Page 1

175326.00

Variable Frequency Drive for

3-phase & single phase AC motors

QUICK START GUIDE

SPECIFICATIONS

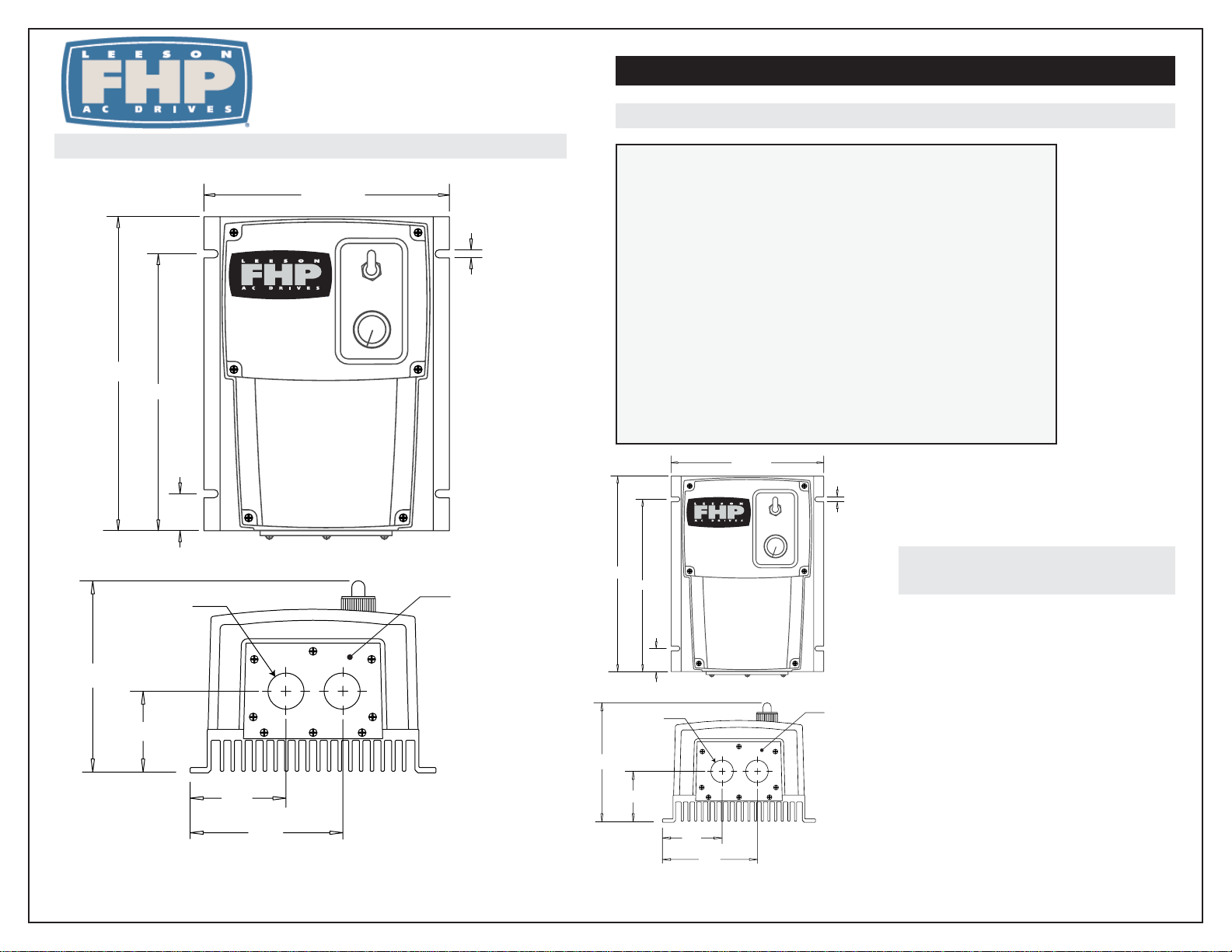

7.200 [183]

6.350 [161]

0.73 [18.5]

CONDUIT HOLES

2 PLACES

0.850

[22]

DIMENSIONS

5.625 [143]

POWER

FWD

OFF

REV

5

6

4

3

2

1

0

SPEED

NEMA 4X

ADJUSTABLE SPEED

REVERSING

AC MOTOR CONTROL

1-Phase Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .* 115/230 VAC

1 or 3 -Phase Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230 VAC

Maximum Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 HP

Maximum Continuous Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 AC

AC Amps In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 / 10 amps

AC Voltage Input Range . . . . . . . . . . . . . .115/230 VAC ± 10%, 50/60 Hz single phase

* Jumper settings MUST

match input line voltage.

Application of 230 VAC

line input when jumpers

are set for 115 VAC will

result in severe damage

to the drive.

Standard Carrier Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 KHz

Adjustable Braking Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 4 ADC

0.188

[5]

7

8

9

Adjustable Braking Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 10 Sec.

Adjustable Minimum Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 30 Hz

Output Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 120 Hz

Adjustable Maximum Output Frequency Range . . . . . . . . . . . . . . . . . . . . . .30 - 120 Hz

Acceleration Time Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12 secs

Deceleration Time Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12 secs

Analog Input Voltage Range (S1 [-] to S2 [+]) . . . . . 0 - 5 VDC, 0 - 10 VDC, 4 - 20 mA

Input Impedance, S1 to S2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~ 100K ohms

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5G max (20 - 50 Hz)

0.1G max (> 50 Hz)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2 lbs

Ambient Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . .10° - 40° C

5.625 [143]

POWER

FWD

OFF

BOTTOM PLATE

7.200 [183]

6.350 [161]

0.850

REV

5

6

4

3

2

1

0

SPEED

NEMA 4X

ADJUSTABLE SPEED

REVERSING

[22]

AC MOTOR CONTROL

0.188

7

9

[5]

8

REMOVING THE

CASE COVER

1. Remove the six (6) phillips screws on the

front case.

4.56 [116]

2.12 [53.8]

2.20

[55.9]

3.40

[86.4]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

4.56 [116]

0.73 [18.5]

CONDUIT HOLES

2 PLACES

2.12 [53.8]

2.20

[55.9]

3.40

[86.4]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

BOTTOM PLATE

NOTE: The two shorter screws (#6 - 32 x 2

1/2) on the front case are used at hole

locations 5 & 6.

2. Remove the five (5) phillips screws on the

bottom plate.

NOTE: DO NOT REMOVE the three (3)

screws securing the bottom plate to the

heatsink.

Page 2

JMP502

JMP501

JMP50

3

3

JMP505

3

JMP505

:

JMP503

&

t

t

.

&

t

.

T

506

ST

CONNECTIONS

f

d

g

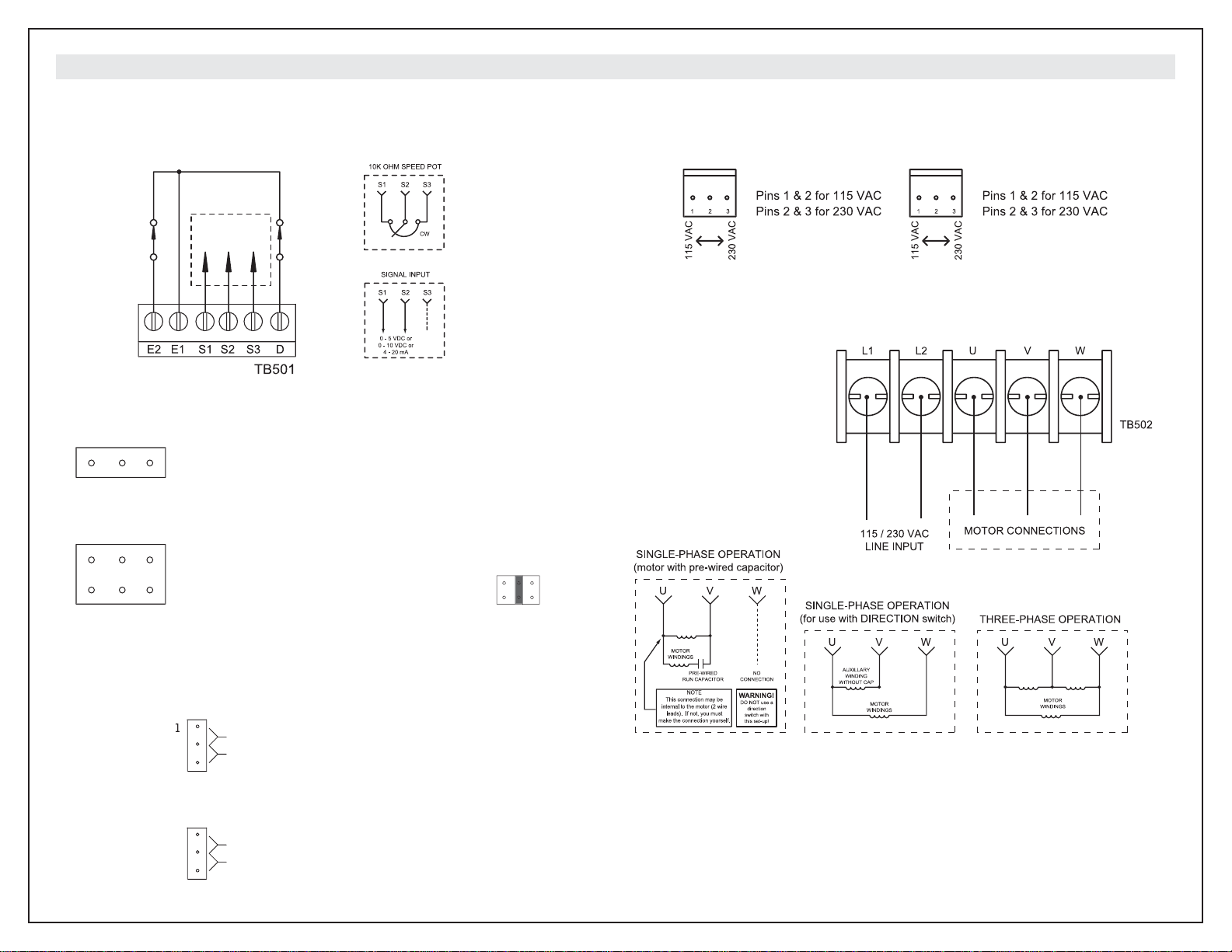

STEP #1-skip this step if provided FWD/OFF/REV and speed potentiometer will be used.

Otherwise disconnect factory-wired connections from the FWD/OFF/REV switch and speed

potentiometer. Connect the enable/disable switch, direction switch, and speed potentiometer or

signal input to TB501 on the TOP board using 20 - 24 AWG wire as shown below.

ENABLE/DISABLE

SWITCH

(open to disable)

TO SPEED POT

OR SIGNAL INPUT

DIRECTION

SWITCH

NOTE:

actory-wired spee

The

potentiometer on the

case cover must be

disconnected prior to

to a signal input

wirin

STEP #2

Configure jumpers JMP504 and JMP505 on the top board for the appropriate signal input.

1 2

JMP504 (on top board)

Pins 1 & 2 for Voltage Input, or using a speed pot.

4

1 2

Pins 2 & 3 for Current Input

JMP505 (on top board)

Pins in Column 1 for 0 - 5 VDC Voltage Input,

or using a speed pot

Pins in Column 2 for 0 - 10 VDC Voltage Input

Pins in Column 3 for 4 - 20 mA Current Input

1 2

example

STEP #4

Configure jumpers JMP501 and JMP502 on the bottom board for 115 or 230 VAC Power Input.

STEP #5

Connect motor leads of a 3phase motor to U, V, and W

(TB502 on BOTTOM board)

using 14 - 16 AWG wire as

shown in the figure below.

STEP #6

Connect 115 or 230 VAC power

input using 12 AWG wire.

NOTE: LEESON strongly

recommends installing an

emergency stop switch on both

the L1 and L2 inputs.

STEP #3

Configure jumpers JMP503 on the bottom board and JMP506 on the top board.

JMP503 (on bottom board)

Pins 1 & 2 to Trip

Pins 2

2

3

V TRIP

ESTAR

1

2

A

3 to Restar

TRIP: Drive has a low voltage fault & mus

be manually re-enabled to restart

RESTART: Drive has a low voltage fault

will momentarily stop then auto-restar

when input voltage returns to minimum level

JMP506 (on top board)

Pins 1 & 2 to Brake

Pins 2 & 3 to Coast

MP

LEESON Electric

www.leeson.com

2100 Washington Street, Grafton, WI 53024-0241, USA

Document Number: 250-0389, Revision 0; Printed in the U.S.A. - May 2004

Phone: 262-377-8810 Fax: 262-377-9025

Copyright 2003 by LEESON Electric - All rights reserved. No part of this document may be reproduced or transmitted in any form without

written permission from LEESON Electric. The information and technical data in this document are subject to change without notice. LEESON

Electric makes no warranty of any kind with respect to this material, including, but not limited to, the implied warranties of its merchantability

and fitness for a given purpose. LEESON Electric assumes no responsibility for any errors that may appear in this document and make no

commitment to update or to keep current the information in this document.

kc0504

Loading...

Loading...