo).

Presione y mantenga presionado el botón de nivel de luz durante 5 segundos o hasta que las luces LED de detección se enciendan y

se apaguen. Las LED destellarán rápidamente durante 10 segundos después de que haya cambiado la configuración.

SOLUCIÓN DE PROBLEMAS

Para cualquier funcionamiento inesperado

1. Verifique la configuración del interruptor DIP.

2. Asegúrese de que los interruptores estén configurados según los ajustes definidos en el cuadro de configuración del interruptor

DIP.

Las luces no se encienden cuando ingresa a la habitación.

Ninguna luz LED destella

1. Verifique que el disyuntor se haya encendido de nuevo.

2. Verifique todas las conexiones del sensor.

La luz LED roja no destella.

1. Cuando se energiza el sensor inicialmente, hay un período de calentamiento de 30 a 60 segundos antes de que la LED se active.

2. Asegúrese de que la sensibilidad PIR esté configurada en 100 % (el interruptor DIP n.º 5 está en la posición de apagado).

La luz LED verde está encendida de manera constante.

Verifique el potenciómetro de sensibilidad ultrasónica. La posición completamente contraria a las manecillas del reloj es la anulación del

sensor. Gire el potenciómetro en el sentido de las manecillas del reloj hasta que la luz LED destelle solamente cuando se produce el

movimiento en el área de cobertura deseada.

Las luces LED rojo y verde destellan

1. Controle todas las conexiones del sensor y del paquete de alimentación.

2. Verifique que el nivel de luz esté activado.

• Si los indicadores LED de presencia parpadean juntos cada unos pocos segundos, el sensor está utilizando la función de nivel

de luz.

• Si no se desea la funcionalidad de nivel de luz, presione y mantenga presionado durante 5 segundos para volver el sensor a la

configuración predeterminada (máximo).

Las luces no se apagan automáticamente.

La luz LED verde destella.

Reduzca la sensibilidad ultrasónica moviendo el potenciómetro de ajuste en sentido contrario a las manecillas del reloj hasta que solo

destelle cuando se produce el movimiento.

La luz LED roja destella brevemente y la luz LED verde no destella.

Verifique que haya utilizado la conexión del interruptor manual. No haga ninguna conexión a esta terminal si no está usando un

interruptor momentáneo de bajo voltaje entre el sensor y el paquete de alimentación.

La luz LED roja destella aleatoriamente.

Fije la sensibilidad PIR al mínimo girando el interruptor DIP 5 a la posición de encendido.

Las luces no se apagan.

Controle todas las conexiones del sensor.

16

Page 17

SERVICIO

Para anular todas las funciones del sensor, ajuste el potenciómetro de sensibilidad ultrasónica completamente en sentido contrario

a las manecillas del reloj (servicio). Esto omite las funciones de control de presencia del sensor, pero permite que las luces puedan

controlarse manualmente con un interruptor de luz, si hay uno instalado.

INFORMACIÓN PARA PEDIDOS

del atenuador Descripción

DT-355 Sensor de presencia con doble tecnología de 360°, voltaje de línea con sensor de nivel de luz

CA-1 Adaptador estético para la instalación en cielo raso con caja de conexiones o caja Wiremold #V5752 cuadradas de 4”.

Todos los sensores son blancos.

WARRANTY INFORMATION INFORMATIONS RELATIVES À LA GARANTIE INFORMACIÓN DE LA GARANTÍA

Wattstopper warranties its products to be free

of defects in materials and workmanship for a

period of five (5) years. There are no obligations

or liabilities on the part of Wattstopper for

consequential damages arising out of, or in

connection with, the use or performance of this

product or other indirect damages with respect

to loss of property, revenue or profit, or cost of

removal, installation or reinstallation.

No. 24038 – 10/17 rev. 3

© Copyright 2017 Legrand All Rights Reserved.

© Copyright 2017 Tous droits réservés Legrand.

© Copyright 2017 Legrand Todos los derechos reservados.

Wattstopper garantit que ses produits sont

exempts de défauts de matériaux et de fabrication

pour une période de cinq (5) ans. Wattstopper

ne peut être tenu responsable de tout dommage

consécutif causé par ou lié à l’utilisation ou

à la performance de ce produit ou tout autre

dommage indirect lié à la perte de propriété, de

revenus, ou de profits, ou aux coûts d’enlèvement,

d’installation ou de réinstallation.

Wattstopper garantiza que sus productos

están libres de defectos en materiales y mano

de obra por un período de cinco (5) años. No

existen obligaciones ni responsabilidades por

parte de Wattstopper por daños consecuentes

que se deriven o estén relacionados con el

uso o el rendimiento de este producto u otros

daños indirectos con respecto a la pérdida

de propiedad, renta o ganancias, o al costo

de extracción, instalación o reinstalación.

800.879.8585

www.legrand.us/wattstopper

Loading...

Loading...