LED Neon Flex Profile 11D, Vivid S 270, Dynamic White 270, Vivid S 270 Pixel, Vivid S 270 RGB User Manual

Version 4.0

Prole 11D User Manual

For Products: Vivid S 270, Vivid S 270 Pixel, Vivid S 270 RGB, Dynamic White 270

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

INCORRECT INSTALLATION AND HANDLING CAN VOID YOUR WARRANTY.

Table of Contents

Unpacking 2-4

White Box 2

Rubber Roll 3

Spool & Unrolling Tray 4

Basic Specications 5

Safety/Warnings 6

Cutting Instructions 7

Snap Connector Assembly 8-13

Swivel Connector Assembly 14-16

RGB 18

Pixel 19-20

Dynamic White 21

Mounting Channels 22-26

Standard, Plastic, Spring Clip 22

Do’s & Don’ts 23-26

Troubleshooting 27

Limited Warranty 28

Appendix 29

Basic Wiring Diagrams 17-21

Static 17

E347880

For More Information

Toll Free: 1 (888) 580-6366

Or Visit www.GLLS.com /contact-us/

www.ledneonex.comwww.GLLS.com

Unpacking

White Box - Custom Fixtures 65ft (20m) Or Less

Use the extraction channel built into the plastic tray to unpack the xtures.

This channel ensures that there will be no improper bending or twisting and helps avoid excessive force

being applied to the internal components.

Gloves have been provided to avoid smudging the surface of the xtures.

DO NOT attempt to remove the xtures from the white plastic tray without using the channel.

2

www.ledneonex.comwww.GLLS.com

Unpacking

Rubber Roll - 164ft (50m) Lengths Of Fixture

It is easiest to unpack the xture with a second person.

1. Unpack all the contents and assemble the provided spindle.

2. Insert the spindle into the center of the spool.

3. Set the spool back into the box with the spindle supported on the edges.

4. Unroll the xture carefully, making sure not to twist it or use excessive force.

1. 2.

3. 4.

DO NOT

Do not wist the light while uncoiling it from the spool.

Do not uncoil the light without assembling the spindle

in the box.

Do not uncoil the light from the

bottom of the spool.

Do not pull on the light from a

distance.

3

www.ledneonex.comwww.GLLS.com

Unpacking

Spool & Unrolling Tray - 164ft (50m) Lengths Of Fixture

It is easiest to unpack the xture with a second person.

1. Unpack all the contents and place the unrolling tray on a at, even surface.

2. Place the spool on the rollers.

3. Unroll the xture carefully, making sure not to twist it or use excessive force. Cut with an anvil cutter.

4. Once necessary cuts have been made, secure the remaining xture to the spool with packing tape.

1. 2.

3.

4.

4

www.ledneonex.comwww.GLLS.com

General Specs

• Operating temperature: -4°F ~ 113°F (-20°C ~ 45°C) (High Voltage: -4°F ~ 95°F (-20°C ~ 35°C))

• Installation (bending) temperature: 32°F ~ 113°F (0°C ~ 45°C)

• For full details and specs please refer to the product’s Spec Sheet

0.63in

(16mm)

12 0 mm

1.14in

(29mm)

0.45in

(11.5mm)

01

Light Type 270° Prole

Max Run Length

Fixture Color Working Voltage Rtd Power Min. Cuting Unit Single Feed Double Feed

Vivid RGB RGB DC 24V CV 3.66W/ft (12W/m) 3.94in (100mm) Seamless: 22.97ft (7m) 45.93ft (14m)

(6 LEDs) Snap: 32.8ft (10m) 65.62ft (20m)

Vivid S R/A/O DC 24V CC 2.19W/ft (7.2W/m) 4.92in (125mm) 49.21ft (15m) 98.43ft (30m)

(10 LEDs)

G/B/W DC 24V CC 3.66W/ft (12W/m) 3.28in (83.3mm) 32.81ft (10m) 65.62ft (20m)

(6 LEDs)

R DC 24V CC 2.19W/ft (7.2W/m) 4.92in (125mm) 49.21ft (15m) 98.43ft (30m)

(10 LEDs)

G/B/Y574/ DC 24V CC 3.66W/ft (12W/m) 3.28in (83.3mm) 32.81ft (10m) 65.62ft (20m)

Y578/Y572 (6LEDs)

Dyn White WW + W DC 24V CC 3.66W/ft (12W/m) 3.28in (83.3mm) 32.81ft (10m) 65.62ft (20m)

(12 LEDs)

RGBW DC 24V CV 3.66W/ft (12W/m) 3.94in (100mm) 16.40ft (5m) 32.81ft (10m)

(6 LEDs)

Vivid Pixel RGB/R/G/ DC 24V CV 3.66W/ft (12W/m) 4.92in (125mm) 32.81ft (10m) 65.62ft (20m)

B/A/W (7 LEDs)

WW + W DC 24V CV 3.66W/ft (12W/m) 3.94in (100mm) 32.81ft (10m) 65.62ft (20m)

(12 LEDs)

RGBW DC 24V CV 4.57W/m (15W/m) 4.92in (125mm) 16.40ft (5m) 32.81ft (10m)

(7 LEDs)

4.72 inch

01| 02

5

www.ledneonex.comwww.GLLS.com

Safety/Warnings

• Before making any cuts, installation,

maintenance or connection, be sure the xture is

disconnected!

• Note: all connectors must be assembled correctly

to achieve IP67 rating.

• Fixture’s rated voltage must match that of the

power supply.

• Power supply must be constant voltage.

• Incorrectly cutting this product will damage the

xture.

• Do not power the light for over 30 minutes in coil

packaging.

• Do not bend past the minimum diameter (Fig. 1)

or twist this xture (Fig. 3, 5). Doing so will result

in damaging the internal circuit board.

• Do not bend the xture in the opposite direction

of its specied bending direction (Fig. 2, 4).

Doing so will damage the internal circuit board.

Correct

Fig. 1

Fig. 2

Incorrect

• Do not operate all channels of color changing

xtures simultaneously at full capacity for

extended periods of time.

• Do not put undue stress or pull excessively on

the cables or injection connectors. This can cause

the connectors to detach or fail. (see page 24-27)

• To extend the life of your xtures, do not operate

lights in daylight temperatures exceeding 140°F

(60°C). Doing so will decrease the lifespan of the

LEDs.

Fig. 3

Fig. 4

Fig. 5

6

www.ledneonex.comwww.GLLS.com

Cutting Instructions

Note:

1. Place the light horizontally when cutting it.

2. Use only factory-recommended cutter.

3. Cut the light according to the following

instructions. Incorrect cutting & operation will

damage the circuitry.

Correct

Incorrect

DO NOT CUT ON AN ANGLE.

7

www.ledneonex.comwww.GLLS.com

Snap Connector & End Cap Assembly

IP67 when assembled correctly.

Snap Connector Snap End Cap

Expanded View

Expanded View

Finished Assembly

Finished Assembly

Before Beginning:

Always select the correct connector for the

end of the light. Connectors are marked with

an 01 and 02 and correspond with the printed

numbers on the xture.

01 | Components of Snap Connector/ End Cap

02 End

Grip Plate (1pc)

Lead Connector (1pc)

[Contains Silicone Gasket

(1pc)]

Compression Clip (1pc) Snap Cover (1pc)

01 End

End Fitting (1pc)

[Contains Silicone Gasket

(1pc)]

02 | Tools

Expanding Tool

8

www.ledneonex.comwww.GLLS.com

Snap Connector & End Cap Assembly

03 | Installation Steps

03.1 | Placing Snap Cover

When placing snap cover, be sure to pay

attention to the direction marked on the

bottom.

The snap end of the cover points towards

the assembly end.

Fig. 1: directions printed on the under side

of the snap cover.

03.2 | Creating a gap for Lead Connector/

End Fitting

Insert the expanding tool behind the PCB.

Move the tool up and down 3 to 5 times

gently to create a small gap.

NEVER insert the expanding tool into the

front side (LED side) of the PCB.

Assembly End

Fig. 1

Snap End of

Snap Cover

Expanding Tool

Placement

PCB

Rear End of

Snap Cover

PVC Tape

Inserting the expanding tool into the

front side of PCB will damage the light

9

www.ledneonex.comwww.GLLS.com

Snap Connector & End Cap Assembly

03.3 | Inserting the Lead Connector/End

Fitting

Carefully insert the pins of the lead

connector/end tting into the gap you

created behind the PCB (Fig. 1).

There should be a space of 0.125in

to 0.25in (2-5mm) between the lead

connector/end tting and the light xture

when properly installed.

DO NOT insert the pins into the front side

of the PCB. (Fig2)

DO NOT split the pins around the PCB

(Fig.3).

0.125-0.25in (2-5mm)

Fig. 2

Snap Connector

Fig. 1

Fig. 3

0.125-0.25in (2-5mm)

Fig. 2

Snap End Cap

Fig. 1

Fig. 3

10

www.ledneonex.comwww.GLLS.com

Snap Connector & End Cap Assembly

03.4 | Preparing theGrip Plate

Unfold the grip plate about 20 degrees on

both sides.

03.5 | Installing the Grip Plate

Place the grip plate onto the assembly

end of the light. Make sure it is facing the

correct way with the extending metal tab

sticking out from the assembly end and

the side edges ush with the cut edge of

the xture.

Make sure the plate is snug to the xture.

Snap Connector

Snap End Cap

11

www.ledneonex.comwww.GLLS.com

Snap Connector & End Cap Assembly

03.6 | Compression clip and Snap Cover

Installation

Align the lead conector and grip plate with

the compression clip (Fig. 4).

Apply even pressure to the lead connector

and light xture, pressing them into the

compression clips until they are sitting

ush along the bottom of the clip with no

gaps. This will pull the xture tight to the

lead connector (Fig. 5).

Snap Connector

Fig. 4

Fig. 5

Snap End Cap

Fig. 4

Fig. 5

12

www.ledneonex.comwww.GLLS.com

Snap Connector & End Cap Assembly

03.6 | Compression clip and Snap Cover

Installation

Slide the snap Cover back towards the lead

connector until you hear it snap into place

(Fig. 6).

Power your xture to ensure that it is working

properly.

Snap Connector

Fig. 6

Snap End Cap

Fig. 6

13

www.ledneonex.comwww.GLLS.com

Swivel Connector & End Cap Assembly

IP20 when assembled correctly.

Swivel Connector

Expanded View

Finished Assembly

Before Beginning:

Always select the correct connector for the

end of the light. Connectors are marked with

an 01 and 02 and correspond with the printed

numbers on the xture.

02 End

Swivel End Cap

Expanded View

Finished Assembly

01 End

01 | Components of Swivel Connector/ End Cap

02 | Tools

Lead Connector (1pc)

Expanding Tool

End Fitting (1pc)

14

www.ledneonex.comwww.GLLS.com

Swivel Connector & End Cap Assembly

03 | Installation Steps

03.1 | Creating a gap for the Lead Connector

Insert the expanding tool behind the PCB.

Move the tool up and down 3 to 5 times

gently to create a small gap.

NEVER insert the expanding tool into the

front side (LED side) of the PCB.

Expanding Tool

Placement

PVC Tape

PCB

Inserting the expanding tool into the

front side of PCB will damage the light

03.2 | Inserting the Lead Connector

Rotate the steel plate so it is aligned

straight with the pin connector (Fig. 1).

Carefully insert the pins of the lead

connector into the gap you created behind

the PCB (Fig. 2).

DO NOT insert the pins into the front side

of the PCB. (Fig3)

DO NOT split the pins around the PCB

(Fig.4).

Swivel Connector

Fig. 3

Fig. 2Fig. 1

Fig. 4

15

www.ledneonex.comwww.GLLS.com

Swivel Connector & End Cap Assembly

03.3 | Rotate the steel plate up on to the bottom

of the xture. Make sure the bottom of the

xture is ush with the bottom of the steel

plate.

03.4 | Installing the Swivel End Cap

Rotate the steel plate 90 degrees so it is

aligned with the face of the end cap.

Line up the end tting with the end of the

xture. Press them together and swing the

steel plate into place.

Make sure the bottom of the xture is ush

with the bottom of the steel plate.

Power your xture to ensure that it is working

properly.

16

www.ledneonex.comwww.GLLS.com

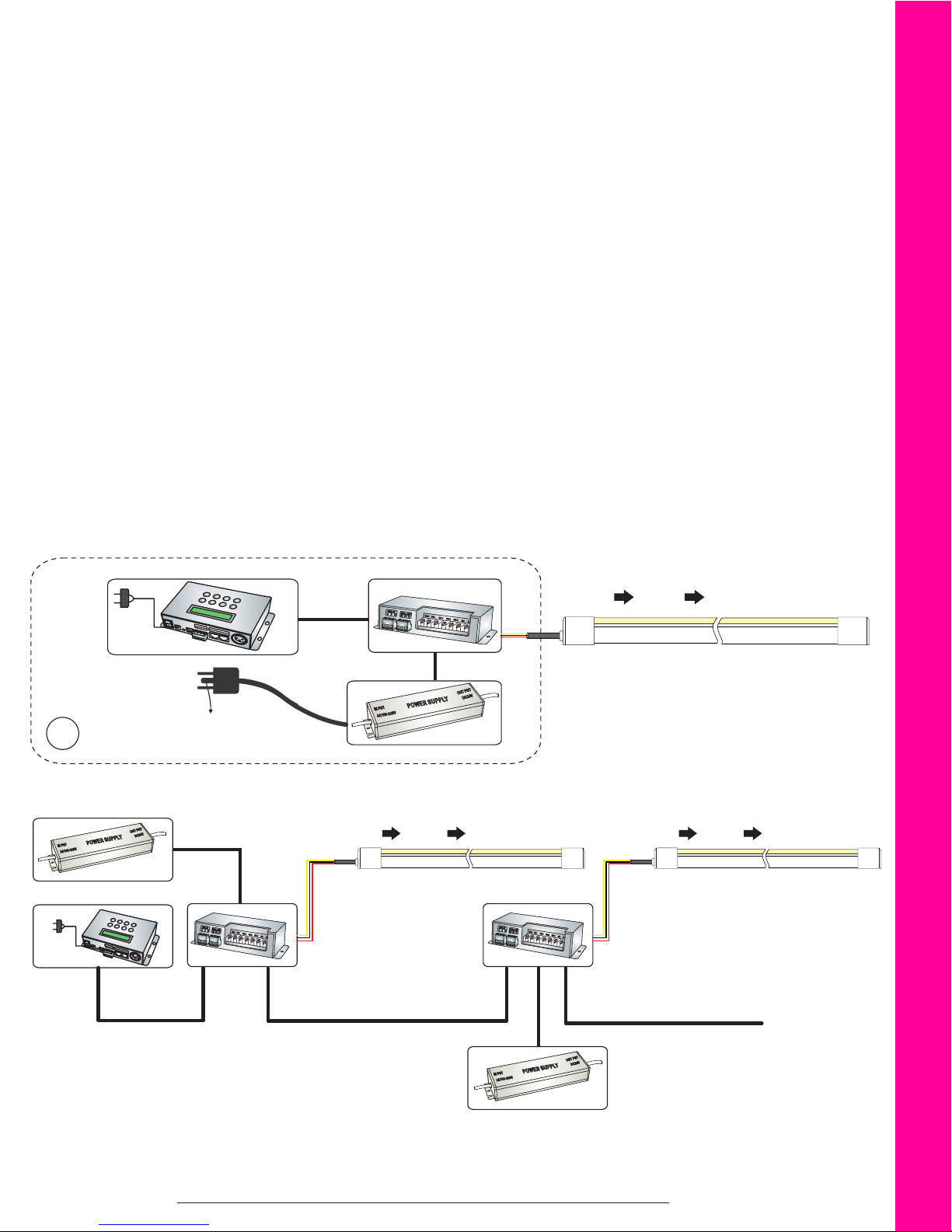

General Wiring Diagrams

Vivid S Wiring

• This LED Neon Flex Fixture is only compatible with a 24V power supply.

• Always observe proper polarity.

• Always add an additional 20% to the maximum load when sizing the power supply.

• Ensure that the power cable drawing current is no more than 80% of its current capacity.

• To minimize the voltage drop and maintain light consistency, do not use excessive lengths of wire

between the power supply and light xture.

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

GND

A1

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

GND

A2

Max Continuous length

Driver

Driver

Dimmer(Optional)

(Compatible with most 0~10V

dimming controllers.)

Dimmer(Optional)

(Compatible with most 0~10V

dimming controllers.)

Instructions for Wiring:

Red Wire Connects to Anode(+)

Black Wire Connects to Cathode(-)

The power supply can drive one length or

①

dierent lengths within allowed maximum

length by feeding light one end.

The power supply can drive one length or

②

dierent lengths within allowed maximum

length by feeding light both ends.

Product Number Color Single Feed Double Feed

NF-11D-T-01-2W-E-XXX-24DC Red/Amber 32.81ft (10m) 65.62ft (20m)

NF-11D-T-01-2W-E-XXX-24DC Green/Blue/White 49.21ft (15m) 98.43ft (30m)

17

www.ledneonex.comwww.GLLS.com

General Wiring Diagrams

Vivid RGB Wiring

• This LED Neon Flex Fixture is only compatible with a 24V power supply.

• Always observe proper polarity.

• Always add an additional 20% to the maximum load when sizing the power supply.

• Ensure that the power cable drawing current is no more than 80% of its current capacity.

• To minimize the voltage drop and maintain light consistency, do not use excessive lengths of wire

between the power supply and light xture.

• Accepts PWM input. Compatible with DMX decoders.

• Accepts PWM input. Compatible with DMX decoders.

Instructions for Wiring Vivid RGB:

Yellow Wire Connects to Anode(+).

Red Wire Connects to the“R”Terminal, Cathode(-).

Green Wire Connects to the “G”Terminal, Cathode(-).

Blue Wire Connects to the“B”Terminal, Cathode(-).

GND

B1

GND

B2

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

Driver

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

Driver

RGB Controller

RGB Controller

①

The RGB light can be powered on by connecting one end to the controller. It can be

dierent lengths or combined with other

connectors, but each length must not exceed

10m and the combined lengths cannot overload the controller.

The RGB light can be powered on by connect-

②

ing both ends to the controller within allowed

maximum 20m.

Max Continuous length

Product Number Single Feed Double Feed

NF-11D-T-01-4W-E-XXX-24DC Seamless: 22.97ft (7m) 45.93ft (14m)

Snap: 32.81ft (10m) 65.62ft (20m)

18

www.ledneonex.comwww.GLLS.com

General Wiring Diagrams

Vivid Pixel Wiring

• This LED Neon Flex Fixture must be operated with a 24V power supply and IC-UCS2903 compatible

controller or decoder.

• Polarity symbols, GND, signal line connection should match on each component properly.

• Always add an additional 20% to the maximum load when sizing the power supply.

• Ensure that the power cable drawing current is no more than 80% of its current capacity.

• To minimize the voltage drop and maintain light consistency, do not use excessive lengths of wire

between the power supply and light xture.

• Accepts PWM input. Compatible with DMX decoders.

• Vivid Pixel is one directional. The signal input direction is always indicated by an arrow marked on

the side of light.

Instructions for Wiring Vivid Pixel:

Red Wire Connects to the“VCC”or Anode(+) Terminal

Yellow Wire Connects to the “Signal”Terminal.

Black Wire Connects to the“GND”or Cathode(-) Terminal

DMX ControllerDMX Decoder

①

POWER

ON

/OFF

LED CO

N

TROLLER

DC V1

2

DM

X

OUT

A B G G

DMX OUT

A B N N N N G G

DMX OUT

Signal

C1

DMX Controller

P

O

W

E

R

O

N

/

O

F

F

LE

D

D

C

O

NTROL

C

V

L

1

E

2

R

DMX OUT

A B G G

DM

X O

A B N N N N G G

U

T

DMX OUT

DMX Output

GND

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

DMX Decoder

DMX Input

DMX Output DMX InputDMX Output

Signal

Signal

DMX Decoder

19

www.ledneonex.comwww.GLLS.com

INPU

50-60H

③

General Wiring Diagrams

Vivid Pixel Wiring

INPUT:AC100~240VA C,

50-60Hz OUTPUT:DC24V

IC-UCS2903 Compatible

Controller

Vivid Pixel can be powered on by connecting one

end to the controller. It can be dierent lengths or

combined with other connectors, but each length

must not exceed 15m and the combined lengths

cannot overload controller.

GND

GND

INPUT:AC100~240VA C,

50-60Hz OUTPUT:DC24V

IC-UCS2903 Compatible

Controller

INPUT:AC100~240VA C,50-60Hz

OUTPUT:DC24V

Signal

INPUT:AC100~240VA C,50-60Hz

OUTPUT:DC24V

Signal

Red and Black Wire

Power Feed Only

Vivid Pixel can be powered on by

connecting both ends to the controller

within allowed maximum 30m.

INPUT:AC100~240VA C,50-60Hz

OUTPUT:DC24V

T:AC100~240VA C,

z OUTPUT:DC24V

IC-UCS 2903 Compatible

Controller

Signal

Vivid Pixel can be powered on by series connecting to the controller within allowed maximum length.

Max Continuous length

Product Number Single Feed Double Feed

NF-11D-T-01-3W-E-XXX-24DC 32.81ft (10m) 65.62ft (20m)

Signal

Use power T-Fe ed connector

20

www.ledneonex.comwww.GLLS.com

General Wiring Diagrams

Dynamic White Wiring

• This LED Neon Flex Fixture is only compatible with a 24V power supply.

• Always observe proper polarity.

• Always add an additional 20% to the maximum load when sizing the power supply.

• Ensure that the power cable drawing current is no more than 80% of its current capacity.

• To minimize the voltage drop and maintain light consistency, do not use excessive lengths of wire

between the power supply and light xture.

• Accepts PWM input. Compatible with DMX decoders.

Instructions for Dynamic White Wiring:

Red Wire Connects to Anode(+).

Yellow Wire Connects to Low Color Temperature Connection, Cathode(-).

Black Wire Connects to High Color Temperature Connection, Cathode(-).

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

GND

B1

GND

B2

INPUT:AC100~240VAC,50-60Hz

OUTPUT:DC24V

Driver

Driver

Max Continuous length

Color T emperature Controller

Color T emperature Controller

①

The Dynamic White light can be powered on

by connecting one end to the controller. It can

be dierent lengths or combined with other

connectors, but each length must not exceed

10m and the combined lengths cannot overload the controller.

The Dynamic White light can be powered on

②

by connecting both ends to the controller

within allowed maximum 20m.

Product Number Single Feed Double Feed

NF-11D-T-01-3W-E-XXX-24DC 32.81ft (10m) 65.62ft (20m)

21

www.ledneonex.comwww.GLLS.com

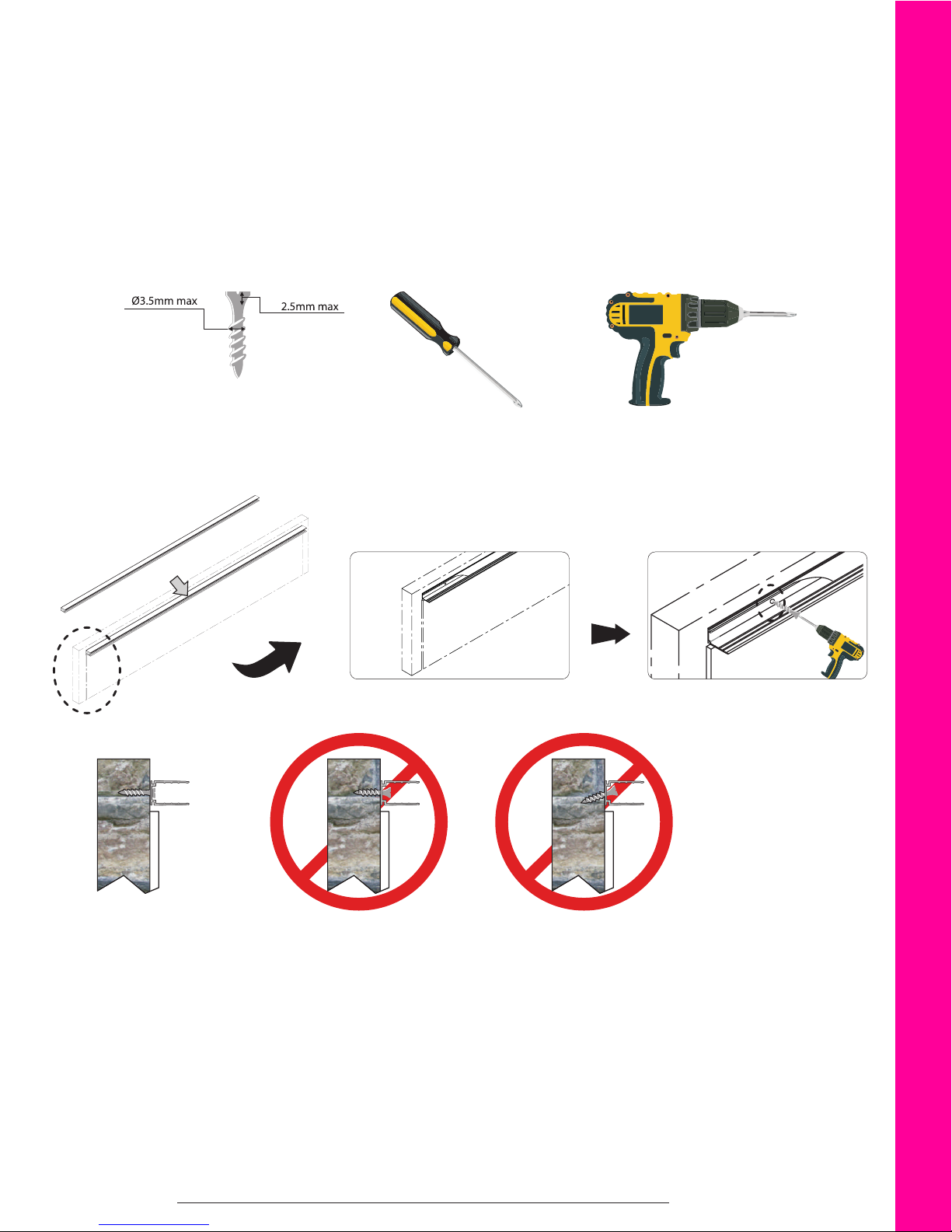

Mounting Channels

Standard, Plastic, & Spring Clip Channel

Tools for Installation

Screw Screwdriver Drill

Correct Installation of Standard Aluminum Channel

Screw into position and

ensure the screw head is

ush with the lower base

of the aluminum prole.

Screw head not ush. Screw at an angle.

22

www.ledneonex.comwww.GLLS.com

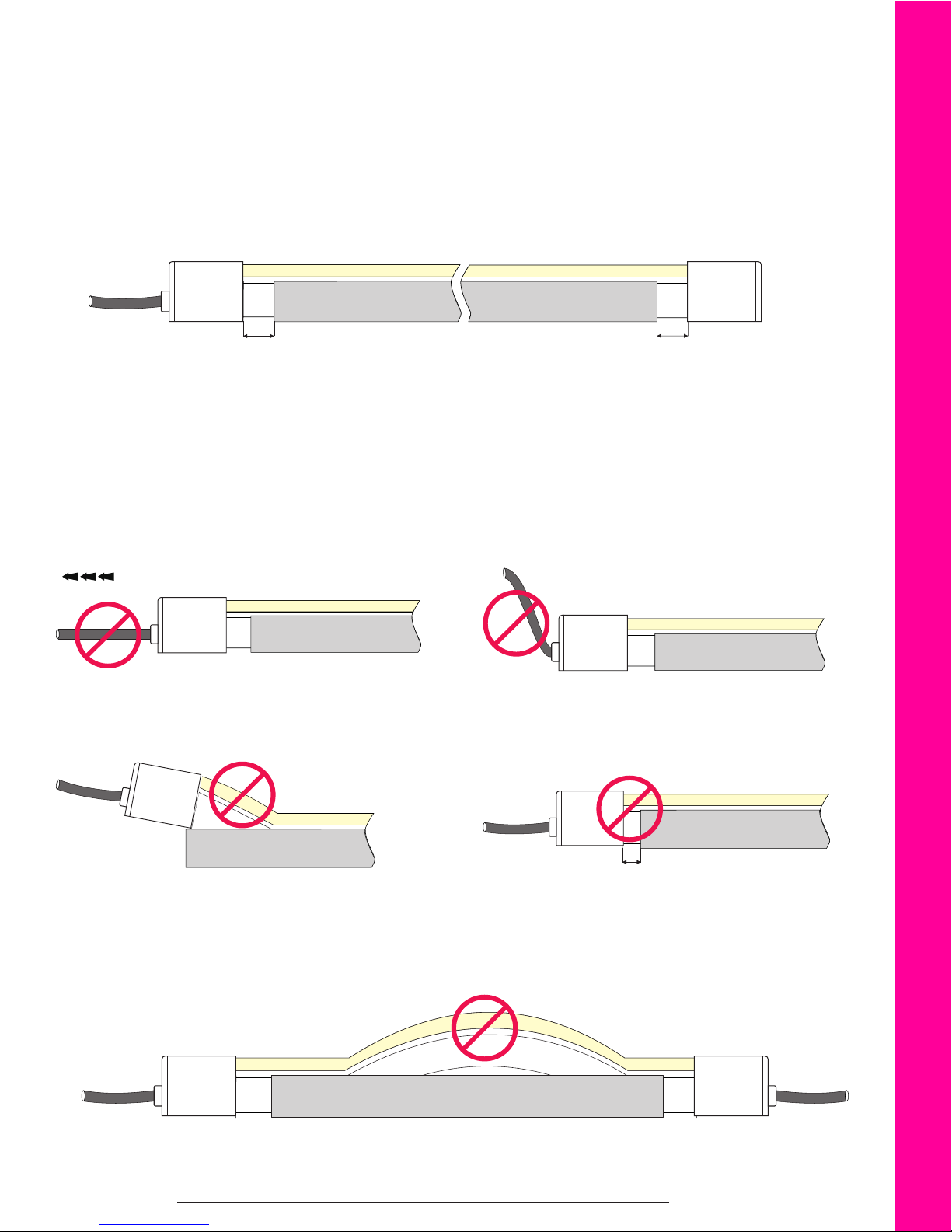

Mounting Channels

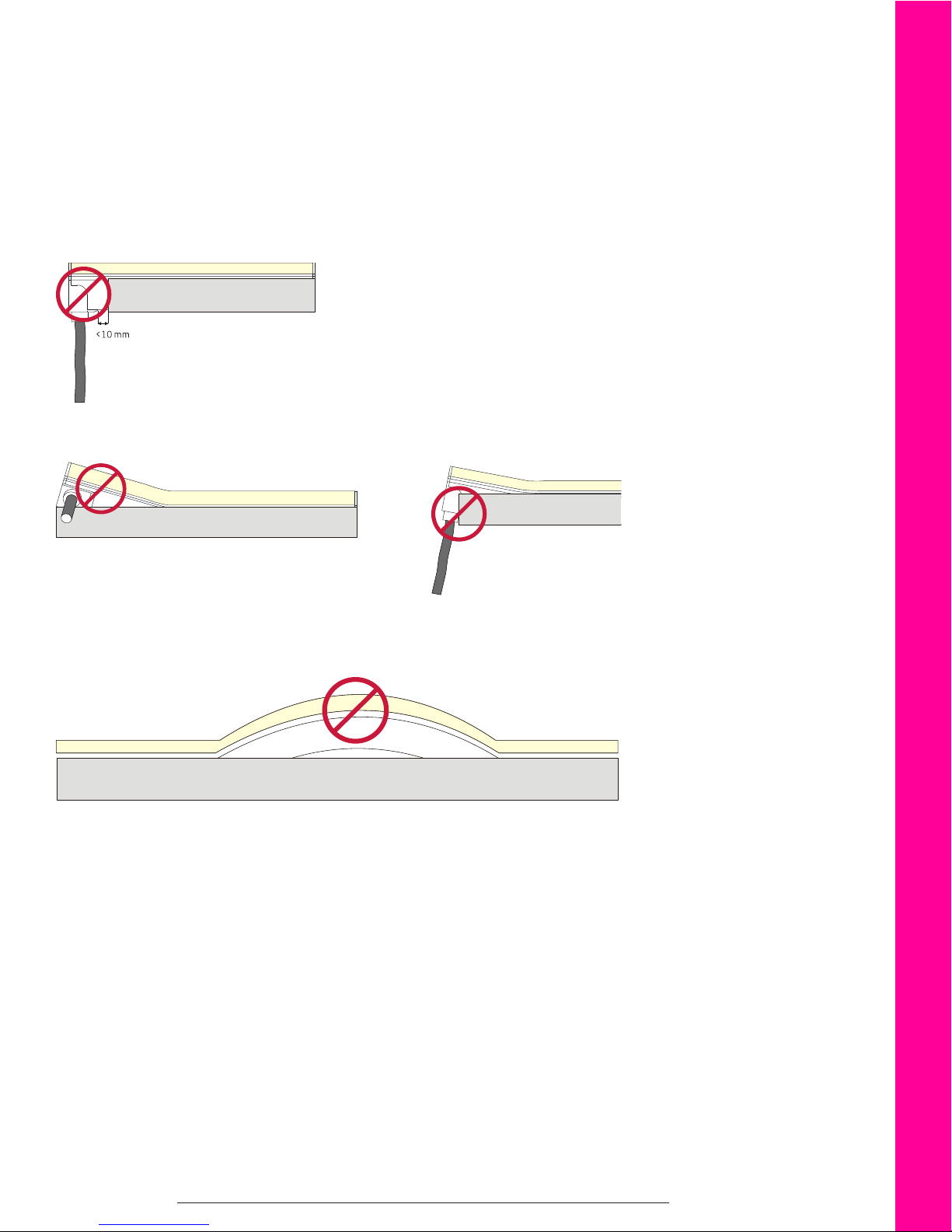

Mounting Channel Do’s and Don’ts

Snap, Swivel & Submersible Connectors and Ends

Do not put undue stress on the cables or connectors.

Leave a space of 0.4 to 0.8in (10 to 20mm) between the end of the channel and the connector.

Incorrect Instalation Methods

Do not put undue stress on the cables or connectors. Do not curl or pull the cable with excessive force.

Do not bend the xture at a sharp angle during installation. Do not leave a space smaller than 0.4in (10mm) between the

connector and the channel.

To avoid warping in the center, only install the xture from one end to the other.

23

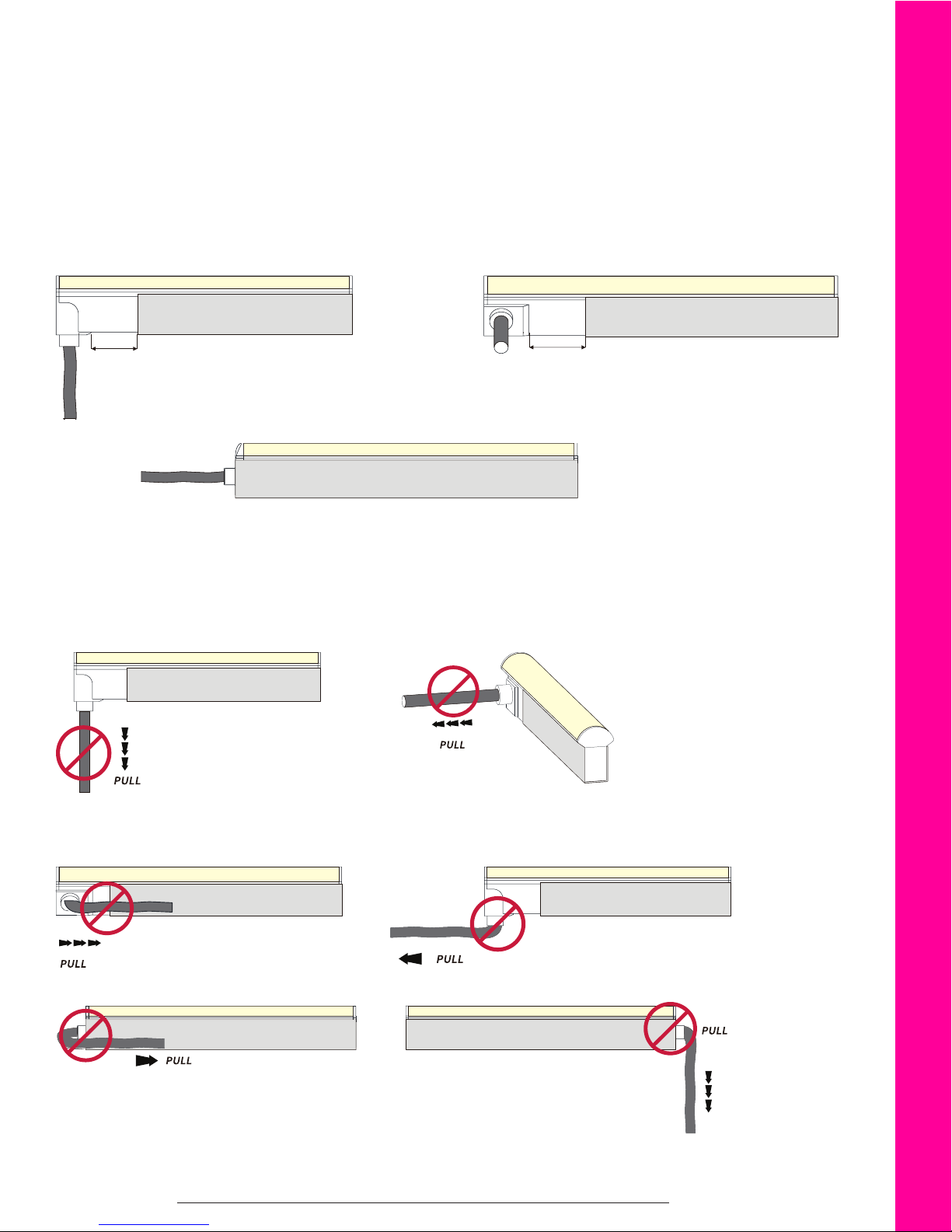

www.ledneonex.comwww.GLLS.com

Mounting Channels

Mounting Channel Do’s and Don’ts

Seamless Connectors and Ends

Do not put undue stress on the cables or connectors.

Leave a space of 0.4 to 0.8in (10 to 20mm) between the end of the channel and the Side or Bottom Exit connector.

For End Exit connectors, make sure the end of the xture is ush with the channel.

Incorrect Instalation Methods

Do not put undue stress on the cables or connectors.

Do not curl or pull the cable with excessive force.

24

www.ledneonex.comwww.GLLS.com

Mounting Channels

Mounting Channel Do’s and Don’ts

Seamless Connectors and Ends (cont)

Do not leave a space smaller than 0.4in (10mm) between the connector and the channel.

Do not force the connectors to t into the mounting channel.

To avoid warping in the center, only install the xture from one end to the other.

25

www.ledneonex.comwww.GLLS.com

01

0

2

Mounting Channels

Mounting Channel Do’s and Don’ts

Correct Bending During Installation

When pressing the xture into the channel, do not bend the xture at an angle greater than 15 degrees.

Avoid bending the light at the rst cutting unit. Do not push the xture to bend smaller than the minimum

bending diameter.

1uni t

<1uni t

01

02

1uni t

The min.be nd diam eter

02

01

The min.be nddiame te r

26

www.ledneonex.comwww.GLLS.com

Troubleshooting

Entire xture doesn’t work.

• Check that the power supply is plugged in, switched on and receiving power.

• Check all light, dimmer or controller connections, connecting from the power supply to the xture.

• Check polarity of all wire connections.

• Make sure power supply output voltage is 24V DC.

• Ensure connector pins are inserted into back side of PCB and properly assembled.

• Make sure your power supply is CV (constant voltage).

Light appears dim or dull at one end.

• Make sure the voltage of the power supply is not lower than that of the light.

• Adjust the dimming level to maximum.

• Attach a lead wire to both ends of the xture shorten xture length to prevent voltage drop.

Light appears excessively bright / is hot to the touch.

• Make sure the voltage of the power supply is not higher than that of the light.

If the rst segment doesn’t work.

• Make sure unit s properly cut. If it has been cut wrong, remove the rst segment, cutting it o properly.

• Check for damage done to the rst LED from improper installation of the connector. If damage has been done, cut out the

rst segment and properly assemble the connector.

• Water ingress due to improper connector assembly could cause a short in the rst segment. Replace length with a new

one.

• External impact damage inside LEDs. Only use your hands to install LED Neon Flex into aluminum prole.

Light is ashing on and o.

• Check the power supply to ensure it supports the length you are using. Select the appropriate strength or install an

additional power supply to support your installation.

• Check that the power supply output voltage is stable.

• Check that front connector is properly installed with good contact with the copper PCB.

• Check that the proper controller is connected.

For more information, and troubleshooting, please refer to our Knowledge Base at www.glls.com/knowledge-base/

27

www.ledneonex.comwww.GLLS.com

3 or 5 Year Limited Warranty

Green LED Lighting Solutions (GLLS) provides a standard 3 year (36-month) limited warranty for “LED Neon Flex Vivid” products

manufactured with PVC encapsulations from the date of purchase to the original buyer. GLLS also provides a 5 year (60-month)

limited warranty for certain “LED Neon Flex Vivid” products when manufactured with Silicone encapsulations from the date of

purchase to the original buyer. This limited warranty covers manufacturer defects in the material and workmanship, only on the faulty

section of the LED Neon Flex Vivid light. Replacement is provided only on the defective section of the LED Neon Flex Vivid light as dened

by its cutting marks. The owner(s) will need to provide proof of purchase at the time of exchange.This Limited Warranty is valid only when

LED Neon Flex Vivid lights are used together with LED Neon FlexVivid approved power supplies, controllers and dimmers for their intended

purpose and are properly installed and wired in accordance with all instructions, building codes, the latest UL Standards of Safety, NEC, CSA

or any other domestic or international safety agencies.

Standard 3 year limited warranty applies to connectors as well. The 5 year limited warranty on Silicone xtures will apply to the connectors

as well.

Warranty Terms and Conditions

Exclusions

GLLS will not cover damage by abuse, misuse, curvature past the recommended bend radius, punctures, cuts, shortening or splicing outside

of the designated cutting marks, disregard for proper cleaning, faulty installation, improper maintenance, including forfeiting the use of a

surge protector, or any repairs not carried out by certied LED lighting professionals.

Items not covered by this warranty are those considered as parts which are prone to failure due to normal wear and tear.

GLLS’ warranty does not cover any ancillary costs of warranty such as, but not limited to, equipment costs, labor, permits, removal, or

reinstallation. GLLS’ warranty is a parts only warranty.

Shipping Conditions

All shipping charges should be pre-paid before delivery. If the requested replacement of service is within the terms of the warranty, the item

will be returned to the purchaser postage paid. Any shipping damage due to carrier mishandling or improper packaging is the responsibility

of the sender. If the product is not within the terms of the warranty GLLS will advise the purchaser of the price of replacement and ship it to

the purchaser upon receipt of payment including shipping charges. Please allow 2-4 weeks for return of product. GLLS takes great pride in

our products and our customer service and we try to satisfy each situation within the same business day. We cannot be held responsible for

shipping delays.

To Obtain Warranty Service

If an LED Neon Flex Vivid S product fails under this warranty, please contact a customer service agent at GLLS www.glls.com or 1-888-850-

NEON (6366). GLLS will replace the product at its own discretion, once verication of the defective product is determined. GLLS’s liability on

any claim shall never exceed the purchase price of the specic product.

Exchanges

All exchanges for products will be honored only after the product has been received by the GLLS warehouse or sales oce. The returning

product will be inspected by the warehouse or sales sta and will be deemed acceptable or not acceptable. If deemed acceptable, the

exchanged product will be shipped to the purchaser. All returns judged not acceptable will receive no refund and will not be returned to the

purchaser until the purchaser has paid the return shipping costs.

Shipping on Exchanges

Shipping costs on exchanges will be judged on extenuating circumstances from the original purchase and assessed by the warehouse or

sales sta.

28

www.ledneonex.comwww.GLLS.com

Appendix

Correlated Color Temperature (CCT)

ANSI Standard

Nominal CCT Categories

Nominal CCT Target CCT and tolerance (K) Target Duv and tolerance

2700K 2725 ± 145 0.000 ± 0.006

3000K 3045 ± 175 0.000 ± 0.006

Remark:

1. Six of the nominal CCTs correspond to those in the uorescent

lamp specication 2700K, 3000K (Warm White), 4100K (Cool

White), 5000K and 6500K (Daylight), respectively.

2. ΔT is given by ΔT=0.0000108xT2+0.0262xT+8.

3. Duv is given by Duv=57700x(1/T)2-44.6x(1/T)+0.0085.

3500K 3465 ± 245 0.000 ± 0.006

4000K 3985 ± 275 0.001 ± 0.006

4500K 4503 ± 243 0.001 ± 0.006

5000K 5028 ± 283 0.002 ± 0.006

5700K 5665 ± 355 0.002 ± 0.006

6500K 6530 ± 510 0.003 ± 0.006

Flexible CCT T2) + Δ T3) DUVT4) ± 0.006

(2700-6500K)

Recomended Lead Wire Length According to Power Consumption

Note: 1. Follow the parameters in the below chart, lead wires longer than the specied lengths will create voltage drop and eventually aect the lumen output of light.

2. The 0.3m lead wire is not included in this chart.

3. Lead wire length over 10m is NOT recommended unless under special circumstances, especially for adressable lights.

Total Watts 22AWG/0.34mm² 20AWG/0.53mm² 18AWG/0.82mm² 17AWG/1.04mm² 16AWG/1.38mm² 14AWG/2.07mm² 12AWG/3.29mm² 10AWG/5.62mm²

10W 118.11ft (36m) 196.85ft (60m) 328.08ft (100m) 393.70ft (120m) 459.32ft (140m) 787.40ft (240m) 1312.34ft (400m) 1968.5ft (600m)

20W 59.06ft (18m) 98.43ft (30m) 164.04ft (50m) 196.85ft (60m) 229.66ft (70m) 393.70ft (120m) 656.17ft (200m) 984.25ft (300m)

30W 39.37ft (12m) 65.62ft (20m) 98.43ft (30m) 124.67ft (38m) 147.64ft (45m) 262.47ft (80m) 426.51ft (130m) 656.17ft (200m)

40W 26.25ft (8m) 49.21ft (15m) 72.18ft (22m) 91.86ft (28m) 114.83ft (35m) 196.85ft (60m) 311.68ft (95m) 459.32ft (140m)

50W 19.69ft (6m) 39.37ft (12m) 59.06ft (18m) 72.18ft (22m) 91.86ft (28m) 157.48ft (48m) 246.06ft (75m) 344.49ft (105m)

60W 16.40ft (5m) 32.81ft (10m) 49.21ft (15m) 59.06ft (18m) 72.18ft (22m) 118.11ft (36m) 196.85ft (60m) 288.71ft (88m)

70W / 26.25ft (8m) 39.37ft (12m) 45.93ft (14m) 59.06ft (18m) 98.43ft (30m) 164.04ft (50m) 236.22ft (72m)

80W / 19.69ft (6m) 32.81ft (10m) 36.09ft (11m) 45.93ft (14m) 78.74ft (24m) 131.23ft (40m) 190.29ft (58m)

90W / 13.12ft (4m) 22.97ft (7m) 26.25ft (8m) 32.81ft (10m) 59.06ft (18m) 98.42ft (30m) 147.64ft (45m)

100W / / 16.40ft (5m) 19.69ft (6m) 22.97ft (7m) 39.37ft (12m) 72.18ft (22m) 104.99ft (32m)

110W / / 9.84ft (3m) 13.12ft (4m) 16.40ft (5m) 26.25ft (8m) 49.21ft (15m) 72.18ft (22m)

120W / / 6.56ft (2m) 8.20ft (2.5m) 9.84ft (3m) / 26.25ft (8m) 39.37ft (12m)

Loading Chart

Power 35W 60W 100W 120W 150W 150W 180W 240W 320W

7.2W Length 16.40ft (5m) 24.61ft (7.5m) 39.37ft (12m) 49.21ft (15m) / 60.70ft (18.5m) 72.18ft (22m) 98.43ft (30m) /

12W Length 8.20ft (2.5m) 14.76ft (4.5m) 24.61ft (12m) 29.53ft (9m) 32.81ft (10m) / 44.29ft (13.5m) 59.06ft (18m) 65.62ft (20m)

Connections Single Double

29

www.ledneonex.comwww.GLLS.com

Loading...

Loading...