Ledco premier 4 series Diagnostic Manual

Page 1

LEDCO PREMIER 4 SERIES LAMINATOR

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

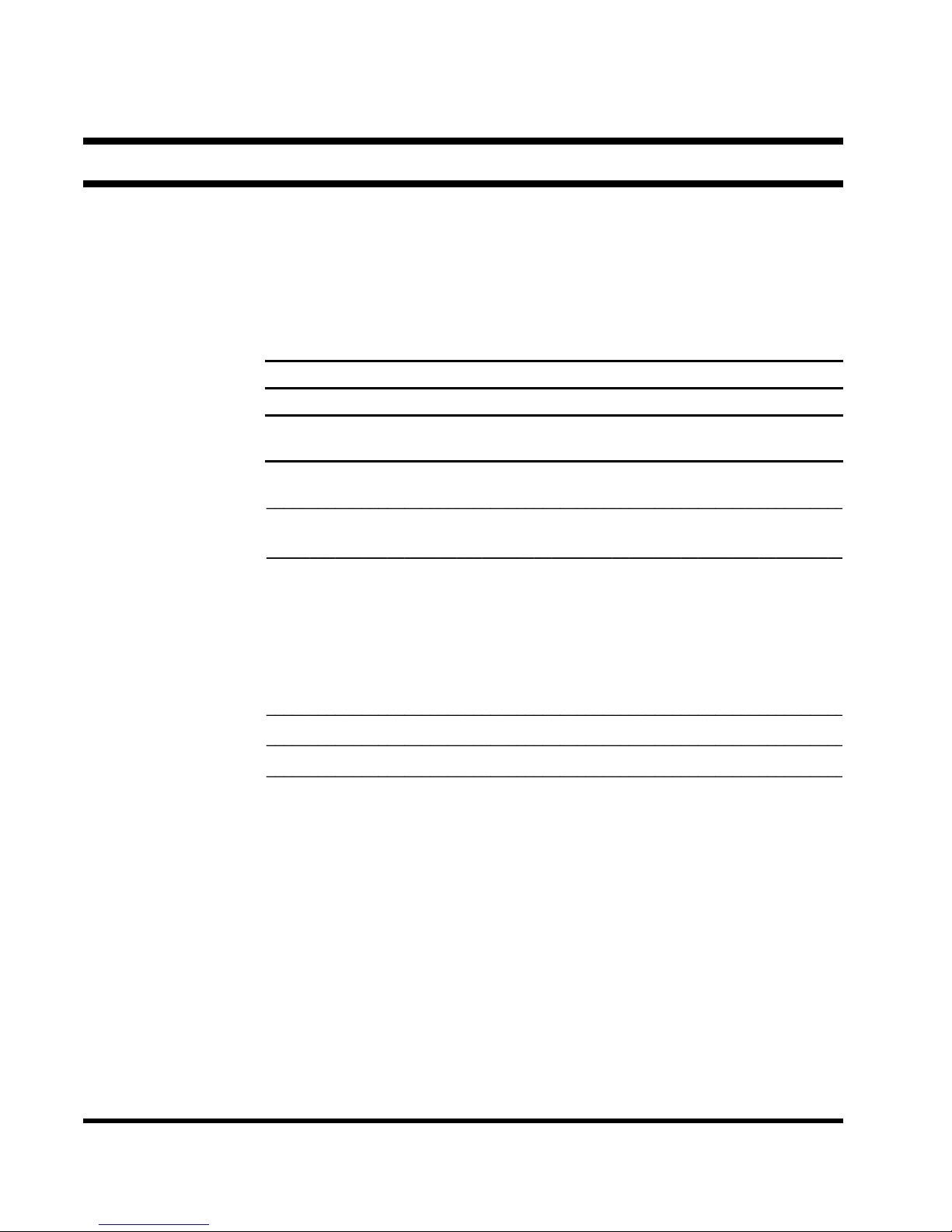

PROBLEM DIAGNOSTIC CHARTS

Procedure Skill

Problem Possible Cause Repair Procedure Number Level

Laminator will not No power Check power cord 1 *

heat up,heat switch does Check heat switch position 2 *

not illuminate (red) when Check heat control fuse 4 *

engaged Check for wires that are 5 **

disconnected, broken or

shorting out

Heat switch failure Check heat switch 6 **

Heater failure Check heaters 7 **

Heat sensor failure Check heat sensor 8 ***

Heat control board Check specific heat control 12 ***

transformer failure board terminals

Heat control board Check heat control 13 ***

relay coil failure board heat sensor terminals

Heat control board relay Check heat control board 14 ***

switch failure relay switch terminals

Heat switch illuminates, Ribbon cable wires to Re-connect plastic wire 5 **

but digital display does display disconnected, harness to the back of

not loose or broken digital display

Re-connect plastic wire 9 ***

harness to heat control

circuit board inside the

machine

Digital display failure Replace digital display 10 **

Ribbon cable failure Replace ribbon cable 11 ***

Heat switch does not Heat sensor wires Check heat sensor wires 5 *

illuminate when disconnected or loose

engaged,digital display

shows three dashes

( - - - )

Heat sensor failure Replace heat sensor 15 **

Ribbon cable failure Replace ribbon cable 11 ***

Heat control board failure Check specific terminals 13,14 ***

at specific terminals on heat control board

Heat control board failure Replace heat control board 16 ***

Skill Level Index: * Basic,End-User ** Intermediate or Dealer *** Advanced or Servicing Dealer/Technician

Page 2

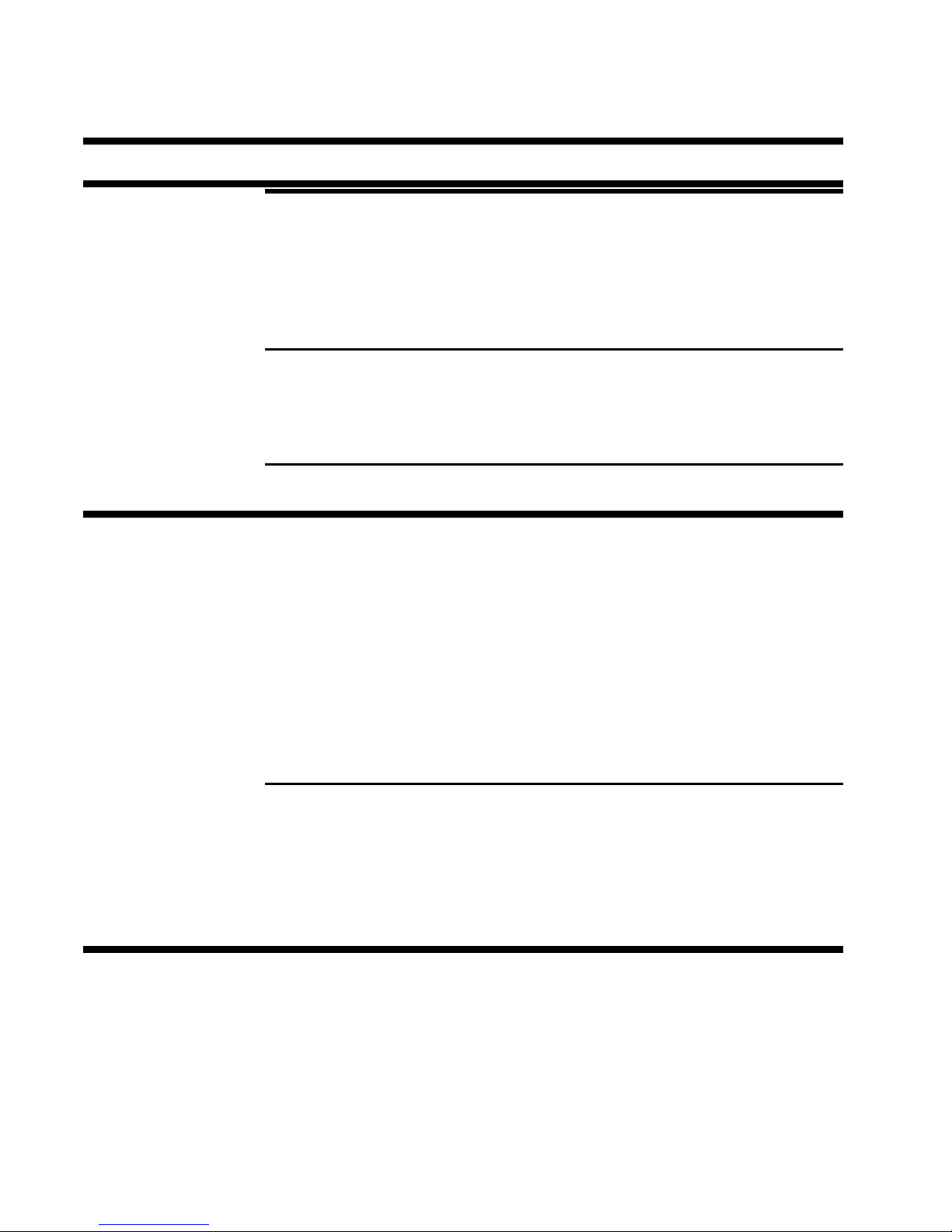

LEDCO PREMIER 4 SERIES LAMINATOR

PROBLEM DIAGNOSTIC CHARTS

Procedure Skill

Problem Possible Cause Repair Procedure Number Level

Laminator heat cannot Heat controls set to "C" Reset heat control for "F"per *

be controlled instructions in owners/

for celcius instead of "F"

for Farenheit

Heat sensor failure Check heat sensor wires. 5 **

Heat control board failure Check specific heat control 13,14 ***

terminals

operators manual

Check heat sensor. 8 ***

Replace heat sensor/bullet

assembly 15 **

Laminating rollers do No power Check power cord. 1 *

not operate Check drive switch position. 17 *

Check drive motor fuse 18 *

Check switch wires. 19 *

Check drive switch 20 **

Check speed dial 21 **

potentiometer

Check drive motor control 25 **

Check drive motor 25 **

Drivetrain failure Check drive chain. 22 *

Check drive sprokets.

Check rubber roll gears 24 *

Replace drive motor control 26 ***

Replace drive motor 27 ***

23 *

Page 3

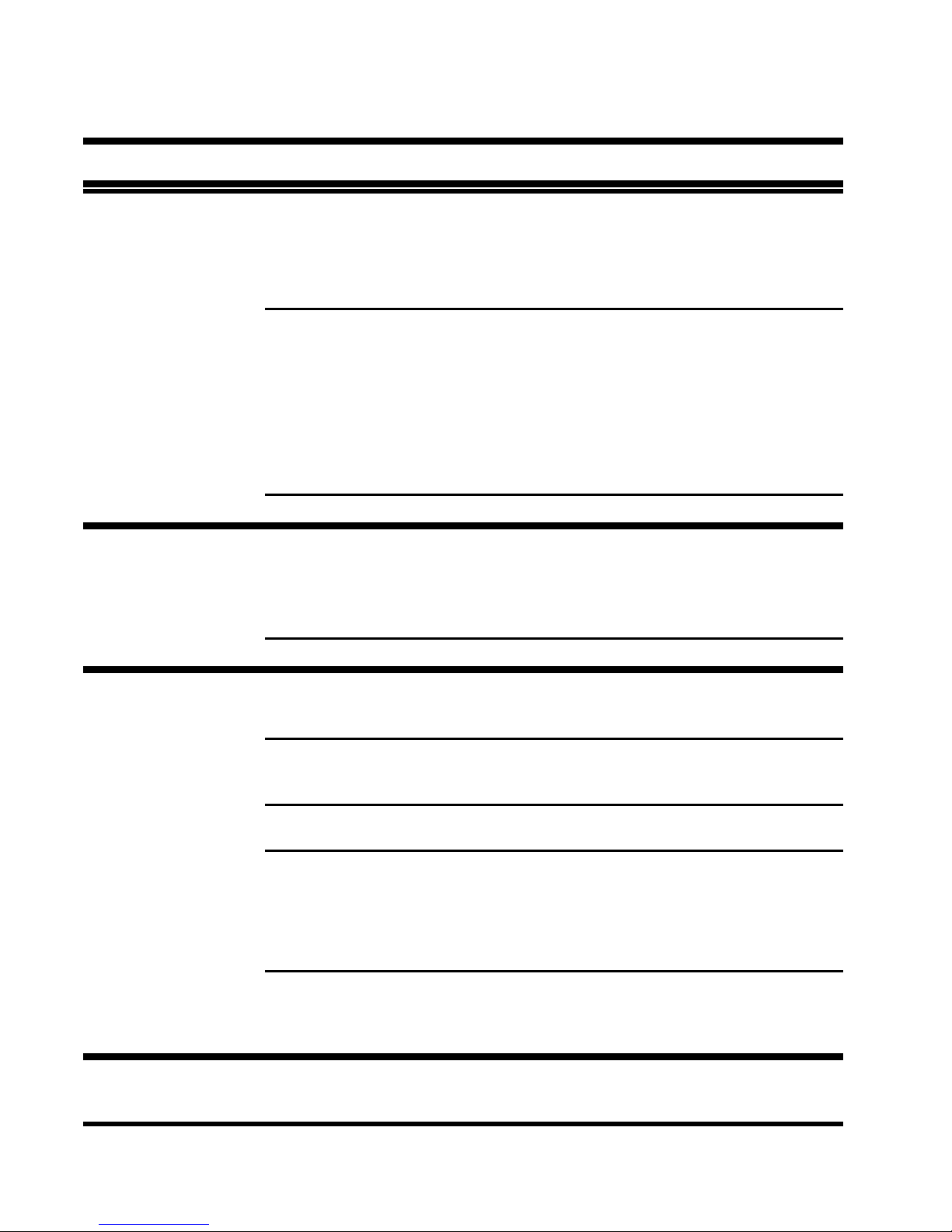

LEDCO PREMIER 4 SERIES LAMINATOR

PROBLEM DIAGNOSTIC CHARTS

Procedure Skill

Problem Possible Cause Repair Procedure Number Level

Skill Level Index: * Basic,End-User ** Intermediate or Dealer *** Advanced or Servicing Dealer/Technician

Laminating rollers Drivetrain failure Check drive chain. 22 *

operate intermittently, 23 *

sometimes with a Check rubber roll gears 24 *

clunking, skipping or Film "wrap-around" Clear minor "wrap-around" 28 *

grinding noise Clear "wrap-around" of 29 **

Drive motor gear failure Replace drive motor 27 ***

Cooling fans do not Check power cord. 1 *

operate Check fan switch position. 32 *

Fan motor failure Replace fan motor(s) 35 ***

The lamination has Item being laminated has Smooth item on feed

wrinkles been folded, rolled, bent table as it is being

or wrinkled. laminated.

Check drive sprokets.

front laminating rolls

Clear "wrap-around" of 30 **

rear laminating rolls

Clear "wrap-around" by 31 ***

removing and cleaning or

replacing rolls

Check fan switch 33 **

Check cooling fans 34 **

Laminating two pieces Only laminate items of the

of unequal thickness same thickness side by side.

side by side.

Thicker material causes This is normal. Trim off

wrinkles on each side. material with wrinkles.

Inadequate supply roll Add tension to take wrinkles

tension. out of film before it gets past

the heat shoes.

Check supply roll dog. 36 *

Check supply roll spring pin. 37 *

Improper rubber roll Check rubber roll dwell line. 38 *

pressure Adjust rubber rolls 39 **

Replace rubber rolls 40 ***

Skill Level Index: * Basic,End-User ** Intermediate or Dealer *** Advanced or Servicing Dealer/Technician

Page 4

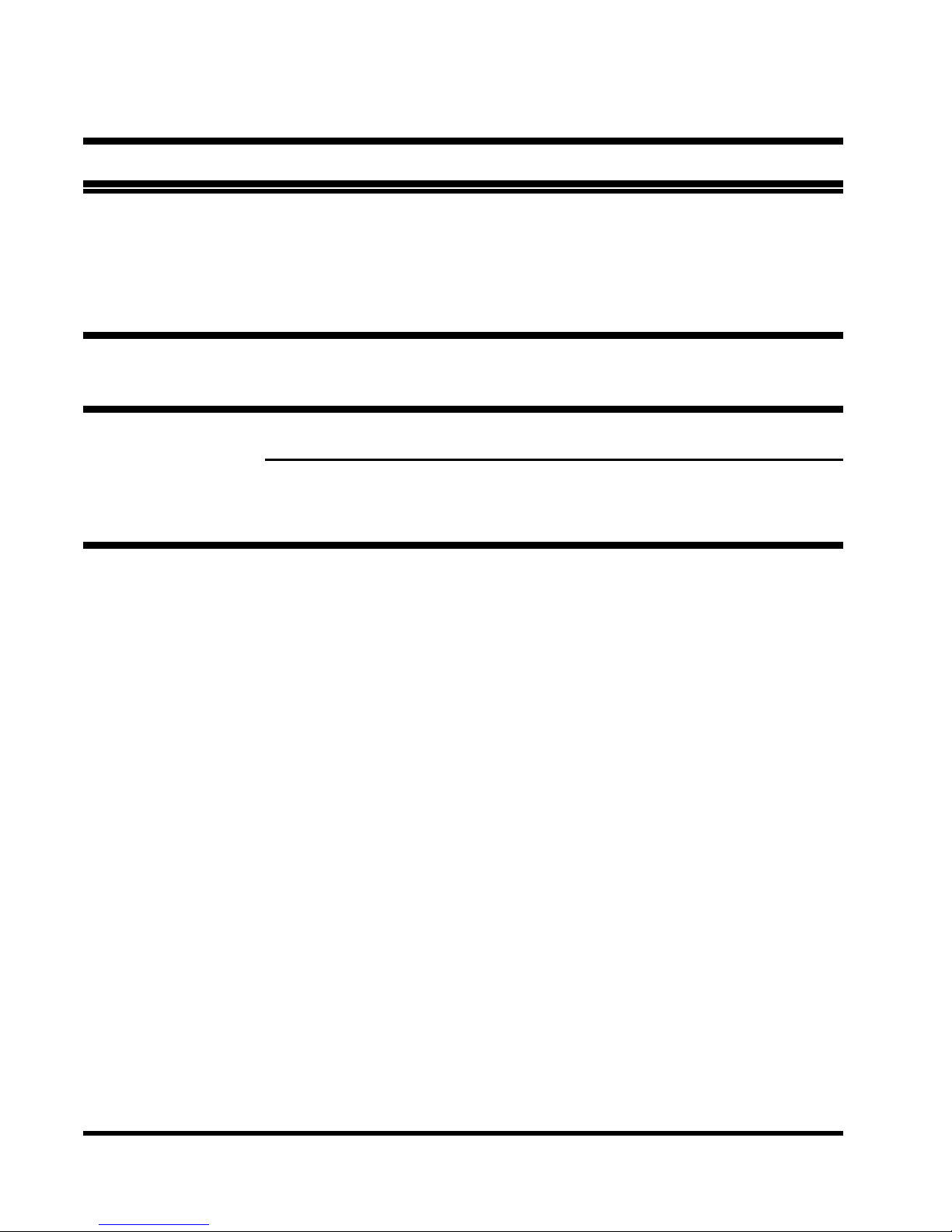

LEDCO PREMIER 4 SERIES LAMINATOR

PROBLEM DIAGNOSTIC CHARTS

Procedure Skill

Problem Possible Cause Repair Procedure Number Level

The film does not Thicker documents Run at a higher temperature

adhere to the document absorb the heat. not to exceed 340 degrees

Thin (1.5 mil) films lose Run at higher temperature

heat from heat shoe to increase speed slightly

the roller nip.

Thicker films do not Reduce speed

absorb enough heat.

.

Film between heat shoe Run a few inches of film

and nip cool while idle. before inserting sheets to

be laminated.

Inkjet print still wet. Let inkjet prints dry at least

2 hours.

Incompatible Inkjet Test samples before

print media and inks. laminating many pieces.

Film shrinks as it Excessive supply roll Reduce supply roll tension.

passed over heat shoe. tension

Excessive heat. Reduce heat.

Laminated item has Excess adhesive is Run a few inches of film

"oily" spot near the created when machine before inserting sheets to

leading edge. left hot and idle for a be laminated.

few minutes.

Milky, hazy line appears Rollers not evenly heated. When warming up the

after initial warm-up machine, keep the rollers

moving slowly.

The machine squeals Dirty heat shoes. Clean heat shoes.

when laminating

Excessive heat. Reduce heat.

Excessive supply roll Reduce supply roll tension.

tension.

Coating on film Try different type or

different brand of film.

Page 5

LEDCO PREMIER 4 SERIES LAMINATOR

PROBLEM DIAGNOSTIC CHARTS

Procedure Skill

Problem Possible Cause Repair Procedure Number Level

Skill Level Index: * Basic,End-User ** Intermediate or Dealer *** Advanced or Servicing Dealer/Technician

Laminated item has Adhesive build-up or Clean the rollers.

pitted, irregular surface. dirt on rollers.

Cuts or other damage Replace rubber rolls. 40 ***

to the rubber rollers

General haziness or Not enough heat. Increase the temperature.

cloudiness in film

after lamination

Bubbles in the center Excessive laminating Adjust rubber rolls 39 **

of the web and/or film roll pressure

not sticking to center Worn rollers Check rubber roll dwell line. 38 *

Replace rubber rolls. 40 ***

Adjust rubber rolls 39 **

Skill Level Index: * Basic,End-User ** Intermediate or Dealer *** Advanced or Servicing Dealer/Technician

Page 6

LEDCO PREMIER 4 SERIES LAMINATOR

PROBLEM DIAGNOSTIC CHARTS

Procedure Skill

Problem Possible Cause Repair Procedure Number Level

Loading...

Loading...