Legion LGB-125 Installation Manual

Owner’s Manual

Includes the Installation, Operation, Maintenance,

and Service of Legion’s

Gas Self-Contained

Steam Jacketed Kettle

For Your Safety

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance. In the event a gas

odor is detected, shut down units at main shut-off valve and contact the local gas company or supplier for service.

Post in a prominent location a set of instructions to be followed in the event the user smells gas. Obtain these from your local

gas company or supplier.

Warning

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury, or death. Read the

installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

The Finest American Quality Since 1897

The Finest American Quality Since 1897

The Finest American Quality Since 1897The Finest American Quality Since 1897

LEGION INDUSTRIES, INC.♦370 MILLS RD.♦WAYNESBORO, GA 30830♦(800) 309-4895♦(706) 554-4411♦FAX: (706) 554-2035

Legion Gas Self-Contained Steam Jacketed Kettle

IMPORTANT!

Uncrating & Inspecting the Equipment

Legion Industries, Inc. is not responsible for loss or damage incurred in transit. The unit has been

assembled, tested, and inspected at the factory prior to shipment. Do not pay the freight bill until the

shipment has been thoroughly inspected!

Uncrate the equipment carefully and inspect for any damage. Also check the contents against the packing

list to make sure all accessories are included.

Important: The carrier is responsible for any shipping damage or lost parts during transit, whether visible or

concealed. You, as the recipient, are responsible for inspection and for filing all claims with the carrier.

Visible Loss/Damage: Be certain to note this on the freight or express receipt and have it signed by the

delivery person. File a claim for damages immediately, regardless of the extent of damage.

Concealed Loss/Damage: If damage is noticed after the equipment is unpacked, notify the freight company

and file a concealed damage claim. This must be done immediately. Be sure to retain the shipping

container for inspection.

i

Legion Gas Self-Contained Steam Jacketed Kettle

Table of Contents

Uncrating & Inspecting the Equipment ................................................................................................................i

Introduction ........................................................................................................................................................iv

Safety Precautions..............................................................................................................................................1

Important Warranty Information..........................................................................................................................2

Service Calls.......................................................................................................................................................3

Section I: Installation..........................................................................................................................................4

1. Positioning the Unit .....................................................................................................................................4

Fig. 1.1: Minimum Clearances................................................................................................................4

2. Draft Hood Installation .............................................................................................................................4

3. Leveling & Securing the Unit....................................................................................................................4

4. Electrical Connection ...............................................................................................................................4

5. Gas Connection.......................................................................................................................................5

Fig. 1.2: Configuration of Gas Connection..............................................................................................5

6. Checking For Gas Leaks .........................................................................................................................6

7. Gas Control - Pressure Verification .........................................................................................................6

Fig. 1.3: Pressure Regulator Specification Pressures (in Inches Water Column)..................................6

To check inlet pressure - with other equipment on the same line turned on and turned off: ......................6

To check outlet pressure - with other equipment on the same line turned on and turned off:....................7

8. Completing the "Installation Checklist" ....................................................................................................8

SECTION II: START-UP & OPERATION..........................................................................................................9

1. Initial Cleaning.............................................................................................................................................9

Removing & Cleaning the Draw-Off Valve: ...............................................................................................10

2. Lighting the Pilot ....................................................................................................................................10

3. Control Functions...................................................................................................................................10

Fig. 2.1: Control Panel Features...........................................................................................................11

Summary of Control Functions:.................................................................................................................11

Shutting Down the Unit:.............................................................................................................................11

How to Start Cooking:................................................................................................................................11

Section III: Service & Maintenance..................................................................................................................12

1. Servicing....................................................................................................................................................12

A) Replacing Primary Thermostat .............................................................................................................12

B) Replacing the Igniti on System Control..................................................................................................14

C) Replacing the Gas Burner or Burner Orifices.......................................................................................14

D) Replacing the Thermocouple and Pilot Burner Assembly....................................................................15

2. Actuator Maintenance and Adjustment..................................................................................................15

A) Actuator Tension Adjustment................................................................................................................15

B) Actuator: Re-Packing With Grease................................................................................................ .......16

Fig. 3.1: Actuator Components & Assembly.........................................................................................16

C) Actuator Replacement ..........................................................................................................................17

Fig. 3.2: Removing/Installing Actuators.................................................................................................17

3. Gas Control System..................................................................................................................................17

A). Maintenance of the Gas Control System.............................................................................................17

Fig. 3.3: VR4200A Gas Control .............................................................................................................18

Fig. 3.4: VR8304 Gas Control...............................................................................................................18

Fig. 3.5: Pilot System for the VR4200A Continuous Pilot Gas Control.................................................19

Fig. 3.6: Pilot System for the VR8304 Intermittent Pilot Gas Control ...................................................19

B) Identifying Unsatisfactory Pilot Flames.................................................................................................21

Fig. 3.7: Examples of Problem Pilot Flames.........................................................................................21

4. Filling Steam Jacket.................................................................................................................................22

Section IV: Caring For Stainless Steel ............................................................................................................23

Section V: Troubleshooting..............................................................................................................................24

1. Troubleshooting-General Problems.........................................................................................................24

ii

Legion Gas Self-Contained Steam Jacketed Kettle

2. Troubleshooting- VR420 0A Gas Control ..................................................................................................25

Fig. 5.1: The VR4200A Continuous Pilot Gas Control..........................................................................25

3. Troubleshooting—VR8304 Gas Control System ......................................................................................26

Fig. 5.2: The VR8304 Gas Control System ..........................................................................................26

Troubleshooting Chart...............................................................................................................................26

Checking the Grounding............................................................................................................................27

Checking the Ignition Cable.......................................................................................................................27

Checking and Adjusting Gas Input and Burner Ignition ............................................................................27

Section VI: Parts List .......................................................................................................................................28

1. General Parts List ....................................................................................................................................28

2. Actuator Parts List & Assembly.................................................................................................................29

Fig. 6.1: Actuator Assembly Diagram ...................................................................................................29

3. Compressio n Draw-Off P ar ts List & Assembly .........................................................................................30

Fig. 6.2: Com pr es sion Draw-O ff Assembly Diagr am............................................................................30

For Your Use & Review ....................................................................................................................................31

Installation Checklist .....................................................................................................................................31

Maintenance & Service Log ..........................................................................................................................32

Legion Limited Warranty and Extended Warranty Coverage...........................................................................33

iii

Legion Gas Self-Contained Steam Jacketed Kettle

Introduction

Congratulations on your Legion equipment purchase. This manual covers the installation, operation, and

maintenance of the Ga s Self-Contained Steam Jacketed Kettle.

This manual contains complete information. By reviewing it thoroughly and following its guidelines, your

equipment will provide you with a lifetime of dependable use.

IMPORTANT! There are three things you need to do as soon as possible after receiving and/or installing

your equipment, since they affect your warranty coverage.

1. Send in your "Warranty Registration Card." This is vital and necessary in the processing of any future

service required on your equipment.

2. Complete the "Installation Checklist," contained in this manual, at the time of installation. This is

necessary for your warranty to be valid.

3. Record the model number, serial number, and installation date for your unit and file this information for

future reference. Space for these entries is provided at the top of the "Maintenance and Service Log"

included at the end of this manual.

If, at any time, you have questions about warranty coverage, operating procedures, service, repairs, or

maintenance, contact:

Legion’s Customer Service Department

Post Office Box 728

Waynesboro, Georgia, 30830

Phone: (800) 887-1988

Fax: (706) 554-2035

Email: service@legionindustries.com

Once again we thank you for the purchase of your equipment. From its versatility, safety features, and

durable constr uction, to its time-tested performance and full HACCP comp liance, you’ve selected the finest

equipment available. We know it will provide you with reliable, efficient service for years to come.

Charles Brown

President

Legion Industries, Inc.

PS: Please visit our web site @ www.legionindustries.com

iv

Legion Gas Self-Contained Steam Jacketed Kettle

Safety Precautions

♦ Installation of the equipment must be done by a qualified technician, knowledgeable of and experienced in

the installation of commercial gas and electrical cooking equipment.

♦ Retain this manual for future reference.

Gas/Combustion Precautions

♦ Your installation must conform to local codes or in the absence of local codes, with the current National Fuel

Gas Code ANSI Z223.1 (latest edition). Do not store or use gasoline or other liquids with flammable vapors

in the vicinity of this equipment.

♦ Always disconnect the fuel source before servicing.

♦ The ignition system controls of this equipment have been factory set for either natural (manufactured) or LP

gas. Do not attempt to use an ignition system control set for natural (manufactured) gas with LP gas or an

ignition system set for LP gas with natural (manufactured) gas. Ignition system controls cannot be field

converted from one gas type to the other.

♦ It is your responsibility to post, in a prominent location, instructions to be followed in the event the user

smells gas. This information must be obtained from your local gas supplier. Until it is obtained, post the

label that came with this manual.

IMPORTANT! In the event gas odor is detected, do the following.

♦ Observe the posted instructions.

♦ Shut down the unit at the main shut-off valve.

♦ Contact the local gas company or supplier—from a phone away from the building—for emergency

service and follow the supplier’s instructions.

♦ If the gas supplier cannot be reached, call the fire department.

♦ Do not use any phone in the building.

♦ Do not light or start any appliance.

♦ Do not touch any electrical switch.

Pressure Testing Precautions on Gas Units

♦ The equipment and its indivi dual shut-off valve must be discon nected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPA).

♦ The equipment must be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of that system at test pressures equal to or less than 1/2 psig (3.45 kPA).

Positioning Precautions

♦ The unit must be placed on a non-combustible floor, under an e xhaust hood, with a fire retardant sy stem

and all connections and placement must comply with all applicable local and national codes. Your

ventilation hood, when installed, must conform to ANSI/UL 705 and ANSI/NFPA 96 (latest edition).

♦ Adequate make- up a ir mu st be prov id ed for e xhau st sy stem s in the ar ea where the equipment is to be

installed.

♦ No frame or restriction shall be constructed around the equipment that will restrict air movement into the

equipment's combustion area or prevent proper combustion.

♦ Adequate clearance for servicing and proper operation must be maintained.

1

Legion Gas Self-Contained Steam Jacketed Kettle

Electrical Precautions

♦ This equipment must be electrically grounded in accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA No. 70 (latest edition) or the Canadian Electrical

Code, CSA C22.1 (latest edition), as applicable.

♦ The pilot flame on this equipment is lit automatically and requires electrical power to operate. Therefore,

never attempt to operate the equipment during a power failure.

General Use Precautions

♦ Always instruct employees on the proper use of this equipment.

♦ Never attempt to move this equipment when it is full of hot oil or another hot liquid.

♦ Never operate this equipment during a power failure.

♦ This equipment is intended for other than household use.

Warning & Operating Plates

♦ All warning and operating plates on the equipment should be in place at all times. If plates are damaged or

lost, replace them immediately.

Product Improvements

♦ Be aware that as continuous product improvement occurs, specifications may be changed without notice.

Important Warranty Information

The Legion Limited Warranty is valid in the Continental United States and Hawaii and is void elsewhere. A

complete statement of warranty terms and conditions is included in this manual. However, to ensure that you are

familiar with the installation, maintenance, and o ther important warranty-related conditions, please study the

following.

The instructions in this manual must be read thoroughly before attempting installation, operation, maintenance, or

service. Legion Industries, Inc. reserves the right to render void any warranty on equipment not installed in

accordance with the manual by a qualified technician, knowledgeable of and experienced in the installation of

commercial gas and electrical cooking equipment.

Legion products are built to comply with applicable standards of manufacturers. Many local codes exist and it is the

responsibility of the equipment owner and installer to comply with these codes.

If the equipment has been changed, altered, modified, or repaired by other than a qualified service technician

during or after the one year limited warranty period, Legion Industries, Inc. shall not be liable for any incidental or

consequential damages to any person or to any property which may result from the use of the equipment

thereafter.

The Limited Warranty does not extend to:

1. Installation and start-up. Proper installation is the responsibility of the owner/installer. Repair services for the

same will not be covered.

2. Malfunction as a result of improper maintenance.

3. Failure as a result of improper use or abuse of equipment.

4. Repair services initiated without prior authorization from Legion.

5. Repair services for problems caused by inadequate gas supply pressure or low voltage supply.

6. Repairs made by anyone other than qualified service personnel recommended by Legion.

7. Damage caused in shipment.

8. Repair services for problems caused by routine maintenance or cleaning.

9. Damage caused by tampering with, removing, or changing a preset control or safety device.

2

Legion Gas Self-Contained Steam Jacketed Kettle

10. Damage caused by hitting the cooking surface with implements or by rubbing or scraping the cooking surface

with abrasive materials.

11. Damage caused by simple adjustments, such as actuator adjustments.

12. Lubrication of grease fittings or actuator springs and gears. These parts should be greased at least once

every six months.

13. Moving other equipment to gain access to the unit.

14. Damages to any part of the unit as a result of cleaning with high-pressure water or steam. Do not spray the

exterior of the equipment with water or steam!

15. Use of any replacement parts other than those supplied or authorized by Legion voids all warranties and can

cause bodily injury to the operator and damage to the equipment.

Refer to your warranty statement for those items that are covered for only a 90-day period.

Service Calls

All repair services under Legion’s Limited Warranty must be authorized in advance by Legion or performed by

Legion. Authorization may be obtained by calling:

(800) 887-1988

(within the Continental U.S. and Hawaii)

8 a.m. through 5 p.m. (EST), Monday through Friday

When calling, please have the following information available:

♦ name, address, and teleph one number of the end-user;

♦ location of the product;

♦ name, model number, and serial number of the product;

♦ description of the problem or defect.

Legion will then issue a service authorization work order number to one of its approved independent servicing

organizations or request that the product or part be shipped to Legion for repair or replacement, as appropriate.

Any defective part subject to a claim under the Limited Warranty must be shipped freight prepaid to Legion for

testing and examination. Legion’s decision as to the cause and nature of any defect under this Limited Warranty

shall be final.

3

Legion Gas Self-Contained Steam Jacketed Kettle

Section I: Installation

IMPORTANT! Installation of the equipment must be done by a qualified technician, knowledgeable of and

experienced in the installation of commercial gas and electrical cooking equipment. It is the responsibility of the

owner and installer to comply with all applicable local and national codes and regulations when installing the unit.

All internal wiring of the equipment is supplied complete and ready for final connection. A wiring diagram is

supplied behind the cover of the unit’s control console. Legion's Engineering Department must approve any

mechanical or electrical changes.

1. Positioning the Unit

WARNING:

• The unit must be placed on a non-combustible floor, under an exhaust hood, with a fire retardant system and all

connections and placement must comply with all applicable local and national codes. Your ventilation hood,

when installed, must conform to ANSI/UL 705 and ANSI/NFPA 96 (latest edition).

• Adequate make-up air must be provided for exhaust systems in the area where the equipment is to be installed.

• No frame or restriction shall be constructed around the equipment that will restrict air movement into the

equipment's combustion area or prevent proper combustion.

• Adequate clearance for servicing and proper operation must be maintained

Position the unit where you intend to use it. A minimum of fifteen (15) inches must be provided for servicing of

controls. Remember to also consider the required clearances of any other adjoining pieces of equipment.

Fig. 1.1: Minimum Clearances

Model Back of Unit Sides of Unit Draft Hood

LGB, LGBE 6” 6" 2”

2. Draft Hood Installation

Warning:

This unit is not suitable for connection to Type B gas vent. It is recommended that flue gases be vented to a

ventilating hood or directly to the atmosphere (outside air).

Connect furnished draft hood to the kettle flue outlet. All units have seven (7) inch diameter flue outlet with the

exception of the LGB/E 20, which has a six (6) inch diameter flue outlet.

3. Leveling & Securing the Unit

The feet of the unit may be adjusted so that the kettle is properly leveled.

4. Electrical Connection

WARNING:

• This equipment must be electrically grounded in accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA No. 70 (latest edition) or the Canadian Electrical Code, CSA

C22.1 (latest edition), as applicable.

4

Legion Gas Self-Contained Steam Jacketed Kettle

• Also, it is required that an electrical cut-off device, such as a fused disconnect switch or equivalent, be installed

in the power supply line between the main power supply and the unit.

• The pilot flame (LGBE only) on this equipment is lit automatically and requires electrical power to operate. The

unit will not operate if the power is off.

• The pilot flame (LGB only) on this equipment is lit manually and requires electrical power to operate. The unit

will not operate if the power is off.

A power cord is provided on the back of the unit, for connecting to the electric power supply. The installer should

verify the electrical requirements of the unit to make sure your power supply line is capable of powering the

equipment properly. This information is listed on the unit’s nameplate.

• Standard 120 Volt Model: Connect a 120 volt, 60 Hz, single (1) phase power cord.

• Optional 240 Volt Model: Connect a 240 volt, 60 Hz, single (1) phase power supply at the junction box.

5. Gas Connection

WARNING:

• Your installation must conform to local codes or in the absence of local codes, with the current National Fuel Gas

Code ANSI Z223.1 (latest edition), the Natural Gas Installation Code, CAN /CGA-B149.1 (latest edition), o r the

Propane Installation Code, CAN/CGA- B149.2 (latest edition), as appli cable.

• Do not store or use gasoline or other liquids with flammable vapors in the vicinity of this equipment.

• Always disconnect the fuel source before servicing.

• The ignition system controls of this equipment have been factory set for either natural (manufactured) or LP gas.

Do not attempt to use an ignition system control set for natural (manufactured) gas with LP gas or an ignition

system set for LP gas with natural (manufactured) gas. Ignition system controls cannot be field converted from

one gas type to the other.

• It is your responsibility to post, in a prominent location, instructions to be followed in the event the user smells

gas. This information must be obtained from your local gas supplier.

Fig. 1.2: Configuration of Gas Connection

1. Shut off the main gas supply

before beginning the gas

connection.

2. Properly configure the gas supply line to be used (see Fig. 1.2). The gas

supply line must be a minimum of 3/4" NPT pipe. It is your responsibility to

ensure that the supply line installed is large enough to achieve the proper

pressure and allow the required volume of gas to flow. A sediment trap must

be installed to protect against contamination of the ignition system control.

Install a manual shut-off valve between the gas supply line and the sediment

trap to allow for maintenance of the trap.

5

Legion Gas Self-Contained Steam Jacketed Kettle

In making the connections, use a good quality joint compound. If LP gas is supplied, a joint compound resistant to

LP gas should be used. Connect the supply line to the ball valve at the rear of the unit. Tighten the connection

securely.

6. Checking For Gas Leaks

WARNING:

• Do not permanently supply gas to the unit until the gas lines have been pressure tested. Faulty operation and

even equipment damage will result if the gas supply falls below requirements.

• The eq uipme nt and its individual shut-off valve must be disconnected from the gas supply pipi ng system during

any pressure testing of that system at test pressures in excess of 14 inch water column (or 1/2 psig or 3.45 kPA).

• The equipment must be isolated from the gas supply piping system by clo sing its individual manual shut-off valve

during any pressure testing of that system at test pressures equal to or less than 14 inch water column (or 1/2

psig or 3.45 kPA).

1. Turn on the main gas supply. With burner off, douse the pipe connections upstream of the ignition system

control with a rich soap and water solution. Bubbles indicate a gas leak. If a leak is detected, tighten pipe

connections. Replace the part if the leak cannot be stopped.

2. With main burner in operation, douse pipe joints and control inlet and outlet with rich soap and water solution.

If another leak is detected, tighten joints and pipe connections. Replace the part if the leak cannot be stopped.

7. Gas Control - Pressure Verification

Using a pressure gauge or a manometer, the installer must record the gas pressure at both the inlet and outlet of

the ignition system control—first with all equipment on the same gas line turned on, then with all equipment turned

off. These readings are necessary for your installation and warranty records. Gas pressure input and output

ratings for your equipment are listed on the unit’s nameplate. Acceptable pressure ranges are provided below. Do

not exceed these ratings. NOTE

must be checked first.

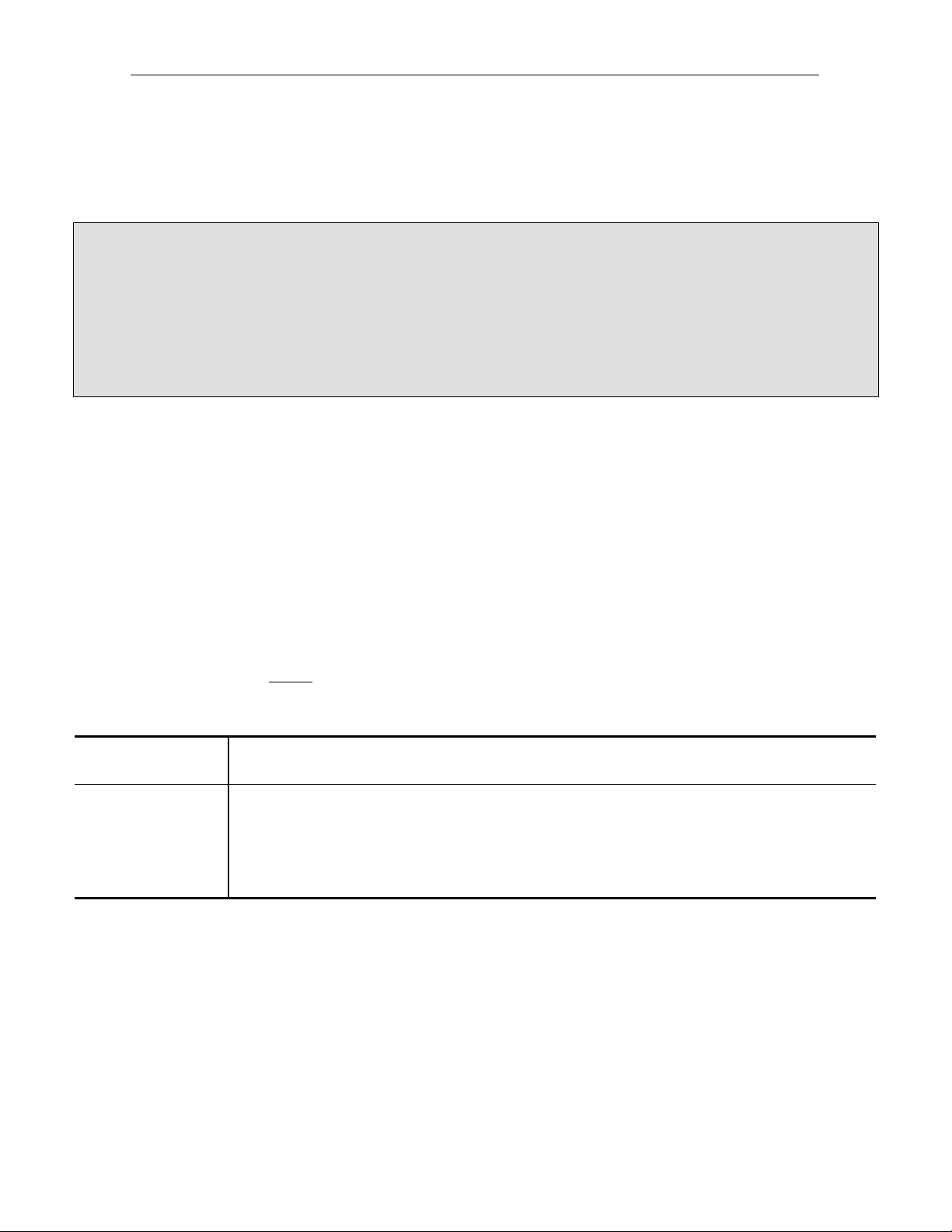

Fig. 1.3: Pressure Regulator Specification Pressures (in Inches Water Column)

Gas Valve Type Type of Gas Nominal Inlet Pressure

Standing Pilot Natural

Intermittent Pilot Natural

To check inlet pressure - with other equipment on the same line turned on and turned

off:

Check the inlet pressure with all equipment on the same gas supply line turned on and turned off.

Note: See Fig. 3.3 or Fig. 3.4 in Section III for a close-up view of the ignition system contro l and its components.

: Since outlet pressure is dependent upon proper inlet pressure, inlet pressure

LP

LP

Range

5.0—7.0" W.C.

12.0—14.0" W.C.

5.0—7.0" W.C.

12.0—14.0" W.C.

Factory Set Nominal Outlet

Pressure

3.5" W.C.

10.0" W.C.

3.5" W.C.

11.0" W.C.

Adjustment Setting

Range

3—5

8—12

3—5

8—12

1. Shut off the gas supply and remove the cover panel of the control console. Remove the inlet pressure tap and

connect the pressure gauge or manometer.

2. Turn the gas supply back on. Light the main burner. The main burner is lit by turning the primary thermostat

dial above room temperature. Note, in the case of standing pilot, you must first light the pilot. For instructions

on lighting the pilot refer to Section II, Startup and Checkout.

6

Legion Gas Self-Contained Steam Jacketed Kettle

3. Record the inlet pressure readings on the Installation Checklist for Warranty Validation. Be sure to take

readings with other equipment on the same line turned on and turned off.

4. Reverse the procedure in step 2 to turn off the main burner and shut off the gas supply before disconnecting

the manometer or pressure gauge.

Important!Always shut off the gas supply

at the manual valve in the gas supply

piping to the unit (or at the tank for LP

gas), before removing the inlet pressure

tap plug to connect or disconnect a

pressure gauge or manometer.

5. Replace the inlet pressure tap plug.

Inlet Pressure Too High? If natural gas pressure exceeds 7" water column or LP gas pressure exceeds 14"

water column, then a pressure-regulating valve must be installed in the gas supply line.

Inlet Pressure Too Low? If natural gas pressure is below 5" water column or LP gas pressure is below 12" water

column, then the installer must determine the problem. Too much equipment may be on the same line or a

larger gas supply line may be required.

Inlet pressure must be correct before checking the outlet pressure.

To check outlet pressure - with other equipment on the same line turned on and turned

off:

Check the outlet pressure with all equipment on the same gas supply line turned on.

1. Be sure the ignition system control knob is in the OFF position. Remove the outlet pressure tap plug and

connect the pressure gauge or manometer. Turn the ignition system control knob to the ON position.

2. Turn the gas supply back on and light the main burner by following Step 2 in the previous procedure for

checking the inlet pressure.

3. Record the outlet pressure readings by following Step 3 in the Check inlet pressure procedure for checking the

inlet pressure.

4. Turn OFF the main burner and shut off the gas supply before disconnecting the manometer or pressure gauge

by reversing the procedure in Step 2 in the previous procedure for checking the inlet pressure.

7

Loading...

Loading...