Page 1

300 N. Opdyke Rd.

Circulato

Auburn Hills, MI 48326

www.legendhydronics.com

www.legendhydronics.com

1-866-752-2055

866-752-2055

HS-808

HYDRAULIC SEPARATOR

Introduction

The HS-808 Hydraulic Separator is a multi-function device that provides hydraulic separation, air elimination

and dirt removal in a single, compact device that requires little maintenance. The HS-808 functions as a

“Bridge and a Disconnect” between a heating/cooling systems power generating unit(s) and the distribution

system. The ow pattern through the HS-808 depends on the ow rates of the primary and secondary sides

of the system. (See ow diagrams in the Size Section) The various mixing patterns internal to a hydraulic

separator create a blending of the primary and secondary ows and temperatures, thus creating a “Bridge”

between the two sides. Modern hydronic systems, especially those that contain low mass, water tube

boilers, like a Mod-Con, generally have a relatively high ow / high head pumping requirement to operate at

peak efciency on the Primary side. In contrast, the Secondary, distribution side of the system, often has a

relatively low, even variable ow, with very little pumping head. The HS-808 Hydraulic Separator provides

a “Disconnect” between these very distinct requirements on the primary and secondary sides of the system,

so that they do not interfere with each other. Hence, the “Bridge and Disconnect” benet of a hydraulic

separator.

Additional features of the HS-808 Hydraulic Separator include: Air & Debris Removal - The ows of both the

primary and secondary sides of the system go into the HS-808 where the uid velocities slow down allowing

air to rise and be vented out through a serviceable automatic air vent, and dirt particles to fall out and collect

at the bottom, ready to be purged out through the Purge Valve with standard ¾” garden hose connection.

High

Eciency

Boiler

To & From Zones

(e.g. Radiant Manifolds)

Installation Guide

Pictured:

HS-808 with LegendConnect™

Adaptors

Zone

Circulators

Boiler

r

Hydraulic

Separator

w/Air Vent

and Purge

Pictured:

Sample System

Advantages of the HS-808

- Provides hydraulic separation between the primary & secondary sides of the system.

- Allows for variable system ow and xed or variable boiler ow, without pump interference between

the two sides.

- Includes a high capacity automatic air vent with service check for the removal of air from the system.

- Includes a drain valve with ¾” garden hose threads for the purging of collected dirt from the system.

- Available in up to 6 different connection types, in multiple sizes.

- Has a ½” plugged port where you could mount a thermometer and / or pressure gauge.

- Includes an aluminum embossed insulation shell and aluminum tape.

Page 2

300 N. Opdyke Rd.

Auburn Hills, MI 48326

www.legendhydronics.com

www.legendhydronics.com

1-866-752-2055

866-752-2055

HS-808

Installation Guide

HYDRAULIC SEPARATOR

HS-808 Size Selection

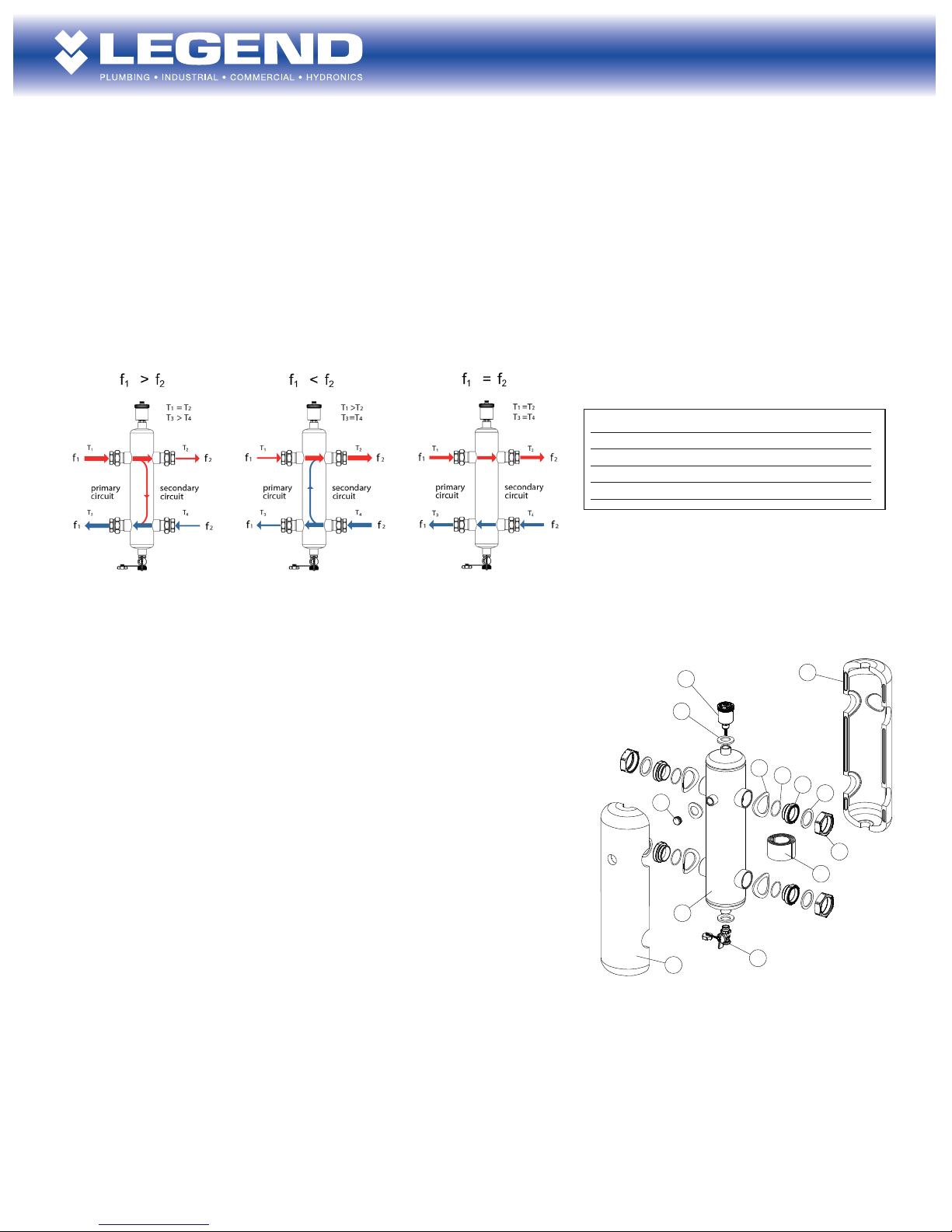

To select the proper size HS-808 for the project, determine the maximum ow rate for both the primary (f1) and secondary (f2) circuits, considering each of the

possible ow conditions for the system as shown in the diagrams below. Select the HS-808 connection size from the Sizing Chart below that can handle the

highest of (f1) and (f2).

SIZING CHART

Connection Size Maximum Flow Rate Cv

1” 11 gpm *

1-1/4” 18 gpm *

1-1/2” 25 gpm *

*The pressure drop through the HS-808 is so low, the Cv is not

measurable.

Installation / Assembly

1. To install the HS-808 Hydraulic Separator, remove the Union Nut (13) and EPDM Gasket (12) from

all four connection ports and set them aside.

2. Install the adhesive insulation rings, (5) & (6) around the stub pipes of the HS-808, to prepare

for the use of the insulating shell. Remove the adhesive backing and attach each piece around the

corresponding connection size.

3. Install the system piping into the selected LegendConnect™ adaptor using standard piping

practices. (For more detailed instructions on installing the LegendConnect™adaptors, please review

the LegendConnect™ Installation Manual.)

4. After the system piping is connected to the LegendConnect™ adaptor, take the union nut (13) that

was removed in step 1, and slide it over the system pipe.

5. Insert the EPDM gasket (12) that was removed in step 1 into the union nut, and hand tighten it to

one of the HS-808 ports.

6. Repeat steps 3 thru 5 for the other three ports.

7. After all four of the LegendConnect™ adaptors have been attached, position the HS-808 in the

desired position in the system and use a wrench to tighten the union nuts. Typically no more than a ¼

turn past hand tight is needed to create a seal.

2

6

5

4

1

7

3

8

11

10

12

13

9

Page 3

300 N. Opdyke Rd.

Auburn Hills, MI 48326

www.legendhydronics.com

www.legendhydronics.com

1-866-752-2055

866-752-2055

HS-808

HYDRAULIC SEPARATOR

Installation / Assembly-continued

8. The Air Vent (2) should always be installed onto the 1/4” x 1/2” Service Check Adapter (included

with the Automatic Air Vent). Thread the male end of the Service Check Adapter into the top 1/2”

port on the HS-808. Thread the 1/4” male threads of the Air Vent into the Service Check Adapter

hand tight¹ only.

9. Thread the male end of the Fill/Purge Valve (3) into a lower 1/2” port of the HS-808 until tight¹.

Orient the Fill/Purge Valve so that the handle can be operated comfortably once the HS-808 is

installed. The opposite end of the Fill/Purge Valve has a 3/4” male garden hose thread (GHT) port

and includes a brass cap with plastic tether. The plastic tether should slide over the end of the GHT

port end of the Fill / Purge Valve. The brass cap, with EPDM gasket included, should be threaded on

to the GHT port of Fill / Purge Valve until ready to use.

10. Install the insulation shell, (7) & (8) on the back side rst, then on the front side. Push the two

halves together and then use the aluminum tape (9) to seal the seams and keep the two halves of

the insulation shell together.

Installation Guide

2

6

5

4

1

7

3

8

11

10

12

13

9

Note: These parts seal together and to the manifold with an EPDM gasket (o-ring). One quarter (1/4) turn beyond

“hand-tight” is normally sufcient to seal properly. If turning beyond 1/4 turn is required to align gauges and

handles then do so, up to one (1) full turn beyond “hand-tight”.

Maintenance

A. Air Vent cleaning (as recommended by system designer, typically once per year minimum) – Remove the

air vent from the 1/4” x 1/2” service check adapter by un-threading counter-clock wise, as quickly as possible.

While un-threading the air vent from the check valve, a small amount of system uid may leak (drip) out, but

should stop upon nal removal from the check valve. This is normal as the check valve mechanism does not

complete close off until the air vent is fully removed. Un-thread the cap on the air vent, counter-clock wise

and remove the internal plastic components. Rinse the plastic components with clean water to wash off any

debris. Check and rinse, as needed, any debris from within the brass air vent body prior to reinserting the plastic

components. Re-attached the air vent cap by tightly threading clock-wise onto the air vent body. Replace the air

vent back into the 1/4” female threads of the check valve, hand tight only.

B. Debris blow out (as recommend by system designer, typically within 1 week of system start-up and a

minimum of once per year thereafter) – If possible, close the isolation valves for the HS-808 to isolate it from

system pressure. If isolation valves have not been installed, the following instructions can still be followed;

however special care should be used when opening the drain valve as excessive loss of system uid may occur.

Remove the brass cap from the GHT on the drain valve. Attach a drain hose with GHT female connection to

the end of the drain valve and locate the open end of the hose in a bucket or suitable drain location. Open the

drain valve (no more than 2 seconds at a time if the HS-808 has not been isolated) to allow the debris collected

at the bottom of the HS-808 to blow out through the hose and into the bucket or suitable drain location. Once

completed, remove the hose from the drain valve and re-install the cap.

PART

1 Body

2 Automatic Air Vent w/ Check

3 Drain Valve w/ GHT

4 Temp. / Pressure Port Plug

5 Adhesive Insulation Ring Lg (x4)

6 Adhesive Insulation Ring Sm (x3)

7 Insulation Shell, front

8 Insulation Shell, back

9 Insulation Tape

10 O-Ring

11 MPT body adapter

12 Adapter gasket

13 Union nut

C. Check system pressure into the HS-808, slowly reapply system pressure and check for leaks. Once it’s

conrmed that there are no leaks, the system can be put back into operation. Especially if no isolation valves were

used, you may need to repeat the ll/purge procedures recommended by the system designer to replace lost uid

and repressurize the system.

Loading...

Loading...