Operations, Service, and Parts Manual

LEEBOY MODEL 8515D CONVEYOR PAVER

Manual No. 1015239-01

This manual applies to

Serial Number 133074

and above.

Thumb Index

SAFETY

INFORMATION AND SPECIFICATIONS

COMPONENT LOCATION

OPERATION

MAINTENANCE

1

2

3

4

5

SCHEMATICS

ILLUSTRATED PARTS LIST

6

7

Disclaimer

All information, illustrations and specications in this manual are based on the latest information available

at the time of publishing. The illustrations used in this manual are intended as representative reference

views only. Moreover, because of our continuous product improvement policy, we may modify information,

illustrations and/or specications to explain and/or exemplify a product, service or maintenance

improvement. We reserve the right to make any change at any time without notice. VT LeeBoy, Inc., VT

LeeBoy, LeeBoy, and Rosco are all the same entity and are used interchangeably.

Title 40, Code of Federal Regulations (CFR) 1068

This product meets certied-emission requirements set by the EPA (Environmental Protection Agency),

governed by Title 40 CFR 1068, which species actions that are prohibited by law and lists civil penalties

for noncompliance. As part of those regulations, modication or rendering inoperative any emissionrelated component can subject you to government penalties (and void your warranty). Tampering with

emission controls is in violation of federal law, and can result in civil penalties of up to $3,750 each day an

engine or piece of equipment is operated in violation.

Please be aware that you are responsible for maintaining the machine and the certied emission engine

installation. Failure to comply to comply could result in penalties as listed above and void the warranty on

this engine and this machine.

For more information, visit: https://www.epa.gov/laws-regulations/regulations

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

Battery posts, terminals and other related accessories contain lead and lead compounds, chemicals

known to the State of California to cause cancer and other reproductive harm. Wash hands after handling.

©2016 VT LeeBoy, Inc.

LeeBoy reserves all copyright and other rights in this manual and the manual’s content. No part of this

manual may be reproduced or used in any way without the written permission of VT LeeBoy, Inc., except as

necessary to operate LeeBoy equipment.

iv

LeeBoy 8515D Conveyor Paver

TABLE OF CONTENTS

Page

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Machine Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Hot Material Precautions . . . . . . . . . . . . . . . . . . . . . . . 1-7

Hydraulic Systems Precautions . . . . . . . . . . . . . . . . . . . 1-7

Refueling Precautions . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Battery Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Starting and Stopping Precautions . . . . . . . . . . . . . . . . . . 1-8

Parking Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Poor Visibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Storage Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Maintenance Precautions . . . . . . . . . . . . . . . . . . . . . . 1-9

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Safety Decals Care . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Decal Installation (Sticker Type) . . . . . . . . . . . . . . . . . . . 1-11

Decal Installation (Top Protected) . . . . . . . . . . . . . . . . . . 1-11

Limited Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Specication Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Torque Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Standard Inch Fasteners . . . . . . . . . . . . . . . . . . . . . . . 2-7

Metric Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Determining Proper Torque . . . . . . . . . . . . . . . . . . . . . 2-9

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

LeeBoy 8515D Conveyor Paver v

Components Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hopper and Conveyors . . . . . . . . . . . . . . . . . . . . . . . 3-3

Augers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operator Platform . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Standard Equipment/Options . . . . . . . . . . . . . . . . . . . . 3-4

Machine Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Left Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Right Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Center Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Steering and Speed Control Box . . . . . . . . . . . . . . . . . . . . . . 3-11

Screed Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Burner Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Propane Tank Controls . . . . . . . . . . . . . . . . . . . . . . . 3-13

Steering Wheel (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Electric Heat (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Receiving the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Initial and Daily Inspection . . . . . . . . . . . . . . . . . . . . . . 4-3

Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Stopping the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

DPF Regeneration (REGEN) . . . . . . . . . . . . . . . . . . . . . . . . 4-4

PV480 Powerview Display . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Gauge Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Set Points and Throttle Speed . . . . . . . . . . . . . . . . . . . . 4-5

Soft Keys (Buttons) . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Status Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

System Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

User Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Regeneration Messages . . . . . . . . . . . . . . . . . . . . . . . 4-14

vi

LeeBoy 8515D Conveyor Paver

Messages, Cautions, Warnings . . . . . . . . . . . . . . . . . . . 4-17

Driving the Paver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Operator Control Station . . . . . . . . . . . . . . . . . . . . . . . 4-18

Steering and Speed Control . . . . . . . . . . . . . . . . . . . . . 4-18

Paver Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Spray Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Heating the Screed . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Hopper Wings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Conveyors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Hydraulic Cut-Off Gates . . . . . . . . . . . . . . . . . . . . . . . 4-23

Electric Flight Screw . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Set the Screed Extension, Flight Screw and Endgate . . . . . . . . . 4-24

Sonic Auger Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Starting to Pave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Basic Paving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Setting the Crown . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Mat Texture Adjustment . . . . . . . . . . . . . . . . . . . . . . . 4-29

815HD Screed Extension Double Adjustment (Option) . . . . . . . . 4-30

Unloading and Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Tie-Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Auger Extensions Option . . . . . . . . . . . . . . . . . . . . . . . 4-32

Umbrella Option . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Screed Sloping Extensions . . . . . . . . . . . . . . . . . . . . . 4-32

Steering Wheel Option . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Roll-Up Curb Attachments . . . . . . . . . . . . . . . . . . . . . . 4-32

Truck Hitch Attachment Option . . . . . . . . . . . . . . . . . . . . 4-33

Electric Screed Options . . . . . . . . . . . . . . . . . . . . . . . 4-33

Topcon® Sonic and Dual Grade Control . . . . . . . . . . . . . . . 4-34

Rubber or Steel Track Options . . . . . . . . . . . . . . . . . . . . 4-34

815HD (Heavy Duty) Electric Screed . . . . . . . . . . . . . . . . . 4-34

LeeBoy 8515D Conveyor Paver

vii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Preparing Paver for Maintenance . . . . . . . . . . . . . . . . . . 5-5

Every 10 Hours or Daily Routine Maintenance . . . . . . . . . . . . 5-5

Every 50 Hours or Weekly Routine Maintenance . . . . . . . . . . . 5-5

Every 100 Hour or Monthly Maintenance . . . . . . . . . . . . . . . 5-6

Every 250 Hours or Quarterly Routine Maintenance . . . . . . . . . 5-6

Every 500 Hours or Semi-Annual Routine Maintenance . . . . . . . 5-6

Every 1000 Hours or Annual Routine Maintenance . . . . . . . . . . 5-6

Torque Hub Lubrication . . . . . . . . . . . . . . . . . . . . . . . 5-6

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Maintenance Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Conveyor Flight Chain . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Conveyor Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Auger Drive Chain Adjustment . . . . . . . . . . . . . . . . . . . . 5-9

Screed Extension Top Guide Adjustment . . . . . . . . . . . . . . . 5-9

Track Tension Pressure Relief . . . . . . . . . . . . . . . . . . . . 5-10

Conveyor Switch Adjustment . . . . . . . . . . . . . . . . . . . . . 5-10

Torque Hub Hydraulic Motor Gear Adjustments . . . . . . . . . . . 5-11

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Check Engine Lubrication Oil . . . . . . . . . . . . . . . . . . . . 5-12

Change Engine Oil and Filter . . . . . . . . . . . . . . . . . . . . . 5-13

Change Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Change Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Water Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Check Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Change Hydraulic Oil and Filter . . . . . . . . . . . . . . . . . . . 5-16

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Battery Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Screed Electric Heat (Option) . . . . . . . . . . . . . . . . . . . . . . . 5-19

Screed Electric Heat Elements . . . . . . . . . . . . . . . . . . . . 5-19

viii

LeeBoy 8515D Conveyor Paver

Element Resistance Testing . . . . . . . . . . . . . . . . . . . . . 5-20

Heating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Generator Voltage Testing . . . . . . . . . . . . . . . . . . . . . . 5-21

Generator Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Front Idler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Track Tension Cylinder . . . . . . . . . . . . . . . . . . . . . . . 5-23

Track Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Track Sprocket (Steel or Poly) . . . . . . . . . . . . . . . . . . . . 5-23

Rubber Track (Option) . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Rear Conveyor Shaft, Bearings and Sprockets . . . . . . . . . . . . 5-24

Conveyor Drive Motors. . . . . . . . . . . . . . . . . . . . . . . . 5-25

Auger and Inner Bearings . . . . . . . . . . . . . . . . . . . . . . 5-25

Auger Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Main Screed Wear Plate . . . . . . . . . . . . . . . . . . . . . . . 5-27

Screed Extension Wear Plate . . . . . . . . . . . . . . . . . . . . 5-28

Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Two-Speed Hydraulic Motors . . . . . . . . . . . . . . . . . . . . 5-30

Conveyor Switch Replacement . . . . . . . . . . . . . . . . . . . . 5-31

Weldment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Plus One . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Test Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . 5-34

PV480 Diagnostic Trouble Code (DTC) Chart. . . . . . . . . . . . . . . . 5-37

Electrical System (1 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Electrical System (2 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Electrical System (3 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Electrical System (4 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Electrical System (5 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Electrical System (6 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Electrical System (7 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Electrical System (8 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Electrical System (9 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Electrical System (10 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Electrical System (11 of 11) . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

LeeBoy 8515D Conveyor Paver

ix

Lower Control, Sloping (Left) . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Lower Control, Sloping (Right) . . . . . . . . . . . . . . . . . . . . . . . 6-27

Lower Control, Non-Sloping (Left) . . . . . . . . . . . . . . . . . . . . . 6-29

Lower Control, Non-Sloping (Right) . . . . . . . . . . . . . . . . . . . . . 6-31

Auxilliary Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Generator Control to Bulkhead Harness . . . . . . . . . . . . . . . . . . 6-35

Bulkhead to Generator Harness . . . . . . . . . . . . . . . . . . . . . . 6-37

Electric Steering Cord, 4 Feet . . . . . . . . . . . . . . . . . . . . . . . 6-39

Dash Assembly (1 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Dash Assembly (2 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . .6-43

Dash Assembly (3 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Dash Assembly (4 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

Dash Assembly (5 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

Gauge Panel (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Gauge Panel (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-53

Plus One Harness (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

Plus One Harness (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Ultrasonic Power Harness . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

Steering Wheel Box (Option) . . . . . . . . . . . . . . . . . . . . . . . . 6-61

Dual joystick control Box (Option) . . . . . . . . . . . . . . . . . . . . .6-63

Electric Heat Control (Option) . . . . . . . . . . . . . . . . . . . . . . . 6-65

Electric Heat Control - Heated Endgates (Option) . . . . . . . . . . . . . . 6-67

Hydraulic Schematic (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 6-69

Hydraulic Schematic (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 6-71

Hydraulic Schematic (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 6-73

Hydraulic Schematic (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 6-75

Illustrated Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Sprocket Drive Track System - 4 Roller Undercarriage . . . . . . . . . . . 7-6

Sprocket Drive Track System - 4 Roller Undercarriage . . . . . . . . . . . 7-8

Rubber Track Undercarriage - 5 Roller Undercarriage . . . . . . . . . . . 7-10

Conveyor Drive Assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . 7-12

Conveyor Drive Assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . 7-14

Hopper Components (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Hopper Components (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Auger Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

x

LeeBoy 8515D Conveyor Paver

Conveyor Drive Cutoff / Screed Lift Cylinders . . . . . . . . . . . . . . . 7-22

Hydraulic Components / (Left) Side Fuel Tank . . . . . . . . . . . . . . . 7-24

Hydraulic Test Port Assembly . . . . . . . . . . . . . . . . . . . . . . . 7-26

H1 Pump & Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Kubota T4F Engine Assembly (1 of 3) . . . . . . . . . . . . . . . . . . . . 7-30

Kubota T4F Engine Assembly (2 of 3) . . . . . . . . . . . . . . . . . . . . 7-32

Kubota T4F Engine Assembly (3 of 3) . . . . . . . . . . . . . . . . . . . . 7-34

Kubota Sheet Metal Covers . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Spray Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Screed Arm Assembly With Toe Point . . . . . . . . . . . . . . . . . . . 7-40

Propane Heater And Automatic Ignitors . . . . . . . . . . . . . . . . . . . 7-42

Control Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Lower Hydraulic Manifold - 6 Valve . . . . . . . . . . . . . . . . . . . . . 7-46

Dash Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Screed Sloping Overview . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Screed Non-Sloping Overview . . . . . . . . . . . . . . . . . . . . . . . 7-52

Screed Frame Sloping - Propane . . . . . . . . . . . . . . . . . . . . . . 7-54

Screed Frame Non-Sloping - Propane . . . . . . . . . . . . . . . . . . . 7-56

Extension Single Adjust Assembly - Propane (Left) . . . . . . . . . . . . . 7-58

Extension Single Adjust Assembly - Propane (Right) . . . . . . . . . . . . 7-60

Extension Double Adjust Assembly - Propane (Left) . . . . . . . . . . . . . 7-62

Extension Double Adjust Assembly - Propane (Right) . . . . . . . . . . . . 7-64

Screed Frame Sloping - Electric . . . . . . . . . . . . . . . . . . . . . . 7-66

Screed Frame Non-Sloping - Electric . . . . . . . . . . . . . . . . . . . . 7-68

Extension Single Adjust Assembly - Electric (Left) . . . . . . . . . . . . . . 7-70

Extension Single Adjust Assembly - Electric (Right) . . . . . . . . . . . . . 7-72

Extension Double Adjust Assembly - Electric (Left) . . . . . . . . . . . . . 7-74

Extension Double Adjust Assembly - Electric (Right) . . . . . . . . . . . . 7-76

Endgate Assembly (Left) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-78

Endgate Assembly (Right) . . . . . . . . . . . . . . . . . . . . . . . . . 7-80

Screed Pull Arm Assembly (Left) . . . . . . . . . . . . . . . . . . . . . . 7-82

Screed Pull Arm Assembly (Right) . . . . . . . . . . . . . . . . . . . . . 7-84

Citrus Tank & Heat Control Box . . . . . . . . . . . . . . . . . . . . . . . 7-86

Vibrator Assembly (Left) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-88

Walk Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-90

Slide Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-92

LeeBoy 8515D Conveyor Paver

xi

Screed Miscellaneous Components . . . . . . . . . . . . . . . . . . . . 7-94

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-96

Power Crown (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-98

Strike Offs And Extensions (Option ) . . . . . . . . . . . . . . . . . . . .7-100

Paver Leveling Control TOPCON System 4 (Option) . . . . . . . . . . . .7-102

Paver Leveling Control TOPCON System P-32 (Option) . . . . . . . . . .7-104

Truck Hitch Assembly (Option) . . . . . . . . . . . . . . . . . . . . . . .7-106

815HD Series Screed 8515 Sloping Overview . . . . . . . . . . . . . . .7-108

815HD Series Screed 8515 Non-Sloping Overview . . . . . . . . . . . . . 7-110

815HD Series Screed Frame Sloping . . . . . . . . . . . . . . . . . . . . 7-112

815HD Series Screed Frame Non-Sloping . . . . . . . . . . . . . . . . . 7-114

815HD Series Vibrator Assembly . . . . . . . . . . . . . . . . . . . . . . 7-116

815HD Series Walk Board Assembly . . . . . . . . . . . . . . . . . . . .7-118

815HD Series Slide Plate Assembly . . . . . . . . . . . . . . . . . . . .7-120

815HD Series Extension Assembly (Left) . . . . . . . . . . . . . . . . . .7-122

815HD Series Extension Assembly (Right) . . . . . . . . . . . . . . . . .7-124

815HD Series Endgate Assembly (Left) . . . . . . . . . . . . . . . . . . .7-126

815HD Series Endgate Assembly (Right) . . . . . . . . . . . . . . . . . .7-128

815HD Series Screed Pull Arm Assembly (Left) . . . . . . . . . . . . . . .7-130

815HD Series Screed Pull Arm Assembly (Right) . . . . . . . . . . . . . .7-132

815HD Series Citrus Tank & Heat Control Box . . . . . . . . . . . . . . .7-134

815HD Series Screed Optional Components . . . . . . . . . . . . . . .7-136

HD Heated Endgate Assembly - Option (1 of 3) . . . . . . . . . . . . . . .7-138

HD Heated Endgate Assembly - Option (2 of 3) . . . . . . . . . . . . . . .7-140

HD Heated Endgate Assembly - Option (3 of 3) . . . . . . . . . . . . . . .7-142

HD Heated LeeBoy Edge Endgate Assembly - Option (1 of 3) . . . . . . . .7-144

HD Heated LeeBoy Edge Endgate Assembly - Option (2 of 3) . . . . . . . .7-146

HD Heated LeeBoy Edge Endgate Assembly - Option (3 of 3) . . . . . . . .7-148

HD Heated Endgate Assembly - Option . . . . . . . . . . . . . . . . . . .7-150

LeeBoy 8515D Conveyor Paverxii

Thank you for purchasing the LeeBoy Model 8515D

Conveyor Paver. We wish you many years of safe and

efcient operation of your LeeBoy product.

READ THIS MANUAL PRIOR TO OPERATING the machine. It is an important part of the machine and should

be kept with in the dedicated storage container provided

at all times. Though you may be familiar with similar

equipment, you MUST read and understand this manual

before operating the machine to help prevent injury or

damage.

This manual is intended as a guide for the safe and

efcient use of your machine, including procedures for

proper operation and maintenance. Use it with all related supplemental books, engine, transmission manuals,

and any other manuals supplied by other manufacturers. Related Service Bulletins should also be reviewed

to provide information regarding some of the recent

changes. If any questions arise concerning this publi-

cation or to order a replacement manual, contact your

authorized LeeBoy dealer.

This manual contains information that was available

at the time of printing and is subject to change without

notice.

Section 1 - Safety: Contains general and specic

safety guidelines for product and safety label locations.

Section 2 - Information and Specications: Contains

warranty, contact information, machine specication

tables, and machine dimensions.

Section 3 - Component Location: Contains overview

of major component locations and functions.

Section 4 - Operation: Contains instructions for safe

operation and information for optional equipment.

Section 5 - Maintenance: Contains routine maintenance procedures, mechanical adjustments, component replacement and troubleshooting charts for

common problems and corrections. (For specic

engine maintenance procedures, refer to the engine

manufacturer manual.)

Section 6 - Schematics: Contains electrical and hydraulic schematics for product functionality.

Section 7 - Illustrated Parts List (IPL): Contains parts

numbers and illustrations for serviceable components.

VT LeeBoy, Inc. is proud to be ISO 9001 certied. The International Standards

Organization (ISO) establishes guidelines to ensure that products and

services are safe, reliable and of good quality. ISO certies companies who

demonstrate compliance with all aspects of product safety, customer

satisfaction, efciency, environmental stewardship and social responsibility.

Our teams work hard to deliver quality industrial machines that exceed

customer expectations and we strive for continuous improvement in

everything we do. The VT LeeBoy family of companies is committed to

total quality management with a strong focus on meeting customer needs.

VT LeeBoy, Inc., is also proud to be an accredited ANAB manufacturer,

which is a certication process comprised of quality standards established

by the American National Standards Institute (ANSI) and the American

Society for Quality (ASQ). The ANSI-ASQ National Accreditation Board

plays an important role in ensuring the safety and quality of goods and

services, along with protecting the environment.

LeeBoy 8515D Conveyor Paver

xiii

NOTES

LeeBoy 8515D Conveyor Paverxiv

Section 1

SAFETY

Page

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Machine Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Hot Material Precautions . . . . . . . . . . . . . . . . . . . . . . . 1-7

Hydraulic Systems Precautions . . . . . . . . . . . . . . . . . . . 1-7

Refueling Precautions . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Battery Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Starting and Stopping Precautions . . . . . . . . . . . . . . . . . . 1-8

Parking Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Poor Visibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Storage Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Maintenance Precautions . . . . . . . . . . . . . . . . . . . . . . 1-9

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Safety Decals Care . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Decal Installation (Sticker Type) . . . . . . . . . . . . . . . . . . . 1-11

Decal Installation (Top Protected) . . . . . . . . . . . . . . . . . . 1-11

LeeeBoy 8515D Conveyor Paver 1-1

Safety

NOTES

LeeBoy 8515D Conveyor Paver1-2

Safety

This manual provides important information to familiarize

you with safe operating and maintenance procedures.

Even though you may be familiar with similar equipment,

you MUST read and understand this manual before

operating the LeeBoy Model 8515D Conveyor Paver

and follow its instructions when operating the machine.

Safety is everyone’s business and our top concern.

Knowing the guidelines covered in this section will help

ensure your safety, the safety of those around you, as

well as proper paver operation.

Keep safety labels in good condition. If safety labels

become missing or damaged, replace them with

new matching labels. Replacement safety labels are

available from your LeeBoy authorized dealer (see

contact information in Section 2).

You can nd more information about occupational health

and safety in the paving industry on the internet. A few

resources are listed below:

www.osha.gov

cdc.gov

www.asphaltpavement.org

LOOK FOR THESE SYMBOLS THROUGHOUT

THIS MANUAL. THESE ITEMS ARE EXTREMELY

IMPORTANT FOR THE SAFETY OF YOU AND

YOUR COWORKERS. READ AND UNDERSTAND

THOROUGHLY. HEED THE WARNINGS AND

FOLLOW THE INSTRUCTIONS.

1

Indicates a hazardous situation which,

if not avoided, will result in death or serious injury.

Indicates a hazardous situation which,

if not avoided, could result in death or serious injury.

Indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

Indicates a situation which can cause

damage to the equipment, personal property and/

or the environment, or cause the machine to operate

improperly.

www.safety.fhwa.dot.gov/

NOTE: Indicates a procedure, practice or condition

that should be followed in order for the

machine or component to function in the

manner intended.

LeeBoy 8515D Conveyor Paver 1-3

Safety

Safety Precautions

The safety messages that follow have CAUTION level

hazards.

Pre-Operation Hazard

Read and understand this Operation Manual

before operating or servicing the engine to

ensure that safe operating practices and maintenance

procedures are followed.

• Never permit anyone to service or operate the

machine without proper training.

• Safety signs and labels are additional reminders for

safe operating and maintenance techniques.

• Contact LeeBoy or an authorized LeeBoy dealer for

additional training.

• Make sure you are aware of all laws and regulations

that are in effect for the location in which the paver is

operated.

• Make sure you have all necessary licenses to operate

the paver.

Electrocution Hazard

Disconnect the battery before welding anywhere on the

machine.

Suffocation Hazard

Carbon monoxide poisoning is a serious

condition that occurs as a result of improper

ventilation.

• Never operate the internal combustion engine on this

machine in an enclosed area with poor ventilation.

Ensure proper ventillation to reduce risk of carbon

monoxide poisoning or death.

Exhaust Hazard

All internal combustion engines create

carbon monoxide gas during operation and

special precautions are required to avoid

carbon monoxide poisoning:

• Never block windows, vents or other means of

ventilation.

• Always ensure that all connections are tightened to

specications after repair is made to the exhaust

system.

The safety messages that follow have DANGER level

hazards.

Power Lines Hazard

If your machine comes into contact with

electric power lines, observe the following:

• Stay in the operators seat.

• Warn other workers to stay away and do not touch any

control or any part of the machine.

• If contact can be broken, drive the machine away from

the danger zone.

• If contact cannot be broken, stay in the operators seat

until told that power is off.

• Failure to observe these directions could result in

electrocution or death.

The safety messages that follow have WARNING

level hazards.

Crush Hazard

Keep bystanders away from work area before and

during operation.

Modification Hazard

Never modify the LeeBoy machine without the written

consent of LeeBoy. Any modication can affect the safe

operation of the paver and may cause personal injury or

death.

LeeBoy 8515D Conveyor Paver1-4

Safety

Exposure Hazard

Operators of the paver must be aware of

their work environment and the equipmnet

needed to work safely.

• Always wear personal protective equipment, including

appropriate clothing, gloves, work shoes, and

protection for eyes and ears, as required by the task

at hand.

Explosion Hazard

While the engine is running or the battery is

charging, hydrogen gas is being produced

and can be easily ignited. Keep the area

around the battery well-ventilated and keep

sparks, open ame, and any other form of

ignition out of the area.

• Always disconnect the negative (-) battery cable

before servicing the paver.

• Do not start the engine by shorting the starter circuit

or any other starting method not stated in this manual.

Only use the starting procedure as described in this

manual to start the engine.

• Never charge a frozen battery. Always slowly warm the

battery to room temperature before charging.

Fire Hazard

When operating machinery there is a risk for

re. Always have appropriate safety

equipment available.

• Keep a charged re extinguisher within reach when

working in an environment where a re may occur.

• Have all re extinguishers checked periodically for

proper operation and/or readiness.

• Always read and follow safety-related precautions

found on containers of hazardous substances

like parts cleaners, primers, sealants and sealant

removers.

• Undersized wiring systems can cause electrical res.

Entanglement/Sever Hazard

Verify there are no people, obstacles or

other equipment near the machine before

starting the engine. Sound the horn as a

warning before starting the engine.

If the engine must be serviced while it is

operating, remove all jewelry and tie back

long hair before operating or servicing the

machine.

• Keep hands, other body parts, and clothing away from

moving/rotating parts.

1

Fire and Explosion Hazard

• Diesel fuel is ammable and explosive under certain

conditions.

• Never use a shop rag to catch fuel.

• Wipe up all spills immediately.

• Never refuel with the engine running.

• Store any containers containing fuel in a well-

ventilated area, away from any combustibles or

sources of ignition.

• Always stop the engine before beginning service.

Before maintenance, remove negative battery cable

from battery post to ensure vehicle is not operated

during maintenance.

• Verify that all guards and covers are properly attached

before starting the engine. Do not start the engine if

any guards or covers are not properly installed on the

paver.

• If you must run the engine during maintenance

procedures, make sure you have a helper to keep

bystanders clear of the paver and make observations

of moving parts as requested by the operator.

• Always turn the start switch to the OFF position after

operation is complete and remove the key from the

switch. Keep the key in your possession when the

paver is not operating.

• Attach a “Do Not Operate” tag near the key switch

while performing maintenance on the equipment.

LeeBoy 8515D Conveyor Paver 1-5

Safety

• Never operate the engine while wearing a headset to

listen to a radio or music because it will be difcult to

hear the warning signals.

• Always start the engine and operate the controls while

seated in the operators seat.

• Always turn the start switch to the OFF position after

operation is complete and remove the key from the

switch. Keep the key in your possession when the

paver is not operating.

• Attach a “Do Not Operate” tag near the key switch

while performing maintenance on the equipment.

Alcohol and Drug Hazard

Never operate the machine while under the

inuence of alcohol, drugs, or when ill.

Piercing Hazard

High-pressure hydraulic uid or fuel can

penetrate your skin and result in serious

injury. Avoid skin contact with high-pressure

hydraulic uid or diesel fuel spray caused by

a hydraulic or fuel system leak such as a

broken hydraulic hose or fuel injection line.

• If you are exposed to high-pressure hydraulic uid or

fuel spray, obtain prompt medical treatment.

• Never check for a hydraulic uid or fuel leak with your

hands. Always use a piece of wood or cardboard.

Have your authorized LeeBoy dealer or distributor

repair the damaged parts.

Coolant Hazard

Coolant must be handled properly to ensure

operator safety.

• Wear eye protection and rubber gloves when handling

engine coolant.

• If contact with the eyes occurs, ush eyes with clean

water for 15 minutes.

• If contact with skin occurs, wash immediately with

soap and clean water.

Burn Hazard

Some of the machine’s surfaces become

very hot during operation and shortly after

shutdown.

• Keep hands and other body parts away from hot

machine surfaces.

• Handle hot components with heat-resistant gloves.

The safety messages that follow have CAUTION level

hazards.

Poor Lighting Hazard

The work area must be well lit to ensure safe and proper

operation.

• Ensure that the work area is adequately illuminated.

Flying Object Hazard

Always wear eye protection when cleaning

the machine with compressed air or highpressure water.

Dust, ying debris, compressed air,

pressurized water or steam may cause eye

injury.

• Always install wire cages on portable safety lights.

Tool Hazard

Always use tools appropriate for the task at hand and

use the correct size tool for loosening or tightening

LeeBoy machine parts.

LeeBoy 8515D Conveyor Paver1-6

Machine Precautions

Safety

The safety messages that follow have NOTICE level

hazards.

Any part that is found defective as a result of inspection

or any part whose measured value does not satisfy the

standard or limit must be replaced.

Always tighten components to the specied torque.

Loose parts can cause damage to the machine or cause

it to operate improperly.

Only use replacement parts approved by LeeBoy. Other

replacement parts may affect warranty coverage.

Follow the guidelines of the EPA or other

governmental agencies for the proper

disposal of hazardous materials such as

engine oil, diesel fuel, and engine coolant.

Consult the local authorities or

reclamation facility.

Dispose of hazardous materials in accordance with

all applicable laws and regulations. Never dispose of

hazardous materials by dumping them into a sewer, on

the ground, or into groundwater or waterways.

Clean all accumulated dirt and debris away from the

body of the paver and its components before you

inspect the paver or perform preventive maintenance

procedures or repairs. Operating a paver with

accumulated dirt and debris will cause premature wear

of paver components. Accumulated dirt and debris also

hinders effective paver inspection.

Retrieve any tools or parts that may have dropped inside

of the paver to avoid improper paver operation.

If any alert indicator illuminates during paver operation,

stop the engine immediately. Determine the cause and

repair the problem before continuing to operate the

paver.

Hot Material Precautions

• Wear protective gear for face, hands, feet, and body

when operating the paver.

• Allow machine to cool before repairing or maintaining

working components.

• If hot asphalt touches skin, ush area immediately with

cold water. DO NOT apply ice to the affected area.

DO NOT ATTEMPT TO REMOVE ASPHALT CEMENT

with products containing solvents or ammonia.

Natural separation will occur in about 48 to 72 hours.

Get medical attention as soon as possible.

• DO NOT remove radiator cap, drain plugs, service

grease ttings, or pressure taps while engine is hot.

Add coolant to the radiator and perform other services

only when the engine is stopped and fully cooled.

Hydraulic Systems Precautions

• Ensure all components are in good working condition.

Replace any worn, cut, abraded, attened or crimped

hoses and metal lines.

• DO NOT attempt makeshift repairs using tape, clamps

or cements. The hydraulic system operates under

extremely high pressure and such repairs could

cause serious injury.

• Wear proper hand and eye protection when checking

for a high pressure leak. Use a piece of wood or

cardboard as a back stop to isolate and identify leaks.

Hydraulic oil under pressure can

cause serious personal injury. Check for oil leaks

with a piece of cardboard. DO NOT expose hands to

possible high-pressure oil. Turn off engine before

attempting to tighten oil lines and ttings.

• Escaping pressurized hydraulic uid has force

sufcient to penetrate the skin, which could cause

serious personal injury. Ensure all pressure is

relieved before disconnecting line, hoses or valves.

1

LeeBoy 8515D Conveyor Paver 1-7

• If injury from concentrated high pressure steam

or hydraulic uid occurs, seek medical attention

immediately. Injuries resulting from hydraulic uid

penetrating the skin’s surface can result in serious

infections or toxic reactions.

Safety

Refueling Precautions

• Do NOT overll the fuel tank as overow creates a re

hazard when spilled on hot components.

• DO NOT smoke when refueling and never refuel when

the engine is running. Fuel is highly ammable and

should be handled with care. Death or serious injury

can occur due to explosion and/or re.

• DO NOT ll tank to capacity. Allow room for expansion

to reduce the risk of fuel expanding and spilling from

the tank.

• Tighten fuel cap securely. Should fuel cap be lost,

replace it with an original manufacturer’s approved

cap. Pressurization of the tank may result from use of

non-approved cap.

• Prevent res by keeping the machine clean of

accumulated debris, grease, and spilled fuel.

• Use ultra-low sulfur diesel fuel (ULSD) only.

Battery Precautions

• Keep all sparks and ames away from batteries, as

gas given off by electrolytes is explosive.

• Acid propelled by an explosion can cause blindness

if it comes in contact with eyes. Always wear safety

glasses when working near batteries.

• If you come in contact with battery electrolyte solution,

wash off immediately. Chemicals can cause burns.

• Always disconnect the battery ground cable before

working on the electrical system to avoid injury from

spark or short circuit. Electrical shock and burns can

occur.

• To avoid electrolyte loss, DO NOT tip batteries more

than 45 degrees.

Starting and Stopping

Precautions

• Check all around the paver to make sure there are no

people working on the machine or in the path of the

machine before starting. DO NOT start until area is

clear. Death or serious injury can occur to bystanders

from being crushed under a moving machine.

• Check brakes, steering and other control devices in

accordance with instructions before starting. Be sure

both steering levers (joysticks) are in neutral with the

neutral lock engaged.

• DO NOT bypass the paver neutral-start system.

DO NOT operate the engine in an

enclosed area without proper ventillation. Exhaust

gasses are odorless and deadly.

Parking Precautions

• Park paver on level ground whenever possible, set

steering levers in neutral and lock. Apply the parking

brake. Park the paver with wheels securely blocked

on grades.

• Remove ignition key when leaving paver parked or

unattended.

Operating Precautions

• Always comply with local regulations regarding

moving equipment on public roads and highways.

• Know and use the hand signals required for a

particular job. Know who has the responsibility for

signaling.

• Make sure that all lights and reectors comply with

state and local regulations. Make sure that they are

clean, in good working order, and can be seen clearly

by all trafc.

• DO NOT stand between the equipment and the truck

while the truck is being backed to the paver. Death or

serious injury can result from being crushed between

the two machines.

• DO NOT ride on attachments.

• Check all gauges and warning instruments for proper

operation. If malfunctions are found, shut down the

machine and report the problem for resolution. If the

failure causes loss of steering control, loss of brake

control, or loss of engine power, stop paver motion as

quickly as possible. Apply parking brake (if equipped).

Keep the machine securely parked until the failure is

corrected or the machine can be safely towed.

• Drive the machine with care. Make sure speed is

compatible with conditions. Use caution on rough

ground, slopes, and while turning.

• Be alert for hazards and obstructions such as ditches,

trees, cliffs, overhead power lines, and areas where

there is danger of a slide.

• Be aware of and understand the job site trafc ow

patterns.

LeeBoy 8515D Conveyor Paver1-8

Safety

• Obey agmen, road signs, and signals.

• Watch for bystanders. Never allow anyone near the

machine during operation. Never allow anyone to

reach into the machine during use.

• Operator must know how to use signaling devices

when roading with a paver. Operator must also

understand which circumstances require use of each

signal. Use tail lights, slow moving vehicle signs, and

warning beacon as needed when traveling on public

roads. It is recommended that you provide an escort

on the road.

• DO NOT tow the paver, except to remove from road or

to load on trailer.

Poor Visibility

Increasingly, asphalt maintenance equipment is used

during less than ideal lighting conditions such as fog

and smog or at night. These conditions present safety

hazardss for workers, bystanders and passing trafc.

When operating under restricted light

conditions, equip the machine with special lighting to

prevent serious injury.

While the machine is equipped with a beacon and a

work light, contact your authorized LeeBoy dealer for

additional lighting packages if working under these

conditions.

Use reective tape on the sides of machines when

working at night. Ensure all workers wear reective

safety vests. Use impact barriers (movable or

stationary) to protect workers and direct the trafc ow

safely away from the work site.

Maintenance Precautions

• DO NOT attempt repairs unless trained to do so.

Refer to manuals and experienced repair personnel

for help.

• Before working on the machine, securely block the

machine and any components that may fall. Block

any working components to prevent unexpected

movement while repairs are being made.

• Always wear safety glasses and other required safety

equipment when servicing or making repairs.

• Disconnect battery before working on the electrical

system.

• Avoid lubrication or mechanical adjustments while the

paver is in motion or while engine is operating.

• If lubrication or mechanical adjustment is necessary,

use extreme caution and complete the following

steps:

1. Place Forward/Reverse control in neutral.

2. Apply neutral lock.

3. Lower screed to ground.

4. Shut off engine.

5. Place equipment in a safe position.

6. Securely block wheels and tracks.

• Never make repairs on pressurized components such

as uid lines, the gas system, or mechanical items until

the pressure has been relieved.

• When servicing or replacing hardened pins, use a

brass drift or other suitable material between the

hammer and pin.

1

Storage Precautions

• Store paver in an area away from human activity.

• DO NOT permit children to play on or around the

stored machine. Serious injury or death can occur

from improper/unauthorized use of the machine.

• Make sure the unit is stored on a surface that is rm,

level, and free of debris.

• Store the machine inside a building or cover securely

with a weatherproof tarpaulin.

LeeBoy 8515D Conveyor Paver 1-9

• Keep brake and steering systems in good operating

condition.

g.

856441

porte.

nt le

s.

Safety

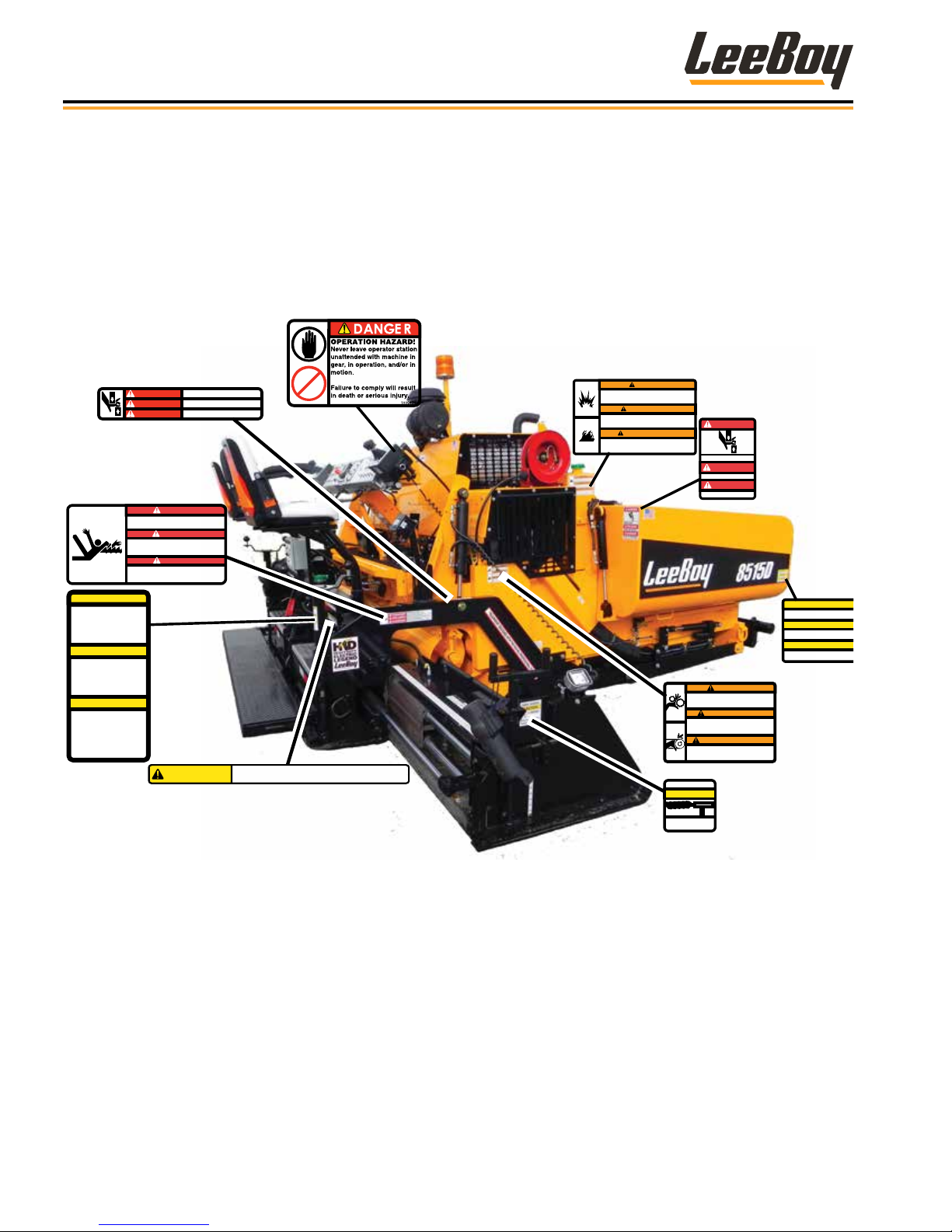

Safety Decals

If your machine is repainted, it is extremely important

that you replace all the CAUTION, WARNING and

DANGER safety decals in the proper locations. (Figure

1-1) For additional help, refer to the parts listing in

Section 7 and contact your authorized LeeBoy dealer to

order a replacement kit.

DANGER

PELIGRO

DANGER

ENTANGLEMENT HAZARD!

Keep hands and clothing clear of augers and conveyors.

Failure to comply will result in death or serious injury.

¡RIESGO DE QUEDAR ATRAPADO!

Mantener las manos y la ropa lejos de los sinfines y

transportadores. Si no se cumple con esta disposición, se

causará la muerte o lesiones graves.

RISQUE D'ENCHEVÊTREMENT !

Maintenir les mains et les vêtements à l’écart des vis et

convoyeurs. Le non-respect de cette règle entraînera des

856442

Flight screw handle must be in

locked position when raising

screed.

Damage may occur to hand, seat or

screw if not locked.

Always remove hand when raising

screed.

PRECAUCION

La manija del tornillo de recorrido

debe estar en la posición trabada

al elevar la plataforma. Se pueden

sufrir lesiones en la mano, o dañar

el asiento o tornillo si no está

trabada. Siempre quitar las manos

al elevar la plataforma.

La poignée de vis d’ailette doit

être en position verrouillée lors du

levage de la plaque de finition.

Une blessure à la main risque de

se produire et le siège ou la vis

d’être endommagé(e) si elle n’est

pas verrouillée. Toujours enlever

la main lors du levage de la

plaque de finition.

blessures graves, voire mortelles.

CAUTION

ATTENTION

856482

Both Sides

PINCH POINT

PUNTO DE APRIETE

POINT DE PINCEMENT

Both Sides

DANGER

PELIGRO

DANGER

Both Sides

CAUTION

856438

WATCH YOUR STEP!

Failure to comply may result in minor or moderate injury.

Both Sides

859789

NOTE: It is the responsibility of the owner and

operator to make sure that all safety labels are

readable and located on the paver as designated by

LeeBoy.

WARNING

EXPLOSION/FIRE HAZARD!

Do not use electric spray system when burners are in use.

Do not fill fuel tank when engine is running or screed is being heated.

Failure to comply could result in death or serious injury.

ADVERTENCIA

¡RIESGO DE EXPLOSION/INCENDIO!

No utilizar el sistema de rociado eléctrico cuando los quemadores están en uso.

No llenar el tanque de combustible con el motor en marcha o si se está calentando la

plataforma.

Both Sides

Si no se cumple con esta disposición, se puede causar la muerte o lesiones graves.

AVERTISSEMENT

RISQUE D’EXPLOSION/INCENDIE !

Ne pas utiliser le système électrique de pulvérisation lorsque les brûleurs sont allumés.

Ne pas faire le plein de carburant avec le moteur en marche ni pendant le réchauffage de

la plaque de finition.

Le non-respect de cette règle risque d’entraîner des blessures graves, voire mortelles.

856444

Both Sides

DANGER

PINCH POINT

PELIGRO

PUNTO DE APRIETE

DANGER

POINT DE PINCEMENT

Both Sides

WARNING

ENTANGLEMENT HAZARD!

Keep hands clear.

Keep guards in place. Replace missing guards or shields.

Failure to comply could result in death or serious injury.

ADVERTENCIA

¡RIESGO DE QUEDAR ATRAPADO!

Mantener las manos alejadas.

Mantener los protectores en su lugar. Sustituir los protectores o escudos

faltantes.

Si no se cumple con esta disposición, se puede causar la muerte o lesiones

graves.

AVERTISSEMENT

RISQUE D'ENCHEVÊTREMENT !

Ne pas approcher les mains.

Maintenir les protections en place. Remplacer les carters et protections qui

manquent.

Le non-respect de cette règle risque d’entraîner des blessures graves, voire

mortelles.

Both Sides

SONIC AUGERS

CAUTION

Ensure cord points

toward front.

859799

Both Sides

856437

73283-1

CAUTION

Keep guidebar latched when transportin

Keep all adjustments tight.

PRECAUCION

Mantener la barra guía trabada durante el trans

Mantener todos los ajustes bien apretados.

ATTENTION

Maintenir la barre de guidage verrouillée penda

transport. Maintenir tous les ajustements serré

Both Sides

Figure 1-1. Safety Labels and Safety Label Locations

LeeBoy 8515D Conveyor Paver1-10

Safety

Safety Decals Care

1. Keep safety decals and signs clean and legible at all

times.

2. Become familiar with the content and the position

of each safety decal. Decals include important

information.

3. Replace decals and signs that are missing or

become impossible to read.

4. When replacing parts that display a safety decal,

ensure that the new part is tted with a decal as well.

5. Obtain replacement safety decals or signs from

your authorized LeeBoy dealer.

Decal Installation (Sticker Type)

1. Be sure that the installation area is clean and dry.

Use hot, soapy water to clean the surface where the

decal will be applied.

2. Thoroughly dry the surface.

3. Measure and t decal before removing the paper

backing.

Decal Installation (Top

Protected)

1. If the decal has a protective top paper, use hot

soapy water on the surface where the decal will be

applied. Leave wet.

2. Determine the proper location, remove protective

back paper and soak decal in clean soapy water

before application. This will help to alleviate air

bubbles in the applied decal.

3. Smooth decal into place with a squeegee and check

for air bubbles.

4. Small air pockets can be pierced with a pin and

smoothed out using a piece of the decal backing.

5. When decal is completely smoothed, carefully

remove top paper.

1

4. For decals with no top protection paper, remove the

smallest split-backed paper.

5. Align decal over the specied area and carefully

press exposed portion into place.

6. Slowly remove the remaining backing and carefully

smooth the remaining portion of the decal into

place.

7. Small air pockets can be pierced with a pin and

smoothed using a piece of the decal backing.

LeeBoy 8515D Conveyor Paver 1-11

Safety

NOTES

LeeBoy 8515D Conveyor Paver1-12

Section 2

INFORMATION AND SPECIFICATIONS

Page

Limited Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Specications Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Torque Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Standard Inch Fasteners . . . . . . . . . . . . . . . . . . . . . . . 2-7

Metric Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Determining Proper Torque . . . . . . . . . . . . . . . . . . . . . 2-9

8515D Conveyor Paver 2-1

Information and Specications

LIMITED WARRANTY POLICY

Warranty

Subject to the limitations, exclusions, and claims procedures set

forth herein, VT LeeBoy, Inc. warrants [to the rst retail purchaser]

that this product will be free from substantial defects in materials

and workmanship during the warranty period.

If a defect in material or workmanship is found, your authorized

LeeBoy Dealer is to be notied during the warranty period.

LeeBoy and its authorized Dealer will repair or replace any part or

component of the unit or part that fails to conform to the warranty

during the warranty period.

The warranty period will begin on the initial start-up, training and

delivery of the unit by the Dealer to the customer, and will expire

after twelve (12) months following the delivery of the product to the

rst retail purchaser. (See Dealer for additional warranty.)

Manufacturers’ Warranties: Engines are warranted by their

manufacturers and may have warranty coverage that differs from

that of LeeBoy. LeeBoy does not warrant any engine.

Replacement parts furnished by LeeBoy are covered for the

remainder of the warranty period applicable to the unit or

component in which such parts are installed.

LeeBoy has the right to repair any component or part before

replacing it with a new one.

All new replacement parts purchased by a LeeBoy Dealer will carry

a six-month warranty.

This Limited Warranty is governed by the laws of the State of North

Carolina.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER EXPRESSED, STATUTORY AND IMPLIED

WARRANTIES APPLICABLE TO UNITS, ENGINES, OR PARTS

INCLUDING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR USE

OR PURPOSE OR AGAINST INFRINGEMENT.

Items Not Covered

LeeBoy is not responsible for the following:

All used units or used parts of any kind.

Repairs due to normal wear and tear or brought about by abuse or

lack of maintenance of the machine.

Attachments not manufactured or installed by LeeBoy.

Liability for incidental or consequential damages of any type

including, but not limited to, lost prots or expenses of acquiring

replacement equipment.

Limitations

VT LeeBoy , Inc. has no obligation for:

Any defects caused by misuse, misapplication, negligence, accident,

or failure to maintain or use in accordance with the most current

operating instructions.

Unauthorized alterations.

Defects or failures caused by any replacement parts or attachments

not manufactured by or approved by LeeBoy.

Failure to conduct normal maintenance and operating service

including, without limitation, providing lubricants, coolant, fuel, tuneups, inspections, or adjustments.

Unreasonable delay, as established by LeeBoy, in making the

applicable units or parts available upon notication of a service notice

ordered by same.

Warranty Responsibility: The warranty responsibility on all engines

rests with the manufacturer of the engine.

Warranty and Parts Support: LeeBoy may have support agreements

with some engine manufacturers for warranty and parts support.

However, LeeBoy does not warrant the engine.

This Limited Warranty sets forth your sole remedy in connection

with the sale or use of the LeeBoy product covered by this Limited

Warranty.

This Limited Warranty extends only to the rst retail purchaser, and is

not transferable.

In the event any portion of this Limited Warranty shall be determined

to be invalid under any applicable law, such provision shall be deemed

null and void and the remainder of the Limited Warranty shall continue

in full force and effect.

Other Limitations

IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT

OR WARRANTY OR ALLEGED NEGLIGENCE OR LIABILITY WITHOUT

FAULT, SHALL LEEBOY BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES INCLUDING, WITHOUT LIMITATION,

LOSS OF PROFIT OR REVENUE, COST OF CAPITAL, COST

OF SUBSTITUTED EQUIPMENT, FACILITIES OR SERVICES,

DOWNTIME COSTS, LABOR COSTS OR CLAIMS OF CUSTOMERS,

PURCHASERS OR LESSEES FOR SUCH DAMAGES. IN NO EVENT

WILL WARRANTY COMPENSATION, OR OTHER DAMAGES

AVAILABLE FROM LEEBOY EXCEED THE PURCHASE PRICE OF

THE PRODUCT.

2-2

8515D Conveyor Paver

CONTACT INFORMATION

Information and Specications

For information regarding parts and repairs about

your LeeBoy product, contact your authorized LeeBoy

dealer. If your dealer is unable to resolve the problem,

contact LeeBoy directly.

Sales Representative:

Dealership Name:

Dealership Address:

Dealership Phone:

Record dealer information in the space provided.

For additional information about LeeBoy, please visit:

www.leeboy.com.

Record of Ownership

Please complete the following information for use if you need to contact LeeBoy for service, parts or literature.

Machine Model Number:

Product Serial Number:

Date of Purchase:

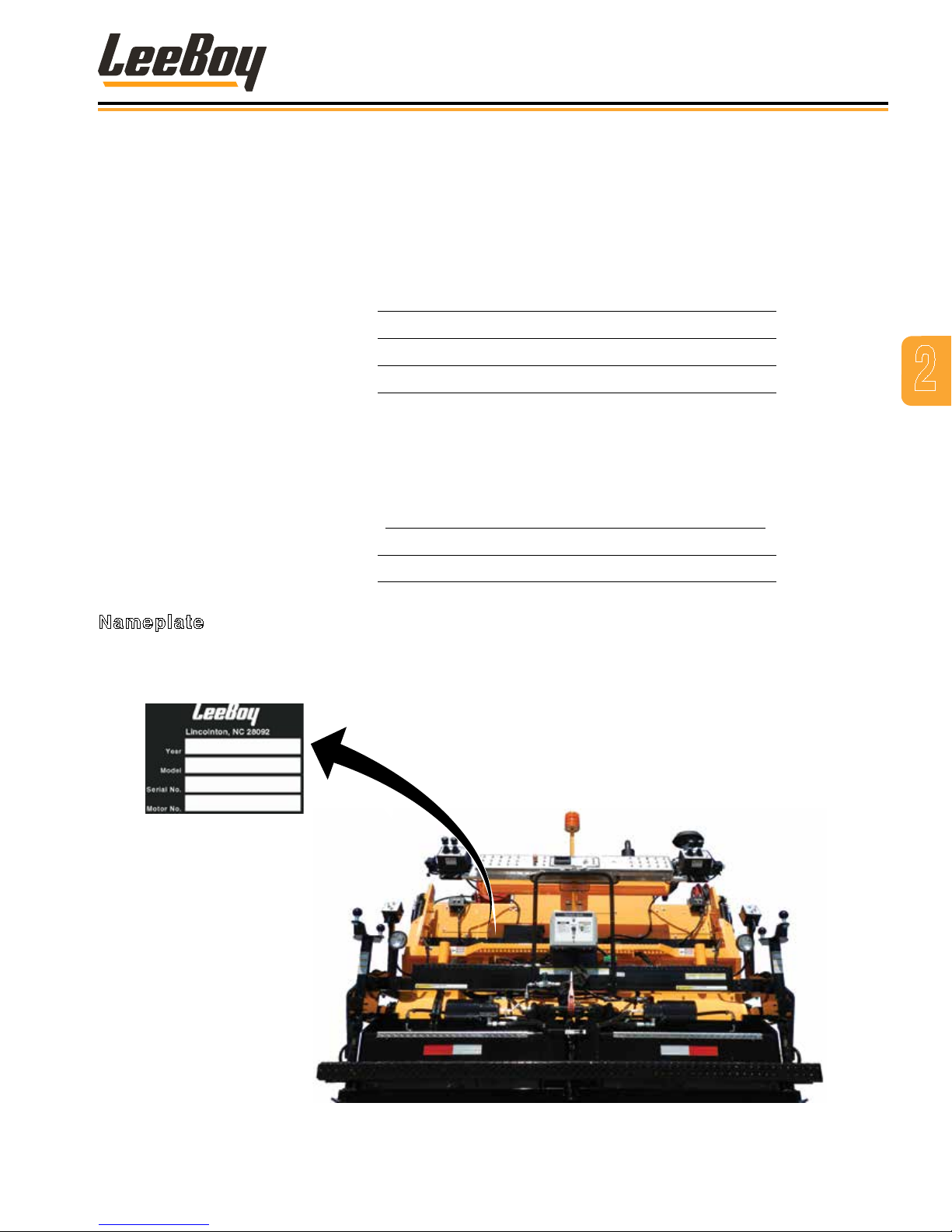

Nameplate

2

The nameplate contains the model and serial numbers used to identify the machine and its components for parts or

service information. Refer to the Engine Operator’s Manual for the location of the engine nameplate.

8515D Conveyor Paver

Figure 2-1. Nameplate Location

2-3

Information and Specications

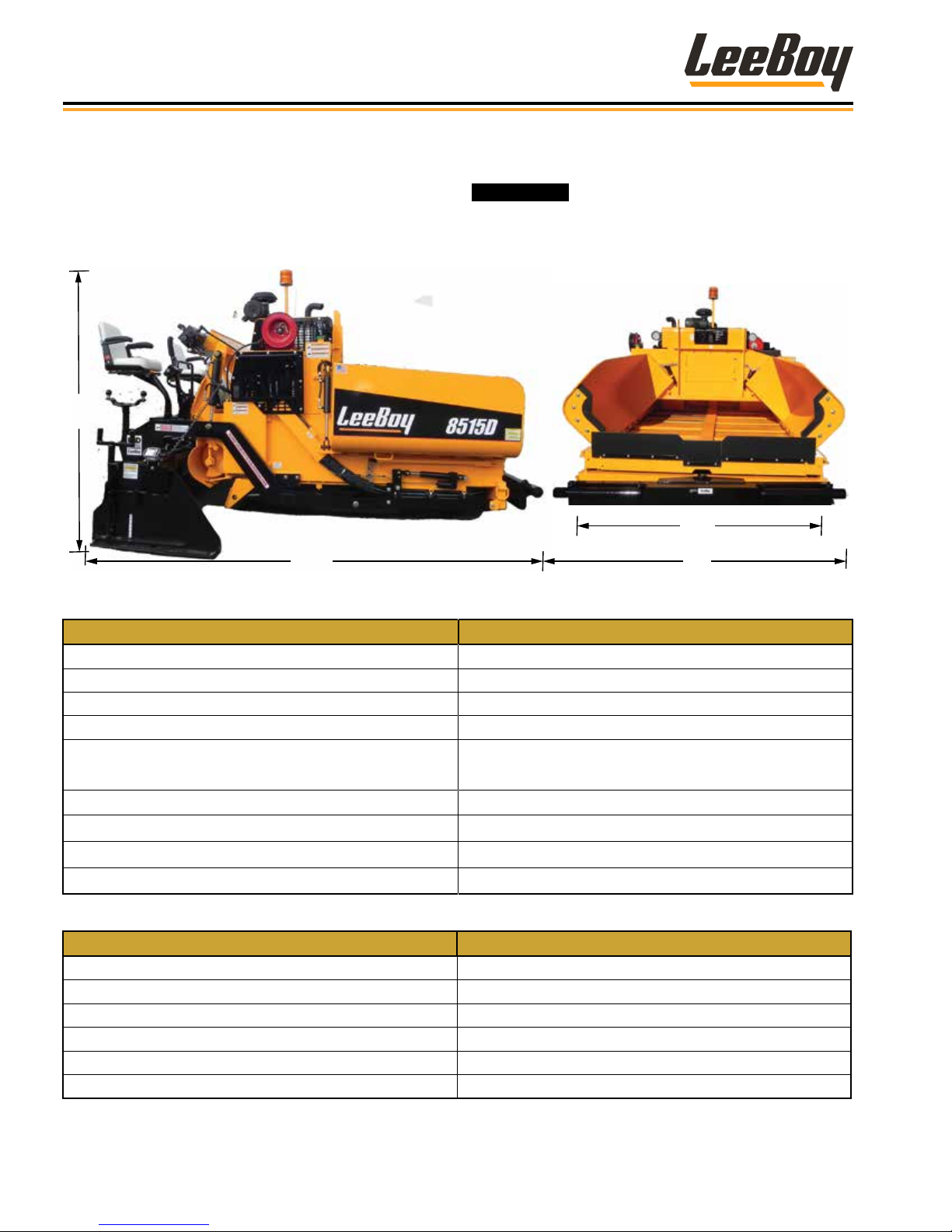

SPECIFICATION CHARTS

The specications provided in this section include

screed weights, dimensions, performance, and torque

values for both metric and standard inch fastener.

8’ 3”

13’ 3”

Table 2-1. Machine Dimensions

ITEM SPECIFICATION

Overall Length 13 ft 3 in (4 m)

Overall Height 8 ft 6 in (2.6 m)

Overall Width (Hopper Wings In) 8 ft 6 in (2.6 m)

Overall Width (Hopper Wings Out) 10 ft (3 m)

Overall Weight

Paving Width 8 - 15 ft (2.4 - 4.6 m)

Extensions Length 3 ft 6 in (30 cm)

components approved by your LeeBoy dealer.

Standard Screed: 17,500 lb (7937 kg)

HD Screed Option: 17,900 (8119 kg)

Replace original equipment only with

8’ 6”

10’

Main Screed Wear Plate

Extension Width of Wear Plate 7” (17.8 cm)

ITEM SPECIFICATION

Manufacturer and Model Kubota, V3800-CR-TE4B, Tier 4 (Final)

Engine Type Vertical Liquid Cooled Diesel, 4-Cylinder

Bore, Stroke and Displacement 3.9 in (100 mm); 4.72 in (120 mm); 230 cu in (3.8 L)

Power Rating 74 HP (55.2 kW)

Intake and Combustion Systems Turbo-Charged, Direct-Injection

Maximum Speed 2200 RPMs

2-4

15” (38 cm)

Table 2-2. Engine Specications

8515D Conveyor Paver

Information and Specications

Table 2-3. Performance Specications

ITEM SPECIFICATION

Travel Speed

Paving Speed 0 - 140 FPM [0 - 2.4 MPM]

Table 2-5. Electrical Specications

ITEM SPECIFICATION

Battery 12 Vdc Maintenance Free, 12 Volts

Cold Cranking Amps (CCA) 1125 CCA

Alternator 12-Volt, Negative-Ground, 60 Amps

Alternator Fan Belt Tension

Starter Voltage and Type 12-Volt, Negative-Ground

Table 2-6. Lubricant Specications

ITEM SPECIFICATION

Engine Oil 15W-40, API, CH-4, CI-4

Hydraulic Oil All-Weather 68

Torque Hub 50 WT Gear Oil

Grease Shell Avania EP Grease or Equivalent

Chain Lube Chain Lube Agent

0 - 230 feet per minute (FPM)

[0 - 3.9 meters per minute (MPM)].

Manual belt tension mechanism keeps serpentine belt

under tension at all times.

2

Table 2-7. Machine System Capacity Specications

ITEM SPECIFICATION

Engine Lubrication Oil (Rell Capacity) 15 qts (14.2 L)

Hydraulic Oil Tank 40 gal (151.4 L)

Torque Hubs 32 oz (.35 L) each

Diesel Fuel 18 gal (68.1 L)

Propane One (1) 20-lb Tank

Antifreeze Glycol-Based, Extended Life; 3.6 gal (13.8 L)

Table 2-8. Hydraulic Pressures Specications

ITEM SPECIFICATION

Drive 3625 psi (249.9 Bar)

Conveyors and Cylinders 2500 - 2700 psi (172.3 - 179.2 Bar)

Augers 2800 - 3000 psi (193 - 206.8 Bar)

Track Tensioning Relief 1500 psi (103.4 Bar)

Charge Pressure 350 - 400 psi (24 - 27.6 Bar)

8515D Conveyor Paver

2-5

Information and Specications

Table 2-9. Hopper Specications

ITEM SPECIFICATION

Size 7.5 Tons (6804 kg)

Height 23 in (584 mm)

Wings 3/8 in (10 mm)

Figure 2-10. Screed Specications

ITEM SPECIFICATION

Screed Weight

Electric Heat (Option)

Propane Heat

Extensions Two (2) 44-inch Hydraulically-Operated

Vibration Two (2) hydraulic vibrators producing 2400 vpm.

Crown/Valley Adjustable, 2-inch crown, 1-1/2 inch of valley

Standard Screed 815HD (Option)

3000 lbs (1360 kg) 3700 lbs (1678 kg)

Two (2) 3412 BTU/hr

electric heat elements on

main screed.

One (1) 3412 BTU/hr

electric heat element on

each extension.

Two (2) 54,000 BTU propane burners on main screed.

One (1) 45,000 BTU propane burner on each extension.

Four (4) 3412 BTU/hr and

one (1) 820 BTU/hr electric

heat elements on main

screed.

One (1) 3412 BTU/hr

electric heat element on

each extension.

Table 2-11. Generator Specications (Electric Heat Option)

ITEM SPECIFICATION

Power 6.5 kW

Voltage 220 Volts

Frequency 60 Hz

2-6

8515D Conveyor Paver

Information and Specications

TORQUE SPECIFICATIONS

The following tables list torque values for standard

hardware. This is a guide for average application

involving typical stresses and machined surfaces.

Values are based upon physical limitations of clean,

plated and lubricated hardware. Under more extreme

conditions, individual torque value should be followed.

Conversion formulas are provided below:

that are not equal in size and grade to the original

equipment.

ft-lb to N•m [ft-lb]*1.3558 = [N•m)

ft-lb to in-lb [ft-lb]*12 = [in-lb]

N•m to in-lb [N•m]*8.8508 = [in-lb]

Never substitute fasteners of any kind

Conversion Formula

Standard Inch Fasteners

Table 2-13. Torque Specications For Standard Inch Fasteners

CAPSCREWS: SAE GRADE 5 CAPSCREWS: SAE GRADE 8

SIZE THREAD

1/4 20 UNC 8 6 11 8 12 9 16 12

28 UNF 10 7 14 9 14 10 19 14

5/16 18 UNC 17 13 23 18 25 18 34 24

24 UNF 19 15 26 20 27 20 37 27

3/8 16 UNC 31 23 42 31 44 33 60 45

24 UNF 35 26 47 35 49 37 66 50

7/16 14 UNC 49 37 66 50 70 52 95 71

20 UNF 55 41 75 56 78 58 106 79

1/2 13 UNC 75 57 102 77 106 80 144 108

20 UNF 85 64 115 87 120 90 163 122

9/16 12 UNC 109 82 148 111 154 115 209 156

18 UNF 121 91 164 123 171 128 232 174

5/8 11 UNC 150 113 203 153 212 159 287 216

18 UNF 170 127 230 172 240 180 325 244

3/4 10 UNC 267 200 362 271 376 282 510 382

16 UNF 297 223 403 302 420 315 569 427

7/8 9 UNC 429 322 582 437 606 455 822 617

14 UNF 474 355 643 481 669 502 907 681

1 8 UNC 644 483 873 655 909 681 1232 923

14 UNF 722 542 979 735 1020 765 1383 1037

1-1/4 7 UNC 1121 840 1520 1139 1817 1363 2464 1848

12 UNF 1241 930 1683 1261 2012 1509 2728 2046

1-1/2 6 UNC 1950 1462 2644 1982 3162 2371 4287 3215

12 UNF 2194 1645 2975 2230 3557 2668 4823 3617

TORQUE (ft lb) TORQUE N•m TORQUE (ft lb) TORQUE N•m

Dry Lubed Dry Lubed Dry Lubed Dry Lubed

2

8515D Conveyor Paver

2-7

Information and Specications

Metric Fasteners

Table 2-14. Torque Specications for Metric Fasteners

CLASS 8.8 [GRADE 5 EQUIVALENT] CLASS 10.9 [GRADE 8 EQUIVALENT]

NOMINAL SIZE

AND PITCH

M4 x 0.7 2 2 3 2 3 2 4 3

M5 x 0.8 5 3 7 4 7 5 9 7

M6 x 1 8 6 11 8 11 8 15 11

M8 x 1.25 19 14 26 19 27 20 37 27

M10 x 1.5 37 28 50 38 53 40 72 54

M12 x 1.75 65 49 88 66 93 70 126 95

M14 x 2 104 78 141 106 148 111 201 150

M16 x 2 161 121 218 164 230 173 312 235

M18 x 2.5 222 167 301 226 318 239 431 324

M20 x 2.5 314 236 426 320 449 337 609 457

M22 x 2.5 428 321 580 435 613 460 831 624

M24 x 3 543 407 736 552 777 582 1053 789

M27 x 3 796 597 1079 809 1139 854 1544 1158

M30 x 3.5 1079 809 1463 1097 1544 1158 2093 1570

TORQUE (ft lb) TORQUE N•m TORQUE (ft lb) TORQUE N•m

Dry Lubed Dry Lubed Dry Lubed Dry Lubed

Hydraulic Fittings

Tightening Flare-Type Tube Fittings

1. Check the are and are seat for defects that might

cause leakage.

2. Align tube with tting before tightening.

3. Lubricate connection.

4. Hand tighten swivel nut until snug.

5. To prevent twisting the tube(s), use two wrenches.

Place one wrench on the connector body and

tighten the swivel nut with the second to the torque

shown in the following table:

NOTE: The torque values shown are based upon

lubricated connections.

Table 2-15. Torque Specications for Steel Flare

Type Tube Fittings

TUBE SIZE

OUTER

DIAMETER

(IN) (IN) (LB FT) (N•m)

3/16 7/16 8 11

1/4 9/16 12 16

5/16 5/8 16 22

3/8 11/16 23 31

1/2 7/8 38 52

5/8 1 54 73

3/4 1 1/4 75 102

7/8 1 3/8 83 113

NUT SIZE

ACROSS

FLATS

TORQUE VALUE

2-8

8515D Conveyor Paver

Determining Proper Torque

LA

L

E

LA

LH

The only reliable method of creating a consistently

leak-free and long-lasting connection is to ensure the

coupling is brought to the proper torque. Using a torque

wrench with crowfoot is the best method, but the ats

method can be used if a torque wrench is not available.

The most straightforward method of determining the

correct torque setting is to multiply the desired torque

by the length of the wrench from the center of the handle

to the center of the drive (L); divided by the length of the

wrench from the center of the handle to the crowfoot

center (LA) as shown below:

L

Figure 2-16. Torque Wrench - Crowfoot

Information and Specications

2

The minimum torque values are

adequate for sealing most applications. Maximum

torque values should never be exceeded.

There are several methods of determining the correct

setting on the torque wrench when using a crowfoot. All

of the methods involve making the setting proportional

to the effective change in length of the wrench multiplied

by the desired nal torque. The equations and

illustration below describe proper measurements.

Equations

• Torque setting if the crowfoot is placed in line with

respect to the wrench:

• Torque setting if the crowfoot is placed at 90° with

respect to the wrench

• To estimate the crowfoot size (E)

TS = TD * L / LA

OR

TS = TD * L / (L+E)

TS = TD * L / LH

OR

TS = TD * L / √(L2 + E2)

Figure 2-17. Measurements Needed

LEGEND

L = Distance from center of torque wrench handle to the

center of socket drive

E = Distance from center of socket drive to the center of

crowfoot

LA = Distance from center of torque wrench handle to

the center of crowfoot

LH = Distance from center of torque wrench handle to

the center of crowfoot, when mounted at 90°

TD = Desired torque at the tting

TS = Torque setting indicated on wrench

E = Drive Size * 0.5 + Distance between Drive and

Open End + Wrench Size * 0.5774

8515D Conveyor Paver

2-9

Mark Line on Nut

Information and Specications

Coupling Installation

Use the following steps for proper coupling installation:

1. Determine the correct torque value for your

coupling.

NOTE: Only use the torque values specied from

the manufacturer. DO NOT use SAE torque

recommendations.

2. Ensure the seal face and threads are clean and in

good condition. O-Rings should be lubricated with

light oil, but threads should be completely dry unless

making pipe thread connections (interference seal).

NOTE: Attach the male end of the hose onto the

equipment rst since it may be necessary to

rotate the entire hose assembly to tighten

the male threads. Then route the hose into

position while avoiding twisting the hose.

3. Tighten the connection (by hand), bringing the seal

face into contact and rotating the nut until it stops.

4. Mark a line across the coupling nut and backup hex

for the ats method verication of coupling torque.

5. Apply a wrench to the backup hex to prevent the

coupling and hose from moving while tightening the

nut with a torque wrench.

Failure to retain the backup hex during

installation will also result in additional clamp load

force that could cause damage to the seal face.

NOTE: The coupling nut must be in motion for an

accurate torque reading. If the nut is stopped

before nal torque value is achieved, it must

be loosened and retightened until the torque

is attained while the nut is in motion.

If a torque wrench cannot t into the coupling area or if

it is unavailable, the ats method may be used to ensure

that the coupling is properly tightened, as shown in the

following gure.

Example 2 Flats

difference

Figure 2-18. Flats Method Tightening

NOTE: The mark placed on the nut and backup hex

after tightening by hand should rotate during

nal tightening according to the table below.

The nut and backup hex can then be marked

to indicate if the coupling loosens over time.

Table 2-19. Flats Method Values for Selected

Terminations

FLATS METHOD VALUES

Termination

Type

JIC -4 1.5 - 1.75

JIC -6 1.0 - 1.5

JIC -8 1.5 - 1.75

JIC -10 1.0 - 1.5

JIC -12 1.0 - 1.5

JIC -16 .75 - 1.0

JIC -20 .75 - 1.0

JIC -24 .75 - 1.0

JIC -32 .75 - 1.0

JIS -4 .5 - 1.5

1. Seal faces must be in contact with the tting fully

tightened by hand before marking ats.

2. The ats method is most accurate for the rst

assembly cycle. For multiple disassembly and

assembly cycles, torque values are more reliable.

Dash Size Flats

2-10