Page 1

Burj Khalifa

Dubai, United Arab Emirates

Booklet available on:

Livret disponible sur:

Folleto disponible en:

Architecture.LEGO.com

Page 2

BurjKhalifa

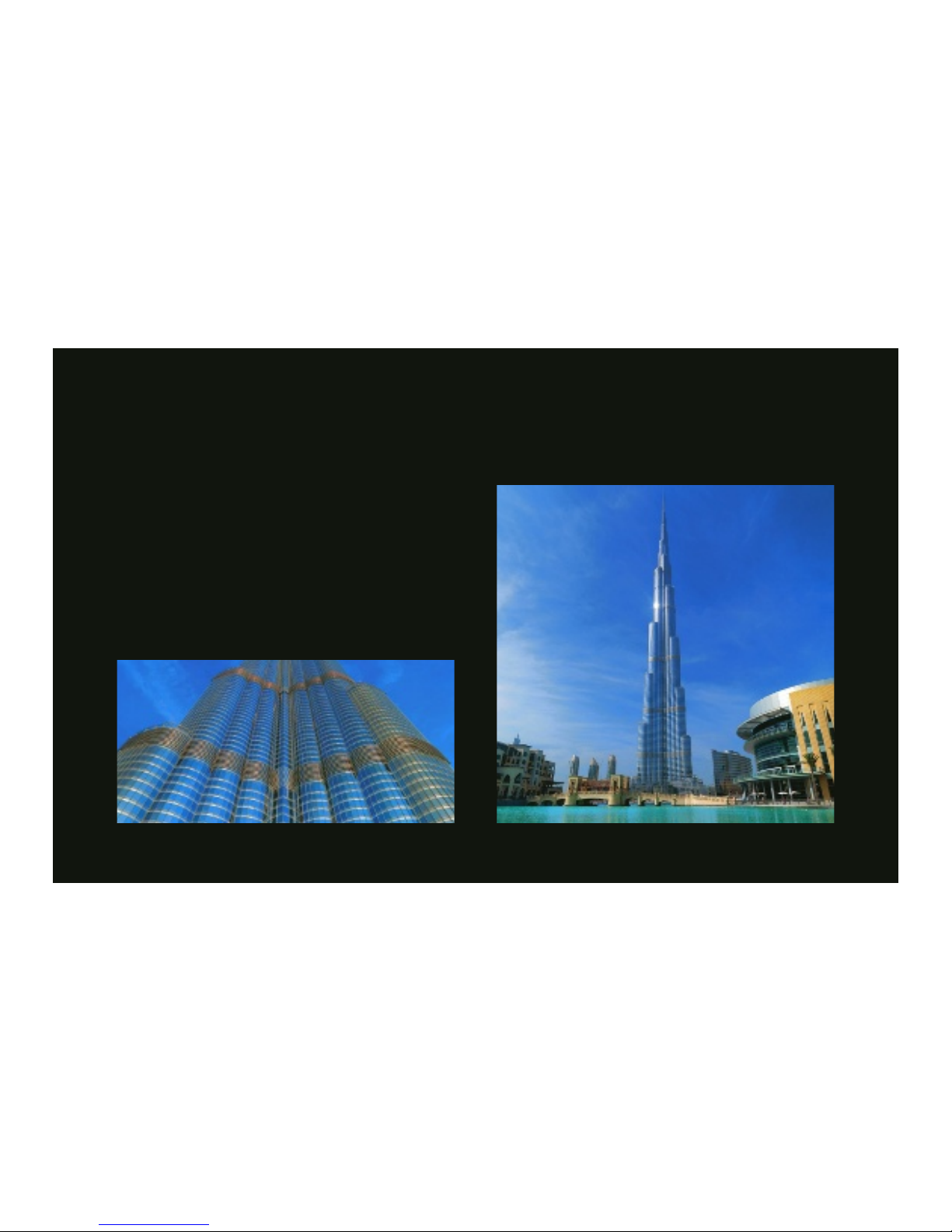

Described as both a ‘Vertical City’ and ‘A Living Wonder,’ Burj

Khalifa, at the heart of downtown Dubai, is also the world’s

tallest building.

Developed by Dubai-based Emaar Properties PJSC,

Burj Khalifa rises gracefully from the desert and honors

the city with its extraordinary union of art, engineering and

meticulous craftsmanship.

At 828 meters (2,716.5 feet), the equivalent of a 200

story building, Burj Khalifa has 160 habitable levels, the most

of any building in the world. The tower was inaugurated on

January 4, 2010, to coincide with the fourth anniversary of

the Accession Day of His Highness Sheikh Mohammed Bin

Rashid Al Maktoum Vice President and Prime Minister of

the UAE and Ruler of Dubai.

Arguably the world’s most interesting construction

project, Burj Khalifa is responsible for a number of world-firsts.

The tower became the world’s tallest man-made structure

just 1,325 days after excavation work started in January 2004.

Burj Khalifa utilized a record-breaking 330,000 cubic

meters (430,000 cubic yards) of concrete;

© Emaar Propertie s PJSC

2

Page 3

39,000 tons of steel reinforcement; 103,000 square meters

(1.1 million square feet) of glass; and 15,500 square meters

(167,000 square feet) of embossed stainless steel. The tower

took 22 million man-hours to build.

With a total built-up area of 526,000 square

meters (5.67 million square feet), Burj Khalifa features

170,000 square meters (1.85 million square feet)

of residential space, over 28,000 square meters

(300,000 square feet) of office space, with remaining area

occupied by a luxury hotel.

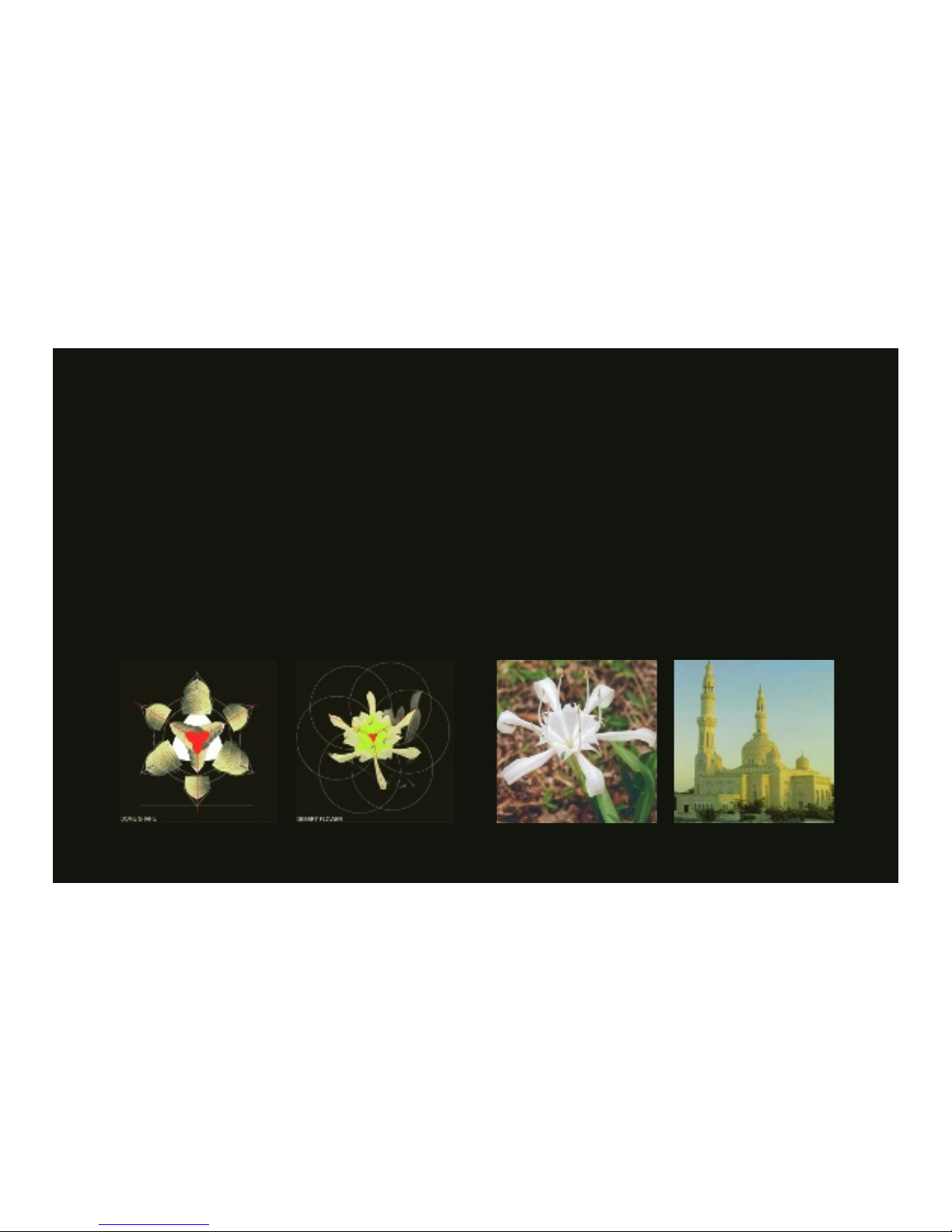

In 2003, as a result of an international design competition,

Skidmore, Owings & Merrill LLP (SOM) was selected from

a group of five international competitors to carry out the

architecture and engineering of the Burj Khalifa.

With famous architecture in the Haj Terminal at Jeddah

Airport and National Commercial Bank, SOM is no stranger

to Middle Eastern design. SOM incorporated patterns and

©EmaarProper tiesPJSC ©EmaarProper tiesPJSC

3

Page 4

elements from traditional Islamic architecture, but

the most inspiring muse was a regional desert flower, the

Hymenocallis, whose harmonious structure is one of the

organizing principles of the tower’s design. Three ‘petals’

are arranged in a triangular shape and unified at the center,

and instead of repeated identical patterns, the architectural

plan appoints successively receding and rotated stories.

The Y-shaped plan is ideal for residential and hotel usage,

with the wings allowing maximum outward views and inward

natural light. Viewed from above or from the base, the tips

of the Y-shaped plan evokes the onion domes of Islamic

architecture. During the design process, engineers rotated

the building 120 degrees from its original layout to reduce

stress from prevailing winds.

©EmaarProper tiesPJSC ©EmaarProper tiesPJSC ©EmaarProper tiesPJSC

©EmaarProper tiesPJSC

4

Page 5

Architecturally, the building transforms itself from a solid

base expression to a vertically expressed middle section of

polished stainless steel projected metal fins and glass. Only

vertical elements were used here, as the fine dust in Dubai’s

air would build up on any horizontal projecting elements.

©EmaarProper tiesPJSC ©Ema arPropertie sPJSC

5

Page 6

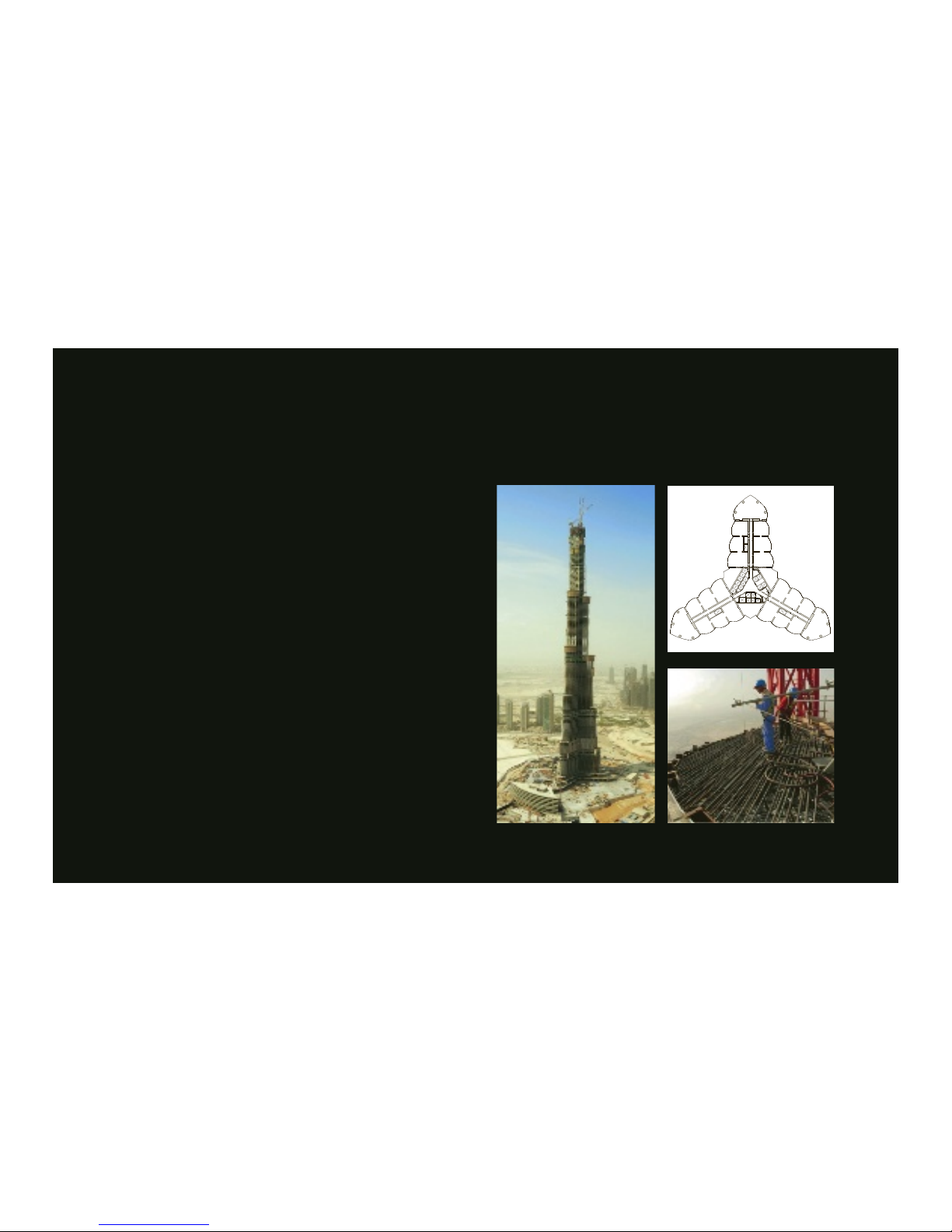

To support the unprecedented height of the building,

the engineers developed a new structural system called

the buttressed core, which consists of a hexagonal core

reinforced by three buttresses that form the ‘Y’ shape. Each

wing, with its own high performance concrete corridor walls

and perimeter columns, buttresses the other wings through

a connection to the six-sided central core, or hexagonal

hub. The result is a tower that is exteremly stiff laterally and

torsionally.

Each tier of the building sets back in a spiral stepping

pattern up the building. The setbacks are organized

with the tower’s grid, such that the building stepping is

accomplished by aligning columns above with walls below

to provide a smooth load path. This allows the construction

to proceed without the normal difficulties associated with

column transfers.

The setbacks are organized such that the tower’s width

changes at each setback. The advantage of the stepping

and shaping is to ‘confuse the wind’. The wind vortices are

never allowed to build up because at each new tier the wind

Thestructuralsystem

© Emaar Properties PJSC Rebar construction © Emaar Properties PJSC

Burj Khalifa structural plan.pdf – © SOM

6

Page 7

encounters a different building shape.

This structural system enables the building to support itself

laterally and keeps it from twisting.

At the top, the central core emerges and transitions to

a special steel framed structure which is sculpted to form a

finished spire. The spire of Burj Khalifa is composed of more

than 4,000 tons of structural steel.

The building utilizes high-speed, non-stop shuttle

elevators to sky lobby floors where passengers transfer to

local elevators serving the floors in between.

Burj Khalifa has 57 elevators

and 8 escalators. Travelling

at 10 meters/sec (33 feet/

sec) per second, they have

the world’s longest travel

distance from lowest to

highest stop. The building

service/fireman’s elevator

will have a capacity of 5,500

kilograms (12,000 pounds)

and is the world’s tallest

service elevator.

To achieve the greatest

efficiencies, the mechanical,

electrical and plumbing

services for Burj Khalifa

were developed all together

during the design phase of

the tower in cooperation with

the architect, structural

Burj Khalifa wind.jpg – © SOM Inside the high-speed elevator

© Emaar Properties PJSC

© Emaar Properties PJSC

7

Page 8

engineers and other consultants. The tower’s water

system supplies an average of 946,000 liters (250,000

gallons) of water daily. At peak cooling, Burj Khalifa will

require about 10,000 tons of cooling, equal to the cooling

capacity provided by about 10,000 tons of melting ice. Dubai’s

hot, humid climate combined with the building’s cooling

requirements creates a significant amount of condensation.

This water is collected and drained in a separate piping system

to a holding tank in the basement car park. The condensate

collection system provides about 57 million liters (15 million

gallons) of supplement water per year, equal to about 20

Olympic-sized swimming pools. The tower’s peak electrical

demand is 50 MVA, equivalent to roughly 500,000 100-watt

light bulbs all operating at the same time.

©EmaarProper tiesPJSC

8

Page 9

FactsaboutBurjKhalifa

Location: .......................... Downtown Dubai,

Dubai, United Arab Emirates

Architect:.......................... Skidmore, Owings & Merrill

LLP (SOM)

Building type: ............... Supertall skyscraper

Materials: ......................... Reflective glazing, aluminum

and textured stainless steel

Construction: ................ Reinforced concrete and steel

Date: ................................... From 2004 to 2010

Floor area: ....................... 464,511 m

2

(5.67 million square feet)

Height: ............................... 828 meters (2,716.5 ft.)

Stories: .............................. 160+ stories

©EmaarProper tiesPJSC

9

Page 10

With the design and engineering of Burj Khalifa, Skidmore,

Owings & Merrill LLP (SOM), joined forces with Dubai based

developers, Emaar Properties PJSC, to redefine what was

possible with supertall buildings.

With a portfolio that includes some of the most

important architectural accomplishments of the 20th and

21st centuries, including the John Hancock Center and Willis

(formerly Sears) Tower, SOM was perfectly placed to carry

out this challenging task.

To create Burj Khalifa — a building that shatters all

previous height records at 828 meters (2,716.5 feet) — a team of

more than 90 designers and engineers combined cutting edge

technology and culturally-influenced design to create a

global icon that will serve as a model for future urban centers.

Thearchitects

10

Page 11

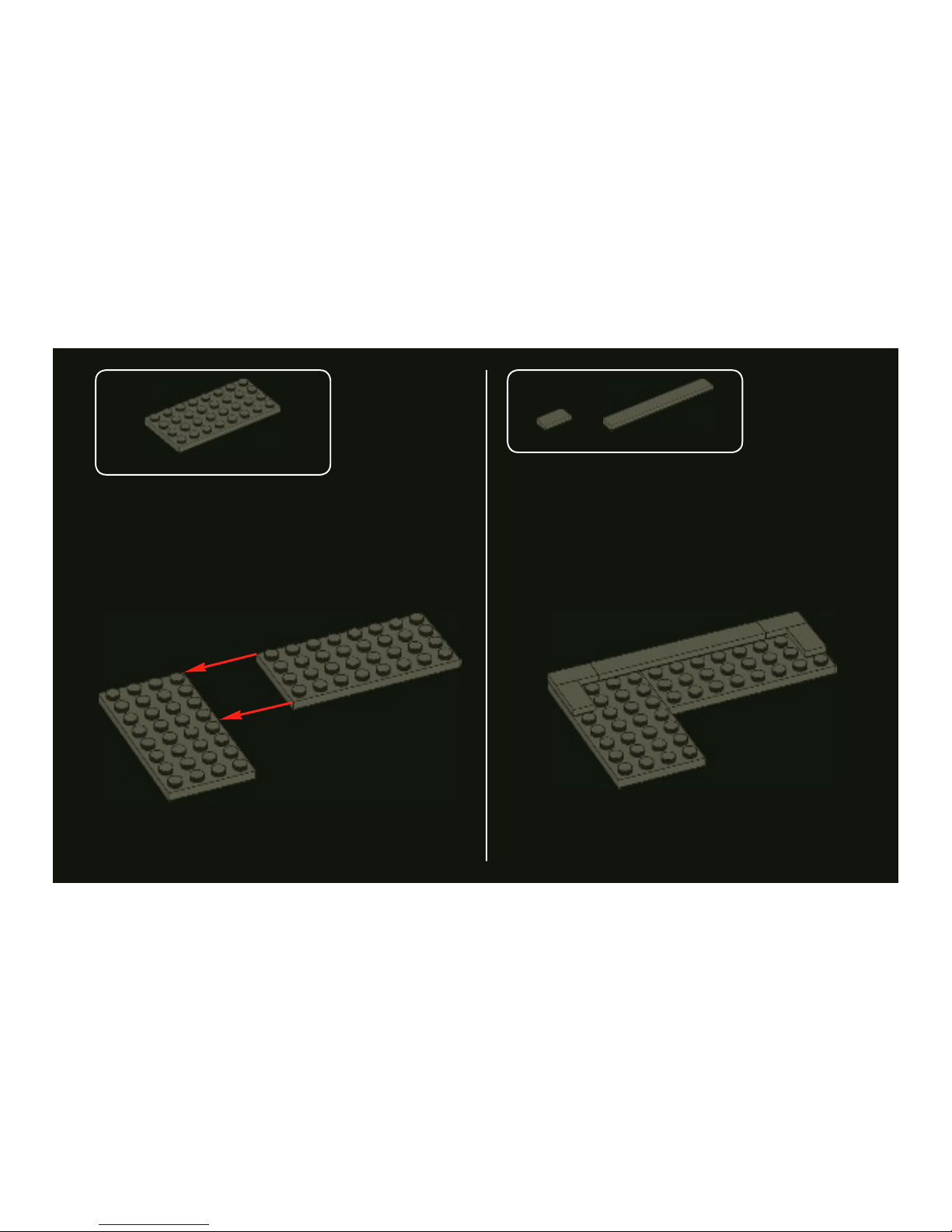

2x

1

4x 1x

2

11

Page 12

2x

3

2x

2x

1x

4

12

Page 13

1x 1x

5

4x

6

13

Page 14

5x

7

2x 1x

8

14

Page 15

20x

9

The interior is inspired by local

culture while staying mindful of the

building’s status as a global icon and

residence. The design features glass,

stainless steel and polished dark

stones, together with silver travertine

fl ooring, Venetian stucco walls,

handmade rugs and stone fl ooring.

15

Page 16

1x

1

2

3x

16

Page 17

3x 3x 3x

3

1 2

3x

17

Page 18

3x 3x

4

10

18

Page 19

1x 1x

11

4x 1x

12

19

Page 20

32x 8x

13

1 2

8x

20

Page 21

4x 3x

14

2x

Over 26,000 glass panels were

used in the exterior cladding of

Burj Khalifa. Over 300 cladding

specialists from China were

brought in for the cladding work

on the tower.

21

Page 22

28x

15

7x

22

Page 23

1x

16

1x

The opening ceremony of Burj Khalifa

featured a display of 10,000 fi reworks, light

beams and fur ther sound, light and water

eff ects. Using 868 powerful stroboscope

lights that are integrated into the façade

and spire, diff erent lighting sequences were

choreographed, together with more than 50

diff erent combinations of the other eff ects.

23

Page 24

4x

17

24

Page 25

18

4x 16x

4x

1 2

It will take 36 workers three

to four months to clean the

entire exterior façade using all

building maintenance units.

25

Page 26

2x 5x

19

26

Page 27

12x

20

3x

27

Page 28

4x 3x

21

2x

28

Page 29

4x

22

29

Page 30

2x 1x

23

30

Page 31

Burj Khalifa is truly the product of international

collaboration; over 60 consulants including 30 on-site

contracting companies from around the world were

involved in the project.

At the peak of construction, over 12,000 professionals and

skilled workers from more than 100 countries were on site

every day. The world’s fastest high-capacity construction

hoists, with a speed of up to 2 meters/sec (6.5 feet/sec)

(120 meters/min), were used to move men and materials.

Over 45,000 cubic meters (1.59 million cubic feet) of

concrete, weighing more than 110,000 tons, were used

to construct the concrete and steel foundations, which

feature 192 piles, buried more than 50 meters (164 feet)

deep. Burj Khalifa employs a record-breaking 330,000

cubic meters (11.6 million cubic feet) of concrete; 39,000

m/t of reinforced steel; 103,000 square meters (1.1 million

square feet) of glass; 15,500 square meters. (166,800 square

feet) of embossed stainless steel; and the tower took

22 million man-hours to build.

The amount of reinforced steel used at the tower, would if

laid end to end extend over a quarter of the way around

the world. The concrete used is equivalent to a sidewalk

1,900 kilometers (1,200 miles) in length, and the weight

of 110,000 elephants. The weight of the empty building

is 500,000 tons.

The tower accomplished a world record for the highest

installation of an aluminum and glass facade, at a height

of 512 meters (1,679.8 feet). The total weight of aluminum

used on Burj Khalifa is equivalent to that of five A380

aircraft, and the total length of stainless steel ‘bull nose’

fins is 293 times the height of the Eiffel Tower in Paris.

ConstructionHighlights

©EmaarProper tiesPJSC

31

Page 32

As an Architectural Artist my desire is to capture the essence

of a particular architectural landmark into its pure sculptural

form. I fi rst and foremost do not view my models as literal

replicas, but rather my own artistic interpretations through

the use of LEGO

®

bricks as a medium. The LEGO brick is

not initially thought of as a material typically used in creating

art or used as an artist’s medium. I quickly discovered the

LEGO brick was lending itself as naturally to my applications

as paint to a painter or metal to a blacksmith. As I explore

how to capture these buildings with the basic shapes of the

bricks and plates, I fi nd the possibilities and challenges they

off er almost magical.

Burj Khalifa

This model has two unique details surrounding its launch. It

is the fi rst International model to be showcased in the LEGO

Architecture line and it is also the latest skyscraper since the

Seattle Space Needle in continuing the Landmark theme. In

terms or design challenges this model really only had a few.

As impressive as the real structure is, when captured in its

smaller LEGO form the only discernable form is its 3-spoke

geometry. Y-shapes & triangular shapes can be tricky to

construct using square bricks. However, in this case the use

of a single Technic 3-bladed rotor propeller establishes the

basis of the entire model. From there I was able to have 9

points and 1 in the central core totaling 10 nodes from which

to build upward vertically, while expanding the propeller to

add 2 downward vertical points from each blade totaling an

additional 6 nodes. So, that single propeller piece anchors all

16 radial nodes and thus capturing the essence of the entire

design.

– Adam Reed Tucker

A Word from the Artist

32

Page 33

“Architecture — a wonderful game”

This was the title, or rather a paraphrase of the French

title (‘L’architecture est un jeu … magnifique’) of a 1985

exhibition hosted by the Pompidou Centre in Paris,

where 30 young European architects were given the

opportunity to play with the famous Danish LEGO

®

bricks. The original idea was actually Dutch, Rotterdam’s

Kunststichting arranging a small event the previous year

where ten local architects were let loose on a large

number of LEGO bricks. Such was the success of this first

initiative that the Pompidou Centre decided to expand

the idea to include 30 young aspiring architects from

across Europe—their goal: to each draw an imaginary

villa which would then, brick by brick, be built at LEGO

HQ in Billund.

During the event, many a quotation was used

from the history of architecture. For example, the Italian

Renaissance architect Palladio was quoted alongside

modernists such as Mies van der Rohe and Gerit Rietveld,

the quotes relating to architectural projects from oil

platforms to romantic ruins. It was a case of ‘no holds

barred’ and even though some of the projects produced

by the 30 talents ended in weird and wonderful pseudophilosophical comments on opportunities, or rather the

lack of same in the Eighties, it was all, nevertheless, a

wonderful game.

33

Page 34

Customer Service

Kundenservice

Service Consommateurs

Servicio Al Consumidor

www.lego.com/service or dial

00800 5346 5555 :

1-800-422-5346 :

References

Textcredits

EmaarPropertiesPJSC

SkidmoreOwings&MerrillLLP

Photocredits

EmaarPropertiesPJSC

SkidmoreOwings&MerrillLLP

34

Page 35

1x

302201

6x

306926

1x

424381 9

3x

416226

1x

4638309

4x

303526

112x

4211412

3x

4211399

3x

4211398

1x

4211414

22x

4211413

3x

4211429

3x

4211445

4x

4211404

5x

4211451

2x

4262978

18x

4211525

13x

4211473

2x

4538098

1x

4211573

Customer Service

Kundenservice

Service Consommateurs

Servicio Al Consumidor

www.lego.com/service or dial

:

00800 5346 5555

:

1-800-422-5346

Page 36

LEGO and the LEGO logo are trademarks of the/sont des marques de commerce de/

son marcas registradas de LEGO Group. ©2011 The LEGO Group. 4647837

Loading...

Loading...