Legacy L8305, L8305-EU, L8306, L8306-EU, L8310 Parts and Technical Service Guide

...

Please read and follow instructions

carefully; otherwise, warranty may be void.

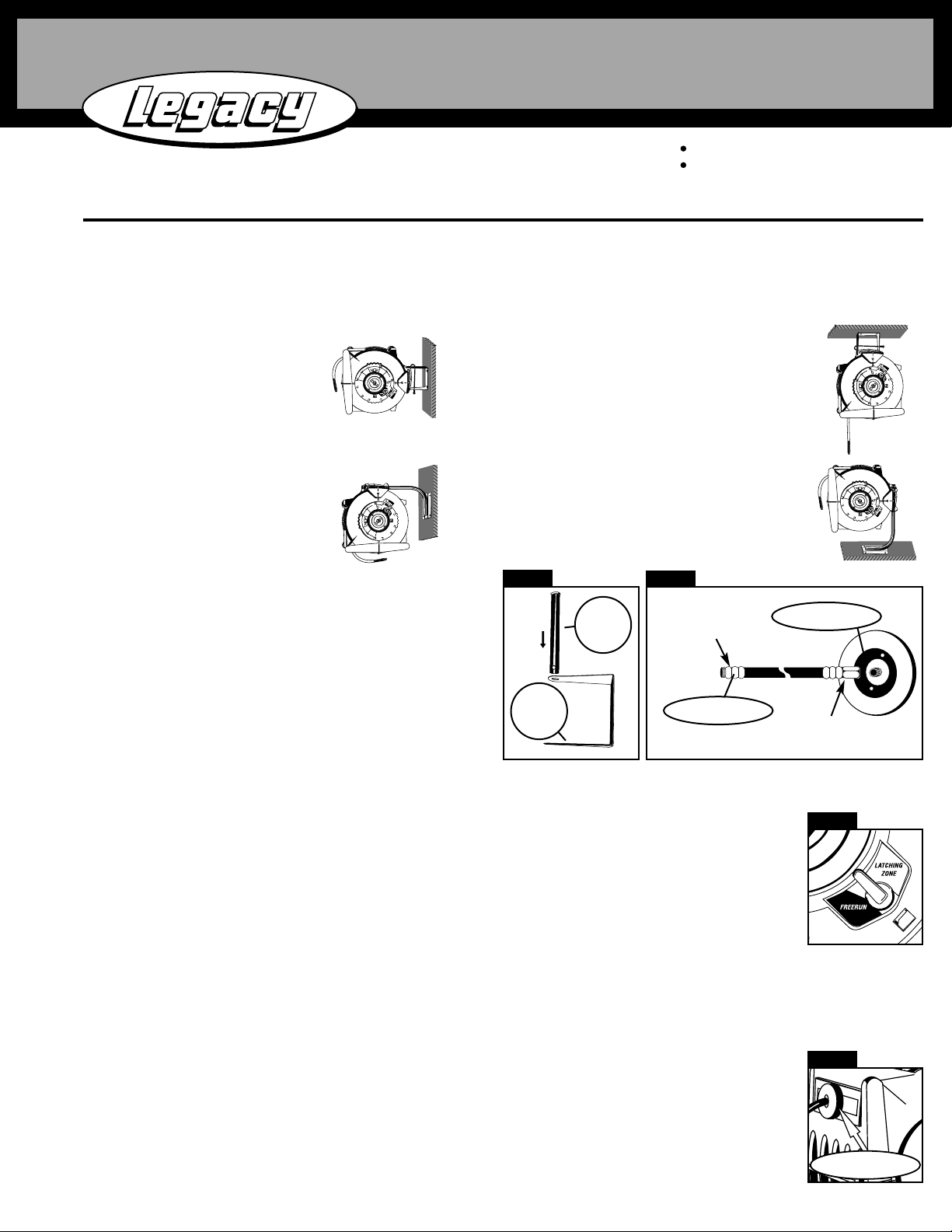

Mounting Options:

CAUTION:

Maximum installation height is 15 ft. (4.5 meters) above ground. Maximum weight of hose end tools is 4 lb. ( 2 kg). Maximum working

pressure is 350 PSI. Do not stand or step on top of reel!

Installation:

LEVELWIND retractable hose reels are designed for minimum assembly.

1) Place bracket on a flat mounting surface. With a pencil trace bracket

back holes onto surface. Use a leveling device to ensure that the

bracket will be level once fastened. Fasten brackets to surface with

screws ( screws are not included ).

2) Remove Bracket Rod (A) from Bracket (B) ( SEE FIGURE 1 )

3) Place reel into bracket making sure the reel hole is aligned with

bracket end holes.

4) Insert Bracket Rod through the aligned holes of Reel and Bracket.

5) Connect female end of lead-in hose to inlet connection on reel.

Connect male end to air or water source ( SEE FIGURE 2 ).

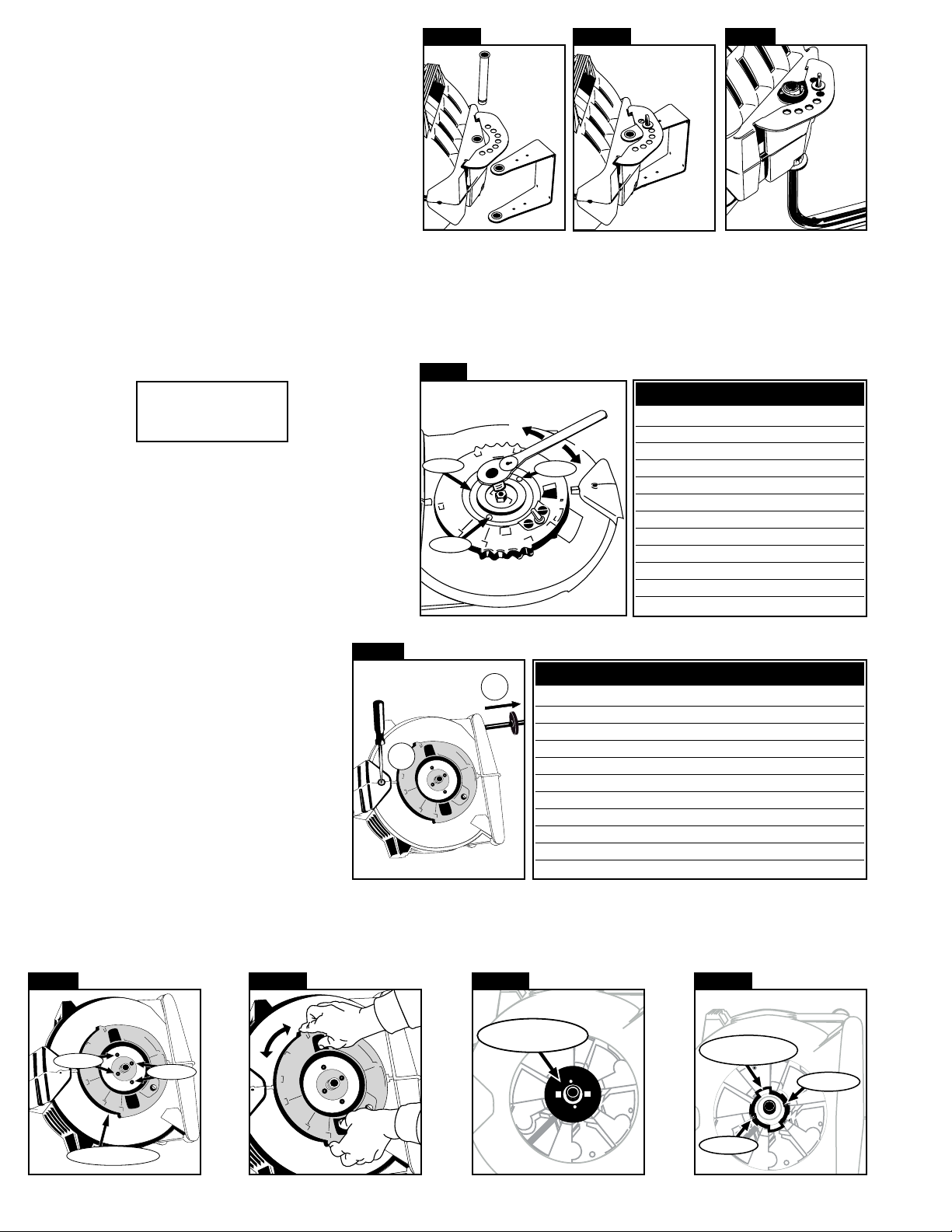

Operating Instructions:

LEVELWIND retractable hose reels can operate in FREERUN or can be latched every 3 ft. by switching to the LATCHING ZONE. Simply turn the mode

switch to desired position! ( SEE FIGURE 3 )

THE “LA TCHING ZONE”: LEVELWIND reels have a single latching zone. The reel can be latched for every drum revolution

approx. 3 feet of hose). There are audible clicking sounds as the spring loaded latch passes over the latching zone. The latching

zone flips the latch so that the latch goes into or by-passes the latching position. Pulling hose straight out off the reel “flips the

latch” so it can go into the latching position. Retracting the hose into the reel keeps the latch “flipped” so that the latch bypasses the latching position.

FREERUN MODE: The hose does not latch in this mode. Hose will automatically retract back into reel. The Hose stopper

position may be adjusted to desired length for application (SEE FIGURE 4)

CAUTION!

Do not release the end of the hose

when rewinding as personal injury or damage could result!

TM

Retractable Air & Water Hose Reels

Parts and Technical Service Guide

Carretes retráctiles para mangueras de aire y de agua guía de componentes y servicio técnico

Dévidoirs de tuyau d'air et d'eau rétractable guide de pièces et de service technique

LLeevveellwwiinndd

TTMM

SSeerriieess

Model L8305 Model L8305-EU Model L8306 Model L8306-EU Model L8310 Model L8310-EU

Model L8335 Model L8335-EU Model L8346 Model L8347 Model L8349

INS8306-0103

MMoouunnttiinngg oovveerrhheeaadd

Up to 15 ft. (4.5 m) from floor. Use

standard Replacement Part L8300-W Wall /

overhead bracket.

MMoouunnttiinngg ttoo wwaallll

Positioned up to 5 ft. (1.8 m) high.

Use standard Replacement Part

L8300-W Wall /Overhead bracket

MMoouunnttiinngg ttoo aa bbeenncchh

Use optional Bench / High Wall mounting

bracket model L8300-B

HHiigghh WWaallll MMoouunnttiinngg

Mount reel between 10 ft. and 15 ft.

high on wall. Use optional Bench / High

Wall mounting bracket Model L8300-B

Fig. 1

Male end to source

Female end to reel inlet

Fig. 2

Reel Inlet

Lead-in Hose

A

Bracket

Rod

B

Bracket

Page 1

LATCHING - Pull out the desired length of hose. As you are pulling out hose from the reel, listen for a “click”. STOP!

Don’t pull any further! If you keep pulling out hose (more than 14”) after hearing the “click”, you will have pulled past the

latching zone. Now, allow the hose to go back into the reel (less than 14”) and the latch will drop into the latching position. The reel is now

latched!

RETRACTING - Assuming the latch is engaged in the latching position, pull out hose until you hear a “click” (approx. 14”). STOP! Don’t

pull any further! If you pull out more than 3 ft. of hose after hearing the “ click”, you will have gone a full drum revolution and back into the

latching zone where the reel will once again be latched. Now, allow the hose to retract back into the reel. The hose reel will continue retracting

hose until it is fully retracted. If you decide to re-latch the reel while you are still retracting hose, simply listen for a click.

STOP! Slowly pull out hose until you hear a second click. STOP! Don’t pull any further. Now, slowly allow the hose back

into the reel (less than 14”) and the latch will drop into the latching position. The reel is now latched.

Fig. 4

Fig. 3

Hose Stopper

SEVEN POSITION LOCKING BRACE

LEVELWIND retractable hose reels can swing freely on bracket or can

be locked in one of seven positions, allowing for specific mounting

requirements.

SSttaannddaarrdd bbrraacckkeett

1) Remove bracket rod from reel. (SEE FIGURE 5A)

2) Place seven position locking brace over bracket so that bracket

rod holes are aligned. Replace bracket rod so that brace, reel &

bracket are attached. (SEE FIGURE 5B)

3) Rotate bracket so that it is at desired angle & lock into place with

fastener. (SEE FIGURE 5B)

Maintenance Procedures

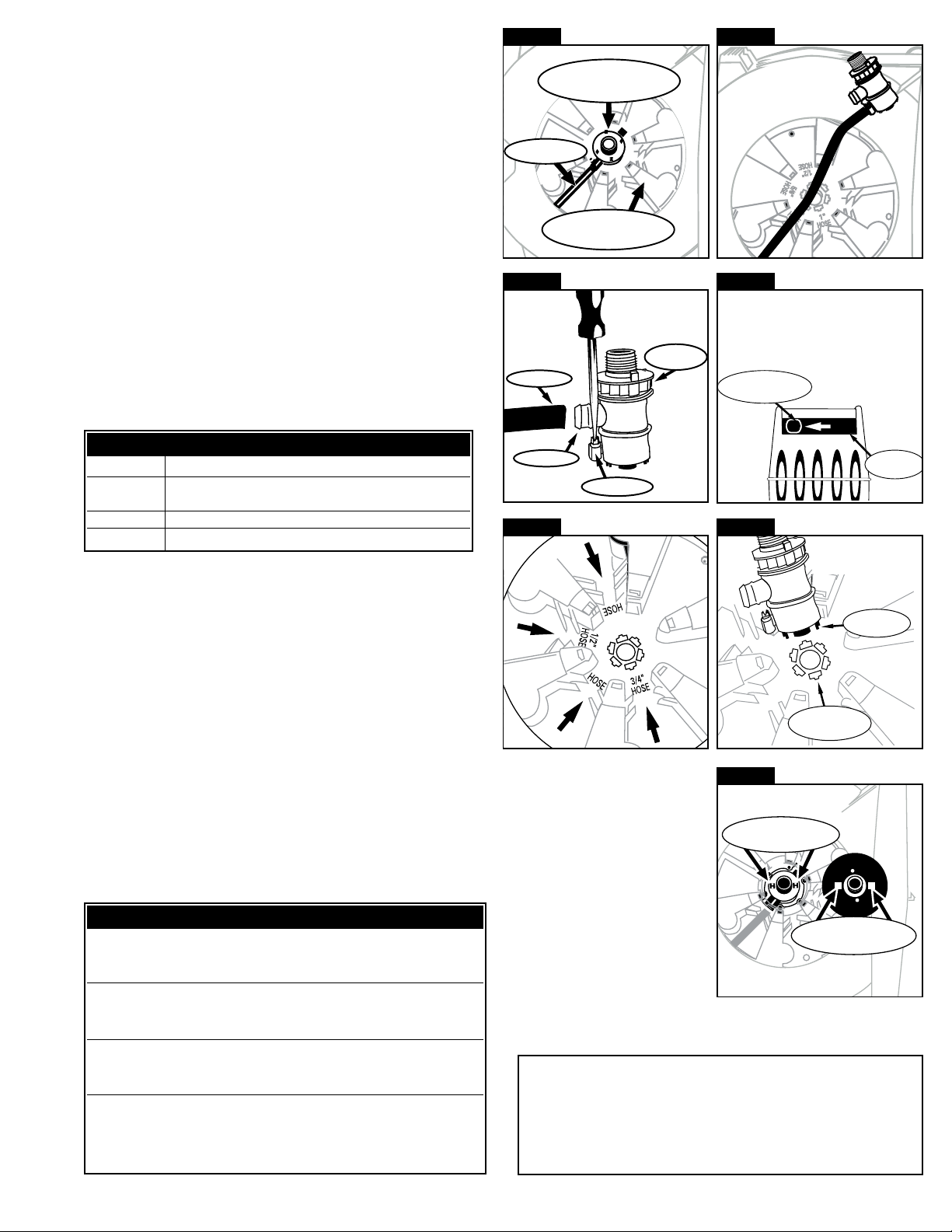

TENSION ADJUSTMENT:

This reel is preloaded with spring tension that is set at the factory. If the reel becomes completely un-tensioned, please identify your hose reel model

number referenced in the Factory Preset Tensioning Table to find out how many turns are needed for proper tensioning. If a heavy air tool is attached

to the end of the hose, you may need to add tension to overcome the weight of this tool. DO NOT EXCEED one full turn past the number of turns

listed in the Factory Preset Tensioning Chart below.

1) Lay reel on its side. ( SEE FIGURE 7 )

2) Place wrench on hub fitting plate nut. HOLD WRENCH FIRMLY.

3) Unscrew hub. DO NOT REMOVE SIDEPLATE.

4) Turn wrench either ½ turn or no more than one full turn. Turn

clock wise to increase tension. Turn counterclockwise to

decrease tension.

5) Replace hub plate screws and tighten. Return reel to mounting

bracket.

HOSE REPLACEMENT:

To ensure proper performance, please consult the Hose

Replacement Kit table for the appropriate part number

to order. Call 1(800) 645-8258 to order kit.

RReeppllaacceemmeenntt HHoossee KKiittss

1) Pull entire length of hose out of reel.

( SEE FIGURE 8 )

2) While entire length of hose is out of the reel, place

long screw driver ( 3/8” in diameter ) all the way

though the the hole located at the back portion of

reel. This eliminates any chance for the reel to

retract while replacing hose.

SSiiddeeppllaattee rreemmoovvaall

3) Locate inlet sideplate. Remove four fasteners (SEE FIGURE 9 ). While placing fingers on grooves located on the top and bottom of sideplate,

depress locking tabs at the same time with thumbs (SEE FIGURE 10). Rotate side plate either way until sideplate unlocks. Remove sideplate.

4) Remove wear plate (SEE FIGURE 11). Unscrew two fasteners on wear ring and remove wear ring (SEE FIGURE 12).

Page 2

Factory Preset Tensioning Table

MMooddeell ## ## ooff TTuurrnnss

L8305 3

L8305-EU 3

L8306 5

L8306-EU 5

L8310 4

L8310-EU 4

L8335 4

L8335-EU 4

L8346 4

L8347 4

L8349 4

Replacement Hose Kits

MMooddeell ## DDeessccrriippttiioonn

RP005005 Replacement Hose Assembly for L8305

RP005005-EU Replacement Hose Assembly for L8305-EU

RP005006 Replacement Hose Assembly for L8306

RP005006-EU Replacement Hose Assembly for L8306-EU

RP005008 Replacement Hose Assembly for L8310

RP0050058-EU Replacement Hose Assembly for L8310-EU

RP005035 Replacement Hose Assembly for L8335

RP005035-EU Replacement Hose Assembly for L8335-EU

RP005047 Replacement Hose Assembly for L8347

RP005049 Replacement Hose Assembly for L8349, L8346

TOOLS REQUIRED:

Phillips Screw Driver

¾” Socket Wrench

Fig. 5a

Fig. 5b

Fig. 6

Fig.7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Optional Bench/High Wall

Mounting Bracket

(see figure 6)

Hub

Screw

Decrease

Increase

Screw

2

1

Screws

Back

Inlet Side Plate

Screws

Front

Wear Plate

Wear Ring

Screws

Screws

5) Pull swivel assembly firmly from hose spool

( SEE FIGURE 13 and 14 ).

6) Unscrew Hose Clamp and pull hose off hose barb on swivel.

(SEE FIGURE 15)

7) Pull remaining length of hose out reel opening located at the reel

front.

8) Take replacement hose through opening located at the front of reel.

Thread hose through hose leveling mechanism. (SEE FIGURE 16)

9) Insert hose through the center of the hose spool. Four openings are

referenced with the following hose I.D. dimensions located at the

center of hose spool: 3/8”, 1/2”,5/8” & 3/4”. Locate the appropriate

hose I.D. and pull through that opening. (SEE FIGURE 17) Pull

enough hose to allow the hose to connect to appropriate hose barb

on swivel.

10)Replace hose onto hose barb, tighten hose clamp onto hose & place

swivel into hose spool housing. Make sure that drive tabs for spool

located on swivel are accepted by tab receivers in hose spool. (SEE

FIGURE 18)

11)Replace wear ring and fasten with wear ring screws. Replace wear

plate so that the swivel drive tabs insert into wear plate tab receivers.

(SEE FIGURE 19)

12)Replace sideplate so that the plate snaps flush to side of reel. Turn

sideplate until locking tabs connect to sideplate.

13)Turn swivel so that fastener holes of swivel and sideplate align.

Replace the four sideplate fasteners and tighten.

14)Remove Screw driver.

15)Retract hose back into reel.

SWIVEL SEAL REPLACEMENT

IMPORTANT:

To ensure proper performance, please refer to the Swivel

Seal Replacement Kit table to order the correct part number. Call 1(800)

645-8258 to order kit.

1) Repeat steps 1- 6 in the HOSE REPLACEMENT procedure.

2) Place hose onto hose barb of new swivel body. Tighten hose clamp

onto hose & place swivel into hose spool housing. Make sure that

drive tabs for spool located on swivel are accepted by tab receivers in

hose spool (SEE FIGURE 18).

3) Replace wear ring and fasten with wear ring screws. Replace wear

plate so that the swivel drive tabs insert into wear plate tab receivers.

(SEE FIGURE 19)

4) Replace sideplate so that the plate snaps flush to side of reel. Turn

sideplate until locking tabs connect to sideplate.

5) Turn swivel so that fastener holes of swivel and sideplate align.

Replace the four sideplate fasteners and tighten.

6) Remove Screw driver.

7) Retract hose back into reel.

Page 3

TECHNICAL ASSISTANCE:

Call 800-645-8258 if you have any questions

regarding the installation or operation of this

reel.

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

Troubleshooting

11)) HHOOSSEE WWIILLLL NNOOTT RREETTRRAACCTT

1a. Pull on hose, push latching switch to FreeRun mode. Retract hose into reel.

1b. Spring is broken. Call service center.

22)) HHOOSSEE WWIILLLL NNOOTT FFUULLLLYY RREETTRRAACCTT

2a. Spring tension too light?

2b. Replacement hose too heavy?

33)) RREEEELL WWIILLLL NNOOTT LLAATTCCHH

3a. Are you releasing hose too quickly?

3b. Broken latching pawl or mode switch?

44)) RREEEELL LLEEAAKKSS

4a. Damaged hose?

4b. Loose fittings?

4c. Worn swivel seals?

Swivel Seal Kits

PPaarrtt ## DDeessccrriippttiioonn

RP005007-38 Seal Replacement kit for reel model L8305, L8305-EU, L8306

L8306-EU, L8310. L8310-EU

RP005007-12 Seal Replacement kit for reel model L8335, L8335-EU

RP005007-58 Seal Replacement kit for reel model L8346, L8347 & L8349

Swivel Body

Hose

Hose Spool

Hose

Swivel

Assembly

Hose Leveling

Mechanism

Hose Barb

Hose Clamp

3/8"

5/8"

Drive Tabs

Tab Receivers

Swivel

Drive T abs

Hose Spool

Reel

Opening

Swivel

Wear Plate

Tab Receivers

LLeeggaaccyy MMaannuuffaaccttuurriinngg CCoommppaannyy

510 57th st. Marion, IA 52302 USA

Tel (319) 373-7305 (800)645-8258 Fax (319) 373-7309

legacy@legacymfg.com www.legacymfg.com

Optional Bench &

High Wall Mounting

Bracket Model L8300-B

Page 4

2

TTWWOO YYEEAARR LLIIMMIITTEEDD WWAARRRRAANNTTYY**

LEGACY MANUFACTURING COMPANY ("LEGACY") warrants that this equipment will be free

from defects in material and workmanship for a period of two (2) year from the date of

purchase, under normal use. LEGACY’S sole obligation under this warranty is limited to

replacing or repairing, free of charge, any equipment that proves to be defective under normal

conditions and use according to the recommendations of LEGACY. To obtain repair or

replacement, the equipment must be shipped to a LEGACY authorized Warranty and Service

Center during the warranty period, transportation charges prepaid, with proof of date of

purchase. In the event of repair or replacement, the warranty period shall not be extended

beyond the original warranty period.

This warranty is extended to the original purchaser only and is not transferable. This warranty

does not apply to normal wear items such as packings, seals, tips and filters, or to equipment

damaged from accident, overload, abuse, misuse, negligence, faulty installation or abrasive or

corrosive materials, or to equipment repaired or altered by anyone not authorized by LEGACY

to repair and alter equipment. No allowance will be granted for any repairs or alterations made

by a purchaser without LEGACY’S prior written consent.

LEGACY WILL BEAR NO OTHER EXPENSE, INCLUDING BUT NOT LIMITED TO LABOR AND

MATERIAL COSTS (OTHER THAN THOSE SPECIFIED HEREIN) OF ANY KIND, AND YOUR

EXCLUSIVE REMEDY, IN LIEU OF ALL INCIDENTAL, SPECIAL, CONSEQUENTIAL OR ANY

OTHER DAMAGES, INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR NEGLIGENCE, IS

LIMITED TO REPAIR OR REPLACEMENT AS HERETOFORE DESCRIBED. THE FOREGOING

WARRANTIES ARE IN LIEU OF ALL OTHER REPRESENTATIONS OR WARRANTIES, EXPRESS

OR IMPLIED OF ANY KIND REGARDING ANY EQUIPMENT, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE OR USE. IN NO CASE SHALL LEGACY BE LIABLE FOR ANY SPECIAL, INCIDENTAL

OR CONSEQUENTIAL DAMAGES BASED UPON BREACH OF WARRANTY, BREACH OF

CONTRACT, NEGLIGENCE, STRICT LIABILITY, OR ANY OTHER LEGAL THEORY.

Unless modified in a writing, signed by both parties, this Limited Warranty is understood to be

the complete and exclusive agreement between the parties, superseding all prior agreements,

oral or written, and all other communications between the parties relating to the subject

matter of this Limited Warranty. Any action for breach of warranty must be commenced

within twelve (12) months following the end of the warranty period.

* If this equipment contains a hose, the hose is warranted for ninety (90) days only. The

remaining portions of this equipment are warranted for two (2) year, as described above.

While necessary maintenance or repairs on your Legacy equipment can be performed by any

company, we recommend that you use only authorized Legacy service centers. Improper or

incorrectly performed maintenance or repair voids this warranty. Contact us at

legacy@legacymfg.com or www.legacymfg.com for ordering, installation instructions. or a list

of authorized service centers.

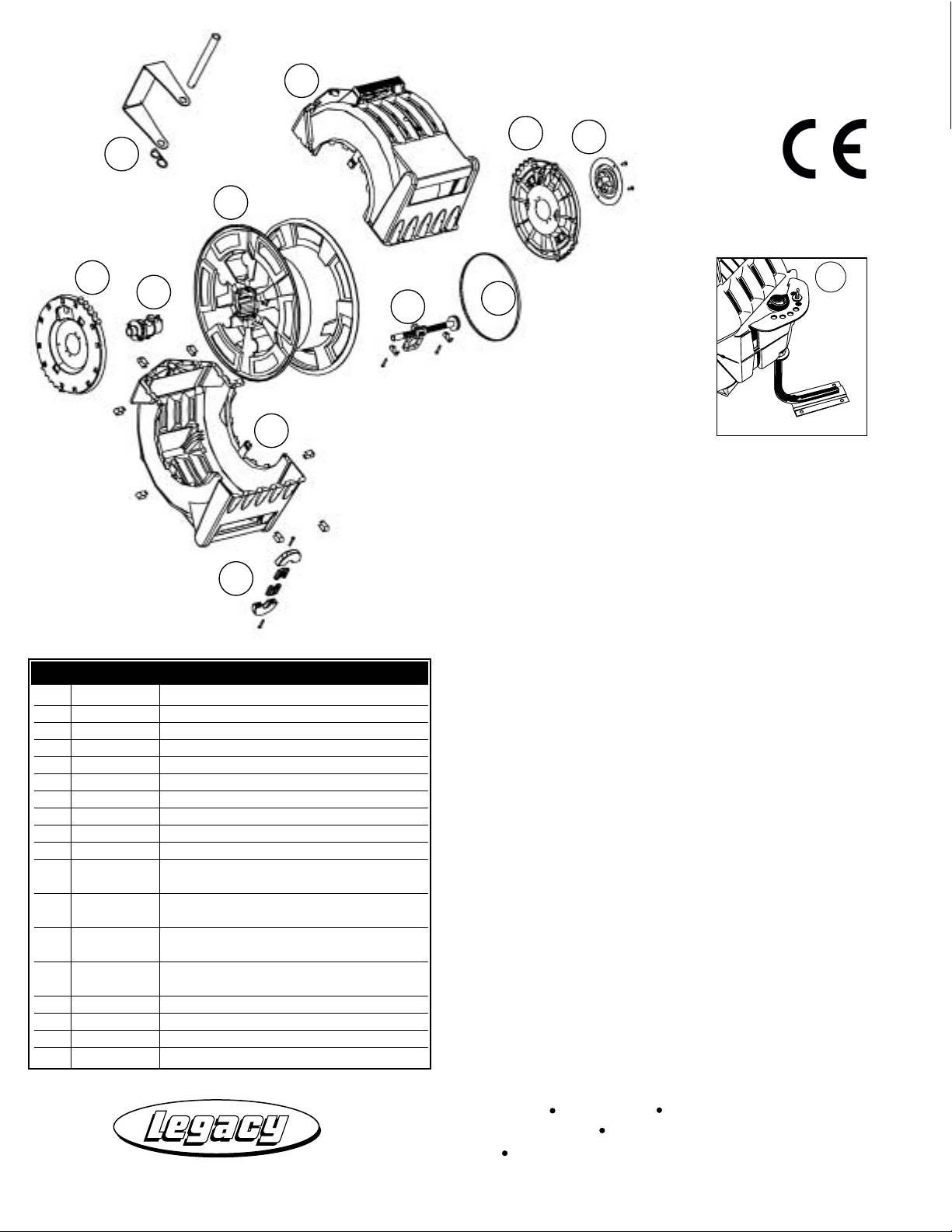

Repair Parts

RReeff.. ## RReeppaaiirr PPaarrtt DDeessccrriippttiioonn

1 L8300-W Bracket for wall or overhead ceiling mounting

1a L8300-B Bracket for high wall, bench or floor mounting

2 RP005000BK Outer Top Case w/Trim Ring Black

3 RP005002BK Swivel Plate Side Assembly Black

4 RP005007-38 Swivel Body Assembly 3/8" hose

4 RP005007-12 Swivel Body Assembly 1/2" hose

4 RP005007-58 Swivel Body Assembly 5/8" hose

5 RP005015 Drum Assembly for 50' hose

5 RP005016 Drum Assembly for 75' hose

6 RP005010-14 Layering Device Assembly for Model L8335

L8335-EU, L8346, L8347 & L8349

6 RP005010-20 Layering Device Assembly for Model L8305

L8305-EU, L8306, L8306-EU, L8310, L8310-EU

7 RP005012-137 Drive Belt for Model L8335, L8335-EU

L8346, L8347 & L8349

7 RP005012-140 Drive Belt for Model L8305, L8305-EU, L8306,

L8306-EU, L8310, L8310-EU

8 RP005004BK Latch Plate Side Assembly Black

9 RP005003 Tension Cover

10 RP005001BK Outer Bottom Case Black

11 RP005011 Hose Stopper

8

9

1

5

3

4

6

7

1a

10

11

TM

Loading...

Loading...