Page 1

ZS1500

High Impedance Active Probe

Instruction Manual

February 2007

Page 2

Warranty

LeCroy warrants this oscilloscope accessory for normal use and operation within specification for a period of

one year from the date of shipment. Spare parts, replacement parts and repairs are warranted for 90 days.

In exercising its warranty, LeCroy, at its option, will either repair or replace any assembly returned within its

warranty period to the Customer Service Department or an authorized service center. However, this will be

done only if the product is determined by LeCroy’s examination to be defective due to workmanship or materials, and the defect is not caused by misuse, neglect, accident, abnormal conditions of operation, or damage

resulting from attempted repair or modifications by a non-authorized service facility.

The customer will be responsible for the transportation and insurance charges for the return of products to the

service facility. LeCroy will return all products under warranty with transportation charges prepaid.

This warranty replaces all other warranties, expressed or implied, including but not limited to any implied warranty of merchantability, fitness or adequacy for any particular purposes or use. LeCroy shall not be liable for

any special, incidental, or consequential damages, whether in contract or otherwise.

Corporate Headquarters

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (845) 578-6020, Fax: (845) 578-5985

Internet: www.lecroy.com

Copyright 2007 by LeCroy Corporation. All rights reserved.

LeCroy, ActiveDSO, JitterTrack, WavePro, WaveMaster, WaveSurfer, WaveLink, WaveExpert, WaveJet, and

Waverunner are registered trademarks of LeCroy Corporation. Other product or brand names are trademarks

or requested trademarks of their respective holders. Information in this publication supersedes all earlier versions. Specifications subject to change without notice.

LeCroy products are covered by International and U.S. patents, issued and pending.

Manufactured under an

ISO 9000 Registered

Quality Management System

Visit www.lecroy.com to view

the certificate.

ZS1500-OM-E Rev C

914907-00 Rev A

This electronic product is subject

to disposal and recycling regulations that vary by country and

region. Many countries prohibit the

disposal of waste electronic equipment in standard waste receptacles.

For more information about proper

disposal and recycling of your

LeCroy product, please visit

www.lecroy.com/recycle.

Page 3

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014:1998

Manufacturer’s Name:

Manufacturer’s Address:

herewith declare that

Product(s) Name: Active Voltage Probe

Model Number(s): ZS1000, ZS1500

including all their options are in conformity with the provisions of the following EC directive(s), including

the latest amendments, and with national legislation implementing these directives:

and that conformity with Council Directive 73/23/EEC is based on

EN 61010-1:2001 Safety requirements for electrical equipment for measurement

control and laboratory use

and that conformity with Council Directive 89/336/EEC is based on

EN 61326/A3:2003 EMC requirements for electrical equipment for measurement

control and laboratory use

Emissions EN 55011/A2:2002 Conducted and Radiated Emissions

Immunity EN 61000-4-2/A2:2001 Electrostatic Discharge

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977

USA

73/23/EEC Low Voltage Directive

89/336/EEC EMC Directive

EN 61000-4-3/A1:2003 RF Radiated Electromagnetic Field

By: David C. Graef European Contact:

Vice President & Chief Technology Officer Your local LeCroy Sales Office or

Place: LeCroy Corporation LeCroy Europe GmbH

700 Chestnut Ridge Road Waldhofer Str 104

Chestnut Ridge, NY 10977 D-69123 Heidelberg

USA Germany

Date: December 18, 2007 Tel: (49) 6221 82700

Fax: (49) 6221 834655

Warning: This is a Class A product. In a domestic environment this product may cause

radio interference, in which case the user may be required to take adequ ate measu res.

Page 4

BLANK PAGE

iv ZS1500-OM-E Rev C

Page 5

Contents

Table of Contents

Safety Information

Operator Safety ................................................................1-1

Conventions Used in this Manual .....................................1-1

Overview

Product Description ..........................................................2-1

Key Benefits ......................................................................2-1

Standard Accessories .......................................................2-2

Optional Accessories ........................................................2-2

Features and Accessories

Probe Head .......................................................................3-1

Description of Standard and Optional Accessories ..........3-1

A. Tips...........................................................................3-1

B. Grounds....................................................................3-3

C. Leads........................................................................3-6

Operation

Handling the Probe ...........................................................4-1

Connecting the Probe to the Test Instrument ...................4-1

Connecting the Probe to the Test Circuit ..........................4-1

Operation with a LeCroy Oscilloscope ..............................4-1

High Frequency Measurements

Input Loading ....................................................................5-1

Inductive Loading (Lead Length) ......................................5-1

Capacitive Loading ...........................................................5-2

Care and Maintenance

Cleaning ............................................................................6-1

Calibration Interval ............................................................6-1

Service Strategy ...............................................................6-1

Returning a Defective Probe .............................................6-1

Replacement Parts ...........................................................6-2

ZS1500-OM-E Rev C v

Page 6

ZS1500 High Impedance Active Probe

Performance Verification

Test Equipment Required .................................................7-1

Preliminary Procedure ......................................................7-2

Functional Check ..............................................................7-3

Procedure .........................................................................7-4

A. Output Zero Voltage .................................................7-4

B. Offset Accuracy ........................................................7-4

C. LF Attenuation Accuracy ..........................................7-7

Adjustment Procedure

Introduction .......................................................................8-1

Test Equipment Required .................................................8-1

Preliminary Procedure ......................................................8-2

Procedure .........................................................................8-3

A. Adjust Output Zero....................................................8-3

B. Adjust Offset Range..................................................8-4

C. Verify Calibration ......................................................8-6

Specifications

Nominal Characteristics ....................................................9-1

Warranted Characteristics ................................................9-1

Typical Characteristics ......................................................9-1

Environmental Characteristics ..........................................9-2

Physical Characteristics ....................................................9-2

Compliance and Certifications ..........................................9-3

Appendix A

Performance Verification Test Record ............................. A-1

Equipment Used: ............................................................. A-1

ZS1500 Test Record ........................................................ A-2

vi ZS1500-OM-E Rev C

Page 7

Safety Information

1 Safety Information

OPERATOR SAFETY

This symbol appears on the product:

This refers you to additional information contained in this manual. The

corresponding information in the manual is similarly denoted.

To avoid personal injury and to prevent fire or damage to the probe or

any products connected to it, review and comply with the following

safety precautions.

Connect to properly grounded instruments. This probe is to be only

used with test instruments with input connectors which the BNC shield

(ring) is connected to earth ground.

Connect the probe properly:

Connect the probe to the measurement instrument before connecting probe input to test circuit. Do not disconnect probe from

test instrument while the test leads are connected to a voltage

source.

Do not apply any potential to the input which exceeds the maximum ratings of the probe (section 9, "Specifications").

Comply with the voltage derating curve. When measuring high frequency signals, be sure to comply with the voltage versus frequency

derating curve (section 9, "Specifications").

Do not use in wet or explosive atmospheres.

For indoor use only. This probe is intended for indoor use and should

be operated in a clean, dry, environment.

Do not use the probe if any part is damaged. All maintenance should

be referred to qualified service personnel.

Avoid physical injury. The probe tips are extremely sharp. Use care

when handling to prevent injury, including accidental skin puncture.

ZS1500-OM-E Rev C 1–1

Page 8

ZS1500 High Impedance Active Probe

Use of the probe and or the test instrument it is connected to in a manner not specified by the manufacturer may impair the protection mechanisms.

CONVENTIONS USED IN THIS MANUAL

The following conventions may appear in this manual:

Note

A Note contains information relating to the use of the product.

CAUTION

A Caution contains information that should be followed to avoid possible

damage to the probe or the products connected to it.

This symbol appears on the product:

This refers you to additional information contained in this manual. The

corresponding information in the manual is similarly denoted.

###

1–2 ZS1500-OM-E Rev C

Page 9

Overview

2 Overview

PRODUCT DESCRIPTION

The 1.5 GHz ZS1500 is a small, high impedance active probe designed

to meet today’s increasing demand for measurements on a variety of

test points.

With low input capacitance and high input resistance, circuit loading is

minimized.

The ZS1500 can be used with LeCroy’s WaveSurfer, WaveRunner,

WaveMaster, and WavePro series platforms with firmware version 4.9.3

or later.

With the ProBus interface, the ZS1500 becomes an integral part of the

oscilloscope. The probe can be controlled from the oscilloscope’s front

panel. The oscilloscope provides power to the probe, so there is no

need for a separate power supply or batteries.

KEY BENEFITS

• High frequency performance

• Low input capacitance

• Wide dynamic range

• ProBus interface

• Four interchangeable tips for probing a variety of test points (one

standard, three optional accessories)

ZS1500-OM-E Rev C 2–1

Page 10

ZS1500 High Impedance Active Probe

STANDARD ACCESSORIES

The ZS1500 probe is shipped with the following standard accessories:

Item: Quantity:

Straight Tip 4

Sprung Hook 2

Right Angle Connector 1

Offset Ground 2

Ground Blade 1

Copper Pad 2

Short Single lead 1

Long Single Lead 1

Instruction Manual 1

Certificate of calibration 1

Y-lead Adapter 1

Color Coding Rings 4 sets

OPTIONAL ACCESSORIES

The following items are available as optional accessories for the

ZS1500 probe:

IC Lead Tip

Discrete SMD Tip

Bent Sharp Tip

Bendable Pogo Ground

Ground Spring with Hook

Solder-in Ground

Square Pin Ground Spring

Short Right-angle Lead

Long Right-angle Lead

For part number information for standard and optional accessories refer

to, Care and Maintenance, Replaceable Parts List.

###

2–2 ZS1500-OM-E Rev C

Page 11

Features and Accessories

3 Features and Accessories

The ZS1500 probe is provided with numerous features and accessories

to make probing and connecting to different test points easier than ever.

PROBE HEAD

The small, low mass probe

head is designed for ease of

use and high performance.

The probe tip socket fits easily onto 0.025 inch square

pins for direct access to test

points. Several different

adapters are available which

connect directly in the probe

socket.

The ground socket will accept

several different ground leads

to provide a short ground

path for high frequency performance.

DESCRIPTION OF STANDARD AND OPTIONAL ACCESSORIES

The following accessories can be pushed into the probe tip socket,

ground socket or any other socketed lead or adapter.

A. Tips

Straight Tip

Rugged tip designed to connect to the smallest vias and

small test points. Fits in

either probe socket.

PK-ZS-001, package of 4

ZS1500-OM-E Rev C 3–1

Page 12

ZS1500 High Impedance Active Probe

IC Lead Tip

Covered in insulation on all

sides (except for a small

edge), this tip was designed

to prevent shorting neighboring IC leads. The gold part of

the tip is not insulated and

should touch the IC lead to be

tested. It is one-size-fits-all

and will work with any IC lead

pitch. Fits in either probe

socket.

The IC Lead Tip is an

optional accessory for the

ZS1500.

PACC-PT003, package of 4

Discrete SMD Tip

The crescent shape of this tip

is designed to fit tightly on

capacitors, resistors, transistors and other surface mount

components with discrete

leads. Fits in either probe

socket.

The SMD Discrete Tip is an

optional accessory for the

ZS1500.

PACC-PT004, package of 4

3–2 ZS1500-OM-E Rev C

Page 13

Features and Accessories

Bent Sharp Tip

B. Grounds

Micro Clip (0.5 mm) Sprung Hook

Made out of titanium, this tip

is ideal for situations that

require the user to hold the

probe parallel to the circuit

board under test. Also gives

the user more control when

holding the probe like a pencil. Fits in either probe socket.

The Bent Sharp Tip is an

optional accessory for the

ZS1500.

PACC-PT005, package of 4

A pincher-like spring hook tip

designed to hold onto fine

pitch leads and small components, commonly found in

SMD ICs. Fits in either probe

socket, or can be used with a

lead.

The Sprung Hook is a standard accessory for the

ZS1500 and available in

black and red.

PK-ZS-007R, PK-ZS-007B,

package of 4 each

ZS1500-OM-E Rev C 3–3

Page 14

ZS1500 High Impedance Active Probe

Ground Spring with Hook

A flexible spring connected to

a square pin that fits into

either of the probe head

sockets. Designed to be used

as a ground lead, there is a

hook on the end of the spring

so that it can probe general

circuits.

The Ground Spring with

Hook is an optional accessory for the ZS1500.

PACC-LD001, package of 4

Square Pin Ground Spring

A flexible spring connected to

a square pin that fits into

either of the probe sockets.

Designed to be attached to a

square pin on the circuit

under test.

The square pin ground spring

is an optional accessory for

the ZS1500 probe.

PACC-LD002, package of 4

3–4 ZS1500-OM-E Rev C

Page 15

Features and Accessories

Offset Ground

The offset pin is designed to

be attached to either socket

of the probe head. The offset

pin is the highest quality

grounding solution and is recommended in high frequency

applications.

The offset ground is designed to connect to the ground socket and

wrap around the probe head. This gives the ability to a probe signal

and ground that are extremely close together. The short length provides high-quality grounding for high-frequency applications.

PK-ZS-002, package of 4

Ground Blade and Copper Pad

The Ground Blade and

Copper Pad are intended to

work together for the best

grounding solution for probing an IC. The Ground

Blade is designed to provide a short, low inductance ground path. The

Copper Pad is adhesive

backed to stick to the top of

an IC, and can then be soldered to the IC ground.

The Copper Pad can also

be used with the Offset

Ground.

PK-ZS-008, package of 4

PK-ZS-009, package of 4

ZS1500-OM-E Rev C 3–5

Page 16

ZS1500 High Impedance Active Probe

C. Leads

While longer leads provide greater flexibility when connecting the probe

to a circuit, the added inductance may degrade the fidelity of high frequency signals. See Section 4 for additional information.

Short and Long Lead

This lead has a socket on one

end and a square pin on the

other to connect to the input

or ground socket of the probe

body, and may be used for

general purpose probing.

PK-ZS-003 (short),

PK-ZS-004 (long), packages

of 4

Y Lead Adapter

This lead is used for both

ground and input lead

simultaneously.

It has two sockets on one

end and two square pins on

the other and may be used

for general purpose probing.

PK-ZS-005, packages of 4

###

3–6 ZS1500-OM-E Rev C

Page 17

Operation

4 Operation

HANDLING THE PROBE

Exercise care when handling and storing the probe. Always handle the

probe by the probe body or compensation box. Avoid putting excessive

strain or exposing the probe cable to sharp bends.

CONNECTING THE PROBE TO THE TEST INSTRUMENT

The ZS1500 probe has been designed for use with LeCroy’s

WaveSurfer, WaveRunner, WaveMaster, and WavePro platforms

equipped with the ProBus interface. When you attach the probe output

connector to the oscilloscope’s input connector, the oscilloscope will

recognize the probe, provide proper termination and activate the probe

control functions in the user interface.

CONNECTING THE PROBE TO THE TEST CIRCUIT

To maintain the high performance capability of the probe in

measurement applications, care must be exercised in connecting the

probe to the test circuit. Increasing the parasitic capacitance or

inductance in the input paths may introduce a “ring” or slow the rise time

of fast signals. Input leads which form a large loop area will pick up any

radiated electromagnetic field which passes through the loop and may

induce noise into the probe input.

Using one of the available accessories makes the ZS1500 probe with its

small profile and low mass head ideally suited for applications in dense

circuitry.

OPERATION WITH A LECROY OSCILLOSCOPE

When the ZS1500 probe is connected to any compatible LeCroy

oscilloscope, the displayed scale factor and measurement values will be

automatically adjusted.

Control through the oscilloscope’s interface can be found in the

Coupling menu of the channel to which the probe is connected.

Turning the Volts/Div knob will control the oscilloscope’s scale factor to

give full available dynamic range up to 2 V/div.

###

ZS1500-OM-E Rev C 4–1

Page 18

ZS1500 High Impedance Active Probe

BLANK PAGE

4–2 ZS1500-OM-E Rev C

Page 19

High Frequency Measurements

5 High Frequency Measurements

INPUT LOADING

When you touch a probe to the circuit under test, the probe will affect

your measurement because of the probe’s input impedance introduced

into the circuit. All probes present resistive, capacitive and inductive

loading.

INDUCTIVE LOADING (LEAD LENGTH)

A significant element in this circuit is the inductance shown in the input

ground leads of the oscilloscope probe.

Figure 5-1. Probe Input Equivalent Circuit

The ground lead is the primary return path for the current resulting from

the input voltage acting on the probe’s input impedance. The ground

lead and input lead inductances act with the probe’s input capacitance

to form series L-C network. The impedance of a series LC network will

drop dramatically at its resonant frequency. This is the cause of the

"ring" we often see after the leading edge of pulses in measured waveforms. This effect is referred to as ground lead corruption. Because it is

impossible to eliminate either the L or C from this circuit, the method to

improve waveform fidelity is to raise the resonant frequency beyond the

bandwidth of interest in the measurement.

The resonant frequency of a simple LC circuit can be represented by:

1

F

Resonance

ZS1500-OM-E Rev C 5–1

------------------

=

2π LC

Page 20

ZS1500 High Impedance Active Probe

The resonant frequency of a series LC circuit can be raised by decreasing the inductance, capacitance or both.

Since the input capacitance is already very low and cannot be reduced,

you can only try to reduce the inductance. This can be accomplished by

using the shortest possible input lead as well as the shortest possible

ground lead.

For example, to obtain the shortest possible ground lead when measuring IC related signals, attach a small piece of copper clad material to the

top of the IC package and connect this to the package grounding wires.

Using the shortest ground lead and input lead available makes probing

signals on the package easier and makes for the shortest lead length for

the best signal fidelity.

To illustrate how dramatic this effect is, we will work a simple example.

Assuming an input capacitance of 0.9 pF and a total lead length (input

and ground) of 2 inches (inductance of ≈ 25 nH/inch) such a setup may

cause ringing with a resonant frequency (f

) of:

0

-------------------------------------------------------------------

f

0

2π 50 10

This frequency is well within the passband of the probe and will therefore show up as part of the measured signal at faster time/div settings.

To determine how fast a waveform to be measured can be without causing ringing on a probe like this, divide the BW (ringing frequency) of the

probe into 0.35:

0.35

t

rise

Any input signal with a rise time faster than 0.47 ns can cause ringing.

CAPACITIVE LOADING

Capacitive loading is usually the most troublesome of the three loading

effects.

It can affect the rise time, bandwidth and delay time measurements.

5–2 ZS1500-OM-E Rev C

---------BW

1

9–

0.9 10

0.35

---------------------

750MHz

750 MHz==

12–

×××

0.47 ns== =

Page 21

High Frequency Measurements

At higher frequencies the capacitive loading can affect the amplitude as

well as the waveshape of the measured signal by introducing an exponential response to the waveform.

For a simple RC network the time constant of this exponential response

is:

t

rise

where C

combined circuit and probe resistance.

For a setup where C

measured rise time will be 0.495 ns, which will correspond to a band-

width of 909 MHz, assuming no inductive loads.

(parallel combination of 250 Ω and 1 MΩ is still 250 Ω)

To illustrate the effect of capacitive loading at higher frequencies:

At a frequency of 750 MHz the reactance of the 0.9 pF capacitance is

236 Ω, and at 1.0 GHz the reactance has been lowered to 177 Ω

is the combined probe and circuit capacitance and R

total

= 0.9 pF and a source resistance is 250 Ω, the

t

(t

=2.2 x 0.9 X 10

rise

250 Ω

Source

V

Figure 5-2. Probe input equivalent circuit

2.2 C

× R

-12

x 250 Ω = 0.495 ns)

Input inductance

×=

total

0.9 pF 1 MΩ

total

total

is

If, at a given frequency, the source impedance is large with respect to

the input impedance, a measurable reduction in the output signal amplitude may occur.

Z

probe

V

out

ZS1500-OM-E Rev C 5–3

--------------------------------------

Z

+

probeZsource

Vin×=

Page 22

ZS1500 High Impedance Active Probe

where:

Z

is the probe’s input impedance and

probe

Z

As an example:

At 750 MHz, where the probe input impedance has reduced to 236 Ω,

and a source resistance of 250 Ω the probe output amplitude is reduced

to:

is the source impedance

source

V

out

236

-----------------------236 250+

###

0.49 Vin×==

5–4 ZS1500-OM-E Rev C

Page 23

Care and Maintenance

6 Care and Maintenance

CLEANING

The exterior of the probe and cable should be cleaned only using a soft

cloth lightly moistened with water or isopropyl alcohol. The use of abrasive agents, strong detergents, or other solvents may damage the

probe. Always ensure that the input leads are free of debris.

Note

The probe case is not sealed and should never be immersed in any

fluid.

CALIBRATION INTERVAL

The recommended calibration interval is one year. (Performance Verification and Adjustment Procedures are included in this manual.)

SERVICE STRATEGY

The ZS1500 probe utilizes fine pitch surface mount devices. It is therefore impractical to attempt to repair in the field. Defective probes must

be returned to a LeCroy service facility for diagnosis and exchange. A

defective probe under warranty will be replaced with a factory refurbished probe. A probe that is not under warranty can be exchanged for

a factory refurbished probe for a modest fee. You must return the defective probe in order to receive credit for the probe core.

RETURNING A DEFECTIVE PROBE

The procedure for returning a defective probe is as follows:

Contact your local LeCroy sales representative to find out where to

return the product. All returned products should be identified by model

number and serial number. Provide your name and contact number and

if possible describe the defect or failure. In case of products returned to

the factory, a Return Authorization Number (RAN) should be used. The

RAN can be established by contacting your nearest LeCroy office, or the

New York Customer Care Center.

Return shipment should be made prepaid. LeCroy cannot accept COD

or Collect Return shipments. We recommend air-freighting. It is impor-

ZS1500-OM-E Rev C 6–1

Page 24

ZS1500 High Impedance Active Probe

tant that the RAN be clearly shown on the outside of the shipping package for prompt redirection to the appropriate department.

1. Contact your local LeCroy sales or service representative to obtain

a Return Authorization Number.

2. Remove all accessories from the probe. Do not include the manual.

3. Pack the probe in its case, surrounded by the original packing material (or equivalent) and box.

4. Label the case with a tag containing

• The RAN

• Name and address of the owner

• Probe model and serial number

• Description of failure

5. Package the probe case in a cardboard shipping box with adequate

padding to avoid damage in transit.

6. Mark the outside of the box with the shipping address given to you

by the LeCroy representative; be sure to add the following:

• ATTN: <RAN assigned by the LeCroy representative>

• FRAGILE

7. Insure the item for the replacement cost of the probe.

8. Ship the package to the appropriate address.

REPLACEMENT PARTS

The probe connection accessories and other common parts can be

ordered through the regional customer care centers. Refer to list below

for LeCroy part numbers. Defective probes can be replaced on an

exchange basis. The replacement exchange probe will have been factory repaired, inspected and calibrated to the same standards as a new

product. In order to obtain an exchange probe, you must return the

defective probe. The returned probe should be sent back to the regional

customer care center without any accessories, manual or case.

6–2 ZS1500-OM-E Rev C

Page 25

Care and Maintenance

Figure 6-1. Replaceable Parts Selected by Input and Ground Accessory

ZS1500-OM-E Rev C 6–3

Page 26

ZS1500 High Impedance Active Probe

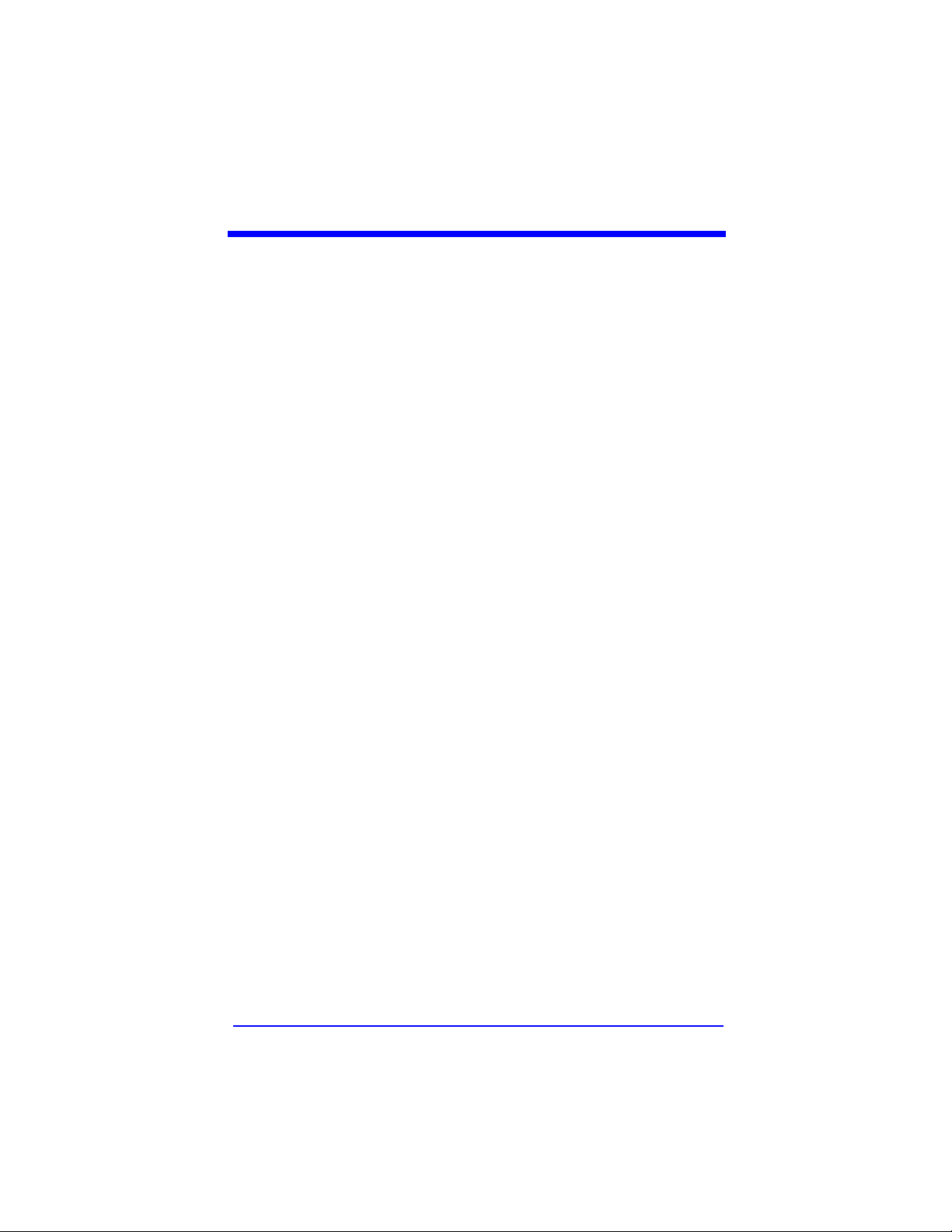

Table 6-1: Replaceable Parts List

Item LeCroy P/N Replacement

Straight Tip PK-ZS-001 4

Offset Ground PK-ZS-002 4

Short Lead PK-ZS-003 4

Long Lead PK-ZS-004 4

Y Lead Adapter PK-ZS-005 4

Right Angle Connector PK-ZS-006 4

Sprung Hook - Red PK-ZS-007R 4

Sprung Hook - Black PK-ZS-007B 4

Ground Blade PK-ZS-008 4

Copper Pad PK-ZS-009 4

Color Coding Rings PK-ZS-010 4 sets

Quantity

IC Lead Tip PACC-PT003 4

Discrete SMD Tip PACC-PT004 4

Bent Sharp Tip PACC-PT005 4

Solder-In Ground PACC-CD007 2

Bendable Pogo Ground PACC-CD008 2

Ground Spring with Hook PACC-LD001 4

Square Pin Ground Spring PACC-LD002 4

Short Right Angle Lead PACC-LD003 4

Long Right Angle Lead PACC-LD004 4

###

6–4 ZS1500-OM-E Rev C

Page 27

Performance Verification

7 Performance Verification

This procedure can be used to verify the warranted characteristics of

the ZS1500 High Frequency Probe.

The recommended calibration interval for the model ZS1500 is one

year. The complete performance verification procedure should be performed as the first step of annual calibration. Test results can be

recorded on a photocopy of the Test Record provided in Appendix A at

the end of the manual.

Performance verification can be completed without removing the probe

covers or exposing the user to hazardous voltages. Adjustment should

only be attempted if a parameter measured in the Performance Verification Procedure is outside the specification limits.

Note

Adjustment should only be performed by qualified personnel.

This procedure tests the following specifications:

• Output Zero Voltage

• Offset Accuracy

• LF Attenuation Accuracy

TEST EQUIPMENT REQUIRED

Table 7-1 lists the test equipment and accessories (or their equivalents)

that are required for performance verification of the ZS1500 Probe.

This procedure has been developed to minimize the number of calibrated test instruments required.

Only the parameters listed in boldface in the "Minimum requirements"

column must be calibrated to the accuracy indicated.

Because the input and output connectors types may vary on different

brands and models of test instruments, additional adapters or cables

may be required.

ZS1500-OM-E Rev C 7–1

Page 28

ZS1500 High Impedance Active Probe

Table 7-1. List of Required Equipment

Description Minimum Requirements Test Equipment Examples

Digital Oscilloscope ProBus interface; Windows-

Digital Multimeter (DMM)

with test probe leads

Function Generator Sine Wave output amplitude

Power Supply 0-12 V, settable to 10 mV HP E3611A

BNC Coaxial Cable (2 ea.) Male to Male, 50 Ω, 36" Cable Pomona 2249-C-36 or

BNC Tee Connector Male to Dual Female Pomona 3285

Calibration Fixture ProBus Extender Cable LeCroy PROBUS-CF01

Terminator, Precision, BNC 50 Ω ± 0.05% LeCroy TERM-CF01

Banana Plug Adapter (2 ea.) Female BNC to Dual Banana

BNC to Mini-grabber BNC Male to Mini-grabber Cable,

based

4.5 digit

DC: 0.1% Accuracy

AC: 0.1% accuracy

adjustable to 14.14 V

into 1 MΩ at 70 Hz

Plug

36"

p-p

(5 V

LeCroy WaveRunner Xi,

WaveSurfer Xs

Agilent Technologies 34401A or

Fluke 8842A-09

Agilent Technologies 33120A or

)

Stanford Research Model DS340

rms

Pomona 5697-36

Pomona 1269

Pomona 5187-C-36

PRELIMINARY PROCEDURE

1. Connect the ZS1500 probe to the female end of the ProBus Extension Cable. Connect the male end of the ProBus Extension Cable to

channel 1 of the oscilloscope.

2. Turn the oscilloscope on and allow at least 30 minutes warm-up time

for the ZS1500 and test equipment before performing the Verification Procedure.

3. Turn on the other test equipment and allow these to warm up for the

time recommended by the manufacturer.

4. While the instruments are reaching operating temperature, make a

photocopy of the Performance Verification Test Record (located in

Appendix A), and fill in the necessary data.

5. Select the channel to which the probe is connected. Set the oscilloscope scale factor to 20 mV/div.

7–2 ZS1500-OM-E Rev C

Page 29

Performance Verification

6. Disconnect the ProBus Extender Cable from the oscilloscope. Verify

that the scale factor changes from 20 mV/div to 2 mV/div.

7. Re-connect the ProBus extender Cable to the oscilloscope.

The warranted characteristics of the ZS1500 are valid at any temperature within the Environmental Characteristics listed in the Specifications.

However, some of the other test equipment used to verify the performance may have environmental limitations required to meet the accuracy needed for the procedure. Make sure that the ambient conditions

meet the requirements of all the test instruments used in his procedure.

Note

The correct operation of the ZS1500 controls requires software version

5.0.0.2 or higher. The software version in the test oscilloscope can be

verified by selecting Utilities, Utilities Setup... from the menu bar, then

the Status tab.

Contact your local LeCroy representative or visit www.lecroy.com if the

software in your oscilloscope requires updating.

FUNCTIONAL CHECK

The functional check will verify the basic operation of the probe functions.

It is recommended that the Functional Check be performed prior to the

Performance Verification Procedure.

1. Return to the factory default settings by:

a. Selecting File, Recall Setup... from the menu bar.

b. Then touching the Recall Default button.

2. Touch the C1 trace label to open the C1 Vertical Adjust dialog.

3. Verify that the probe sensed (ZS1500) is displayed as a dialog tab.

ZS1500-OM-E Rev C 7–3

Page 30

ZS1500 High Impedance Active Probe

PROCEDURE

A. Output Zero Voltage

1. Connect one end of a BNC cable to the female BNC connector on

the probe end of the ProBus extender cable. Connect the precision

50 Ω terminator to the other end of the BNC cable.

2. Connect the banana plugs of the Precision terminator to the input of

the DMM. Make sure that the plug corresponding to the BNC shield

(marked "Ground") is connected to the LO or COMMON input of the

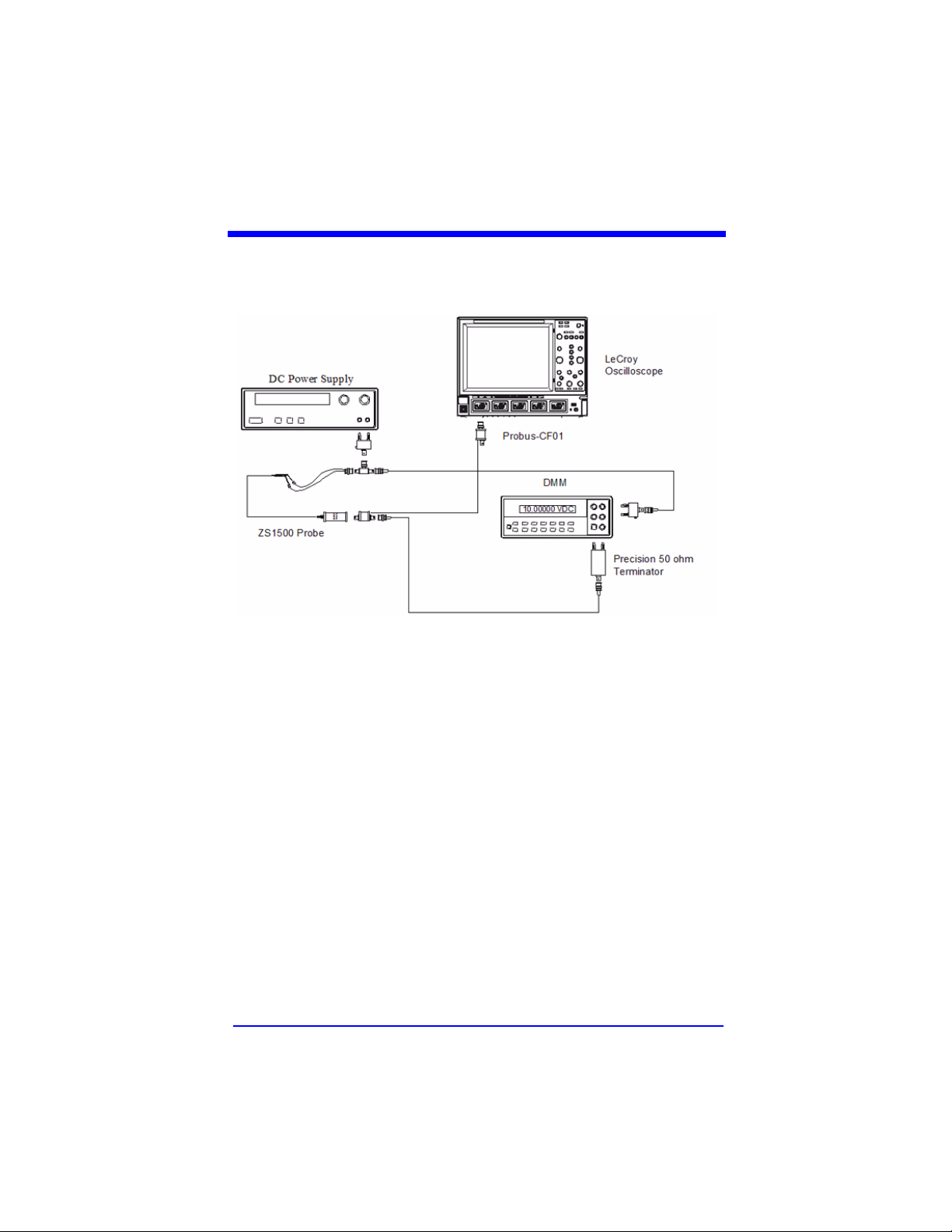

DMM. Refer to Figure 7-1 for setup information.

Figure 7-1. Output Zero Voltage Test Setup

3. Set the OFFSET on the oscilloscope to zero.

4. Set the DMM to read DC Volt on the most sensitive range.

5. Record the voltage measured on the DMM to 10 µV resolution as

"Output Zero Voltage" in the Test record.

6. Check that the voltage indicated by the DMM is between ±800 µV.

7. Disconnect the DMM from the precision 50 Ω terminator. Leave the

remaining setup in place for the next step.

B. Offset Accuracy

1. Connect the BNC end of the BNC to mini-grabber cable to a female

end of the BNC tee adapter and connect a female BNC to dual

7–4 ZS1500-OM-E Rev C

Page 31

Performance Verification

banana plug adapter to the male end of the BNC tee. (Refer to Figure 7-2).

Figure 7-2. Offset and LF Attenuation Accuracy Test Setup

2. Carefully insert the Straight Tips (supplied in accessory kit) into the

sockets of the probe head. Attach the red lead of the mini-grabber to

the signal input and the black lead to the ground input of the probe

head.

3. Set the power supply to approximately 0 Volt.

4. Plug the dual banana plug adapter with probe attached into the output terminals of the power supply with ground side of the adapter

(and the ground side of the probe head) connected to the positive

terminal of the power supply.

5. Attach a BNC cable to the unused female port of the BNC tee and a

dual banana plug adapter to the other end of the cable and plug the

dual banana plug adapter into the DMM input. Make sure the side of

the banana plug adapter corresponding to the BNC shield (marked

"GROUND") is connected to the LOW or COMMON input of the

DMM.

6. Adjust the power supply to an output of 10.0 V ± 100 mV as indi-

ZS1500-OM-E Rev C 7–5

Page 32

ZS1500 High Impedance Active Probe

cated on the DMM.

7. Record the DMM reading, which should be a negative number, to

10 mV resolution as "Power Supply Negative Output Voltage" in the

Test Record.

8. Add 10 (to correct for the +10 V offset as described in step B-13) to

the "PS Negative Output Voltage" recorded in step B-7. (Do NOT

adjust the power supply output amplitude).

9. Divide the resulting sum by 10.

10. Record the answer to three significant places as "Expected Negative

Output Voltage" in the test record.

11. Remove the banana plug adapter, connected to the power supply,

from the DMM and connect the precision 50 Ω terminator to the

DMM, making sure that the banana plug side marked "GROUND" is

connected to the LOW or COMMON input of the DMM.

12. Set the DMM to read DC Volt on the most sensitive range.

13. Verify that the display for channel 1 is turned ON. Turn the oscilloscope OFFSET knob to read +10.00 V on the oscilloscope display.

14. After the DMM has settled, record the reading to 100 µV resolution

as "Measured Negative Output Voltage" in the Test Record.

15. Subtract the measured voltage as recorded in step B-14 from the

expected output voltage recorded in step B-10. Be sure to include

the sign of each of the values in the calculation.

16. Record the answer to three significant places as "Offset Error Voltage" in the Test Record.

17. Verify that the error is between ±10.8 mV.

Note:

The error term is derived from the Offset Accuracy specification of ±1%

±8 mV. Using a 10.0 V offset setting, the maximum error would be 108

mV referred to the input, which becomes ±10.8 mV error referred to the

÷

output (taking into account the

18. Using the oscilloscope’s OFFSET knob, set the probe offset to 0 V,

as indicated in the on-screen display.

7–6 ZS1500-OM-E Rev C

10 attenuation).

Page 33

Performance Verification

19. Remove the dual banana plug adapter with the ZS1500 attached

from the power supply and reconnect to the supply but now with the

grounded side of the banana plug (and grounded socket of the

probe head) connected to the negative terminal of the power supply

output.

20. Disconnect the DMM from the precision 50 Ω terminator and connect the DMM to the dual banana plug adapter connected to the

power supply output.

21. Record the DMM reading, which should be a positive number, to 10

mV resolution as "Power Supply Positive Output Voltage" in the Test

Record.

22. Subtract 10 from the output voltage recorded in step B-21. Divide

this number by 10.

23. Record the result to three significant places as "Expected Positive

Output Voltage" in the Test Record.

24. Set the oscilloscope OFFSET to –10.00 V as read on the oscilloscope display.

25. Remove the banana plug adapter from the DMM and connect the

precision 50 Ω terminator to the DMM, making sure that the banana

plug side marked "GROUND" is connected to the LOW or COM-

MON input of the DMM.

26. Record the DMM reading to three significant places as "Measured

Positive Output Voltage" in the Test Record.

27. Subtract the Measured Output Voltage as recorded in step B-26

from the Expected Output Voltage recorded in step B-23. Be sure to

include the sign of the values in the calculation.

28. Record the result to 100 µV resolution as "Offset Error Voltage" in

the Test Record.

29. Verify that the output error is between ±10.8 mV.

30. Return the oscilloscope offset to 0 Volt. Leave the setup connections for the next step.

C. LF Attenuation Accuracy

1. Disconnect the BNC tee at the power supply from the dual banana

plug adapter. Connect the BNC tee to the output of the function gen-

ZS1500-OM-E Rev C 7–7

Page 34

ZS1500 High Impedance Active Probe

erator. (Use a 50 Ω termination if the function generator requires

such a load.) Refer to Figure 7-3.

Figure 7-3. LF Attenuation Accuracy setup

2. Disconnect the DMM from the precision 50 Ω terminator and con-

nect the DMM to the dual banana plug adapter connected to the

function generator output.

3. Set the DMM to read AC Volt and set the range to measure 5.0

Vrms.

4. Set the mode of the function generator to sine wave, the frequency

to 70 Hz and the output amplitude to 5 Vrms ±10 mV as measured

on the DMM.

5. Record the output voltage to 1 mV resolution as "Generator Output

Voltage" in the Test Record. Be careful not to alter the output amplitude after the reading is recorded.

6. Divide the reading recorded in step C-5 by 10 and record the result

with 100 µV resolution as "Expected Output Voltage, top range" in

the Test Record.

7. Remove the banana plug adapter, connected to the function generator, from the DMM and connect the precision 50 Ω terminator to the

DMM, making sure that the banana plug side marked "GROUND" is

7–8 ZS1500-OM-E Rev C

Page 35

Performance Verification

connected to the LOW or COMMON input of the DMM.

8. After the DMM reading has stabilized, record the reading to 100 µV

resolution as "Measured Output Voltage, top range" in the Test

Record.

9. Calculate the error by dividing the measured output voltage

recorded in step C-8 by the expected top output voltage recorded in

step C-6. Subtract 1 from this ratio and multiply by 100% to get the

error in percent.

Measured Output Voltage

⎛⎞

Error

10. Record the calculated error to two decimal places (±0.xx%) as "Gain

Error, top range" in the test record.

11. Verify that the error is less than ±1.0 %.

12. Disconnect the precision 50 Ω terminator from the DMM.

13. Connect the banana plug adapter connected via a BNC cable to the

BNC tee at the function generator to the DMM. Verify that the side of

the plug marked "Ground" is connected to the LOW or COMMON

input of the DMM.

--------------------------------------------------------------

=

⎝⎠

Expected Output Voltage

1–

100%

×

14. Adjust the sine wave generator output amplitude to approximately

2.5 Vrms as measured on the DMM.

15. Record the reading to 1 mV resolution as "Generator Output Voltage, mid range" in the Test Record. Be careful not to alter the output

amplitude after the reading is recorded.

16. Divide the reading recorded in step C-15 by 10.

17. Record the result to 100 µV resolution as "Expected Output Voltage,

mid range" in the test record.

18. Remove the banana plug adapter from the DMM and connect the

precision 50 Ω terminator to the DMM, making sure that the banana

plug side marked "GROUND" is connected to the LOW or COM-

MON input of the DMM.

ZS1500-OM-E Rev C 7–9

Page 36

ZS1500 High Impedance Active Probe

19. After the DMM has stabilized, record the reading to 100 µV resolu-

tion as "Measured Output Voltage, mid range" in the Test record.

20. Calculate the error by dividing the measured output voltage

recorded in step C-19 by the expected top output voltage recorded

in step C-17. Subtract 1 from this ratio and multiply by 100% to get

the error in percent.

Measured Output Voltage

⎛⎞

Error

21. Record the calculated error to two decimal places (±0.xx %) as

"Gain Error, mid range" in the Test record.

22. Verify that the mid range gain error is less than ±1.0%

This completes the Performance Verification of the ZS1500. Complete

and file the Test Record, as required to support your internal calibration

procedure.

--------------------------------------------------------------

=

⎝⎠

Expected Output Voltage

1–

100%

×

Apply suitable calibration label to the ZS1500 housing as required.

###

7–10 ZS1500-OM-E Rev C

Page 37

Adjustment Procedure

8 Adjustment Procedure

INTRODUCTION

You can use this procedure to adjust the ZS1500 probe to meet the warranted specifications. This procedure should only be performed if the

probe fails to meet the Performance verification tests for Output Zero or

Offset Accuracy.

Gain which affects LF attenuation accuracy cannot be adjusted during

routine calibration. Probes which fail LF frequency accuracy during performance verification must be returned to the factory for rework.

If the probe cannot be adjusted to meet the Performance verification limits, repair may be necessary.

To assure probe accuracy, check the calibration of the ZS1500 every

1000 hours or once a year if used infrequently. Before calibration, thoroughly clean and inspect the probe as outlined in the Care and Maintenance section.

To assure the probe will meet the published specifications over the

entire temperature range, adjustment must be performed in a controlled

ambient environment with temperature of 23 °C ±5 °C.

Caution

The adjustment procedure will require removal of the probe control circuit cover. This cover is part of the ESD protection system of the

ZS1500. To protect the probe, you should perform the entire procedure

on a static dissipating work surface. Wear an antistatic wrist strap and

follow standard static control procedures.

TEST EQUIPMENT REQUIRED

Table 8-1 lists the test equipment and accessories (or their equivalents)

that are required for complete calibration of the ZS1500 Probe. Specifications given for the test equipment are the minimum necessary for

accurate calibration. All test equipment is assumed to be correctly calibrated and operating within the specification listed. Detailed operating

ZS1500-OM-E Rev C 8–1

Page 38

ZS1500 High Impedance Active Probe

instructions for the test equipment are not given in this procedure. Refer

to the test equipment manual if more information is needed

If alternate test equipment is substituted, control settings or calibration

equipment setups may need to be altered.

Table 8-1. List of Required Equipment

Description Minimum Requirements Test Equipment

Examples

Digital Oscilloscope ProBus interface; Windows-

based

Digital Multimeter

(DMM) with test probe

leads

Power Supply 0-12 V, settable to 10 mV HP E3611A

BNC Coaxial Cable (2

ea.)

BNC Tee Connector Male to Dual Female Pomona 3285

Calibration Fixture ProBus Extender Cable LeCroy PROBUS-CF01

Terminator, Precision, BNC

Banana Plug Adapter

(2 ea.)

BNC to Mini-grabber BNC Male to Mini-grabber

4.5 digit

DC: 0.1% Accuracy

AC: 0.1% accuracy

Male to Male, 50 Ω, 36"

Cable

50 Ω ±0.05% LeCroy TERM-CF01

Female BNC to Dual Banana

Plug

Cable, 36"

LeCroy WaveRunner Xi or

WaveSurfer Xs

Agilent Technologies

34401A or

Fluke 8842A-09

Pomona 2249-C-36 or

Pomona 5697-36

Pomona 1269

Pomona 5187-C-36

PRELIMINARY PROCEDURE

1. Remove the two screws that secure the plastic cover on the cable

end of the ProBus interface housing.

2. Gently pull on the probe cable to slide the circuit board assembly

from the metal housing.

3. Connect the ZS1500 probe to the female end of the ProBus extension cable, being careful to line up all six pins of the probe connector. Connect the male end of the ProBus extension cable to channel

1 of the oscilloscope.

8–2 ZS1500-OM-E Rev C

Page 39

Adjustment Procedure

4. Apply power to the oscilloscope and test equipment.

5. Allow at least 30 minutes warm-up time for the ZS1500 and test

equipment before starting the calibration procedure.

PROCEDURE

A. Adjust Output Zero Voltage

1. Connect one end of a BNC cable to the probe end of the ProBus

extension cable. Connect the Precision 50 Ω Terminator to the other

end of the BNC cable.

2. Connect the banana plugs of the precision 50 Ω terminator to the

input of the DMM. Make sure the plug corresponding to the BNC

shield (marked ’Ground’) is connected to the LO or COMMON input

of the DMM. Refer to Figure 8-1 for setup information.

Figure 8-1. Output Zero Voltage Adjustment Setup

3. Select the channel to which the probe and ProBus extender is connected. Set OFFSET on the oscilloscope to zero as indicated on the

on-screen display.

4. Set the DMM to read DC Volt on the most sensitive range.

5. Verify that the probe inputs are not connected to any signal.

6. Adjust OFFSET ZERO on the board until the DMM reads

0 V ±100 µV. Refer to Figure 8-2 for adjustment location.

ZS1500-OM-E Rev C 8–3

Page 40

ZS1500 High Impedance Active Probe

7. Leave the setup connections in place for the next step.

OFFSET RANGE

OUTPUT ZERO

Figure 8-2. Adjustment Locations

B. Adjust Offset Range

1. Connect the BNC end of the BNC to mini-grabber cable to a female

end of the BNC tee adapter and a female BNC to dual banana plug

adapter to the male end of the BNC tee.

2. Carefully insert Straight Tips (supplied in the accessory kit) into the

ZS1500 probe head sockets. Attach the red lead of the mini-grabber

to the signal input and the black lead to the ground input of the

probe.

3. Set the power supply for approximately 0 Volt.

4. Plug the dual banana plug adapter, with the probe attached, into the

output terminal of the power supply. Make sure the side of the

banana plug corresponding to the probe ground and BNC ground is

connected to the negative terminal of the power supply.

5. Attach a BNC cable to the unused female port of the BNC tee and a

dual banana plug adapter to the other end of the BNC cable and

plug this into the DMM. Make sure the side of the banana plug corresponding to the BNC shield (marked ’GROUND’) is connected to the

LO or COMMON input of the DMM. Refer to Figure 8-3 for setup

information.

6. Using the DMM to monitor the voltage, adjust the power supply to an

output of 10.00 V ±10 mV. Record the reading.

8–4 ZS1500-OM-E Rev C

Page 41

Adjustment Procedure

Figure 8-3. Offset Range Adjustment setup

7. Remove the banana plug adapter from the DMM connect the precision 50 Ω terminator into the DMM Input. Make sure the side of the

banana plug corresponding to the BNC shield (marked ’GROUND’)

is connected to the LO or COMMON input of the DMM.

8. Verify that the display for channel 1 is turned on. Set the oscilloscope OFFSET knob to –10.00 V. as read on the oscilloscope

screen.

9. Set the DMM to read DC Volt on the most sensitive range.

10. Subtract 10.0 V from the power supply output voltage recorded in

step B-7. Be sure to keep track of the sign of the result.

11. A d j u s t OFFSET RANGE until the DMM reads the same voltage ±1

mV as calculated in step B-11. Be sure the sign agrees.

12. Repeat steps A-3 through A-7 of the Adjust Offset Zero procedure.

13. Disconnect the probe from the ProBus extender and re-install the

circuit board into the probe case, being careful to align the ProBus

interface connector with the opening on the other end of the case.

ZS1500-OM-E Rev C 8–5

Page 42

ZS1500 High Impedance Active Probe

C. Verify Calibration

Repeat the Performance Verification procedure to ensure compliance

with the warranted specifications.

Apply a calibration sticker, if required, in accordance with your quality

control procedures.

###

8–6 ZS1500-OM-E Rev C

Page 43

Specifications

9 Specifications

NOMINAL CHARACTERISTICS

Nominal characteristics describe parameters and attributes that are

guaranteed by design, but do not have associated tolerances.

Input Dynamic range ±8 V

Offset Range ±12 V

Maximum Input Voltage 20 V

Intended Output Load 50 Ω

Attenuation ÷10

Output Connector ProBus

Interface ProBus

Oscilloscope Full Compatibility LeCroy oscilloscope with firmware ver-

1

Subject to input voltage vs. frequency derating. See Figure 9-1.

1

sion 5.0.0.2 or later

WARRANTED CHARACTERISTICS

Warranted characteristics are parameters with guaranteed performance. Unless otherwise noted, tests are provided in the Performance

Verification Procedure for all warranted specifications.

Low Frequency Attenuation

Accuracy ±0.50% plus uncertainty of 50 Ω termi-

nation

Output Zero ±2 mV, referred to the input

TYPICAL CHARACTERISTICS

Typical characteristics are parameters with no guaranteed performance.

Tests for typical characteristics are not provided in the Performance

Verification Procedure.

Bandwidth (Probe only) 1.5 GHz

ZS1500-OM-E Rev C 9–1

Page 44

ZS1500 High Impedance Active Probe

Input Capacitance 0.9 pF

DC Input Resistance 1 MΩ

ENVIRONMENTAL CHARACTERISTICS

Temperature, warranted 15 to 35 °C

Temperature, operating 0 °C to 50 °C

Temperature, non-operating -40 °C to 71 °C

Relative Humidity 80% max. up to 31 °C, decreasing lin-

early to 45% max. at 50 °C

Altitude up to 2000 m

PHYSICAL CHARACTERISTICS

Probe Head Size:

Length 61 mm (2.4 in.)

Width 7.3 mm (0.29 in.)

Height 13.1 mm (0.52 in.)

Cable Length 1.3 m (51.1 in.)

Weight:

Probe only 100 g (3.5 oz.)

Shipping 0.85 kg (1.87 lbs.)

Input Sockets Signal and ground sockets are com-

patible with 0.635 mm (0.025 in)

square pins, and 0.91 mm (0.036 in)

maximum diameter round pins

9–2 ZS1500-OM-E Rev C

Page 45

Input Voltage vs. Fre quency

100

10

1

Voltage [V] AC pk

0.1

1 10 100 1000 10000

Frequency [MHz]

Figure 9-1. Input Voltage vs. Frequency

COMPLIANCE AND CERTIFICATIONS

Specifications

CE Declaration of Conformity

Low Voltage Directive: EN 61010-2-031:2002

Safety requirements for electrical

equipment for measurement control

and laboratory use.

Part 031: Particular requirements for

hand-held probe assemblies for electrical measurement and test.

E M C D i r ec t i v e : E N 61 3 2 6 / A 3 :2 0 0 3

EMC requirements for electrical equipment for measurement control and

laboratory use.

ZS1500-OM-E Rev C 9–3

Page 46

ZS1500 High Impedance Active Probe

Electromagnetic Emissions: EN 55011/A2:2002 Class A Radiated

Emissions.

Electromagnetic Immunity: EN 61000-4-2/A2:2001 Electrostatic

Discharge.

(Air/Contact Discharge: 4 kV)

EN 61000-4-3/A1:2003

RF Radiated Electromagnetic Field

(80 MHz to 1 GHz; 3 V/m)

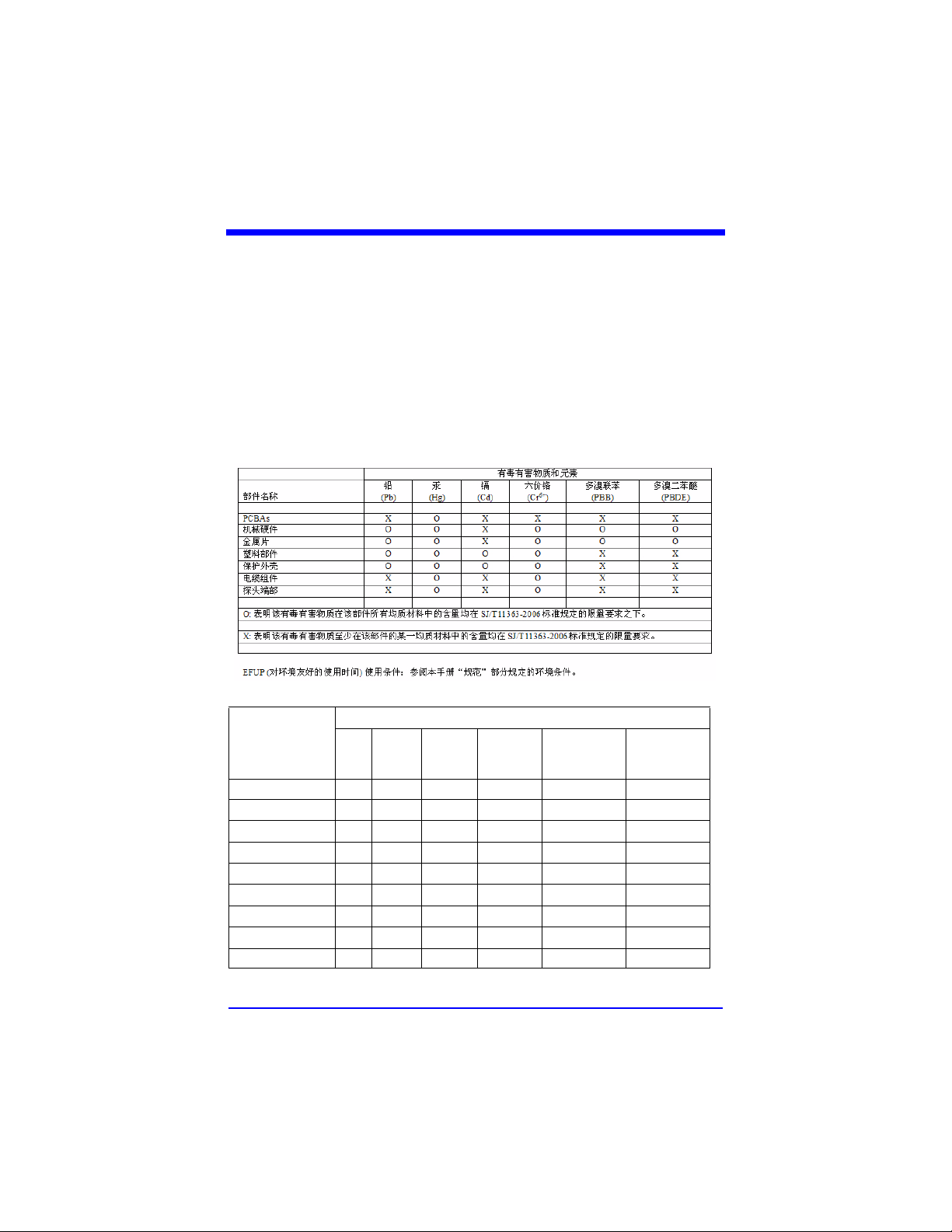

Toxic or Hazardous Substances and Elements

6+

)

Polybrominated

Biphenyls

(PBB)

Part Name Lead

PCBAs X O X X X X

Mechanical Hardware O O X O O O

Sheet Metal O O X O O O

Plastic Parts O O O O X X

Protective Case O O O O X X

Cable Assemblies X O X O X X

Probe Tips X O X O X X

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr

Polybrominated

Diphenyl Ethers

(PBDE)

9–4 ZS1500-OM-E Rev C

Page 47

Specifications

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement specified in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogenous materials used for

this part is above the limit requirement specified in SJ/T11363-2006.

EFUP (Environmental Friendly Use Period) Use Conditions: refer to the environmental

conditions stated in the specifications section of this Manual.

###

ZS1500-OM-E Rev C 9–5

Page 48

ZS1500 High Impedance Active Probe

BLANK PAGE

9–6 ZS1500-OM-E Rev C

Page 49

Appendix A

Appendix A

PERFORMANCE VERIFICATION TEST RECORD

This record can be used to record the results of measurements made

during the performance verification of the ZS1500 High Impedance

Active Probe.

Photocopy this page and record the results on the copy. File the completed record as required by applicable internal quality procedures.

The section in the test record corresponds to the parameters tested in

the performance verification procedure. The numbers preceding the

individual data records correspond to the steps in the procedure that

require the recording of data. Results to be recorded in the column

labeled “Test Result” are the actual specification limit check. The test

limits are included in all of these steps. Other measurements and the

results of intermediate calculations that support the limit check are to be

recorded in the column labeled “Intermediate Results”.

Permission is granted to reproduce these pages for the purpose of

recording test results.

Probe Model: ZS1500___________________

Serial Number: _________________________

Asset or Tracking Number: _________________________

Date: _________________________

Technician: _________________________

ZS1500-OM-E Rev C A–1

Page 50

ZS1500 High Impedance Active Probe

EQUIPMENT USED:

MODEL SERIAL

OSCILLOSCOPE

DIGITAL MULTIMETER

FUNCTION

GENERATOR

1

The function generator used in this Performance Verification Procedure is used for making relative measurements. The output of the generator is measured with a DMM or

oscilloscope in this procedure. Thus, the generator is not required to be calibrated.

1

NUMBER

CALIBRATION

DUE DATE

N/A

ZS1500 TEST RECORD

Step Description Intermediate data

Test Result

Output Zero Voltage

A-5 Output Zero Voltage (Test limit ≤ ±800 µV)_____________ V

LF Attenuation Accuracy

B-7 Generator Output Voltage ______________ V

B-8 Expected Output Voltage, top range ______________ V

B-10 Measured Output Voltage, top range ______________ V

B-12 Gain Error, top range (Test limit ≤ ±1.0%) ______________%

B-17 Generator Output Voltage ______________ V

B-19 Expected Output Voltage, mid range ______________ V

B-21 Measured Output Voltage, mid range ______________ V

B-23 Gain Error, mid range (Test limit ≤ ±1.0%) ______________%

###

A–2 ZS1500-OM-E Rev C

Page 51

Appendix A

Notes

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

ZS1500-OM-E Rev C A–3

Page 52

ZS1500 High Impedance Active Probe

Notes

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

A–4 ZS1500-OM-E Rev C

Loading...

Loading...