Page 1

LCA16

LOGIC CONTROLLED AMPLIFIER*

OPERATING INSTRUCTIONS

and trouble-shooting guide

LECTROSONICS, INC.

* US PATENT NUMBER 5204908

Rio Rancho, NM

Page 2

INTRODUCTION

Thank you for selecting the Lectrosonics LCA16 Logic Controlled Amplifier. The LCA16 is a modular multi-channel

amplifier designed to minimize feedback and audio regeneration problems in conference room sound installations

using distributed speaker systems. The speakers may be wall mounted, ceiling mounted, table mounted or any

combination thereof. For proper operation, the automatic mixer must have logic signal outputs which indicate

individual microphone activity.

The LCA16, in conjunction with an automatic mixer (such as the Lectrosonics Modular Audio Processor system)

controls the gain of each speaker, individually, in response to activity on any of the microphones in the sound

system. Any speaker can be attenuated or turned off completely by the logic output signals from the automatic

mixer channels. In addition, each channel includes a balanced line level output which may be used to drive

external amplifiers.

Each of the 16 output channels in the LCA16 provides 5 Watts into a 4 Ohm speaker (3 Watts into an 8 Ohm

speaker) and a balanced line output. A straight forward switch matrix allows each individual output channel to be

attenuated by any combination of the 16 logic inputs.

The LCA16 has integral power supplies and is designed for mounting in a standard 19-inch equipment rack. Three

front panel LEDs per channel indicate the level of attenuation. The switch matrix and attenuation level controls are

located behind a removable panel to prevent tampering or accidental mis-adjustment.

TABLE OF CONTENTS

INTRODUCTION .......................................... 1

GENERAL TECHNICAL DESCRIPTION .......................... 2

CONTROLS AND FUNCTIONS - FRONT PANEL ................... 3

CONTROLS AND FUNCTIONS - REAR PANEL .................... 5

PRE-CONFIGURING THE LCA16 PRIOR TO INSTALLATION,

16 or FEWER MICS PER LCA16 ............. 6

PRE-CONFIGURING THE LCA16 PRIOR TO INSTALLATION,

MORE THAN 16 MICS PER LCA16 ............ 8

INSTALLATION ........................................... 10

SYSTEM ADJUSTMENT ..................................... 12

SPECIFICATIONS ......................................... 13

SERVICE AND REPAIR ..................................... 14

RETURNING UNITS FOR REPAIR ............................. 14

APPENDIX 1 - POWER LOSS vs CABLE RUN .................... 15

APPENDIX 2 - LCA16 SYSTEM WORKSHEET .................... 16

WARRANTY ........................................ Back cover

1

Page 3

GENERAL TECHNICAL DESCRIPTION

DIFFERENTIAL

L

O

G

I

C

I

N

P

U

T

S

"A"

ATTENUATION

"B"

ATTENUATION

ATTENUATION

NO

ATTENUATION

"B"

ATTENUATION

"A"

ATTENUATION

NO

PWR

AMP

SPKR +

SPKR -

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16 16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16 LINES

16 LINES 16 LINES

TO CHANNELS 2 THROUGH 16

MAIN LEVEL

L O G IC S IG N A L CO N D IT IO NIN G L O G IC S IG N A L CO NDIT IO N IN G

LINE OUT -

LINE OUT +

GROUND

BALANCED

LINE DRIVER

ATTENUATION

SELECT LOGIC

AND

LED DRIVERS

"A"

ATTENUATION

"B"

SELECT SWITCHES

ATTENUATION

SELECT SWITCHES

FRONT

PANEL

LEDs

CH. 1

TO CHANNELS 2 THROUGH 16

AUDIO

BALANCED

INPUT

AUDIO

THROUGH

OUTPUT

INPUT

AMPLIFIER

SIGNAL

PRESENT

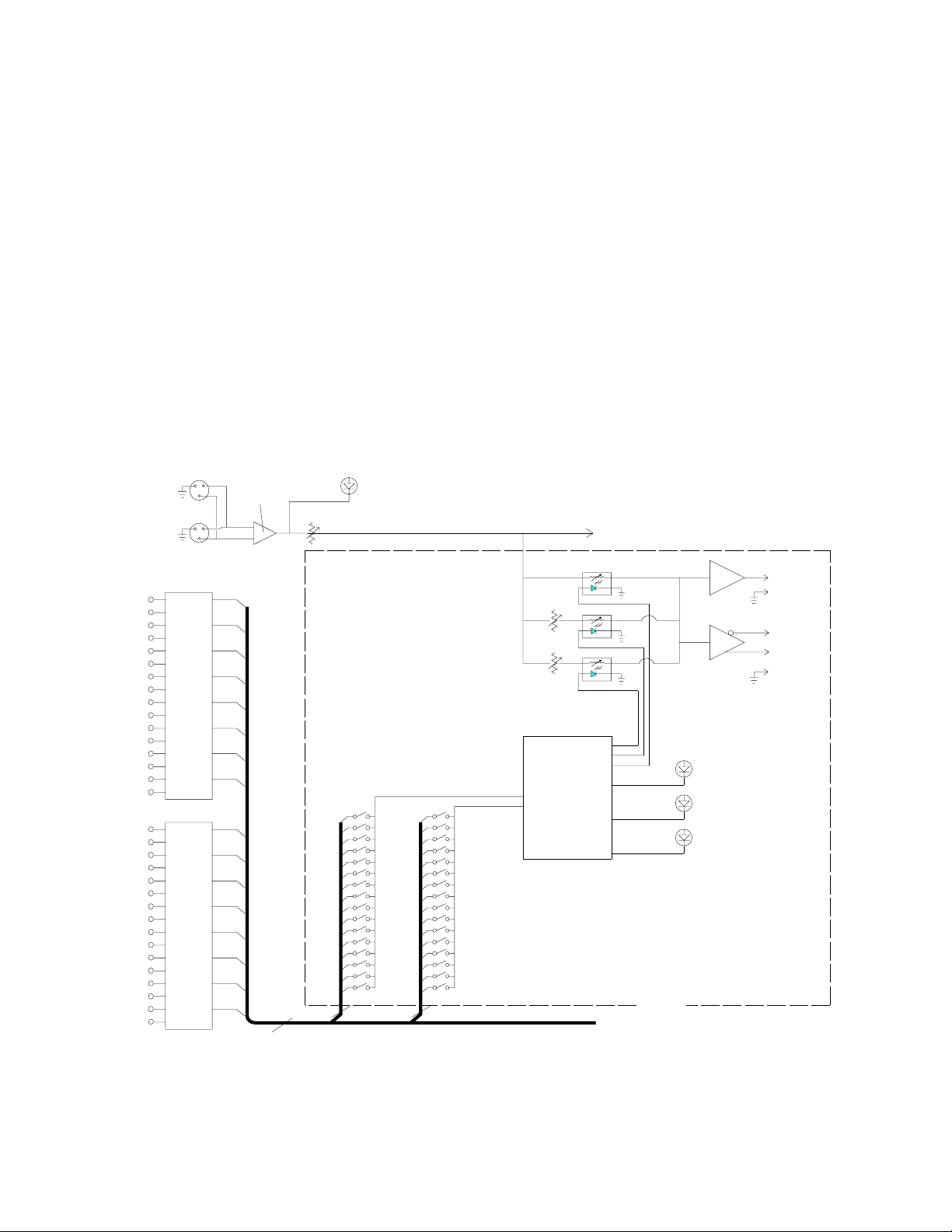

In the following illustration is a simplified block diagram of the LCA16 showing one amplifier channel. All channels

are identical.

The audio input of the LCA16 is an RF filtered, electronically balanced differential amplifier. An AUDIO THRU

output is provided so the audio signal can be "daisy chained" to other devices if required. A SIGNAL PRESENT

LED on the front panel indicates the presence of signal above -20dBv. The audio signal passes through the MAIN

LEVEL control before being distributed to the output channel amplifiers. Each output channel employs a dedicated

power amplifier. The amplifiers are fully protected from short circuits, thermal overloads or highly reactive loads.

Each amplifier is individually fused, so in the event of catastrophic failure of any single channel, no other channels

will be affected. Each output channel also includes a balanced line level output which is simultaneously available to

drive external amplifiers, or other audio equipment.

The logic input signal conditioning circuits are specially designed to accept a wide variety of logic signals, ranging

from relay contact closures to TTL logic levels. Each logic input passes through a time constant circuit with

hysteresis. This guarantees minimum "signal chopping" caused by changing attenuation during pauses in speech.

Photo-conductive opto-isolators are employed to switch the level of attenuation of the audio. These devices

eliminate the abrupt audible changes that occur when hard switching is used.

Figure 1 - LCA16 Block Diagram

2

Page 4

CONTROLS AND FUNCTIONS - FRONT PANEL

0

1

2

3

4

5

6

7

8

9

LECTROSONICS, INC.

LOGIC CONTROLLED AMPLIFIER

AUTOMATIC SPEAKER / LINE OUTPUT CONTROL

PO W E R

SI G N AL

PR ESEN T

PO W E R

MA I N L EVEL

10

ATTE NUATION MODE

LCA16

CH . 3

ON A B

ATTE NUATI ON

CH. 4

ON A B

A TTE NU A TIO N

CH. 7

ON A B

ATTENU ATIO N

CH. 8

ON A B

ATTE NUA T ION

CH. 11

ON A B

ATTE NUATIO N

CH. 1 2

ON A B

ATTE NUA TIO N

CH. 14

ON A B

ATTE NUATIO N

CH. 16

ON A B

ATTE NUA TIO N

ON A B

ATTENUA TI ON

CH . 1

ON A B

ATTE N UA T IO N

CH. 2

ON A B

ATT E NUAT IO N

CH. 5

ON A B

ATTENUATION

CH. 6

ON A B

ATTE NUATIO N

CH. 9

ON A B

ATTE NUATI ON

CH. 1 0

ON A B

ATTE NUA T I ON

CH. 13

ON A B

ATTE NUAT ION

CH. 15

POWER SWITCH

Controls the application of AC power to the LCA16.

POWER LED

Indicates the presence of AC power to the LCA16.

MAIN LEVEL

Controls the overall output level of the sound system.

SIGNAL PRESENT LED

Indicates the presence of audio signal to the LCA16.

ON LED

(Channels 1-16) Indicates the output channel is in the "on" state (not attenuated).

ATTENUATION LEDS

A LED: (Channels 1-16) Indicates the output channel is at the "A" attenuation level.

B LED: (Channels 1-16) Indicates the output channel is at the "B" attenuation level.

Figure 2 - LCA16 Front Panel

3

Page 5

ATTENUATION DIP SWITCHES (located behind front panel cover)

SWITCH

NUMBERS

ATTENUATION CONTROL POTS

3A

1

1

1

0

5

1

1

2

2 2

9

2

2

3

O

3

O

3

15

O

3

O

3

P

P

P

P

E

E

E

E

DIP SWITCHES

4 4 4

4

4

N

5

5

N

5

3B

N

5

N

5

6

6 6

6

6

0

5

9

7

7 7

7

7

8 8 8

15 8

8

9

1

1

0

5

1

1

10

2

2

9

2

2

11

O

3

O

3

O

3

O

3

12

4 4

4A

4 4

15

P

P

P

P

E

E

E

E

13

N

5

N

5

N

5

N

5

0

5

4B

14

6 6

6 6

15

7 7

9

7 7

16

8 8

15

8 8

3A

1

1

0

5 1

1 1 1

1

0

5 1

1

1

3A

3A

1

1

0

3A

5 1

1

1

1

1

0

5 1

1

2

2 2

9

2

2

2

2

2

9

2

2 2

9

2

2

2

2 2

9

2

2

2

O 3O

3

15

O 3O 33O

3O 3

15

O

3O 3

3

O

3

P

O

3

15

O

3

P

O

3

3

O

P

3

O

P

3

15

O

P

3

O

P

3

P

P

P P

P P

P

P

P

4 4

P

4

4

4

4

4

4

4

E

4 4

4

E

4 4

4

E

4

E

4

4

4

E

E

E E

E

E

E

E

E

E

E

E

3B

N

N

5N 5

3B

N

5N 5

5N 5N 5

3B

N

5

N

5

5

N

5N 5

N

5N 5

5

N

5

N

5

0

3B

5

N

5

5

6 6

6

6

6

6 6

6

6

6

0

5

0

5

6 6

0

5

6

6

6 6

6

6

6

9

9

7 7

9

7

7

7 7

7

9

7

7

7 7

7

7

7

7 7

7

7

7

8 8

15

8

8

8

8

8

15

8

8

8 8

15

8

8

8 8 8

15

8

8

8

1

1

0

5

1

1

9

1

1

051

1

9

1

1

0

5

1

1

9

1

1

051

1

2 2

9

2

2

10

2

2

9

2 2 10

POWER

2

2

9

2 2 10

2 2

9

2 2

O

O 3 O 3

O

3O 3

O 3O

3

11

O

3

O

3

15

O

3O 3 11

O

3

O

3

15

O

3O 3

11

O 3 3

15

P

P

P

P

P

15

P

P

P

P

P

P

P

4

P

4

4A

P

4

P

4 12

P

4

E

4

4A

E

4E 4

4 4

4A

E

4

E

4

12

4

E

4

4A

E

4E 4

12

E

E

E E E

5N5

N

N

5 N 5

N

5

N 5

13

N

5N5

N

5N5 13

N 5

N

5N5 13

N

0

N

E

E

E

5 5

N

5

5

6

7

8

5

9

15

4B

0

6

7

8

6

7

8 16

15

14

6

7

8

6

7

8

5

9

15

4B

0

6

7

8

6

7

8

16

15

146

7

8

6

7

8

5

9

15

4B

0

6

7

8

6

7

8

16

15

14

6

7

8

6

7

8

9

15

4B

6

7

8

6

7

8

6

7

8

POWER

SIGNAL

PRESENT

1

2

3

4

5

6

7

8

O

P

E

N

5

9

15

3A

5

9

15

3B

3A 3B

4A 4B

0

0

ATTENUATION LEVEL

1

2

3

4

5

6

7

8

O

P

E

N

1

2

3

4

5

6

7

8

O

P

E

N

1

2

3

4

5

6

7

8

O

P

E

N

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

ATTENUATION LEVEL

1

2

3

4

5

6

7

8

5

9

15

3A

5

9

15

3B

0

0

O

P

E

N

1

2

3

4

5

6

7

8

O

P

E

N

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

ATTENUATION LEVEL

1

2

3

4

5

6

7

8

5

9

15

3A

5

9

15

3B

1

2

3

4

5

6

7

8

0

0

1

2

3

4

5

6

7

8

O

P

E

N

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

ATTENUATION LEVEL

1

2

3

4

5

6

7

8

5

9

15

3A

5

9

15

3B

0

0

O

P

E

N

1

2

3

4

5

6

7

8

O

P

E

N

1

2

3

4

5

6

7

8

0

1

2

3

4

10

5

6

7

8

9

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

5

9

15

5

9

15

4A

4B

0

0

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

5

9

15

5

9

15

4A

4B

0

0

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

5

9

15

5

9

15

4A

4B

0

0

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

5

9

15

5

9

15

4A

4B

0

0

1

2

3

4

5

6

7

8

O

P

E

N

O

P

E

N

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

MAIN LEVEL

LOGIC CONT ROLLED A MPLIFIER.

LECTROSONICS, INC

These switches are used to programs which microphone (or microphones) connected to the 16 LOGIC INPUTS will

trigger the "A" and "B" attenuation levels for each of the 16 output channels. Four banks of switches (eight

switches per bank) are allocated to each channel. Two of the switch banks (16 switches) trigger the "A" attenuation

level, the other two switch banks trigger the "B" attenuation level. The switch number is printed on the circuit board

alongside the switch assemblies (disregard the numbers printed on the switch assembly itself).

ATTENUATION LEVEL CONTROLS (located between the DIP switch assemblies)

These control the amount of "A" and "B" level attenuation for each output channel. "A" level attenuation always

takes priority over "B" level attenuation and, therefore, the "A" control must always be set to a higher setting than

the "B" control.

An enlarged view of the speaker #7 and #8 sections of the attenuation selection DIP switches and attenuation level

controls is shown below. The attenuation select switches provide the means to select which microphones will

attenuate each speaker and to what attenuation level. The output of each speaker amplifier may be attenuated

from 0dB to completely off by means of the two continuously variable preset adjustment potentiometers ("A" and

"B"). Therefore, each speaker may be attenuated by one or more microphones on either (or both) of the "A" or "B"

levels as shown in the examples on page 7 and 8.

Figure 3 - Dip Switch Detail

4

Page 6

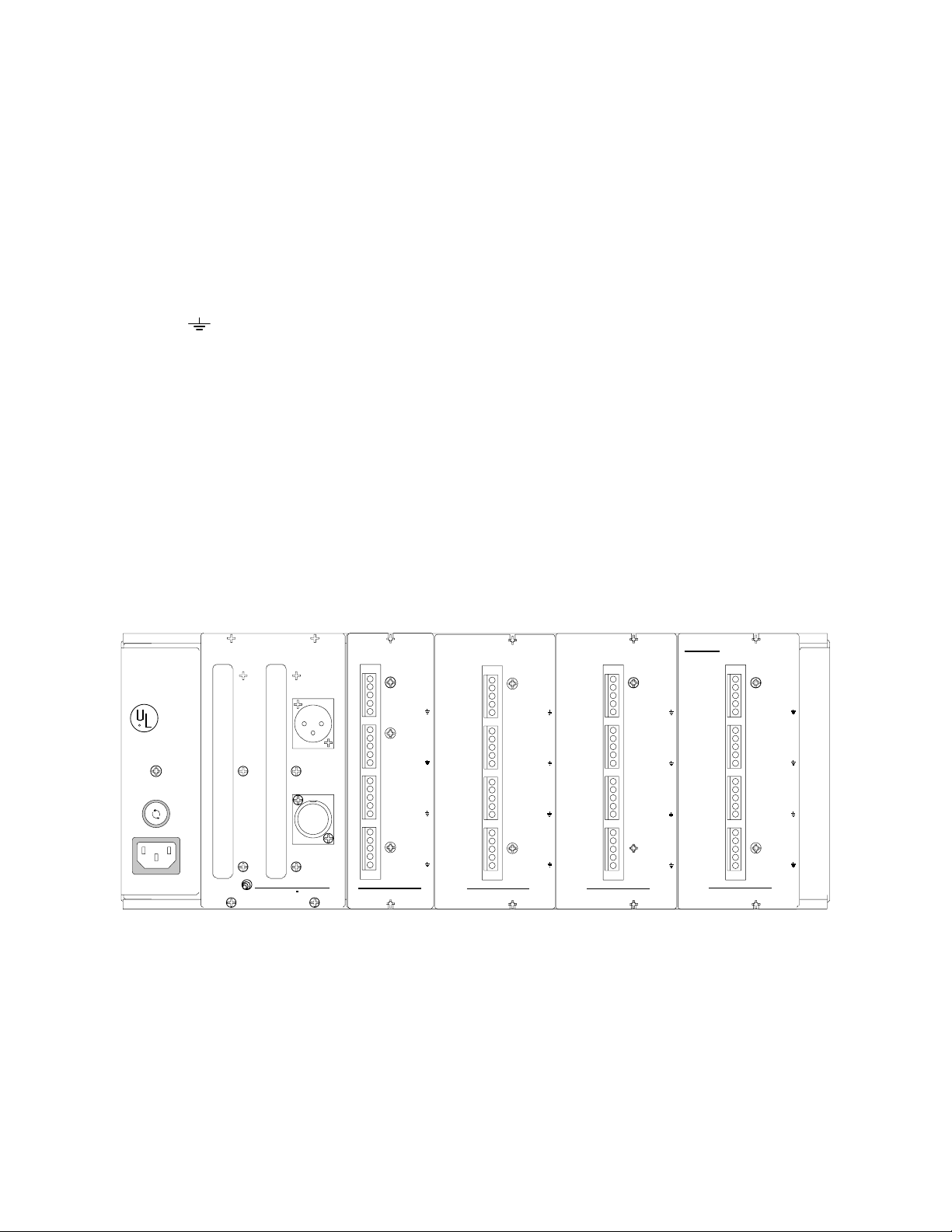

CONTROLS AND FUNCTIONS - REAR PANEL

SPKR OUT

Connects to the individual speakers in the sound system. SPKR OUT (+) is the "hot" terminal, and SPKR OUT (-)

is ground.

LINE OUT +/-

Provides balanced line level drive to external amplifiers or other equipment. The LINE OUT signal is attenuated

identically to its associated speaker output. Output impedance is 600 ohms, and is suitable for driving both low and

high impedance inputs.

LINE OUT

Provides the ground connection for the balanced line driver.

LOGIC INPUTS

Connects to the logic outputs of an automatic mixer, or to other types of contact closure. Logic Input (+) connects

to the (+) terminal of logic output on an automatic mixer, and the Logic Input (-) is ground.

AUDIO INPUT

Receives the audio signal for the sound system. This input is electronically balanced and RF filtered, and uses a

standard 3 pin XLR female connector.

AUDIO THRU

Outputs the signal received by the Audio Input for daisy chaining applications. This output is directly in parallel with

the AUDIO INPUT.

FUSE

Protects the unit in case of internal overload. Replace only with a 1.5 amp slow blow fuse.

SER NO

LECTROSONICS, INC.

RIO RANCHO, NM - USA

WARNING

TO REDUCE THE RISK OF FIRE

OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS EQUIPMENT TO

RAIN OR MOISTURE.

LISTED

COMMERCIAL

AUDIO

EQUIPMENT

R

4L01

US PATENT PENDING

CAUTION

TO REDUCE THE RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE

1 1/2A, 250V "SLO-BLO" FUSE.

F

E

U

S

S

E

U

F

F

U

S

E

120V AC

200 WATTS

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO

NOT REMOVE COVER. NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING TO.

QUALIFIED SERVICE PERSONNEL.

+

9

-

L

+

10

O

G

+

11

I

C

+

12

-

+

13

-

+

14

-

+

15

-

+

16

-

CAUTION

+

1

-

2

-

3

-

+

4

-

+

5

-

I

+

N

6

-

P

U

+

7

T

-

S

AUDIO THRU

+

8

-

LECTROSONICS, INC.

AUDIO INPUT

MADE IN USA RI O RA NCHO , NM

13

14

15

16

AM 4

LCA16 OU TP UT MODU L E

SER NO

SPKR

SPKR

LINE OUT

LINE OUT

LINE OUT

SPKR

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

SPKR

SPKR

LINE OUT

LINE OUT

LINE OUT

SPKR

SPKR

LINE OUT

LINE OUT

LINE OUT

SER NO

+

OUT

-

OUT

+

-

+

OUT

-

+

-

+

OUT

-

OUT

+

-

+

OUT

-

OUT

+

-

9

10

11

12

AM 4

LC A16 OUT P UT MODULE

SPKR OUT

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

SPKR

SPKR

LINE OUT

LINE OUT

LINE OUT

SPKR OUT

SPKR

LINE OUT

LINE OUT

LINE OUT

SPKR

SPKR

LINE OUT

LINE OUT

+

-

5

+

-

+

OUT

-

OUT

+

-

OUT

+

-

+

OUT

-

OUT

+

-LINE OUT

+

-

6

7

8

AM 4

LCA16 OU TP UT MODU L E

SER NO

SPKR OUT

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

SPKR OUT

SPKR

LINE OUT

LINE OUT

LINE OUT

SPKR OUT

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

SPKR

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

+

-

+

-

+

-

OUT

+

-

+

-

+

-

+

OUT

-

+

-

Figure 5 - LCA16 Rear Panel

SP KR OUT: O HMS

5W R M S @ 4 O H M S

3. 5 W R M S @ 8 O H M S

LI NE OUT:

60 0 OHM B ALANCED

AM 4

LCA16 OU TP U T MOD U L E

1

2

3

4

SER NO

CL A S S 2 WIRING

M A Y B E U S ED

OUT

SPKR

OUT

SPKR

LINE OUT

LINE OUT

OUT

SPKR

OUT

SPKR

LINE OUT

LINE OUT

SPKR OUT

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

SPKR OUT

SPKR OUT

LINE OUT

LINE OUT

LINE OUT

+

-

+

-LINE OUT

+

-

+

-LINE OUT

+

-

+

-

+

-

+

-

5

Page 7

PRE-CONFIGURING THE LCA16 PRIOR TO INSTALLATION,

16 or FEWER MICS PER LCA16

This procedure should be performed prior to installation. The LCA16 SYSTEM WORKSHEET (Appendix 2) will

assist you in setting up the LCA16 before going on site. While the actual setup is quite simple, it is recommended

that you use this worksheet, especially if this is your first installation using the LCA16 Logic Controlled Amplifier.

Using the LCA16 SYSTEM WORKSHEET

PROCEDURE 1 - Use this procedure if you have 16 or fewer microphones per LCA16 in this installation. This

procedure assumes a 1:1 relationship between microphones and logic terminals. If you have more than 16

microphones per LCA16, then skip this section and use procedure 2.

To fill out this chart, you need a floor plan of the room showing both speaker and microphone placement. See

below for an example of a floor plan with notations showing mics, speakers, and attenuation zones.

STEP 1 - On your floor plan, assign consecutive numbers to each microphone, starting with #1.

STEP 2 - Assign consecutive numbers to each speaker on the floor plan, again starting with #1.

STEP 3 - On your LCA16 SYSTEM WORKSHEET, assign the microphones to logic inputs in the first column on

the left. Simply transfer the microphone numbers from your floor plan to the crossed boxes. See

Example 1.

STEP 4 - Assigning Attenuation Levels In this step you will be noting in each box how much the speakers will

be affecting each microphone.

4A Start with the box where the SPEAKER 1 column intersects the microphone 1 (logic input 1) row. Check you

floor plan. If speaker 1 will be a potential source of feedback for microphone 1, then mark that box. Use an

"A" for speakers which are very close to the microphone and a "B" for those which are located further from

the microphone. While still referring to the floor plan, move down to the next box in the speaker 1 column

where it intersects the microphone 2 row. If speaker 1 will also affect microphone 2, then mark that box

accordingly.

If this speaker will have no effect, then leave the box blank.

4B Repeat this step for every box in the grid where a speaker and microphone/logic input intersect.

A LEVEL ATTENUATION ZONE FOR MIC 1

B LEVEL ATTENUATION ZONE FOR MIC 1

SPEAKER

A

B

STEP 4

1

TABLE

EXCERPT FROM

ROOM PLAN

SPKR

1

SPKR

2

2

SPEAKER

MICROPHONE

CHAIR

3

STEP 3

1 2 3 4

Assigned

Mics

1

1

A B B

2

2

3

3

Figure 6 - Example 1

6

Page 8

STEP 5 - Setting the DIP switches Upon completion of the chart you will have a grid which can now be used for

setting the DIP switches on the LCA16. See Example 2 below. Each speaker output on the LCA16 has a

set of dip switches on the front panel. There are two banks of 16 switches aligned vertically above a set of

LED indicators. The left bank of switches is for "A" level attenuation. The right bank of switches is for "B"

attenuation. DIP switches are set to the ON position by depressing them to the right. You will set these

switches according to the A and B notations on your LCA16 SYSTEM WORKSHEET.

For example, according to the worksheet in Example 2, speaker 1 has two microphones which it affects.

Speaker 1 will need to be attenuated to "A" level for microphone 1 and attenuated to "B" for microphone

2.

Speaker 2 will need to be attenuated to "B" level for microphones 1 and 3 and attenuated to "A" level for

microphone 2.

The illustrations below indicate how the switches will need to be set according to the worksheet.

DOT INDICATES "ON" CONDITION.

7A 7B 8A 8B

1

2

3

OPEN OPEN

4

5

6

7

8

9

10

11

12

13

14

15

16

OPEN OPEN

5

0

9

15

7A

7B

5

0

9

15

5

0

9

15

OPENOPEN

8A

8B

5

0

9

15

OPENOPEN

1

2

3

LOGIC

Assigned

1

2

3

Mics

1 2 3 4

A B

B A

B

SPEAKER

Figure 7 - Example 2

STEP 6 - Make your initial settings for the "A" and "B" levels of attenuation. If you have not yet determined a starting

level of attenuation for your speakers, it is suggested that all "A" levels be set for full attenuation (completely

off) and the "B" levels set for 5 to 9dB of attenuation. PLEASE NOTE THAT THE "A" LEVEL WILL

ALWAYS TAKE PRIORITY OVER "B" LEVEL, SO BE CERTAIN THE "A" LEVEL IS SET TO THE

GREATER ATTENUATION.

The levels of attenuation are set by adjusting the small recessed pots found between each pair of output

channel DIP switches located on the front panel. See the illustration above. These controls are set with a

small screwdriver (provided with the LCA16). Fully clockwise sets the channel to completely off. Set all

active channels.

The LCA16 is now pre-configured and may be installed in the rack. Proceed to page 10, INSTALLATION.

7

Page 9

PRE-CONFIGURING THE LCA16 PRIOR TO INSTALLATION,

MORE THAN 16 MICS PER LCA16

PROCEDURE 2 - Use this procedure for those installations where there are more microphone channels than logic

inputs.

The only difference between this setup and the setup described previously is that you have assigned multiple

microphones to the same logic input because they are affected by the same group of speakers. This practice

is only necessary when the number of microphones exceeds the number of logic inputs in the installation.

Using the LCA16 SYSTEM WORKSHEET

To fill out this chart, you will need a floor plan of the room showing both speaker and microphone placement. See

below for an example of a floor plan with notations showing mics, speakers, and attenuation zones.

STEP 1 - On your floor plan, assign consecutive numbers to each microphone, starting with #1.

STEP 2 - Assign Consecutive numbers to each speaker on the floor plan, again starting with #1.

STEP 3 - This step is critical for assigning multiple microphones to the same logic input. As you look at your floor plan,

check to see which microphones will be affected by exactly the same speakers. These microphone channels

can be wired to the same logic inputs. For example, if microphones 1 and 2 are both affected by the same

speaker, then you can assign both mics to logic input 1 (see Example 3). These logic input assignments will

assist you when wiring the twisted pair wires from your logic connections on the automatic mixer to the logic

connections on the LCA16. Repeat this step for each group of microphones.

STEP 4 - Assigning Attenuation Levels. In this step you will be noting in each box how much the speakers need to

be attenuated.

4A Start with the box where the SPEAKER 1 column intersects the logic input 1 row. Check your floor plan. If

the speaker 1 will be a potential source of feedback for microphone 1, then mark that box. Us an "A" for

speakers which are very close to the microphone and a "B" for those which are located further from the

microphone. While still referring to the floor plan, move down to the next box in the speaker 1 column (where

it intersects with logic input 2). If speaker 1 may also be a source of feedback for the mics assigned to logic

input 2, then mark that box accordingly.

If it is unlikely that feedback will occur, then leave the box blank.

4B Repeat this step for every box in the grid where a microphone/logic input row and a speaker column

intersect.

A LEVEL ATTENUATION ZONE FOR MIC 1

1 2

1

TABLE

EXCERPT FROM

ROOM PLAN

2

3

SPEAKER

MICROPHONE

B LEVEL ATTENUATION ZONE FOR MIC 1

CHAIR

4

5

STEP 3

Assigned

1

1

3

2

5

3

Figure 8 - Example 3

8

SPEAKER

1

2 3 4

Mics

A

2

4

B

A

B

B

STEP 4

Page 10

STEP 5 - Setting the DIP switches Upon completion of the chart you will have a grid which can now be used for

setting the DIP switches on the LCA16. See Example 4 below. Each speaker output on the LCA16 has a

set of DIP switches on the front panel. There are two banks of 16 switches aligned vertically above each

LED bank. The left bank of switches is for "A" level attenuation. The right bank of switches is for "B"

attenuation. DIP switches are set to the ON position by depressing them to the right. You will set these

switches according to the notations written on your LCA16 WORKSHEET.

For example, according to the worksheet in Example 4, speaker 1 is attenuated by two logic inputs.

Speaker 1 will need maximum attenuation ("A" level) for logic input 1 (microphones 1 and 2) and partial

attenuation ("B" level) for logic input 2 (microphones 3 & 4).

Speaker 2 will need to be attenuated partially ("B" level) for logic inputs 1 and 3 and fully attenuated ("A"

level) for logic input 2.

The illustrations below show how the switches will need to be set according to the chart.

DOT INDICATES "ON" CONDITION.

7A 7B 8A 8B

1

2

3

OPEN OPEN

4

5

6

7

8

9

10

11

12

13

14

15

16

OPEN OPEN

5

0

9

15

OPEN OPEN

7A

7B

5

0

9

15

5

0

9

15

8A

8B

5

0

9

15

OPEN OPEN

1

2

3

LOGIC

Assigned

1

2

3

Mics

1 2 3 4

BA

B A

B

SPEAKER

Figure 9 - Example 4

STEP 6 - Make your initial settings for the "A" and "B" levels of attenuation. If you have not yet determined a starting

level of attenuation for your speakers, it is suggested that all "A" levels be set for full attenuation (completely

off) and the "B" levels set for 5 to 9dB of attenuation. PLEASE NOTE THAT THE "A" LEVEL WILL

ALWAYS TAKE PRIORITY OVER "B" LEVEL, SO BE CERTAIN THE "A" LEVEL IS SET TO THE

GREATER ATTENUATION.

The levels of attenuation are set by adjusting the small recessed pots found between each pair of output

channel DIP switches located on the front panel. See the illustration above. These controls are set with a

small screwdriver (provided with the LCA16). Fully clockwise sets the channel to completely off.

The LCA16 is now pre-configured and may be installed in the rack. Proceed to page 10, INSTALLATION.

9

Page 11

INSTALLATION

The LCA16 is designed to be mounted in a standard 19-inch equipment or cabinet. Adequate ventilation must be

provided which can normally be accomplished by leaving at least two open rack spaces (3 1/2 inches) above and below

the unit. Generally, the LCA16 should be positioned such that the intake air (from the bottom of the unit) is the coolest

available in the rack. If there are fans in the rack for cooling, optimum placement will be determined by the fan position.

INTERCONNECTIONS

Refer to your LCA16 SYSTEM WORKSHEET to see which microphone is connected to each LOGIC INPUT, and

which speaker is connected to which output channel. Your room sketch will also be helpful. Number each

speaker and microphone and tag the wire pairs. Doing this prior to making any interconnections will save a

great deal of time during the initial setup. It is not necessary to install microphones and speakers in any

particular order.

Audio Connection from Mixer / Signal Processor

Electrical connection to the AUDIO INPUT is made using a standard 3-pin XLR type connector. Pin 2 is audio "hot" (+),

pin 3 is audio "cold" (-), and pin 1 is ground (shield). If an unbalanced source is used for audio input, connect the

source ground to pins 1 and 3 at the LCA16, and source "hot" to pin 2. The use of a two-wire plus shield cable is

recommended, with the shield left unconnected at the source end and connected to signal ground at the LCA16 end

regardless of whether the source is balanced or unbalanced.

Logic Connections From Mixer

Electrical connection to the LOGIC INPUTS is made using stripped and tinned insulated hookup wire, 18 to 24 gauge. If

connecting to Lectrosonics’ AP4 Modular Audio Processor modules, simply connect the LOGIC OUT (+) of the AP4 to

the LOGIC INPUT (+) of the LCA16, and the LOGIC OUT (-) of the AP4 to the LOGIC INPUT (-) of the LCA16. If

multiple microphones are assigned to the same logic input, the logic connections may be connected in parallel.

If connection is being made to relay contacts, the polarity of the connection is unimportant. When connecting to the logic

outputs of other manufactures’ equipment, treat the LOGIC INPUT (-) on the LCA16 as "ground" and the LOGIC INPUT

(+) on the LCA16 as "signal" or "hot". Internally, the LOGIC INPUT (+) on the LCA16 is connected through 100k Ohm

to +5 Volts, so any logic output or other contact system which is interfaced to the LCA16 must be capable of sinking 50

microamps of continuous current. The LOGIC INPUTS of the LCA16 are active low.

Speaker Connections

Electrical connections to the SPKR OUT terminals are made using any two wire cable of 22 gauge or larger. Refer to

the table in Appendix 1 for power loss vs cable distance data. The best practice is to tin the leads before insertion into

the terminal blocks to eliminate wire "whiskers" that might cause intermittent connections. The SPKR OUT terminals

drive low impedance loads (4 Ohms and above) directly, making a matching transformer at the speaker unnecessary.

The SPKR OUT + output terminal is in phase with pin 2 of AUDIO INPUT. The SPKR OUT - terminal is connected to

system ground. Neither of the output terminals should be connected to any other grounds (e.g. building grounds, cold

water grounds, etc.) or to any source of voltage. The only connections that should be made are to the speaker itself.

Line Out to Recorder or External Amplifier

Electrical connections to the LINE OUT terminals can be made in one of two ways, depending on whether a balanced or

unbalanced input is to be driven. In both cases a two-wire plus shield type of cable should be used. For driving a

balanced input, LINE OUT + connects to the signal "hot" (pin 2 on a standard XLR 3-pin connector), and LINE OUT -

connects to the signal "cold" (pin 3 on a standard XLR 3-pin connector). LINE OUT is connected to the shield of

the cable. It is not necessary to connect the shield to anything at the other end of the cable. The connection at the

LCA16 end is sufficient for shielding.

With a balanced system, there is no need to connect the grounds together. An additional benefit of this is that the

possibility of ground loops will be eliminated. For driving an unbalanced input, LINE OUT + is connected to the "signal"

terminal of the input to be driven, and the LINE OUT is connected to the "ground" terminal of the input. Note that

both "signal" and "ground" should be carried on the two wires of the cable. The shield should be connected to LINE

OUT on the LCA16 end and left unconnected on the other end.

10

Page 12

INTERCONNECTION DIAGRAM

LOUDSPEAKERS

LOGI C OUTPUTS

LOGI C OUTPUTS

LOGI C OUTPUTS

-

+

GND

RT N

SND

SN D

RT N

GND

+

-

-

+

GND

RT N

SN D

LOGIC OUTP UTS

SN D

RTN

GN D

+DC

-DC

MIC INPUT 1

MIC INPUT 2

MIC INPUT 3

MIC IN PUT 4

AUTOM ATIC MICROP HON E PR EAM P

70V DISTRIBUTED SYSTEM

TO MICROPHONES

FROM AUDIO OUTPUT OF MIXER

AUTOMATIC

MICROPHONE

MIXER

TWISTED PAIR

LOGIC

CONNECTIONS

LINE

SPEAKER

LEVEL

OUTPUTS

LISTED

COMMERCIAL

AUDIO

EQUIPMENT

4L01

120V AC

200 WATTS

US PATENT PENDING

R

MADE IN USA RIO RAN CHO, NM

LECTROSONICS, INC.

S

T

U

P

N

I

AUDIO THRU

8

7

6

5

16

15

14

13

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

AUDIO INPUT

C

I

G

O

L

-

+

-

-

-

+

-

-

-

4

3

2

1

12

10

9

-

+

9

10

11

12

SP KR

OUT

+

-

LINE OUT

SP KR O U T

+

-

LINE O UT

LINE O UT

LCA 16 OUTPUT MODULE

AM 4

13

14

15

16

SP KR

OU T

+

-

LINE OUT

SP KR

OUT

+

-

LINE O U T

LINE OUT

SP KR O U T

+

-

LINE O U T

SP KR

OUT

+

-

LINE O U T

LINE O U T

SP KR

OU T

+

-

LINE OUT

SP KR O U T

+

-

LINE O U T

LINE O U T

LCA 16 O UT PUT M ODU

AM 4

SER NO

+

+

+

11

EXTERNAL

AMPLIFIER

LCA 16 LOGIC CONTROLLED AMPLIFIER

F

U

S

E

F

U

S

E

F

U

S

E

LEVEL

OUPUTS

Figure 13 - Interconnection Diagram

11

Page 13

ATTENUATION SETTINGS

AND SPEAKER SYSTEM ADJUSTMENTS

The steps and procedures in this section should be followed only after all wiring and audio connections have been

completed, and the system components have been installed. It is also necessary to complete the worksheet for speaker

attenuation and the pre-configuration instructions for the LCA16 before attempting the adjustments in this section.

MAIN LEVEL ADJUSTMENT ON THE LCA16

The pre-configuration instructions on pages 6 through 9 simply provide a "starting point" for further adjustment. The

settings suggested in that section are based upon typical experience gathered from the field. The actual settings for a

particular system may vary from these settings once the final set up is completed.

Ideally, the LCA16 should provide just enough attenuation to prevent feedback while allowing maximum speaker system

coverage. Attenuation beyond what is necessary for feedback control can make the operation of the LCA16 audible as

the speaker system attenuates in response to microphone activity. In many installations, the operation of the sound

system is almost transparent. In other words, the talkers do not actually hear themselves over the speaker system as

they talk, yet adequate reinforcement is provided so that more distant listeners can hear them clearly.

The first step in the final set up is to complete the attenuation settings for a single speaker zone, and then use these

settings as a guide for subsequent adjustments. The final adjustment of this first speaker zone will provide a setting for

the LCA16 MAIN LEVEL control. Once the MAIN LEVEL control is set for the first speaker zone, it should be left alone

for adjustment of the rest of the speaker zones.

Select a zone in the central part of the room and activate a microphone within it. Gradually increase the MAIN LEVEL

on the LCA16 until an adequate volume is achieved. If feedback occurs before adequate gain can be achieved,

increase the attenuation level of the speakers near the open microphone and then continue to increase the sound

system level. If additional attenuation is required, it often requires a change in the DIP switch settings indicated by the

original worksheet (more speakers may need to be attenuated). Activate each microphone in this zone (if there is more

than one) and check for adequate gain. Re-adjust the attentuation levels as needed.

If adequate gain cannot be achieved, even with excessive speaker attenuation, the basic sound system design may

be at fault. In this case, it may be time to re-evaluate the mouth to microphone distances and/or the basic microphone

and speaker system layout in the room.

If there is more than enough gain, reduce the amount of attenuation of the speakers near the open microphone.

Remember that the most transparent operation will be achieved with the least amount of attenuation. Use only enough

attenuation to control feedback.

Once adequate gain is achieved on the first zone, leave the MAIN LEVEL control on the LCA16 alone for adjusting the

remaining channels.

SETTING ATTENUATION LEVELS ON REMAINING CHANNELS

With the LCA16 MAIN LEVEL control set for the first zone (see above), repeat the above procedure for each of the

remaining speaker zones. Be sure to check all microphones in each speaker zone as you proceed.

AUTOMATIC MIXER THRESHOLD ADJUSTMENT

If the sound system (loudspeakers) open unused microphone channels during the adjustment process, increase the turnon threshold setting on the automatic mixer just enough to keep the unused channels from turning on. This control is

labeled THRESHOLD on the Lectrosonics AC1 controller.

12

Page 14

Audio Input:

Connectors: 3-pin female XLR, electronically balanced and RF filtered

Impedance: 20K Ohms balanced, 10K Ohms unbalanced

Max Input Level: +8dBv

Thru Output:

Connectors: 3-pin male XLR, parallel with Audio Input

Logic Input:

Connectors: Terminal Strip

Impedance: 100K Ohms in parallel with 2.2uF pulled up to +5 volts

Speaker Output:

Connectors: Terminal Strip

Load Impedance: 4 Ohms or greater

Protection: Short circuit

THD (20Hz-20KHz): Less than .25% @ 5 watts, 4 Ohms (80KHz filter)

IMD (60Hz/7KHz): Less than .25% @ 5 watts, 4 Ohms (80KHz filter)

Noise (20Hz-20KHz): Less than -75dBv (Gain control at unity)

SPECIFICATIONS

Open circuit

Thermal

Excessively reactive load

Line Output:

THD (20Hz-20KHz): Less than .05% @ 4dBv

IMD (60Hz/7KHz): Less than .05% @ 4dBv

Noise (20Hz-20KHz): Less than -90dBv

Attenuation Method: Automatic Rated-controlled Variable Attenuation*

Power Consumption: 160 Watts maximum

* US PATENT NUMBER 5204908

13

Page 15

SERVICE AND REPAIR

If your system malfunctions, you should attempt to correct or isolate the trouble before concluding that the equipment

needs repair. Make sure you have followed the setup procedure and operating instructions. Check out the interconnecting cords and then go through the TROUBLE SHOOTING section in the manual

We strongly recommend that you do not try to repair the equipment yourself and do not have the local repair shop

attempt anything other than the simplest repair. If the repair is more complicated than a broken wire or loose

connection, send the unit to the factory for repair and service. Don’t attempt to adjust any controls inside the units.

Once set at the factory, the various controls and trimmers do not drift with age or vibration and never require

readjustment. There are no adjustments inside that will make a malfunctioning unit start working.

LECTROSONICS service department is equipped and staffed to quickly repair your equipment. In-warranty repairs are

made at no charge in accordance with the terms of the warranty. Out of warranty repairs are charged at a modest flat

rate plus parts and shipping. Since it takes almost as much time and effort to determine what is wrong as it does to

make the repair, there is a charge for an exact quotation. We will be happy to quote approximate charges by phone for

out of warranty repairs.

RETURNING UNITS FOR REPAIR

You will save yourself time and trouble if you will follow the steps below:

A. DO NOT return equipment to the factory for repair without first contacting us by letter or by phone. We need to

know the nature of the problem, the model number and the serial number of the equipment. We also need a phone

number where you can be reached 8 am to 4 pm (Mountain Standard Time).

B. After receiving your request, we will issue you a return authorization number (R.A.). This number will help speed

your repair through our receiving and repair departments. The return authorization number must be clearly shown

on the outside of the shipping container.

C. Pack the equipment carefully and ship to us, shipping costs prepaid. If necessary, we can provide you with the

proper packing materials. UPS is usually the best way to ship the units. Heavy units should be "double-boxed" for

safe transport.

D. We also strongly recommend that you insure the equipment, since we cannot be responsible for loss of or damage

to equipment that you ship. Of course, we insure the equipment when we ship it back to you.

Mailing address: Shipping address: Telephones:

Lectrosonics, Inc. Lectrosonics, Inc. (505) 892-4501

PO Box 15900 581 Laser Rd. (800) 821-1121

Rio Rancho, NM 87174 Rio Rancho, NM 87124 FAX: (505) 892-6243

USA USA

World Wide Web: http://www.lectrosonics.com email: sales@lectrosonics.com

14

Page 16

APPENDIX 1 - POWER LOSS vs CABLE RUN

The table below indicates power loss vs cable run for various wire gauges. Nominal output power for the LCA16 is 5

watts at 4 ohms and 3 watts at 8 ohms.

22 AWG Wire, 4 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 4.8W 4.5W .3W

50ft. 4.5W 4.0W .5W

100ft. 4.0W 3.2W .8W

250ft. 3.1W 1.9W 1.2W

18 AWG Wire, 4 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 4.9W 4.7W .2W

50ft. 4.7W 4.3W .4W

100ft. 4.4W 3.7W .7W

250ft. 3.6W 2.6W 1.0W

16 AWG Wire, 4 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 4.9W 4.8W .1W

50ft. 4.8W 4.6W .2W

100ft. 4.6W 4.2W .4W

250ft. 4.0W 3.2W .8W

22 AWG Wire, 8 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 2.9W 2.7W .2W

50ft. 2.7W 2.5W .2W

100ft. 2.5W 2.1W .4W

250ft. 2.0W 1.3W .7W

20 AWG Wire, 8 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 2.9W 2.8W .1W

50ft. 2.8W 2.6W .2W

100ft. 2.7W 2.4W .2W

250ft. 2.3W 1.7W .6W

18 AWG Wire, 8 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 3.0W 2.9W .1W

50ft. 2.9W 2.8W .1W

100ft. 2.8W 2.6W .2W

250ft. 2.5W 2.1W .4W

16 AWG Wire, 8 ohm load

Distance Total Power Available Load Power Wire Loss

25ft. 3.0W 2.9W .1W

50ft. 2.9W 2.8W .1W

100ft. 2.9W 2.7W .2W

250ft. 2.7W 2.4W .3W

15

Page 17

1

2

3

4

5

APPENDIX 2 - LCA16 SYSTEM WORKSHEET

DIPSWITCH SETTINGS

SPEAKER

Assigned

Mics

1 2 3 4 5 6 7 8 910 11 12 13 14 15 16

LOGIC INPUT

6

7

8

9

10

11

12

13

14

15

16

16

Page 18

LIMITED ONE YEAR WARRANTY

The equipment is warranted for one year from date of purchase against defects in

materials or workmanship provided it was purchased from an authorized dealer.

This warranty does not cover equipment which has been abused or damaged by

careless handling or shipping. This warranty does not apply to used or

demonstrator equipment.

Should any defect develop, we will, at our option, repair or replace any defective

parts without charge for either parts or labor. If we cannot correct the defect in

your equipment, we will replace it at no charge with a similar new item. We will

pay for the cost of returning your merchandise to you.

This warranty applies only to items returned to us, shipping costs prepaid, within

one year from the date of purchase.

This warranty gives you specific legal rights. You may have additional legal rights

which vary from state to state.

LECTROSONICS, INC.

581 LASER ROAD

RIO RANCHO, NM 87124 USA July 6, 1999

Loading...

Loading...