LeeBoy 8510b Service Manual

Operations, Service

And Parts Manual

LeeBoy Model 8510B Conveyor Paver

Manual No. 1003096-02

Thumb Index

Introduction

Safety

General Information

Specifications

Component Location

1

2

3

4

5

Operation

Maintenance

Troubleshooting

Schematics

Illustrated Parts List (IPL)

6

7

8

9

10

Disclaimer And Copyright

Disclaimer:

All information, illustrations and specications in this manual are based on the latest information available at the time

of publishing. The illustrations used in this manual are intended as representative reference views only. Moreover,

because of our continuous product improvement policy, we may modify information, illustrations and/or specications

to explain and/or exemplify a product, service or maintenance improvement. We reserve the right to make any

change at any time without notice. VT LeeBoy, Inc., VT LeeBoy, and LeeBoy are all the same entity and are used

interchangeably.

©2010 VT LeeBoy, Inc.

LeeBoy reserves all copyright and other rights in this manual and the manual’s content. No part of this manual may

be reproduced or used in any way without the written permission of LeeBoy, except as necessary to operate LeeBoy

equipment.

This manual has been most recently updated 03/11 to apply to units with serial number 56635 and higher:

Refer to manual no. 986947 for units with serial number 44987 to 56634.

PDF le last modied on: 03/03/11

Return to

iv LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Table Of Contents

Page

Table Of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Safety Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Limited Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Items Not Covered . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Other Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Record of Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Torque Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Operator Platform . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Specication charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Return to

LeeBoy Model 8510B Conveyor Paver v

Last Viewed

Return to

Thumb Index

Table Of Contents

Torque Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Metric Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Inch Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Full Torque Nut Coupling Installation . . . . . . . . . . . . . . . . . 4-9

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Location of Operation Panels and Controls . . . . . . . . . . . . . . . . . 5-2

Main Dash Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Main Dash Panel (continued) . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Speed and Steering Control Module - Joysticks

Steering and Speed Control Module - Wheel

. . . . . . . . . . . . . . 5-8

. . . . . . . . . . . . . . . . 5-10

Hydraulic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Paving Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Electric Screed Operation Controls . . . . . . . . . . . . . . . . . . . . 5-16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Pre-Start Inspection and Preparation . . . . . . . . . . . . . . . . . . . . 6-4

Starting The Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Preliminary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Engine Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Stopping the Engine . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Activating and Deactivating Operator Control Station . . . . . . . . . 6-5

Paver Driving Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Electronic Control Steering Box . . . . . . . . . . . . . . . . . . . 6-5

Paver Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Conveyor Operation . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Hydraulic Cutoff Gates Operation . . . . . . . . . . . . . . . . . . 6-8

Sonic Augers Operation . . . . . . . . . . . . . . . . . . . . . . . 6-8

Auger Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Electric Flight Screws Operation . . . . . . . . . . . . . . . . . . . 6-9

Spray Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Burner Ignition Procedure . . . . . . . . . . . . . . . . . . . . . . 6-10

Electric Heating Controls . . . . . . . . . . . . . . . . . . . . . . 6-12

Starting To Pave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Setting Screed To Pave . . . . . . . . . . . . . . . . . . . . . . . 6-13

Return to

vi LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Table Of Contents

Setting Screed End Gates . . . . . . . . . . . . . . . . . . . . . . 6-15

Setting Screed Extensions . . . . . . . . . . . . . . . . . . . . . . 6-16

Mat Texture Adjustment . . . . . . . . . . . . . . . . . . . . . . . 6-16

Unloading And Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Tie Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Electric Screed Heating System (Option) . . . . . . . . . . . . . . . . . 6-19

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Control Box

Cycle Timer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Element Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Element Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Element Connections . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Element Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Truck Hitch Attachment (Option) . . . . . . . . . . . . . . . . . . . . . . 6-23

Umbrella (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Lubrication Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Preparing Paver for Maintenance . . . . . . . . . . . . . . . . . . 7-6

Paver Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

10-Hour or Daily Routine Maintenance . . . . . . . . . . . . . . . . 7-7

50-Hour (Initial) or Weekly Routine Maintenance . . . . . . . . . . . 7-7

100-Hour or Monthly Routine Maintenance . . . . . . . . . . . . . . 7-8

250-Hour or Quarterly Routine Maintenance . . . . . . . . . . . . . 7-8

500-Hour or Semi-Annual Routine Maintenance . . . . . . . . . . . 7-8

1000-Hour or Annual Routine Maintenance . . . . . . . . . . . . . . 7-8

Maintenance Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Extension Top Guide Adjustment . . . . . . . . . . . . . . . . . . . 7-9

Replacing Screed Extension Wear Plates . . . . . . . . . . . . . . 7-9

Replacing Screed Main Wear Plates . . . . . . . . . . . . . . . . . 7-10

Raising Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Lowering Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Return to

LeeBoy Model 8510B Conveyor Paver vii

Last Viewed

Return to

Thumb Index

Table Of Contents

Conveyor Flight Chain Adjustment . . . . . . . . . . . . . . . . . . 7-12

Automatic Track Adjustment . . . . . . . . . . . . . . . . . . . . . 7-12

Conveyor Drive Chain Adjustment . . . . . . . . . . . . . . . . . . 7-13

Torque Hub Hydraulic Motor Adjustment . . . . . . . . . . . . . . . 7-13

Auger Drive Chain Adjustment

. . . . . . . . . . . . . . . . . . . . 7-14

Torque Hub Lubrication . . . . . . . . . . . . . . . . . . . . . . . 7-14

Track Tension Pressure Relief . . . . . . . . . . . . . . . . . . . . 7-14

Conveyor Limit Switch Adjustment . . . . . . . . . . . . . . . . . . 7-15

Electrical System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Generator Voltage Testing . . . . . . . . . . . . . . . . . . . . . . 7-16

Generator Speed Tuning . . . . . . . . . . . . . . . . . . . . . . . 7-17

Generator Capacitor Replacement . . . . . . . . . . . . . . . . . . 7-19

Testing Element Relays . . . . . . . . . . . . . . . . . . . . . . . 7-19

Element Resistance Testing . . . . . . . . . . . . . . . . . . . . . 7-20

Battery Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

General Information . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Engine Lubrication Oil - Kubota . . . . . . . . . . . . . . . . . . . 7-21

Changing Engine Lubrication Oil Filter . . . . . . . . . . . . . . . . 7-22

Engine Lubrication Oil - CAT . . . . . . . . . . . . . . . . . . . . . 7-23

Changing Engine Lubrication Oil Filter . . . . . . . . . . . . . . . . 7-24

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Engine Fuel Filters . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Engine Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

General Information . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Checking Hydraulic Oil Level . . . . . . . . . . . . . . . . . . . . 7-26

Adding Hydraulic Oil To Hydraulic Oil Reservoir . . . . . . . . . . . 7-26

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Removal & Installation Procedures . . . . . . . . . . . . . . . . . . . . . 7-28

Track Component Replacement . . . . . . . . . . . . . . . . . . . 7-28

Rubber Track Replacement . . . . . . . . . . . . . . . . . . . . . 7-30

Torque Hub Replacement . . . . . . . . . . . . . . . . . . . . . . 7-31

Rear Conveyor Shaft Replacement . . . . . . . . . . . . . . . . . . 7-32

Auger And Inner Bearing Replacement . . . . . . . . . . . . . . . . 7-33

Return to

viii LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Table Of Contents

Screed Extensions, Slides Or Bushing Replacement . . . . . . . . . 7-34

Screed Wear Plate Replacement. . . . . . . . . . . . . . . . . . . 7-34

Extension Wear Plate Replacement . . . . . . . . . . . . . . . . . 7-35

Tandem Pump Replacement . . . . . . . . . . . . . . . . . . . . . 7-35

2-Speed Hydraulic Motor Replacement

. . . . . . . . . . . . . . . 7-36

Safety Label Installation . . . . . . . . . . . . . . . . . . . . . . . 7-37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Electric Screed

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Conveyor Asphalt Paver . . . . . . . . . . . . . . . . . . . . . . . 8-3

Controller User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Vibrator/Electric Actuator Relay And Backup Alarm Outputs . . . . . 8-6

Pump Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Brake Release/Pump Neutral Bypass Valve . . . . . . . . . . . . . 8-6

Optimize Dual Joystick Steering Control Box: . . . . . . . . . . . . . 8-7

Optimize Steering Wheel With FNR Joystick Control Box: . . . . . . . 8-8

Calibrate Steering Wheel With FNR Joystick Control Box: . . . . . . 8-9

Steering/Acceleration And Deceleration . . . . . . . . . . . . . . . 8-10

Steering Box Control Selection . . . . . . . . . . . . . . . . . . . 8-10

Neutral Safety Lockout . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Critical Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Electrical 1 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Electrical 2 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Electrical 3 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Electrical 4 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Electrical 5 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Electrical 6 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Hydraulic Hosing 1 of 5 . . . . . . . . . . . . . . . . . . . . . . . 9-15

Hydraulic Hosing 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . 9-17

Hydraulic Hosing 3 of 5 . . . . . . . . . . . . . . . . . . . . . . . 9-19

Hydraulic Hosing 4 of 5 . . . . . . . . . . . . . . . . . . . . . . . 9-21

Hydraulic Hosing 5 of 5 . . . . . . . . . . . . . . . . . . . . . . . 9-23

Hydraulic 1 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Return to

LeeBoy Model 8510B Conveyor Paver ix

Last Viewed

Return to

Thumb Index

Table Of Contents

Hydraulic 2 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

Hydraulic 3 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Hydraulic 4 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Illustrated Parts List (IPL) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Quick Reference Guide - Filters

. . . . . . . . . . . . . . . . . . . 10-3

Sprocket Drive Track System (4 Roller Undercarriage) . . . . . . . 10-4

Sprocket Drive Track System (4 Roller Undercarriage) (continued) . . 10-6

Rubber Track Undercarriage (5 Roller Undercarriage) . . . . . . . . 10-8

Conveyor Drive Assembly

. . . . . . . . . . . . . . . . . . . . . .10-10

Conveyor Drive Assembly (continued) . . . . . . . . . . . . . . . . 10-12

Hopper Components . . . . . . . . . . . . . . . . . . . . . . . .10-14

Hopper Components (continued) . . . . . . . . . . . . . . . . . .10-16

Auger Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .10-18

Auger Assembly (continued) . . . . . . . . . . . . . . . . . . . . .10-20

Conveyor Drive Cutoff, Screed Lift Cylinders . . . . . . . . . . . . .10-22

Hydraulic Components LH Side and Fuel Tank . . . . . . . . . . . .10-24

H1 Pump & Controls . . . . . . . . . . . . . . . . . . . . . . . . .10-26

Kubota Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-28

Kubota Engine (continued) . . . . . . . . . . . . . . . . . . . . . 10-30

Kubota Engine (continued) . . . . . . . . . . . . . . . . . . . . . .10-32

Cat Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-34

Cat Engine (continued) . . . . . . . . . . . . . . . . . . . . . . . 10-36

Spray Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-38

Screed Arm Assembly With Toe Point . . . . . . . . . . . . . . . .10-40

Propane Heater And Automatic Ignitors . . . . . . . . . . . . . . .10-42

Paver Leveling Control (TOPCON) System 4 . . . . . . . . . . . . .10-44

Paver Leveling Control (TOPCON) System 5 . . . . . . . . . . . . .10-46

Truck Hitch Assembly . . . . . . . . . . . . . . . . . . . . . . . .10-48

Controls - Right Side High Deck . . . . . . . . . . . . . . . . . . .10-50

Controls - Right Side Low Deck . . . . . . . . . . . . . . . . . . .10-52

Controls - Left Side . . . . . . . . . . . . . . . . . . . . . . . . .10-54

Main Valve Manifold Detail . . . . . . . . . . . . . . . . . . . . . .10-56

Kubota Sheet Metal Cover - High Deck . . . . . . . . . . . . . . . .10-58

Kubota Sheet Metal Cover - High Deck (continued) . . . . . . . . . 10-60

Kubota Sheet Metal Cover - Low Deck . . . . . . . . . . . . . . . .10-62

Kubota Sheet Metal Cover - Low Deck (continued) . . . . . . . . . .10-64

Return to

x LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Table Of Contents

CAT Sheet Metal Cover - High Deck . . . . . . . . . . . . . . . . 10-66

CAT Sheet Metal Cover - High Deck (continued) . . . . . . . . . . 10-68

CAT Sheet Metal Cover - Low Deck . . . . . . . . . . . . . . . . .10-70

CAT Sheet Metal Cover - Low Deck (continued) . . . . . . . . . . .10-72

Strike Offs And Extensions

. . . . . . . . . . . . . . . . . . . . . .10-74

Instrument Panel Dash - Controls and Gauges . . . . . . . . . . . .10-76

Instrument Panel Dash - Relays and Fuses . . . . . . . . . . . . . .10-78

Screed Non-sloping Overview . . . . . . . . . . . . . . . . . . . 10-80

Screed Frame Non-Sloping - Propane

. . . . . . . . . . . . . . . .10-82

Extension Single Adjust LH Assembly - Propane . . . . . . . . . . .10-84

Extension Single Adjust RH Assembly - Propane . . . . . . . . . . 10-86

Extension Double Adjust LH Assembly - Propane . . . . . . . . . . 10-88

Extension Double Adjust RH Assembly - Propane . . . . . . . . . 10-90

Screed Frame Non-Sloping - Electric . . . . . . . . . . . . . . . .10-92

Vibrator Assembly LH . . . . . . . . . . . . . . . . . . . . . . . .10-94

Vibrator Assembly RH . . . . . . . . . . . . . . . . . . . . . . . 10-96

Walk Board Assembly . . . . . . . . . . . . . . . . . . . . . . . 10-98

Slide Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . 10-100

Extension Single Adjust LH Assembly - Electric . . . . . . . . . . . 10-102

Extension Single Adjust RH Assembly - Electric . . . . . . . . . . 10-104

Extension Double Adjust LH Assembly - Electric . . . . . . . . . . 10-106

Extension Double Adjust RH Assembly - Electric . . . . . . . . . . 10-108

Endgate LH Assembly . . . . . . . . . . . . . . . . . . . . . . . 10-110

Endgate RH Assembly . . . . . . . . . . . . . . . . . . . . . . . 10-112

Screed Pull Arms LH Assembly . . . . . . . . . . . . . . . . . . 10-114

Screed Pull Arms RH Assembly . . . . . . . . . . . . . . . . . . 10-116

Citrus Tank & Heat Control Box . . . . . . . . . . . . . . . . . . 10-118

Screed Miscellaneous Components . . . . . . . . . . . . . . . 10-120

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-122

Alphabetical Parts Index . . . . . . . . . . . . . . . . . . . . . . . . . 10-124

Return to

LeeBoy Model 8510B Conveyor Paver xi

Last Viewed

Return to

Thumb Index

Table Of Contents

NOTES

Return to

Thumb Index

Return to

Last Viewed

LeeBoy Model 8510B Conveyor Paverxii

LeeBoy Model 8510B Conveyor Paver

Section 1

Introduction

1

Thank you for purchasing the LeeBoy Model 8510B

Conveyor Paver. We wish you many years of safe and

efcient operation of your paver.

READ THIS MANUAL PRIOR TO OPERATING the paver

This manual is an important part of the paver and should

be kept with the paver at all times in the dedicated

storage container on the paver. Even though you may

be familiar with similar equipment, you MUST read and

understand this manual before operating this paver.

Reading the manual will help you and others avoid injury

and help prevent any damage to the paver. If this manual

becomes lost or damaged, contact your authorized

LeeBoy Dealer immediately to order a replacement (see

Contact Information in Section 3).

This manual is intended as a guide for the safe and

efcient use of the paver. This manual covers the

procedures for proper operation and maintenance of

the paver. This manual contains information that was

available at the time of printing and is subject to change

without notice.

This manual should be used with all related

supplemental books, engine and transmission manuals,

and parts books. Related Service Bulletins should be

reviewed to provide information regarding some of the

recent changes.

This manual provides information for use by the

equipment operator under the following headings:

Safety—See Section 2 for important safety guidelines

information.

General Information—See Section 3 for important

warranty, contact, and nameplate information.

Specications—See Section 4 for all major system

specications and typical torque value tables.

Component Location—See Section 5 for general

overview of controls and major components.

Operation—See Section 6 for control functionality and

normal equipment operation.

Maintenance—See Section 7 for basic preventive

maintenance and repair procedures.

Troubleshooting—See Section 8 for problem

descriptions and recommended solution tables.

Schematics—See Section 9 for schematic diagrams of

electrical wiring.

Illustrated Parts List (IPL)—See Section 10 for

illustrations, descriptions and part numbers of available

service parts.

If any questions arise concerning this publication or

others, contact your local LeeBoy Dealer for the latest

available information.

Return to

LeeBoy Model 8510B Conveyor Paver 1-1

Last Viewed

Return to

Thumb Index

Introduction

NOTES

Return to

Thumb Index

Return to

Last Viewed

LeeBoy Model 8510B Conveyor Paver1-2

LeeBoy Model 8510B Conveyor Paver

Section 2

Safety

Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2

Safety Label Locations

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Return to

LeeBoy Model 8510B Conveyor Paver 2-1

Last Viewed

Return to

Thumb Index

Safety

This manual provides important information to familiarize

you with safe operating and maintenance procedures.

Even though you may be familiar with similar equipment,

you MUST read and understand this manual before

operating the LeeBoy Model 8510B Conveyor Paver

and follow its instructions when operating the paver.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Safety is everyone’s business and is our top concern.

Knowing the guidelines covered in this section and in

Section 1 will help ensure your safety, the safety of those

around you and the paver’s proper operation.

LOOK FOR THESE SYMBOLS WHICH POINT OUT

ITEMS OF EXTREME IMPORTANCE TO THE SAFETY

OF YOU AND YOUR COWORKERS. READ AND

UNDERSTAND THOROUGHLY. HEED THE WARNING

AND FOLLOW THE INSTRUCTIONS.

Keep safety labels in good condition. If safety labels

become missing or damaged, replacement safety labels

are available from your LeeBoy Dealer (see Contact

Information in Section 3 and Safety Label Installation

in Section 7).

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates a situation which can cause damage to the

equipment, personal property and/or the

environment, or cause the LeeBoy Model 8510B

Conveyor Paver to operate improperly.

NOTE: Indicates a procedure, practice, or condition

that should be followed in order for the paver or

component to function in the manner intended.

Return to

2-2 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Safety

Safety Precautions

The safety messages that follow have CAUTION level

hazards.

Pre-Operation Hazard

Read and understand this Operation

Manual before operating or servicing

the engine to ensure that safe operating

practices and maintenance procedures are

followed.

• Never permit anyone to service or operate the LeeBoy

Model 8510B Conveyor Paver without proper training.

• Safety signs and labels are additional reminders for

safe operating and maintenance techniques.

• Contact LeeBoy or an authorized LeeBoy Dealer for

additional training.

• Make sure you are aware of all laws and regulations

that are in effect where the paver is operated. Make

sure you have all necessary licenses to operate the

paver.

Explosion Hazard

While the engine is running or the battery is

charging, hydrogen gas is being produced

and can be easily ignited. Keep the area

around the battery well-ventilated and keep

sparks, open ame and any other forms of

ignition out of the area.

• Always disconnect the negative (-) battery cable

before servicing the paver.

• Do not start the engine by shorting the starter circuit

or any other starting method not stated in this manual.

Only use the starting procedure as described in this

manual to start the engine.

• Never charge a frozen battery. Always slowly warm

the battery to room temperature before charging.

Fire and Explosion Hazard

• Diesel fuel is ammable and explosive under certain

conditions.

• Never use a shop rag to catch the fuel.

• Wipe up all spills immediately.

2

The safety messages that follow have WARNING

level hazards.

Crush Hazard

Keep bystanders away from work area before and

during operation.

Modification Hazard

Never modify the LeeBoy Model 8510B Conveyor Paver

without written consent of LeeBoy. Any modication can

affect the safe operation of the paver and may cause

personal injury or death.

Exposure Hazard

Always wear personal protective

equipment, including appropriate clothing,

gloves, work shoes, and eye and hearing

protection, as required by the task at hand.

• Never refuel with the engine running.

• Store any containers containing fuel in a wellventilated area, away from any combustibles or

sources of ignition.

Fire Hazard

Have appropriate safety equipment

available. Have all re extinguishers

checked periodically for proper operation

and/or readiness.

• Always read and follow safety-related precautions

found on containers of hazardous substances

like parts cleaners, primers, sealants and sealant

removers.

• Undersized wiring systems can cause an electrical

re.

Return to

LeeBoy Model 8510B Conveyor Paver 2-3

Last Viewed

Return to

Thumb Index

Safety

Alcohol and Drug Hazard

The safety messages that follow have WARNING

level hazards.

Exhaust Hazard

All internal combustion engines create

carbon monoxide gas during operation and

special precautions are required to avoid

carbon monoxide poisoning:

• Always ensure that all connections are tightened to

specications after repair is made to the exhaust

system.

Entanglement/Sever Hazard

Verify there are no people, obstacles or other

equipment near the LeeBoy Model 8510B Conveyor

Paver before starting the engine. Sound the horn as a

warning before starting the engine.

If the engine must be serviced while it is

operating, remove all jewelry, tie back long

hair and keep hands, other body parts and

clothing away from moving/rotating parts.

• Always stop the engine before

beginning service.

• Verify that all paver guards and covers

are attached properly to the paver before

starting the engine.

• If you must run the engine during maintenance

procedures, make sure you have a helper to keep

bystanders clear of the paver and make observations

of moving parts as requested by the operator.

• Always turn the start switch to the OFF position after

operation is complete and remove the key from the

switch. Keep the key in your possession when the

paver is not operating.

• Attach a “Do Not Operate” tag near the key switch

while performing maintenance on the equipment.

• Never operate the engine while wearing a headset to

listen to music or radio because it will be difcult to

hear the warning signals.

• Always start the engine or operate the controls while

you are seated in the operators seat.

Never operate the engine or 8510B Paver

while under the inuence of alcohol or

drugs, or when ill.

Piercing Hazard

Avoid skin contact with high-pressure hydraulic uid or

diesel fuel spray caused by a hydraulic or fuel system

leak such as a broken hydraulic hose or fuel injection

line. High-pressure hydraulic uid or fuel

can penetrate your skin and result in

serious injury. If you are exposed to highpressure hydraulic uid or fuel spray, obtain

prompt medical treatment.

• Never check for a hydraulic uid or fuel leak with your

hands. Always use a piece of wood or cardboard.

Have your authorized LeeBoy Dealer or distributor

repair the damage.

Flying Object Hazard

Always wear eye protection when cleaning

the LeeBoy Model 8510B Conveyor Paver

with compressed air or high-pressure

water. Dust, ying debris, compressed air,

pressurized water or steam may injure your

eyes.

Coolant Hazard

Wear eye protection and rubber gloves

when handling engine coolant. If contact

with the eyes or skin should occur, ush

eyes and wash immediately with clean

water.

Burn Hazard

Some of the paver surfaces become very

hot during operation and shortly after

shutdown.

• Keep hands and other body parts away

from hot paver surfaces.

• Handle hot components with heat-resistant gloves.

Return to

2-4 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Safety

The safety messages that follow have CAUTION level

hazards.

Poor Lighting Hazard

Ensure that the work area is adequately illuminated.

Always install wire cages on portable safety lights.

Tool Hazard

Always use tools appropriate for the task at hand and

use the correct size tool for loosening or tightening

LeeBoy Model 8510B Conveyor Paver parts.

Working Under Hopper of Paver

Always use the safety brace provided .

When working under hopper of paver use safety

brace provided.

The safety messages that follow have NOTICE level

hazards.

Any part which is found defective as a result of

inspection or any part whose measured value does not

satisfy the standard or limit must be replaced.

Always tighten components to the specied torque.

Loose parts can cause LeeBoy Model 8510B Conveyor

Paver damage or cause it to operate improperly.

Only use replacement parts approved by LeeBoy. Other

replacement parts may affect warranty coverage.

Follow the guidelines of the EPA or other

governmental agencies for the proper

disposal of hazardous materials such as

engine oil, diesel fuel and engine coolant.

Consult the local authorities or reclamation

facility.

Clean all accumulated dirt and debris away from the

body of the paver and its components before you

inspect the paver or perform preventive maintenance

procedures or repairs. Operating a paver with

accumulated dirt and debris will cause premature wear

of paver components. Accumulated dirt and debris also

hinders effective paver inspection.

2

Retrieve any tools or parts that may have dropped inside

of the paver to avoid improper paver operation.

Dispose of hazardous materials in accordance with

all applicable laws and regulations. Never dispose of

hazardous materials by dumping them into a sewer, on

the ground, or into groundwater or waterways.

If any alert indicator illuminates during paver operation,

stop the engine immediately. Determine the cause and

repair the problem before continuing to operate the

paver.

Return to

LeeBoy Model 8510B Conveyor Paver 2-5

Last Viewed

Return to

Thumb Index

Safety

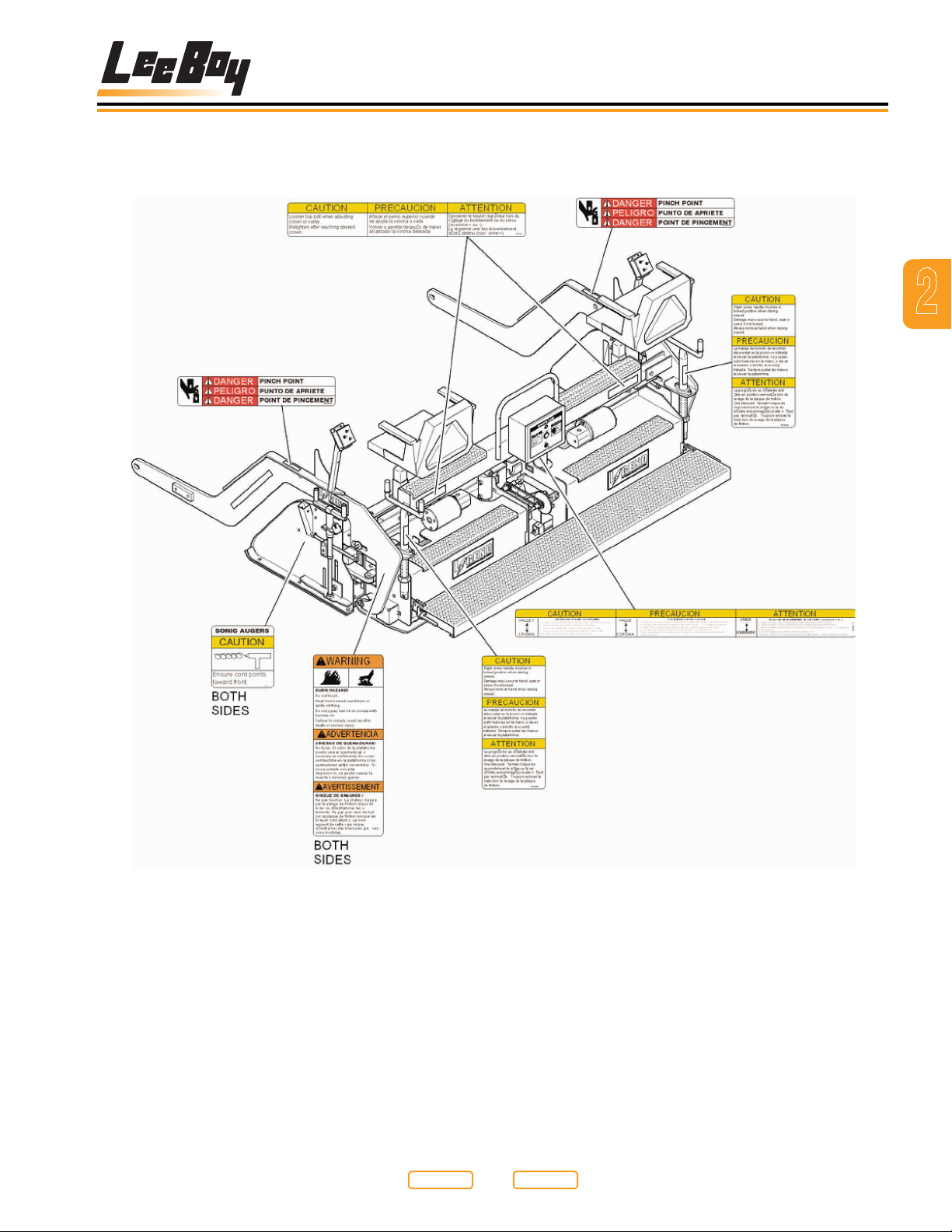

Safety Label Locations

Safety Precautions

If your LeeBoy Model 8510B Conveyor Paver has been

repainted, it is extremely important that all the decals

referring to CAUTION, WARNING, and DANGER be

replaced in their proper locations. The illustrations

on this page will aid you in determining the proper

locations; for additional help, you should refer to the

parts listing in the parts section of this manual and note

the description column.

A description of location is provided below for each

safety label. For additional instructions, contact your

dealer (see Contact Information in Section 3).

NOTE: It is the responsibility of the owner and operator

to make sure that all safety labels are readable

and located on paver as designated by LeeBoy.

8510B Conveyor Paver Safety Labels and Safety Label Locations

Figure 2-1

Return to

2-6 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Safety

2

8510B Electric Screed Safety Labels and Safety Label Locations

Figure 2-2

Return to

LeeBoy Model 8510B Conveyor Paver 2-7

Last Viewed

Return to

Thumb Index

Safety

NOTES

Return to

Thumb Index

Return to

Last Viewed

LeeBoy Model 8510B Conveyor Paver2-8

LeeBoy Model 8510B Conveyor Paver

Section 3

General Information

Page

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Limited Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Items Not Covered . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Other Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Record of Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3

Return to

LeeBoy Model 8510B Conveyor Paver 3-1

Last Viewed

Return to

Thumb Index

General Information

Limited Warranty Policy

Warranty

1. Subject to the limitations, exclusions, and claims

procedures set forth herein, LeeBoy warrants [to

the rst retail purchaser] that this product will be

free from [substantial] defects in materials and

workmanship during the warranty period.

2. If a defect in material or workmanship is found, your

authorized LeeBoy Dealer is to be notied during

the warranty period. LeeBoy and its authorized

Dealer will repair or replace any part or component

of the unit or part that fails to conform to the

warranty during the warranty period.

3. The warranty period will begin on the initial startup, training and delivery of the unit by the Dealer

to the customer, and will expire after twenty-four

(24) months following the delivery of the paver to

the rst retail purchaser. (See Dealer for additional

warranty).

4. Manufacturers’ Warranties: Engines are warranted

by their manufacturers and may have warranty

coverage that differs from that of LeeBoy. LeeBoy

does not warrant any engine.

5. Replacement parts furnished by LeeBoy are

covered for the remainder of the warranty period

applicable to the unit or component in which such

parts are installed.

6. LeeBoy has the right to repair any component or

part before replacing it with a new one.

7. All new replacement parts purchased by a LeeBoy

Dealer will carry a six-month warranty.

8. This Limited Warranty is governed by the laws of the

State of North Carolina.

THE FOREGOING WARRANTY IS EXCLUSIVE AND

IN LIEU OF ALL OTHER EXPRESSED, STATUTORY

AND IMPLIED WARRANTIES APPLICABLE TO

UNITS, ENGINES, OR PARTS INCLUDING WITHOUT

LIMITATION, ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR USE OR PURPOSE OR AGAINST

INFRINGEMENT.

Limitations

LeeBoy has no obligation for:

1. Any defects caused by misuse, misapplication,

negligence, accident or failure to maintain or use

in accordance with the most current operating

instructions.

2. Unauthorized alterations.

3. Defects or failures caused by any replacement

parts or attachments not manufactured by or

approved by LeeBoy.

4. Failure to conduct normal maintenance and

operating service including, without limitation,

providing lubricants, coolant, fuel, tune-ups,

inspections or adjustments.

5. Unreasonable delay, as established by LeeBoy, in

making the applicable units or parts available upon

notication of a service notice ordered by same.

6. Warranty Responsibility: The warranty responsibility

on all engines rests with the manufacturer of the

engine.

7. Warranty and Parts Support: LeeBoy may

have support agreements with some engine

manufacturers for warranty and parts support.

However, LeeBoy does not warrant the engine.

8. This Limited Warranty sets forth your sole remedy

in connection with the sale or use of the LeeBoy

product covered by this Limited Warranty.

9. This Limited Warranty extends only to the rst retail

purchaser, and is not transferable.

10. In the event any portion of this Limited Warranty

shall be determined to be invalid under any

applicable law, such provision shall be deemed null

and void and the remainder of the Limited Warranty

shall continue in full force and effect.

Return to

3-2 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

General Information

Items Not Covered

LeeBoy is not responsible for the following:

1. All used units or used parts of any kind.

2. Repairs due to normal wear and tear or brought

about by abuse or lack of maintenance of the

Machine.

3. Attachments not manufactured or installed by

LeeBoy.

4. Liability for incidental or consequential damages of

any type including, but not limited to, lost prots or

expenses of acquiring replacement equipment.

5. Miscellaneous charges.

Other Limitations

IN NO EVENT, WHETHER AS A RESULT OF BREACH

OF CONTRACT OR WARRANTY OR ALLEGED

NEGLIGENCE OR LIABILITY WITHOUT FAULT, SHALL

LEEBOY BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES INCLUDING, WITHOUT

LIMITATION, LOSS OF PROFIT OR REVENUE, COST

OF CAPITAL, COST OF SUBSTITUTED EQUIPMENT,

FACILITIES OR SERVICES, DOWNTIME COSTS,

LABOR COSTS OR CLAIMS OF CUSTOMERS,

PURCHASERS OR LESSEES FOR SUCH DAMAGES.

IN NO EVENT WILL WARRANTY COMPENSATION,

OR OTHER DAMAGES AVAILABLE FROM LEEBOY,

EXCEED THE PURCHASE PRICE OF THE PRODUCT.

3

Return to

LeeBoy Model 8510B Conveyor Paver 3-3

Last Viewed

Return to

Thumb Index

General Information

Contact Information

For information regarding parts and repairs about your

LeeBoy product, rst contact the dealer you purchased

your product from.

Sales Representative:

Dealership Name:

Dealership Address:

Dealership Phone:

Record of Ownership

Please ll out the following information and use it

when you need to contact LeeBoy for service, parts or

literature.

Paver Model Number:

Paver Serial Number:

Date of Purchase:

Nameplate

If you have a persistent problem your dealer is unable to

resolve, contact LeeBoy directly.

Record dealer information in the space provided.

For additional information about LeeBoy, please visit:

www.leeboy.com.

Nameplate (Figure 3-1) contains the specic model number and serial number used to identify the components for any parts or service information.

Nameplate Location

Figure 3-1

Return to

3-4 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

LeeBoy Model 8510B Conveyor Paver

Section 4

Specifications

Page

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4

Torque Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Operator Platform . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Specication charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Torque Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Metric Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Inch Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Full Torque Nut Coupling Installation . . . . . . . . . . . . . . . . . 4-9

Return to

LeeBoy Model 8510B Conveyor Paver 4-1

Last Viewed

Return to

Thumb Index

Specications

General Information

The descriptions and specications provided in this

section are applicable to the LeeBoy Model 8510B

Conveyor Paver.

This section contains a description of how the major

components operate. It also includes specications for

the major system components. Included in this section

are paver weights, dimensions, performance, and major

system specications for the paver.

Engine

The LeeBoy Model 8510B Conveyor Paver uses either

a Kubota, V3600-T-E3B 84.5 HP or CAT, C3.4 T NA 83

HP four-cylinder engine to drive the hydraulic function

pump and steering pump. The engine is mounted near

the center of the paver and is accessible through

several access doors in the engine cover.

A fuel lift pump mounted on the engine draws diesel fuel

from the fuel tank. The fuel tank is mounted at the right of

the engine compartment.

An air cleaner is mounted on the top of the right-hand

pump cover. The air cleaner removes ne particles such

as dust, sand, chaff and lint from the air.

As air is taken into the air cleaner assembly, a cyclone

type action deposits some of the ne particles in the

evacuator mounted on the bottom of the air cleaner

housing. The evacuator is held closed during engine

operation by suction. When the engine is shut off the

weight of the debris helps to open the rubber aps

allowing the debris to fall out. The rubber aps can also

be squeezed to open for cleaning.

Primary and secondary fuel lters remove contaminants

from the diesel fuel before the fuel ows to the injection

pump for injection into the engine combustion chamber.

A radiator mounted on the left side of the unit cools the

engine. As coolant ows through the radiator, airow

from the engine-driven fan removes heat from the

coolant.

Hydraulic System

The hydraulic system includes four hydraulic pumps

driven by the engine: 1) Left Drive Pump, 2) Right Drive

Pump, 3) Conveyor Pump, 4) Auger and Cylinder Pump.

The auxiliary pumps are mounted on the rear of the drive

pumps, to the right side of the engine, and driven by the

drive pump output shaft. This gear type pump provides

hydraulic ow to operate all the hydraulic cylinders used

to control the paver functions.

Each auxiliary pump has it’s own suction hose from the

tank. The conveyor pump will also charge the Left and

Right Drive Pumps.

Torque Hubs

The paver drive system contains two torque hubs. The

torque hubs provide power to propel the tracks.

Hopper

The hopper wings are hydraulically controlled to raise

and lower. The hopper wings also hinge in and out to

allow for more compact transportation. The hopper

when fully open can hold a payload up to 7 tons.

Material in the hopper is moved toward the back of the

paver to the screed by conveyors. Each conveyor is

activated independently at the operator platform and is

controlled on and off with limit switches.

Augers

The Augers rotates clockwise (CW) and counter

clockwise (CCW) to assist in moving material from the

conveyors to the screed. The augers can be manually

controlled at the operator platform on the paver or by

the screed operator on the screed.

The auger can also be controlled automatically when

the sonic auger system is installed and active. The sonic

auger sensor mounted on the screed end gates detect

the amount of material present and control the auger to

keep the material ow constant.

Refer to the engine owner’s Operation and Maintenance

Manual for a complete description of the engine.

Return to

4-2 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Operator Platform

The operator platform allows easy and convenient

control of most all functions of the paver and screed.

The paver can be operated from either the left-hand or

right-hand side depending on which control panel side

is active and best suited to the working conditions.

Return to

Last Viewed

Specications

Screed

The Screed is the last part of the paver that contacts

the paved material. Operation of the screed is usually

done by the screed operator. Paving material is fed from

the hopper and conveyor to the augers to the front of

the Screed. The Screed has hydraulically controlled

extensions that move in and out to allow a wider paving

base from 8 ft up to 15 ft.

Screed heating is accomplished by either LPG burners,

or by electric heating elements mounted directly to the

wear plates.

The hydraulically driven vibrators mounted on the main

screed frame can be used to increase paving material

compaction.

Electrical System

The electrical system is powered by a 12-volt battery

mounted in the engine compartment located under

the covers on the right side of the paver forward of the

operator’s platform.

The battery produces 12 volts DC and maintains 1125

cold cranking amperes (CCA). An engine-mounted

alternator capable of at least 60 amperes charging

capacity keeps the battery charged during normal

operation. The battery charge rate can be monitored

using the voltmeter on the center operator dash panel.

Electrically heated pavers come equipped with a

generator. The generator is mounted on the paver under

the hopper oor near the right hand track.

The generator is hydraulically driven by the rst section

of the rear pump on the engine pump stack. When the

paver is at full rpm, and the hydraulic system is at normal

operating temperature, the generator should operate

at a sufcient speed to produce between 220VAC and

240VAC.

All LeeBoy generators are equipped with an integrated

generator speed control manifold. This manifold should

not require adjustment, but if there is a need to ne tune

the generator speed, there is an adjustment on the

manifold (see Generator Speed Tuning in Section 7).

Generator speed tuning should only be

done by an authorized LeeBoy Dealer.

All output power from the generator is passed through

the main breaker for safety. All output power is lost

when this breaker is in the “tripped” or “off” position. The

location of the generator main output breaker is shown

in Figure 6-22.

The paver has heating controls to provide the necessary

connection and control of the output power from the

generator to the heating elements. It is necessary to

maintain all components of the heating controls system

in good working order to maintain safe and efcient

screed heating.

The Heating Control or Distribution/Control Box is

mounted near the middle of the screed and is easily

accessible to the screed operator when a heating cycle

is required.

4

There is a ve second delay after the heat cycle is

initiated before the actual electric load is sent to the

heating elements from the generator. This delay is to

allow the generator to reach optimal operating speed

before the electrical load is required.

Once the heat cycle is started, a pre-programmed timer

controls the amount of time for output power from the

generator to go through the element connection supply

plugs coming out of the bottom of the Heating Control

Box to the heating elements.

Any element lead can be plugged into any supply plug

under the heating control/distribution box. All six plugs

are equally rated.

Each element is sized to t properly in your screed, and

provide sufcient power to heat your screed plate to a

temperature that mix will not drag or stick to the lower

surface of the screed plate.

To know that the element is correct, you should read a

resistance between 28 ohms and 60 ohms (see Testing

Element Relays in Section 7).

Return to

LeeBoy Model 8510B Conveyor Paver 4-3

Last Viewed

Return to

Thumb Index

Specications

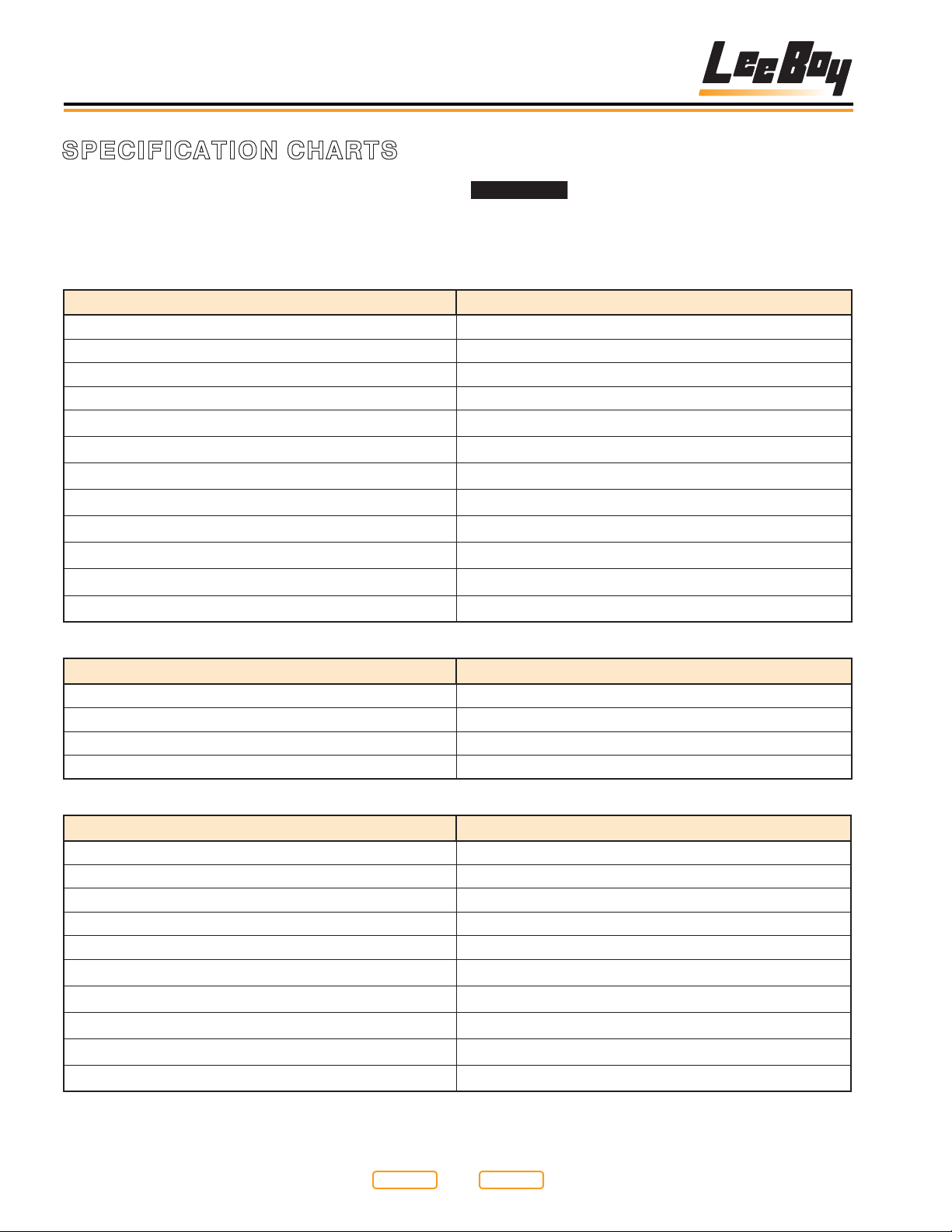

Specification charts

The specications provided in this section are

applicable to the LeeBoy Model 8510B Conveyor Paver.

Included in this section are specications for paver

weights, dimensions, performance, and torque values for

both metric and standard inch fasteners.

Replace original equipment only with

LeeBoy approved components.

Table 4-1. Dimension Specications (See Figure 4-1)

ITEM SPECIFICATION

Overall Length 12’ 5.5” (380 cm)

Overall Height 8’ 6” (259 cm)

Overall Width (hopper wings in) 8’ 6” (259 cm)

Overall Width (hopper wings out) 10’ (305 cm)

Paver Weight (with screed) 17,300 lbs (7,847kg)

Basic Paving Width 8’ (2.44m)

Maximum Paving Width 15’ (4.57m)

Screed Plate Material 3/8” (9.5mm) AR400 Steel

Main Screed Wear Plate 15” (.38m)

Extensions Width of Wear Plate 7” (17.8cm)

Extensions Length 3’6” (1.07m)

Walkway Width 12” (30.5cm) W/Extension

Table 4-2. Performance Specications

ITEM SPECIFICATION

Travel Speed 240 FPM (0.73 KPM)

Paving Speed 140 FPM (0.37 KPM)

Coverage: Basic Screed Width 8’ (244 cm)

Coverage: Maximum Screed Width 15’ (457 cm)

Table 4-3. Kubota Tier 3 Engine Specications

ITEM SPECIFICATION

Manufacturer and Model Kubota, V3600-T-E3B

Emission Regulation Tier 3 / Stage III A

Type Vertical 4-cycle Liquid Cooled Diesel

Number of Cylinders 4

Bore, Stroke, and Displacement 3.86” (98 mm) ; 4.72” (120 mm); 220.9 in

Combustion System Direct Injection

Intake System Turbocharged

Power Rating kW - HP 63.0 kW - 84.5 HP

Maximum Speed 2400 to 2500 rpm

3

(3.62 L)

Fuel Filter Type Kubota Diesel

Return to

4-4 LeeBoy Model 8510B Conveyor Paver

Thumb Index

Return to

Last Viewed

Loading...

Loading...