Page 1

WM

Watertight Transmitter

With Digital Hybrid Wireless® Technology

US Patent 7,225,135

INSTRUCTION MANUAL

Fill in for your records:

Serial Number:

Purchase Date:

Rio Rancho, NM, USA

www.lectrosonics.com

Page 2

WM

Introduction

The WM transmitter is designed to resist damage

when used in wet or dusty conditions and also offer

a comprehensive feature set that makes it equally at

home in film and television production and on stage.

A solid machined aluminum housing with a corrosion

resistant finish hosts dual battery compartments, a

moisture sealed control panel with backlit LCD and

enlarged membrane switches. Recessed seats for the

O-rings in the battery caps and input jack allow the

caps and mic connector to be tightened securely without excessive deformation of the O-rings.

The antenna is made of an extremely durable, multistrand alloy that will withstand heavy abuse. It is

mounted with a compression sealed strain relief that

prevents dust and moisture from entering the housing.

As the first stage in the signal processing chain, the

input preamp section includes very high quality, low

noise components with a wide range of gain adjustment in 1 dB increments and a DSP-controlled input

limiter. Dual color LEDs on the control panel accurately

indicate audio input level for precise gain adjustment.

Easily accessed screens on the LCD simplify setup

and adjustments.

Output power is adjustable to provide either extended

operating range or extended battery life as needed for

the application.

The Digital Hybrid Wireless® design (US Patent

7,225,135) combines 24-bit digital audio with analog

FM resulting in a system that has the same operating

range as analog systems, the same spectral efficiency

as analog systems, the same long battery life as analog systems, plus the excellent audio fidelity typical of

pure digital systems.

The DSP-based design works with all Digital Hybrid

receivers, and is backward compatible for use with

Lectrosonics 200 Series, 100 Series, IFB receivers

and some other brands of analog wireless receivers.

2

LECTROSONICS, INC.

Page 3

Watertight Transmitter

Table of Contents

Introduction .............................................................................................................................................................................................2

General Technical Description ..............................................................................................................................................................4

Servo Bias Input....................................................................................................................................................................................4

No Pre-Emphasis/De-Emphasis ...........................................................................................................................................................4

Low Frequency Roll-Off ........................................................................................................................................................................4

Input Limiter ..........................................................................................................................................................................................4

Signal Encoding and Pilot Tone ............................................................................................................................................................5

Microprocessor Control .........................................................................................................................................................................5

Compatibility Modes ..............................................................................................................................................................................5

Control Panel ........................................................................................................................................................................................5

Wide-Band Deviation ............................................................................................................................................................................5

Variable Power Output ..........................................................................................................................................................................5

Battery Operation .................................................................................................................................................................................. 5

Output Isolator ......................................................................................................................................................................................5

Controls and Functions .........................................................................................................................................................................6

LCD Screen ..........................................................................................................................................................................................6

Power LED ............................................................................................................................................................................................ 6

Audio Input Jack ....................................................................................................................................................................................6

Battery Compartment and Thumb Screw ..............................................................................................................................................6

Modulation LEDs ...................................................................................................................................................................................6

AUDIO Button .......................................................................................................................................................................................6

FREQ Button .........................................................................................................................................................................................6

Up/Down Arrows ...................................................................................................................................................................................6

Antenna .................................................................................................................................................................................................6

Battery Compartments ........................................................................................................................................................................... 7

About Batteries .......................................................................................................................................................................................7

Input Connector ......................................................................................................................................................................................7

Equivalent Input Circuit Diagram ..........................................................................................................................................................7

Operating Instructions ...........................................................................................................................................................................8

Power Up and Boot Sequence .............................................................................................................................................................. 8

Power Down ..........................................................................................................................................................................................8

Standby Mode .......................................................................................................................................................................................8

Menus and Settings ................................................................................................................................................................................9

UP Arrow Settings ..................................................................................................................................................................................9

Compatibility Mode ...............................................................................................................................................................................9

Input Type ..............................................................................................................................................................................................9

RF Power Output ..................................................................................................................................................................................9

LCD Backlight .......................................................................................................................................................................................9

Frequency Step Size ...........................................................................................................................................................................10

DOWN Arrow Settings .......................................................................................................................................................................... 10

Remote Control ...................................................................................................................................................................................10

Auto Power Restore ............................................................................................................................................................................10

Audio Mute ..........................................................................................................................................................................................11

FREQ Button Settings ..........................................................................................................................................................................12

AUDIO Button Settings ........................................................................................................................................................................12

Low Frequency Roll-off .......................................................................................................................................................................12

Input Gain ...........................................................................................................................................................................................12

LectroRM ...............................................................................................................................................................................................13

Troubleshooting ....................................................................................................................................................................................14

Accessories and Replacement Parts ..................................................................................................................................................16

Straight Whip Antennas .......................................................................................................................................................................17

Preventing Corrosion ...........................................................................................................................................................................18

Desiccant Battery Caps .......................................................................................................................................................................18

Battery Door Update.............................................................................................................................................................................18

Re-conditioning (drying out) the caps and desiccant beads ............................................................................................................... 19

Replacing the desiccant beads ...........................................................................................................................................................19

Specifications ......................................................................................................................................................................................20

Service and Repair ...............................................................................................................................................................................22

Returning Units for Repair ..................................................................................................................................................................22

Rio Rancho, NM

3

Page 4

WM

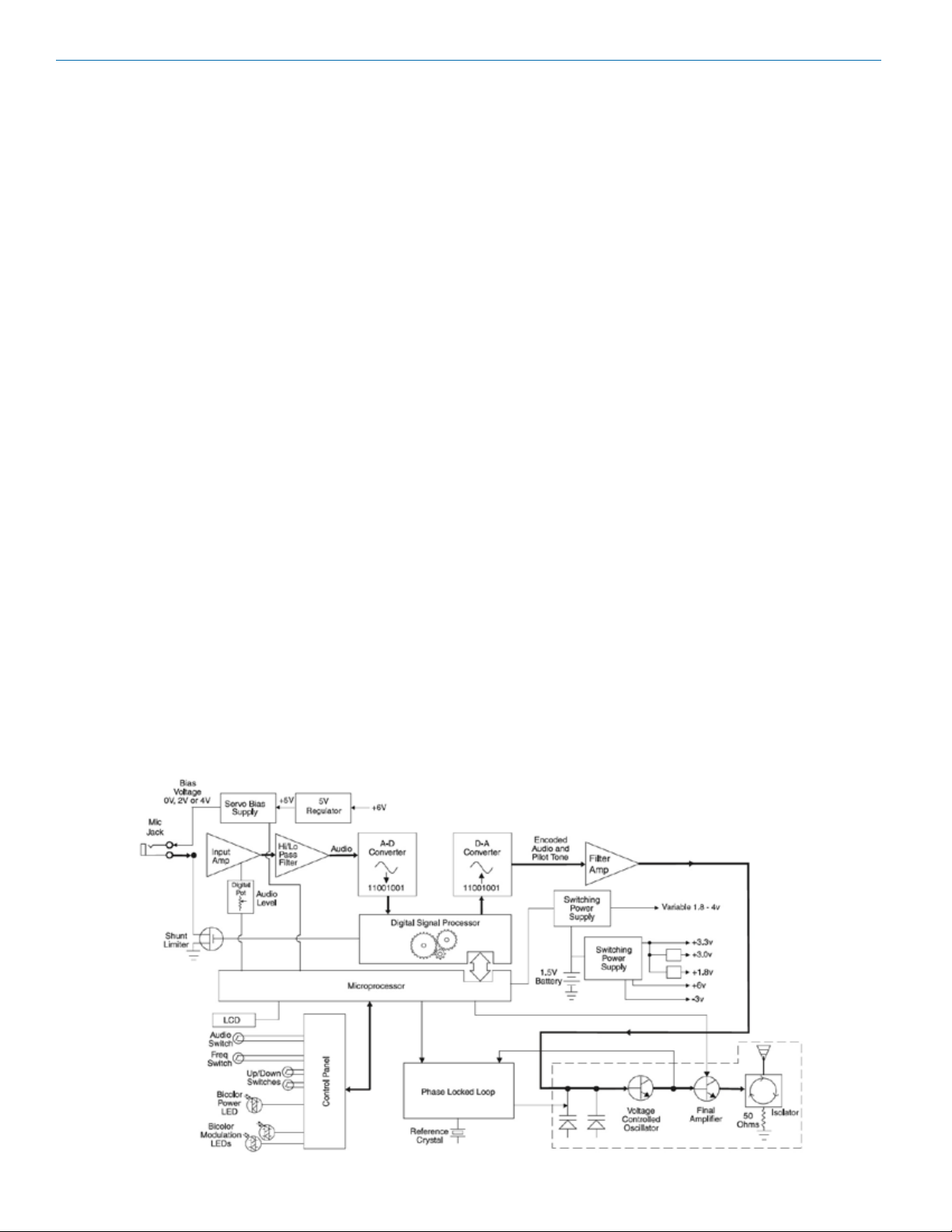

General Technical Description

Servo Bias Input

The voltage and current requirements of the wide variety of electret microphones used in professional applications has caused confusion and compromises in the

wiring needed for wireless transmitters. To address this

problem, the unique Servo Bias input circuit provides

an automatically regulated voltage over a very wide

range of current for compatibility with all microphones.

Digital Hybrid Wireless® Technology

All wireless links suffer from channel noise to some

degree, and all wireless microphone systems seek to

minimize the impact of that noise on the desired signal. Conventional analog systems use compandors for

enhanced dynamic range, at the cost of subtle artifacts

(typically “pumping” and “breathing”). Wholly digital systems defeat the noise by sending the audio information

in digital form, at the cost of some combination of power,

bandwidth and resistance to interference.

Digital Hybrid systems overcome channel noise in a

dramatically new way, digitally encoding the audio in

the transmitter and decoding it in the receiver, yet still

sending the encoded information via an analog FM

wireless link. This proprietary algorithm is not a digital

implementation of an analog compandor but a technique that can be accomplished only in the digital domain, even though the inputs and outputs are analog.

Because it uses an analog FM link, the Digital Hybrid

system enjoys all the benefits of conventional FM wireless systems and it does away with the analog compandor and its artifacts.

No Pre-Emphasis/De-Emphasis

The Digital Hybrid design results in a signal-to-noise ratio

high enough to preclude the need for conventional preemphasis (HF boost) in the transmitter and de-emphasis

(HF roll off) in the receiver. This eliminates the potential

for distortion of signals with abundant high-frequency

information.

Low Frequency Roll-Off

The low frequency roll-off can be set for a 3 dB down

point at 35, 50, 70, 100, 120 and 150 Hz to control

subsonic and very low frequency audio content in

the audio. The actual roll-off frequency will vary slightly

depending upon the low frequency response of the

microphone.

Excessive low frequency content can drive the transmitter into limiting, or in the case of high output sound

systems, it can even cause damage to loudspeaker

systems. The roll-off is normally adjusted by ear while

listening as the system is operating.

Input Limiter

A DSP-controlled analog audio limiter is employed before the A-D converter. The limiter has a range of more

than 30 dB for excellent overload protection. A dual release envelope makes the limiter acoustically transparent while maintaining low distortion. It can be thought

of as two limiters in series, a fast attack and release

limiter followed by a slow attack and release limiter.

The limiter recovers quickly from brief transients, with

no audible side effects, and also recovers slowly from

sustained high levels to keep audio distortion low while

preserving short term dynamics.

4

LECTROSONICS, INC.

Page 5

Watertight Transmitter

Signal Encoding and Pilot Tone

In addition to controlling the limiter, the DSP also encodes the digitized audio from the A/D converter and

adds an ultrasonic pilot tone to control the squelch in

the receiver. A pilot tone squelch system provides a reliable method of keeping a receiver output muted (audio

mute) even in the presence of significant interference.

When the system is operating in the Nu Hybrid mode,

a different pilot tone frequency is generated for each

carrier frequency to prevent inadvertent squelch problems in multi-channel sytems.

Microprocessor Control

A microprocessor monitors user command inputs from

the control panel buttons and numerous other internal

signals. It works intimately with the DSP to ensure the

audio is encoded according to the selected Compatibility Mode and that the correct pilot tone is added to the

encoded signal.

Compatibility Modes

Along with providing peerless audio quality with wide

frequency response and dynamic range in Nu Hybrid

mode, the technology used in the WM Transmitter

includes compatibility modes for Lectrosonics Mode 3

and IFB receivers.

Control Panel

The control panel includes four membrane switches and

an LCD screen to adjust the operational settings. Multicolor LEDs are used to indicate audio signal levels for

accurate gain adjustment and for battery status.

Wide-Band Deviation

±75 kHz deviation improves the signal to noise ratio and

audio dynamic range of a wireless system dramatically,

compared to other designs that use ±30 kHz to 40 kHz

deviation. Wide deviation combined with a high powered transmitters makes a significant improvement in

signal to noise ratio and operating range.

Battery Operation

Switching power supplies convert battery voltages to

operate various circuit stages with maximum efficiency.

The firmware “remembers” the settings when the batteries are exhausted. After new batteries are installed,

a quick press of the AUDIO and FREQ buttons will turn

the power back on and return to the previous settings.

This is a unique behavior that takes place only when

the batteries fail during operation. If the unit is turned

off manually, a quick press of the buttons will turn it on

in the “standby” mode instead.

Because the battery caps make contact with the battery before the cap is seated, the power does not turn

back on automatically. This allows both batteries to

be installed and the caps tightened before power is

restored.

Output Isolator

The RF output circuit includes a magnetically polarized

ferrite called an isolator that suppresses IM (intermodulation) that can take place in the final amplifier.

IM in this case would result from external RF signals

from outside sources entering a transmitter through its

antenna and appearing in the final amplifier. These signals can then mix with the transmitter’s output signal to

create new interfering signals.

The isolator works like a one-way “check valve” that

lets the intended signal generated in the transmitter

travel to the antenna to be transmitted, but it directs

RF signals coming back into the antenna from outside

sources to ground and keeps them from entering the

final amplifier. This greatly reduces IM produced when

multiple transmitters are used in close proximity to one

another (several feet apart). The isolator also provides

additional RF output stage protection against static

shock.

Variable Power Output

This advanced feature allows the operator to optimize

the transmitter for maximum battery life, or for maximum operating range. Power output is selected using

the LCD in a setup mode while the RF output of the

transmitter is turned off.

Rio Rancho, NM

5

Page 6

WM

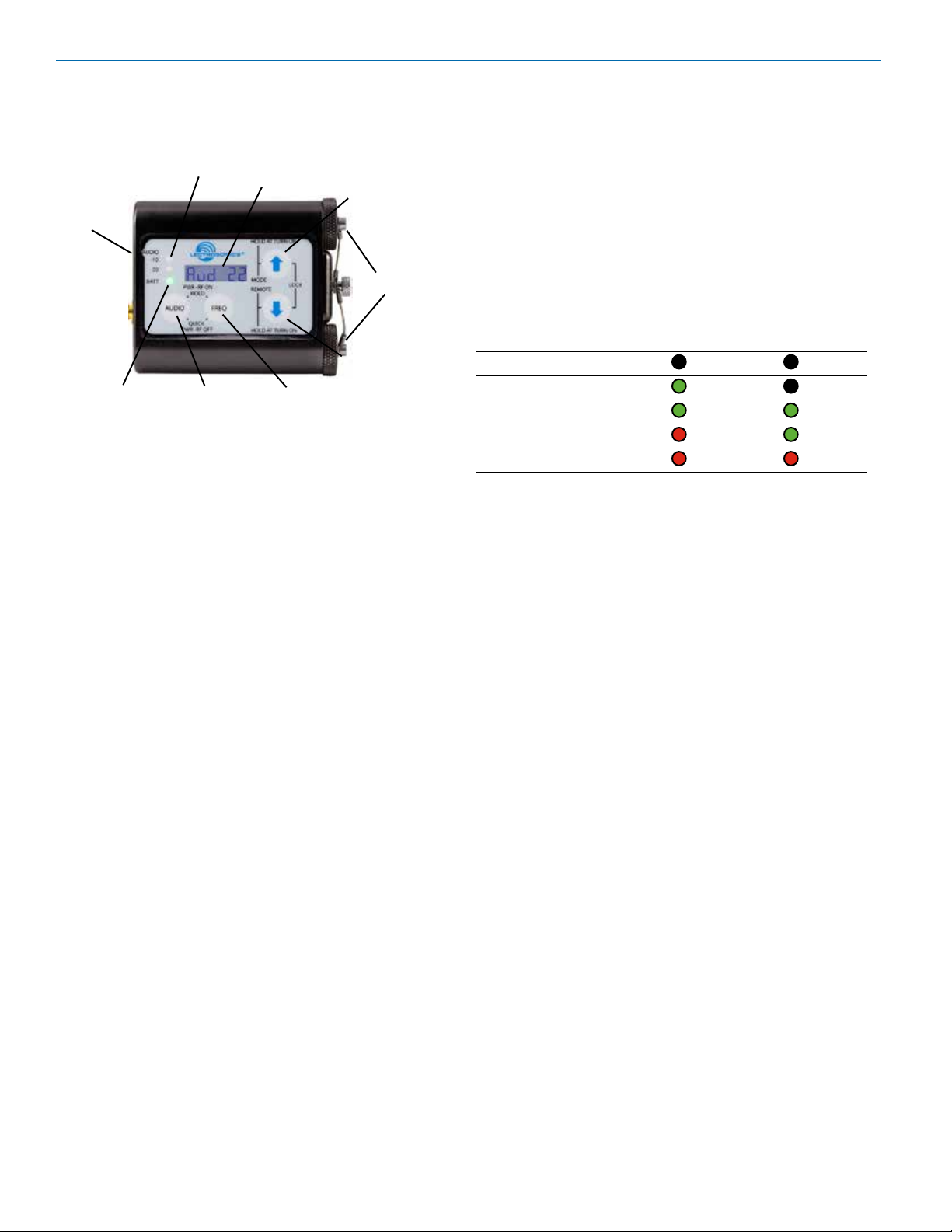

Controls and Functions

Modulation

LEDs

LCD

Audio

Input Jack

PWR LED

AUDIO

Button

FREQ

Button

LCD Screen

The display is a highly visible, backlit LCD with screens

for making all setup and level adjustments. The transmitter can be powered up with or without the RF output

turned on. With the RF output turned off, all adjustments can be made without creating interference for

other wireless systems in the vicinity.

For normal powering up and down, a countdown appears in the LCD. The buttons must be pressed for

the duration of the countdown, which helps to prevent

accidentally turning the transmitter on or off.

Power LED

The PWR LED glows green when the battery is good.

The color changes to red when there is about 30

minutes of operation left with the recommended lithium

battery. When the LED begins to blink red, there are

only a few minutes of life.

A weak battery will sometimes cause the PWR LED

to glow green immediately after the unit is turned on,

but will soon discharge to the point where the LED will

turn red or the unit will turn off completely. When the

transmitter is in SLEEP mode, the LED blinks green

every few seconds.

Audio Input Jack

This is a threaded locking connector that accepts the

Lectrosonics watertight WP connector.

Battery Compartment and Thumb Screw

The large knurled thumbscrews are retain the batteries

and maintain solid battery contact. The lanyard keeps

the battery caps attached, but it can be removed if

desired using a 1/16 inch hex key (Allen wrench).

UP Arrow

Battery

Compartment

Caps

DOWN Arrow

Modulation LEDs

Proper input gain adjustment is critical to ensure the

best audio quality. Two red/green LEDs will glow to accurately indicate modulation levels. The input circuitry

includes a wide range DSP-controlled limiter to prevent

distortion during high peak levels.

It is important to set the gain (audio level) high enough

to achieve full modulation during louder peaks in the

audio. The DSP-controlled limiter can handle peaks

over 30 dB above full modulation, so with an optimum

setting, the LEDs will flash red during use. If the LEDs

never flash red, the gain is too low. The -20 LED turns

red at 0 dB (full modulation).

Signal Level -20 LED -10 LED

Less than -20 dB Off Off

-20 dB to -10 dB Green Off

-10 dB to +0 dB Green Green

+0 dB to +10 dB Red Green

Greater than +10 db Red Red

AUDIO Button

The AUDIO button is used to display the gain and low

frequency roll-off settings. The UP and DOWN arrows

adjust the values. This button is also used with the

FREQ button to enter standby mode and to power the

transmitter on or off.

FREQ Button

The FREQ Button displays the selected operating frequency and also toggles the LCD between displaying

the actual operating frequency in MHz and a two-digit

hexadecimal number that corresponds to the equivalent Lectrosonics Frequency Switch Setting. This button is also used with the AUDIO button to enter standby

mode and to power the transmitter on or off.

Up/Down Arrows

The Up and Down arrow buttons are used to select the

values on the various setup screens and to lock out

the control panel. Pressing both arrows simultaneously

enters the lock countdown. When an attempt is made

to change a setting while the control panel is locked,

a message will flash on the LCD as a reminder that

the unit is locked. Once locked, the buttons can only

be unlocked by removing the batteries, or with the RM

remote control.

Antenna

The fixed whip antenna is constructed with a flexible,

woven, galvanized steel mesh cable.

6

LECTROSONICS, INC.

Page 7

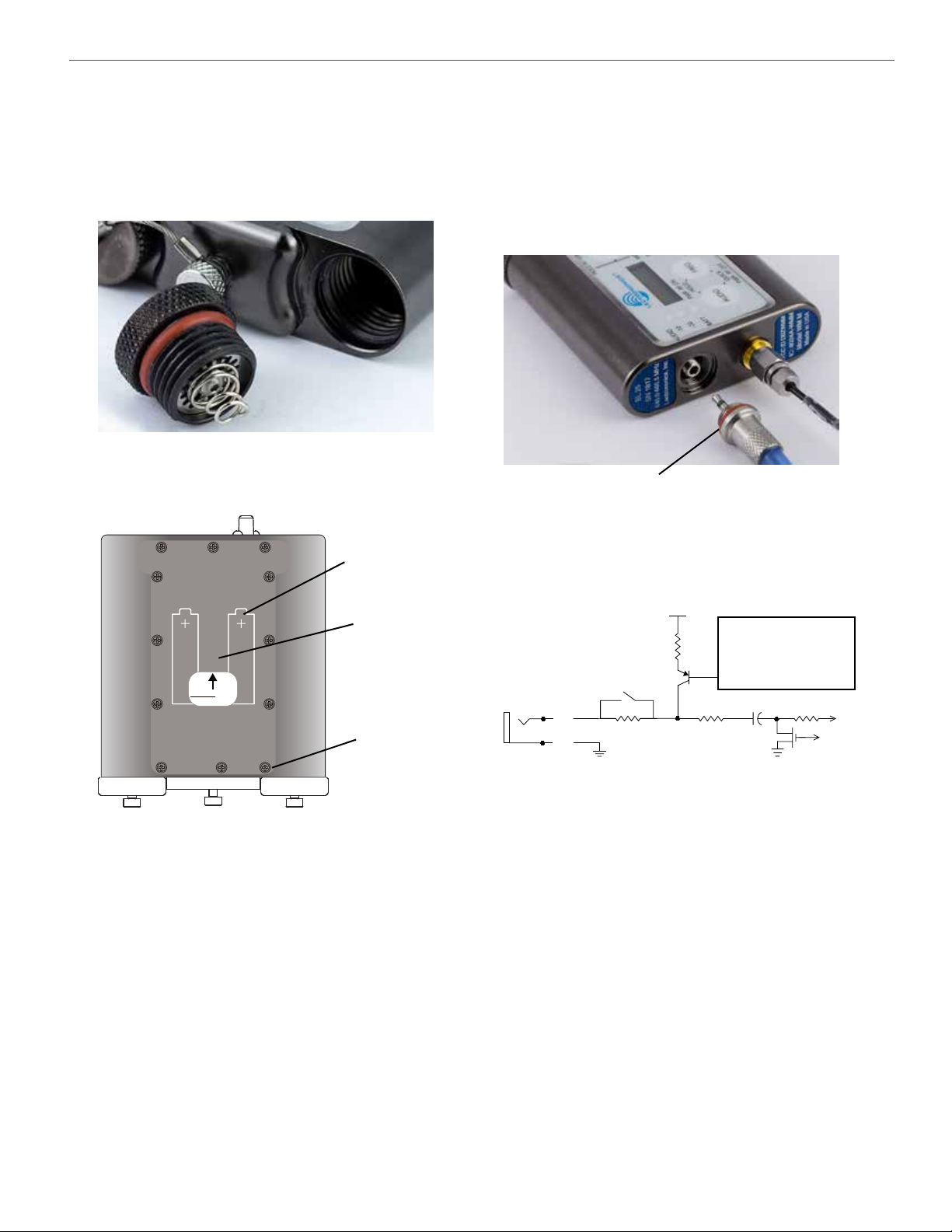

Watertight Transmitter

d

+5 VDC

Battery Compartments

The battery compartments are a rugged, straightforward design with a recessed entry that captures

the O-ring on the cap. The spring contact on the cap

maintains solid contact on the battery regardless of its

exact length.

The O-rings should be kept clean and dry, and coated

with petroleum jelly on a regular basis. See page 11 for

more information on preventing corrosion.

Battery polarity

is marked on the

rear cover

Input Connector

The threaded WP watertight plug on the microphone cable fits into a recessed jack on the top panel. The recess

in the opening retains the O-ring when the plug is tightened. The Lectrosonics M152WP lavaliere microphone is

supplied with the WP plug already installed. Other microphones can also be terminated with this plug by following

the instructions included with the WP connector kits.

Treat O-ring with petroleum jelly before

connecting (see page 11)

Equivalent Input Circuit

Diagram

Do not cover

vent holes

•

•

•

•

•

DO NOT COVER

VENT HOLES

Unscrew battery

caps to insert

batteries

About Batteries

The transmitter is powered by two AA batteries.

Lithium batteries are recommended for longest life,

which typically provides over 7.5 hours of operation at

room temperature with the output set to 250 mW. At 50

mW, the runtime is typically over 14 hours with lithium

batteries.

The PWR LED glows green when the battery is good.

The color changes to red at a mid-point of operating

life, and will continue to glow red until the battery gets

close to the end of its life. When the LED begins to

blink red, there are only a few minutes remaining.

The exact point at which the LED turns red will vary

with battery brand and condition, temperature and current drain. The LED is simply a reminder intended to

catch your attention, not an exact indicator of remaining time.

WM Equivalent

Input Circuit Wiring

closed for mic level

open for line level

MIC

GND

(menu item)

20k

332 Ohm

200 Ohm

Servo Bias

0, 2, 4V

Roll-off

35, 50, 70, 100, 120, 150 Hz

(menu selectable)

30uF/10V

100 Ohm

+

To Limiter Control

To Virtual Groun

Audio Amplifier

Rio Rancho, NM

7

Page 8

WM

Operating Instructions

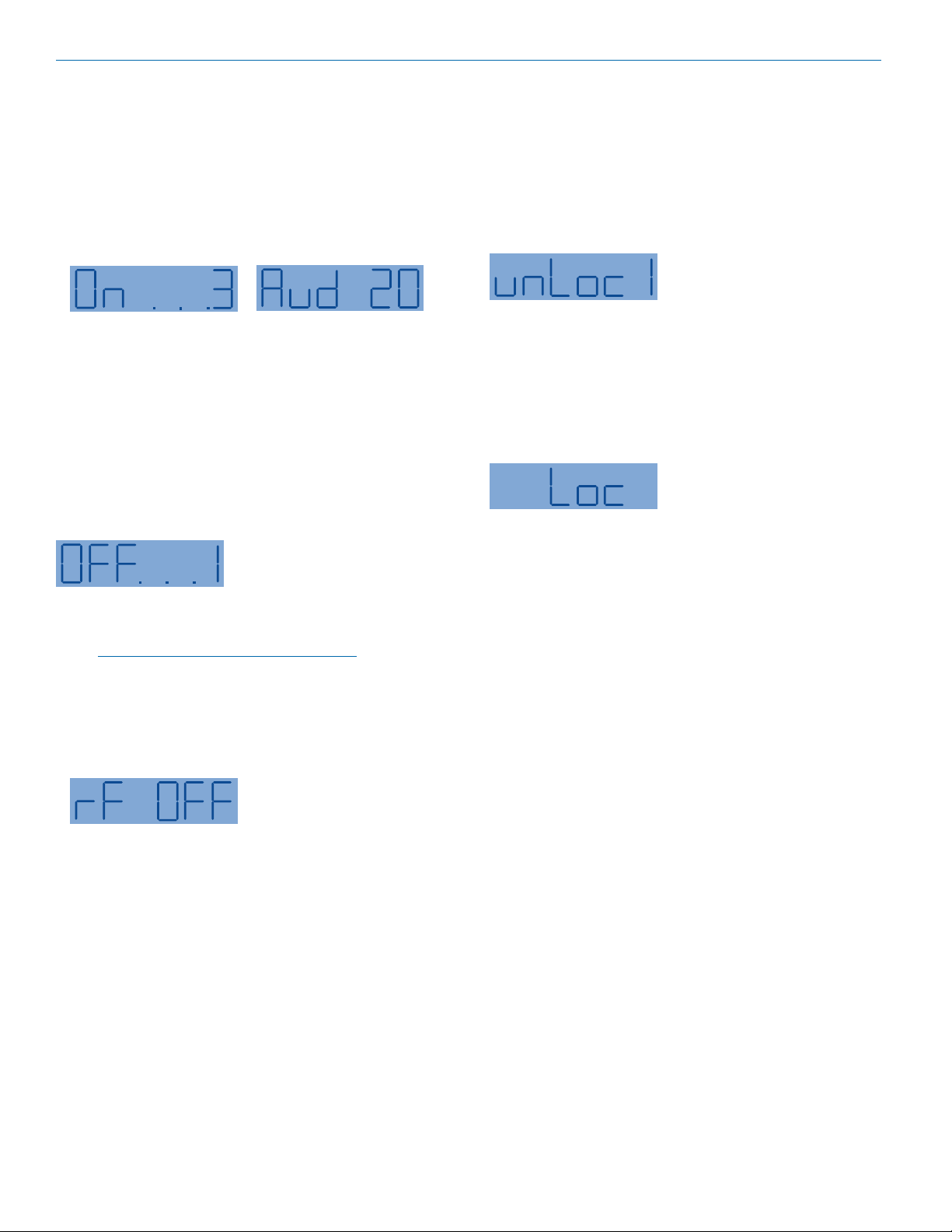

Power Up and Boot Sequence

Simultaneously press and hold the AUDIO and FREQ

buttons until the startup count is completed. The

screen will display a count from 1 to 3 as the unit boots

up, then it switches to the Audio screen. As the unit

turns on, the Modulation LEDs and PWR LED all glow

red, then green, and then revert to normal operation.

The LCD displays a boot sequence which consists of

four screens ending with the audio screen similar to

this example:

• Company name: Lectro

• Frequency block/Firmware Ver.: b22r2.4

• Power level: Pr 100

• Compatibility mode: CP IFB

• Audio (Input gain): Aud 22

Power Down

Simultaneously press and

hold the AUDIO and FREQ

buttons while observing that

the word “OFF” appears in the LCD along with a counter.

The screen will display a countdown from 3 to 1 and the

unit will then turn off.

Lock/Unlock the Keypad

The control panel buttons can be locked out to avoid

inadvertent changes in the settings or turning the

unit off unintentionally. Simultaneously pressing and

holding both the UP and DOWN arrow buttons during

normal operation starts a countdown timer.

The timer starts at three and counts down to zero.

When the timer reaches zero, the transmitter’s controls

are locked.

With the controls locked, the AUDIO and FREQ buttons can still be used to display current settings. Any

attempt to change a setting by pressing either the Up

or Down arrow button will result in an on-screen Loc

reminder that the controls are locked.

Once the transmitter is locked, it cannot be unlocked

or powered off using the buttons. The only ways to

unlock a locked transmitter are to remove the battery

or unlock it via the RM remote control.

Note: If the AUDIO and FREQ buttons are

released before the LCD goes blank at the end of

the countdown, the unit will not turn off. Instead,

it will stay energized and the display will return to

the previous screen.

Standby Mode

With the unit off, quickly

press both AUDIO and

FREQ buttons, and release

before counter reaches “0” to enter the “standby”

mode. In this mode the RF output is turned off so

adjustments can be made without interfering with other

systems operating in the same location. The LCD

displays rf OFF to remind you that the unit is not

transmitting.

Use the AUDIO and FREQ buttons to access the various setup screens. When the adjustments are complete, press both the AUDIO and FREQ buttons briefly

to save the settings and turn the unit off.

8

LECTROSONICS, INC.

Page 9

Watertight Transmitter

Menus and Settings

There are four locations for setup options and settings

accessed with the control panel:

• UP Arrow Menu and Settings

• DOWN Arrow Menu and Settings

• AUDIO button settings

• FREQ button settings

UP Arrow Settings

With the unit turned off, hold the UP arrow button and

simultaneously press the AUDIO and FREQ buttons.

Each successive press of the AUDIO button will step

through the setup screens.

• Compatibility Mode

• Input Type

• RF Power Output

• LCD Backlight

• Frequency Step Size

Use the UP and DOWN arrow buttons to scroll through

the options. The selected options will automatically be

stored when the power is turned off. Press both the

AUDIO and FREQ buttons to exit the menu and turn

the power off.

Input Type

The input can be configured for electret or dynamic

microphones or a line level input.

The transmitter features unique Servo Bias input circuitry that automatically adjusts the current to maintain

a selected bias voltage for electret microphone. This

effectively overcomes a traditional problem with variations in output levels and power supply currents of

different microphones.

Press the UP and DOWN arrows to select the desired

input type:

• LInE Bias turned off; line level impedance

• PH oFF Bias turned off for dynamic mics

• PH 2 Bias at 2 volts for electret mics

• PH 4 Bias at 4 volts for electret mics

The correct bias is specified by the microphone manufacturer. 4 volts is typical for most electret lavaliere

microphones. 2 volts is preferred by some mic manufacturers such as Countryman for the very small B6

and E6 models.

Hold the UP

arrow button

Then press the AUDIO and FREQ

buttons at the same time

Note: The unit is automatically set to “standby” in

this setup mode; with rF OFF not displayed.

Compatibility Mode

These modes provide

DSP-based emulations for

use with earlier Lectrosonics

equipment and with some

models from other manufacturers.

• CP NU Hybr: Nu Hybrid mode

• CP IFb: IFB Series mode

• CP 3: Mode 3 (contact the factory

for details)

RF Power Output

This setting provides an

option for the trade-off

between operating range

and battery life. The lowest

power setting provides maximum battery life, and the

highest power setting provides maximum operating

range and can also help to suppress some types of

interference from broadband RF noise.

NOTE: See the specifications for typical

operating times for each power level.

• Pr 50 for maximum battery life

• Pr 100 is an intermediate setting

• Pr 250 for maximum operating range

LCD Backlight

The backlight on the display

can be set to stay on all the

time or to turn off after either

30 seconds or 5 minutes of

inactivity on the panel switches. The backlight will turn

on and the timer will start over when a button is

pressed. Use the UP and DOWN arrow buttons to

select the desired setting.

• bl 5 Stay on for five minutes

• bl 30 Stay on for 30 seconds

• bl on Stay on continuously

Rio Rancho, NM

9

Page 10

WM

Frequency Step Size

This menu item allows frequencies to be selected in

either 25 kHz or 100 kHz increments. If the desired

frequency ends in .025, .050 or .075 MHz, the 25 kHz

step size must be selected.

Normally, the receiver is used to find a clear operating frequency. All Lectrosonics Digital Hybrid receivers

provide a scanning function to quickly find prospective

frequencies with little or no RF interference. In other

cases, a frequency may be specified by officials at a

large event such as the Olympics or a major league

ball game. Once the frequency is determined, set the

transmitter to match the associated receiver.

• Stp 100 Frequency steps in 100kHz increments

• Stp 25 Frequency steps in 25 kHz increments

DOWN Arrow Settings

Hold the DOWN arrow button and simultaneously

press the AUDIO and FREQ buttons. Each successive

press of the AUDIO button will step through the setup

screens.

• Remote Control

• Auto Power Restore

• Audio Mute

Use the UP and DOWN arrow buttons to scroll through

the options. The selected options will automatically be

stored when the power is turned off. Press both the

AUDIO and FREQ buttons to exit the menu and turn

the power off.

Hold the DOWN

arrow button

Then press the AUDIO and FREQ

buttons at the same time

Remote Control

Transmitter settings can be configured using special

tones generated by a smartphone using a remote

control application such as Lectro RM (available on the

AppStore or Google Play). Enable this feature on the

transmitter with the following menu items:

• rc on Enables the remote function

• rc oFF Disables the remote function

If a remote control signal is detected but the function is

turned off, the message rc oFF will be displayed briefly

on the transmitter’s LCD to confirm that a valid signal

was received, but that the transmitter is not configured

to respond to it.

Auto Power Restore

This setting determines how the transmitter is powered

up again after the batteries have become exhausted in

normal operation.

When this function is turned on, the unit will power

up to normal operation with a brief press of the AUDIO and FREQ buttons after the batteries have been

replaced.

When this function is turned off, the AUDIO and FREQ

buttons need to be held in for the completion of the

count to turn the unit back on for normal operation.

This is a unique behavior that takes place only when

the batteries fail during operation. If the unit is turned

off manually, a quick press of the buttons will turn it on

in the “standby” mode instead.

The firmware is written this way because the battery

caps make contact with the battery before the cap

is seated, and the fact that there are two separate

battery caps to tighten. This allows both batteries to

be installed and the caps tightened before power is

restored. It also makes turning the unit back on easier

when wearing gloves since the buttons do not need to

be held in.

• PbAc 1 Turns power restore ON

10

LECTROSONICS, INC.

Page 11

• PbAc 0 Turns power restore OFF

Audio Mute

Beginning with firmware v2.6 on the US version, the

AUDIO button can be configured to work as a mute

button by turning this setting on. A quick press of the

AUDIO button will then mute the audio and a message

will appear on the LCD confirming that the audio is

muted. Another quick press turns the audio back on.

• At on Enables the audio mute function

• At oFF Disables the audio mute function

During operation, the LCD will continuously display the

state of audio muting as a reminder, showing the audio

as ON or OFF.

The AUDIO button will still work to set Input Gain by

pressing and holding it in for a few seconds, however,

if the audio is muted, no sound will be heard during the

adjustment.

If the transmitter is in “standby,” the Low Frequency

Roll-off can be adjusted whether or not the audio mute

function is enabled. When the audio mute function is

enabled and the unit is turned on and transmitting,

only the audio level (input gain) can be adjusted by

holding the AUDIO button in for a few seconds.

Watertight Transmitter

Rio Rancho, NM

11

Page 12

WM

FREQ Button Settings

The frequency can be displayed either in MHz or as a

two-digit hexadecimal number and it can be set when

the unit is in “standby” or when the transmitter is powered up in the normal operating mode.

MHz Hex Code

The hexadecimal numbering system is unique to

Lectrosonics where two alphanumeric characters correspond to the left and right switch settings on earlier

analog transmitters that had mechanical rotary switches to adjust frequency.

• Press the FREQ button repeatedly to toggle

between either the MHz screen or the Hex Code

screen.

• While holding the FREQ button, use the UP or

DOWN arrow buttons to move the operating frequency up or down from the current setting.

The two-digit hex code is easier to remember, which

can be handy when setting up a multi-channel system.

AUDIO Button Settings

Low Frequency Roll-off

It is possible that the low

frequency roll-off point could

affect the gain setting, so it’s

generally good practice to make this adjustment before

adjusting the input gain. Press and hold the AUDIO

button while selecting the desired roll-off frequency

with the UP and DOWN arrows.

• LF 35 35 Hz

• LF 50 50 Hz

• LF 70 70 Hz

• LF 100 100 Hz

• LF 120 120 Hz

• LF 150 150 Hz

The roll-off is often adjusted by ear while monitoring

the audio.

Input Gain

Properly set, this adjustment

maximizes the signal to

noise ratio of the system,

and prevents loud peaks from being distorted. The

input gain can be adjusted with the unit in the “standby” mode or while powered up in normal operation.

The control panel Modulation LEDs indicate the audio

level and limiter activity.

This gain adjustment matches the transmitter gain with

the microphone’s output level, the user’s voice level

and the position of the microphone.

It is desirable to to set the gain so that some limiting

occurs on louder peaks. The limiter is very transparent

and its effect is not audible until the system is close to

overload. In other words, don’t be shy about turning

up the gain. You can turn the gain up to maximum and

listen for distortion or compression to get a feel for how

much headroom is available.

Signal Level -20 LED -10 LED

Less than -20 dB

-20 dB to -10 dB

-10 dB to +0 dB Green Green

+0 dB to +10 dB Red Green

Greater than +10 db

Note: Different voices will usually require

different gain settings, so check this adjustment

as each new person uses the system. If several

different people will be using the transmitter and

there is not time to make the adjustment for each

individual, adjust it for the loudest voice.

Warning: If the wireless system is connected

to a live sound system, turn the sound system

level down first to avoid severe feedback.

1) Position the microphone in the location where it

will be used in actual operation.

2) Place the transmitter in the “standby” mode or turn

it on for normal use.

3) While speaking or singing into the microphone at

the same voice level that will be used, observe

the LEDs on the control panel. Hold the AUDIO

button and press the UP or DOWN arrow buttons

to adjust the gain until the -20 LED flickers red on

louder peaks. This LED turns red at the instant

full modulation takes place and the very onset of

limiting. The red color does not indicate overload

or clipping.

-20 LED should flicker

red during louder peaks

in the audio

If the unit was set up in “standby” mode, it will be

necessary to turn the transmitter off, then power it up

again in normal operation so the RF output will be on.

Then the other components in the sound or recording

system can be adjusted.

NOTE: Do not use the gain adjustment to control

the volume of the sound system or the recorder

level.

Off Off

Green Off

Red Red

12

LECTROSONICS, INC.

Page 13

Watertight Transmitter

LectroRM

By New Endian LLC

LectroRM is a mobile application for iOS and Android

operating systems. Its purpose is to remotely control a

variety of Lectrosonics transmitters.

The app remotely changes settings on the transmitter through the use of encoded audio tones, which

when received by the attached microphone, will alter

the configured setting. The app was released by New

Endian, LLC in September 2011. The app is available

for download and sells for about $20 US on the Apple

App Store and Google Play Store.

LectroRM’s remote control mechanism is the use of an

audio sequence of tones (dweedles) that are interpreted by the transmitter as a configuration change. The

settings available in LectroRM are:

• Audio Level (input gain)

• Frequency

• Sleep Mode

• Lock Mode

• RF output power

• Low frequency roll-off

• LEDs ON/OFF

User Interface

The user interface is different between the iOS and

Android versions, although the available settings are

essentially the same.

iOS

Android

The Android version keeps all settings on the same

page and allows the user to navigate between the

activation buttons for each setting. The activation

button must be long pressed to activate. The Android

version also allows users to keep a configurable list of

full sets of settings.

Activation

For a transmitter to respond to remote control audio

tones, the transmitter must meet certain requirements:

• The transmitter must be turned on in either

standby or operating mode.

• The WM transmitter must have firmware version

2.4 or later for all settings to be available.

• The transmitter microphone must be within range.

• The transmitter must be configured to enable

remote control activation.

Please be aware this app is not a

Lectrosonics product. It is privately

owned and operated by New Endian LLC,

www.newendian.com.

The iOS version keeps each available setting on a

separate page with the list of options for that setting.

The “Activate” toggle switch must be enabled to show

the button which will then generate the “dweedle” tone.

The iOS version’s default orientation is upside-down

but can be configured to orient right-side up. The

purpose for this is to orient the device’s speaker, which

is at the bottom of the device, closer to the transmitter

microphone.

Rio Rancho, NM

13

Page 14

WM

Troubleshooting

Before going through the following chart, be sure that you have a good battery in the transmitter. It is important that

you follow these steps in the sequence listed.

SYMPTOM POSSIBLE CAUSE

TRANSMITTER PWR LED OFF 1) Battery is inserted backwards or dead.

2) Transmitter not powered up. (See Operating Instructions,

Power UP and Boot Sequence.)

TRANSMITTER PWR LED BLINKS GREEN EVERY FEW SECONDS, TRANSMITTER

DOES NOT RESPOND OTHERWISE 1) Transmitter has been put to sleep by the remote control.

Either use the remote control to wake it up again or remove

and reinsert the transmitter battery.

AUDIO LEVEL LEDs NOT LIGHTING 1) Gain control set to minimum.

2) Wrong input type selected (such as Line instead of PH 4)

3) Batteries are dead or installed backwards. Check PWR LED.

4) Mic capsule is damaged or malfunctioning.

5) Mic cable damaged or mis-wired.

RECEIVER RF INDICATOR OFF 1) Transmitter not turned on, or is in Standby mode.

2) Transmitter battery is dead.

3) Receiver antenna missing or improperly positioned.

4) Transmitter and receiver not on same frequency or block.

Check switches/display on transmitter and receiver.

5) Operating range is too great.

6) Defective transmitter antenna.

NO SOUND (OR LOW SOUND LEVEL), RECEIVER INDICATES PROPER AUDIO MODULATION

1) Receiver output level set too low.

2) Receiver output disconnected, or cable defective or mis-wired.

3) Sound system or recorder input is turned down.

DISTORTED SOUND 1) Transmitter gain (audio level) is far too high. Check audio level

LEDs and receiver audio levels during use.

2) Receiver output may be mismatched with the sound system or

recorder input. Adjust output level on receiver to the correct level

for the recorder, mixer or sound system. (Use the receiver’s Tone

function to check level.)

3) Transmitter is not set to same frequency as receiver. Check that

operating frequency on receiver and transmitter match.

4) Receiver/Transmitter Compatibility mode mismatched.

EXCESSIVE FEEDBACK 1) Transmitter gain (audio level) too high. Check gain adjustment

and/or reduce receiver output level.

2) Talent standing too close to speaker system.

3) Mic is too far from user’s mouth.

14

LECTROSONICS, INC.

Page 15

Watertight Transmitter

SYMPTOM POSSIBLE CAUSE

HISS AND NOISE -- AUDIBLE DROPOUTS 1) Transmitter gain (audio level) far too low.

2) Receiver antenna missing or obstructed.

3) Transmitter antenna broken or missing.

4) Operating range too great.

5) Signal interference. Turn off transmitter. If receiver’s signal

strength indicator does not drop to nearly zero, this indicates an

interfering signal may be the problem. Try a different operating

frequency.

“Loc” APPEARS IN DISPLAY WHEN ANY BUTTON IS PRESSED

1) Control Panel is locked.

(See Operating Instructions, Lock/Unlock the Keypad)

“Hold” APPEARS IN DISPLAY WHEN ARROW BUTTONS ARE PRESSED

1) Reminder that it is necessary to hold down the AUDIO or

FREQ button to make adjustments to the audio gain or

frequency settings.

“PLL” APPEARS IN DISPLAY 1) Indication that the PLL is not locked. This is a serious condition

that requires factory repair. It may be possible to operate on

another frequency far removed from the one that was selected

when the condition was indicated.

TRANSMITTER WON’T RESPOND TO REMOTE CONTROL

1) If LCD blinks “rc oFF”, transmitter has not been configured

to respond to the remote control.

See Down Arrow Settings and LectroRM.

2) If LCD blinks “- - - - - -”, transmitter is already set as

requested by the remote control.

3) If transmitter does not respond at all, try moving the

remote control closer to the microphone or increasing the

remote control’s loudness setting.

4) Make sure transmitter is not in Sleep mode.

Rio Rancho, NM

15

Page 16

WM

Accessories and

Replacement Parts

Spring Loaded Belt Clip

Model WMBCSL spring loaded belt clip. Includes hardware kit shown below.

Wire Belt Clip

Model WMBCWIRE includes hardware kit shown

below.

WPMC-10

Watertight connector kit,10 piece, to terminate lavaliere microphones for use with the WM transmitter.

Replacement O-rings

Model ORINGKIT/WM Includes replacement O-rings

for battery caps and microphone plug with WM style

connector, and petroleum jelly pouch.

Belt Clip Hardware Kit

Included with SL and WIRE type belt clips. Provides

mounting of belt clips with either set screws using allen

wrench, or thumb screws.

WPMC-3

Watertight connector kit, 3 piece, to terminate lavaliere

microphones for use with the WM transmitter.

Separate parts:

P/N 35877 O-ring; .433” ID x .623” OD

P/N 35750 O-ring; .312” ID x .437” OD

P/N 32408 petroleum jelly pouch; 5 grams

Replacement battery caps

Model WMDESIKIT includes replacement battery

caps, O-rings, lanyards, thumbscrew and allen wrench.

Includes moisture absorbing

desiccant beads inside caps

See page 18 for details.

16

LECTROSONICS, INC.

Page 17

Straight Whip Antennas

Whip Length

This is a full size cutting template used to cut the

length of the whip for a particular frequency. Lay the

uncut antenna on top of this drawing and trim the whip

length to the desired frequency.

After cutting the antenna to the desired length, mark

the antenna by installing a color cap or sleeve to indicate the color listed in the table below

Note: Check the scale of your printout - his line should be 6.00 inches long (152.4 mm)

944

Watertight Transmitter

The supplied caps can be used several different ways:

1) A color cap on the end of the whip

2) A color sleeve next to the connector with a black cap

on the end of the whip (trim the closed end of the

colored cap off with scissors to make a sleeve).

3) A color sleeve and color cap (cut the cap in half with

scissors).

22

23

24

25

26

27

28

29

21

20

19

470

BLOCK FREQUENCY CAP/SLEEVE ANTENNA

RANGE COLOR WHIP LENGTH

470 470.100 - 495.600 Black w/ Label 5.67”

19 486.400 - 511.900 Black w/ Label 5.23”

20 512.000 - 537.500 Black w/ Label 4.98”

21 537.600 - 563.100 Brown w/ Label 4.74”

22 563.200 - 588.700 Red w/ Label 4.48”

23 588.800 - 607.950 Orange w/ Label 4.24”

NOTE:

Not all Lectrosonics products are built on all of the blocks covered in

this table.

Factory supplied antennas precut to length include a label with the

frequency range. Label is not supplied with this kit.

Rio Rancho, NM

17

Page 18

WM

Preventing Corrosion

Whenever the transmitter has been exposed to moisture or perspiration, follow the instructions below to

minimize the risk of corrosion.

DRY THE UNIT BEFORE REMOVING THE

MICROPHONE CONNECTOR OR BATTERY

CAPS.

If the transmitter has been exposed to salt water,

rinse it with fresh water and then dry the exterior of

the transmitter thoroughly with a clean paper towel or

cloth. Remove all moisture around the battery caps

and microphone cable connector.

After removing the battery caps and microphone connector, wipe off any residual moisture around the battery compartment and microphone jack openings and

on the battery caps and microphone connector.

The O-rings should be coated with Vaseline® or an

equivalent petroleum jelly* before each use to ensure

the seals are watertight.

DO NOT USE ANYTHING OTHER THAN

PURE PETROLEUM JELLY TO LUBRICATE

THE O-RINGS. Silicon-based lubricants will

dissolve the O-rings.

Store the unit with no batteries installed, battery caps

removed and the microphone disconnected to allow

any buildup of humidity and moisture to evaporate.

Also see the section in the back of this manual entitled

Desiccant Battery Caps.

Battery Door Update

Early WM transimitters were supplied with standard

battery door caps. The newer battery caps include a

drying agent in a cavity to help absorb moisture inside

the transmitter. The caps are available in a kit for updating older transmitters.

Kit consists of pre-assembled battery doors

with thumbscrew and hex key (Allen wrench)

Remove old center screw with the supplied hex key

(Allen wrench).

Install new battery caps and tighten the thumb screw

by hand. The thumbscrew is removed to recondition

(dry out) the desiccant beads.

Desiccant Battery Caps

Early WM transmitters were shipped with standard

battery caps. Later engineering developed an updated

battery cap design that contained moisture absorbing

desiccant beads to protect the interior of the transmitter from excess humidity. These caps are available as

a kit to update early WM transmitters, or to replace lost

or damaged caps.

Beads are amber/orange

in color when able to

absorb moisture.

These battery doors on the WM will absorb small

amounts of moisture and humidity from the inside of

the transmitter. You must still be careful to keep moisture out of the WM by opening it only in dry or sheltered areas and by making sure the battery surfaces

are dry before installing them. Always use the WP waterproof mic connector in wet conditions. The desiccant

doors will only remove a few drops of moisture.

Beads are stored

inside the cap to

absorb moisture

through the vent

holes.

Eventually, the desiccant beads absorb enough moisture that they will become ineffective and turn green

or blue instead of the normally dry color of amber/

orange. To recharge the desiccant, it must be heated

to 200 to 400 degrees F for at least an hour, preferably

more. The desiccant, the silicone O-ring seals and the

doors can withstand maximum temperatures up to 400

degrees F (205 degrees C).

The doors can be put into an oven at 200 degrees F

for several hours. As the heat drives out the absorbed

moisture, the desiccant will turn back to its normal

amber/orange color.

Do not put the WM transmitter itself into any

oven or heating device.

After heating, particularly at higher temperatures, the

O-rings will likely need a tiny dab of petroleum jelly

(Vaseline*) to replace the lubricant that may migrate in

the heat.

18

LECTROSONICS, INC.

Page 19

Watertight Transmitter

Re-conditioning (drying out) the caps and

desiccant beads

An easy way to heat the doors is to use a coffee mug

warmer, which typically costs about $10. The surface

temperature of about 220 degrees (F) will dry the

doors and desiccant, but it will not disturb any light

lubricant (like the Vaseline petroleum provided with

the WM) that is on the O-ring seals.

It is also possible to use the mug warmer to dry out the

doors without removing them from the case as shown

below. Do not place the transmitter on this heated

surface. Lay it to one side as shown.

Replacing the desiccant beads

When the beads remain darker green or blue, they

may not be absorbent any longer and should be replaced. Remove the screw that retains the spring and

vented cover with a small Phillips screwdriver.

While the cap assembly is apart and the beads removed, the parts can be cleaned to remove dust and

corrosion. The best way to clean the parts is with petroleum jelly (Vaseline). Apply the petroleum jelly and

then wipe the parts clean.

The mug warmer used for testing consumed 17 watts,

so it could even be used on a sound cart AC supply

without being a huge drain on the batteries.

The color of the desiccant beads can be observed by

shining a pen light on one edge of the battery cap to

illuminate the desiccant. Ideally, they will be an amber/

orange color at room temperature.

Vented cover

Do not use a silicone based oil or grease as it

will dissolve the O-rings.

Do not expose the desiccant beads to any

cleaning liquids or other materials.

Replace the beads with new, amber colored ones. Fill

the cavity to just below the top of the threaded stem

that holds the cover in place so that the cavity is full,

but the beads are not compressed when the vented

cover is replaced.

The desiccant beads are silica gel grade 52, manufactured by a US Company named ADCOA under part

number SG52002. Large containers can be purchased

from ADCOA, and small quantities are available from

Lectrosonics. Contact Lectrosonics for details.

*Vaseline is a registered trademark of Conopco, Inc.

Rio Rancho, NM

19

Page 20

WM

z1

+6

Specifications

Operating frequencies:

Block 470 470.100 - 495.675

Block 19 486.400 - 511.975

Block 20 512.000 - 537.575

Block 21 537.600 - 563.175

Block 22 563.200 - 588.775

Block 23a 588.800 - 607.950

Channel Spacing: 25 kHz or 100 kHz

Frequency selection: Control panel mounted membrane switches

RF Power output: Switchable; 50, 100 or 250 mW

Compatibility Modes (3) Nu Hybrid, IFB, Mode 3

Pilot tone: 3.5 kHz deviation (Nu Hybrid)

Frequency stability: ± 0.002%

Spurious radiation: Compliant with ETSI EN 300 422-1 v1.4.2

Equivalent input noise: –125 dBV, A-weighted

Input level:

Dynamic mic: 0.5 mV to 50 mV before limiting.

Greater than 1 V with limiting.

Electret lavaliere mic: 1.7 uA to 170 uA before limiting.

Greater than 5000 uA (5 mA) with limiting.

Line level input: 17 mV to 1.7 V before limiting.

Greater than 5 V with limiting.

Input impedance:

Dynamic mic: 300 Ohms

Electret lavaliere: Input is virtual ground with servo adjusted

constant current bias

Line level: > 2.7 k Ohms

Input limiter: Soft limiter, 30 dB range

Bias voltages: Selectable; 2V, 4V and Off

Gain control range: 44 dB; panel mounted membrane switches

Modulation indicators: Dual bicolor LEDs indicate modulation of

–20, -10, 0, +10 dB referenced to full modulation

Controls: Control panel with LCD and four membrane

switches

AA battery compartments are O-ring sealed

Low frequency roll-off: Adjustable from 35 to 150 Hz

Audio Frequency Response: 35 Hz to 20 kHz, +/-1 dB (The low frequency

roll-off is adjustable - see graph above)

Signal to Noise Ratio (dB):

(Note: the dual envelope “soft”

limiter provides exceptionally

good handling of transients

using variable attack and release

time constants. The gradual onset of limiting in the design begins below full modulation,

which reduces the measured figure for SNR without limiting by 4.5 dB)

Total Harmonic Distortion: 0.2% typical (Nu Hybrid mode)

Audio Input Jack: 2.5 mm locking micro; threaded for stainless

sleeve on WP connector

Antenna: Flexible, unbreakable steel cable.

Batteries: 1.5 Volt AA (lithium recommended)

Power Setting: Battery Life:

(HH:MM)

50 mW (2 AA): 13:00

100 mW (2 AA): 10:45

250 mW (2 AA): 5:45

+3

0dB

Mic in 35 Hz

-3

Roll-off

Line in

-6

-9

-12

Mic in 150 Hz

Roll-off

30

100

1kH

20k

0k

SmartNR No Limiting w/Limiting

OFF 103.5 108.0

NORMAL 107.0 111.5

FULL 108.5 113.0

Weight: 5.33 oz. (151 grams) with lithium batteries

Housing Dimensions: 2.98 x 2.55 x 0.77 inches

75.7 x 64.8 x 19.6 mm

(including battery caps)

Emission Designator: 110KF3E

The recess in the battery compartment

Specifications subject to change without notice.

traps the O-ring for a tight seal.

20

LECTROSONICS, INC.

Page 21

Watertight Transmitter

Rio Rancho, NM

21

Page 22

WM

Service and Repair

If your system malfunctions, you should attempt to correct or isolate the trouble before concluding that the equipment needs repair. Make sure you have followed the setup procedure and operating instructions. Check the interconnecting cables and then go through the Troubleshooting section in this manual.

We strongly recommend that you do not try to repair the equipment yourself and do not have the local repair shop

attempt anything other than the simplest repair. If the repair is more complicated than a broken wire or loose connection, send the unit to the factory for repair and service. Don’t attempt to adjust any controls inside the units. Once

set at the factory, the various controls and trimmers do not drift with age or vibration and never require readjustment.

There are no adjustments inside that will make a malfunctioning unit start working.

LECTROSONICS’ Service Department is equipped and staffed to quickly repair your equipment. In warranty repairs

are made at no charge in accordance with the terms of the warranty. Out-of-warranty repairs are charged at a modest flat rate plus parts and shipping. Since it takes almost as much time and effort to determine what is wrong as it

does to make the repair, there is a charge for an exact quotation. We will be happy to quote approximate charges by

phone for out-of-warranty repairs.

Returning Units for Repair

For timely service, please follow the steps below:

A. DO NOT return equipment to the factory for repair without first contacting us by email or by phone. We need to

know the nature of the problem, the model number and the serial number of the equipment. We also need a

phone number where you can be reached 8 A.M. to 4 P.M. (U.S. Mountain Standard Time).

B. After receiving your request, we will issue you a return authorization number (R.A.). This number will help speed

your repair through our receiving and repair departments. The return authorization number must be clearly

shown on the outside of the shipping container.

C. Pack the equipment carefully and ship to us, shipping costs prepaid. If necessary, we can provide you with the

proper packing materials. UPS is usually the best way to ship the units. Heavy units should be “double-boxed”

for safe transport.

D. We also strongly recommend that you insure the equipment, since we cannot be responsible for loss of or dam-

age to equipment that you ship. Of course, we insure the equipment when we ship it back to you.

Lectrosonics USA:

Mailing address: Shipping address: Telephone:

Lectrosonics, Inc. Lectrosonics, Inc. (505) 892-4501

PO Box 15900 561 Laser Rd. Ste. 102 (800) 821-1121 Toll-free

Rio Rancho, NM 87174 Rio Rancho, NM 87124 (505) 892-6243 Fax

USA USA

Web: E-mail:

www.lectrosonics.com sales@lectrosonics.com

Lectrosonics Canada:

Mailing Address: Telephone: E-mail:

720 Spadina Avenue, (416) 596-2202 Sales: colinb@lectrosonics.com

Suite 600 (877) 753-2876 Toll-free Service: joeb@lectrosonics.com

Toronto, Ontario M5S 2T9 (877-7LECTRO)

(416) 596-6648 Fax

22

LECTROSONICS, INC.

Page 23

Page 24

m

LIMITED ONE YEAR WARRANTY

The equipment is warranted for one year from date of purchase against defects in

materials or workmanship provided it was purchased from an authorized dealer. This

warranty does not cover equipment which has been abused or damaged by careless

handling or shipping. This warranty does not apply to used or demonstrator equipment.

Should any defect develop, Lectrosonics, Inc. will, at our option, repair or replace any

defective parts without charge for either parts or labor. If Lectrosonics, Inc. cannot

correct the defect in your equipment, it will be replaced at no charge with a similar new

item. Lectrosonics, Inc. will pay for the cost of returning your equipment to you.

This warranty applies only to items returned to Lectrosonics, Inc. or an authorized

dealer, shipping costs prepaid, within one year from the date of purchase.

This Limited Warranty is governed by the laws of the State of New Mexico. It states the

entire liablility of Lectrosonics Inc. and the entire remedy of the purchaser for any

breach of warranty as outlined above. NEITHER LECTROSONICS, INC. NOR

ANYONE INVOLVED IN THE PRODUCTION OR DELIVERY OF THE EQUIPMENT

SHALL BE LIABLE FOR ANY INDIRECT, SPECIAL, PUNITIVE, CONSEQUENTIAL,

OR INCIDENTAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE

THIS EQUIPMENT EVEN IF LECTROSONICS, INC. HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL THE LIABILITY OF

LECTROSONICS, INC. EXCEED THE PURCHASE PRICE OF ANY DEFECTIVE

EQUIPMENT.

This warranty gives you specific legal rights. You may have additional legal rights which

vary from state to state.

581 Laser Road NE • Rio Rancho, NM 87124 USA • www.lectrosonics.com

(505) 892-4501 • (800) 821-1121 • fax (505) 892-6243 • sales@lectrosonics.co

19 October 2018

Loading...

Loading...