Page 1

SPN16i/SPN32i

Input Only Processors

16i

32i

INSTALLATION and STARTUP GUIDE

Fill in for your records:

Serial Number:

Purchase Date:

See

Quick Start

Essential Settings

on page 5

Visit the ASPEN Support web site:

www.lectrosonics.com/aspensupport/

Also link from the home page: www.lectrosonics.com

Rio Rancho, NM, USA

www.lectrosonics.com

Page 2

ASPEN Input Only Processors

2

LECTROSONICS, INC.

Page 3

Important Safety Instructions

Installation and Startup Guide

This symbol, wherever it appears, alerts

you to the presence of uninsulated dangerous voltage inside the enclosure -- voltage

that may be sufficient to constitute a risk of

shock.

This symbol, wherever it appears, alerts

you to important operating and maintenance instructions in the accompanying

literature. Please read the manual.

When using your telephone equipment, basic safety

precautions should always be followed to reduce the

risk of fire, electrick shock and injury to persons, including the following:

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with a dry cloth.

7) Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

8) Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized

or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding

type plug has two blades and third grounding prong.

The wider blade or the third prong are provided

for your safety. If the provided plug does not fit into

your outlet, consult an electrician for replacement of

the obsolete outlet.

10) Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles, and the point where they exit from the apparatus.

11) Only use attachments/accessories specified by the

manufacturer.

12) Use only with the cart, stand, tripod,

bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to avoid injury

from tip-over.

13) Unplug this apparatus during lightning storms or

when unused for long periods of time.

14) Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or

plug is damaged, liquid has been spilled or objects

have fallen into the apparatus, the apparatus has

been exposed to rain or moisture, does not operate

normally, or has been dropped.

15) WARNING -- TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE.

16) The AC mains plug, or appliance coupler shall be

readily available to the operator as a means of

power disconnection, if applicable.

17) Unit shall be connected to a MAINS socket outlet

with a protective earthing connection.

18) Do not use this product near water for example,

near a bathtub, washbowl, kitchen sink or laundry

tub, in a wet basement or near a swimming pool.

19) Avoid using a telephone (other than a cordless

type) during an electrical storm. There may be a

remote risk of electric shock from lightning.

20) Do not use the telephone to report a gas leak in the

vicinity of the leak.

21) Use only the power cord and batteries indicated in

this manual. Do not dispose of batteries in a fire.

They may explode. Check with local codes for possible special disposal instructions.

22) “CAUTION: To reduce the risk of fire, use only No.

26 AWG or larger (e.g., 24 AWG) UL Listed or CSA

Certified Telecommunication Line Cord”

SAVE THESE INSTRUCTIONS

Rio Rancho, NM

3

Page 4

ASPEN Input Only Processors

FCC Part 15 Compliance

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

CAUTION: Changes or modifications not expressly

approved by Lectrosonics, Inc. could void the user’s

authority to operate the equipment.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may

cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user

will be required to correct the interference at his own

expense.

Table of Contents

Important Safety Instructions............................................. 3

Inspection of the Unit .......................................................... 4

Introduction .......................................................................... 5

Quick Start Essential Settings ........................................... 5

Front Panel ........................................................................... 6

Rear Panel ............................................................................ 7

Hardware Installation .......................................................... 8

Installing the chassis into a rack ........................................ 8

Cables ............................................................................... 8

Audio Connectors ............................................................. 8

Audio Inputs-Unbalanced ................................................... 8

Programmable Inputs ......................................................... 9

Programmable Outputs ...................................................... 9

ASPEN RS-232 Port (PC Connection) ............................ 10

Cabling of Stacked Units .................................................. 10

Using the LCD .................................................................... 11

Stacking Multiple Units ..................................................... 14

Software and Firmware Updates ...................................... 14

Creating an ASPEN Installer Disk .................................... 15

Firmware Update Procedure ............................................. 15

Software Installation ......................................................... 16

USB Driver Installation ...................................................... 17

Using the Software GUIfor Minimum Setup .................... 21

FCC Part 15 Compliance ................................................... 22

Service and Repair ............................................................ 23

Returning Units for Repair ............................................... 23

Inspection of the Unit

Compare the packing list enclosed with the unit with the

original order. Inspect all items for damage. Immediately

call 1-800-821-1121 to report any items that are missing or damaged. The sooner you notify us, the sooner

you will get any needed replacement items shipped to

your location.

4

LECTROSONICS, INC.

Page 5

Installation and Startup Guide

Introduction

The SPN16i and SPN32i processors are used as a

Slaves in a stack of ASPEN processors. There are no

physical outputs on these “input only” processors. As

their descriptions imply, the only outputs are into the

system matrix that is common to all processors in the

stack. The ASPEN digital matrix provides a maximum

of 48 total outputs, but there is no limit to the number

of inputs that can be added to a system by stacking

multiple units.

Multiple processors are interconnected via the ASPEN

bus, which operates at 1 Gbps to conduct data from the

lowermost Slave to the Master. All signals are gathered

in the Master and then returned to the lower Slaves via

the ASPEN bus.

When multiple units are stacked, Master and Slave

units are automatically detected and configured according to the cabling between units. Since the data from

the Slave units in the system is gathered in the Master,

a single connection between a computer and the Master allows access to the data from all units in the stack.

Audio propagates through the ASPEN bus in the same

manner as data. The throughput latency of all audio

inputs in a stack is automatically synchronized to maintain absolute signal phase at the audio outputs.

Any of the ASPEN mixer models and the conference

model can be used as the Master in the system:

• SPN8128input,12outputmixer

• SPN161216input,12outputmixer

• SPN162416input,24outputmixer

• SPN241224input,12outputmixer

• SPNConfteleconferenceInterface

Quick Start Essential

Settings

IMPORTANT: Do not connect the processor to

a USB port until AFTER the software has been

installed.

Wiring and Cable Connections

All inputs and control devices must be connected following the pinouts and polarity shown on pages 7 thru 9.

Interconnect Multiple Units

When multiple units are used, interconnect them via the

ASPEN ports on the rear panels. (see page 9)

Critical Settings for Mixer Models

Several settings must be made before the processor will

pass signals correctly:

• Inputlevelsmustbeset

• Crosspointsmustbedened

The settings are made using the computer interface.

Special Settings for SPN Conference

If the sound system includes an SPN Conference processor, two of the final mixes must be used to generate

the input signals for the AEC (acoustic echo canceller).

Details for this critical setting are included in the Installation Guide for the SPN Conference processor.

Signal Processing

Audio quality is significantly improved by using the various signal processing functions included in all channels.

All processes can be fully enabled without limitation

on DSP resources. There is no “gas gauge” limitation

regardless of how many processes and stages are

enabled.

Every input channel includes settings for:

• Delay

• Noisereductionlter

• Equalization

• ADFE(autodigitalfeedbackeliminator)

• Compressor

Rio Rancho, NM

5

Page 6

ASPEN Input Only Processors

Front Panels

16i

SPN16i

32i

SPN32i

LCD Rotary Encoder and Switches

LCD and Rotary Encoder (SPN32i only)

Backlit display shows activity and setup screens for

adjustment of all settings. Rotary encoder includes a

“center switch” for item selection. UP, DOWN, LEFT,

RIGHT switches are used for navigation and adjustments of settings.

USB Port

Comm LED

Alert LED

POWER Switch

Power LED

Status LEDs

• CommLED: blinkstoindicateUSBcommunication

• AlertLED: glowsduringMasterResetandfault

condition

• PowerLED: glowstoindicatepowerON

USB Port

Standard USB connector for the setup and control of

the processor with Windows XP, Vista or 7 operating

systems.

6

LECTROSONICS, INC.

Page 7

Rear Panel

SPN16i chassis (rear panel) P/N 26058

silkscreening

8 Dec 2009 BCJ added label placement markers

24 May 2012 BCJ added CE mark

Cooling Fan

Outlet

Installation and Startup Guide

Programmable Input

and Output Ports

SPN 16i

SPN 32i

100-240V

50/60Hz 15W

RS-232

Power Inlet RS232

Serial Port

DATECODE

S/N LABEL

Adaptive Proportional Gain Mixing

US Patent 5,414,776

100-240V

50/60Hz 30W

RS-232

PROG IN

ETHERNET

Ethernet

Port

PROG IN

PROG IN

ETHERNET

Power Inlet

Standard IEC 60320 grounded C14 socket.

RS-232 Port

Used for setup and control with computer systems and

remote control devices such as touch panels.

Ethernet Port

Used for remote access, setup and control.

GND

+5V

PROG

OUT

ASPEN PORT

ASPEN

Ports

GND

+5V

PROG

OUT

ASPEN PORTS

GND

+5V

PROG

OUT

DATECODE

S/N LABEL

INPUTS

Mic/Line Inputs

INPUTS

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

INPUTS

ASPEN Bus Data/Audio Ports

RJ-45 jacks carry the audio signals and data between

units stacked together.

Mic/Line Inputs

Balanced analog audio connections with depluggable

Phoenix style connectors.

Programmable Input and Output Ports

Programmable inputs or outputs used with pots and

switches to enable control over a variety of parameters

or to indicate the current state of a programmable input

using external LEDs.

Rio Rancho, NM

7

Page 8

ASPEN Input Only Processors

Hardware Installation

Installing the chassis into a rack

Install the chassis so that the cooling fan vent is not

blocked. Mount with 4 rack screws using the appropriate mounting holes. Use nylon washers to prevent

damage to the front panel’s finish when tightening the

mounting screws.

All ASPEN processors have internal switching power

supplies that can tolerate voltages ranging from 100

to 240 VAC. Use an approved power cord with an IEC

60320 C13 connector.

Cables

It is recommended to use lacing bars for cable strain

relief when mounting in a rack. Use only professional

audio cable with proper shielding – typically, two conductor plus ground/shield.

Audio Connectors

The analog audio inputs are connected through 5 pin

de-pluggable connectors. Strip the insulation back

1/8 to 3/16” but do not tin (apply solder to) the leads.

Insert the wire into a de-pluggable connector, leaving

less than 1 mm of bare wire exposed, then tighten the

retaining screw.

Audio Inputs – Unbalanced

Unbalanced audio sources include items such as

consumer VCR’s, DVD players, etc., which can be connected with either two wire or three wire cables. The (+)

terminal of the source is connected to the (+) terminal

of the processor. The shield and (–) connections are

made as shown here.

Three wire cables should have the shield connected to

the (–) connector at the source end of the cable.

Source

Unbalanced source to

ASPEN input – 3-wire cable

Two wire cables should have a jumper between the

processor (–) input and ground.

Shield

Processor

Caution: Do not overtighten the screws.

Retaining Screw

(Do not overtighten)

5-pin depluggable

connector

Do not leave more than

1 mm of exposed wire

beyond the connector.

Do not apply

solder to leads

Note the labeling on the rear panel for the positive and

negative leads. Ground is shared between two connections (the center pin).

Note: ASPEN processors do not have a “pin 1

problem.” Inputs and outputs are true differential

connections.

Source

Shield

Processor

Unbalanced source to

ASPEN input – 2-wire cable

Audio Inputs – Balanced

Balanced audio sources connect to the processor inputs in a straight “pin to pin” configuration.

Shield

Source

Processor

Balanced source to

ASPEN input

8

LECTROSONICS, INC.

Page 9

Installation and Startup Guide

10K Linear Potentiometer

CCW

CW

+5V

To Programmable Input Pin

Gnd

Contact Closure as Programmable Input

To Programmable Input Pin

Gnd

DC Voltage Source as Programmable Input

To Programmable Input Pin

0VDC (Off) to +5VDC (On)

Gnd

Potentiometer Connection for

Analog Control of Gain

380 Ohms

Pro gr amma b le Output Pi n

380 Ohms

Programmable Output Pin

1N4001

or equi v .

Exte r na l

DC V oltag e

Source

(<40VDC)

Rel a y Coi l

Coil current <100mA

Pro gr amma b le Output Pi n

Relay is on when the programmable output is active

+5VDC

+5VDC

GND

LED is ON when the programmable output is active

GND

LED is OFF when the programmable output is active

Programmable Inputs

Programmable inputs are provided to enable external

control over a variety of parameters. Each input can

respond to a contact closure, a DC voltage source, or

the variable voltage output from a potentiometer. The

following illustrates common connections to the programmable input pins.

Programmable

Inputs

Programmable

Outputs

Ground

Programmable Outputs

Programmable outputs are used for several purposes:

• indicatethecurrentstateofaprogrammableinput

• monitoractivityontelephoneorcodecinterfaces

• monitoractivepresetchanges

Each programmable output is the electrical equivalent

of a contact closure to ground. When a programmable

output is “active,” it conducts current to ground. When

the programmable output is “inactive,” no current flows

to ground. The maximum usable voltage for the programmable outputs is 40 V and they will safely conduct

up to 100 mA DC continuous.

Both LEDs and 5V relay coils can be powered by the

+5 V DC pins on the programmable input connector, as

long as the maximum combined current for all LEDS

and relay coils does not exceed 100 mA.

Rio Rancho, NM

+5VDC

Note: The diagram above shows an external DC source powering the relay coil. This is necessary whenever coil voltages

exceed 5 volts.

LOGIC INPUTS

LOGIC IN 3

IN 3

ON

OFF

CCW

IN 1

CW

10K

LINEAR

POT

LOGIC OUTPUTS

GROUND

5VDC

380 TO

500 OHM

ANODE CATHODE

LED

LOGIC

OUT 7

Cathode

Anode

R

Anode

V

Cathode

9

Page 10

ASPEN Input Only Processors

ASPEN RS-232 Port

Here is the wiring diagram for the ASPEN RS-232 Port

for connecting to a PC.

Wiring Diagram

ASPEN Device to PC

ASPEN

RS-232

Port

DCE pin

functions

Female

jack

TX

RX

GND

1

2

3

4

5

6

7

8

9

Male

connector

1

2

3

4

5

6

7

8

9

Female

connector

DCD

RX

TX

DTR

GND

DSR

RTS

CTS

RI

Host

Serial

Port

(PC)

DTE pin

functions

Male jack

Cabling Of Stacked Units

In a stacked configuration, ASPEN processors must

be interconnected as shown here. Each Slave unit in

a stack gathers data and audio signals from the unit

below it, adds its own signals and passes the total on to

the unit above it. At the top of the stack, the Master unit

gathers all signals from below, adds its own and then

sends the total back down the bus to all Slave units

below it. In this manner, all Slave units have access to

all inputs on any unit in the stack.

Each circuit board has an upper and a lower CAT-5 connector. Since there are two circuit boards in a 2RU unit

such as the SPN1624, the circuit boards are connected

in the same manner as if they were in separate chassis. The ASPEN bus is bidirectional, handling data and

audio signal forward and back propagation through a

single cable connection.

1RU SPN

Conference

configured as

Master

ASPEN PORT

2RU SPN1624

configured as

intermediate

Slave

1RU SPN16i

configured

as lowermost

Slave

The processors automatically configure themselves for

Master and Slave status as determined by the cabling.

If a unit is connected to another unit above it through

the upper connector, it is automatically configured as

a Slave. If there is no unit above it, then it becomes a

Master.

10

LECTROSONICS, INC.

Page 11

Installation and Startup Guide

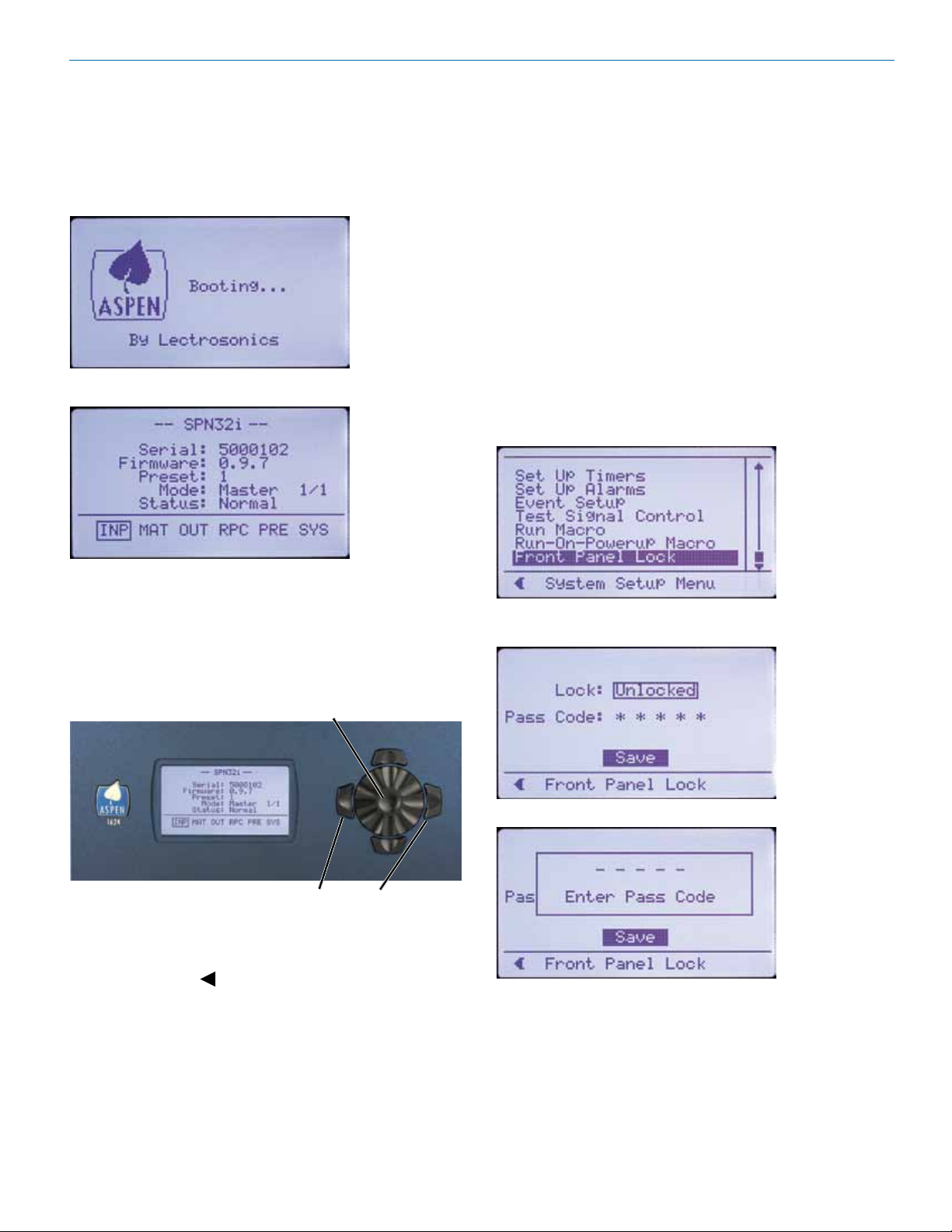

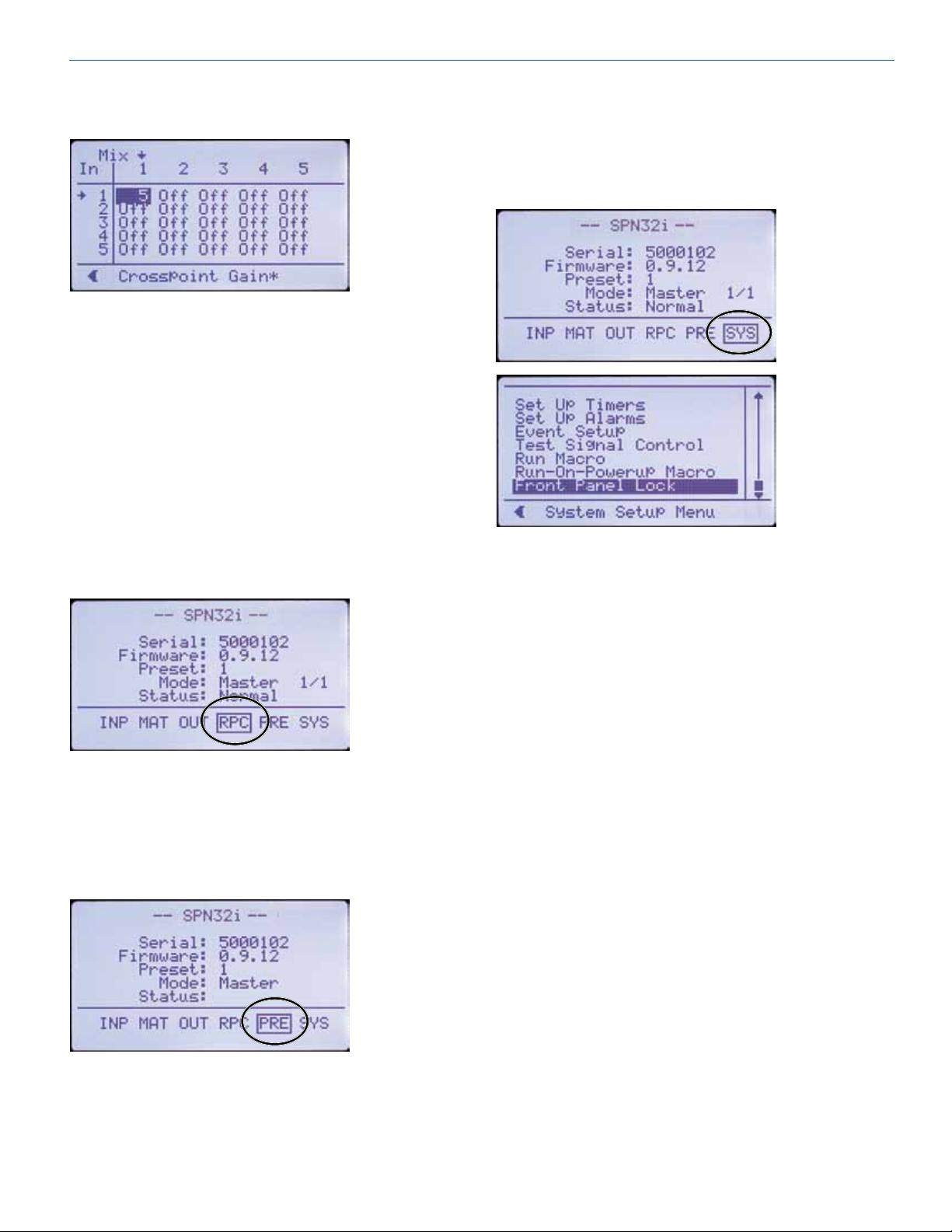

Using the LCD

The LCD can be used to perform a simple setup, to

check current settings or make adjustments without using a computer interface.

Boot Screen

Main Window

Shortcut Buttons

• LCDBacklightToggle:Press both the LEFT and

RIGHT (9:00 and 3:00 o’clock) buttons to turn the

backlight on and off.

• EmergencyMute(panicbutton):Pressing the UP

and DOWN buttons together will mute all outputs to

remedy situations such as runaway feedback.

• RestoreDefaultSettings(MasterReset):Hold

in the LEFT and UP buttons while turning on the

power to restore the factory default settings. The

Alert LED will glow white during the process, which

takes about 75 seconds to complete.

Panel Lock/Unlock

From the Main Window, use the rotary control to select

SYS in the lower row window and press the center

switch. Then scroll down with the rotary control to the

menu item named Front Panel Lock and press the cen-

ter switch to enter the setup screen.

Navigation Control

The navigation control for the LCD consists of a rotary

control and four directional buttons for selection of

menu items and to enter values. The four outer buttons

are referenced as LEFT, RIGHT, UP and DOWN. Pressing the center of the rotary control provides a “select” or

“center switch” function.

Center Switch

Press both Left and Right buttons to

turn the LCD backlight OFF and ON

The LEFT (9:00 o’clock) functions as a BACK button

to return to the previous menu from setup screens as

prompted by the symbol in the lower left corner of

the LCD.

Select the Unlocked/Locked item with the rotary control,

press the center switch.

A prompt will appear asking you to enter the passcode.

The factory default passcode is five presses of the center switch. Once the correct passcode is entered, the

panel will allow access to the screen items to change

the unlocked/locked status, enter a new passcode and

save the results.

The passcode can consist of any combination of five

successive button presses of the four outer switches

and the center switch such as: LEFT > RIGHT > UP >

DOWN > CENTER.

Rio Rancho, NM

11

Page 12

ASPEN Input Only Processors

After selecting the mode and/or changing the passcode,

select SAVE with the rotary control and press the center

switch to save the settings.

A progress bar

will appear as the

settings are saved.

Press the LEFT (9:00 o’clock) button to return to the

previous screen.

Master Reset

Hold the LEFT and UP buttons in at power up to restore

factory default settings.

Select Mic/Line Input Setup (Input Levels is a dymanic

display that shows bar graphs of activity).

Navigate to each cell and enter a value. For microphones, 40 to 50 dB is a normal value. For line levels,

0 dB is a commonly used value. If phantom power is

needed, be sure to check the 48V cell for each microphone using the rotary control.

WARNING: Master Reset will remove all stored

settings, unlock the control panel and reset the

passcode to five center button presses.

Master Reset takes about 75 seconds to complete

while the center (white) LED on the front panel stays lit.

The display will then return to the Main Window and the

right (blue) LED will light up to indicate power ON and a

“ready” status.

Initial Setup

The processor requires a minimum setup before it will

pass signals:

• InputGainValue

• CrosspointGainValue

• OutputGainValue

These three minimum settings can be made with the

LCD or software GUI.

Input Setup

Select [INP] on the Main Window.

Matrix Crosspoint Setup

Select [MAT] on the Main Window.

Scroll to the desired Crosspoint setting and select it.

The UP and DOWN buttons can also be used to scroll

the menu items.

12

LECTROSONICS, INC.

Page 13

Installation and Startup Guide

Adjust to the desired value with the rotary control and

press the control to store the value. (the Crosspoint

Gain setting screen is shown here as an example)

After all values have been set, press the LEFT button to

return to the previous menu.

Additional Filters and Processing

After the basic signal flow and levels are established,

further refinements can be added with the extensive set

of signal processing built into the processor. Browse the

menus for inputs and outputs to discover the available

resources.

Rear Panel Controls

Select [RPC] in the Main Window to access a setup

menu to configure external controls such as pots and

switches. While settings can be made with the LCD

interface, it is recommended that you use the software

GUI instead.

Global System Settings

Select [SYS] in the Main Window to access a setup

menu for a variety of global settings including headphone monitoring, date and time setup, timer and event

programming, front panel lockout, network interface

settings and others.

Preset Recall and Settings

Select [PRE] in the Main Window to access a setup

menu to store and recall presets and other options to

define preset activities. It is useful for information, however, it is recommended that you use the software GUI

instead, which will provide access to presets stored on

the computer disk drive.

Rio Rancho, NM

13

Page 14

ASPEN Input Only Processors

Network Interface

IMPORTANT: Always consult your network

administrator before attempting to connect and

configure a processor for a network interface.

The [SYS] tab menu also includes Network Settings.

The settings must be correctly set before connecting

into a network.

Software and Firmware

Updates

Check for the latest versions of the control panel software and to see that the hardware includes the latest

firmware.

ASPEN models with a front panel LCD will display the

firmware version on the LCD and in the control panel

GUI after the software is installed. Other models display

the firmware version in the GUI only. Firmware updates

require that the ASPEN software be installed to enable

a connection and use the update utility included in the

software.

Firmware

version

Stacking Multiple Units

If Slave units are not powered up when the Master unit

boots up, the Slave may not be detected for several

minutes. It is good practice to turn on all units simultaneously or turn on Slave units before turning on the

Master unit.

Check the LCD display on the Master unit to see if it

has detected all the Slaves.

Check Mode on

the Master unit

to verify the

detection of all

Slaves.

Shown here is 1

of 2.

The Master unit will always be number one in the stack

as shown here, and each slave will be numbered in the

order that it is connected with the cabling of the ASPEN

port jacks.

Firmware version

Obtaining Updates

The latest versions of software and firmware are provided on the disk supplied with the unit and downloadable from the Aspen Support section on Lectrosonics

website.

Lectrosonics home page: http://www.lectrosonics.com

ASPENSoftware:Uninstall any previous version before installing an updated version.

Downloaded files arrive in a .zip format. Extract the files

to a folder on your local drive and then run “setup.exe”

to install the program.

FirmwareUpdates:Downloaded files arrive in a single

.zip file with the model number and version indicated by

the filename.

Extract the file to a folder on your local drive. The resulting filename will indicate the model number and version, followed by the extension “.update.”

14

LECTROSONICS, INC.

Page 15

Installation and Startup Guide

Creating an ASPEN

Installer Disk

If you do not have the disk supplied with the processor, go to either of the following sites and download the

ASPEN Installation Disk .iso file.

http://www.lectrosonics.com/aspensupport/

Link from the home page: http://www.lectrosonics.com

Save the file to your local drive in a familiar location.

Open a disk copier utility such as Roxio Classic and

select the operation to Burn from a Disk Image File.

NOTE: The .iso file cannot be simply copied to the

disk. The disk recording utility must run a process

that creates a disk from a stored image file.

The .iso file format is recognized by almost any disk

creation software.

Firmware Update

Procedure

1) Install ASPEN software. See the next page for an

example of the installation procedure.

2) Launch the software. After the panel opens, click on

File > Update. The Update Wizard screen will open

to confirm that the software is ready for a firmware

update, with instructions on connecting and configuring the processor.

3) On the processor, hold the recessed pushbutton

switch in with a pen or paper clip and turn on the

power to the processor. The unit will boot into the

Firmware Update... mode and the white Alert LED

on the processor front panel will glow.

Recessed pushbutton for firmware updates

4) Connect the processor to the computer with the

USB cable. When the USB connection is confirmed

(typically with a beep sound on the computer),

continue by following the on screen prompts in the

Update Wizard.

5) When prompted, use the “Browse” button to point at

the firmware update file and click Next to continue.

Rio Rancho, NM

Browse

button

6) Do not disturb the USB cable connection during the

update process. The firmware update takes up to

15 minutes to complete. Be sure the computer does

not “Time Out” during the update process.

7) When the update is complete, click Finish to exit the

Update Wizard.

8) Cycle the power on the processor to restart using

the updated firmware.

15

Page 16

ASPEN Input Only Processors

Software Installation

NOTE: Uninstall previous version before installing

the software.

The example shown here illustrates the installation procedure using Windows XP. The screens that appear at

each step using another operating system will vary, but

the general steps are very similar.

Insert the disk into the drive and wait for the opening

screen to appear. Click on Install ASPEN Software to

launch the installer.

It is usually best to accept the default folder for the

installation. Click on Next to continue.

When the Welcome screen appears, click on Next.

The End User License Agreement screen appears.

Click on Next to confirm the installation and continue.

When the installation is complete the final screen will

appear. Click on Close to finish the installation.

Click on I Agree, then on Next to continue.

16

LECTROSONICS, INC.

Page 17

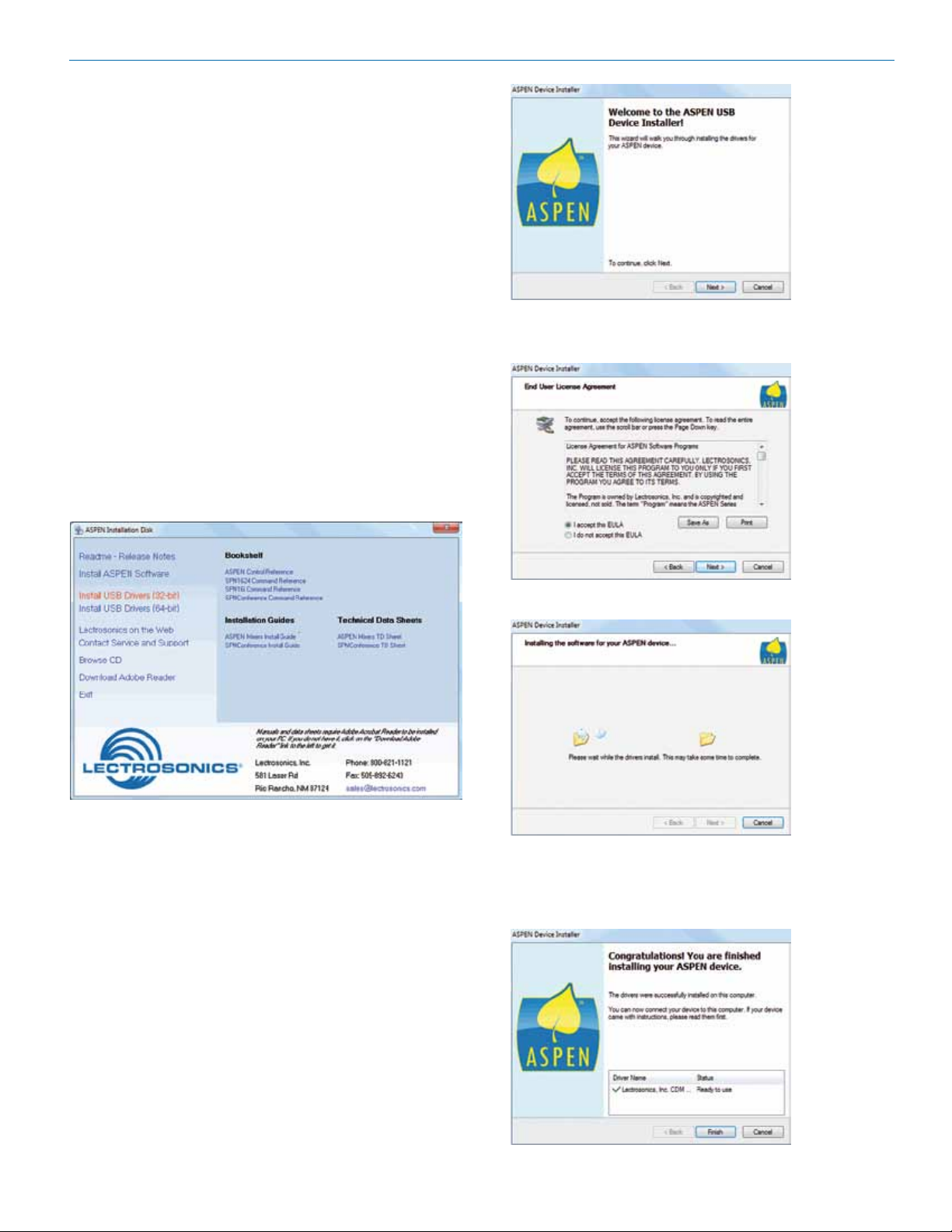

USB Driver Installation

The ASPEN USB drivers are installed from the ASPEN

Installation Disk which comes with each device, by running the ASPEN Device Installer. Normally this is done

before connecting an ASPEN device to the PC for the

first time, but it can be done afterwards if necessary.

The driver installation only needs to be done once on

each PC that will be connected to an ASPEN unit.

If an ASPEN device is connected to a PC without prior

installation of the drivers from the ASPEN Installation

Disk, manual installation is possible for Windows XP

and Vista operating systems using the New Hardware

Found wizard. In the case of Windows 7, there is no

New Hardware Found wizard, so manual installation is

a bit more involved. In any of these cases it’s not really

necessary if you have the installation disk. Just cancel

the New Hardware Found wizard (if open) and run the

ASPEN Device Installer from the Installation Disk.

Installation with ASPEN Device Installer

Place the ASPEN Installation Disk into the CD-ROM

drive. If “AutoRun” is enabled on that drive then the

ASPEN Installation Disk utility will open.

Installation and Startup Guide

Click Next to proceed.

The End User License Agreement is presented.

Note: If AutoRun is not enabled then use Start->Run to

run “autoRun.exe” on the drive holding the ASPEN Install Disk. For example, if the CD-ROM drive is drive E:

then run “E:\autoRun.exe” to open the ASPEN Software

CD utility.

Click on the appropriate driver for your system:

• InstallUSBDrivers(32-bit)

• InstallUSBDrivers(64-bit)

The ASPEN Device Installer opens.

Accept, then click Next to proceed.

The drivers are installed from the CD.

When installation is complete, the Driver Name and

Status are displayed. Click Finish to close the Device

Installer.

Rio Rancho, NM

17

Page 18

ASPEN Input Only Processors

Using the Software GUI

for Minimum Setup

An Input, crosspoint and output must be defined to create a path that allows the processor to pass a signal.

This required minimum setup can be accomplished

quickly using the sofware GUI.

Launch the ASPEN Control Panel. The first screen is

blank with tabs at the top of the window to select the

desired action.

Select the Connect tab and then click on the method of

communication; in this example, USB.

Thispopupwill

appear with

the Master unit

displayed

Define inputs, crosspoints and outputs on the appropriate tabs for a required minimum setup.

NOTE: Matrix crosspoints must be assigned in

the Input Only processor and output sources must

be assigned to these crosspoints in a Mixer or

Conference processor to allow the signals to be

delivered to the system outputs.

Click to

scroll

tabs

A popup window will appear with a list of processors

that are connected. Click on a unit inside the popup

window to add it to the control panel list.

Click on the desired unit

in the control panel list.

Click on the desired unit in the list to open a control

panel for that processor. The panel opens to the Activ-

ity window, which is a real time level display.

The Device Settings tab opens access to several setup

screens such as Preset Management.

Device Settings tab

Category bar for access to

setup screens

18

LECTROSONICS, INC.

Page 19

Installation and Startup Guide

Service and Repair

If your system malfunctions, you should attempt to correct or isolate the trouble before concluding that the equipment

needs repair. Make sure you have followed the setup procedure and operating instructions. Check the interconnecting cables and then go through the Troubleshooting section in this manual.

We strongly recommend that you do not try to repair the equipment yourself and do not have the local repair shop

attempt anything other than the simplest repair. If the repair is more complicated than a broken wire or loose connection, send the unit to the factory for repair and service. Don’t attempt to adjust any controls inside the units. Once

set at the factory, the various controls and trimmers do not drift with age or vibration and never require readjustment.

Therearenoadjustmentsinsidethatwillmakeamalfunctioningunitstartworking.

LECTROSONICS’ Service Department is equipped and staffed to quickly repair your equipment. In warranty repairs

are made at no charge in accordance with the terms of the warranty. Out-of-warranty repairs are charged at a modest

flat rate plus parts and shipping. Since it takes almost as much time and effort to determine what is wrong as it does

to make the repair, there is a charge for an exact quotation. We will be happy to quote approximate charges by phone

for out-of-warranty repairs.

Returning Units for Repair

For timely service, please follow the steps below:

A. DO NOT return equipment to the factory for repair without first contacting us by e-mail or by phone. We need

to know the nature of the problem, the model number and the serial number of the equipment. We also need a

phone number where you can be reached 8 A.M. to 4 P.M. (U.S. Mountain Standard Time).

B. After receiving your request, we will issue you a return authorization number (R.A.). This number will help speed

your repair through our receiving and repair departments. The return authorization number must be clearly shown

on the outside of the shipping container.

C. Pack the equipment carefully and ship to us, shipping costs prepaid. If necessary, we can provide you with the

proper packing materials. UPS or FEDEX is usually the best way to ship the units. Heavy units should be “double-boxed” for safe transport.

D. We also strongly recommend that you insure the equipment, since we cannot be responsible for loss of or dam-

age to equipment that you ship. Of course, we insure the equipment when we ship it back to you.

LectrosonicsUSA:

Mailingaddress: Shippingaddress: Telephone:

Lectrosonics, Inc. Lectrosonics, Inc. (505) 892-4501

PO Box 15900 581 Laser Rd. (800) 821-1121 Toll-free

Rio Rancho, NM 87174 Rio Rancho, NM 87124 (505) 892-6243 Fax

USA USA

Web: E-mail:

www.lectrosonics.com sales@lectrosonics.com

LectrosonicsCanada:

MailingAddress: Telephone: E-mail:

49 Spadina Avenue, (416) 596-2202 Sales: colinb@lectrosonics.com

Suite 303A (877) 753-2876 Toll-free Service: joeb@lectrosonics.com

Toronto, Ontario M5V 2J1 (877-7LECTRO)

(416) 596-6648 Fax

Rio Rancho, NM

19

Page 20

ASPEN Input Only Processors

581 Laser Road NE • Rio Rancho, NM 87124 USA • www.lectrosonics.com

(505) 892-4501 • (800) 821-1121 • fax (505) 892-6243 • sales@lectrosonics.com

LIMITED THREE YEAR WARRANTY

The equipment is warranted for three years from date of purchase against defects in

materials or workmanship provided it was purchased from an authorized dealer. This

warranty does not cover equipment which has been abused or damaged by careless

handling or shipping. This warranty does not apply to used or demonstrator equipment.

Should any defect develop, Lectrosonics, Inc. will, at our option, repair or replace any

defective parts without charge for either parts or labor. If Lectrosonics, Inc. cannot

correct the defect in your equipment, it will be replaced at no charge with a similar new

item. Lectrosonics, Inc. will pay for the cost of returning your equipment to you.

This warranty applies only to items returned to Lectrosonics, Inc. or an authorized

dealer, shipping costs prepaid, within three years from the date of purchase.

This Limited Warranty is governed by the laws of the State of New Mexico. It states the

entire liablility of Lectrosonics Inc. and the entire remedy of the purchaser for any

breach of warranty as outlined above. NEITHER LECTROSONICS, INC. NOR

ANYONE INVOLVED IN THE PRODUCTION OR DELIVERY OF THE EQUIPMENT

SHALL BE LIABLE FOR ANY INDIRECT, SPECIAL, PUNITIVE, CONSEQUENTIAL,

OR INCIDENTAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE

THIS EQUIPMENT EVEN IF LECTROSONICS, INC. HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL THE LIABILITY OF

LECTROSONICS, INC. EXCEED THE PURCHASE PRICE OF ANY DEFECTIVE

EQUIPMENT.

This warranty gives you specific legal rights. You may have additional legal rights which

vary from state to state.

13 March 2013

Loading...

Loading...