Page 1

DM84

Digital Matrix Processor

• 8-in/4-out digital matrix architecture in a stackable configuration

• Programmable front panel level controls with activity LEDs

• 6 filters, 6 feedback eliminators (ADFE), compressor and delay on each input

• 9 filters, delay and compressor/limiter on each output

• USB and RS-232 interfaces for setup and comprehensive remote control

• Balanced, floating differential inputs and outputs - no pin 1 problem

• Digital I/O ports for "daisy chaining" and to connect other LecNet 2 devices

• Proportional gain auto mixing algorithm with AutoSkew

TECHNICAL DATA

™

- US Patent 5,414,776

• 128 global macros, each with up to 64 commands, and 115 characters per command

The DM84 combines a stackable 8-in/4-out automatic

matrix mixer with a powerful DSP signal processing

package and extensive remote control capabilities for any

sound system application with multiple microphones and

loudspeakers. Multiple DM84 units can be stacked to

expand the matrix with unlimited inputs and up to 12

outputs. The unit also supports the full LecNet2 digital

matrix, so it can also be integrated with other DM Series

processors in 24 output systems.

The primary applications are in sound reinforcement and

recording in boardrooms, courtrooms, worship centers,

distance learning systems, hotels and other applications

that benefit from matrix signal routing, automatic mixing

and remote control options. Once setup is completed with

the supplied LecNet2 software, the unit runs as a standalone device. Front panel controls are provided to make

minor adjustments to the input and output levels, expanding its usefulness into stand-alone applications. The

adjustment range of each control is defined in the software setup to optimize it for various needs.

The DSP features include a full complement of filters,

ADFE (automatic digital feedback eliminators), compressors, limiters and delay on every channel to optimize the

signal processing needed for every application. This

processing is available at the inputs to compensate for

microphone placement and signal characteristics, or to

adjust for differences in tonal quality or dynamics of

various signal sources. Each output has individual filters

and a proprietary, adaptive time constant compressor/

limiter to feed recorders or power amplifiers.

Extensive control capability is built into the unit with an

intuitive command structure to allow external control with

USB or RS-232 connections. Touch panel control systems

easily integrate into the command structure. Remote

control, monitoring and setup can also be done via

ethernet connections using a low cost interface provided

by another manufacturer.

Up to 128 macros can be stored in internal memory. Each

macro can contain up to 64 commands, with 115 characters in each command. Macros can be invoked with serial

commands from touch panel control systems or contact

switches connected to the logic I/O ports on the rear

panel. The macros can be chained so that one macro can

call another one, which may call yet another one. In

addition, a built-in macro recorder greatly simplifies the

creation and use of macros.

The audio inputs and outputs are balanced, differential

circuits (no pin 1 problem) to eliminate noise from external RF and power sources, even with long cable runs.

The patented gain proportional automatic mixing algorithm* is applied at the crosspoints in the matrix so each

input can behave differently at each output. For example,

input 4 can be a microphone that participates in the NOM

attenuation applied by the auto mixing algorithm at some

of the ouputs, and operate as a direct signal for recording

at other outputs.

Rio Rancho, NM, USA

www.lectrosonics.com

Page 2

General Overview

The LecNet2 product group introduces a powerful series

of audio components and unique solutions for the design

and installation of sound systems with multiple microphones and loudspeakers. The DM84 is a very useful

member of this family in that it can satisfy cost conscious

applications in stand-alone operation, or function as a

building block to configure larger systems. It addresses

the full digital matrix of the DM Series so it can also be

used with other models to add additional inputs and

outputs. The range of the front panel level controls can be

configured to suit specific preferences.

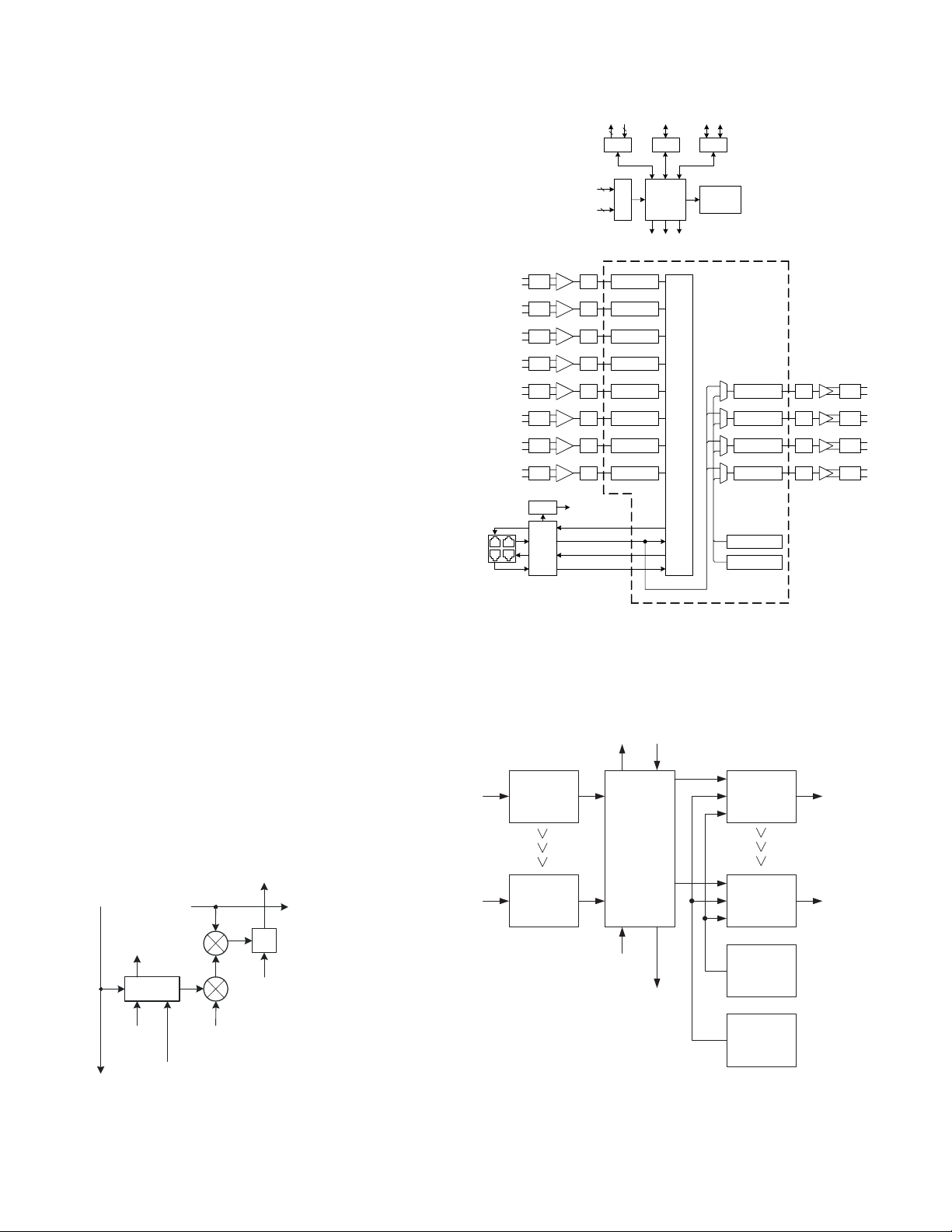

Digital Matrix

The digital signal flow provides an expandable digital

matrix with no crosspoint limitations. Automatic mixing

takes place at the crosspoint in the matrix so that every

input can participate in every output group at a different

level and with a different auto mixing behavior to optimize

the channel behavior for specific purposes.

In addition, a DANI (Digital Audio Network Interface) bus

is provided so that the digital audio signals and data from

the master and slave units are connected in stacked

configurations in larger sound systems.

Automixer Cell

The Automixer Cell is the core of the matrix. It is where

level control for the automatic mixing algorithm, mixing

mode and crosspoint gain is applied using data gathered

from other channels and devices. In a stacked configuration, the cell receives data from the master unit above it

and from the slave units below it. The final mix is generated in the master unit and the data is returned back to

slave units to implement automatic mixing.

TxTxRx

Rx

Quad RJ -45 Conn

Output Volume Control Pots

Phan

In 1

On/Off

Phan

In 2

On/Off

Phan

In 3

On/Off

Phan

In 4

On/Off

Phan

In 5

On/Off

Phan

In 6

On/Off

Phan

In 7

On/Off

Phan

In 8

On/Off

Sync Audio Fr ame Sync

Digital

Audio

Network

Interface

(DANI)

Input Gain Control Pots

Prog

Prog

Prog

Prog

12 + 2 Submix + Mix Control

12 + 2 Mix + Mix Control

12 + 2 Mix + Mix Control

12 + 2 Submix + Mix Control

Prog I /O Conn

11

8

4

A/D Signal Pr ocessi ngProg

A/D Signal Pr ocessi ng

A/D Signal Pr ocessi ngProg

A/D Signal Pr ocessi ng

A/D Signal Pr ocessi ngProg

A/D Signal Pr ocessi ng

A/D Signal Pr ocessi ngProg

A/D Signal Pr ocessi ng

DB25

Prog I/O

Port

LecNet 2 C onn

1/8 '' Jack

8

RS-232

Port

Micro

12

Control ler

A/D

Control Signals

DM84 Functional Block Diagram

Front & Rear

USB B Conn

USB

Port

8 input 4 output

tric olor s ignal

indicat or LEDs

SHARC is a r egister ed tradem ark of

8 by 24 (+ 2) Automati c Mixing Matri x

Off: No signal

Green : Signal present

Orange : Compr essor/ lim iter active

Red: Cl ipping

Third Generation

®

DSP

SHARC

Analog Devices , Inc.

Signal Pr ocessi ng D/A

Signal Pr ocessi ng D/A

Signal Pr ocessi ng D/A

Signal Pr ocessi ng D/A

1 kH z Tone Gener ator

Pink N oise Gener etor

Out

Out 1

Atten

Out

Out 2

Atten

Out

Out 3

Atten

Out

Out 4

Atten

Power of the Mix

The Power of the Mix is the reference used to determine

the gain to be applied to each individual output channel.

In a multi-unit stacked configuration, this data is sent to

the slaves from the master unit.

Crosspoint Gain

Crosspoint Gain is the gain selected with the control

panel that determines the level at the output.

Submix

Power of the Mix

Digital Matrix Functional Block Diagram

(single crosspoint shown)

Audio Input

Power of the

Submix

Automixer

Cell

Power of the

Submix

Mixing Mode

- Auto

- Direct

- Override

- Background

- Phantom

Crosspoint Gain

-70 to 20 dB

1 dB steps

+

Submix

24 Output Submixes

2 Expansion Submixes

26 Automixing Aux. Data

Input #1

Processing

Input #8

Processing

24 Output Submixes

2 Expansion Submixes

26 Automixing Aux. Data

DM84 Signal Flow

2 Expansion Signals

Automixing Control Data

24 by 12+2

Automatic

Mixing

Matrix

2 Expansion Signals

Automixing Control Data

Output #1

Processing

Output #4

Processing

Tone

Generator

1 kHz, 0 dBu

Pink Noise

Generator

0 dBu

2

Page 3

Mixing Mode

The automatic mixing algorithm applies a patented gain

proportional algorithm (

#5,402,500

output to behave differently relative to the other inputs

assigned to the output.

Five different mixing modes are available:

) allowing each input assigned to a particular

Auto - In automatic mode the input applied to the

crosspoint is mixed into the output channel using

the the Adaptive Proportional Gain automixing

algorithm in the normal manner. This is the most

common setting.

Direct - In Direct mode the automixing algorithm is

bypassed.

Override - Override mode is selected when it is

required that the input applied to the crosspoint

always dominates the output channel when it

becomes active.

Background - Background mode is selected when

it is required that the input applied to the crosspoint

dominates the output channel only when all other

inputs are inactive.

Phantom - A special mode that allows an input to

participate in the auto mixing activity at one or more

crosspoints, but the audio signal is not delivered to

the output. In essence, the NOM mixing activity is

separated from the actual audio signal. This allows

NOM attenuation to take place between zones in a

mix-minus sound system design. It preserves the

discrete signal routing implemented in a mix-minus

sound reinforcement system that isolates microphones and loudspeakers.

US Patents #5,414,776

and

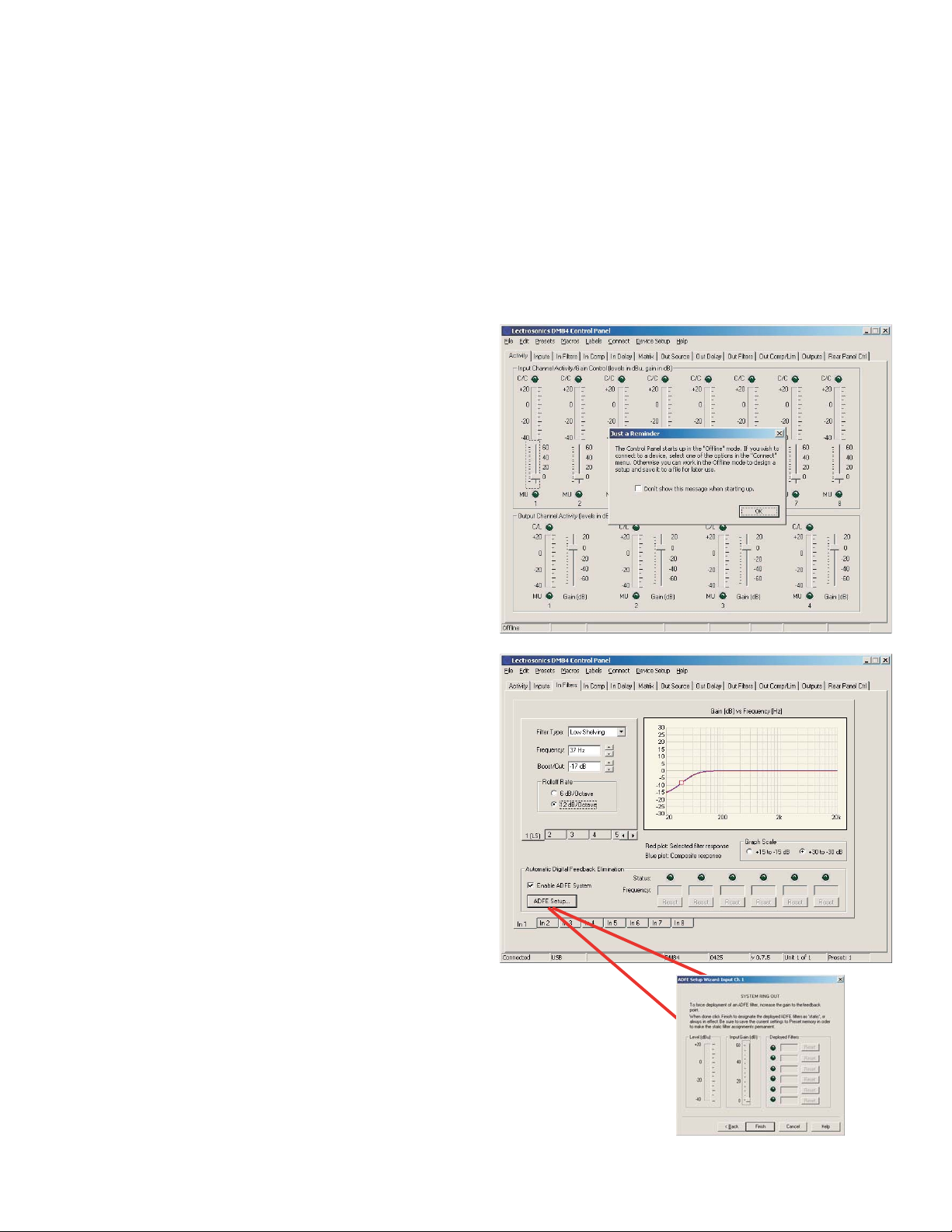

LecNet2 Software

Software is included with the DM84 and available for

download from the website at:

The software is used primarily for setup, with the configuration saved on file and into the unit's memory for actual

operation. Once configured, the DM84 runs without a

host computer.

The software is user-friendly, with a variety of screens

provided for each section of the signal flow and system

design. The software runs under Windows

operating systems using a familiar tabbed layout. A few

sample screens are shown below.

www.lectrosonics.com

®

2000 and XP

.

*Windows is a registered trademark of Microsoft Corp.

3

Page 4

Input Processing

Each input channel provides individual stages for gain,

filtering and compression and delay.

Input Gain

The input applies software controllable gain with a level

indicator and clipping indicator.

Filters

Up to six filters can be implemented at each input to

idealize the signal equalization.

The filter types include:

Low pass

High pass

Band pass

Parametric EQ

Low shelving

High shelving

Filter slopes can be selected with 6 or 12 dB per octave

Butterworth or Bessel parameters. Multiple filters can be

assigned to create steeper slopes in 6 dB steps.

ADFE (automatic digital feedback eliminator)

Six narrowband notch filters are automatically placed on

ringing and/or oscillating frequencies to cancel acoustic

feedback. A pop-up screen provides a utility to manually

increase the gain in small increments to “ring out” the

sound system. As the ringing begins to occur the filters

are automatically placed. The filters can then be stored as

static filters in the presets.

Input Compressor

The compressor implementation is a unique “soft knee”

type based on an RMS level detector controlled by a

single time constant parameter. This is a new design

which responds to varying rates of change in the signal

level by dynamically adjusting the attack and release

times for best performance. Adjustment is simplified by

entering a single value (half of the desired release time).

The attack time is then applied by the DSP to vary with

the signal.

The default value is 100 ms, which sets the release time

at about 200 ms. The attack time is signal controlled and

varies from about 2 ms to about 100 ms as is needed to

handle the signal dynamics. See the reference manual

for a closer look at this unique and very effective compressor.

Compressor adjustment parameters include:

Threshold

Time Constant

Compression ratio

Makeup gain

Delay

The input delay can be set up to 100 ms in .50 ms

increments. The delay can also be set according to

distance in either feet or meters.

Indicator

Clipping

Detector

A/D

Coarse Gain

0 to 50 dB,

10 dB steps

Input Gain & Polarity

-10 to +60 dB

1 dB steps

Fine Gain & Polarity

-10 to 10 dB,

1 dB steps

0 - 100 ms

0.5 ms steps

Typical Input Signal Processing Blocks

Delay

Six Filter

Stages

Off, LP, HP, BP,

PEQ, LS, HS

6 or 12 dB/oct.

Butterworth or Bessel

when applicable

Gain Reduction Indicator

Six ADFE

Filters

Enable/Disable

Activity Indicator

Compressor

Threshold

Time Constant

Ratio

Makeup Gain

Indicator

Level Meter

4

Page 5

Output Processing

Output Source Select

In normal operation the digital matrix delivers the audio

signals to the outputs, which consist of the final mixes

backpropagated from the master unit in the system via

the Digital Audio Network Interface (DANI), with 12 mixes

from the main matrix and 2 mixes from the expansion

matrix. Internal pink noise and 1 kHz tone generators are

also available at each output for diagnostics, setup and

sound masking purposes.

Output Gain and Level Indicator

The output level can be adjusted from - 70 dBu to +20

dBu in 1 dB steps to perfectly match the requirements of

the device being fed by the channel. A bar graph is

provided by the on screen GUI to accurately indicate the

output level as it operates and is adjusted.

Delay

A delay of up to 250 ms in .50 ms increments is provided

at each output. The delay can also be set according to

distance in either feet or meters.

Filters

Up to nine filters can be implemented at each output to

idealize the signal equalization:

Low pass

High pass

Band pass

Parametric EQ

Low shelving

High shelving

Filter slopes can be selected with 6 or 12 dB per octave

Butterworth or Bessel parameters. Multiple filters can be

assigned with the same values to to creater steeper

slopes in 6 dB steps.

Gain Reduction Indicator

Output Compressor and Limiter

A versatile compressor and limiter are provided at each

output to control the average level and dynamics of the

audio signal, and restrict the maximum output level to

optimize the channel for its purpose. Compression is

often needed when the channel is feeding a recorder, and

limiting is often used to protect a loudspeaker system and

reduce distortion and amplifier overload.

The compressor implementation is a unique “soft knee”

type based on an RMS level detector controlled by a

single time constant parameter. This is a new design

which responds to varying rates of change in the signal

level by dynamically adjusting the attack and release

times for best performance. Adjustment is simplified by

entering a single value (half of the desired release time).

The attack time is then applied by the DSP to vary with

the signal.

The default value is 100 ms, which sets the release time

at about 200 ms. The attack time is signal controlled and

varies from about 2 ms to about 100 ms as is needed to

handle the signal dynamics. See the reference manual

for a closer look at this unique and very effective compressor.

Compressor adjustment parameters include:

Threshold

Time Constant

Compression ratio

Makeup gain

Limiter adjustment parameters include:

Threshold

Time Constant

Indicator

Activity Indicator

Activity Indicator

Level Meter

Delay Compressor Limiter

0 - 250 ms

0.5 ms steps

Typical Output Signal Processing Blocks

Nine Filter

Stages

Off, LP, HP, BP,

PEQ, LS, HS

6 or 12 dB/oct.

Butterworth or Bessel

when applicable

Threshold

Time Constant

Ratio

Makeup Gain

Threshold

Time Constant

Output Gain

-70 - +20 dB

1 dB steps

5

Page 6

The DANI Bus and Back Propagation

The core of the DM Series processors consists of a digital

matrix and a digital bus called DANI (digital audio network

interface). The digital matrix is common to all units in a

system. The DANI bus interconnects the hardware to

allow access to the matrix signal flow and transfer data

required for automatic mixing functions. In order to

understand the power and functions available with this

architecture it is helpful to think of them as entities

separate from the hardware.

In this sense a DM processor is simply a hardware-based

tap into the digital matrix via the DANI bus to interface

various types of microphones and audio equipment with

the digital matrix. Thus connected, the processors

distribute audio signals and share information about each

input and output to provide a myriad of features and

functions.

When multiple DM processors are stacked, each unit

participates with the digital structure in several ways:

• Delivering audio signals from its input terminals into

the forward-propagated submix bus

• Passing back-propagated final mix signals from the

unit above it to the next unit below it

• Applying gain and signal processing to the audio

signals at its input terminals

• Delivering audio signals to its output terminals as

selected by the setup

• Applying signal processing to the signals routed to

its output terminals

• Receiving and transmitting data required for the

automatic mixing process in the matrix

The digital matrix is common to all processors in the

stack, with automatic mixing taking place at the

crosspoints in the digital matrix. The output of each

crosspoint is then available at a variety of output terminals

on various processors in the stack.

Different processor models interface with the digital matrix

in different manners. Audio signals and data are propagated from the Slaves to the Master unit in a stack, then

the data and some of the final mix signals in the Master

are back propagated to the Slaves. This provides additional final mix outputs at the output terminals on the

Slave units.

DM Series

Slave

Slave

Processor

DM Series

Processor

DM Series

Processor

Master

Automatic Mixing Matrix

MASTER

SLAVE

Audio Submix

and Data

Forward Propagation

Audio Submix

and Data

Forward Propagation

Audio Final Mix

and Data

Back Propagation

Audio Final Mix

and Data

Back Propagation

SLAVE

6

Page 7

Hardware Control

The DM84 processor has programmable inputs which can

be used to control a wide variety of functions. Depending

on the function assigned to them, these programmable

inputs may be connected to momentary contact switches,

toggle switches, or potentiometers. When used with a

switch, the inputs are activated by by connecting them to

ground through the switch contacts, called a “contact

closure.” When used with a variable resistor, the inputs

respond to the applied voltage in the range 0 to 5 VDC.

Another feature of the rear panel control interface are a

set of programmable outputs which can be set up to

indicate either audio input channel activity or programmable input status. Programmable outputs act as an

electronic “contact closure” to ground. When the output is

active, the contact is closed (conducting to ground).

When the output is inactive, the contact is open (not

conducting to ground).

An important application of the rear panel control interface is to manage what is called the rear panel gain for

input and output audio channels. This is an additional gain

value that is added to the “main” gain value for a channel

to give the total gain applied. Rear panel gain is limited to

the range -60dB to 0dB, and therefore is actually intended

to function as a variable attenuator for the audio channel.

The purpose is to allow some amount of gain or level

control by the end user in a safe manner, using one of the

programmable inputs.

A typical application of rear panel gain is to allow adjustment of the level of an audio output (driving a speaker)

downward from some maximum by means of turning a

potentiometer connected to a programmable input which

has been set up to use the Analog Output RP Gain

Control function.

Complete details on the use of Rear Panel control is

provided in the Installation Guide and in the Control Panel

GUI provided with the unit.

Command Language

A very powerful, yet intuitive command language allows

complete control over DM Series processors with short

commands delivered via the USB or RS-232 ports. The

language and structure makes programming remote

control functions very easy. Individual function settings

and signal routing can be customized for a particular

application during setup, recalled from various screens

during operation, or recalled by other brands of remote

control systems. The RS-232 serial port is completely

compatible with control systems from AMX®, Crestron

and with Extron® IPL Series ethernet adapters which

allow remote control via standard networks. A complete

library and explanation of the commands and the command structure is available in the DM84 Reference

Manual.

®

Macros

A comprehensive macro utility greatly expands the

remote control capability. The DM84 can be remotely

controlled using commands sent over USB, a serial port,

or a network connection. An extensive text-based command language is defined for the DM84. Touch panel

controllers, for instance, use this command interface.

Macros are predefined groups of commands that are

stored internally by the DM84. All of the commands

contained in the macro can then be executed by issuing a

single Run command to the DM84. There are two advantages to this approach:

• Efficiency - only one command needs to be sent to

the DM to execute complex actions, which may

involve dozens of individual commands.

• Modularity - frequently executed sequences can be

implemented as a macro which can be reused in

other control designs, or combined with other macros

to form complex actions.

Up to 128 macros can be stored in the DM84 nonvolatile

memory. Macros are global in scope, meaning that they

are not associated with any particular preset. Each macro

can contain up to 64 commands, with 115 characters in

each command. Macros may be given a descriptive title

which is stored along with the command list.

Macros can be chained if necessary, meaning that one

macro can call another macro by virtue of containing a

run command. A run command issued from within a

macro will be delayed until after the first macro has

finished running. In other words, macros aren’t nested,

they always run sequentially (chaining). The best practice

when chaining macros is to make the run command the

last command in a macro.

The control panel contains a Macro Editor which is used

to create new macros or edit existing ones when the PC

is connected to a DM. Macros may also be opened and

saved as files, making it possible to work with them in

offline mode as well.

The control panel also contains a Macro Recorder which

allows a sequence of commands to be captured as a

macro without typing them into the Macro Editor. The

Macro Recorder works by capturing the commands

generated by the control panel when the mouse and

keyboard are used to make changes to the DM84 settings. The macro recorder can run be while connected to

a DM or used in offline mode to create command sets in

advance of the installation.

AMX, Crestron and Extron are registered trademarks of the

respective companies.

7

Page 8

Front Panel

The DM84 is housed in a single space 19” rack mount

assembly. The front panel provides input and output level

controls to make adjustments manually while the system

is operating. Multi-color LEDs indicate activity on each

input and output channel. A Mode switch allows booting

the unit as a Master when it is configured as a Slave and

powered up by itself.

Rear Panel

LecNet 2

A universal 100-240 VAC power supply with a standard

AC receptacle is provided on the rear panel. The USB and

RS-232 jacks are used for computerized setup, firmware

updates and to control systems during operation. Logic

input and output connections are made via a DB-25 jack.

Specifications

Audio inputs

Gain: -10 dB to +60 dB; programmable 1 dB steps

Input impedance: 2.5 k Ohm

Phantom voltage:15V, programmable

Connector: 5-pin Phoenix

Audio outputs: Floating balanced, either side can be grounded

Nominal level: 0 dBu all outputs, -40 dBu selectable on

outputs 9 through 12

Output impedance:

•450 Ohm differential programmable outputs at line level

•5 Ohm differential programmable outputs at microphone level

Input Dynamic Range: 96 dB at -50 dBu input level; 102 dB at all

other levels (unweighted 20 - 20 kHz)

Output Dynamic Range: 105 dB (unweighted 20 - 20 kHz)

Audio Performance:

IMD + noise: 0.1% max.

0.02% nominal input level

THD + noise: 0.1% (worst case)

0.02% nominal input level

EIN: -126 dBu

The Status LED indicates steadily in normal operation

and blinks in the presence of several different errors. A

USB port on the front panel allows easy access for setup

or troubleshooting from the front side of the rack. The

power switch is a rocker type with positive action.

RJ-45 jacks interface with other DM Series components

via the DANI bus. The balanced differential inputs and

outputs are paired on standard depluggable connectors

sharing a ground to reduce the amount of wiring needed.

Connectors:

Audio I/O: 5-pin Phoenix

Expansion: RJ45

Logic I/O: DB25

Serial: Standard USB and mini TRS

Digital Audio Network Interface ( DANI):

Physical level: LVDS (Low Voltage DIfferential Signal)

high speed

Connector: Four RJ-45

Cable quality: Shielded CAT-5

Transmission speed: 50 Mbits/s

Programmable control inputs

Number of inputs: 11

Analog voltage range: 0-5V

Logic input: TTL, LVTTL, CMOS, LVCMOS

Programmable control outputs

Number of logic outputs: 8

Logic control: Active low

Max sink current: 100 mA

Max supply voltage: 40 V

Supply voltage for control I/O: 5 V

Max current: 750 mA

Power requirements: 100-240 VAC, 47-63 Hz

Power consumption: 15 Watts

581 Laser Road NE • Rio Rancho, NM 87124 USA • www.lectrosonics.com

(505) 892-4501 • (800) 821-1121 • fax (505) 892-6243 • sales@lectrosonics.com

DM84TD - 20 July 2006

Loading...

Loading...