Page 1

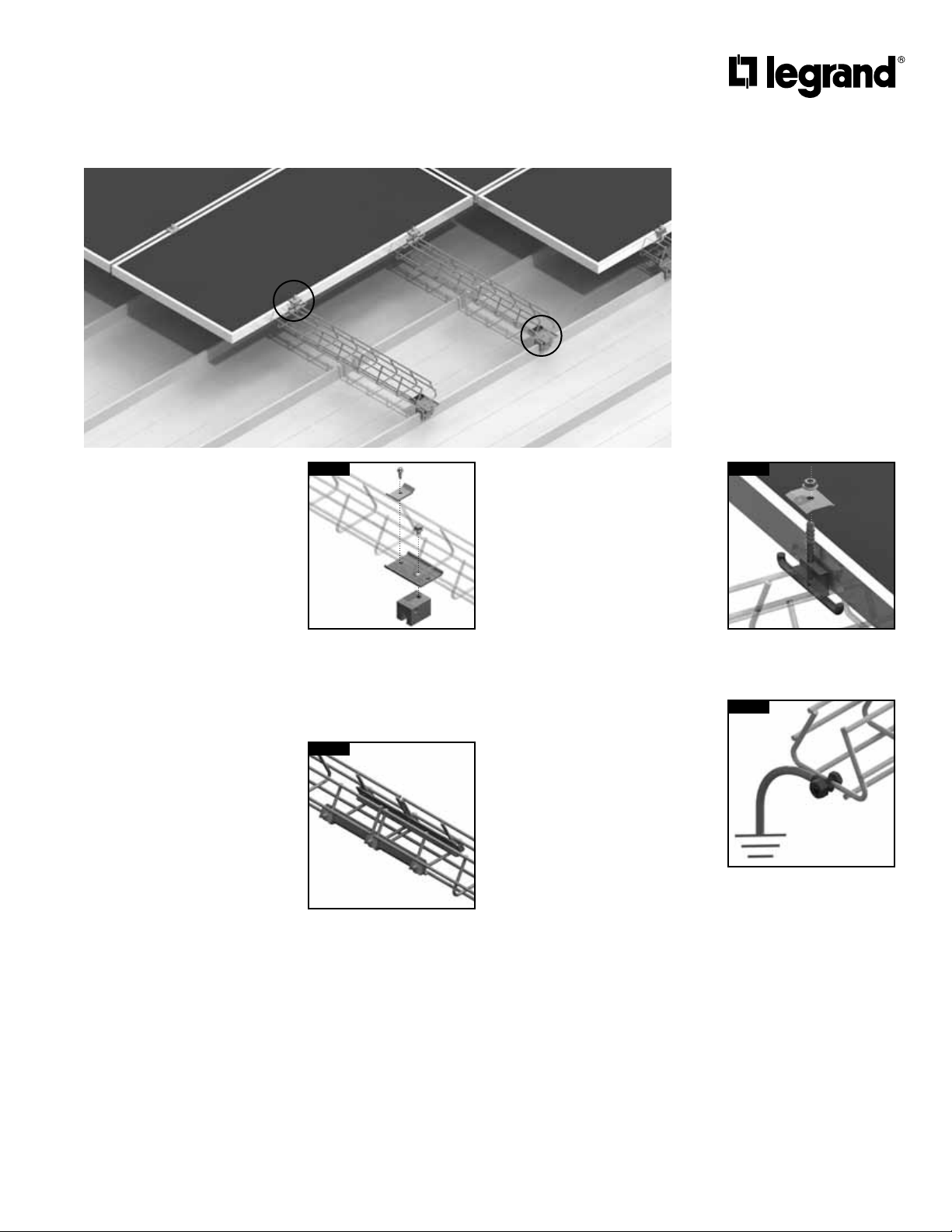

Solar panels supported by Delta Strut

on Metal Raised Seam Roof

C

A

Legrand Delta Strut Solar Systems

have passed electrical/bonding

testing per UL 2703. The following

paragraph states the scope of the

UL standards:

These requirements cover rack

mounting systems and clamping devices

for flat-plate photovoltaic modules and

panels that comply with the standard

for Flat-Plate Photovoltaic Modules

and Panels, UL 1703, intended for

installation on or integral with buildings,

or to be freestanding (i.e., not attached

to buildings), in accordance with the

National Electrical Code, ANSI/NFPA 70

and Model Building Codes.

Installation Instructions:

1. Snap chalk lines for each DS

(Delta Strut) stringer row.

Rows should be located at even

intervals allowing roughly 1/4 of

the total PV length to overhang

the top and bottom stringer

(Allow 1/8” minimum between

panel rows for expansion).

2. Install DS-S5 clamps to roof

seams as required. Install on

roof seams (not exceeding

maximum span of 60” or roof

loading requirements).

3. Attach DSBRSW washer to

DS-S5 seam clamps using

bolt provided. Then attach DS

stringers to DSBRSW/DS-S5

assembly using DSPCC clamp

and self-threading screws

(sold separately). [Figure A]

4. Splice sections of DS together

using a DSSA splice kit (install

splices on both inside corners

of DS for a single splice). Torque

nuts to 6-8 ft/lbs. [Figure B]

FIGURE A

DSPCC

DSBRSW

DS-S5

For optimal holding strength,

screw tension should be 160

to 180 inch pounds on 22

ga. steel and 130 to 150 inch

pounds for all other metals

and thinner gauges of steel.

FIGURE B

DSSA

Use two DSSA to splice any two

sections of Delta Strut tray.

5. Pull string cabling into DS

stringer row.

6. Position first PV panel at the

beginning of first run, checking

for position and square, then

attach to DS using DSEHDC

(End Bolt/Clamp). Torque nuts

to 6-8 ft/lbs.

7. Connect PV cables to stringer

cables and secure cabling to

DS. Be aware that cabling is live

at this point.

8. Add next PV panel in run. Use

DSMHDC (Middle Bolt/Clamp Patent Pending) in areas where

two panels adjoin, ending each

row by utilizing a DSEHDC

(End Bolt/Clamp). Torque nuts

to 6-8 ft/lbs. [Figure C]

9. Each solar row to be connected

to Earth as specified in NEC

using proper sized ground

conductor and UL Listed

Split-bolt lug connected to

Delta Strut. [Figure D]

FIGURE C

DSMHDC is spring-loaded and

stays in position while panels

are positioned.

FIGURE D

Use GNDSB split-bolt lug

grounding connector to

properly ground each solar

support row.

DSMHDC

GNDSB

Page 2

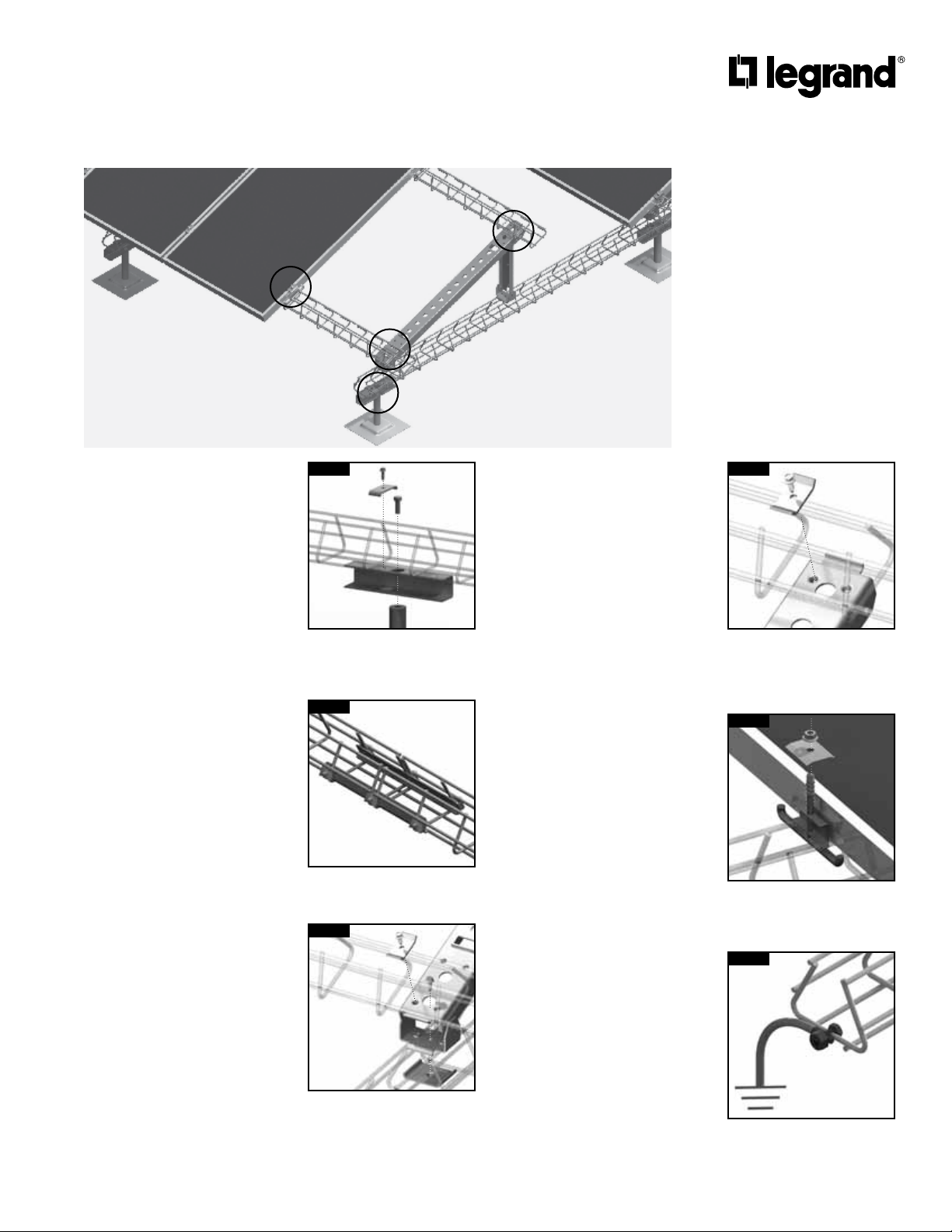

Solar panels mounted to Delta Strut

on Membrane Roof with Stanchions

D

E

C

A

Legrand Delta Strut Solar Systems

have passed electrical/bonding

testing per UL 2703. The following

paragraph states the scope of the

UL standards:

These requirements cover rack

mounting systems and clamping devices

for flat-plate photovoltaic modules and

panels that comply with the standard

for Flat-Plate Photovoltaic Modules

and Panels, UL 1703, intended for

installation on or integral with buildings,

or to be freestanding (i.e., not attached

to buildings), in accordance with the

National Electrical Code, ANSI/NFPA 70

and Model Building Codes.

Installation Instructions:

1. Snap chalk lines for each DS

(Delta Strut) support row.

Rows should be located at

even intervals (not exceeding

maximum span of 60” or roof

loading requirements).

2. Snap a second set of chalk lines

at a right angle to position angle

support legs. Actual spacing

should be in accordance with

the drawings provided with each

DS shipment.

3. Install stanchions along support

row according to manufacturer’s

recommendations and roofing

requirements. Install at even

intervals with (not exceeding

maximum span of 60” or roof

loading requirements).

4. Attach DS to stanchions with

DSPEBK (Pedestal Extension

Bracket Kit). [Figure A]

5. Splice sections of DS together

using a DSSA splice (install

splices on both inside corners

of DS for a single splice). Torque

nuts to 6-8 ft/lbs. [Figure B]

6. Install and splice all DS rows

before beginning next steps.

7. Install DSBEA (Angle Support

Assemblies). Attach rear

support to DS support first by

pivoting leg forward then secure

to DS using clamp and selfthreading screw. Attach front

clamp in the same manner.

[Figure C]

FIGURE A

DSPEBK

Bolt is tightened using socket

wrench or power drill thru

access hole.

FIGURE B

DSSA

Use two DSSA to splice any two

sections of Delta Strut tray.

FIGURE C

DSPCC

DSBEA

DSBPW

Self-threading screw is

tightened using socket wrench

or power drill thru access hole.

8. Install DS stringers to angle

supports. Position DS in angle

bracket saddle, then secure

with a DSPCC (Connection

Clamp and self-threading

screw). [Figure D]

9. Splice sections of DS stringers

together using a DSSA splice

kit (install splices on both

inside corners of DS for a single

splice).

10. Position first PV panel at the

beginning of first run, check for

position and square, then attach

to DS using DSEHDC (End Bolt/

Clamp). Torque nuts to 6-8 ft/lbs.

11. Add next PV panel in run. Use

DSMHDC (Middle Bolt/Clamp Patent Pending) in areas where

two panels adjoin. Torque nuts

to 6-8 ft/lbs. [Figure E]

12. Pull feeder cabling into DS

stringer row. Connect PV cables

to feeder cables and secure

cabling to DS. Be aware that

cabling is live at this point.

13. Each solar row to be connected

to Earth as specified in NEC

using proper sized ground

conductor and UL Listed

Split-bolt lug connected to

Delta Strut. [Figure F]

FIGURE D

Use punched pilot hole on

either side of bracket to allow

connection clamp clearance

from cross wire.

FIGURE E

DSMHDC is spring-loaded and

stays in position while panels

are positioned.

FIGURE F

Use GNDSB split-bolt lug

grounding connector to

properly ground each solar

support row.

DSPCC

DSMHDC

GNDSB

Page 3

Solar panels mounted to Delta Strut

on Membrane Roof with Cablo-Port

supports and hold down stanchions

E

B

D

A

Legrand Delta Strut Solar Systems

have passed electrical/bonding

testing per UL 2703. The following

paragraph states the scope of the

UL standards:

These requirements cover rack

mounting systems and clamping devices

for flat-plate photovoltaic modules and

panels that comply with the standard

for Flat-Plate Photovoltaic Modules

and Panels, UL 1703, intended for

installation on or integral with buildings,

or to be freestanding (i.e., not attached

to buildings), in accordance with the

National Electrical Code, ANSI/NFPA 70

and Model Building Codes.

Installation Instructions:

1. Snap chalk lines for each DS

support row. Rows should be

located at even intervals with

a maximum distance of 60”.

Actual spans should be based

upon roof loading requirements.

2. Snap a second set of chalk lines

at a right angle to position angle

support legs. Actual spacing

should be in accordance with

the drawings provided with each

DS shipment.

3. Position each Cablo-Port

support along support row at

even intervals with a maximum

distance of 60”. Always follow

roof load requirements provided

by a certified engineer. No

gluing is necessary.

4. Install hold down stanchions

along support row

according to manufacturer’s

recommendations and roofing

requirements.

5. Lay-in sections of DS and insert

into metal brackets on top of

the Cablo-Port. Secure with fold

down tabs. [Figure A]

6. Attach DS to hold down

stanchions with DSBRSW

washer and bolt. Torque nuts to

6-8 ft/lbs. [Figure B]

7. Splice sections of DS together

using a DSSA splice kit splice

(install splices on both inside

corners of DS for a single

splice). Install and splice all DS

support rows before beginning

next steps. [Figure C]

FIGURE A

Secure each Cablo-Port using

only a screwdriver.

FIGURE B

DSBRSW

Use DSBRSW washer and bolt

to secure array from wind lift.

FIGURE C

DSSA

Use two DSSA to splice any two

sections of Delta Strut tray.

8. Install DSBEA (Angle Support

Assemblies). Attach rear

support to DS support first by

pivoting leg forward then secure

to DS using clamp and selfthreading screw. Attach front

clamp in the same manner.

[Figure D]

9. Install DS stringers to angle

supports. Position DS in angle

bracket saddle, then secure

with a DSPCC (Connection

Clamp) and self-threading

screw. [Figure D]

10. Splice sections of DS stringers

together using a DSSA splice

(install splices on both inside

corners of DS for a single

splice).

11. Position first PV panel at the

beginning of first run, check for

position and square, then attach

to Delta Strut using DSEHDC

(End Bolt/Clamp). Torque nuts

to 6-8 ft/lbs.

12. Add next PV panel in run. Use

DSMHDC (Middle Bolt/Clamp Patent Pending) in areas where

two panels adjoin. Torque nuts

to 6-8 ft/lbs. [Figure E]

13. Pull feeder cabling into DS

stringer row. Connect PV cables

to feeder cables and secure

cabling to DS. Be aware that

cabling is live at this point.

14. Each solar row to be connected

to Earth as specified in NEC

using proper sized ground

conductor and UL Listed Splitbolt lug connected to Delta

Strut. [Figure F]

FIGURE D

DSPCC

DSBEA

DSBPW

Self-threading screw is

tightened using socket wrench

or power drill thru access hole.

FIGURE E

DSMHDC is spring-loaded and

stays in position while panels

are positioned.

FIGURE F

Use GNDSB split-bolt lug

grounding connector to

properly ground each solar

support row.

DSMHDC

GNDSB

Page 4

Solar panels mounted to Delta Strut

on Membrane Roof with Pan Ballast

D

A

C

Legrand Delta Strut Solar Systems

E

have passed electrical/bonding

testing per UL 2703. The following

paragraph states the scope of the

UL standards:

These requirements cover rack

mounting systems and clamping devices

for flat-plate photovoltaic modules and

panels that comply with the standard

for Flat-Plate Photovoltaic Modules

and Panels, UL 1703, intended for

installation on or integral with buildings,

or to be freestanding (i.e., not attached

to buildings), in accordance with the

National Electrical Code, ANSI/NFPA 70

and Model Building Codes.

Installation Instructions:

1. Snap chalk lines for each DS

support row. Rows should be

located at even intervals with

a maximum distance of 60”.

Actual spans should be based

upon roof loading requirements.

2. Snap a second set of chalk lines

at a right angle to position angle

support legs. Actual spacing

should be in accordance with

the drawings provided with each

DS shipment.

3. Center each pan at the

intersection of each chalk line

to position it at the base of each

angle support leg. Attach DS to

proper sized DSXXX ballast pan

with a DSPCC (clip) and bolt.

[Figure A]

4. Splice sections of DS together

using a DSSA splice (install

splices on both inside corners

of DS for a single splice). Torque

nuts to 6-8 ft/lbs (see image

above). [Figure B]

5. Load DSXXX ballast pans with

concrete ballast on both sides of

DS support row.

6. Install DSBEA (Angle Support

Assemblies). Attach rear

support to DS support first by

pivoting leg forward then secure

to DS using clamp and selfthreading screw. Attach front

clamp in the same manner.

[Figure C]

FIGURE A

Load DSXXX ballast pans

with standard 4” x 8” x 16”

concrete blocks.

FIGURE B

DSSA

Use two DSSA to splice any two

sections of Delta Strut tray.

FIGURE C

DSPCC

DSBEA

DSBPW

7. Install DS stringers to angle

supports. Position DS in angle

bracket saddle, then secure

with a DSPCC (Connection

Clamp) and self-threading

screw. [Figure D]

8. Splice sections of DS stringers

together using a DSSA splice

install splices on both inside

corners of DS for a single

splice).

9. Position first PV panel at the

beginning of first run, check for

position and square, then attach

to Delta Strut using DSEHDC

(End Bolt/Clamp). Torque nuts

to 6-8 ft/lbs.

10. Add next PV panel in run. Use

DSMHDC (Middle Bolt/Clamp Patent Pending) in areas where

two panels adjoin. Torque nuts

to 6-8 ft/lbs. [Figure E]

11. Pull feeder cabling into DS

stringer row. Connect PV cables

to feeder cables and secure

cabling to DS. Be aware that

cabling is live at this point.

12. Each solar row to be connected

to Earth as specified in NEC

using proper sized ground

conductor and UL Listed Splitbolt lug connected to Delta

Strut. [Figure F]

FIGURE D

Use punched pilot hole on

either side of bracket to allow

connection clamp clearance

from cross wire.

FIGURE E

DSMHDC is spring-loaded and

stays in position while panels

are positioned.

FIGURE F

DSPCC

DSMHDC

GNDSB

Self-threading screw is

tightened using socket wrench

or power drill thru access hole.

Use GNDSB split-bolt lug

grounding connector to

properly ground each solar

support row.

Page 5

Solar panels mounted Delta Strut

on Gravel Roof with Concrete Pier Ballast

C

A

Legrand Delta Strut Solar Systems

have passed electrical/bonding

testing per UL 2703. The following

paragraph states the scope of the

UL standards:

These requirements cover rack

mounting systems and clamping devices

for flat-plate photovoltaic modules and

panels that comply with the standard

for Flat-Plate Photovoltaic Modules

and Panels, UL 1703, intended for

installation on or integral with buildings,

or to be freestanding (i.e., not attached

to buildings), in accordance with the

National Electrical Code, ANSI/NFPA 70

and Model Building Codes.

Installation Instructions:

1. Snap chalk lines for each DS

support row. Rows should be

located at even intervals with

a maximum distance of 60”.

Actual spans should be based

upon roof loading requirements.

2. Snap a second set of chalk

lines at a right angle to position

DSCBP10-160 (concrete pier

ballast). Actual spacing should

be in accordance with the

drawings provided with each DS

shipment.

3. Place DSCBP10-160 (concrete

pier ballast) using a dolly (or

transfer bar).

4. Install DS stringers to

DSCBP10-160 concrete pier

ballast. Position DS stringer

over poured-in metal mounting

bracket and secure with a

DSPCC (Connection Clamp) and

self-threading screw. [Figure A]

5. Splice sections of DS together

using a DSSA splice (install

splices on both inside corners

of DS for a single splice). Torque

nuts to 6-8 ft/lbs. [Figure B]

FIGURE A

Concrete pier ballasts are

weather resistant and keep

array in place during high

wind events.

FIGURE B

DSSA

Use two DSSA to splice any two

sections of Delta Strut tray.

6. Position first PV panel at the

beginning of first run, check for

position and square, then attach

to DS using DSEHDC (End Bolt/

Clamp). Torque nuts to 6-8 ft/lbs.

7. Add next PV panel in run. Use

DSMHDC (Middle Bolt/Clamp Patent Pending) in areas where

two panels adjoin. Torque nuts

to 6-8 ft/lbs. [Figure C]

8. Pull feeder cabling into DS

stringer row. Connect PV cables

to feeder cables and secure

cabling to DS. Be aware that

cabling is live at this point.

9. Each solar row to be connected

to Earth as specified in NEC

using proper sized ground

conductor and UL Listed Splitbolt lug connected to Delta

Strut. [Figure D]

FIGURE C

DSMHDC is spring-loaded and

stays in position while panels

are positioned.

FIGURE D

Use GNDSB split-bolt lug

grounding connector to

properly ground each solar

support row.

DSMHDC

GNDSB

Page 6

Roof mounted solar panels supported by

Delta Strut and USS Angle Support

E

A

B/C

Legrand Delta Strut Solar Systems

have passed electrical/bonding

testing per UL 2703. The following

paragraph states the scope of the

UL standards:

These requirements cover rack

mounting systems and clamping devices

for flat-plate photovoltaic modules and

panels that comply with the standard

for Flat-Plate Photovoltaic Modules

and Panels, UL 1703, intended for

installation on or integral with buildings,

or to be freestanding (i.e., not attached

to buildings), in accordance with the

National Electrical Code, ANSI/NFPA 70

and Model Building Codes.

Installation Instructions:

1. Snap chalk lines for each

Universal Solar Support (USS)

row. Rows should be located at

even intervals with a maximum

distance of 60”. Actual spans

should be based upon roof

loading requirements.

2. Snap a second set of chalk

lines at a right angle to

correctly position the Delta

Strut stringers. Actual spacing

will vary based upon PV

panes size, angle and shading

requirements.

3. Place USS according to

chalk lines.

4. Load USS with concrete ballast

blocks in each of the three

cavities. Additional ballast can

be added to each USS base by

stacking ballast blocks on both

sides of the base. This should

be done within the loading

requirements of the roof and the

wind requirements of the array.

[Figure A]

5. Install Delta Strut stringers to

angle supports. Position Delta

Strut using the built-in position

tabs, then secure with a DSPCC

Connection Clamp and selfthreading screw. [Figures B, C]

FIGURE A

Load Universal Solar Support

(USS) with standard 4” x

8” x 16” concrete blocks.

Ballast blocks can be

stacked for greater wind load

requirements.

FIGURE B

Position Delta Strut stringers

using built in positioning tabs

on USS.

FIGURE C

DSPCC

6. Splice sections of Delta Strut

together using a DSSA splice

kit. Use both splices in the kit

for a single splice. Torque nuts

to 6-8 ft/lbs. [Figure D]

7. If you are using an Adjustable

Universal Solar Support (USSA),

you can adjust the support

height to make allowances for

low areas in the roof.

8. Attach cable bracing onto rear

and front of USS supports using

Cable Bracing Kit.

9. Place feeder cables into Delta

Strut stringer row(s).

10. Position first PV panel at the

beginning of first run, check for

position and square, then attach

to Delta Strut using DSEHDC

End Bolt/Clamp. Torque nuts to

6-8 ft/lbs.

11. Add next PV panel in run. Use

DSMHDC (Middle Bolt/Clamp Patent Pending) in areas where

two panels adjoin. Torque nuts

to 6-8 ft/lbs. [Figure E]

12. Connect PV cables and secure

cabling to Delta Strut. Be aware

that cabling is live at this point.

13. Each solar row to be connected

to Earth as specified in NEC

using proper sized ground

conductor and UL Listed Splitbolt lug connected to Delta

Strut. [Figure F]

FIGURE D

DSSA

Use two DSSA to splice any two

sections of Delta Strut tray.

FIGURE E

DSMHDC is spring-loaded and

stays in position while panels

are positioned.

FIGURE F

DSMHDC

GNDSB

Use punched pilot hole in USS

to allow connection clamp

clearance from cross wire.

Use GNDSB split-bolt lug

grounding connector to

properly ground each solar

support row.

Loading...

Loading...