Page 1

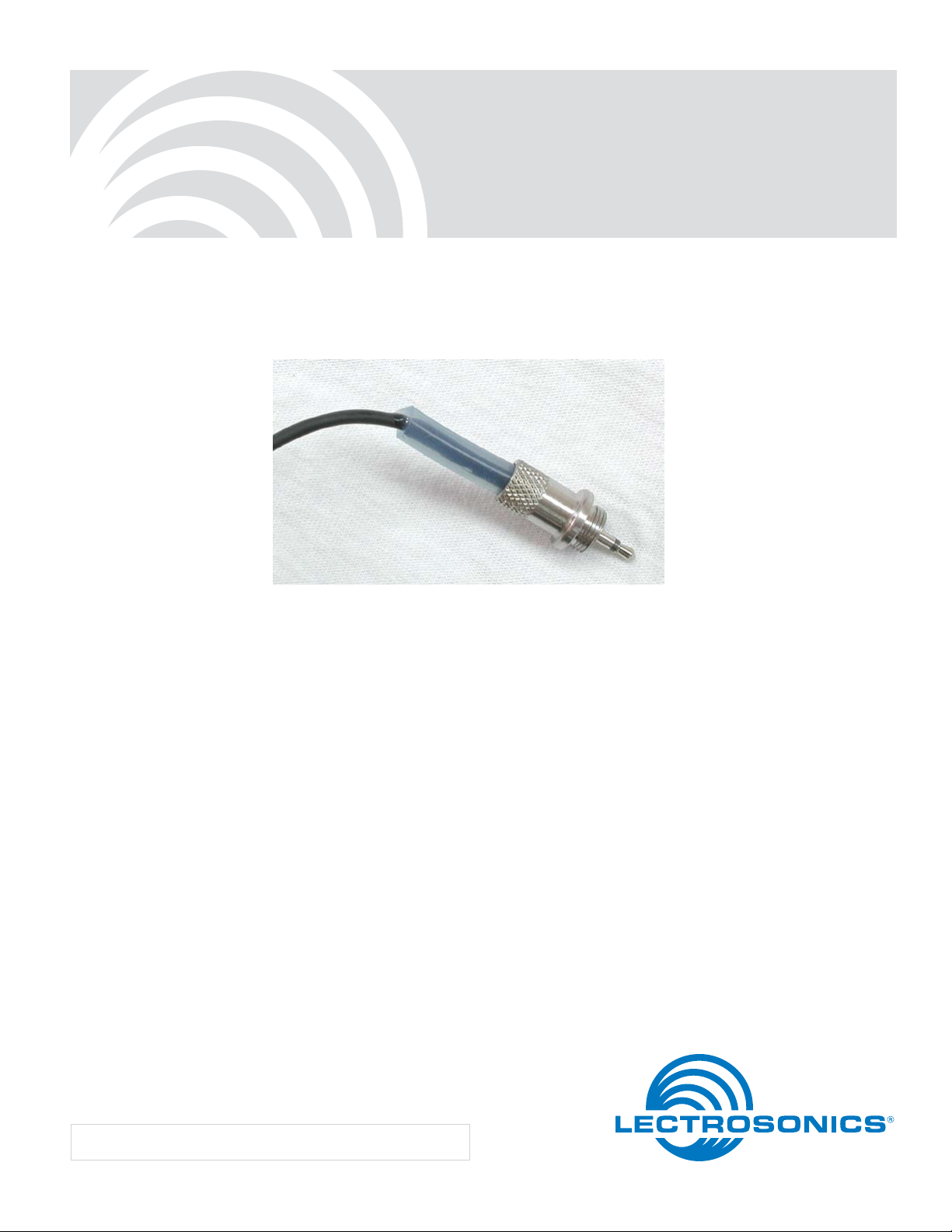

WPMC-3

WPMC-10

Watertight Microphone Plug Kit

ASSEMBLY INSTRUCTIONS

Fill in for your records:

Purchase Date:

Rio Rancho, NM, USA

www.lectrosonics.com

Page 2

WPMC-3 / WPMC-10

2

LECTROSONICS, INC.

Page 3

Watertight Microphone Plug Kit

Table of Contents

Safety Warnings ......................................................................................................................................................................................4

Solder ....................................................................................................................................................................................................4

Alcohol ..................................................................................................................................................................................................4

Silicon Sealant ......................................................................................................................................................................................4

Introduction .............................................................................................................................................................................................5

3 Piece Waterproof Connector Kit Contents .........................................................................................................................................5

10 Piece Waterproof Connector Kit Contents .......................................................................................................................................5

Additional Tools and Supplies ...............................................................................................................................................................5

Two-Wire Microphone Assembly Procedure ........................................................................................................................................6

Three-Wire Microphone Assembly Procedure .....................................................................................................................................7

Comments On Three Wire Microphones ...............................................................................................................................................7

Final Assembly Procedure.....................................................................................................................................................................8

Service and Repair ...............................................................................................................................................................................14

Returning Units for Repair ..................................................................................................................................................................14

Limited One Year Warranty................................................................................................................................................... Back Cover

Rio Rancho, NM

3

Page 4

WPMC-3 / WPMC-10

Safety Warnings

Solder

a) When soldering, protect yourself and others. Read,

understand and follow the manufacturer’s instructions, Material Safety Data Sheets (MSDS) and

these workplace safety practices:

b) Use local fans to keep fumes and gasses from your

breathing area.

c) Wear safety glasses or a face shield.

d) Do not eat in work area.

e) Wash hands thoroughly before eating or smoking.

Alcohol

When cleaning with alcohol, protect yourself and others.

Read, understand and follow the manufacturer’s instructions, Material & Safety Data Sheets (MSDS) and

these workplace safety practices:

a) Flammable — keep away from fire or heat sources.

b) Use only in well ventilated area.

c) Wear Latex gloves.

d) Wear safety glasses or face shield.

Silicon Sealant

When working with silicone sealant, protect yourself

and others. Read, understand and follow the manufacturer’s instructions, Material & Safety Data Sheets

(MSDS) and these workplace safety practices:

a) Use only in well ventilated area.

b) Wear cloth gloves.

c) Wear safety glasses or face shield.

d) Caution — Wearers of contact lenses must not

handle their contact lenses until all sealant has

been cleaned from hands and fingertips.

4

LECTROSONICS, INC.

Page 5

Introduction

Watertight Microphone Plug Kit

This manual covers the assembly of the watertight connectors on the microphones for the Lectrosonics waterresistant wireless transmitters. It is very important that

these procedures be followed exactly to ensure a watertight seal at the microphone connector. A good seal will

prevent any moisture from entering the transmitter and

possibly causing corrosion of the internal parts.

CAUTION: If the transmitter is wet (either due

to immersion or high levels of perspiration),

BEFORE opening any covers or connectors,

carefully blot the transmitter dry with a clean

paper towel or cloth. Remove all moisture.

After opening any connector or cover,

carefully blot up any remaining moisture that

may have remained around the seal. THIS IS

IMPORTANT! DO NOT CLOSE ANY COVER

OR CONNECTOR BEFORE MAKING CERTAIN

THERE IS NO MOISTURE IN OR NEAR THE

OPENING. After use, it is important to store

the transmitter in a dry place with all access

doors and connectors opened to allow any

internal humidity to evaporate. Specifically,

open the battery door, the frequency cover

plate and fully unscrew and remove the

microphone connector before storing. Do NOT

store wet and do NOT store sealed. If moisture

is sealed inside the unit it has nowhere to go

other than to chemically react with and destroy

components and the printed circuit board.

3 Piece Waterproof Connector Kit Contents

In the 3 piece waterproof connector kit (Part #WPMC-3)

you should find:

1. 5 ea silicone tubing, 1”long (Part #35680)

2. 5 ea submini phone plug (0.100”) without shell (Part

#21540, SwitchCraft 850 type)

3. 3 ea stainless steel shell (Part #26481)

4. 10 ea red silicone “O” ring (Part #35750)

5. 3 ea plastic dispensers (Part #56113)

6. 6 ea gray nozzles for dispensers (Part #56114)

7. Tube of flowable silicone sealant (Dow Corning

#734) (Part #32376)

8. Material Safety Data Sheets (MSDS)

10 Piece Waterproof Connector Kit Contents

In the 10 piece waterproof connector kit (Part #WPMC-

10) you should find:

1. 15 ea silicone tubing, 1”long (Part #35680)

2. 15 ea submini phone plug (0.100”) without shell

(Lectro #21540, SwitchCraft 850 type)

3. 10 ea stainless steel shell (Part #26481)

4. 30 ea red silicone “O” ring (Part #35750)

5. 7 ea plastic dispensers (Part #56113)

6. 15 ea gray nozzles for dispensers (Part #56114)

7. 1 tube of flowable silicone sealant (Dow Corning

#734) (Part #32376)

8. Material Safety Data Sheets (MSDS)

Additional Tools and Supplies

You will also need a small soldering iron, needle nose

pliers, good wire cutters and wire strippers. Isopropyl

alcohol or alcohol wipes to clean the parts will be necessary if the parts have become oily or dirty. If the mic

wire is tight in the silicone tubing, a drop of isopropyl

alcohol makes a good lubricant that will evaporate completely after assembly. Ensure that the isopropyl alcohol

you use is clean and does not contain oils. We use a

generic medical grade alcohol that is labeled “Isopropyl

Alcohol 91%” and is certified to be oil free.

Rio Rancho, NM

5

Page 6

WPMC-3 / WPMC-10

Two-Wire Microphone Assembly Procedure

The following procedure pertains to a typical two-wire

electret microphone. For non-standard microphones,

contact Lectrosonics Customer Service:

1. Using a pair of scissors or a utility knife, cut a one

inch length from the clear silicon tubing. Ensure the

cuts are clean and square.

2. Cut the cable of your microphone to the length you

prefer (recommended length is approximately 40

inches).

3. Insert the cable through the tubing and then the

plug shell.

Note: If necessary, dip both the cut piece of

silicone tubing and the end of the microphone

cable in alcohol to lubricate them.

4. Strip the outer insulation of the cable back approximately 1/4”.

5. Comb the braid or shield wires to one side and twist

together.

6. Strip the audio wire back approximately 1/8”.

7. Insert the twisted shield wire through the hole in the

strain relief of the plug. Solder and

trim. (See Figure 1.)

8. Solder the audio wire to the plug.

9. Crimp the strain relief over the cable and insulation.

(See Figure 2.)

10. Test the microphone for proper operation and gain.

Strain Relief

Figure 2 - All connections soldered and crimped

Note: It is highly suggested that you test the

microphone before proceeding any further. It will

be much harder to repair connections once the

connector is waterproofed.

11. Screw the plug into the plug cover and tighten. (Put

a broad rubber band around the sleeve of the plug

to protect the sleeve from the needle nose serrations.)

IMPORTANT: At this point, go to the Final

Assembly Procedure on Page 8 to finish the

assembly.

Audio Wire

Braided Shield

(Not Shown)

Hole in Strain Relief

(Not Shown)

Figure 1. Shield Wire Soldered

Plug Cover

Audio Wire

Plug

6

LECTROSONICS, INC.

Page 7

Watertight Microphone Plug Kit

Three-Wire Microphone Assembly Procedure

The following procedure pertains to a typical three-wire

electret microphone. For non-standard microphones,

contact Lectrosonics Customer Service:

1. Using a pair of scissors or a utility knife, cut a one

inch length from the clear silicon tubing. Ensure the

cuts are clean and square.

2. Cut the cable of your microphone to the length you

prefer (recommended length is approximately 40

inches).

3. Insert the cable through the tubing and then the

plug shell.

Note: If necessary, dip both the cut piece of

silicone tubing and the end of the microphone

cable in alcohol to lubricate them.

4. Strip the outer insulation of the cable back approximately 1/4”.

5. Comb the braid or shield wires to one side and twist

together.

Strip the Bias wire (Drain) back about 1/8”.

6.

7. Insert the twisted shield wire through the hole in the

strain relief of the plug. Solder and

trim. (See Figure 1.)

8. Solder the Bias (Drain) wire to the plug.

10. Crimp the strain relief over the cable and insulation.

If the Source (Audio) wire is not needed, bend it

around and crimp with cable and insulation. (See

Figure 2.)

Strain Relief

Source (Audio) Wire

(See “Comments on Three-

Wire Microphones”)

Figure 2 - All connections soldered and crimped

Bias (Drain) Wire

Braided Shield

(Not Shown)

10. Screw the plug into the plug cover and tighten. (Put

a broad rubber band around the sleeve of the plug

to protect the sleeve from the needle nose serrations.)

IMPORTANT: At this point, go to the Final

Assembly Procedure on Page 8 to finish the

assembly.

Plug Cover

Bias (Drain)

Plug

Ground (Shield)

(Not Shown)

Source (Audio)

Figure 1. Shield Wire Soldered

9. Test the microphone for proper operation and gain.

(See “Comments on Three-wire Microphones” before proceding past this step.)

Warning: It is highly suggested that you test

the microphone before proceeding any further.

It will be much harder to repair connections

once the connector is waterproofed. Also,

read “Comments on Three-Wire Microphones”

before proceeding to next step.

Comments On Three Wire Microphones

Three wire microphones cannot be used directly with

the MM series transmitters. They must be slightly

modified to make them act as if they are two wire mics.

Three wire mics have a ground lead, a source (or

audio) lead and a drain (or drain) lead. The source and

the drain refer to connections to a Field Effect Transistor (FET) in the microphone capsule. Either the source

or drain can provide an audio signal. In fact, a two-wire

electret mic is just a three-wire mic with the source

lead removed from the user’s access. For any electret

microphone, the internal FET must have a resistor from

source to ground. Usually, the manufacturer builds this

into the capsule but not always. You may need to add

this resistor. Simply try soldering up the Drain (Bias)

lead to the plug center pin and the Ground (Shield) to

the connector strain relief. If this gives you good mic

level, then use it. If the level is very low or inaudible, add

a 1/8 Watt resistor between the Source (Audio) lead

and ground. We will be happy to mail you a few, if you

can’t find any locally. A good starting value is 1k to 2k

Ohms. The smaller the resistor; the higher the gain. If

you have questions, call Lectrosonics Customer Service

for assistance.

Rio Rancho, NM

7

Page 8

WPMC-3 / WPMC-10

Final Assembly Procedure

This procedure applies to both 2-wire and 3-wire microphones:

1. Locate the tube of RTV and the RTV dispenser

(Part #56113). (It looks like a syringe without a

needle).

2. Replace the light blue cap on the RTV dispenser

with one of the gray nozzles (Part #56114), then

remove the plunger and set it aside.

3. Remove the top of the tube of RTV, reverse it and

pierce the metalic seal at the top of the tube.

4. Squeeze approximately 1/2 inch of RTV from the

tube into the RTV dispenser. Replace the cap on

the tube of RTV and set it aside.

5. Replace the plunger in the RTV dispenser. While

pointing the nozzle upward, gently push the plunger

into the RTV dispenser until any excess air is

squeezed out.

6. Using the RTV dispenser, fill the plug cover with

flowable silicone sealant (see Figure 1) to approximately halfway between the plug strain relief and

the top of the plug cover (1/16” from the top). Allow

the RTV settle for a few minutes and then slide the

tubing down into the plug cover as far as it will go.

Wipe off any excess sealant that may be forced out

of the plug shell with a paper towel.

7. Insert the nozzle of the dispenser deep into the

top of the tubing and fill the tubing with RTV. (See

Figures 2 & 3.)

8. Hang the cable so the connector dangles freely

straight down to cure for at least 8 hours (overnight

is better). This will ensure a watertight bond between the sealant, cable, cover and silicone tubing.

9. Lubricate an

O-ring (Part

#35750) with

a petroleumbased jelly or

white grease

and install in

the groove of

the plug cover.

Do not use a

silicone-based

grease as

silicone oils

Figure 4 - Location O-Ring grove

will attack the

O-ring material. (See Figure 4.)

O-ring groove

Figure 1 - Filling the Plug Cover with RTV

Figure 2 - Injecting the sealant deep into the tubing

Caution: For efficiency, you may be tempted

to install the O-ring at the beginning of this

procedure. DO NOT DO THIS! If you install

the O-Ring before the RTV sealant has the

opportunity to cure thoroughly, you run the

risk of the RTV sealant bonding to the O-ring

since it is also silicone. The O-ring must be

free to move to seal properly.

10. The assembly is now finished and ready for use.

8

Figure 3 - Pulling the nozzle out as the tubing fills with sealant

LECTROSONICS, INC.

Page 9

Watertight Microphone Plug Kit

Rio Rancho, NM

9

Page 10

WPMC-3 / WPMC-10

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 1 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

1. IDENTIFICATION OF THE SUBSTANCE AND OF THE COMPANY

Dow Corning Corporation

South Saginaw Road

Midland, Michigan 48686

24 Hour Emergency Telephone:

Customer Service:

Product Disposal Information:

CHEMTREC:

(989) 496-5900

(989) 496-6000

(989) 496-6315

(800) 424-9300

MSDS No.: 01907506 Revision Date: 2001/10/17

Generic Description: Silicone elastomer

Physical Form: Viscous Liquid

Color: Colorless

Odor: Acetic acid odor

NFPA Profile: Health 2 Flammability 2 Instability/Reactivity 0

Note: NFPA = National Fire Protection Association

2. OSHA HAZARDOUS COMPONENTS

CAS Number Wt % Component Name

17689-77-9 3.0 - 7.0 Ethyltriacetoxysilane

4253-34-3 1.0 - 5.0 Methyltriacetoxysilane

541-02-6 <1.0 Decamethylcyclopentasiloxane

556-67-2 <1.0 Octamethylcyclotetrasiloxane

108-24-7 <=0.1 Acetic anhydride

64-19-7 <=0.1 Acetic acid

The above components are hazardous as defined in 29 CFR 1910.1200.

3. EFFECTS OF OVEREXPOSURE

Acute Effects

Eye: Direct contact may cause moderate irritation.

Skin: May cause moderate irritation.

Inhalation: Irritates respiratory passages very slightly.

Oral: Low ingestion hazard in normal use.

Prolonged/Repeated Exposure Effects

Skin: No known applicable information.

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 2 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

Inhalation:

No known applicable information.

Oral: No known applicable information.

Signs and Symptoms of Overexposure

No known applicable information.

Medical Conditions Aggravated by Exposure

No known applicable information.

The above l isted potential effects of overexposure are based on actual data, results of studies performed upon similar

compositions, component data a nd/or expert review of the product. Please refer to Section 11 for the detailed toxicology

information.

4. FIRST AID MEASURES

Eye: Immediately flush with water for 15 minutes. Get medical attention.

Skin: Remove from skin and wash thoroughly with soap and water or waterless cleanser.

Get medical attention if irritation or other ill effects develop or persist.

Inhalation: No first aid should be needed.

Oral: No first aid should be needed.

Comments: Treat according to person's condition and specifics of exposure.

5. FIRE FIGHTING MEASURES

Flash Point: 188.6 °F / 87 °C (Closed Cup)

Autoignition

Temperature:

Not determined.

Flammability Limits in Air: Not determined.

Extinguishing Media: On large fires use dry chemical, foam or water spray. On small fires use carbon dioxide

(CO2), dry chemical or water spray. W ater can be used to cool fire exposed containers.

Fire Fighting Measures: Self-contained breathing apparatus and protective clothing should be worn in fighting

large fires involving chemicals. Determine the need to evacuate or isolate the area

according to your local emergency plan. Use water spray to keep fire exposed

containers cool.

Unusual Fire Hazards: None.

Hazardous Decomposition Products

Thermal breakdown of this product during fire or very high heat conditions may evolve the following hazardous

decomposition products: Carbon oxides and traces of incompletely burned carbon compounds. Silicon dioxide.

Formaldehyde.

LECTROSONICS, INC.

10

Page 11

Watertight Microphone Plug Kit

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 4 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

Skin: Wash at mealtime and end of shift. Contaminated clothing and shoes should be

removed as soon as practical and thoroughly cleaned before reuse. Chemical

protective gloves are recommended.

Suitable Gloves: Silver Shield(R). 4H(R).

Inhalation: No respiratory protection should be needed.

Suitable Respirator: None should be needed.

Personal Protective Equipment for Spills

Eyes: Use proper protection - safety glasses as a minimum.

Skin: Wash at mealtime and end of shift. Contaminated clothing and shoes should be

removed as soon as practical and thoroughly cleaned before reuse. Chemical

protective gloves are recommended.

Inhalation/Suitable

Respirator:

No respiratory protection should be needed.

Precautionary Measures: Avoid eye contact. Avoid skin contact. Use reasonable care.

Comments: Product evolves acetic acid (HOAc) when exposed to water or humid air. Provide

ventilation during use to control HOAc within exposure guidelines or use respiratory

protection.

Note: These precautions are for room temperature handling. Use at elevated temperature or aerosol/spray applications may

require added precautions.

9. PHYSICAL AND CHEMICAL PROPERTIES

Physical Form: Viscous Liquid

Color: Colorless

Odor: Acetic acid odor

Specific Gravity @ 25°C: 1.03

Viscosity: 350 cSt

Freezing/Melting Point: Not determined.

Boiling Point: > 35C/95F

Vapor Pressure @ 25°C: Not determined.

Vapor Density: Not determined.

Solubility in Water: Not determined.

pH: Not determined.

Volatile Content: < 5 %

Note: The above information is not intended for use in pr e paring product specifications. Contact Dow Corning before writing

specifications.

10. STABILITY AND REACTIVITY

Chemical Stability: Stable.

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 3 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

6. ACCIDENTAL RELEASE MEASURES

Containment/Clean up: Determine whether to evacuate or isolate the area according to your local emergency

plan. Observe all personal protection equipment recommendations described in

Sections 5 and 8. For large spills, provide diking or other appropriate containment to

keep material from spreading. If diked material can be pumped, store recovered

material in appropriate container. Clean up remaining materials from spill with suitable

absorbant. Clean area as appropriate since some silicone materials, even in small

quantities, may present a slip hazard. Final cleaning may require use of steam,

solvents or detergents. Dispose of saturated absorbant or cleaning materials

appropriately, since spontaneous heating may occur. Local, state and federal laws and

regulations may apply to releases and disposal of this material, as well as those

materials and items employed in the cleanup of releases. You will need to determine

which federal, state and local laws and regulations are applicable. Sections 13 and 15

of this MSDS provide information regarding certain federal and state requirements.

Note: See section 8 for Personal Protective Equipment for Spills. Call Dow Corning Corporation, (989) 496-5900,

if additional information is required.

7. HANDLING AND STORAGE

Use with adequate ventilation. Product evolves acetic acid (HOAc) when exposed to water or humid air. Provide

ventilation during use to control HOAc within exposure guidelines or use respiratory protection. Avoid eye contact.

Avoid skin contact.

Static electricity will accumulate and may ignite vapors. Prevent a possible fire hazard by bonding and grounding

or inert gas purge. Keep container closed and away from heat, sparks, and flame. Keep container closed and

store away from water or moisture.

8. EXPOSURE CONTROLS / PERSONAL PROTECTION

Component Exposure Limits

CAS Number Com ponent Name Exposure Limits

17689-77-9 Ethyltriacetoxysilane See acetic acid comments.

4253-34-3 Methyltriacetoxysilane See acetic acid comments.

Acetic acid is formed upon contact with water or humid air. Provide adequate ventilation to control exposures

within guidelines of OSHA PEL: TWA 10 ppm and ACGIH TLV: TWA 10 ppm, STEL 15 ppm.

Engineering Controls

Local Ventilation: None should be needed.

General Ventilation: Recommended.

Personal Protective Equipment for Routine Handling

Eyes: Use proper protection - safety glasses as a minimum.

Rio Rancho, NM

11

Page 12

WPMC-3 / WPMC-10

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 5 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

Hazardous

Polymerization:

Hazardous polymerization will not occur.

Conditions to Avoid: None.

Materials to Avoid: Oxidizing material can cause a reaction. Water, moisture, or humid air can cause

hazardous vapors to form as described in Section 8.

11. TOXICOLOGICAL INFORMATION

Special Hazard Information on Components

No known applicable information.

12. ECOLOGICAL INFORMATION

Environmental Fate and Distribution

Complete information is not yet available.

Environmental Effects

Complete information is not yet available.

Fate and Effects in Waste Water Treatment Plants

Complete information is not yet available.

Ecotoxicity Classification Criteria

Hazard Parameters (LC50 or EC50) High Medium Low

Acute Aquatic Toxicity (mg/L) <=1 >1 and <=100 >100

Acute Terrestrial Toxicity <=100 >100 and <= 2000 >2000

This table is adapted from "Environmental Toxicology and Risk Assessment", ASTM STP 1179, p.34, 1993.

This table can be used to classify the ec otoxicity of this product when ecotoxicity data is listed above. Please read the other information

presented in the section concerning the overall ecological safety of this material.

13. DISPOSAL CONSIDERATIONS

RCRA Hazard Class (40 CFR 261)

When a decision is made to discard this material, as received, is it classified as a hazardous waste? No

State or local laws may impose additional regulatory requirements regarding disposal.

Call Dow Corning Corporate Environmental Management, (989) 496-6315, if additional information is required.

14. TRANSPORT INFORMATION

DOT Road Shipment Information (49 CFR 172.101)

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 6 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

Proper Shipping Name: COMBUSTIBLE LIQUID, N.O.S.

Hazard Technical Name: ACETOXYSILANE

Hazard Class: COMBUSTIBLE LIQUID

UN/NA Number: NA1993

Packing Group: III

Remarks: Above applies only to containers over 119 gallons or 450 liters.

Ocean Shipment (IMDG)

Not subject to IMDG code.

Air Shipment (IATA)

Not subject to IATA regulations.

Call Dow Corning Transportation, (989) 496-8577, if additional information is required.

15. REGULATORY INFORMATION

Contents of this MSDS comply with the OSHA Hazard Communication Standard 29 CFR 1910.1200.

TSCA Status: All chemical substances in this material are included on or exempted from listing on the

TSCA Inventory of Chemical Substances.

EPA SARA Title III Chemical Listings

Section 302 Extremely Hazardous Substances:

None.

Section 304 CERCLA Hazardous Substances:

None.

Section 312 Hazard Class:

Acute: Yes

Chronic: No

Fire: Yes

Pressure: No

Reactive: No

Section 313 Toxic Chemicals:

None present or none present in regulated quantities.

Supplemental State Compliance Information

California

12

LECTROSONICS, INC.

Page 13

Watertight Microphone Plug Kit

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 7 of 7

DOW CORNING(R) 734 FLOWABLE SEALANT, CLEAR

Warning: This product contains the following chemical(s) listed by the State of California under the Safe Drinking

Water and Toxic Enforcement Act of 1986 (Proposition 65) as being known to cause cancer, birth defects or

other reproductive harm.

None known.

Massachusetts

No ingredient regulated by MA Right-to-Know Law present.

New Jersey

CAS Number Wt % Component Name

70131-67-8 > 60.0 Dimethyl siloxane, hydroxy-terminated

112945-52-5 7.0 - 13.0 Amorphous fumed silica

17689-77-9 3.0 - 7.0 Eth yltriacetoxysilane

4253-34-3 1.0 - 5.0 Meth yltriacetoxysilane

Pennsylvania

CAS Number

Wt % Component Name

70131-67-8 > 60.0 Dimethyl siloxane, hydroxy-terminated

112945-52-5 7.0 - 13.0 Amorphous fumed silica

17689-77-9 3.0 - 7.0 Eth yltriacetoxysilane

16. OTHER INFORMATION

Prepared by: Dow Corning Corporation

These data are offered in good faith as typical values and not as product specifications. No warranty, either

expressed or implied, is hereby made. The recommended industrial hygiene and safe handling procedures are

believed to be generally applicable. However, each user should review these recommendations in the specific

context of the intended use and determine whether they are appropriate.

(R) indicates Registered Trademark

Rio Rancho, NM

13

Page 14

WPMC-3 / WPMC-10

Service and Repair

If your system malfunctions, you should attempt to correct or isolate the trouble before concluding that the equipment

needs repair. Make sure you have followed the setup procedure and operating instructions. Check the interconnecting cables and then go through the Troubleshooting section in this manual.

We strongly recommend that you do not try to repair the equipment yourself and do not have the local repair shop

attempt anything other than the simplest repair. If the repair is more complicated than a broken wire or loose connection, send the unit to the factory for repair and service. Don’t attempt to adjust any controls inside the units. Once

set at the factory, the various controls and trimmers do not drift with age or vibration and never require readjustment.

There are no adjustments inside that will make a malfunctioning unit start working.

LECTROSONICS’ Service Department is equipped and staffed to quickly repair your equipment. In warranty repairs

are made at no charge in accordance with the terms of the warranty. Out-of-warranty repairs are charged at a modest

flat rate plus parts and shipping. Since it takes almost as much time and effort to determine what is wrong as it does

to make the repair, there is a charge for an exact quotation. We will be happy to quote approximate charges by phone

for out-of-warranty repairs.

Returning Units for Repair

For timely service, please follow the steps below:

A. DO NOT return equipment to the factory for repair without first contacting us by email or by phone. We need

to know the nature of the problem, the model number and the serial number of the equipment. We also need a

phone number where you can be reached 8 A.M. to 4 P.M. (U.S. Mountain Standard Time).

B. After receiving your request, we will issue you a return authorization number (R.A.). This number will help speed

your repair through our receiving and repair departments. The return authorization number must be clearly shown

on the outside of the shipping container.

C. Pack the equipment carefully and ship to us, shipping costs prepaid. If necessary, we can provide you with the

proper packing materials. UPS is usually the best way to ship the units. Heavy units should be “double-boxed” for

safe transport.

D. We also strongly recommend that you insure the equipment, since we cannot be responsible for loss of or dam-

age to equipment that you ship. Of course, we insure the equipment when we ship it back to you.

Lectrosonics USA:

Mailing address: Shipping address: Telephone:

Lectrosonics, Inc. Lectrosonics, Inc. (505) 892-4501

PO Box 15900 581 Laser Rd. (800) 821-1121 Toll-free

Rio Rancho, NM 87174 Rio Rancho, NM 87124 (505) 892-6243 Fax

USA USA

Web: E-mail:

www.lectrosonics.com sales@lectrosonics.com

Lectrosonics Canada:

Mailing Address: Telephone: E-mail:

49 Spadina Avenue, (416) 596-2202 Sales: colinb@lectrosonics.com

Suite 303A (877) 753-2876 Toll-free Service: joeb@lectrosonics.com

Toronto, Ontario M5V 2J1 (877-7LECTRO)

(416) 596-6648 Fax

14

LECTROSONICS, INC.

Page 15

Watertight Microphone Plug Kit

Rio Rancho, NM

15

Page 16

581 Laser Road NE • Rio Rancho, NM 87124 USA • www.lectrosonics.com

(505) 892-4501 • (800) 821-1121 • fax (505) 892-6243 • sales@lectrosonics.com

LIMITED ONE YEAR WARRANTY

The equipment is warranted for one year from date of purchase against defects in

materials or workmanship provided it was purchased from an authorized dealer. This

warranty does not cover equipment which has been abused or damaged by careless

handling or shipping. This warranty does not apply to used or demonstrator equipment.

Should any defect develop, Lectrosonics, Inc. will, at our option, repair or replace any

defective parts without charge for either parts or labor. If Lectrosonics, Inc. cannot

correct the defect in your equipment, it will be replaced at no charge with a similar new

item. Lectrosonics, Inc. will pay for the cost of returning your equipment to you.

This warranty applies only to items returned to Lectrosonics, Inc. or an authorized

dealer, shipping costs prepaid, within one year from the date of purchase.

This Limited Warranty is governed by the laws of the State of New Mexico. It states the

entire liablility of Lectrosonics Inc. and the entire remedy of the purchaser for any

breach of warranty as outlined above. NEITHER LECTROSONICS, INC. NOR

ANYONE INVOLVED IN THE PRODUCTION OR DELIVERY OF THE EQUIPMENT

SHALL BE LIABLE FOR ANY INDIRECT, SPECIAL, PUNITIVE, CONSEQUENTIAL,

OR INCIDENTAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE

THIS EQUIPMENT EVEN IF LECTROSONICS, INC. HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL THE LIABILITY OF

LECTROSONICS, INC. EXCEED THE PURCHASE PRICE OF ANY DEFECTIVE

EQUIPMENT.

This warranty gives you specific legal rights. You may have additional legal rights which

vary from state to state.

February 13, 2007

Loading...

Loading...