Page 1

UM300B

FREQUENCY-AGILE UHF

BELT-PACK TRANSMITTER

EURO MODEL

OPERATING INSTRUCTIONS

and trouble-shooting guide

LECTROSONICS, INC.

www.lectrosonics.com

0885

Page 2

TABLE OF CONTENTS

INTRODUCTION ................................................................................................... 3

GENERAL TECHNICAL DESCRIPTION ............................................................. 4

CONTROLS AND FUNCTIONS ........................................................................... 6

BATTERY INSTALLATION .................................................................................... 8

OPERATING INSTRUCTIONS ............................................................................. 8

OPERATING NOTES ............................................................................................. 9

ADJUSTING THE TRANSMITTER FREQUENCY .............................................. 9

MICROPHONE CORD TERMINATION .............................................................. 10

5-PIN INPUT JACK WIRING............................................................................... 11

A6U UHF ANTENNA ........................................................................................... 13

TROUBLESHOOTING ......................................................................................... 14

SPECIFICATIONS AND FEATURES.................................................................. 15

SERVICE AND REPAIR ........................................................................ Back cover

WARRANTY ........................................................................................... Back cover

2

Page 3

Frequency Agile UHF Belt-Pack Transmitter

INTRODUCTION

Thank you for selecting the Lectrosonics UM300B frequency agile, belt-pack transmitter. The UM300B combines over 80 years of engineering experience with the very

latest components, in a design that addresses the most demanding professional

applications.

The design of the UM300B was the direct result of numerous conversations with

users, staging and touring companies and dealers across the US. The specific

concerns and needs brought up in these conversations led directly to the development of the operational features offered on the UM300B. Up to two hundred fifty six

frequencies are user selectable to alleviate interference problems in travelling

venues, and the low frequency roll-off is user adjustable to adapt to varying acoustic

environments and preferences.

The UM300B is a rugged, machined aluminum package with a removable, spring

loaded belt clip. The input section provides a correct input tap for virtually any

microphone or line level audio source. 5 Volts of bias voltage is available to power

electret mics with either positive or negative bias. Level indicating LEDs are provided

on the control panel to make level settings quick and accurate, without having to

view the receiver. The battery compartment accepts any 9 Volt alkaline battery and

makes a positive connection via self-adjusting contacts. The antenna is a detachable, locking 1/4 wavelength flexible bronze cable that connects to a 50 Ohm SMA

port on the transmitter.

Only the UM300B transmitter is covered in this manual. Companion receivers are

covered in separate manuals. The UM300B will operate with any 300 Series Lectrosonics receiver in the same frequency group.

Lectro Model: UM300B

Int. App No: RO192WM

Modulation Type: 180KF3E

Freq. Range: 844.8 - 862 MHz

Ser. No: XXXXXX - Block 33

Rio Rancho, NM – USA

3

Page 4

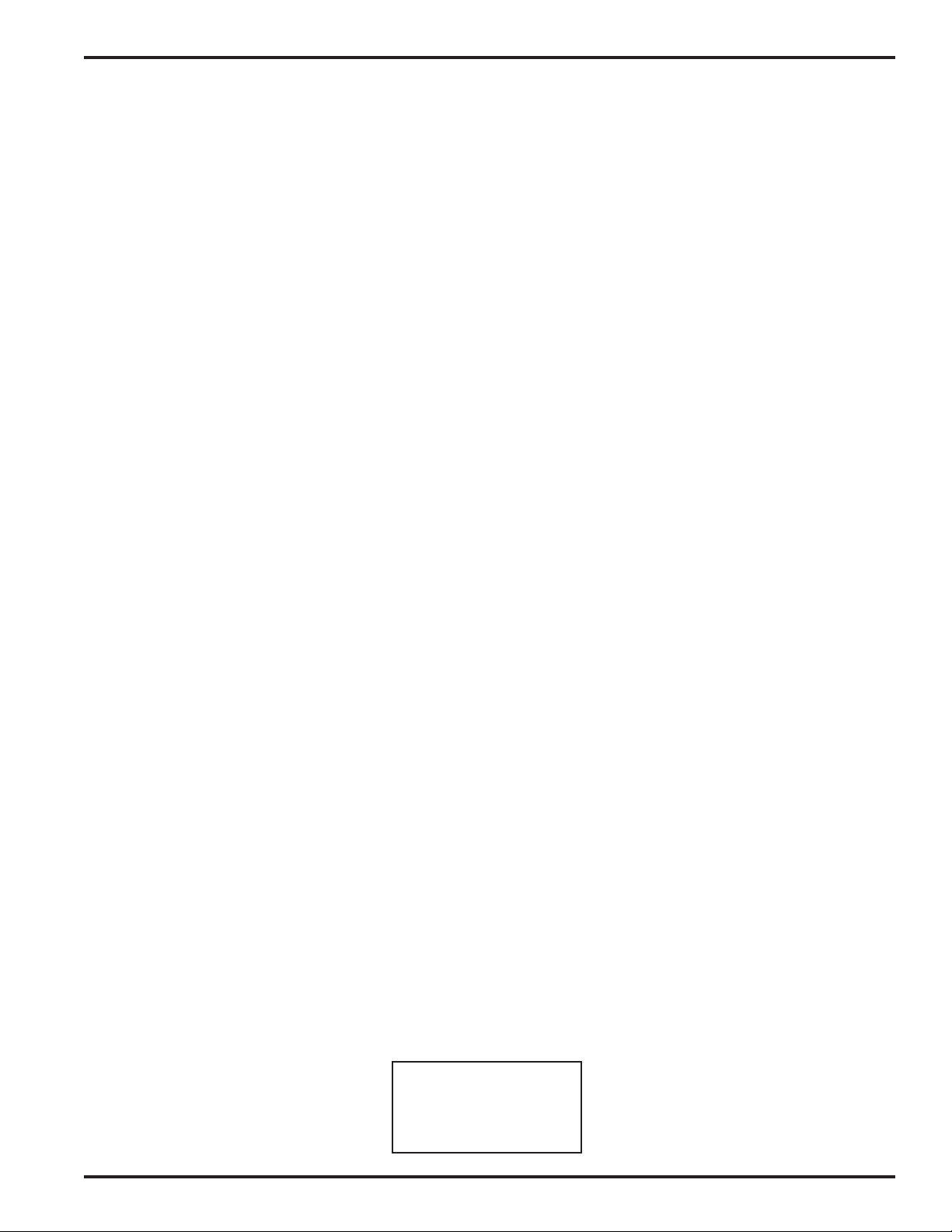

GENERAL TECHNICAL DESCRIPTION

The UM300B transmitters are comprised of a number of functional sub-systems as shown in the block diagram

below.

GENERAL

The 300 system uses 50kHz wide deviation for an extremely high signal to noise ratio. The transmitter circuits are all

regulated to allow full output power from the beginning (9 Volts) to the end (6.5 Volts) of battery life. The input amplifier uses a Motorola 33178 op amp for ultra low noise operation. It is gain controlled with a wide range input compressor which cleanly limits input signal peaks over 30dB above full modulation.

DUAL BAND COMPANDOR

Traditionally, compandors have been a source of distortion in wireless microphone systems. The basic problem with

conventional systems is that the attack and decay times are always a compromise. If the time constants are fast,

high frequency transients will not be distorted, but this will cause low frequency distortion. If the time constants are

slower, low frequency audio distortion will be low, but high frequency transients will then be distorted. The 300

system introduces an entirely new approach to solving this basic problem, called “dual-band companding.”

There are actually two separate compandors in the 300 system, one for high frequencies and one for low frequencies. A crossover network separates the frequency bands at 1kHz with a 6dB per octave slope, followed by separate

high and low frequency compandors. The attack and release times in the high frequency compandor are fast enough

to keep high frequency transient distortion at a low level, and the low frequency compandor uses slower time constants, reducing low frequency distortion to well below that of a conventional compandor.

MIC

JACK

1

2

3

4

5

FREQ

SWITCHES

LIMIT

LED

+5V BIAS

SUPPLY

BUFFER

SHUNT

LIMITER

SYNTHESIZER

uP

LF

ROLL-OFF

INPUT

AMP

AUDIO

LEVEL

SET

LED

LOW PASS

FILTER

2

E PROM

LP

FILTER

PEAK AUDIO

INDICATOR &

LIMITER

DRIVER

COMPANDOR

Vref

BASS

TREBLE

COMPANDED

LP FILTER

HP FILTER

AUDIO

UM300B Block Diagram

PILOT

TONE

OSC

Vreg

+5VDC

Vreg

+3.6VDC

VOLTAGE

CONTROLLED

OSCILLATOR

COMPANDED AUDIO

PWR

TRANSMITTER

TO XMTR

DELAY

+9VDC

PWR

LED

4

Page 5

Frequency Agile UHF Belt-Pack Transmitter

NO PRE-EMPHASIS/DE-EMPHASIS

The signal to noise ratio of the 300 system is high enough to preclude the need for conventional pre-emphasis (HF

boost) in the transmitter and de-emphasis (HF roll off) in the receiver. Pre-emphasis and de-emphasis in an FM

radio system usually provides about a 10dB improvement in the signal to noise ratio of the system, but the high

frequency boost in the transmitter must be removed in a purely complementary manner or else the frequency

response of the original audio signal will be altered.

Pre-emphasis can also cause distortion in the receiver. As this signal is passed through the IF filters in the receiver,

distortion can be produced, most noticeable at full modulation. De-emphasis cannot be applied until the signal is

converted into audio, so there is no way around this problem short of eliminating pre-emphasis altogether. Neither of

these problems occur in the 300 system. The dual-band compandor in the 300 Series system essentially provides a

dynamic pre-emphasis/de-emphasis function with extremely low distortion.

PILOT TONE SQUELCH

The 300 system utilizes an ultrasonic tone modulation of the carrier to operate the receiver squelch. This “pilot tone”

consists of a 32kHz signal mixed with the audio signal following the microphone preamp, just after the compandor, to

control the audio output muting of the receiver. The pilot tone is filtered out of the audio signal immediately after the

detector in the receiver so that it does not influence the compandor or various gain stages. The basic benefit of the

pilot tone squelch system is that the receiver will remain muted until it receives the pilot tone from the matching

transmitter, even if a strong RF signal is present on the carrier frequency of the system. This is extremely important

in applications that include an automatic microphone mixer.

WIDE-BAND DEVIATION

±50kHz deviation improves the capture ratio, signal to noise ratio and AM rejection of a wireless system dramatically,

compared to the more commonly used ±15kHz deviation.

LONG BATTERY LIFE

High efficiency circuits throughout the design allow over 7hours of operation using a single 9 Volt alkaline battery. (A

9V lithium battery will provide over 17 hours of operation.) The battery compartment is a unique mechanical design

which automatically adjusts to fit any brand of battery. The battery contacts are spring loaded to prevent “rattle” as

the unit is handled.

FREQUENCY AGILITY

The transmitter section uses a synthesized, frequency selectable main oscillator The frequency is extremely stable

over a wide temperature range and over time.

Two rotary switches, located on the side panel of the unit, provide a maximum of 256 frequencies in 25kHz steps

minimum over a maximum range of 25.5MHz. This alleviates carrier interference problems in mobile or travelling

applications.

ANTENNA

At UHF frequencies, where wavelengths and antennas are shorter than at VHF frequencies, a resonant length wire is

preferred over using the microphone cable as the antenna. The antenna on the UM300B consists of a flexible 1/4

wavelength bronze cable, detachable via an SMA connector. The impedance of this connector is 50 Ohms.

Rio Rancho, NM – USA

5

Page 6

CONTROLS AND FUNCTIONS

LECTROSONICS

FREQUENCY

COARSE

FINE

0

0

F

F

1

E

D

C

B

A

1

E

2

2

3

3

D

C

4

4

B

5

5

6

6

A

9

9

7

7

8

8

UM300B

0

–20

FREQUENCY

ADJUST

LF ROLL-OFF

ADJUST

75 Hz

35

150

LF ROLL OFF

LECTRO UM300B - Int. App No: RO192WM

Modulation Type: 180KF3E

Freq. Range: 844.8 - 862 MHz

Ser. No: XXXXXX - Block 33

OFF ON

AUDIO

LEVEL

ANTENNA

INPUT JACK

The input on the UM300B accommodates virtually every lavalier, hand-held or shotgun microphone available. Line

level signals can also be accommodated. Use a Switchcraft TA5F connector on the cord. See the separate sheet

titled “Transmitter 5-Pin Input Jack Wiring” regarding the correct connections for various microphones, and

other sources.

ON/OFF SWITCH

Turns the battery power on and off. Even when the switch is turned off or on abruptly, the pilot tone muting system

prevents “thumps” or transients from occurring.

“ON” LAMP

Glows brightly when the battery is good and the ON/OFF switch is ON. A weak or dim lamp means that the battery

is weak. When the light goes out there is about 15 to 30 minutes of operation left. If the lamp fails to light, the

battery should be replaced.

The “ON” lamp is connected to a precision battery test circuit that continuously monitors battery voltage. The LED is

at full brightness with a new 9 Volt alkaline battery. As the battery voltage drops during use, the LED brightness will

also decrease. After about 7 hours of operation the battery voltage will be about 6.5 Volts and the LED will be

completely out.

FREQUENCY ADJUST

0

1

These two rotary switches adjust the center frequency of the carrier. The left

switch (COARSE) changes the operating frequency by larger increments and the

right switch (FINE) changes it in small increments per step. These steps are

determined by the programming in the unit. Refer to the chart of settings provided with the unit.

F

E

D

C

B

A

2

3

4

5

6

9

7

8

Since the internal circuits are all tightly regulated and the RF output stage has a

separate discrete regulator, the transmitter will continue to operate to a battery voltage of 6.5 Volts. From 6.5 Volts to

6 Volts, the transmitter will still operate, but with degraded performance. Please note that a weak battery will sometimes light the POWER LED immediately after turn on, but will soon discharge to the point where the LED will go out,

just like a flashlight with “dead” batteries.

The combination of an accurate battery condition indicator and regulation of all internal circuits provides much longer

battery life, as well as consistent performance over the life of the battery.

0

1

F

E

D

C

B

A

2

3

4

5

6

9

7

8

6

Page 7

MODULATION LEDS

Indicate the proper setting of the MIC LEVEL control.

“-20” LED -- Flickers or glows when sufficient audio is present.

Frequency Agile UHF Belt-Pack Transmitter

“0” LED -- Lights up when the input level is high enough to cause limiting. The input limiter has a very high

overload threshold (over 30 dB). Generally speaking, some limiting is desirable in normal operation to

improve the signal to noise ratio of the system. The limiting action is not audible and does not create distortion. A highly trained ear would hear only the compression of the peaks in the audio signal, which is desirable with most tape recorders and many sound reinforcement systems.

AUDIO LEVEL

Used to adjust the audio input level for the proper modulation.

ANTENNA

The flexible wire antenna supplied with the transmitter is cut to 1/4 wavelength of the center of the frequency block

(the frequency range) of the transmitter. It is removable via an SMA connector. The SMA connector is a 50 Ohm RF

port which can also be connected directly to test equipment. Replacement antennas are available in pre-cut lengths

for specific frequency blocks, or as a kit with instructions to cut the antenna for any frequency block.

ADJUSTABLE LOW FREQUENCY ROLL-OFF

A 18dB per octave low frequency roll-off is provided in the audio section, with the -3dB point adjustable from 35Hz to

150Hz. The actual roll-off frequency will vary somewhat according to the low frequency response of the mic capsule

being used.

The low frequency roll-off control is used to prevent undesirable subsonic (or very low frequency) audio, often

produced by air conditioning systems, automobile traffic and other sources from causing the compandor to mistrack.

Excessive low frequency content in the audio input can cause “pumping and breathing” of background noise or

modulation of the program audio in recording applications. In sound reinforcement systems, excessive low frequency content can cause excessive power amplifier drain or even damage to loudspeaker systems. By rotating the

control clockwise, the hinge point of the roll-off is increased to reduce the level of low frequencies. In controlled

situations, such as a motion picture production set indoors where environmental noise is minimal, the control can be

rotated counter-clockwise to permit low frequency audio to be captured.

THE BELT CLIP

The belt clip may be removed for special applications by removing one screw.

The circuitry is tightly packed into this unit. A longer screw will permanently damage the transmitter! Use only

Lectrosonics PN:28528 which is a Phillips head, 4-40 x 3/16", FL100 screw.

USE ONLY THE SCREW THAT IS SUPPLIED

Rio Rancho, NM – USA

7

Page 8

BATTERY INSTALLATION

The transmitter is powered by a standard alkaline or lithium 9 Volt battery. It is important that you use ONLY an

ALKALINE or LITHIUM battery for longest life. Standard zinc-carbon batteries marked “heavy-duty” or “long-

lasting” are not adequate. Ni-cad rechargeable batteries will only provide 1.5 hours of operation, or less, and will

run down quite abruptly. Alkaline batteries provide over 7 hours of operation. Lithium batteries can be used to

provide up to 17 hours. Care should be taken not to leave a fully discharged lithium battery in the transmitter, as

swelling of the battery can make it difficult to remove from the compartment. The battery status circuitry is designed

for the voltage drop over the life of alkaline batteries.

To open the battery compartment, press outward on the cover door in the direction of the arrow as shown in the

drawing. Only firm, sliding pressure is needed to open and close the battery door. Swing the door open and take

note of the polarity marked inside showing the location of the positive (+) and negative (-) terminals. You can see the

large and small contact holes inside the battery compartment with the door open.

Swing the

Press outward on the

battery door in this

direction

door open

Insert the battery correctly and close the cover by pressing the door closed and across, reversing the opening

procedure illustrated above. If the battery is inserted incorrectly, the door will not close. Do not force the door

closed.

OPERATING INSTRUCTIONS

1) Install a fresh battery according to the instructions above.

2) Insert the microphone plug into the input jack, aligning the pins; be sure that the connector locks in.

3) Attach the antenna to the SMA connector on the top of the transmitter.

4) Mute the sound system.

5) Turn the transmitter power switch to the “ON” position.

8

Page 9

Frequency Agile UHF Belt-Pack Transmitter

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

6) Position the microphone in the location you will use in actual operation.

7) While speaking or singing at the same voice level that will actually be used, observe the MODULATION LEDs.

Adjust the AUDIO LEVEL control knob until the LEDs begin to light. Start at a low setting where neither LED

lights as you speak. Gradually, turn the gain up until one LED lights, then the other.

The -20 LED lights when the audio level is about 20dB below full modulation. The “0” LED lights when the limiter

begins to operate. There is over 30dB of limiting range without overload above the “0” LED, so it is desirable that

the it lights up occasionally during use.

8) Once the gain has been adjusted, the audio system audio can be turned on to make level adjustments. Set the

power switch to the ON position and adjust the receiver and/or sound system level as required. Please note,

there will be a delay between the moment the switch is thrown and the time when audio will actually

appear at the receiver output. This intentional delay eliminates turn on thumps, and is controlled by the pilot

tone squelch control.

OPERATING NOTES

The AUDIO LEVEL control knob should not be used to control the volume of your sound system or recorder levels.

This gain adjustment matches the transmitter gain with the user’s voice level and microphone positioning.

If the audio level is too high — both LEDs will light frequently or stay lit. This condition may reduce the dynamic

range of the audio signal.

If the audio level is too low — neither LED will light, or the -20 LED will light dimly. This condition may cause hiss and

noise in the audio, or pumping and breating in the background noise.

The first LED turns on 20dB below full deviation. The “0” LED turns on at full deviation and indicates that the input

shunt compressor is operating. The input limiter will handle peaks over 30dB above full modulation, regardless of the

gain control setting. The limiter uses a true absolute value circuit to detect both positive and negative peaks. The

attack time is 5 milliseconds and the release time is 200 milliseconds. Occasional limiting is desirable, indicating that

the gain is correctly set and the transmitter is fully modulated for optimum signal to noise ratio.

Different voices will usually require different settings of the AUDIO LEVEL control, so check this adjustment as each

new person uses the system. If several different people will be using the transmitter and there is not time to make

the adjustment for each individual, adjust it for the loudest voice.

ADJUSTING THE TRANSMITTER FREQUENCY

If you are experiencing interference from another signal on your frequency, you may want to change the operating

frequency of your system. The left switch (COARSE) changes the operating frequency by larger increments and the

right switch (FINE) changes it in small increments per step. These steps are determined by the programming in the

unit. Refer to the chart of settings provided with the unit. If you are experiencing interference, change the operating frequency in FINE steps to find a

clear channel. If it is not possible to find a clear channel using the FINE

switch, return it to its original position and change the COARSE switch by

one click then try the FINE switch again.

To gain access to these switches, slide the access door sideways with a

fingernail.

With the UCR300 receiver, the front panel LED character display will indicate the correct transmitter switch settings.

Rio Rancho, NM – USA

9

Page 10

MICROPHONE CORD TERMINATION

TA5F Connector Assembly

1

2 3

VIEW FROM SOLDER

SIDE OF PINS

4

5

0.15"

0.3"

Heatshrink

Tubing

Mic Cord Stripping Instructions

Caution!

Do not allow the shield wire to touch any

metal part of the connector shell.

The shield wire is the antenna on VHF

models and poor operating range will result.

Rubber

Rubber

Insulation

Note: This termination is required on VHF transmitters and will still work fine on UHF transmitters.

10

Crimp

Tabs

Shield Wire

Crimp

Tabs

Insulation

Page 11

Frequency Agile UHF Belt-Pack Transmitter

5-PIN INPUT JACK WIRING

The wiring diagrams shown on the next page represent the basic wiring necessary for the most common types of

microphones and other audio inputs. Some microphones may require extra jumpers or a slight variation on the

diagrams shown.

Caution - When wiring the connector, do not use the connector body for any electrical connections.

A common mistake is to use the connector body as an audio ground. The connector body is

already used as an RF ground on VHF models and no other use is permitted.

It’s virtually impossible to keep completely up to date on changes that other manufacturers make to their products. It

is possible that you may encounter a microphone that differs from these instructions. If this occurs please call our

toll-free number listed on page 13 of this instruction manual. Our service department can answer your questions

regarding microphone compatibility.

When used on a wireless transmitter, the microphone element is in the proximity of the RF coming from the transmitter. The nature of electret microphones makes them sensitive to RF, which can cause problems with the microphone/

transmitter compatibility. If the electret microphone is not designed properly for use with wireless transmitters, it may

be necessary to install a chip capacitor in the mic capsule or connector to block the RF from entering the electret

capsule. This modification is shown on the next page.

LECTROSONICS

4

3

5

2

1

1

2

3

4

5

NEG GND (OR BIAS)

POS BIAS (OR GND)

MIC

SOURCE LOAD

LINE IN

330PF

1uH

330PF

100

1K

10K

5V Mic Bias

5mA max

+

To Mic Amp

Transmitter

Input Jack

VHF transmitters use the shield of the microphone cord as the antenna. The UM300B uses a 1/4 wave flexible wire

to radiate the RF signal. There is really not much difference between these two approaches, with respect to the

UHF Transmitter Equivalent Input Circuit

effect of the RF on the microphone capsule. Even in transmitters that utilize a “dangling wire,” the microphone is still

part of the “ground plane” and is therefore still in the antenna circuit.

PIN 1 Shield (ground) for positive biased electret lavalier microphones. Bias voltage source for negative biased

electret lavalier microphones. Shield (ground) for dynamic microphones and line level inputs.

PIN 2 Shield (ground) for negative biased electret lavalier microphones. Bias voltage source for positive biased

electret lavalier microphones.

PIN 3 Low impedance microphone level input for dynamic microphones. Also accepts hand-held electret micro-

phones provided the microphone has its own built-in battery.

PIN 4 1K Ohm source load for non-Lectrosonics electret microphones. Use in conjunction with other pins to

provide attenuation of high level input signals.

PIN 5 High impedance, line level input for tape decks, mixer outputs, musical instruments, etc.

Rio Rancho, NM – USA

11

Page 12

RF BYPASSING

R

3

Some mics require RF protection to keep the radio signal

from affecting the capsule, even though the transmitter

input circuitry is already RF bypassed (see schematic

diagram).

If the mic is wired as directed, and you are having

difficulty with squealing, high noise, or poor frequency

response; RF is likely to be the cause.

The best RF protection is accomplished by installing RF

2 WIRE MIC 3 WIRE MIC

Preferred locations for bypass capacitors

SHIELD

AUDIO

CAPSULE

TA5F

CONNECTOR

Alternate locations for bypass capacitors

CAPSULE

SHIELD

AUDIO

BIAS

TA5F

CONNECTO

bypass capacitors at the mic capsule. If this is not

possible, or if you are still having problems, capacitors

can be installed on the mic wires inside the TA5F connector housing.

Install the capacitors as follows: Use 330 pF capacitors. Capacitors are available from Lectrosonics. Please specify

the part number for the desired lead style.

Leaded capacitors: P/N 15117 Leadless capacitors: P/N SCC330P

All Lectrosonics lavalier mics are already bypassed and do not need any additional capacitors installed for proper

operation.

BODY GROUND

Caution - When wiring the connector, do not use the connector body for any electrical connections. A common

mistake is to use the connector body as an audio ground. The connector body is already used as an RF ground on

VHF models and no other use is permitted.

LINE LEVEL SIGNALS

The normal hookup for line level signals is: Signal Hot to pin 5, Signal Gnd to pin 1, pin 4 jumped to pin 1, and pin 3

jumped to pin 1. This gives a 40dB attenuator that allows signal levels much higher than 3V to be applied without

distortion.

If more headroom is needed, insert a 100k resistor in series with pin 5. Put this resistor inside the TA5F connector to

minimize noise pickup.

If lower than normal line levels (less than 1V) are expected, use this hookup: Signal Hot to pin 5, Signal Gnd to pin

1, and pin 4 jumpered to pin 1. This provides a 20dB attenuator allowing signals as high as 3V to be applied without

distortion.

WIRING HOOKUPS FOR DIFFERENT SOURCES

PIN

PIN

1

2

3

4

5

1

2

3

4

5

4

3

TA5F

PLUG

4

3

TA5F

PLUG

1

5

2

1

5

2

3 WIRE ELECTRET MIC

POSITIVE BIAS

2 WIRE ELECTRET MIC

POSITIVE BIAS

SHIELD

BIAS

AUDIO

SHIELD

AUDIO

PIN

PIN

1

2

3

4

5

1

2

3

4

5

4

3

TA5F

PLUG

4

3

TA5F

PLUG

1

5

2

1

5

2

2 WIRE ELECTRET MIC

NEGATIVE BIAS

SLEEVE

TIP

LINE LEVEL

RCA or 1/4 " PLUG

SHIELD

AUDIO

SHIELD

AUDIO

SHIELD

WIRE ELECTRET MIC

NEGATIVE BIAS

12

BIAS

AUDIO

PIN

1

2

3

4

5

4

3

TA5F

PLUG

1

5

2

2

3

DYNAMIC

MIC LEVEL

PIN

1

1

2

3

Dynamic LO Z mic or electret with

manufacturers power supply.

SHIELD

PIN

1

2

3

4

5

4

3

TA5F

PLUG

1

5

2

Page 13

Frequency Agile UHF Belt-Pack Transmitter

A6U UHF ANTENNA

This is a full size cutting template. Lay the actual antenna on top of this drawing and cut at the

mark for the desired frequency group.

Install cap on end of antenna

after cutting to length.

Black cap

Colored sleeve

31

33

28

27

29

32

30

25

26

23

24

22

21

Frequency Blocks

Kits are shipped from the factory with caps of the various colors plus a black cap. After cutting the antenna to the

desired block length, select the properly colored cap and cut off the closed end to make the colored sleeve. Slide the

colored sleeve onto the antenna as shown above then slide the black cap onto the cut end of the antenna.

FREQUENCY ANT SLEEVE ANTENNA

BLOCK RANGE COLOR WHIP LENGTH

21 537.600 - 563.100 Brown 4.74"

22 563.200 - 588.700 Red 4.48"

23 588.800 - 614.300 Orange 4.24”

24 614.400 - 639.900 Yellow 4.01"

25 640.000 - 665.500 Green 3.81"

26 665.600 - 691.100 Blue 3.62"

27 691.200 - 716.700 Violet (Pink) 3.46"

28 716.800 - 742.300 Grey 3.31"

29 742.400 - 767.900 White 3.18"

30 768.000 - 793.500 Orange/Black 3.08"

31 793.600 - 819.100 Orange/Brown 2.99”

32 819.200 - 844.700 Orange/Red 2.92”

33 844.800 - 862.000 Orange/Orange 2.87”

The sleeve color follows the standard resistor color code for the second

numeral in the group number.

*IMPORTANT

Whip Length

Measure the length of the whip that protrudes outside of the SMA connector.

Rio Rancho, NM – USA

13

Page 14

TROUBLESHOOTING

Before going through the following chart, be sure that you have a good battery in the transmitter. It is important that

you follow these steps in the sequence listed.

SYMPTOM POSSIBLE CAUSE

TRANSMITTER BATTERY LED OFF 1) Battery is inserted backwards.

2) Battery is dead.

NO TRANSMITTER MODULATION LEDs 1) Gain control turned all the way down.

2) Battery is in backwards. Check power LED.

3) Mic capsule is damaged or malfunctioning.

4) Mic cable damaged or mis-wired.

RECEIVER RF LAMP OFF 1) Transmitter not turned on.

2) Transmitter battery is dead.

3) Receiver antenna missing or improperly positioned.

4) Transmitter and receiver not on same frequency. Check

switches/display on transmitter and receiver.

5) Operating range is too great.

6) Transmitter antenna not connected

NO SOUND (OR LOW SOUND LEVEL),

RECEIVER MOD LEVEL LEDs ARE ON 1) Receiver output level set too low.

2) Receiver output is disconnected; cable is defective

or mis-wired.

3) Sound system or recorder input is turned down.

DISTORTED SOUND 1) Transmitter gain (audio level) is far too high. Check mod

level lamps on transmitter and receiver as it is being used.

(refer to pages 8/9 for details on gain adjustment)

2) Receiver output may be mis-matched with the sound

system or recorder input. Adjust output level on receiver

to the correct level for the recorder, mixer or sound

system.

3) Excessive wind noise or breath “pops.” Re-position

microphone and/or use a larger windscreen.

4) Transmitter is not set to same frequency as receiver.

Check that frequency select switches on receiver and

transmitter match.

HISS AND NOISE -- AUDIBLE DROPOUTS 1) Transmitter gain (audio level) far too low.

2) Receiver antenna missing or obstructed.

3) Transmitter antenna missing.

4) Operating range too great.

EXCESSIVE FEEDBACK 1) Transmitter gain (audio level) too high. Check gain

adjustment and/or reduce receiver output level.

2) Transmitter too close to speaker system.

3) Mic is too far from user’s mouth.

14

Page 15

Frequency Agile UHF Belt-Pack Transmitter

SPECIFICATIONS AND FEATURES

Operating frequencies: 525.000 to 862.00 MHz

Frequency selection: Up to 256 frequencies

RF Power output: 50 mW (nominal)

Pilot tone: 32.764 kHz (± 2Hz); 5kHz deviation

Frequency stability: ± 0.002%

Deviation: ± 50 kHz (max)

Spurious radiation: 90 dB below carrier

Equivalent input noise: –126 dBV

Input level: Nominal 2 mV to 300 mV, before limiting.

Input impedance: Taps provided for 500, 1k, 10k Ohm

Input compressor: Soft compressor, >30 dB range

Gain control range: 43 dB; semi-log rotary control

Modulation indicators: Dual LEDs indicate modulation level 20dB below

Low frequency roll-off

adjustment: –18dB/octave; 35Hz to 150Hz

Controls: 2 position “OFF-ON” slide switch for noiseless turn on/turn off operation.

low

Audio Input Jack: Switchcraft 5 pin locking (TA5F)

Antenna: Detachable, flexible wire supplied. 50 Ohm port allows

Battery: Precision compartment auto-adjusts to accept any known alkaline 9 Volt

battery. (We’ve tried 125 different ones!)

Battery Life: 7 hours (alkaline); 17 hours (lithium)

Weight: 6.3 ozs. including battery

Dimensions: 3.1 x 2.4 x .75 inches

Greater than 50V maximum, with limiting.

limiting and at the onset of limiting.

Front panel knob adjusts audio gain. Recessed control on side panel adjusts

frequency rolloff. Rotary switches on side panel adjust transmitter frequency.

connection to test equipment.

Specifications subject to change without notice.

This product meets the CE Compliance Standards - ETS 300 445; January

1996 and I ETS 300 422 (December 1995). A copy of the Declaration of

Conformity may be requested from your dealer or by contacting the factory

directly:

Lectrosonics, Inc.

Marketing Department

581 Laser Rd. NE, Rio Rancho, NM 87124 USA

tel: 505-892-4501 fax: 505-892-6243 e-mail: marketing@lectrosonics.com

Rio Rancho, NM – USA

15

Page 16

LIMITED ONE YEAR WARRANTY

LIMITED ONE YEAR WARRANTY

The equipment is warranted for one year from date of purchase against defects in

materials or workmanship provided it was purchased from an authorized dealer. This

warranty does not cover equipment which has been abused or damaged by careless

handling or shipping. This warranty does not apply to used or demonstrator equipment.

Should any defect develop, Lectrosonics, Inc. will, at our option, repair or replace any

defective parts without charge for either parts or labor. If Lectrosonics, Inc. cannot

correct the defect in your equipment, it will be replaced at no charge with a similar new

item. Lectrosonics, Inc. will pay for the cost of returning your equipment to you.

This warranty applies only to items returned to Lectrosonics, Inc. or an authorized

dealer, shipping costs prepaid, within one year from the date of purchase.

This Limited Warranty is governed by the laws of the State of New Mexico. It states the

entire liablility of Lectrosonics Inc. and the entire remedy of the purchaser for any

breach of warranty as outlined above. NEITHER LECTROSONICS, INC. NOR

ANYONE INVOLVED IN THE PRODUCTION OR DELIVERY OF THE EQUIPMENT

SHALL BE LIABLE FOR ANY INDIRECT, SPECIAL, PUNITIVE, CONSEQUENTIAL,

OR INCIDENTAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE

THIS EQUIPMENT EVEN IF LECTROSONICS, INC. HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL THE LIABILITY OF

LECTROSONICS, INC. EXCEED THE PURCHASE PRICE OF ANY DEFECTIVE

EQUIPMENT.

This warranty gives you specific legal rights. You may have additional legal rights which

vary from state to state.

SERVICE AND REPAIR

If your system malfunctions, you should attempt to correct or isolate the trouble before concluding that the equipment

needs repair. Make sure you have followed the setup procedure and operating instructions. Check out the interconnecting cords and then go through the TROUBLESHOOTING section in the manual

We strongly recommend that you do not try to repair the equipment yourself and do not have the local repair shop

attempt anything other than the simplest repair. If the repair is more complicated than a broken wire or loose connection, send the unit to the factory for repair and service. Don’t attempt to adjust any controls inside the units.

Once set at the factory, the various controls and trimmers do not drift with age or vibration and never require readjustment. There are no adjustments inside that will make a malfunctioning unit start working.

LECTROSONICS, INC.

581 LASER ROAD

RIO RANCHO, NM 87124 USA

www.lectrosonics.com

September 14, 2001

Loading...

Loading...