Page 1

ELECTRIC MOTORS

GEARMOTORS AND DRIVES

Installation and Service Instructions for

180-210 C-Face Motors

LEESON ELECTRIC P.O. BOX 241 2100 Washington Street Grafton, WI 53024-0241 U.S.A

A Subsidiary of Regal-Beloit Corporation

For replacement parts refer to

sheet part number 8-078-917-77.

Instructions and parts list also available

at www.rexnord.com/stearns.

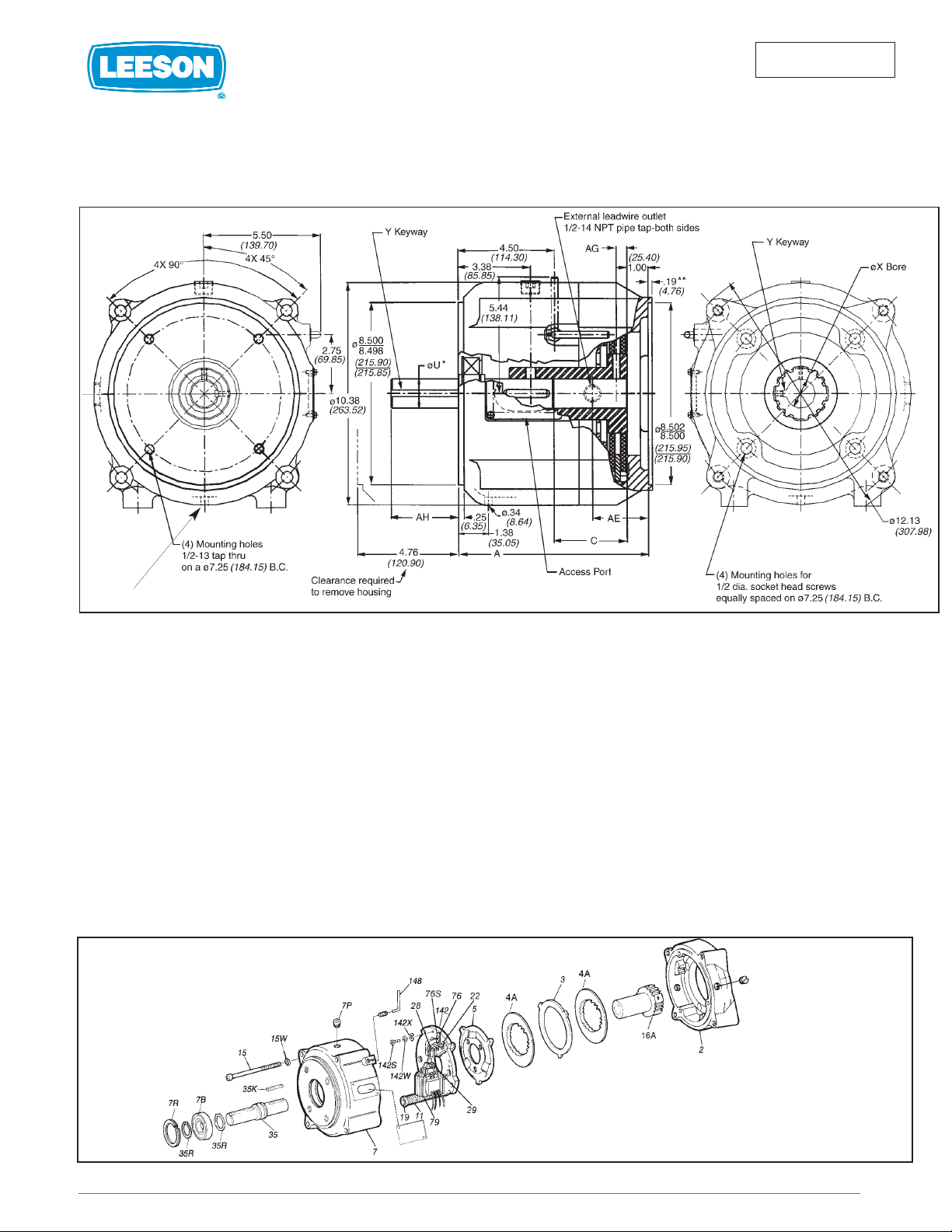

Figure 1 (for dimensions see page 4.)

Figure 2

Drain plug

(WASHGUARD brakes only)

Important

Please read these instructions carefully before

installing, operating, or servicing your brake. Failure

to comply with these instructions could cause injury

to personnel and/or damage to property if the brake

is installed or operated incorrectly. For definition of

limited warranty/ liability, contact Leeson Electric

Corporation, P.O. Box 241, 2100 Washington

Street, Grafton, WI, 53024-0241, (262) 377-8810.

Caution

1. Installation and servicing must be made in compliance with all local safety codes including

Occupational Safety and Health Act (OSHA). All

wiring and electrical connections must comply

with the National Electric Code (NEC) and local

electric codes in effect.

2. Do not install the brake in atmospheres containing explosive gases or dusts.

3. To prevent an electrical hazard, disconnect

power source before working on the brake. If

power disconnect point is out of sight, lock disconnect in the off position and tag to prevent

accidental application of power.

4. Make certain power source conforms to the

requirements specified on the brake nameplate.

5. Be careful when touching the exterior of an operating brake. Allow sufficient time for brake to cool

before disassembly. Surfaces may be hot

enough to be painful or cause injury.

6. Do not operate brake with housing removed. All

moving parts should be guarded.

7. Installation and servicing should be performed

only by qualified personnel familiar with the construction and operation of the brake.

8. For proper performance and operation, only genuine Stearns parts should be used for repairs

and replacements.

9. After usage, the brake interior will contain burnt

and degraded friction material dust. This dust

must be removed before servicing or adjusting

the brake.

DO NOT BLOW OFF DUST using an air hose. It

is important to avoid dispersing dust into the air

or inhaling it, as this may be dangerous to your

health.

a) Wear a filtered mask or a respirator while

removing dust from the inside of a brake.

b) Use a vacuum cleaner or a soft brush to

remove dust from the brake. When brushing,

avoid causing the dust to become airborne.

Collect the dust in a container, such as a bag,

which can be sealed off.

10. The motor should not be run with the brake in

the manual release position to avoid overheating of friction disc(s).

P/N 8-078-927-28

effective 03/25/2005

Page 2

General Description

The 87,700 Series coupler is a spring-set, electrically released, self adjusting brake. The double C-face allows the brake to directly couple a

C-face motor to a C-face gear reducer. Or, for

in-line application, the brake can be mounted

directly to a foot mounted

C-face motor, using the bearing mounted output

shaft as an in-line drive shaft.

Note: Coupler brake is designed for in-line

applications only. Do not apply overhung or side

load to brake output shaft.

I. Installation Procedure

Note 1: Check face of motor to which brake is

to be mounted, to be sure NEMA dimensions of

0.004″ T.I.R. on concentricity and face run out

are met. Shaft run out is to be within 0.002″

T.I.R. Maximum shaft end float is 0.020″. Use

standard length NEMA shaft.

Note 2: The effectiveness of the dust-tight

waterproof brake enclosure depends on a fully

enclosed motor C-face as the brake face is not

sealed.

A. Remove hub (16) from brake assembly. With

key (not furnished) in place on motor shaft,

slide hub onto shaft to 1” (± 1/32”) of standard motor C-face. Tighten the three set

screws over the motor shaft to 290 in-lb (on

single disc brake, the set screw over the

keyway should be tightened to 87 in-lb).

Note 3: On most applications, particularly in

vertical position, a set screw dimple drilled

into shaft is recommended.

B. Remove housing bolts (15), lock washers

(15W) and housing (7).

C. Depress solenoid plunger (29) and tie

plunger to frame (79).

D. Remove entire support plate assembly (142)

by evenly unscrewing screws (142S).

Remove screws, conical spring washers

(142W), and flat washers (142X).

E. Remove pressure plate (5), friction disc (4)

and stationary disc (3).

F. Attach endplate (2) to NEMA C-face of

motor using four 1/2-13 socket head cap

screws and medium spring lock washers

(not supplied) torque per manufacturer’s

specifications. (Head of cap screws must

not project above friction surface.)

Note 4: If motor, with or without reducer, is

to be ceiling mounted after assembly, entire

brake will have to be rotated 180° or upside

down so it will be positioned with solenoid

plunger (29) above frame when final assembly is mounted on ceiling. Similarly, for horizontal wall mounting, rotate 90°.

G. Reassemble friction discs (be sure

friction discs slide freely, file I.D. if necessary), springs (if vertical), stationary discs,

and pressure plate in correct sequence and

position. All parts must

slide freely. The universal mounting pressure

plate presently used has three tapered reliefs

on outboard face.

Note 5: Brakes with a single friction disc do

not have stationary discs. Vertically mounted

brakes will have springs to separate stationary discs (except one disc vertical below).

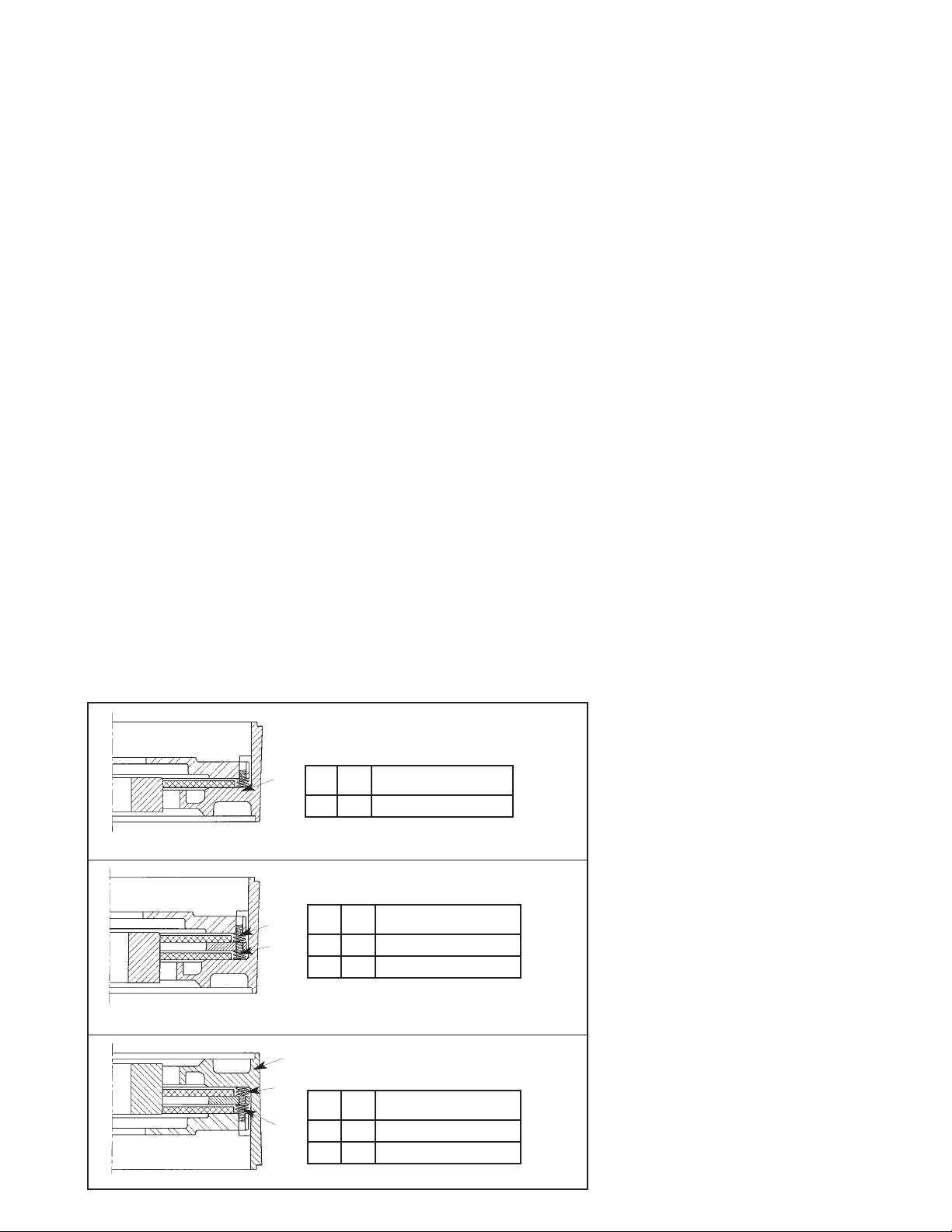

Note color coded sequence of springs (figures 2A, 2B, & 2C) for proper assembly of

vertical mounting components.

H. Mount support plate assembly, torque

screws to 50 in-lbs in endplate. Conical

spring washer installed under the screw

head. Flat washer used under the

conical spring washer only with

aluminum support plate. Be sure that assembly is mounted with the solenoid

in a vertical position (plunger above frame)

as shown when brake is horizontal. If

plunger is not tied down and has allowed the

mechanism to overadjust, it will have

to be reset before mounting support plate.

In this case the lever arm throat will

be near, or touching, the pinion teeth. Refer

to

Self-Adjust Maintenance. Loosen pres-

sure spring cap screw (19) until pressure

spring (11) is free, mount support plate

assembly to endplate, and retighten spring

cap screw until snug. Do not overtighten!

Torque to a maximum of

100 in-lbs.

I. Remove plunger tie-down. Manually

lift solenoid plunger to maximum travel

and release. Complete electrical connections, (See Section on

Electrical

Connection of Brake.) Depress solenoid

plunger manually or electrically, and allow

it to snap up.

Repeat this process several times to set air

gap on solenoid. (Check

Self-Adjust

Maintenance Section for proper gap meas-

urement, or corrective action for improper

gap.)

J. See Section on Electrical Connection of

Brake

.

K. Assemble housing and shaft assembly, rotat-

ing shaft (35) to engage key (35K) into hub

keyway. Be sure housing is assembled with

manual release on right hand (solenoid) side

(looking at output shaft side) or release lever

(148) will not latch. Replace housing bolts

and tighten evenly to 118 lb-ft of torque.

L. Remove access plug (7P). Insert a 3/16″

hex wrench and tighten the two set screws

to 290 in-lb. (set screws are located 120°

either side of the keyway).

M. For reducer application, mount and secure

brake/motor combination to mounting face of

reducer.

For alignment when brake shaft is direct-connected to another shaft by a coupling refer to

coupling manufacturer′s suggested procedure. Side or overhung load is not permitted.

Consult factory for reversing applications.

II. Electrical Connection of Brake

CAUTION 1: Inverter Motor and Special

Control Systems. This brake contains a single

phase AC coil that requires instantaneous

power within ± 10% of rating at the coil. A separate power source is required when this brake

is used in conjunction with a motor or control

system that limits voltage or current input (i.e.

inverter motors) or causes a ramping of the

power supply.

Note 1: Be sure lead wires to coil are not tight

or pinched, and that leads will not be rubbed by

friction disc, trapped between solenoid plunger

and frame, caught between lever arm and endplate, or by linkage.

Note 2: See figure 3 for dual voltage coil connection and connect to any two leads of single

or three-phase motor of the same voltage. The

brake can also be wired to external switch contacts providing proper voltage other than that

used to control the motor. Normally, the motor

and brake contacts are interlocked.

Note 3: To use a 230 volt coil (or a 230/460

dual voltage coil connected for 230 volts) with a

230/460 dual voltage three-phase motor, the

brake leads are connected across two motor

terminals as shown, or other equivalent combinations. If a 230 volt brake coil is

2

1 Friction Disc - Vertical Above

Item

No.

No.

Req.

Description

1 3 Blue Vertical Push-in Spring

1

Figure 2A

Figure 2B

2 Friction Discs - Vertical Above

Item

No.

No.

Req.

Description

1 3 Plain Vertical Push-in Spring

2 3 Red Vertical Push-in Spring

2

1

Figure 2C

2 Friction Discs - Vertical Below

Endplate

Item

No.

No.

Req.

Description

1 3 Blue Vertical Push-in Spring

2 3 Red Vertical Push-in Spring

2

1

Page 3

connected as shown in figures 4 and 5 the

motor can be operated on either 230 volts or

460 volts with no effect on brake operation.

III. General Maintenance

Warning! Any mechanism or load held in posi-

tion by the brake should be secured to prevent

possible injury to personnel or damage to

equipment before any disassembly of the

brake is attempted or the manual release lever

is operated on the brake. Observe all

cautions

listed at the beginning of this manual.

Note 1: Replacement part kits for many items

are available and contain retrofit instructions.

Note 2: Do not lubricate any part of the brake

as this may cause a malfunction and/or loss of

torque.

A. Coil replacement

All standard NEMA AC voltage coils are available in kits. Select coil kit from appropriate

replacement parts list for the particular brake

series being serviced.

B. Friction disc replacement

Note: Replace friction discs in single disc

brakes when wear surface area is one half the

original disc thickness (1/4″). In multiple disc

brakes, replace all friction discs when throat of

lever arm is within 1/16″ of touching teeth of

pinion.

C. Self-adjust maintenance

Since the self-adjust brake automatically

adjusts itself for friction disc wear, maintenance

is held to a minimum. The solenoid is factory

set with a 13/16″ to 15/16″ air gap, and

requires no resetting, even when changing friction discs. The gap is determined by the position of wrap spring stop (76). Should air gap

change, follow the steps listed below:

1. If (stop) screws (76S) had been loosened

and retightened, the air gap may require

resetting. The gap is measured between

mating surfaces of plunger (29) and solenoid

frame (79), and may be increased by raising

slightly, or decreased by lowering slightly,

wrap spring stop (76). Be sure to retighten

(stop) screws (76S). Manually lift plunger to

maximum travel and release. Depress

plunger, manually or electrically, and allow it

to snap up. Repeat several times, then

recheck air gap for factory setting of 13/16″

to 15/16″.

Note: To measure solenoid air gap on verti-

cally mounted brakes, grasp solenoid link to

hold plunger in a free horizontal position and

move toward solenoid frame until spring

pressure is felt. Holding firmly in this position

measure air gap between mating (ground)

surface on solenoid frame and solenoid

plunger. Adjust to proper gap as directed in

Self-Adjust Maintenance. Check gap by

again holding plunger as directed.

2. Tang of wrap spring must be below, and

must make contact with, wrap spring stop

(76) when

solenoid lever

(28) is manually raised. If

stop is bent

outward, allowing tang to

bypass it,

rebend to

square position, assemble

correctly, and reset solenoid air gap as

described in Paragraph 1.

3. Should air gap have decreased or disappeared, the solenoid lever and pinion

assembly (8) may have

become contaminated

due to lubrication or

residue as a result of

overheating of brake.

For reference purposes

refer to Figure 7. Tang A

should align with the

centerline of hole B.

Use kit #5-66-7371-00 if

replacement is necessary.

4. Check condition and positioning of

pinion and rack assembly. Replace parts as

necessary with complete assemblies.

D. Solenoid lever and pinion assembly

replacement

If pinion teeth are worn, replace entire assembly. Consult appropriate parts list for kit number. Check sector gear of lever arm for wear.

If sector gear teeth of lever arm are worn,

replace entire lever arm assembly available as

a kit from appropriate repair parts list. Also

check pinion teeth for wear.

E. Drain plug removal (WASHGUARD

brakes only)

If moisture has accumulated inside the brake

enclosure, remove the drain plug (location

shown in Figure 1). Replace plug after fluid has

drained.

IV. Troubleshooting

A. If brake does not stop properly or

overheats, check the following:

1. Is manual release engaged, and is motor

energized?

2. Friction discs may be excessively worn,

charred or broken.

3. Hub may have become loose and shifted

on shaft.

4. Is hub clean and do friction discs slide

freely?

5. Are controls which govern start of brake

cycles operating properly?

6. Are limit switches, electric eyes, etc. functioning properly?

7. On vertically mounted brakes, are

springs in place in disc pack?

See P/N 8-078-937-06.

8. Have mounting faces loosened?

9. Pressure spring may be improperly assembled or broken.

10. Is solenoid air gap adjusted correctly?

(See

Self-Adjust Maintenance,

Section III, Item D.)

11. Check linkage for binding. The approximate

pressure applied to the top of the solenoid

link to move plunger is:

If excessive force is required, determine

cause of binding and correct. Do not overlook bent, worn or broken plunger guides

as a possible cause for binding.

12. Solenoid lever stop (22) must be in place

on support plate.

13. Solenoid may not be energizing and releasing the brake. Check voltage at the coil and

compare to the coil and/or nameplate voltage rating.

14. A voltage drop may be occurring. If excessive drop in voltage is noted, check wire

size of power source. Correct as needed.

Note: A method to check voltage at coil is

to insert a block of wood of the approximate thickness of the solenoid air gap

between the solenoid frame and plunger.

(The block will prevent brake from releasing when coil is energized.) Connect voltmeter leads at the coil terminals or lead

wires. Energize coil. Voltmeter needle will

not fluctuate and reading can be taken.

Reading should be taken immediately and

the coil de-energized to prevent over-heating of the coil. Compare voltage reading

with coil rating.

15. Check slots of endplate for wear at the

areas where stationary discs are in contact.

Grooves in the slots can cause hang-up or

even breakage of ears of stationary discs.

If grooving is noted, replace endplate.

16. Check that heads of mounting bolts do not

extend above wear surface of endplate.

17. Check pressure spring length to insure correct compressed height. Approximate original spring lengths are given in the following

table so that correct setting may be verified

and corrected if necessary. With worn friction discs, add amount of wear to the

approximate spring length shown in table.

Figure 6

Figure 7

16 lbs#8 coil

9 lbs#6 coil (25 lb-ft)

5-1/2 lbs#6 coil (15 lb-ft)

3 lbs#5 coil

3

AC Voltage Coil Connection

Figure 3

3 and 421High voltage

–2 and 41 and 3Low voltage

Tie Leads

Power Line BPower Line A

For

Figure 4 Figure 5

Class B Coil (black)

Air

gap

Page 4

4

PART NUMBERS

Leeson

Part Num-

ber

Stearns Part

Number

Brake

Coil

Rating

(VAC)

NEMA

Enclosure

Brake

Bore &

Shaft

Dia.

(U/X)

NEMA

Frame

Size

Dimensions (Inches)

A C

AEAGA

H

175583.00 1087721011QG

230/460

2

1-1/8”

180

8.38

2.81

2.12

0.19

2.62

175584.00 1087722B11QG

4X

175585.00 1087731011QG

2

8.38

2.81

2.12

0.19

2.62

175586.00 1087732B11QG

4X

175587.00 1087741031QG

2

1-3/8”

210

8.38

2.81

2.12

0.19

3.12

175588.00 1087742B31QG

4X

175589.00 1087751031QG

2

8.88

3.31

2.62

0.44

3.12

175590.00 1087752B31QG

4X

18. If a heater is supplied and excess rusting

has occurred in brake, check power source

to heater to be sure it is operating and that

heater is not burned out.

19. If stopping time is more than two seconds

(rule of thumb) and/or the application is

more than five stops per minute, check

thermal requirements of load versus thermal rating of brake.

20. Use Loctite

®

242 to secure link screw nut

to link screw if vibration causes nut to

loosen.

B. If brake hums, solenoid pulls in slowly, or coil burns out, check the following:

1. Voltage supply at coil versus coil rating.

2. Is solenoid air gap excessive?

(See Self-Adjust Maintenance.)

3. Shading coils may be broken.

4. Plunger guides may be excessively worn.

Does solenoid plunger rub on solenoid

frame laminations? If so, replace plunger

guides.

5. Solenoid frame and plunger may be excessively worn.

6. Is solenoid dirty?

7. Solenoid mounting screws may have

become loose, causing frame to shift and

plunger to seat improperly.

8. Sector gear and pinion teeth may be jamming due to excessive tooth wear.

9. Excessive voltage drop when motor starts.

Check size of lead wires for motor starting

current and solenoid inrush current. See

Section IV-A, Item 11, 12, 14 and 15.

C. If brake is noisy during stopping:

1. Check mounting face run out, mounting rabbet eccentricity and shaft run out. See

Installation Procedure, Section I, Note 1.

Correct as required.

2. Check for signs of the outside diameter of

the friction disc(s) rubbing on the inside

diameter of the endplate. This would indicate

brake is eccentric with respect to the motor

shaft and/or the shaft is deflecting during a

stop. Check alignment and shaft diameter.

Also check for worn motor bearings. If

realignment does not correct the problem, a

larger diameter shaft may be required. Shaft

deflection may also be caused by excessive

overhang of brake from motor bearing.

Additional shaft support may be required.

3. Check for bad motor bearings. Replace

if necessary. Check for excessive shaft endfloat. Correct as required.

Color

Torque

(lb-ft)

Compressed

Spring Length

White 15 3-1/4”

Orange 25 & 50 3-1/4”

Purple 35 3-1/4”

Loading...

Loading...