LeeBoy 785 Operation, Service And Parts Manual

OPERATIONS, SERVICE

AND PARTS MANUAL

785 MOTOR GRADER

785 MOTOR GRADER MANUAL

Manual No. 985480

Courtesy of Machine.Market

Courtesy of Machine.Market

LIMITED WARRANTY

POLICY AND PROCEDURES

688 North Highway 16

Denver, North Carolina 28037

www.LeeBoy.com

WARRANTY

1. If a defect in material or workmanship is

found and the authorized dealer is notified

during the warranty period, LeeBoy will

repair or replace any part or component of

the unit or part that fails to conform to the

warranty during the warranty period.

2. The warranty date will begin upon the

completion of the warranty form by the initial

customer and will expire after twelve (12)

months have passed. The Warranty Card

should be filled out within (10) days of

delivery of the unit.

3. Engines are warranted by their

manufacturers and may have warranty

coverage that differs from that of LeeBoy.

4. Replacement parts furnished by LeeBoy are

covered for the remainder of the warranty

period applicable to the unit or component in

which such parts are installed.

5. LeeBoy has the right to repair any

component or part before replacing it with a

new part.

6. All new replacement parts purchased by a

LeeBoy dealer will carry a six (6) month

warranty. Remanufactured parts purchased

by a LeeBoy dealer will carry a ninety (90)

day warranty.

ITEMS NOT COVERED

LeeBoy is not responsible for the following:

1. Charges for travel time, mileage, or

overtime.

2. Charges related to transporting the product

to and from the place at which warranty

work is performed.

3. Airfreight charges related to transporting

repair parts to the place at which warranty

work is performed.

4. All used units or used parts of any kind.

5. Repairs due to normal wear and tear, or

brought about by abuse or lack of

maintenance of the equipment, except for

premature failures, conveyor chains,

polytrack pads, and track rails.

6. Attachments not manufactured or installed by

LeeBoy.

7. Liability for incidental or consequential

damages of any type including, but not

limited to lost profits or expenses of acquiring

replacement equipment.

8. Miscellaneous charges.

LIMITATIONS

LeeBoy has no obligation under this warranty for:

1. Any defects caused by misuse,

misapplication, negligence, accident or failure

to maintain or use in accordance with the

most current operating instructions.

2. Unauthorized alterations.

3. Defects or failures caused by any

replacement parts or attachments not

manufactured by or approved by LeeBoy.

4. Failure to conduct normal maintenance and

operating service, including without limitation,

providing lubricants, coolant, fuel, tune-ups,

inspections or adjustments.

5. Unreasonable delay, as established by

LeeBoy, in making the applicable units or

parts available upon notification of a service

notice ordered by LeeBoy.

6. The warranty responsibility on all engines

rests with the respective manufacturer.

7. LeeBoy may have support agreements with

some engine manufacturers for warranty and

parts support.

OTHER WARRANTIES

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER EXPRESSED STATUTORY AND

IMPLIED WARRANTIES APPLICABLE TO UNITS ENGINES,

OR PARTS WITHOUT LIMITATION, ALL IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR USE OR PURPOSE. IN NO EVENT,

WHETHER AS A RESULT OF BREACH OF CONTRACT OR

WARRANTY, OR ALLEGED NEGLIGENCE OR LIABILITY

WITHOUT FAULT, SHALL LEEBOY BE LIABLE FOR

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

INCLUDING WITHOUT LIMITATION, LOSS OF PROFIT OR

REVENUE, COST OF CAPITAL, COST OF SUBSTITUTED

EQUIPMENT, FACILITIES OR SERVICES DOWNTIME

COSTS, LABOR COSTS OR CLAIMS OF CUSTOMERS,

PURCHASERS OR LESSEES FOR SUCH DAMAGES.

785 MOTOR GRADER

Courtesy of Machine.Market

785 MOTOR GRADER

USER'S REFERENCE GUIDE

DELIVERY DATE______________________________________

UNIT SERIAL NUMBER_________________________________

ENGINE TYPE________________________________________

ENGINE NUMBER_____________________________________

DEALER'S NAME AND ADDRESS

_____________________________________________________

_____________________________________________________

PHONE NUMBER_______________________________________

EQUIPMENT HOURS____________________________________

SERVICE MANAGER ____________________________________

688 North Highway 16 • Denver, North Carolina 28037 • www.LeeBoy.com • (704) 966-3300

785 MOTOR GRADER

Courtesy of Machine.Market

785 MOTOR GRADER

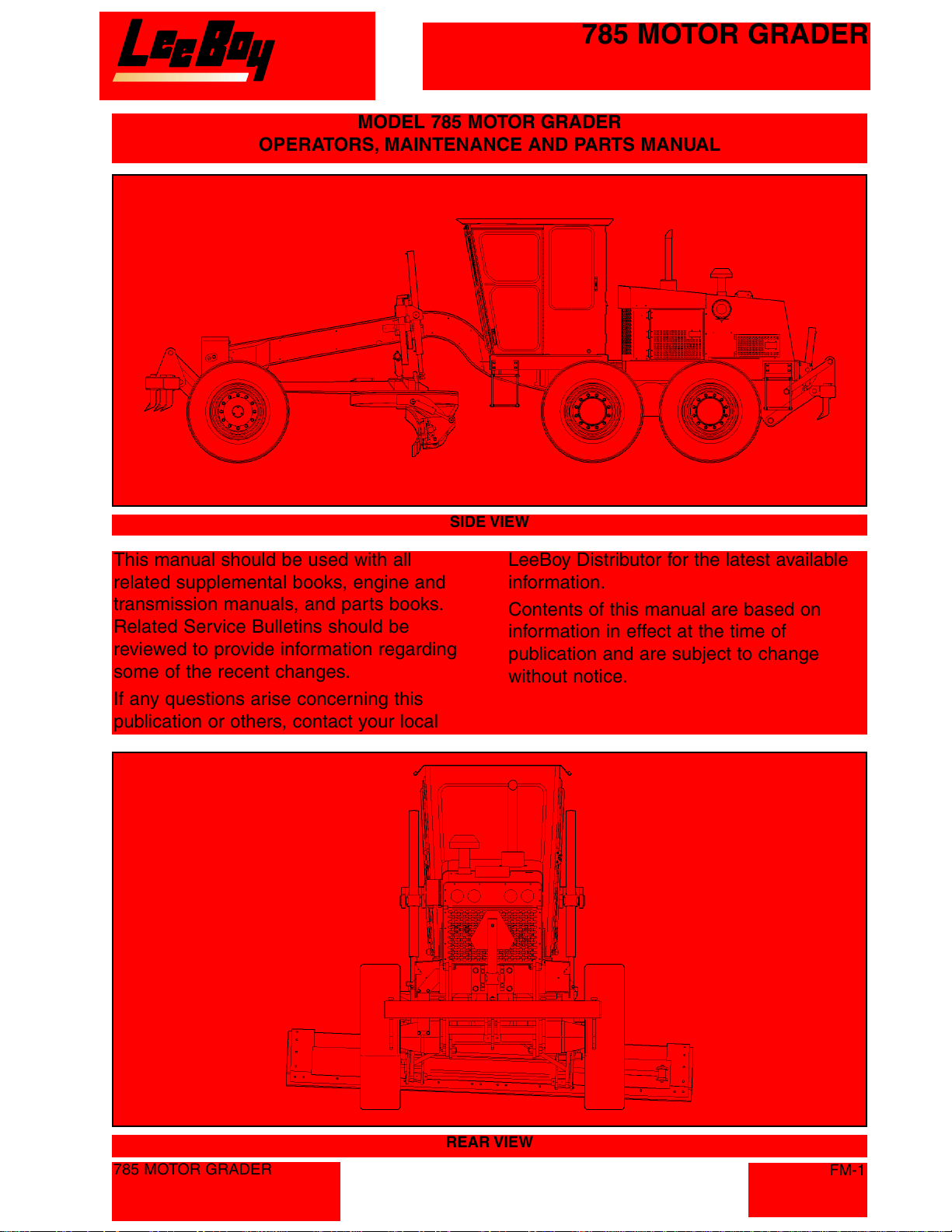

MODEL 785 MOTOR GRADER

OPERATORS, MAINTENANCE AND PARTS MANUAL

This manual should be used with all

related supplemental books, engine and

transmission manuals, and parts books.

Related Service Bulletins should be

reviewed to provide information regarding

some of the recent changes.

If any questions arise concerning this

publication or others, contact your local

SIDE VIEW

LeeBoy Distributor for the latest available

information.

Contents of this manual are based on

information in effect at the time of

publication and are subject to change

without notice.

785 MOTOR GRADER

REAR VIEW

FM-1

Courtesy of Machine.Market

785 MOTOR GRADER

SAFETY INSTRUCTIONS

IIMMPPOORRTTAANNTT

This manual provides important

information to familiarize you with safe

operating and maintenance procedures.

Even though you may be familiar with

similar equipment, you MUST read and

understand this manual before operating

this unit.

Safety is everyone's business and is one

of your primary concerns. Knowing the

guidelines covered in the following

paragraphs and in Section 1 will help

YOU MUST FOLLOW ALL DANGER SAFETY

NOTES. IF YOU DO NOT FOLLOW THE

INSTRUCTIONS, YOUR MISTAKE MIGHT LIKELY

RESULT IN VERY SERIOUS INJURY OR DEATH.

provide for your safety, for the safety of

those around you, and for the motor

grader's proper operation.

LOOK FOR THESE SYMBOLS WHICH

POINT OUT ITEMS OF EXTREME

IMPORTANCE TO YOU AND YOUR

COWORKERS SAFETY. READ AND

UNDERSTAND THOROUGHLY. HEED

THE WARNINGS AND FOLLOW THE

INSTRUCTIONS.

DANGER

FM-2

WARNING

WARNING safety notes must ALSO be followed.

Your mistake might result in SERIOUS INJURY to

yourself or others.

CAUTION

CAUTION safety notes are ALSO very important.

They point out to you where your mistakes could

cause PHYSICAL HARM to you or others, or

damage to the machine.

785 MOTOR GRADER

Courtesy of Machine.Market

785 MOTOR GRADER

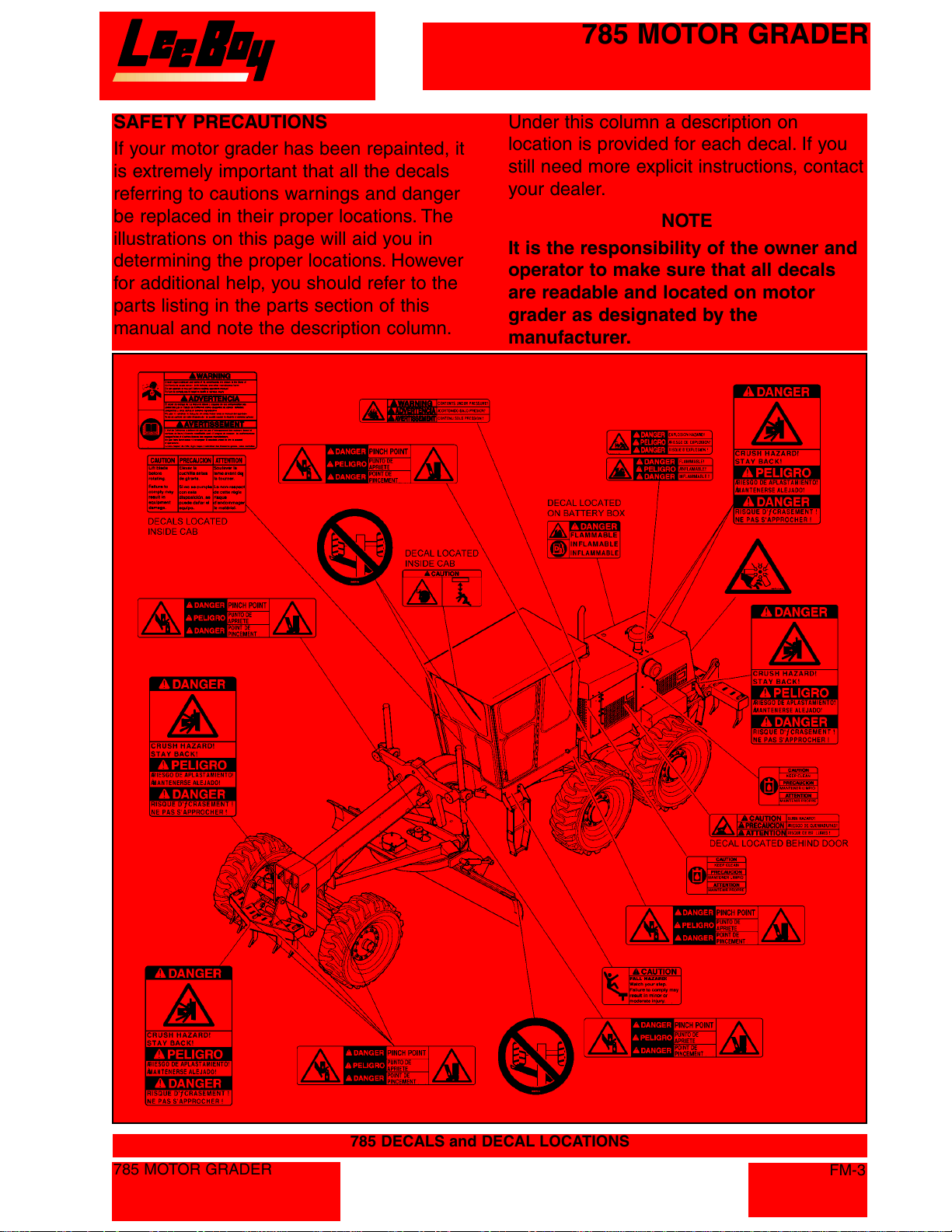

SAFETY PRECAUTIONS

If your motor grader has been repainted, it

is extremely important that all the decals

referring to cautions warnings and danger

be replaced in their proper locations. The

illustrations on this page will aid you in

determining the proper locations. However

for additional help, you should refer to the

parts listing in the parts section of this

manual and note the description column.

Under this column a description on

location is provided for each decal. If you

still need more explicit instructions, contact

your dealer.

NOTE

It is the responsibility of the owner and

operator to make sure that all decals

are readable and located on motor

grader as designated by the

manufacturer.

785 MOTOR GRADER

785 DECALS and DECAL LOCATIONS

FM-3

Courtesy of Machine.Market

785 MOTOR GRADER

PRE-START INSPECTION

INSPECT machine. Have any malfunctioning,

broken or missing parts corrected or replaced

before using. Hydraulic hoses should be checked

daily for wear and leaks. Replace if damaged.

CHECK that all the instruction and safety labels are

in place and readable. These are as important as

any other equipment on the machine.

READ and FOLLOW all instruction decals.

WEAR OSHA required safety equipment when

running the motor grader.

FILL the fuel tank with the engine off. Never fill fuel

tank near an open flame, when smoking.

Make sure all covers and guards are in place.

OPERATING SAFETY

ALWAYS make sure no person or object is in your

line of travel BEFORE starting.

WORK slowly in tight areas.

DO NOT run engine in a closed building for long

periods of time.

AVOID steep hills if possible.

ALWAYS look BEFORE changing your direction of

travel.

AVOID leaving engine running without operator

present.

ALWAYS wear your seatbelt.

NEVER attempt to jump clear of a tipping machine.

FATAL crushing injuries will result.

BEFORE moving machine, check that all persons

are clear.

When a signal person is used, BE SURE the

person is in view at all times.

To prevent rollaway accidents, MAKE SURE

machine is properly secured before leaving

operator's seat.

NEVER attempt to mount or stop a moving

machine.

USE handholds and steps when getting on or off

machine. Be CAREFUL of slippery conditions.

STOPPING SAFETY

ALWAYS park the motor grader on solid, level

ground in low range. If this is not possible, always

park the motor grader at a right angle to the slope.

USE proper flags, barriers and warning devices

especially when parking in areas of traffic.

DRIVING SAFETY

Know location of all bystanders before moving

machine.

BE SURE backup warning system is properly

operating.

USE a signal person when moving the machine.

AVOID power line, serious injury or death may

result.

KEEP riders off the machine.

MAINTENANCE SAFETY

NEVER work on the motor grader with the engine

running.

NEVER fill the fuel tank with the engine running.

DO NOT change the engine governor settings.

ALWAYS replace damaged or lost decals.

DISCONNECT battery cables when working on the

electrical system or when welding on the unit.

IF battery needs a charge, be sure battery charger

is off when making connections.

BE SURE the correct battery polarity is observed

(negative (-) to negative (-) and positive (+) to

positive (+), when connecting a battery charger or

jumper cable.

CLEAN trash from machine. Keep engine

compartment and operator's station clean.

WARN others of Service Work. Before performing

any machine work attach a "DO NOT OPERATE"

tag to steering wheel.

UNDERSTAND the service procedure before

beginning work.

ALWAYS lower attachments and implements to the

ground before servicing. If work is required on a

lifted machine or attachment, properly SUPPORT

machine attachment or implement before working

on it.

FM-4

785 MOTOR GRADER

Courtesy of Machine.Market

Section 1

INTRODUCTION

TABLE OF CONTENTS

Page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

CONTROLS AND OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

MAINTENANCE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

NAMEPLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

8500 Conveyor Paver

1-1

Courtesy of Machine.Market

Section 1

INTRODUCTION

GENERAL INFORMATION

This manual contains Specification information,

Controls and Operating Procedures, Maintenance

and Repair Procedures and Parts Lists for the 785

Motor Grader.

SPECIFICATIONS

Refer to Section 2 - SPECIFICATIONS in this

manual for all major system specifications and for

typical torque value tables.

CONTROLS AND OPERATING

INSTRUCTIONS

Refer to Section 3 - OPERATION.

The operator of this equipment should READ,

UNDERSTAND, and FOLLOW the operating

instructions, Cautions, and Warnings provided in

the front of this manual and in the OPERATION

section.

WARNING: Do not attempt to operate the 785

Motor Grader unless fully trained

in the machine operation, only

authorized personnel should oper-

ate the Model 785 Motor Grader. All

instructions provided in this manu-

al and on the machine operating

and warning decals must be fol-

lowed to prevent damage to the

equipment and/or injury to operat-

ing personnel.

MAINTENANCE PROCEDURES

Refer to Section 4 - MAINTENANCE in this manual

for all maintenance and repair procedures.

CAUTION: All maintenance instructions

provided in this manual should be

followed to insure safety of the

personnel performing the

maintenance and to prevent

damage to the machine.

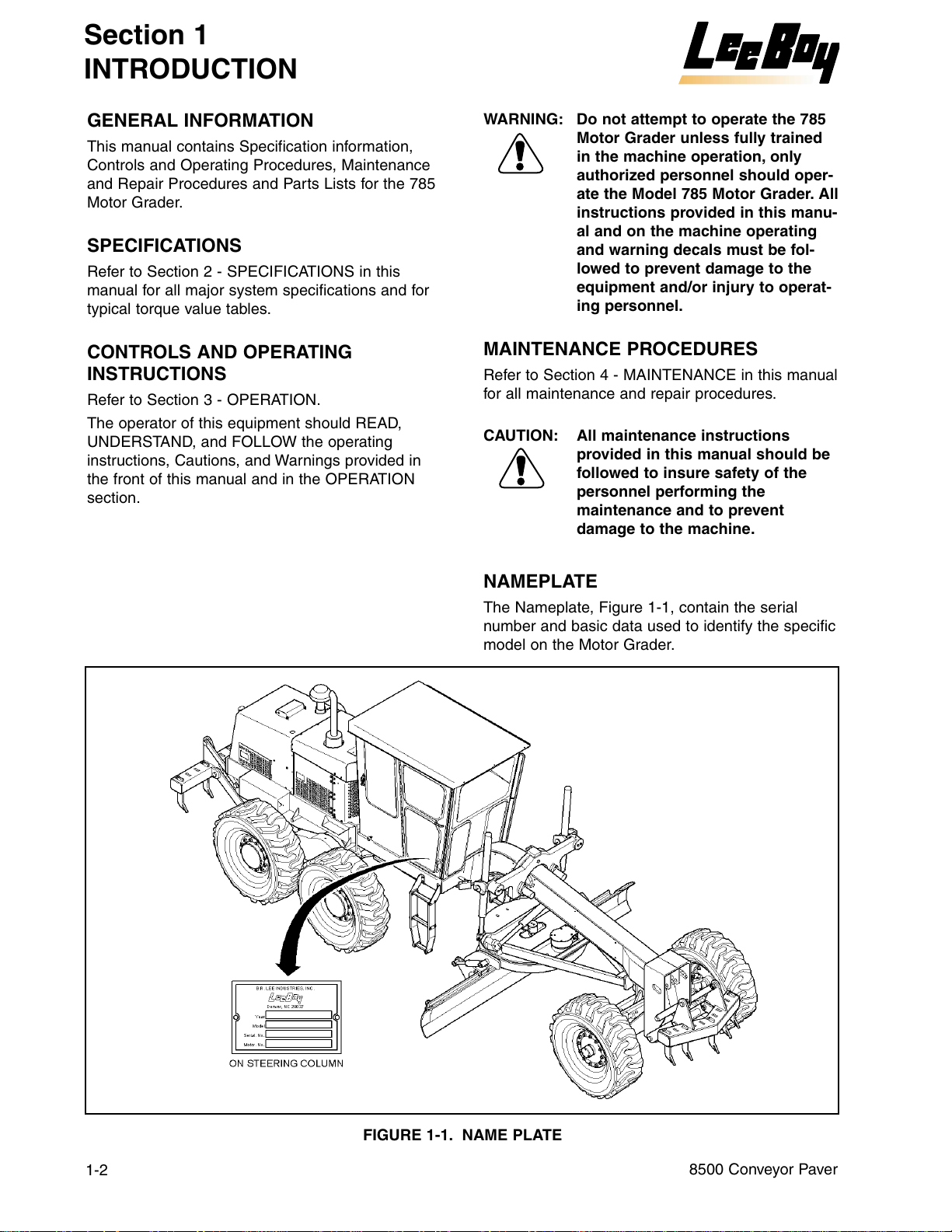

NAMEPLATE

The Nameplate, Figure 1-1, contain the serial

number and basic data used to identify the specific

model on the Motor Grader.

1-2

FIGURE 1-1. NAME PLATE

8500 Conveyor Paver

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

TABLE OF CONTENTS

Page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

TABLE 2-1. ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

TABLE 2-2. ELECTRICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

TABLE 2-3. DIMENSION SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

TABLE 2-4. PERFORMANCE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

TABLE 2-5. SCARIFIER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

TABLE 2-6. MACHINE SYSTEM CAPACITY SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

TABLE 2-7. MOLDBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

TABLE 2-8. HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

TABLE 2-9 TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

TABLE 2-10. TYPES OF LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

TABLE 2-11. TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

TABLE 2-12. TORQUE SPECIFICATIONS FOR STANDARD INCH FASTENERS . . . . . . . . . . . . . . .2-6

TABLE 2-13. TORQUE SPECIFICATIONS FOR METRIC FASTENERS . . . . . . . . . . . . . . . . . . . . . .2-7

785 Motor Grader

2-1

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

GENERAL INFORMATION

The specifications provided in this section are applicable to the Model 785 Motor Grader. Included in this section

are machine weights, dimensions, performance and torque values for both metric and standard inch fasteners.

TABLE 2-1. ENGINE SPECIFICATIONS

ITEM CHARACTERISTIC

ENGINE

Manufacturer . . . . . . . . . . . . . . . . . . . . . .Cummins 3.9L

Horsepower . . . . . . . . . . . . . . . . . . . . . . .130 HP @2500 rpm

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . .Four Stroke Turbo Charged and Charge Air

Cooled, In-Line 4 cylinder Diesel engine

(Tier II Compliant)

Bore & Stroke . . . . . . . . . . . . . . . . . . . . .4.02 in. [102 mm] x 4.72 in. [120 mm]

Displacement . . . . . . . . . . . . . . . . . . . . .238 cu. In.

Compression Ratio . . . . . . . . . . . . . . . . .18:01

Maximum Net Torque . . . . . . . . . . . . . . .355 Pound/Foot @1500 rpm

Lubrication system . . . . . . . . . . . . . . . . .Pressure System With Full Flow Filter

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . .Two Stage Dry Element

Engine Oil Type . . . . . . . . . . . . . . . . . . .10W-40

Capacity . . . . . . . . . . . . . . . . . . . . . . . . .10 Quarts [9.46 liter]

ENGINE COOLING SYSTEM

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . .Liquid,

ENGINE FUEL

Type Used . . . . . . . . . . . . . . . . . . . . . . . .Diesel Fuel

Fuel Capacity . . . . . . . . . . . . . . . . . . . . .50 gallons [189.3 liters]

FUEL FILTER

Spin-On . . . . . . . . . . . . . . . . . . . . . . . . .Cummins P/N 3991498/Fleetguard FS19616

In-Line . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 981937

2-2

TABLE 2-2. ELECTRICAL SPECIFICATIONS

ITEM CHARACTERISTIC

BATTERY

Number Per Machine . . . . . . . . . . . . . . . .Two maintenance free

Ampere Hour Rating . . . . . . . . . . . . . . . .950 CCA

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .12 Volts

ALTERNATOR

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .12 Volt, negative ground

Output Amperage . . . . . . . . . . . . . . . . . .100 Amps

Fan Belt Tension . . . . . . . . . . . . . . . . . . .Belt tension mechanism keeps serpentine

belt under tension at all times

STARTER

Manufacturer . . . . . . . . . . . . . . . . . . . . . .(See Engine Starter plate)

Voltage and Type . . . . . . . . . . . . . . . . . . .12 Volt, negative ground

785 Motor Grader

Courtesy of Machine.Market

SPECIFICATIONS

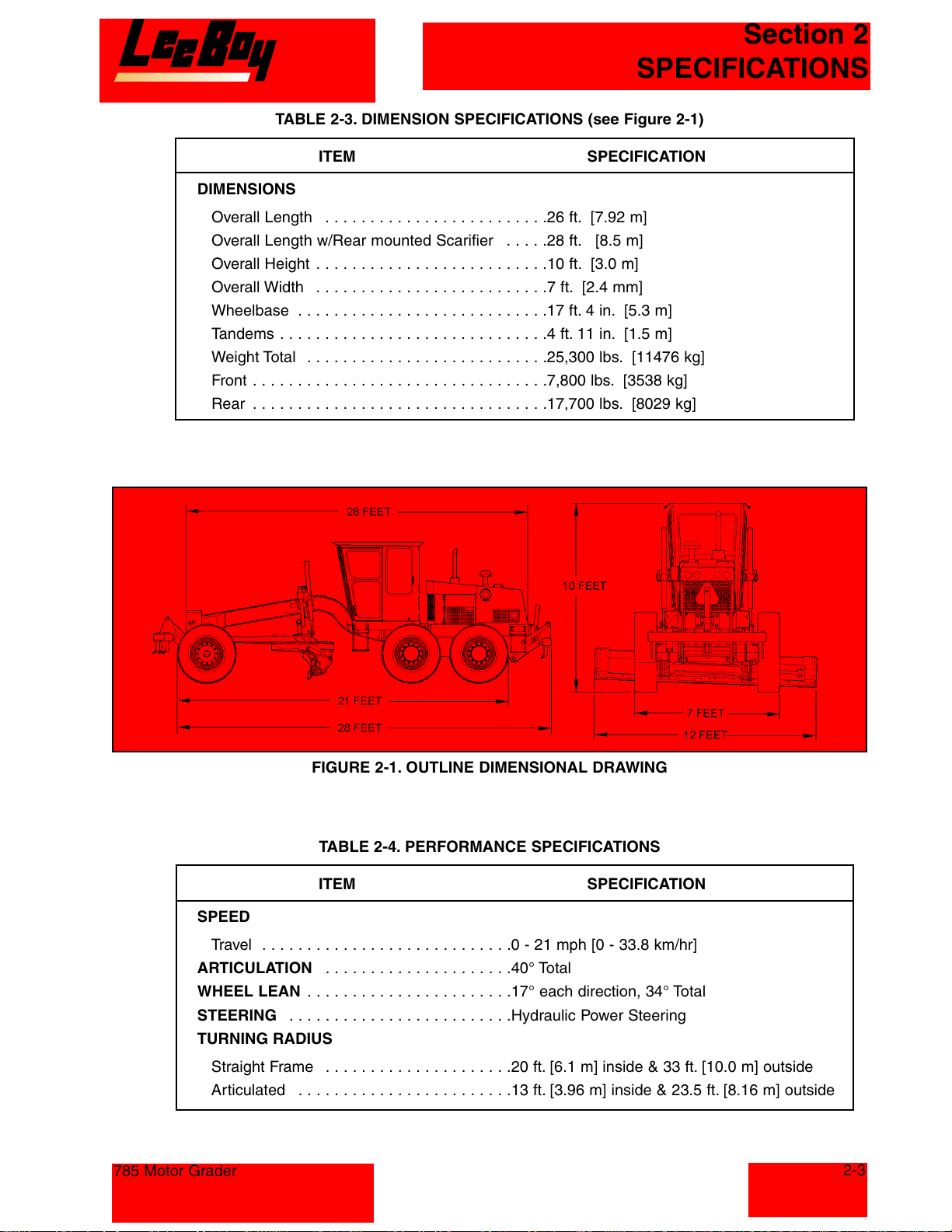

TABLE 2-3. DIMENSION SPECIFICATIONS (see Figure 2-1)

ITEM SPECIFICATION

DIMENSIONS

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . .26 ft. [7.92 m]

Overall Length w/Rear mounted Scarifier . . . . .28 ft. [8.5 m]

Overall Height . . . . . . . . . . . . . . . . . . . . . . . . . .10 ft. [3.0 m]

Overall Width . . . . . . . . . . . . . . . . . . . . . . . . . .7 ft. [2.4 mm]

Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 ft. 4 in. [5.3 m]

Tandems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 ft. 11 in. [1.5 m]

Weight Total . . . . . . . . . . . . . . . . . . . . . . . . . . .25,300 lbs. [11476 kg]

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7,800 lbs. [3538 kg]

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17,700 lbs. [8029 kg]

Section 2

SPEED

Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 21 mph [0 - 33.8 km/hr]

ARTICULATION . . . . . . . . . . . . . . . . . . . . .40° Total

WHEEL LEAN . . . . . . . . . . . . . . . . . . . . . . .17° each direction, 34° Total

STEERING . . . . . . . . . . . . . . . . . . . . . . . . .Hydraulic Power Steering

TURNING RADIUS

Straight Frame . . . . . . . . . . . . . . . . . . . . .20 ft. [6.1 m] inside & 33 ft. [10.0 m] outside

Articulated . . . . . . . . . . . . . . . . . . . . . . . .13 ft. [3.96 m] inside & 23.5 ft. [8.16 m] outside

785 Motor Grader

FIGURE 2-1. OUTLINE DIMENSIONAL DRAWING

TABLE 2-4. PERFORMANCE SPECIFICATIONS

ITEM SPECIFICATION

2-3

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

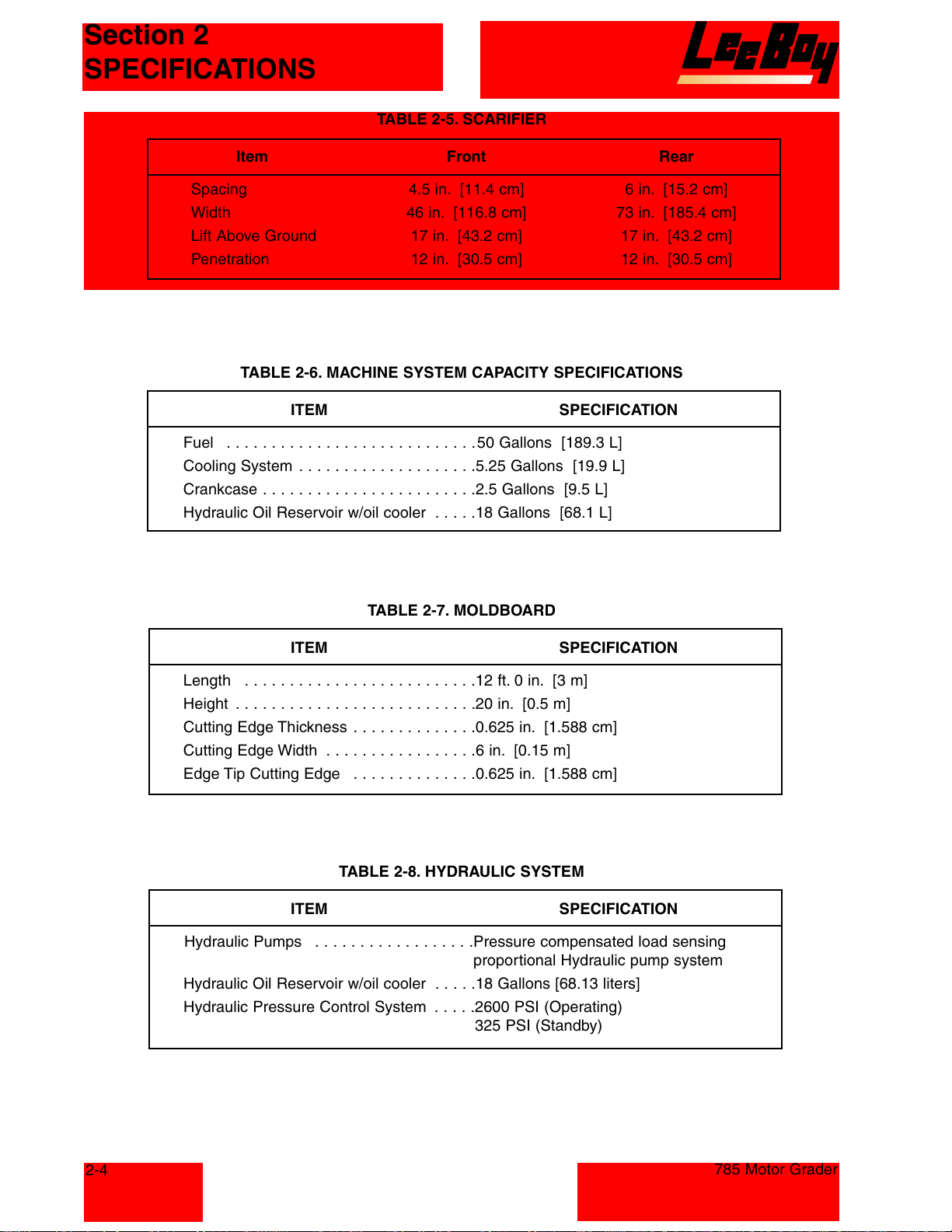

Item Front Rear

Spacing 4.5 in. [11.4 cm] 6 in. [15.2 cm]

Width 46 in. [116.8 cm] 73 in. [185.4 cm]

Lift Above Ground 17 in. [43.2 cm] 17 in. [43.2 cm]

Penetration 12 in. [30.5 cm] 12 in. [30.5 cm]

TABLE 2-6. MACHINE SYSTEM CAPACITY SPECIFICATIONS

ITEM SPECIFICATION

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 Gallons [189.3 L]

Cooling System . . . . . . . . . . . . . . . . . . . .5.25 Gallons [19.9 L]

Crankcase . . . . . . . . . . . . . . . . . . . . . . . .2.5 Gallons [9.5 L]

Hydraulic Oil Reservoir w/oil cooler . . . . .18 Gallons [68.1 L]

TABLE 2-5. SCARIFIER

TABLE 2-7. MOLDBOARD

ITEM SPECIFICATION

Length . . . . . . . . . . . . . . . . . . . . . . . . . .12 ft. 0 in. [3 m]

Height . . . . . . . . . . . . . . . . . . . . . . . . . . .20 in. [0.5 m]

Cutting Edge Thickness . . . . . . . . . . . . . .0.625 in. [1.588 cm]

Cutting Edge Width . . . . . . . . . . . . . . . . .6 in. [0.15 m]

Edge Tip Cutting Edge . . . . . . . . . . . . . .0.625 in. [1.588 cm]

TABLE 2-8. HYDRAULIC SYSTEM

ITEM SPECIFICATION

Hydraulic Pumps . . . . . . . . . . . . . . . . . .Pressure compensated load sensing

proportional Hydraulic pump system

Hydraulic Oil Reservoir w/oil cooler . . . . .18 Gallons [68.13 liters]

Hydraulic Pressure Control System . . . . .2600 PSI (Operating)

325 PSI (Standby)

2-4

785 Motor Grader

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

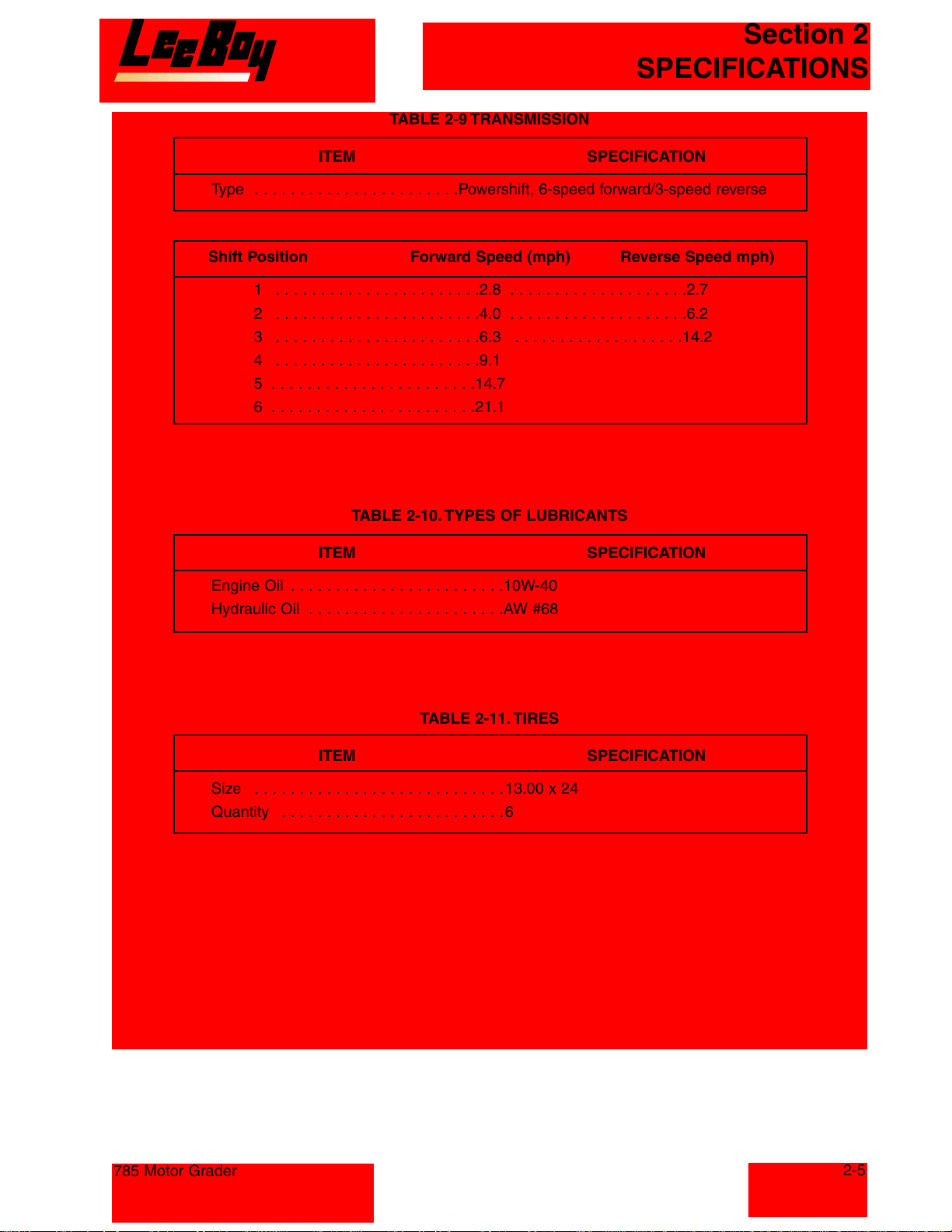

TABLE 2-9 TRANSMISSION

ITEM SPECIFICATION

Type . . . . . . . . . . . . . . . . . . . . . . .Powershift, 6-speed forward/3-speed reverse

Shift Position Forward Speed (mph) Reverse Speed mph)

1 . . . . . . . . . . . . . . . . . . . . . . .2.8 . . . . . . . . . . . . . . . . . . . .2.7

2 . . . . . . . . . . . . . . . . . . . . . . .4.0 . . . . . . . . . . . . . . . . . . . .6.2

3 . . . . . . . . . . . . . . . . . . . . . . .6.3 . . . . . . . . . . . . . . . . . . .14.2

4 . . . . . . . . . . . . . . . . . . . . . . .9.1

5 . . . . . . . . . . . . . . . . . . . . . . .14.7

6 . . . . . . . . . . . . . . . . . . . . . . .21.1

TABLE 2-10. TYPES OF LUBRICANTS

ITEM SPECIFICATION

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . .10W-40

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . .AW #68

TABLE 2-11. TIRES

ITEM SPECIFICATION

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.00 x 24

Quantity . . . . . . . . . . . . . . . . . . . . . . . . . 6

785 Motor Grader

2-5

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

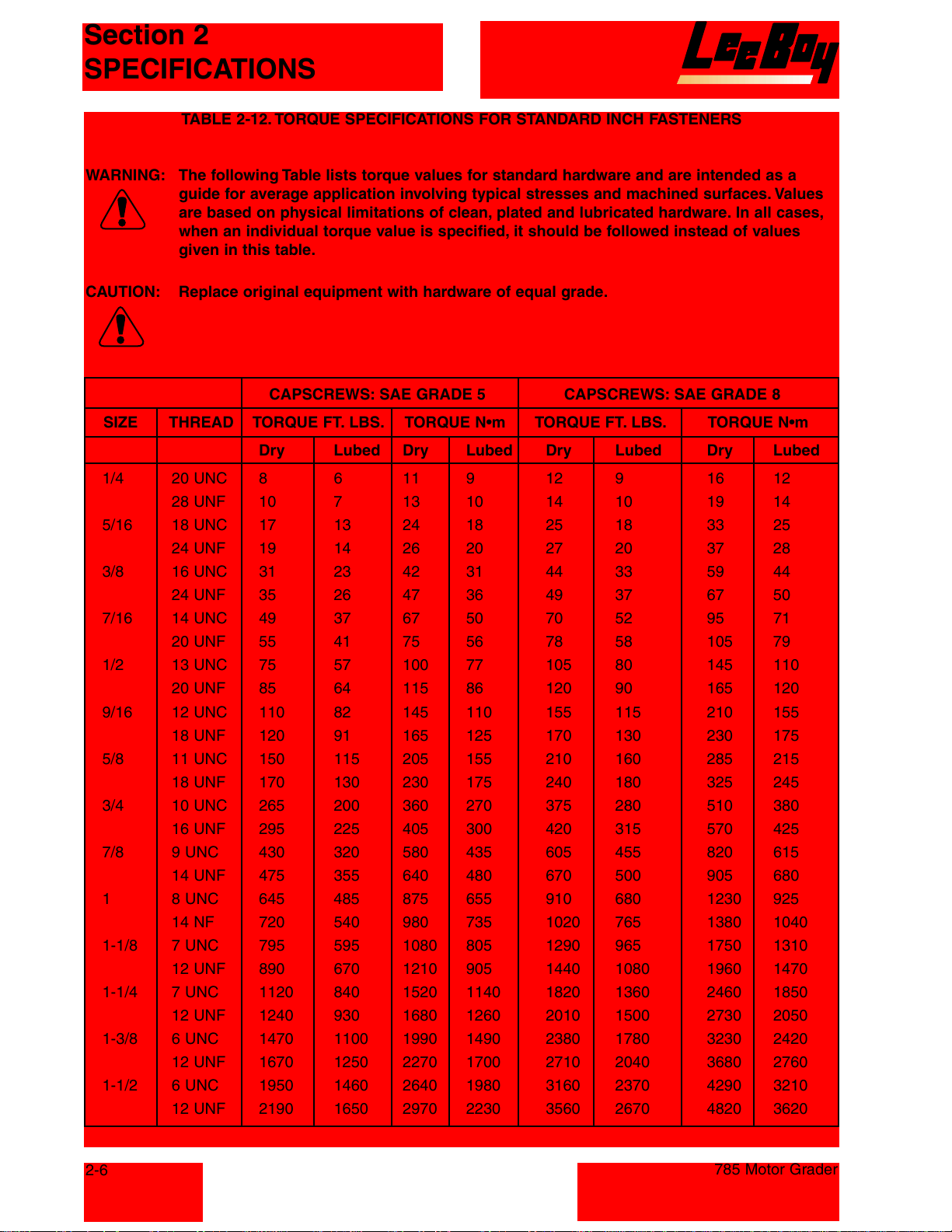

TABLE 2-12. TORQUE SPECIFICATIONS FOR STANDARD INCH FASTENERS

WARNING: The following Table lists torque values for standard hardware and are intended as a

guide for average application involving typical stresses and machined surfaces. Values

are based on physical limitations of clean, plated and lubricated hardware. In all cases,

when an individual torque value is specified, it should be followed instead of values

given in this table.

CAUTION: Replace original equipment with hardware of equal grade.

CAPSCREWS: SAE GRADE 5 CAPSCREWS: SAE GRADE 8

SIZE THREAD TORQUE FT. LBS. TORQUE N•m TORQUE FT. LBS. TORQUE N•m

Dry Lubed Dry Lubed Dry Lubed Dry Lubed

1/4 20 UNC 8 6 11 9 12 9 16 12

28 UNF 10 7 13 10 14 10 19 14

5/16 18 UNC 17 13 24 18 25 18 33 25

24 UNF 19 14 26 20 27 20 37 28

3/8 16 UNC 31 23 42 31 44 33 59 44

24 UNF 35 26 47 36 49 37 67 50

7/16 14 UNC 49 37 67 50 70 52 95 71

20 UNF 55 41 75 56 78 58 105 79

1/2 13 UNC 75 57 100 77 105 80 145 110

20 UNF 85 64 115 86 120 90 165 120

9/16 12 UNC 110 82 145 110 155 115 210 155

18 UNF 120 91 165 125 170 130 230 175

5/8 11 UNC 150 115 205 155 210 160 285 215

18 UNF 170 130 230 175 240 180 325 245

3/4 10 UNC 265 200 360 270 375 280 510 380

16 UNF 295 225 405 300 420 315 570 425

7/8 9 UNC 430 320 580 435 605 455 820 615

14 UNF 475 355 640 480 670 500 905 680

1 8 UNC 645 485 875 655 910 680 1230 925

14 NF 720 540 980 735 1020 765 1380 1040

1-1/8 7 UNC 795 595 1080 805 1290 965 1750 1310

12 UNF 890 670 1210 905 1440 1080 1960 1470

1-1/4 7 UNC 1120 840 1520 1140 1820 1360 2460 1850

12 UNF 1240 930 1680 1260 2010 1500 2730 2050

1-3/8 6 UNC 1470 1100 1990 1490 2380 1780 3230 2420

12 UNF 1670 1250 2270 1700 2710 2040 3680 2760

1-1/2 6 UNC 1950 1460 2640 1980 3160 2370 4290 3210

12 UNF 2190 1650 2970 2230 3560 2670 4820 3620

2-6

785 Motor Grader

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

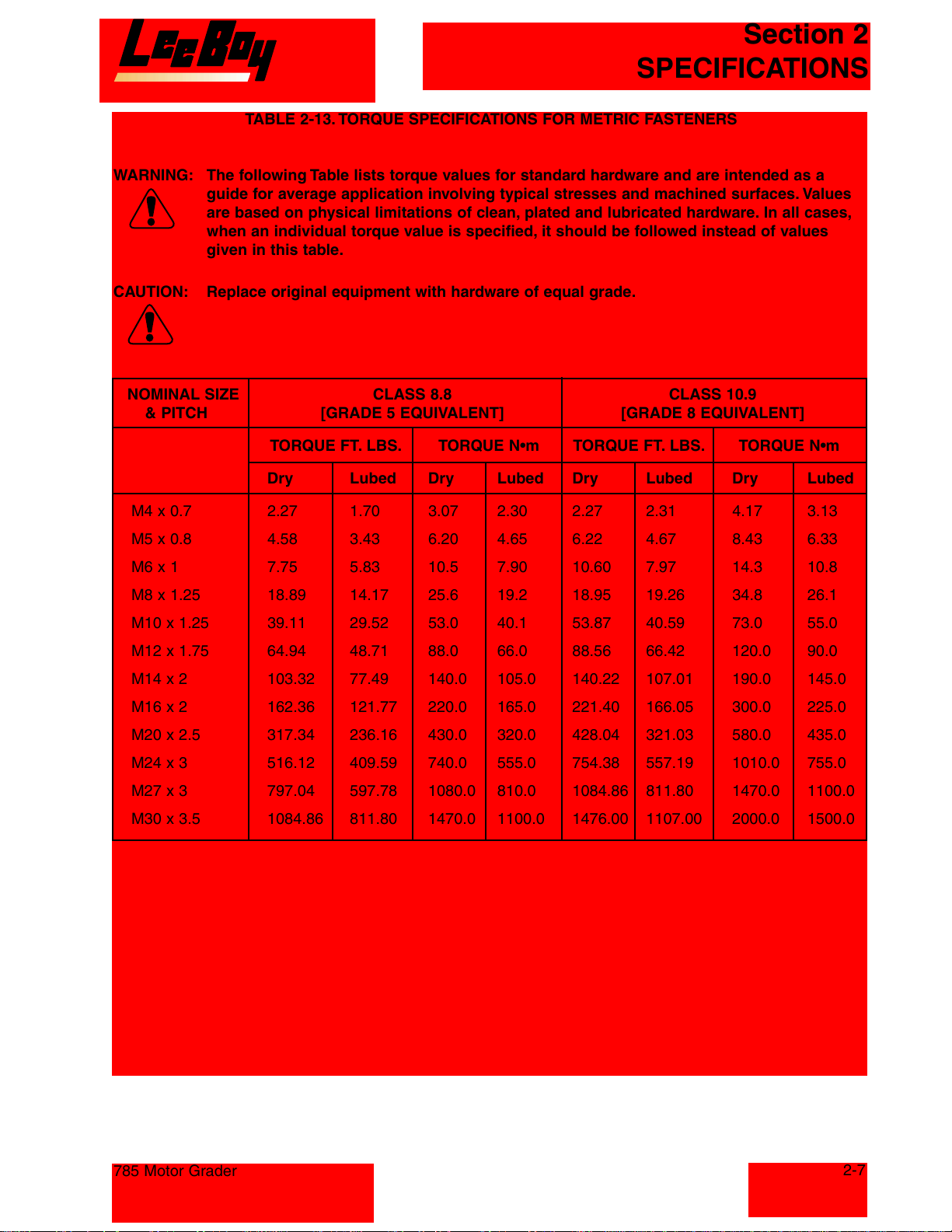

TABLE 2-13. TORQUE SPECIFICATIONS FOR METRIC FASTENERS

WARNING: The following Table lists torque values for standard hardware and are intended as a

guide for average application involving typical stresses and machined surfaces. Values

are based on physical limitations of clean, plated and lubricated hardware. In all cases,

when an individual torque value is specified, it should be followed instead of values

given in this table.

CAUTION: Replace original equipment with hardware of equal grade.

NOMINAL SIZE CLASS 8.8 CLASS 10.9

& PITCH [GRADE 5 EQUIVALENT] [GRADE 8 EQUIVALENT]

TORQUE FT. LBS. TORQUE N•m TORQUE FT. LBS. TORQUE N•m

Dry Lubed Dry Lubed Dry Lubed Dry Lubed

M4 x 0.7 2.27 1.70 3.07 2.30 2.27 2.31 4.17 3.13

M5 x 0.8 4.58 3.43 6.20 4.65 6.22 4.67 8.43 6.33

M6 x 1 7.75 5.83 10.5 7.90 10.60 7.97 14.3 10.8

M8 x 1.25 18.89 14.17 25.6 19.2 18.95 19.26 34.8 26.1

M10 x 1.25 39.11 29.52 53.0 40.1 53.87 40.59 73.0 55.0

M12 x 1.75 64.94 48.71 88.0 66.0 88.56 66.42 120.0 90.0

M14 x 2 103.32 77.49 140.0 105.0 140.22 107.01 190.0 145.0

M16 x 2 162.36 121.77 220.0 165.0 221.40 166.05 300.0 225.0

M20 x 2.5 317.34 236.16 430.0 320.0 428.04 321.03 580.0 435.0

M24 x 3 516.12 409.59 740.0 555.0 754.38 557.19 1010.0 755.0

M27 x 3 797.04 597.78 1080.0 810.0 1084.86 811.80 1470.0 1100.0

M30 x 3.5 1084.86 811.80 1470.0 1100.0 1476.00 1107.00 2000.0 1500.0

785 Motor Grader

2-7

Courtesy of Machine.Market

Section 2

SPECIFICATIONS

NOTES

2-8

785 Motor Grader

Courtesy of Machine.Market

Section 3

OPERATION

TABLE OF CONTENTS

Page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

OPERATING CONTROLS, INDICATORS, AND GAUGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Operating Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Stopping Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Inspection Before Initial Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Preliminary Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Adjusting Front Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Air Conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Defroster Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Opening Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Cab Door Release Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Cab Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Console Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

DRIVING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Using Booster Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Engine Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Auto Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Moving Forward/Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Stopping and Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Moving Forward/Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Stopping and Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

OPERATING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Blade Lift Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Moldboard Slide Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Blade Tilt Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

785 Motor Grader

Courtesy of Machine.Market

3-1

Section 3

OPERATION

Circle Turn Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Circle Shift Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Articulation Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Leaning Wheel Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Scarifier Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Differential Lock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Moving Blade to Bank Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Blade Side Thrust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Blade Pitch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Pile Spreading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

TABLE OF CONTENTS (Continued)

Page

Back Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Vee Ditching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

First Pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Second Pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Third Pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Spreading Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Cutting Back Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Cleaning Ditches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Road Crowning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Bank Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Slope Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Cul De Sacs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

LOADING THE GRADER ON A TRAILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

TOWING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-2 785 Motor Grader

Courtesy of Machine.Market

Section 3

OPERATION

GENERAL INFORMATION

This section provides the Operating Instructions for

the Model 785 Motor Grader.

It is important to read, understand, and follow all

"Precautions, Operating Instructions and Warnings"

written in this manual before starting or operating

the machine.

DANGER: Failure to observe the “Precautions,

Operating Instructions and

Warnings” provided in this manual

can cause serious injury or death.

Only authorized personnel, who are

fully trained in the machine opera-

tion, can operate the Model 785

Motor Grader.

This machine should be kept in good mechanical

condition at all times.

WARNING: Do not operate a machine needing

repair. Put an information tag on

the instrument panel that says,

“DO NOT OPERATE”. Remove the

key from the ignition switch.

Repair all damage at once. Minor

damage can result in major system

failures.

OPERATING CONTROLS, INDICATORS,

AND GAUGES

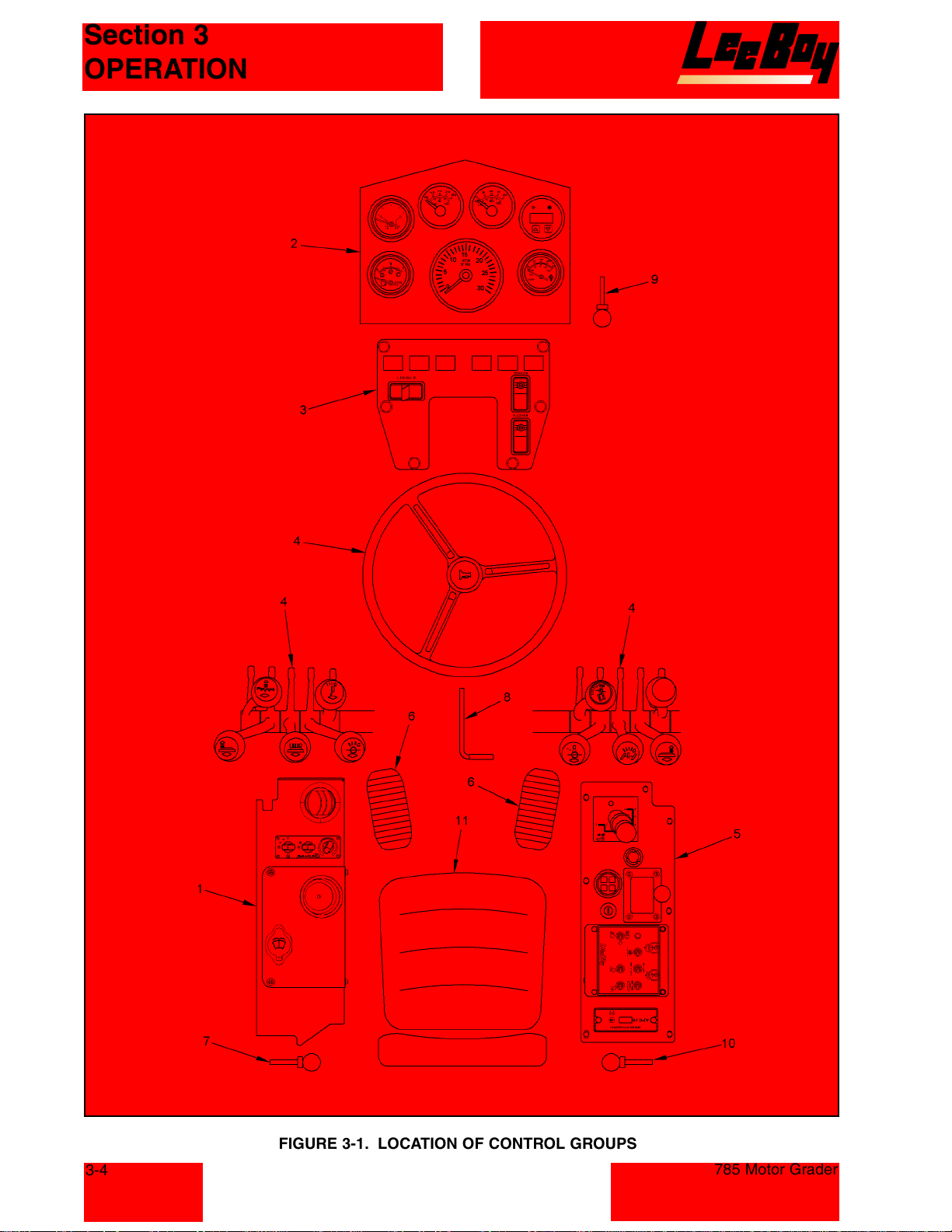

Operating controls for the Model 785 Motor Grader

are shown in Figures 3-1 through 3-6 and listed in

Tables 3-1 through 3-6.

WARNING: Do not start or operate the Model

785 Motor Grader before reading,

understanding and following all

information given in this section

and shown on the machine. The

operators must read and under-

stand the function of all controls,

indicators, and gauges before

starting the engine. Serious injury

or death can result if these proce-

dures are not followed.

785 Motor Grader

3-3

Courtesy of Machine.Market

Section 3

OPERATION

3-4

FIGURE 3-1. LOCATION OF CONTROL GROUPS

785 Motor Grader

Courtesy of Machine.Market

Section 3

OPERATION

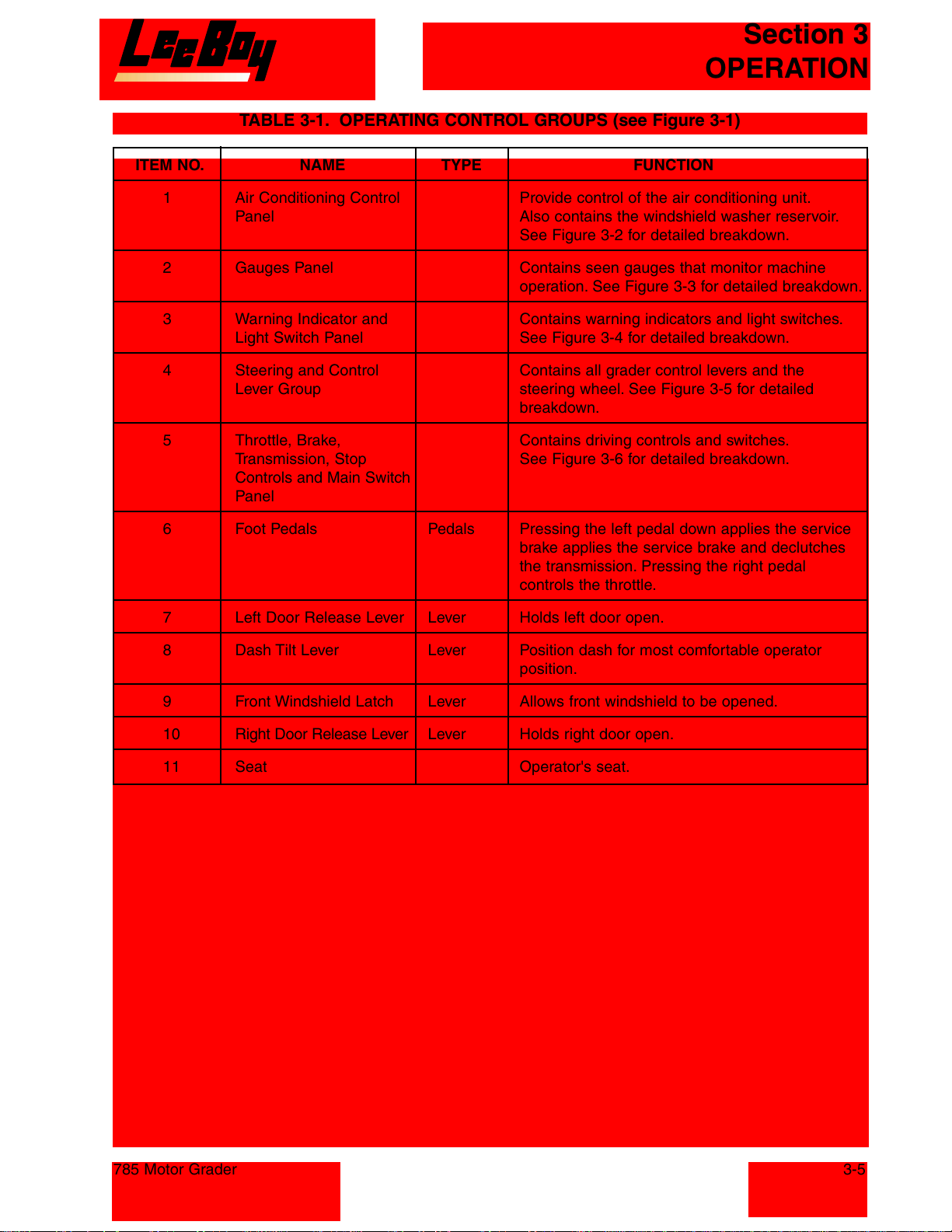

TABLE 3-1. OPERATING CONTROL GROUPS (see Figure 3-1)

ITEM NO. NAME TYPE FUNCTION

1 Air Conditioning Control Provide control of the air conditioning unit.

Panel Also contains the windshield washer reservoir.

See Figure 3-2 for detailed breakdown.

2 Gauges Panel Contains seen gauges that monitor machine

operation. See Figure 3-3 for detailed breakdown.

3 Warning Indicator and Contains warning indicators and light switches.

Light Switch Panel See Figure 3-4 for detailed breakdown.

4 Steering and Control Contains all grader control levers and the

Lever Group steering wheel. See Figure 3-5 for detailed

breakdown.

5 Throttle, Brake, Contains driving controls and switches.

Transmission, Stop See Figure 3-6 for detailed breakdown.

Controls and Main Switch

Panel

6 Foot Pedals Pedals Pressing the left pedal down applies the service

brake applies the service brake and declutches

the transmission. Pressing the right pedal

controls the throttle.

7 Left Door Release Lever Lever Holds left door open.

8 Dash Tilt Lever Lever Position dash for most comfortable operator

position.

9 Front Windshield Latch Lever Allows front windshield to be opened.

10 Right Door Release Lever Lever Holds right door open.

11 Seat Operator's seat.

785 Motor Grader

3-5

Courtesy of Machine.Market

Section 3

OPERATION

3-6

FIGURE 3-2. AIR CONDITIONING CONTROL PANEL

785 Motor Grader

Courtesy of Machine.Market

Section 3

OPERATION

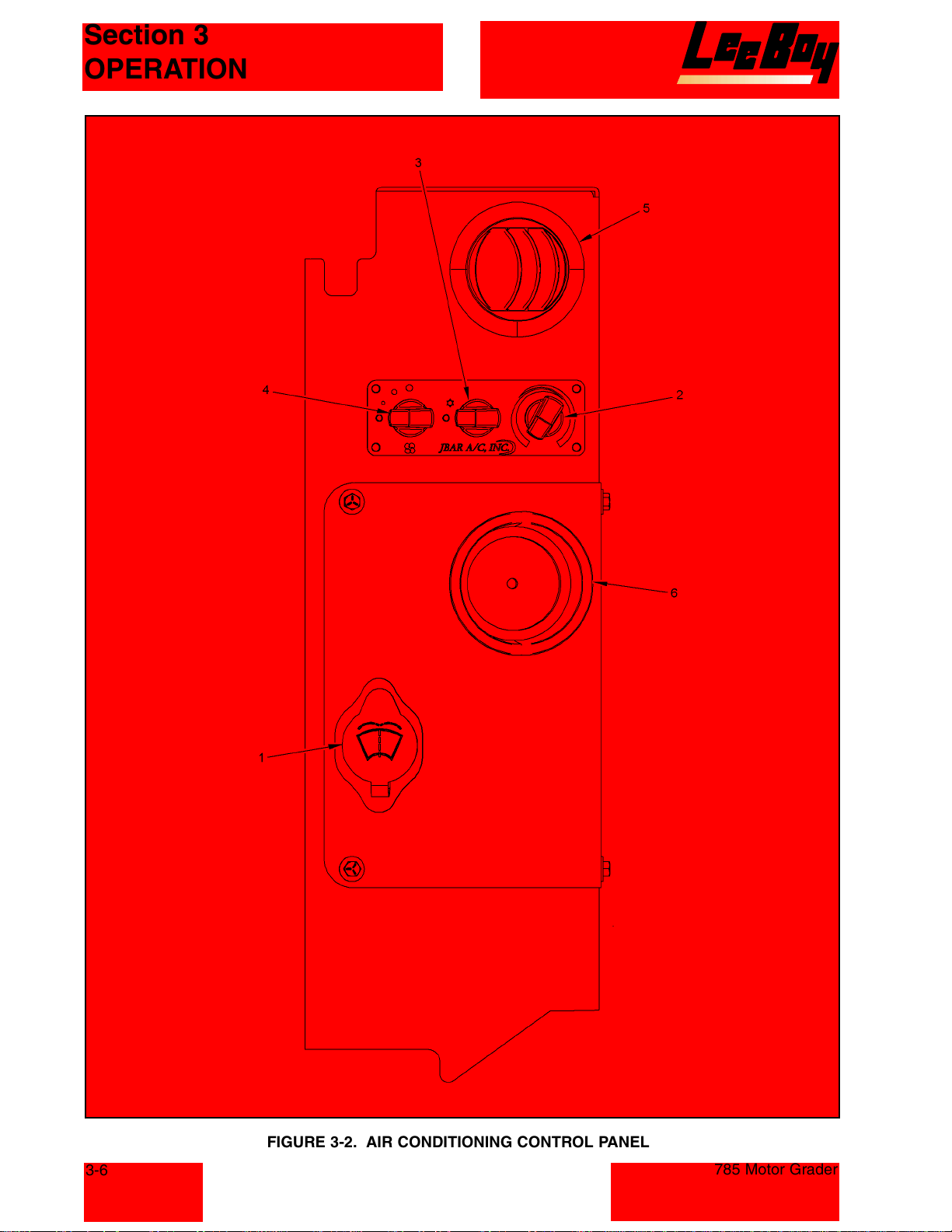

TABLE 3-2. AIR CONDITIONING CONTROL PANEL (see Figure 3-2)

ITEM NO. NAME TYPE FUNCTION

1 Washer Fluid Reservoir Provides storage for the windshield washer fluid.

2 TEMP Switch Rotary Adjusts the output temperature of the air

switch conditioner.

3 A/C On/Off Switch 2-Position Turns air conditioner On or Off.

toggle

switch

4 Fan Speed Rotary Adjust speed of blower fan.

switch

5 Vent Opening Output vent for the air conditioner output air.

6 Cup Holder Hold drinking cup.

785 Motor Grader

3-7

Courtesy of Machine.Market

Section 3

OPERATION

3-8

FIGURE 3-3. GAUGE PANEL

785 Motor Grader

Courtesy of Machine.Market

Section 3

OPERATION

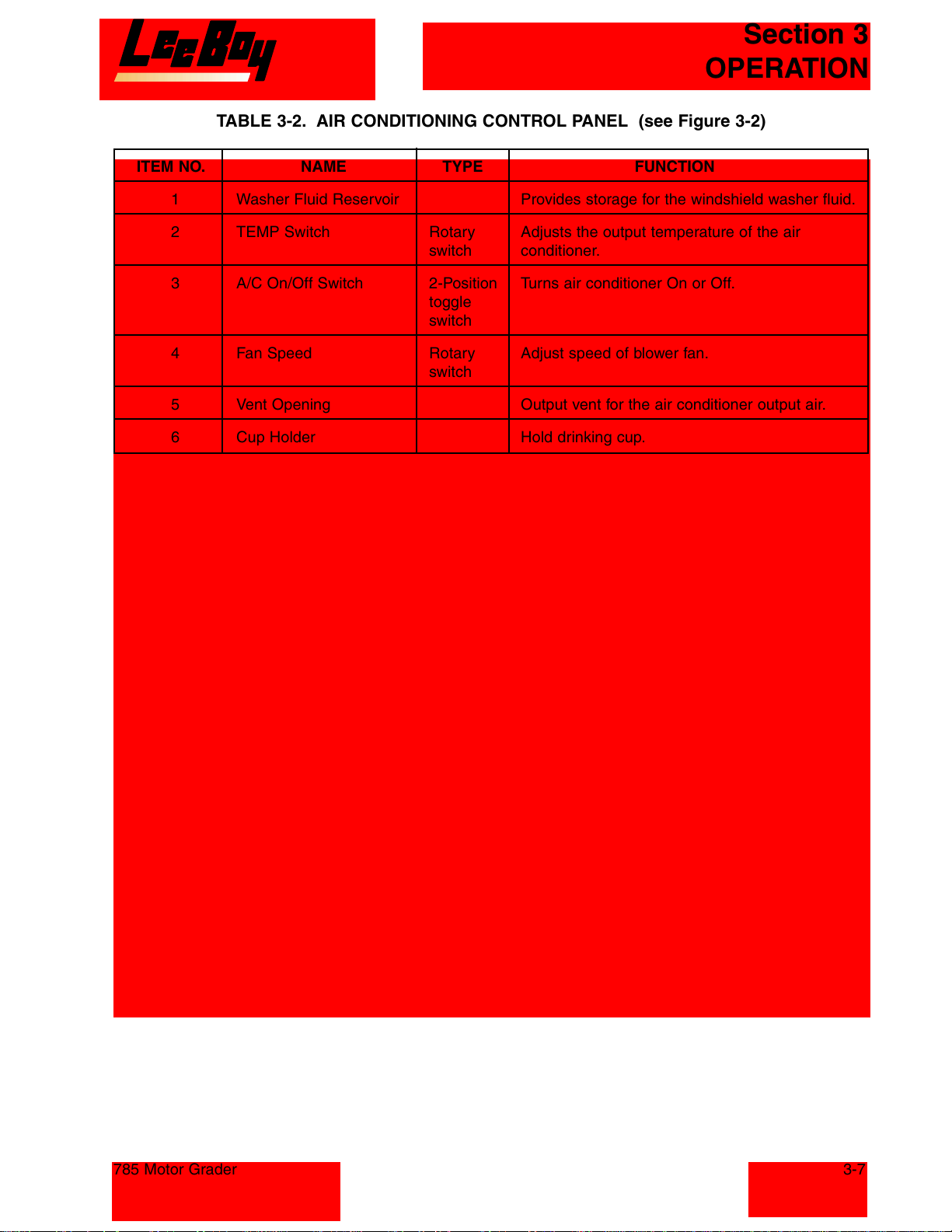

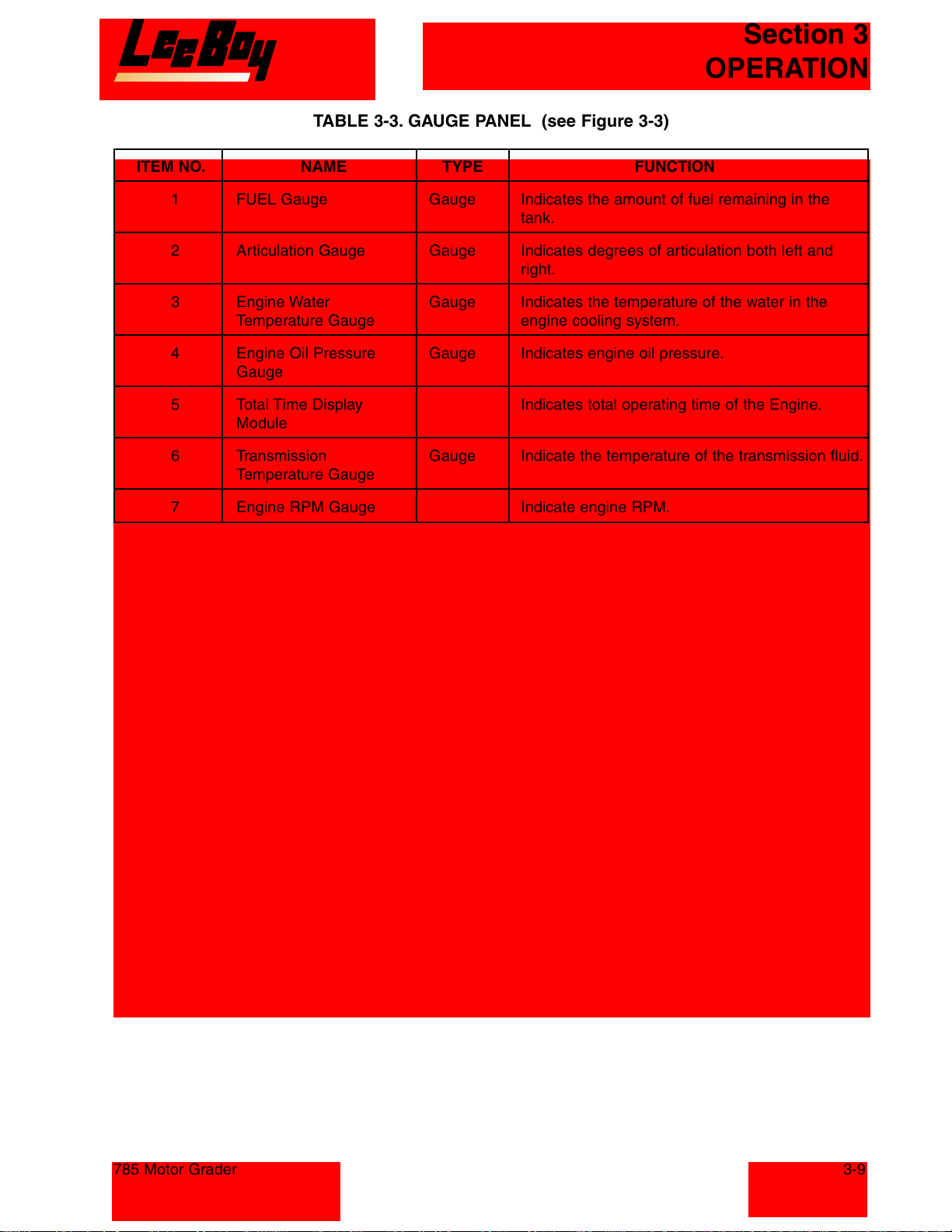

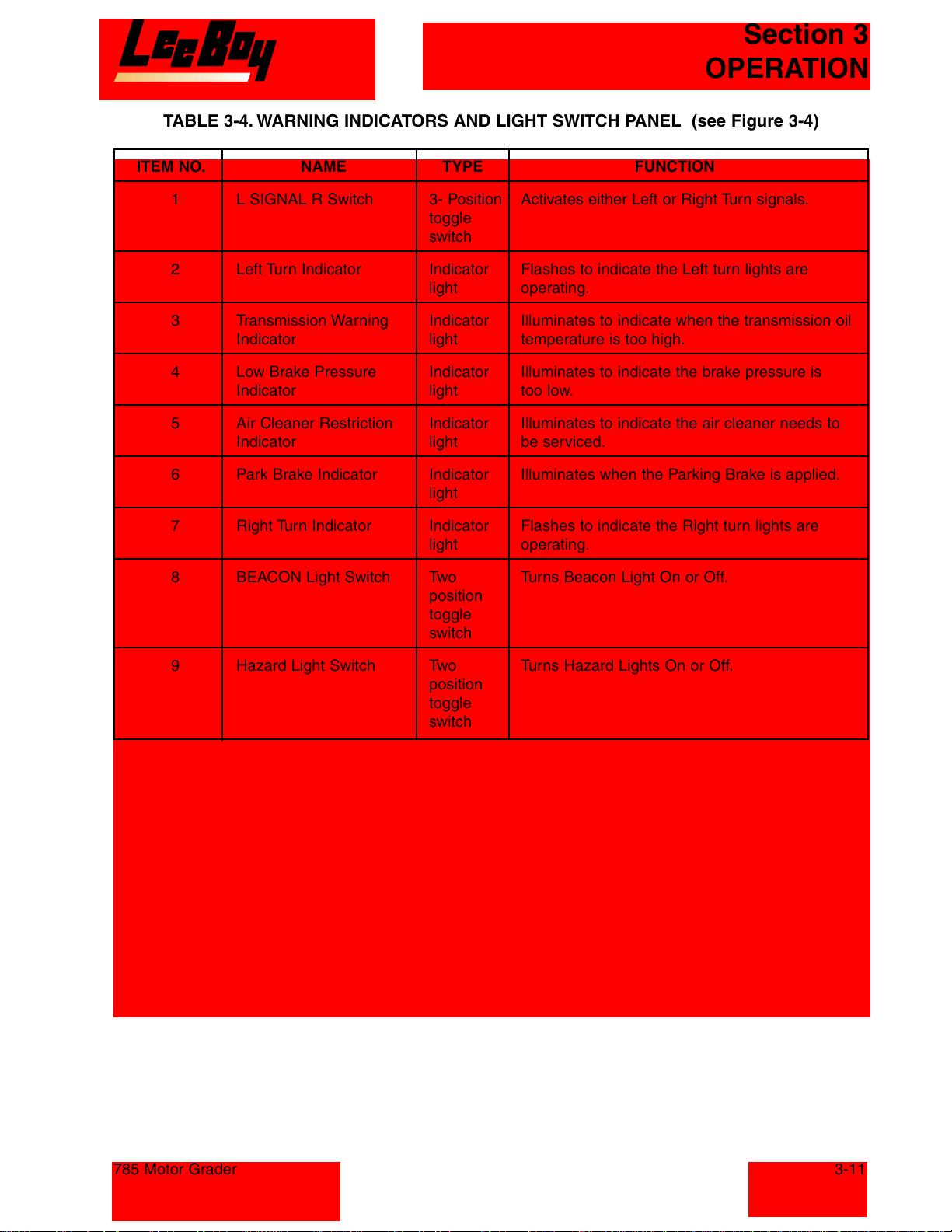

TABLE 3-3. GAUGE PANEL (see Figure 3-3)

ITEM NO. NAME TYPE FUNCTION

1 FUEL Gauge Gauge Indicates the amount of fuel remaining in the

tank.

2 Articulation Gauge Gauge Indicates degrees of articulation both left and

right.

3 Engine Water Gauge Indicates the temperature of the water in the

Temperature Gauge engine cooling system.

4 Engine Oil Pressure Gauge Indicates engine oil pressure.

Gauge

5 Total Time Display Indicates total operating time of the Engine.

Module

6 Transmission Gauge Indicate the temperature of the transmission fluid.

Temperature Gauge

7 Engine RPM Gauge Indicate engine RPM.

785 Motor Grader

3-9

Courtesy of Machine.Market

Section 3

OPERATION

3-10

FIGURE 3-4. WARNING INDICATORS AND LIGHT SWITCH PANEL

785 Motor Grader

Courtesy of Machine.Market

Section 3

OPERATION

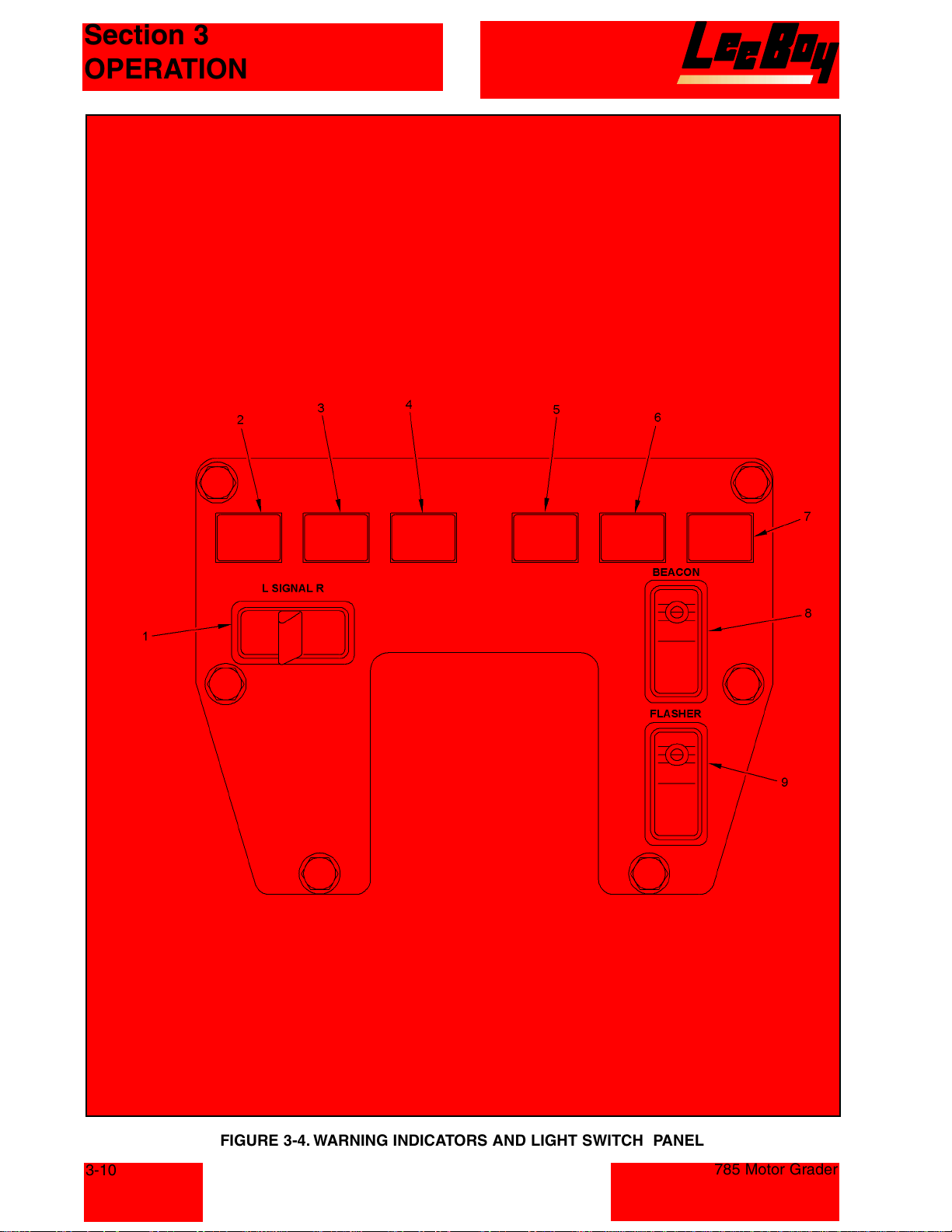

TABLE 3-4. WARNING INDICATORS AND LIGHT SWITCH PANEL (see Figure 3-4)

ITEM NO. NAME TYPE FUNCTION

1 L SIGNAL R Switch 3- Position Activates either Left or Right Turn signals.

toggle

switch

2 Left Turn Indicator Indicator Flashes to indicate the Left turn lights are

light operating.

3 Transmission Warning Indicator Illuminates to indicate when the transmission oil

Indicator light temperature is too high.

4 Low Brake Pressure Indicator Illuminates to indicate the brake pressure is

Indicator light too low.

5 Air Cleaner Restriction Indicator Illuminates to indicate the air cleaner needs to

Indicator light be serviced.

6 Park Brake Indicator Indicator Illuminates when the Parking Brake is applied.

light

7 Right Turn Indicator Indicator Flashes to indicate the Right turn lights are

light operating.

8 BEACON Light Switch Two Turns Beacon Light On or Off.

position

toggle

switch

9 Hazard Light Switch Two Turns Hazard Lights On or Off.

position

toggle

switch

785 Motor Grader

3-11

Courtesy of Machine.Market

Section 3

OPERATION

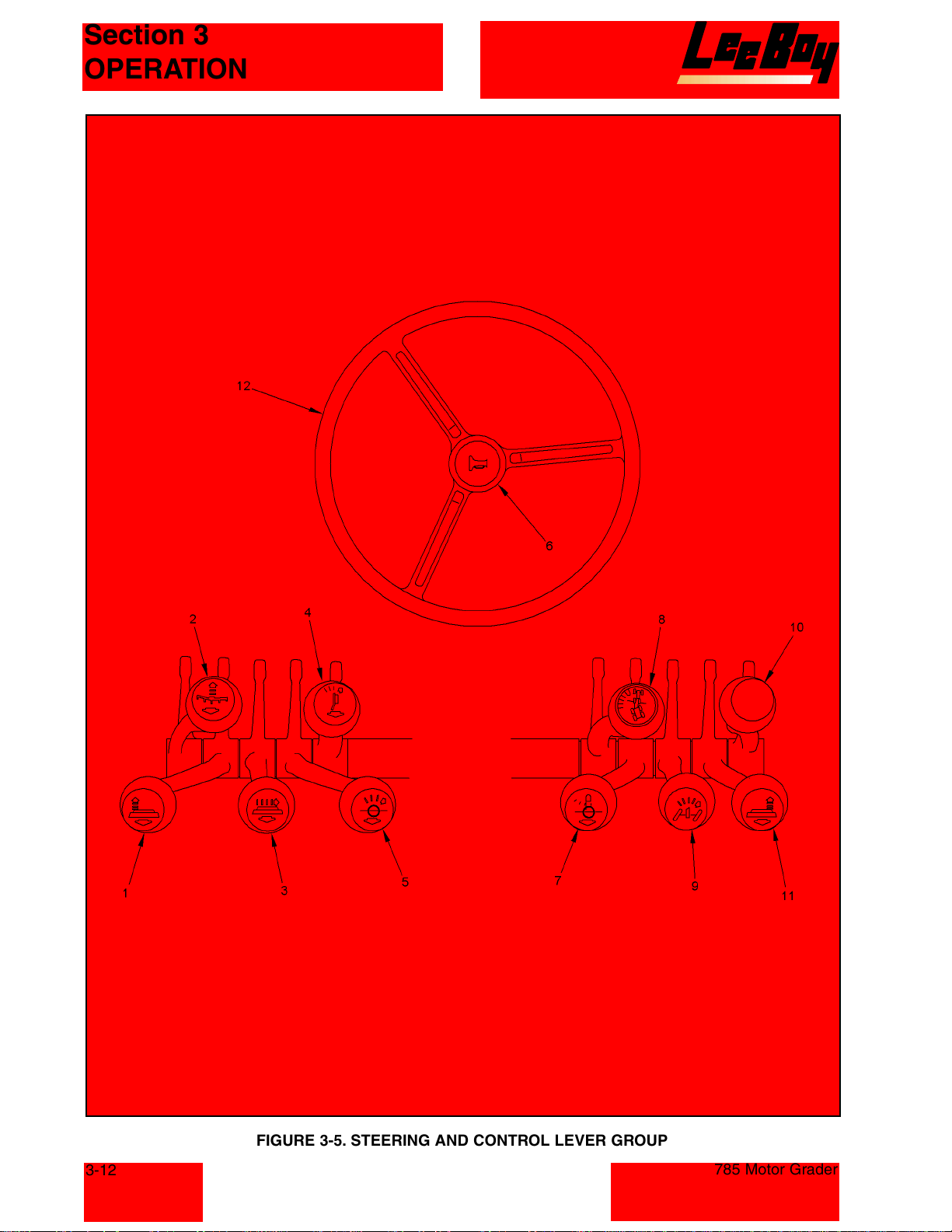

3-12

FIGURE 3-5. STEERING AND CONTROL LEVER GROUP

785 Motor Grader

Courtesy of Machine.Market

Loading...

Loading...