Page 1

WELCOME

Welcome to on-line help. Use this on-line manual for assistance in normal operation of your LeCroy oscilloscope. You can also use it for help

with LeCroy software options that you may have purchased.

Use the Table of Contents or Index at left to find information.

Page 2

HOW TO USE ON-LINE HELP

A

Type Styles

ctivators of pop-up text and images appear as green, underlined, italic: Pop-up. To close pop-up text and images after opening them, touch

the pop-up text again.

Link text appears blue and underlined: Link

window. After making a jump, you can touch the Back

left. With each touch of the

icon, you return to the preceding Help screen.

Back

. Links jump you to other topics, URLs, or images; or to another location within the same Help

icon in the toolbar at the top of the Help window to return to the Help screen you just

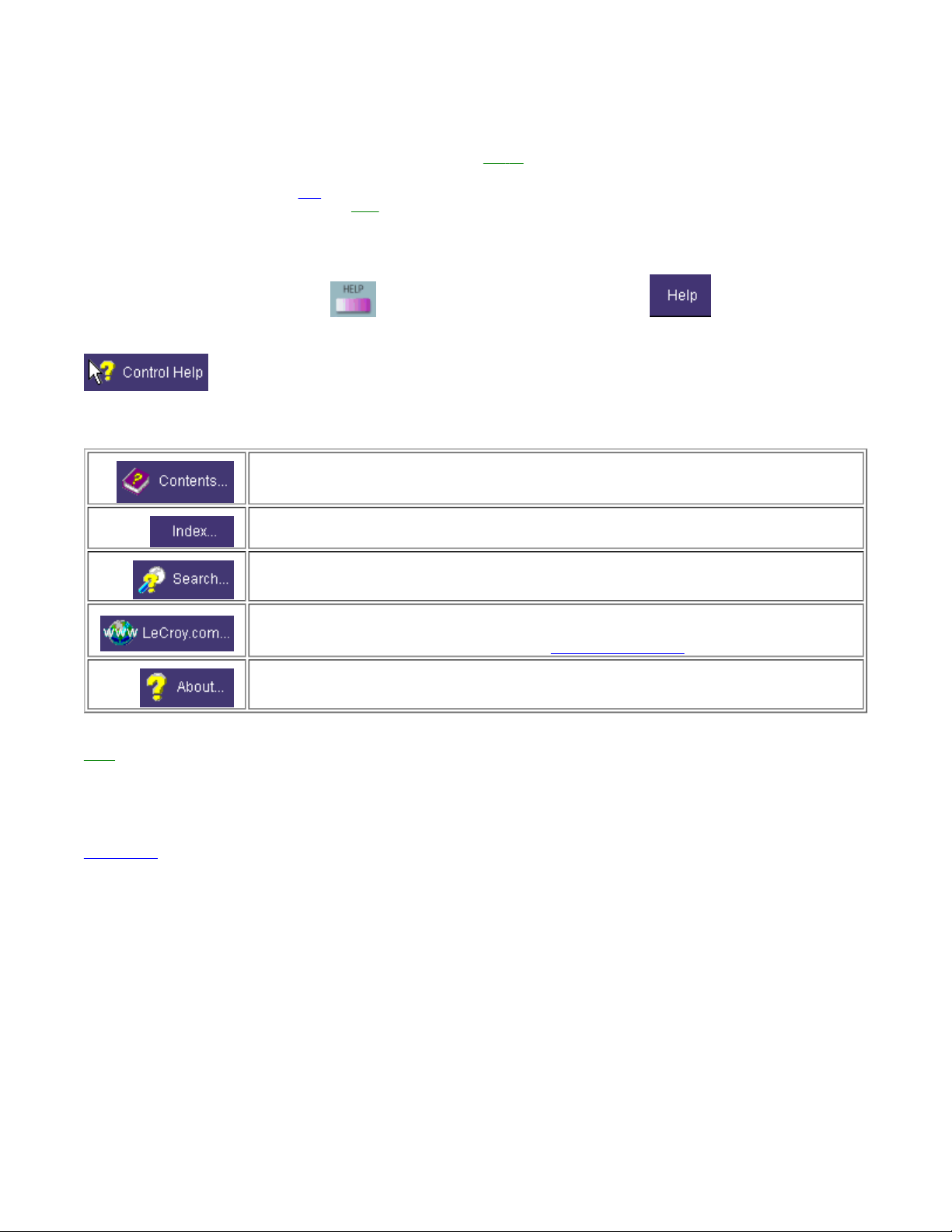

Instrument Help

When you press the front panel

a menu: you can choose either to have information found for you automatically or to search for information yourself.

If you want context-sensitive Help, that is, Help related to what was displayed on the screen when you requested Help, touch

about. The instrument will automatically display Help about that control.

If you want information about something not displayed on the screen, touch one of the buttons inside the drop-down menu to display the online Help manual:

Once opened, the Help window will display its navigation pane: the part of the window that shows the Table of Contents and Index. When you

touch anywhere outside of the Help window, this navigation pane will disappear to reveal more of your signal. To make it return, touch the

Show

icon at the top of the Help window or touch inside the Help information pane.

in the drop-down menu, then touch the on-screen control (or front panel button or knob) that you need information

button (if available), or touch the on-screen

ELP

H

Contents

Index

Search

www.LeCroy.com

and other useful information. This feature requires that the instrument be connected to the internet through

the Ethernet port on the scope's rear panel. Refer to Remote Communication

About

displays the Table of Contents.

displays an alphabetical listing of keywords.

locates every occurrence of the keyword that you enter.

connects you to LeCroy's Web site where you can find Lab Briefs, Application Notes,

opens the Utilities "Status" dialog, which shows software version and other system information.

button , you will be presented with

Help

for setup instructions.

Windows Help

In addition to instrument Help, you can also access on-line Help for Microsoft® Windows®. This help is accessible by minimizing the scope

application, then touching the

Top of Page

button in the Windows task bar at the bottom of the screen and selecting

Start

Help

.

Page 3

RETURNING A PRODUCT FOR SERVICE OR REPAIR

If you need to return a LeCroy product, identify it by its model and serial numbers. Describe the defect or failure, and give us your name and

telephone number.

For factory returns, use a Return Authorization Number (RAN), which you can get from customer service. Write the number clearly on the

outside of the shipping carton.

Return products requiring only maintenance to your local customer service center.

If you need to return your scope for any reason, use the original shipping carton. If this is not possible, be sure to use a rigid carton. The scope

should be packed so that it is surrounded by a minimum of four inches (10 cm) of shock absorbent material.

Within the warranty period, transportation charges to the factory will be your responsibility. Products under warranty will be returned to you

with transport prepaid by LeCroy. Outside the warranty period, you will have to provide us with a purchase order number before the work can

be done. You will be billed for parts and labor related to the repair work, as well as for shipping.

You should prepay return shipments. LeCroy cannot accept COD (Cash On Delivery) or Collect Return shipments. We recommend using air

freight.

Top of Page

Page 4

TECHNICAL SUPPORT

You can get assistance with installation, calibration, and a full range of software applications from your customer service center. Visit the

LeCroy Web site at http://www.lecroy.com for the center nearest you.

Page 5

STAYING UP-TO-DATE

To maintain your instrument’s performance within specifications, have us calibrate it at least once a year. LeCroy offers state-of-the-art

performance by continually refining and improving the instrument’s capabilities and operation. We frequently update both firmware and

software during service, free of charge during warranty.

You can also install new purchased software options in your scope yourself, without having to return it to the factory. Simply provide us with

your instrument serial number and ID, and the version number of instrument software installed. We will provide you with a unique option key

that consists of a code to be entered through the Utilities' Options dialog to load the software option.

Top of Page

Page 6

WARRANTY

The instrument is warranted for normal use and operation, within specifications, for a period of three years from shipment. LeCroy will either

repair or, at our option, replace any product returned to one of our authorized service centers within this period. However, in order to do this

we must first examine the product and find that it is defective due to workmanship or materials and not due to misuse, neglect, accident, or

abnormal conditions or operation.

LeCroy shall not be responsible for any damage caused by improper connection to incompatible equipment, or for any damage or

malfunction caused by the use of non-LeCroy supplies.

Spare and replacement parts, and repairs, all have a 90-day warranty.

The oscilloscope’s firmware has been thoroughly tested and is presumed to be functional. Nevertheless, it is supplied without warranty of any

kind covering detailed performance. Products not made by LeCroy are covered solely by the warranty of the original equipment manufacturer.

Top of Page

Page 7

COPYRIGHT

© 2004 by LeCroy Corporation. All rights reserved.

LeCroy, ActiveDSO, ProBus, SMART Trigger, JitterTrack, WavePro, and Waverunner are registered trademarks of LeCroy Corporation.

WaveMaster and X-Stream are trademarks of LeCroy Corporation. Information in this publication supersedes all earlier versions.

Specifications subject to change without notice.

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (845) 578 6020

Fax: (845) 578 5985

Internet: www.lecroy.com

ISO

9001:2000

FM 65813

Manufactured under an ISO 9000 Registered Quality Management System

Windows License Agreement

LeCroy's agreement with Microsoft prohibits users from running software on LeCroy X-Stream oscilloscopes that is not relevant to measuring,

analyzing, or documenting waveforms.

END-USER LICENSE AGREEMENT FOR LECROY® X-STREAM™ SOFTWARE

IMPORTANT-READ CAREFULLY: THIS END-USER LICENSE AGREEMENT (“EULA”) IS A LEGAL AGREEMENT BETWEEN THE

INDIVIDUAL OR ENTITY LICENSING THE SOFTWARE PRODUCT (“YOU” OR “YOUR”) AND LECROY CORPORATION (“LECROY”)

FOR THE SOFTWARE PRODUCT(S) ACCOMPANYING THIS EULA, WHICH INCLUDE(S): COMPUTER PROGRAMS; ANY “ONLINE”

OR ELECTRONIC DOCUMENTATION AND PRINTED MATERIALS PROVIDED BY LECROY HEREWITH (“DOCUMENTATION”);

ASSOCIATED MEDIA; AND ANY UPDATES (AS DEFINED BELOW) (COLLECTIVELY, THE “SOFTWARE PRODUCT”). BY USING AN

INSTRUMENT TOGETHER WITH OR CONTAINING THE SOFTWARE PRODUCT, OR BY INSTALLING, COPYING, OR OTHERWISE

USING THE SOFTWARE PRODUCT, IN WHOLE OR IN PART, YOU AGREE TO BE BOUND BY THE TERMS OF THIS EULA. IF YOU DO

NOT AGREE TO THE TERMS OF THIS EULA, DO NOT INSTALL, COPY, OR OTHERWISE USE THE SOFTWARE PRODUCT; YOU MAY

RETURN THE SOFTWARE PRODUCT TO YOUR PLACE OF PURCHASE FOR A FULL REFUND. IN ADDITION, BY INSTALLING,

COPYING, OR OTHERWISE USING ANY MODIFICATIONS, ENHANCEMENTS, NEW VERSIONS, BUG FIXES, OR OTHER

COMPONENTS OF THE SOFTWARE PRODUCT THAT LECROY PROVIDES TO YOU SEPARATELY AS PART OF THE SOFTWARE

PRODUCT (“UPDATES”), YOU AGREE TO BE BOUND BY ANY ADDITIONAL LICENSE TERMS THAT ACCOMPANY SUCH UPDATES.

IF YOU DO NOT AGREE TO SUCH ADDITIONAL LICENSE TERMS, YOU MAY NOT INSTALL, COPY, OR OTHERWISE USE SUCH

UPDATES.

THE PARTIES CONFIRM THAT THIS AGREEMENT AND ALL RELATED DOCUMENTATION ARE AND WILL BE DRAFTED IN

ENGLISH. LES PARTIES AUX PRÉSENTÉS CONFIRMENT LEUR VOLONTÉ QUE CETTE CONVENTION DE MÊME QUE TOUS LES

DOCUMENTS Y COMPRIS TOUT AVIS QUI S’Y RATTACHÉ, SOIENT REDIGÉS EN LANGUE ANGLAISE.

1. GRANT OF LICENSE.

1.1 License Grant.

nontransferable license (the “License”) to: (a) operate the Software Product as provided or installed, in object code form, for your own internal

business purposes, (i) for use in or with an instrument provided or manufactured by LeCroy (an “Instrument”), (ii) for testing your software

product(s) (to be used solely by you) that are designed to operate in conjunction with an Instrument (“Your Software”), and (iii) make one copy

for archival and back-up purposes; (b) make and use copies of the Documentation; provided that such copies will be used only in connection

with your licensed use of the Software Product, and such copies may not be republished or distributed (either in hard copy or electronic form)

to any third party; and (c) copy, modify, enhance and prepare derivative works (“Derivatives”) of the source code version of those portions of

the Software Product set forth in and identified in the Documentation as “Samples” (“Sample Code”) for the sole purposes of designing,

developing, and testing Your Software. If you are an entity, only one designated individual within your organization, as designated by you,

may exercise the License; provided that additional individuals within your organization may assist with respect to reproducing and distributing

Sample Code as permitted under Section 1.1(c)(ii). LeCroy reserves all rights not expressly granted to you. No license is granted hereunder

for any use other than that specified herein, and no license is granted for any use in combination or in connection with other products or

services (other than Instruments and Your Software) without the express prior written consent of LeCroy. The Software Product is licensed as

a single product. Its component parts may not be separated for use by more than one user. This EULA does not grant you any rights in

connection with any trademarks or service marks of LeCroy. The Software Product is protected by copyright laws and international copyright

treaties, as well as other intellectual property laws and treaties. The Software Product is licensed, not sold. The terms of this printed, paper

EULA supersede the terms of any on-screen license agreement found within the Software Product.

1.2 Upgrades.

have no right to use or access the Software Product unless you are properly licensed to use a product identified by LeCroy as being eligible

Subject to the terms and conditions of this EULA and payment of all applicable fees, LeCroy grants to you a nonexclusive,

If the Software Product is labeled as an “upgrade,” (or other similar designation) the License will not take effect, and you will

Page 8

for the upgrade (“Underlying Product”). A Software Product labeled as an “upgrade” replaces and/or supplements the Underlying Product.

You may use the resulting upgraded product only in accordance with the terms of this EULA. If the Software Product is an upgrade of a

component of a package of software programs that you licensed as a single product, the Software Product may be used and transferred only

as part of that single product package and may not be separated for use on more than one computer.

1.3. Limitations.

any software or documentation that is similar to any of the Software Product or Documentation; (b) encumber, transfer, rent, lease, time-share

or use the Software Product in any service bureau arrangement; (c) copy (except for archival purposes), distribute, manufacture, adapt, create

derivative works of, translate, localize, port or otherwise modify the Software Product or the Documentation; (d) permit access to the Software

Product by any party developing, marketing or planning to develop or market any product having functionality similar to or competitive with the

Software Product; (e) publish benchmark results relating to the Software Product, nor disclose Software Product features, errors or bugs to

third parties; or (f) permit any third party to engage in any of the acts proscribed in clauses (a) through (e). In jurisdictions in which transfer is

permitted, notwithstanding the foregoing prohibition, transfers will only be effective if you transfer a copy of this EULA, as well as all copies of

the Software Product, whereupon your right to use the Software product will terminate. Except as described in this Section 1.3, You are not

permitted (i) to decompile, disassemble, reverse compile, reverse assemble, reverse translate or otherwise reverse engineer the Software

Product, (ii) to use any similar means to discover the source code of the Software Product or to discover the trade secrets in the Software

Product, or (iii) to otherwise circumvent any technological measure that controls access to the Software Product. You may reverse engineer

or otherwise circumvent the technological measures protecting the Software Product for the sole purpose of identifying and analyzing those

elements that are necessary to achieve Interoperability (the “Permitted Objective”) only if: (A) doing so is necessary to achieve the Permitted

Objective and it does not constitute infringement under Title 17 of the United States Code; (B) such circumvention is confined to those parts of

the Software Product and to such acts as are necessary to achieve the Permitted Objective; (C) the information to be gained thereby has not

already been made readily available to you or has not been provided by LeCroy within a reasonable time after a written request by you to

LeCroy to provide such information; (D) the information gained is not used for any purpose other than the Permitted Objective and is not

disclosed to any other person except as may be necessary to achieve the Permitted Objective; and (E) the information obtained is not used (1)

to create a computer program substantially similar in its expression to the Software Product including, but not limited to, expressions of the

Software Product in other computer languages, or (2) for any other act restricted by LeCroy’s intellectual property rights in the Software

Product. “Interoperability” will have the same meaning in this EULA as defined in the Digital Millennium Copyright Act, 17 U.S.C. §1201(f), the

ability of computer programs to exchange information and of such programs mutually to use the information which has been exchanged.

1.4

PRERELEASE CODE.

not at the level of performance and compatibility of the final, generally available product offering. The Prerelease Code may not operate

correctly and may be substantially modified prior to first commercial shipment. LeCroy is not obligated to make this or any later version of the

Prerelease Code commercially available. The License with respect to the Prerelease Code terminates upon availability of a commercial

release of the Prerelease Code from LeCroy.

2.

SUPPORT SERVICES.

have no obligation to revise or update the Software Product or to support any version of the Software Product. At LeCroy’s sole discretion,

upon your request, LeCroy may provide you with support services related to the Software Product (“Support Services”) pursuant to the LeCroy

policies and programs described in the Documentation or otherwise then in effect, and such Support Services will be subject to LeCroy’s thencurrent fees therefor, if any. Any Update or other supplemental software code provided to you pursuant to the Support Services will be

considered part of the Software Product and will be subject to the terms and conditions of this EULA. LeCroy may use any technical

information you provide to LeCroy during LeCroy’s provision of Support Services, for LeCroy’s business purposes, including for product

support and development. LeCroy will not utilize such technical information in a form that personally identifies you.

3. PROPRIETARY RIGHTS.

3.1 Right and Title.

property or other proprietary rights, images, icons, photographs, text, and “applets” embodied in or incorporated into the Software Product,

collectively, “Content”), and all Derivatives, and any copies thereof are owned by LeCroy and/or its licensors or third-party suppliers, and is

protected by applicable copyright or other intellectual property laws and treaties. You will not take any action inconsistent with such title and

ownership. This EULA grants you no rights to use such Content outside of the proper exercise of the license granted hereunder, and LeCroy

will not be responsible or liable therefor.

3.2 Intellectual Property Protection.

notices contained on or in copies of the Software Product or Documentation.

3.3 Confidentiality.

defined below) of the other party without the written consent of the disclosing party. A party receiving Confidential Information from the other

shall use the highest commercially reasonable degree of care to protect the Confidential Information, including ensuring that its employees

and consultants with access to such Confidential Information have agreed in writing not to disclose the Confidential Information. You shall

bear the responsibility for any breaches of confidentiality by your employees and consultants. Within ten (10) days after request of the

disclosing party, and in the disclosing party's sole discretion, the receiving party shall either return to the disclosing party originals and copies

of any Confidential Information and all information, records and materials developed therefrom by the receiving party, or destroy the same,

other than such Confidential Information as to which this EULA expressly provides a continuing right to the receiving party to retain at the time

of the request. Either party may only disclose the general nature, but not the specific financial terms, of this EULA without the prior consent of

the other party; provided either party may provide a copy of this EULA to any finance provider in conjunction with a financing transaction, if

such provider agrees to keep this EULA confidential. Nothing herein shall prevent a receiving party from disclosing all or part of the

Confidential Information as necessary pursuant to the lawful requirement of a governmental agency or when disclosure is required by

operation of law; provided that prior to any such disclosure, the receiving party shall use reasonable efforts to (a) promptly notify the disclosing

party in writing of such requirement to disclose, and (b) cooperate fully with the disclosing party in protecting against any such disclosure or

obtaining a protective order. Money damages will not be an adequate remedy if this Section 4.3 is breached and, therefore, either party shall,

in addition to any other legal or equitable remedies, be entitled to seek an injunction or similar equitable relief against such breach or

threatened breach without the necessity of posting any bond. As used herein, “Confidential Information” means LeCroy pricing or information

concerning new LeCroy products, trade secrets (including without limitation all internal header information contained in or created by the

Software Product, all benchmark and performance test results and all Documentation) and other proprietary information of LeCroy; and any

business, marketing or technical information disclosed by LeCroy, or its representatives, or you in relation to this EULA, and either (i)

disclosed in writing and marked as confidential at the time of disclosure or (ii) disclosed in any other manner such that a reasonable person

would understand the nature and confidentiality of the information. Confidential Information does not include information (A) already in the

possession of the receiving party without an obligation of confidentiality to the disclosing party, (B) hereafter rightfully furnished to the receiving

Except as specifically permitted in this EULA, you will not directly or indirectly (a) use any Confidential Information to create

Portions of the Software Product may be identified as prerelease code (“Prerelease Code”). Prerelease Code is

At LeCroy’s sole discretion, from time to time, LeCroy may provide Updates to the Software Product. LeCroy shall

All right, title and interest in and to the Software Product and Documentation (including but not limited to any intellectual

You may not alter or remove any printed or on-screen copyright, trade secret, proprietary or other legal

Except for the specific rights granted by this EULA, neither party shall use or disclose any Confidential Information (as

Page 9

party by a third party without a breach of any separate nondisclosure obligation to the disclosing party, (C) publicly known without breach of

A

this EULA, (d) furnished by the disclosing party to a third party without restriction on subsequent disclosure, or (e) independently developed by

the receiving party without reference to or reliance on the Confidential Information.

4. TERMINATION.

This EULA will also terminate if you breach any of the terms or conditions of this EULA. You agree that if this EULA terminates for any

reason, the License will immediately terminate and you will destroy all copies of the Software Product (and all Derivatives), installed or

otherwise, the Documentation, and the Confidential Information (and all derivatives of any of the foregoing) that are in your possession or

under your control. The provisions of Sections 1.3, 4, 6, 7, 8, and 9 will survive any termination or expiration hereof.

5. U.S. GOVERNMENT RESTRICTED RIGHTS.

the United States Government (any such unit or agency, the “Government”), the Government agrees that the Software Product or

Documentation is “commercial computer software” or “commercial computer software documentation” and that, absent a written agreement to

the contrary, the Government’s rights with respect to the Software Product or Documentation are, in the case of civilian agency use, Restricted

Rights, as defined in FAR §52.227.19, and if for Department of Defense use, limited by the terms of this EULA, pursuant to DFARS

§227.7202. The use of the Software Product or Documentation by the Government constitutes acknowledgment of LeCroy’s proprietary rights

in the Software Product and Documentation. Manufacturer is LeCroy Corporation, 700 Chestnut Ridge Road, Chestnut Ridge, NY 10977

USA.

6. EXPORT RESTRICTIONS.

that is the direct product of the Software Product (the foregoing collectively referred to as the “Restricted Components”), to any country,

person, entity or end user subject to U.S. export restrictions. You specifically agree not to export or re-export any of the Restricted

Components (a) to any country to which the U.S. has embargoed or restricted the export of goods or services, which currently include, but are

not necessarily limited to Cuba, Iran, Iraq, Libya, North Korea, Sudan and Syria, or to any national of any such country, wherever located, who

intends to transmit or transport the Restricted Components back to such country; (b) to any end user who you know or have reason to know

will utilize the Restricted Components in the design, development or production of nuclear, chemical or biological weapons; or (c) to any enduser who has been prohibited from participating in U.S. export transactions by any federal agency of the U.S. government. You warrant and

represent that neither the BXA nor any other U.S. federal agency has suspended, revoked or denied your export privileges. It is your

responsibility to comply with the latest United States export regulations, and you will defend and indemnify LeCroy from and against any

damages, fines, penalties, assessments, liabilities, costs and expenses (including reasonable attorneys' fees and court costs) arising out of

any claim that the Software Product, Documentation, or other information or materials provided by LeCroy hereunder were exported or

otherwise accessed, shipped or transported in violation of applicable laws and regulations.

7. RISK ALLOCATION.

7.1 No Warranty.

IS/ARE BEING PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND. LECROY, FOR ITSELF AND ITS SUPPLIERS, HEREBY

DISCLAIMS ALL WARRANTIES, WHETHER EXPRESS OR IMPLIED, ORAL OR WRITTEN, WITH RESPECT TO THE SOFTWARE

PRODUCT OR ANY SUPPORT SERVICES INCLUDING, WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF TITLE OR NONINFRINGEMENT, MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, ACCURACY, INTEGRATION, VALIDITY,

EXCLUSIVITY, MERCHANTABILITY, NON-INTERFERENCE WITH ENJOYMENT, FITNESS FOR ANY PARTICULAR PURPOSE, AND ALL

WARRANTIES IMPLIED FROM ANY COURSE OF DEALING OR USAGE OF TRADE. YOU ACKNOWLEDGE THAT NO WARRANTIES

HAVE BEEN MADE TO YOU BY OR ON BEHALF OF LECROY OR OTHERWISE FORM THE BASIS FOR THE BARGAIN BETWEEN THE

PARTIES.

7.2. Limitation of Liability.

NY CLAIM OR ACTION, SHALL NOT EXCEED THE GREATER OF THE AMOUNT ACTUALLY PAID BY YOU FOR THE SOFTWARE

PRODUCT OR U.S.$5.00; PROVIDED THAT IF YOU HAVE ENTERED INTO A SUPPORT SERVICES AGREEMENT WITH LECROY,

LECROY’S ENTIRE LIABILITY REGARDING SUPPORT SERVICES WILL BE GOVERNED BY THE TERMS OF THAT AGREEMENT.

LECROY SHALL NOT BE LIABLE FOR ANY LOSS OF PROFITS, LOSS OF USE, LOSS OF DATA, INTERRUPTION OF BUSINESS, NOR

FOR INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES OF ANY KIND, WHETHER UNDER THIS EULA

OR OTHERWISE ARISING IN ANY WAY IN CONNECTION WITH THE SOFTWARE PRODUCT, THE DOCUMENTATION OR THIS EULA.

SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE EXCLUSION OR LIMITATION MAY NOT APPLY TO YOU. THESE LIMITATIONS ARE INDEPENDENT FROM ALL OTHER

PROVISIONS OF THIS EULA AND SHALL APPLY NOTWITHSTANDING THE FAILURE OF ANY REMEDY PROVIDED HEREIN.

7.3 Indemnification. You will defend, indemnify and hold harmless LeCroy and its officers, directors, affiliates, contractors, agents, and

employees from, against and in respect of any and all assessments, damages, deficiencies, judgments, losses, obligations and liabilities

(including costs of collection and reasonable attorneys’ fees, expert witness fees and expenses) imposed upon or suffered or incurred by them

arising from or related to your use of the Software Product.

8. GENERAL PROVISIONS.

8.1 Compliance with Laws.

Software Product, and the performance by you of your obligations hereunder, of any jurisdiction in or from which you directly or indirectly

cause the Software Product to be used or accessed.

8.2 No Agency. Nothing contained in this EULA will be deemed to constitute either party as the agent or representative of the other party, or

both parties as joint venturers or partners for any purpose.

8.3 Entire Agreement; Waiver; Severability.

hereof. No provision of, right, power or privilege under this EULA will be deemed to have been waived by any act, delay, omission or

acquiescence by LeCroy, its agents, or employees, but only by an instrument in writing signed by an authorized officer of LeCroy. No waiver

by LeCroy of any breach or default of any provision of this EULA by you will be effective as to any other breach or default, whether of the

same or any other provision and whether occurring prior to, concurrent with, or subsequent to the date of such waiver. If any provision of this

EULA is declared by a court of competent jurisdiction to be invalid, illegal or unenforceable, such provision will be severed from this EULA and

all the other provisions will remain in full force and effect.

8.4 Governing Law;

USA, without regard to its choice of law provisions. The United Nations Convention on Contracts for the International Sale of Goods will not

apply to this EULA. Exclusive jurisdiction and venue for any litigation arising under this EULA is in the federal and state courts located in New

York, New York, USA and both parties hereby consent to such jurisdiction and venue for this purpose.

This EULA will remain in force until termination pursuant to the terms hereof. You may terminate this EULA at any time.

If any Software Product or Documentation is acquired by or on behalf of a unit or agency of

You agree that you will not export or re-export the Software Product, any part thereof, or any process or service

THE SOFTWARE PRODUCT IS NOT ERROR-FREE AND THE SOFTWARE PRODUCT AND SUPPORT SERVICES

LECROY’S LIABILITY FOR DAMAGES FOR ANY CAUSE WHATSOEVER, REGARDLESS OF THE FORM OF

You will comply with all laws, legislation, rules, regulations, and governmental requirements with respect to the

This EULA constitutes the entire agreement between the parties with regard to the subject matter

Jurisdiction; Venue. This EULA will be governed by and construed in accordance with the laws of the State of New York,

Page 10

8.5 Assignment. This EULA and the rights and obligations hereunder, may not be assigned, in whole or in part by you, except to a successor

to the whole of your business, without the prior written consent of LeCroy. In the case of any permitted assignment or transfer of or under this

EULA, this EULA or the relevant provisions will be binding upon, and inure to the benefit of, the successors, executors, heirs, representatives,

administrators and assigns of the parties hereto.

8.6 Notices.

confirmed fax, by confirmed e-mail, by certified mail, postage prepaid and return receipt requested, or by a nationally recognized express

delivery service. All notices will be in English and will be effective upon receipt.

8.7 Headings.

provisions.

8.8 Acknowledgment.

counsel review this EULA, (c) this EULA has the same force and effect as a signed agreement, and (d) issuance of this EULA does not

constitute general publication of the Software Product or other Confidential Information.

Top of Page

All notices or other communications between LeCroy and you under this EULA will be in writing and delivered personally, sent by

The headings used in this EULA are intended for convenience only and will not be deemed to supersede or modify any

Licensee acknowledges that (a) it has read and understands this EULA, (b) it has had an opportunity to have its legal

Page 11

VIRUS PROTECTION

Because your scope runs on a Windows-based PC platform, it must be protected from viruses, as with any PC on a corporate network. It is

crucial that the scope be kept up to date with Windows Critical Updates, and that anti-virus software be installed and continually updated.

Visit http://www.lecroy.com/dsosecurity

and related matters.

for more information regarding Windows Service Pack compatibility with LeCroy operating software,

Page 12

SPECIFICATIONS

p

Specifications are subject to change without notice.

Note:

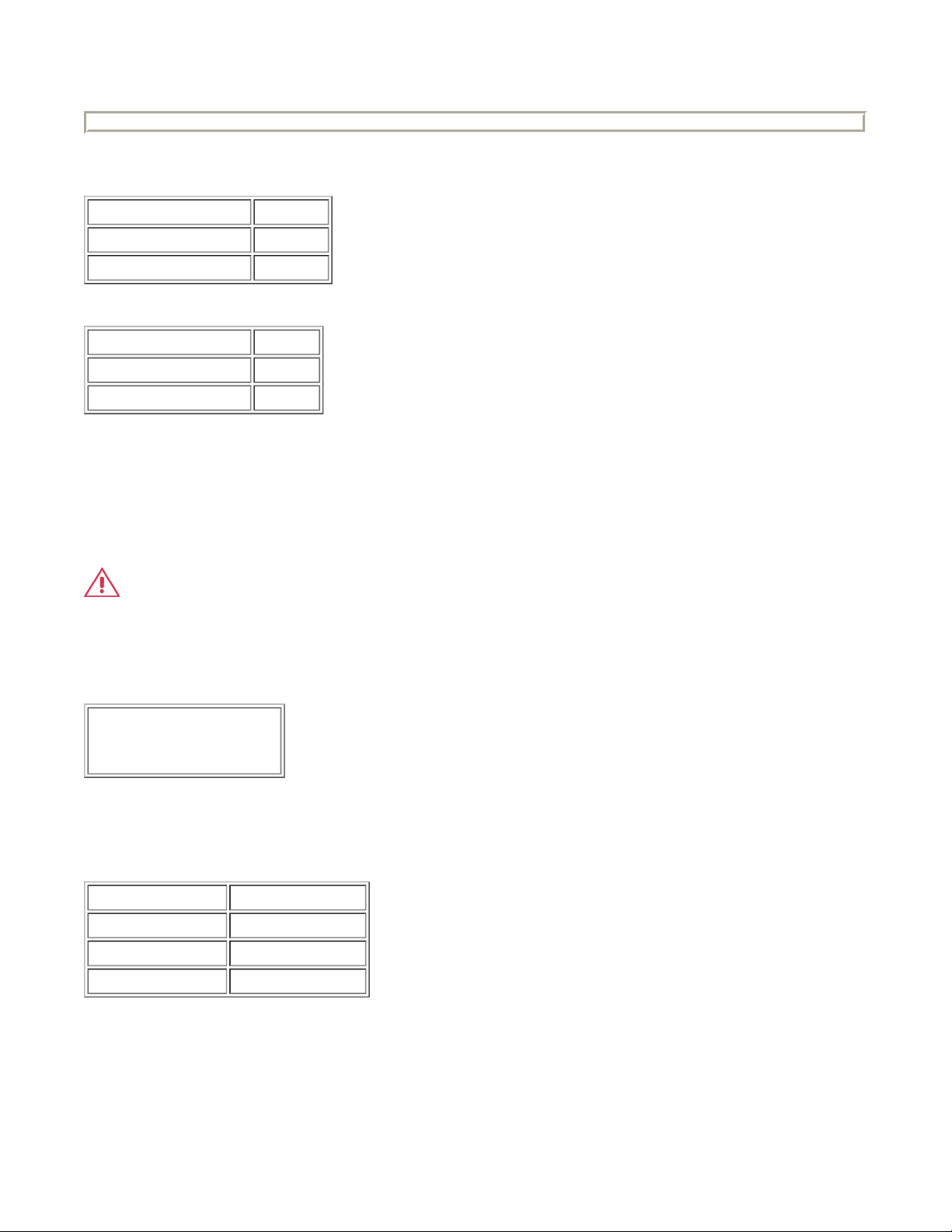

Vertical System

Bandwidth (-3 dB @ 50 ohms):

WaveSurfer 422 and 424 200 MHz

WaveSurfer 432 and 434 350 MHz

WaveSurfer 452 and 454 500 MHz

Input Channels:

Rise Time (typical):

WaveSurfer 422 and 424 1.75 ns

WaveSurfer 432 and 434 1.00 ns

WaveSurfer 452 and 454 750 ps

Bandwidth Limiters:

z Full

z 200 MHz

z 20 MHz (WaveSurfer 424/422)

Input Impedance:

Input Coupling:

Max Input Voltage: +/-

Installation (Overvoltage) Category:

Vertical Resolution:

Sensitivity:

DC Gain Accuracy:

Offset Range:

+/-1 V @ 1.0 mV to 49 mV/div

+/-10 V @ 50 mV to 0.49 V/div

+/-100 V @ 0.5 V to 10 V/div

4 (WaveSurfer 424, 434, 454); 2 (WaveSurfer 422, 432, 452)

1 Mohms // 16 pF or 50 ohms +/-1%

DC 50 ohm, DC 1Mohm, GND, AC 1Mohm

400 Vpk (CAT I), +/-300 Vpk (CAT II)

8 bits

50 ohms: 1 mV/div to 2 V/div; 1 Mohms: 1 mV/div to 10 V/div

+/-(1.5% + 0.5% of full scale)

CAT I

Offset Accuracy:

+/-(1.0% + 0.5% of full scale + 1 mV)

Horizontal System

Timebases:

Time/div Range:

WaveSurfer 454/452 200 ps to 1000 s/div

WaveSurfer 434/432 500 ps to 1000 s/div

WaveSurfer 424/422 1 ns to 1000 s/div

Roll Mode 200 ms 1000 s/div

Math & Zoom Traces:

Clock Accuracy:

Interpolator Resolution:

Internal timebase common to 4 input channels

4 independent zoom traces; 1 math/zoom trace

</= 10 ppm

5 ps

Acquisition System

Single-shot Sample Rate/Ch:

Sam

le Rate (RIS mode):

1 GS/s

50 GS/s

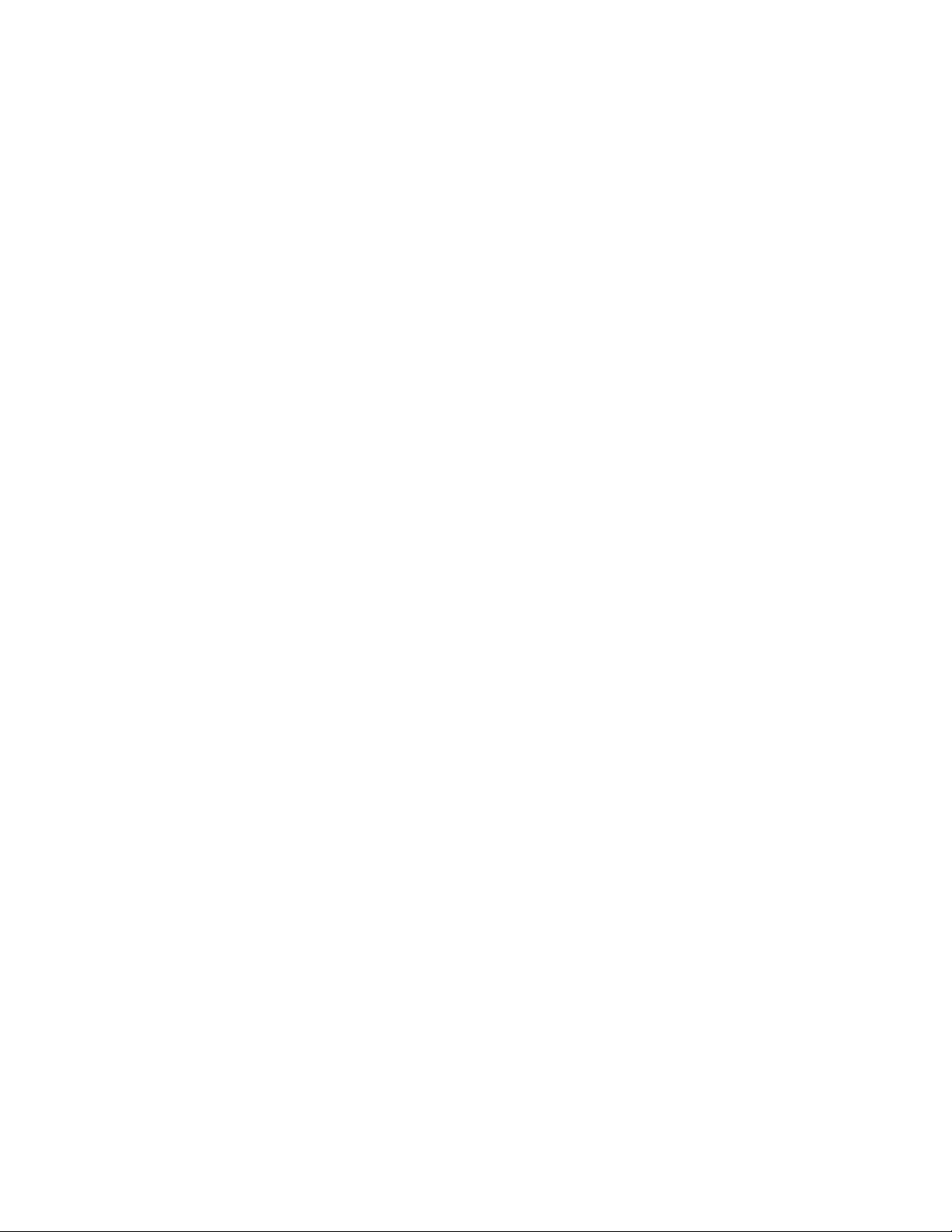

Page 13

2 Channel Max.:

Standard Record Length:

Max. Record Length (optional):

Standard Capture Time:

Max. Capture Time (optional):

2 GS/s

500 kpts/Ch (interleaved); 250 kpts/Ch (all channels)

2 Mpts/Ch (interleaved); 1 Mpts/Ch (all channels)

up to 250 µs at full sample rate

up to 1 ms at full sample rate

Acquisition Processing

Averaging:

Enhanced Resolution (ERES) -- optional with MathSurfer package:

Envelope (Extrema) -- optional with MathSurfer package:

Continuous averaging to 1 million sweeps

from 8.5 to 11 bits vertical resolution

Envelope, floor, roof for up to 1 million sweeps

Triggering System

Normal, Auto, Single, and Stop

Modes:

Sources:

available for battery or DC operation.

Slope:

Coupling Modes:

Pre-trigger Delay:

Post-trigger Delay:

Holdoff by Time or Events:

Internal Trigger Range:

External Trigger Range:

External Trigger Impedance:

Any input channel, External, Ext/10, or Line; slope, level, and coupling are unique to each source (except Line). Line input is not

CH1 to CH4, Ext, Ext/10: Positive, Negative, Window; Line (except DC/battery power): Positive, Negative

AC, DC, HF, HFRej, LFRej (except Line trigger)

0 to 100% of horizontal time scale

0 to 10,000 divisions

Up to 20 s, or from 1 to 99,999,999 events

+/-5 div from center

EXT/10 +/-5 V; EXT +/-500 mV

50 ohms, 1 Mohms

Basic Triggers

Edge/Slope/Line:

Triggers when the signal meets the slope (positive, negative, window) and level condition.

SMART Triggers -- Standard

Triggers on positive or negative glitches with widths selectable from 600 ps to 20 s or on intermittent faults.

Glitch:

Triggers on positive or negative glitches with widths selectable from 2 ns to 20 s or on intermittent faults. Includes exclusion mode

Width:

(trigger on intermittent faults by specifying the normal width period).

Logic (Pattern):

or don't care. The High and Low level can be selected independently. Triggers at start or end of pattern.

TV -- Composite Video:

(up to 1500 lines).

Logic combination (AND, NAND, OR, NOR) of 5 inputs (4 channels and external trigger input). Each source can be high, low,

Triggers selectable fields (1, 2, 4, or 8), positive or negative slope, for NTSC, PAL, SECAM, or non-standard video

SMART Triggers -- Optional

Triggers on positive or negative runts defined by two voltage limits and two time limits. Select between 2 ns and 20 ns. Includes

Runt:

exclusion mode (trigger on intermittent faults by specifying the normal width period).

Slew Rate:

(trigger on intermittent faults by specifying the normal width period).

Interval (Signal or Pattern):

sources is 2 ns to 20 s, or 1 to 99,999,999 events. Includes exclusion mode (trigger on intermittent faults by specifying the normal width

period).

Dropout:

intermittent faults by specifying the normal width period).

Qualified (State or Edge):

sources is 2 ns to 20 s, or 1 to 99,999,999 events. Includes exclusion mode (trigger on intermittent faults by specifying the normal width

period).

Triggers on edge rates. Select limits for dV, dt, and slope. Select edge limits between 2 ns and 20 ns. Includes exclusion mode

Triggers on a source if a given state (or transition edge) has occurred on another source. Delay between

Triggers if the input signal drops out for longer than a selectable timeout between 2 ns and 20 s. Includes exclusion mode (trigger on

Triggers on any input source only if a defined state or edge occurred on another input source. Delay between

Automatic Setup

Autosetup:

Vertical Find Scale:

dynamic range.

Automatically sets timebase, trigger, and sensitivity to display a wide range of repetitive signals.

Automatically sets the vertical sensitivity and offset for the selected channels to display a waveform with maximum

Page 14

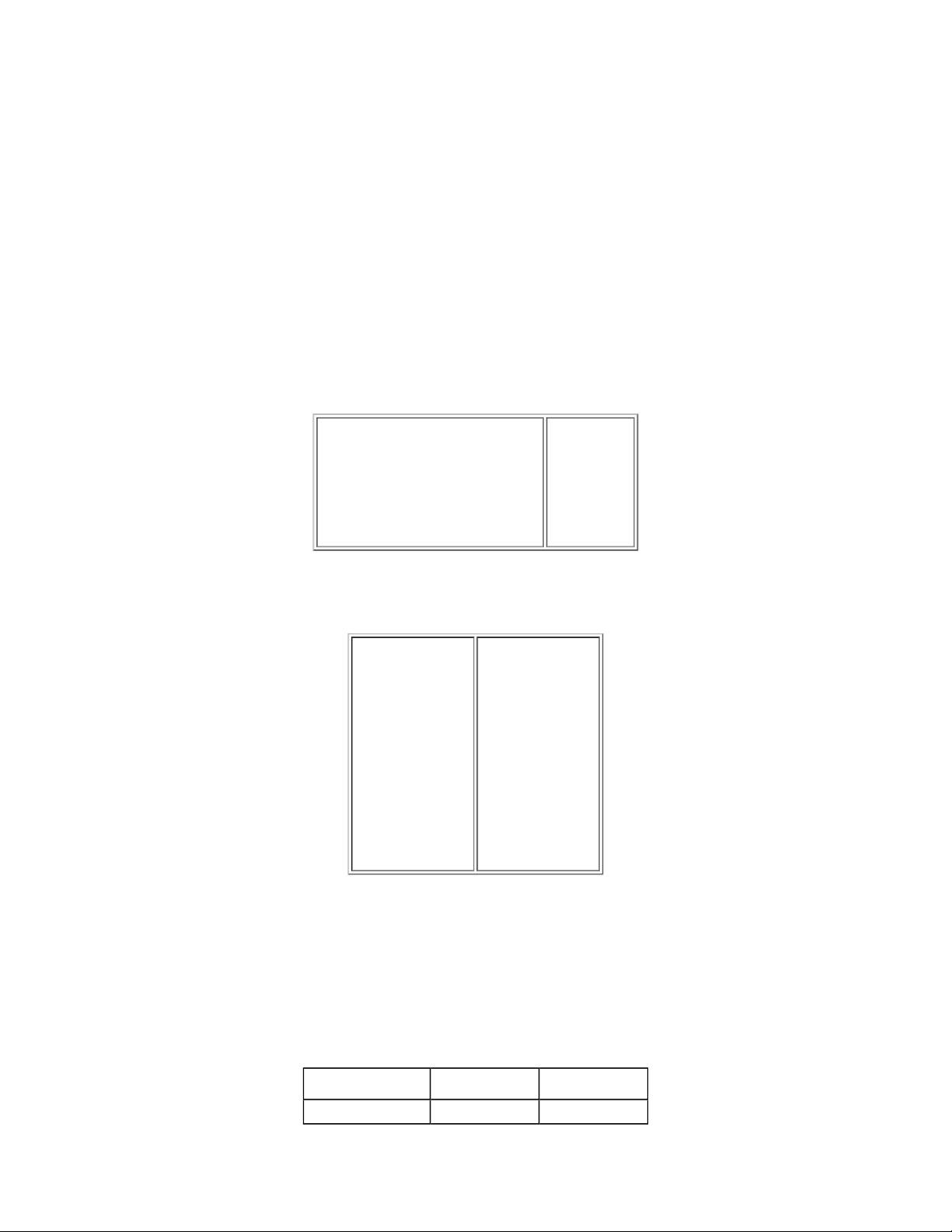

Documentation and Connectivity

Printing:

Email:

SMTP (no additional program needed).

Waveform Memories:

Waveform File Data:

Screen Images:

to one of the three USB 2.0 ports. Images can be saved in a variety of formats, and with white or black background.

Waveform Labeling (Annotation):

Hardcopy Front Panel Button:

and save to the clipboard.

Networking:

IP address.

Remote Control:

USB Ports:

External Monitor Port Standard:

(Centronics)

Serial Port:

Audio Port:

Connect to any WindowsXP-compatible printer. Load any standard WindowsXP printer driver onto the unit as future needs require.

Configure the unit to send an email of a screen image in a variety of formats, using MAPI (i.e., through a default email program) or

Save waveform data as a reference trace to be compared to channels, zooms, or math functions.

Save waveform data in the following formats: binary, ASCII, Excel, Mathcad, MATLAB.

Save a screen image to the internal hard drive, a user-supplied USB memory stick, or any other peripheral device connected

Attach up to 10 labels to any combination of waveforms. Labels appear on screen images.

Configure the front panel Hardcopy button to send an email, save a screen image, save waveform file data,

Standard 10/100Base-T Ethernet interface (RJ-45 connector). Connect to any network using DHCP with automatically assigned

Via LeCroy Remote Command Set (via Ethernet)

3 USB ports (one on front of instrument) support Windows compatible devices

15-pin D-Type female SVGA-compatible connector for external color parallel port 25-pin D-type female

9-pin D-type male (not for remote oscilloscope control)

Mic Input, Line Input, Line Output

Probing

One PP007-WS per channel (standard). A variety of optional passive and active probes is available.

Probes:

To avoid incorrect measurements, ensure that your probes have the correct model number (PP007-WS). Do not use probes with model

number PP007 or PP007-WR. Only model PP007-WS will provide the specified performance.

Probe System – ProBus:

Scale Factors:

Caution

Automatically detects and supports a wide variety of compatible probes.

Automatically or manually selected depending on probe used

Color Waveform Display

Color 10.4-inch flat panel TFT LCD with high resolution touch screen

Type:

Resolution:

Real Time Clock:

Grid Styles:

Waveform Display Styles:

SVGA; 800 x 600 pixels

Date, hours, minutes, and seconds displayed with waveform; SNTP support to synchronize to precision internet clocks

Single, XY, Single+XY

Sample dots joined or dots only

Analog Persistence Display

Analog and Color-graded Persistence:

Persistence Selections:

Persistence Aging Time:

Sweeps Displayed:

Select analog or color.

From 500 ms to infinity

All accumulated or all accumulated with last trace highlighted

Variable saturation levels; stores each trace's persistence data in memory

Zoom Expansion Traces

Display up to 4 Zoom traces.

Rapid Signal Processing

Processor:

Intel Celeron 850 with MS WindowsXP Embedded platform

Internal Waveform Memory

Waveform:

media).

M1, M2, M3, M4 (Store full-length waveforms with 16 bits/data point.) Or save to any number of files (limited only by data storage

Setup Storage

Page 15

Front Panel and Instrument Status:

A

p

Save to the internal hard drive or to a USB connected peripheral device.

Auxiliary Output

Signal Types:

Calibrator Signal:

Control Signals:

Select from calibrator or control signals output from front panel.

1 kHz, 1 V square wave

trigger enabled, trigger out, or pass/fail

Auxiliary Input

Signal Types:

Select External Trigger input on front panel. EXT: 100 mV/div; EXT/10: 1 V/div

Math Tools (standard)

Operators include sum, difference, product, ratio, and FFT (up to 25 kpts with power spectrum output and rectangular,Von Hann, and Flattop

windows). One math function may be defined at a time.

Extended Math (MathSurfer option)

dds chaining of two math functions, rescaling to different units, and the following additional math functions:

absolute value

averaging (summed and continuous)

derivative

envelope

enhanced Resolution (to 11 bits)

floor

integral

invert

reciprocal

roof

square

square root

Measure Tools (standard)

Display any 6 parameters together with statistics, including their average, high, low, and standard deviations. Measurements can be gated to

focus on only a portion of the waveform.

amplitude

area

base

delay

duty cycle

fall 80-20%

fall time (90-10%)

frequency

maximum

mean

minimum

overshoot-

overshoot+

peak-to-peak

period

rise 20-80%

rise time (10-90%

rms

skew

std. deviation

top

width

Pass/Fail Testing

Test multiple parameters against selectable parameter limits at the same time. Pass or fail conditions can initiate actions including: document

to local or networked files, email the image of the failure, save waveforms, or send a pulse out at the front panel auxiliary BNC output.

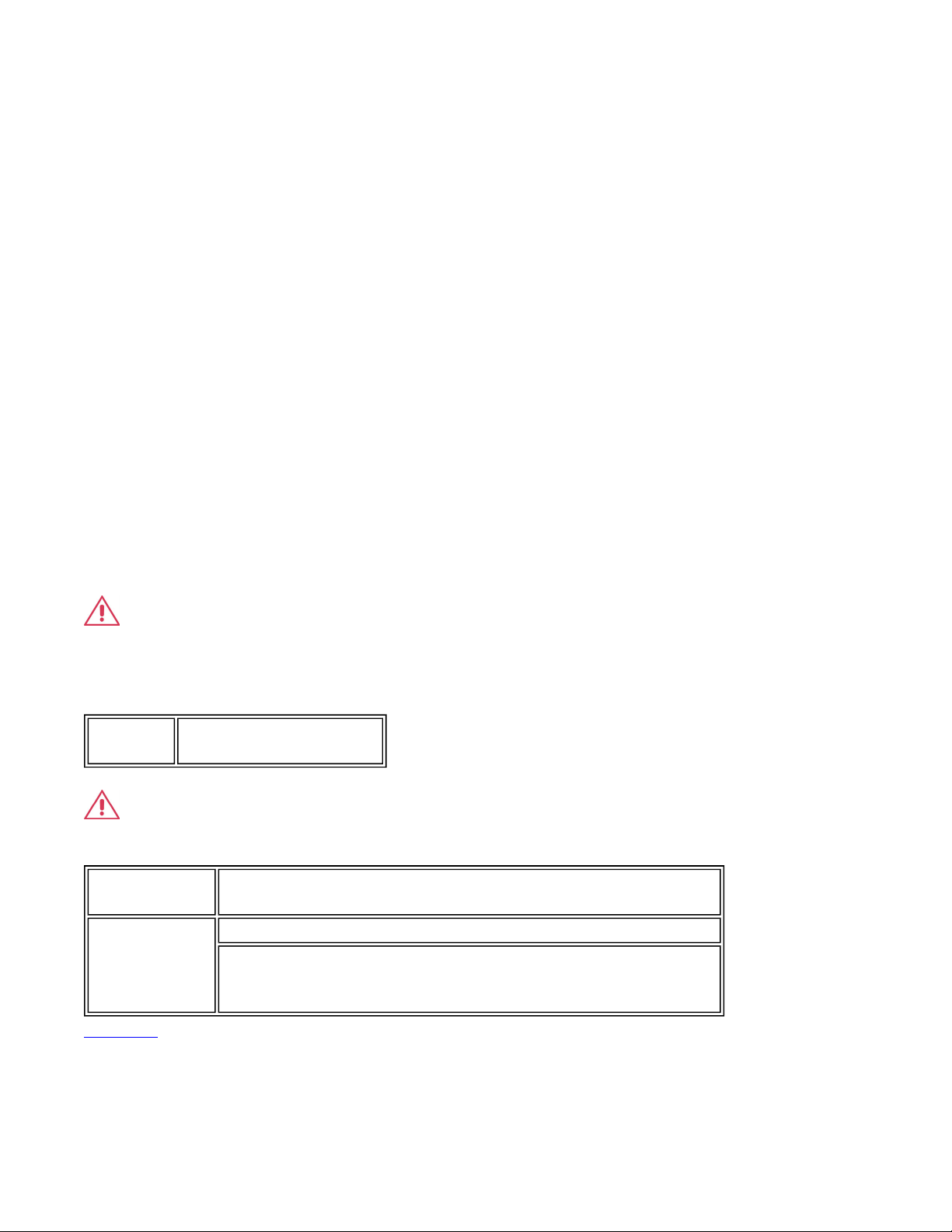

General

Auto Calibration:

Power Requirements:

single-phase 100 to 120 V

Power Consum

Ensures specified DC and timing accuracy is maintained for 1 year minimum.

The instrument operates from a single-phase, 100 to 240 V

(+/-10%) AC power source at 400 Hz (+/-5%).

rms

Voltage Range: 90 to 132 V

Frequency Range: 380 to 420 Hz 47 to 63 Hz

On State: up to 200 VA (4-channel models) or 170 VA (2-channel models) depending on accessories installed

tion:

rms

(+/-10%) AC power source at 50/60 Hz (+/-5%), or

rms

90 to 264 V

rms

Page 16

(probes, external printer, PC port plug-ins, etc.)

A

Physical Dimensions (HWD):

Net Weight:

6.8 kg (15 lbs.)

260 mm x 340 mm x 152 mm (10.25 in. x 13.4 in. x 6.0 in.); height measurement excludes foot pads

Warranty and Service

3-year warranty; calibration recommended yearly

Optional service programs include extended warranty, upgrades, and calibration services.

Environmental Characteristics

Temperature

Operating:

Storage (non-operating):

Humidity

Operating:

Storage (non-operating):

ltitude

Operating:

Storage (non-operating):

Random Vibration

Operating:

Non-operating:

Shock

Functional Shock:

5 to 40 °C

-20 to +60 °C

5 to 80% RH (non-condensing) at or below 30 °C; upper limit derates linearly to 55% RH (non-condensing) at 40 °C

5 to 95% RH (non-condensing) as tested per MIL-PRF-28800F

Up to 3048 m (10,000 ft) at or below 25 °C

Up to 12,192 m (40,000 ft)

0.31 g

, 5 Hz to 500 Hz, 15 minutes in each of 3 orthogonal axes

rms

2.4 g

, 5 to 500 Hz, 15 minutes in each of 3 orthogonal axes

rms

20 g peak, half sine, 11 ms pulse, 3 shocks (positive and negative) in each of 3 orthogonal axes, 18 shocks total

Certifications

CE Approved, UL (Std. UL 3111-1) and cUL (Std. CSA C22.2 No. 1010-1) listed.

CE Declaration of Conformity

The oscilloscope meets requirements of EMC Directive 89/336/EEC for Electromagnetic Compatibility and Low Voltage Directive 73/23/EEC

for Product Safety.

EMC Directive:

89/336/EEC

EN61326-1:1997+A1:1998+A2:2001

Warning

This is a Class A product. In a domestic environment this product may cause radio interference, in which case the user may be required to

take appropriate measures.

Low Voltage Directive:

Product Safety

Top of Page

73/23/EEC

EN 61010-1:2001

Safety requirements for electrical equipment for measurement, control, and laboratory use.

Installation Category II

Pollution Degree 2

Protection Class 1

Page 17

SAFETY REQUIREMENTS

Safety Symbols and Terms

Operating Environment

Cooling

AC Power Source

Power and Ground Connections

On/Standby Switch

Calibration

Cleaning

Abnormal Conditions

This section contains information and warnings that must be observed to keep the instrument operating in a correct and safe condition. You

are required to follow generally accepted safety procedures in addition to the safety precautions specified in this section.

Safety Symbols and Terms

Where the following symbols or terms appear on the instrument’s front or rear panels, or in this manual, they alert you to important safety

considerations.

This symbol is used where caution is required. Refer to the accompanying information or documents in order to protect

against personal injury or damage to the instrument.

This symbol warns of a potential risk of shock hazard.

This symbol is used to denote the measurement ground connection.

This symbol is used to denote a safety ground connection.

This symbol shows that the switch is a On/Standby switch. When it is pressed, the DSO’s state toggles between

Operating and Standby state. This switch is not a disconnect device. To completely remove power to the DSO, the

power cord must be unplugged from the AC outlet after the DSO is placed in Standby state.

This symbol is used to denote "Alternating Current."

The CAUTION sign indicates a potential hazard. It calls attention to a procedure, practice or condition which, if not

CAUTION

WARNING

CAT I

followed, could possibly cause damage to equipment. If a CAUTION is indicated, do not proceed until its conditions are

fully understood and met.

The WARNING sign indicates a potential hazard. It calls attention to a procedure, practice or condition which, if not

followed, could possibly cause bodily injury or death. If a WARNING is indicated, do not proceed until its conditions are

fully understood and met.

Installation (Overvoltage) Category rating per EN 61010-1 safety standard and is applicable for the oscilloscope front

panel measuring terminals. CAT I rated terminals must only be connected to source circuits in which measures are

taken to limit transient voltages to an appropriately low level.

Operating Environment

The instrument is intended for indoor use and should be operated

in a clean, dry environment with an ambient temperature within

the range of 5 °C to 40 °C.

Direct sunlight, radiators, and other heat sources should

Note:

be taken into account when assessing the ambient temperature.

The design of the instrument has been verified to conform to EN

61010-1 safety standard per the following limits:

WARNING

The DSO must not be operated in explosive, dusty, or wet/damp

atmospheres.

Page 18

Installation (Overvoltage) Categories II (Mains Supply Connector)

& I (Measuring Terminals)

Pollution Degree 2

Protection Class I

Note:

Installation (Overvoltage) Category II refers to local distribution

level, which is applicable to equipment connected to the mains

supply (AC power source).

Installation (Overvoltage) Category I refers to signal level, which

is applicable to equipment measuring terminals that are

connected to source circuits in which measures are taken to

limit transient voltages to an appropriately low level.

Pollution Degree 2 refers to an operating environment where

normally only dry non-conductive pollution occurs. Occasionally

a temporary conductivity caused by condensation must be

expected.

Protection Class I refers to a grounded equipment, in which

protection against electric shock is achieved by Basic Insulation

and by means of a connection to the protective ground

conductor in the building wiring.

CAUTION

Protect the DSO’s display touch screen from excessive impacts

with foreign objects.

CAUTION

Do not exceed the maximum specified front panel terminal (CH1,

CH2, CH3, CH4, EXT) voltage levels. Refer to Specifications for

more details.

Cooling Requirements

The instrument relies on forced air cooling with internal fans and

ventilation openings. Care must be taken to avoid restricting the

airflow around the apertures (fan holes) at the sides, front, and

rear of the DSO. To ensure adequate ventilation it is required to

leave a 10 cm (4 inch) minimum gap around the sides, front, and

rear of the instrument.

AC Power Source

The instrument operates from a single-phase, 100 to 240 V

(+/-10%) AC power source at 50/60 Hz (+/-5%), or single-phase

100 to 120 V

No manual voltage selection is required; the instrument

automatically adapts to line voltage.

Depending on the accessories installed (front panel probes, PC

port plug-ins, external printer, etc.), the instrument can draw up to

200 VA (4-channel models) or 170 VA (2-channel models).

(+/-10%) AC power source at 400 Hz (+/-5%).

rms

rms

CAUTION

Do not connect or disconnect probes or lest leads while they are

connected to a voltage source.

CAUTION

Do not block the ventilation holes located on both sides and rear

of the DSO.

CAUTION

Do not allow any foreign matter to enter the DSO through the

ventilation holes, etc.

Note:

The instrument automatically adapts itself to the AC line input

within the following ranges:

Voltage Range:

Frequency Range:

90 to 264 V

47 to 63 Hz 380 to 420 Hz

rms

90 to 132 V

rms

Power and Ground Connections

The instrument is provided with a grounded cord set containing a

molded three-terminal polarized plug and a standard IEC320

(Type C13) connector for making line voltage and safety ground

connection. The AC inlet ground terminal is connected directly to

WARNING

Page 19

A

the frame of the instrument. For adequate protection against

electrical shock hazard, the power cord plug must be inserted into

a mating AC outlet containing a safety ground contact. Use only

the power cord specified for this instrument and certified for the

country of use.

The DSO should be positioned to allow easy access to the

socket-outlet. To completely remove power to the DSO, unplug

the instrument’s power cord from the AC outlet after the DSO is

placed in Standby state.

In Standby state the DSO is still connected to the AC supply. The

instrument can only be placed in a complete Power Off state by

physically disconnecting the power cord from the AC supply. It is

recommended that the power cord be unplugged from the AC

outlet if the DSO is not being used for an extended period of time.

See On/Standby Switch

for more information.

Electrical Shock Hazard!

Any interruption of the protective conductor inside or outside of

the DSO, or disconnection of the safety ground terminal creates a

hazardous situation.

Intentional interruption is prohibited.

CAUTION

The outer shells of the front panel terminals (CH1, CH2, CH3,

CH4, EXT) are connected to the instrument’s chassis and

therefore to the safety ground.

On/Standby Switch

The front panel On/Standby switch controls the operational state of the DSO. This toggle switch is activated by momentarily pressing and

releasing it.

There are two basic DSO states: On or Standby. In the "On" state, the DSO, including its computer subsystems (CPU, hard drive, etc,) is fully

powered and operational. In the "Standby" state, the DSO, including computer subsystems, is powered off with the exception of some

"housekeeping" circuitry (approximately 2 watts dissipation).

lways use the On/Standby switch to place the DSO in Standby state so that it executes a proper shutdown process (including a Windows

shutdown) to preserve settings before powering itself off. This can be accomplished by pressing and holding in the On/Standby switch for

approximately 5 seconds.

To power off completely, place the DSO in Standby state, then disconnect the power cord.

Note:

Calibration

The recommended calibration interval is one year. Calibration should be performed by qualified personnel only.

Cleaning

Clean only the exterior of the instrument, using a damp, soft cloth.

Do not use chemicals or abrasive elements. Under no

circumstances allow moisture to penetrate the instrument. To

avoid electrical shock, unplug the power cord from the AC outlet

before cleaning.

Electrical Shock Hazard!

No operator serviceable parts inside. Do not remove covers.

Refer servicing to qualified personnel.

WARNING

Abnormal Conditions

Operate the instrument only as intended by the manufacturer.

If you suspect the DSO’s protection has been impaired,

disconnect the power cord and secure the instrument against any

unintended operation.

The DSO’s protection is likely to be impaired if, for example, the

instrument shows visible damage or has been subjected to severe

transport stresses.

Proper use of the instrument depends on careful reading of all

instructions and labels.

Top of Page

Any use of the DSO in a manner not specified by the

manufacturer may impair the instrument’s safety protection. The

instrument and related accessories should not be directly

connected to human subjects or used for patient monitoring.

WARNING

Page 20

FRONT PANEL CONTROLS

Front Panel Buttons and Knobs

The control buttons of the instrument's front panel are logically grouped into analog and special functional areas. Analog functions are included

in the Horizontal , Trigger , and Vertical groups of control buttons and knobs.

Some of the front panel knobs are also special function push buttons. By pressing the knobs, you can activate functions such as Find

Note:

Level, Zero Vertical Offset, and Zero Delay. The

Sometimes you may want to change a value without using the numeric keypad. In that case, simply touch once inside the data entry field in

the scope dialog area (the field will be highlighted in yellow), then use the Adjust

knob functions as a toggle between fine and coarse adjustment.

DJUST

A

knob to dial in values into the selected field.

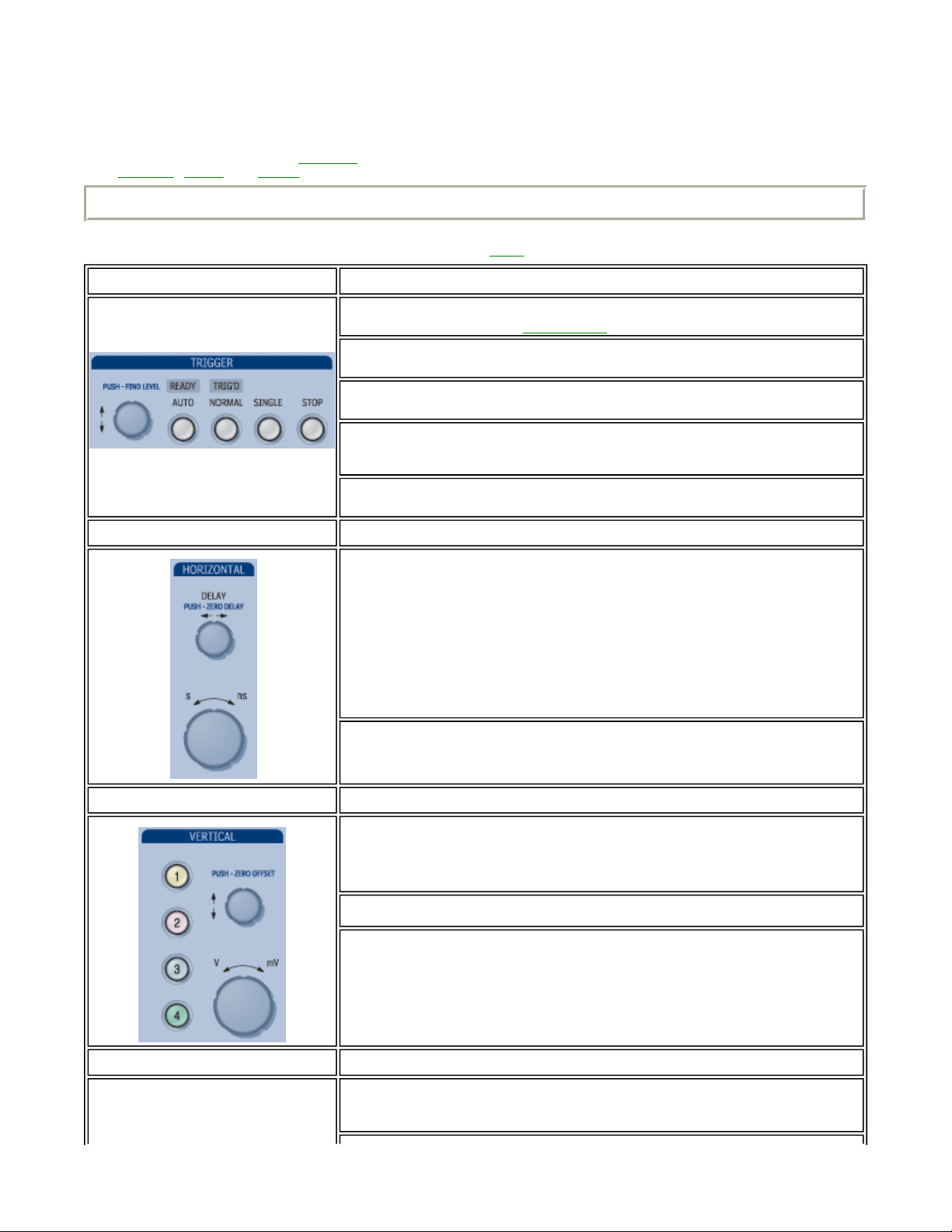

Trigger Control:

Horizontal Control:

The

which is indicated in the

Press

knob selects the trigger threshold level. Push this knob to quickly find the level,

EVEL

L

to display your trace.

UTO

A

Trigger

descriptor label

triggers the scope after a time-out, even if the trigger

UTO

A

.

conditions are not met.

N

triggers the scope each time a signal is present that meets the conditions set for the

ORMAL

type of trigger selected.

arms the scope to trigger once (single-shot acquisition) when the input signal meets

INGLE

S

the trigger conditions set for the type of trigger selected. If the scope is already armed, it will

force a trigger.

prevents the scope from triggering on a signal. If you boot up the instrument with the

TOP

S

trigger in Stop mode, the message "no trace available" will be displayed.

horizontally positions the scope trace on the display so you can observe the signal

DELAY

prior to the trigger time. It adjusts the pre- and post-trigger time. Push this knob to quickly set

the delay to zero, in which case the trigger point is positioned in the middle of the display grid.

When Zoom is selected, this button is used to position the zoom trace horizontally on the grid.

Vertical Control:

Cursor Control:

Sets the time/division of the timebase (acquisition system).

The

ERTICAL OFFSET

V

knob adjusts the vertical offset of a channel. Press the knobs to quickly

set the offset to zero for the selected channel.

When Zoom is selected, this button is used to position the zoom trace vertically on the grid.

The

OLTS/DIVISION

V

knob sets the vertical gain of the channel selected.

The channel number buttons only turn a channel on or off; they do not display the setup dialog

for the channel. A lighted channel button indicates that the channel trace is On and that the

front panel controls are dedicated to that channel.

To display a channel's setup dialog, select the channel from the

drop-down menu. Or,

Vertical

touch the channel descriptor label twice.

The

cursor button turns on cursors and, with each additional push, cycles through the

YPE

T

different types -- horizontal (time) and vertical (amplitude), then turns them off. For an FFT

math function, frequency cursors can also be displayed.

Page 21

The top and bottom knobs control the vertical and horizontal position of the cursors,

depending on the type selected (vertical or horizontal). Cursors can be turned on by rotating

either knob, and the cursors' position can be read in the Cursors Setup dialog (selectable from

the menu bar) where you can also set both cursors to move in unison (tracking).

Push in the cursor control knobs at any time to return the cursors to their default starting

positions.

Cursor values are displayed on-screen in the channel/trace descriptor labels and underneath

the trigger and timebase descriptor labels.

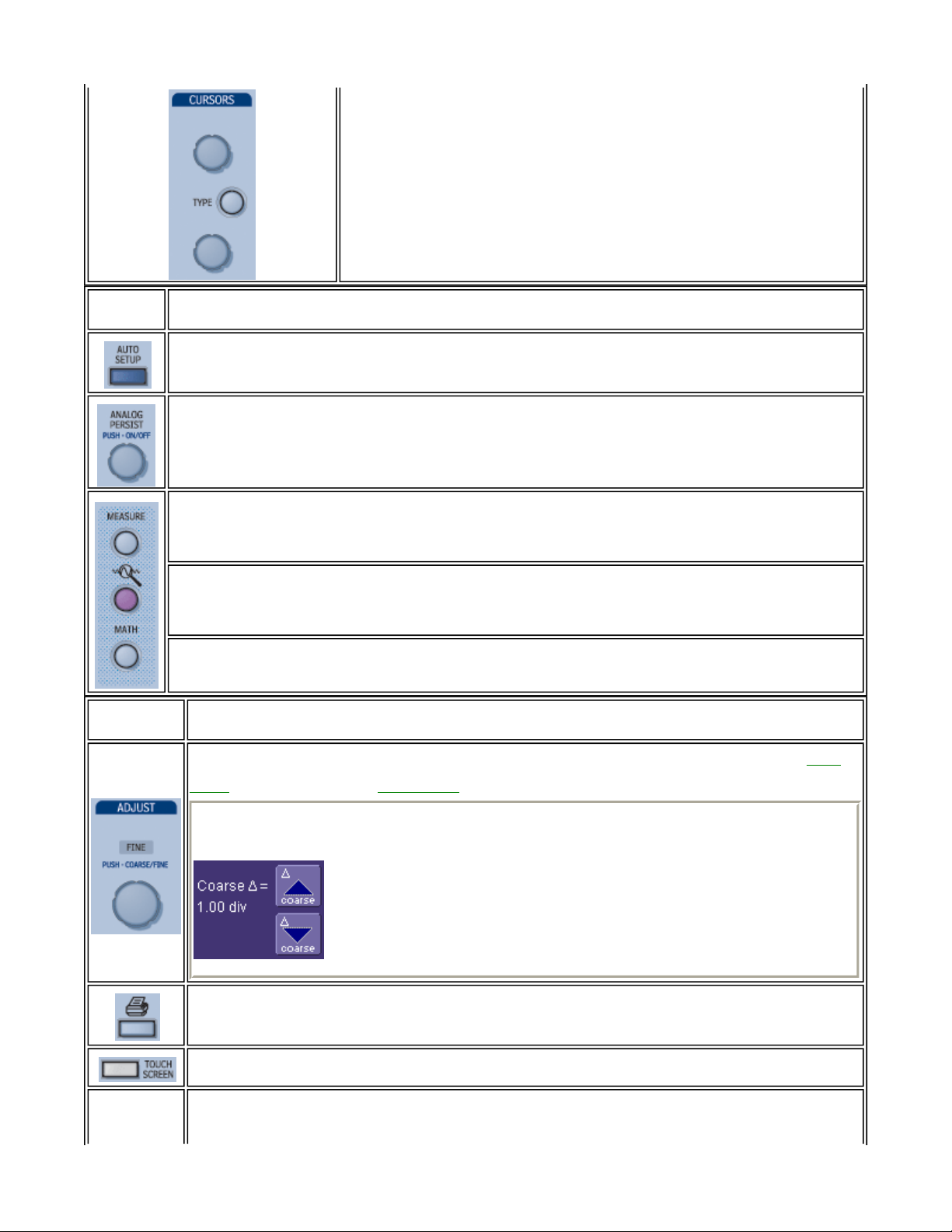

Special

Features:

General

Control:

UTO SETUP

A

trigger conditions, to display a wide variety of signals.

NALOG PERSIST

A

automatically sets the scope's horizontal timebase (acquisition system), vertical gain and offset, as well as

provides a three dimensional view of the signal: time, voltage, and a third dimension related to the

frequency of occurrence, as shown by a color-graded (thermal) or intensity-graded (analog) display. Push the button to turn

persistence on, then continue pushing the button to cycle through analog and color-graded persistence, and finally to turn

persistence off. When color-graded persistence is selected, you can rotate the knob to vary the saturation level.

Pushing the

M

button opens the Measure dialog, which enables you to set up six parameter measurements with

EASURE

statistics. Push again to close the measure dialog.

The

UICKZOOM

Q

button toggles zooms of all displayed channel traces on and off. If there is a math trace displayed when you

push this button, the math trace will be automatically turned off to free a slot for a zoom trace.

Pushing the

button opens the Math setup dialog and turns on the math trace. Push again to close the Math dialog.

ATH

M

By default, the

knob to toggle to

by touching twice inside a data entry field . Then use the keypad to type in the value.

keypad

You can set the granularity (delta) of the coarse adjustment by double-tapping inside the data entry field, then

Note:

touching the

Advanced

knob makes coarse adjustments (that is, digits to the left of the decimal point). Press the Adjust

DJUST

A

and adjust digits to the right of the decimal point. To enter exact values, you can also display a

Fine

checkbox in the pop-up numeric keypad. The keypad presents

delta up/down buttons to

Coarse

set the delta:

.

In the pop-up keypad, be sure to leave the

checkbox unchecked to adjust the coarse delta.

Fine

The printer button prints the displayed screen to a file, a printer, the clipboard, or sends it as e-mail. Select the device and

format it in the Utilities - Hardcopy dialog.

T

C

OUCH SCREEN

LEAR SWEEPS

activates or deactivates the touch screen.

clears data from multiple sweeps (acquisitions) including: persistence trace displays, averaged traces,

and parameter statistics.

Page 22

Top of Page

Page 23

ON-SCREEN TOOLBARS, ICONS, AND DIALOG BOXES

Menu Bar Buttons

The menu bar buttons at the top of the scope's display are designed for quick setup of common functions. At the right end of the menu bar is a

quick setup button that, when touched, opens the setup dialog associated with the trace or parameter named beside it. The named trace or

parameter is the one whose setup dialog you last opened: . This button also appears as an undo button after front

panel buttons

after you perform the Autosetup or QuickZoom operation.

UTOSETUP

A

and

UICKZOOM

Q

are pressed. If you want to perform an Undo operation, it must be the very next operation

Dialog Boxes

The dialog area occupies the bottom one-third of the screen. To expand the signal display area, you can minimize each dialog box by touching

the

Top of Page

tab at the right of the dialog box.

Close

Page 24

ALTERNATE ACCESS METHODS

The instrument often gives you more than one way to access dialogs and menus.

Mouse and Keyboard Operation

In the procedures we focus on front panel and touch-screen operation, but if you have a mouse connected to the instrument, you can also

click on objects. Likewise, if you have a keyboard connected, you can use it instead of the virtual keyboard provided by the instrument.

Tool Bar Buttons

The procedures also focus on the use of the menu bar at the top of the screen to access dialogs and menus. However, on several dialogs

common functions are accessible from a row of buttons that save you a step or two in accessing their dialogs. For example, at the bottom of

the Channel Setup dialog, these buttons perform the following functions:

A pop-up menu allows you to select up to six measurements to compute on this channel without leaving the

Channel Setup dialog. The parameter automatically appears below the grid.

Creates a zoom trace of the channel trace whose dialog is currently displayed.

A pop-up menu allows you to select a math function from this menu without leaving the Channel Setup dialog. A

math trace of the channel whose dialog is currently open is automatically displayed.

Loads the channel trace into the next available memory location (M1 to M4).

Top of Page

Automatically performs a vertical scaling that fits the waveform into the grid.

Opens a Labeling pop-up menu that allows you to create labels tied to the waveform.

Page 25

TRACE DESCRIPTORS

V

Trace Annotation

To Turn On a Channel Trace Label

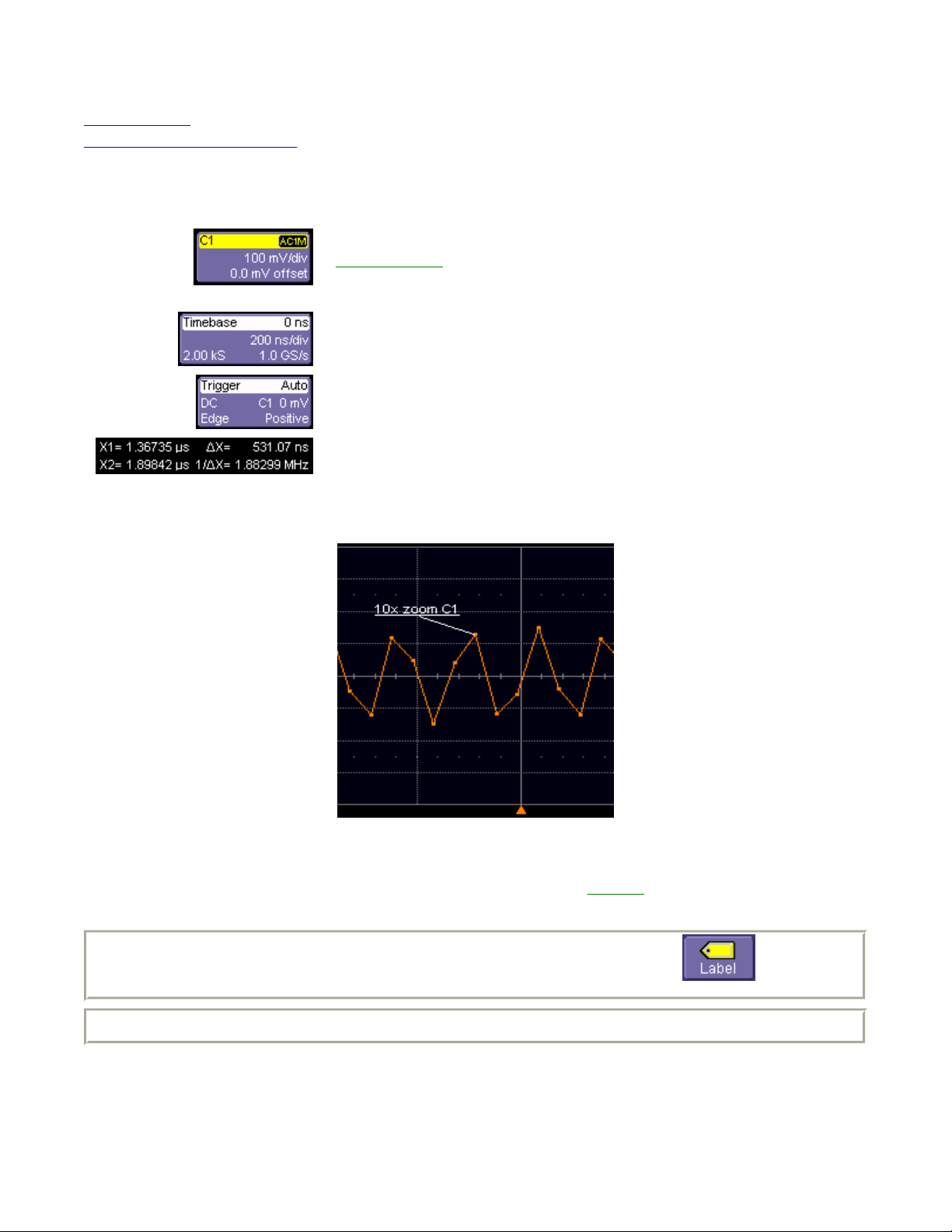

Vertical and horizontal trace descriptors (labels) are displayed below the grid. They provide a summary of your channel, timebase, and trigger

settings. To make adjustments to these settings, touch the respective label to display the setup dialog for that function. Channel labels need to

be touched twice unless they are active.

Channel trace labels show the vertical settings for the trace, as well as cursor information if

cursors are in use. In the title bar of the label are also included indicators for deskew (DSQ),

coupling (DC/GND), bandwidth limiting (BWL), and averaging (AVG). These indicators have a

long and short form

Besides channel traces, math and parameter measurement labels are also displayed. Labels

are displayed only for traces that are turned on.

.

The title bar of the

sampling information is given below the title bar.

The title bar of the

title bar is given the coupling (DC), trigger type (Edge), source (C1), level (0 mV), and slope

(Positive).

Shown below the TimeBase and Trigger labels is setup information for horizontal cursors,

including the time between cursors and the frequency.

TimeBase

Trigger

label shows the trigger delay setting. Time per division and

label shows the trigger mode: Auto, Normal, or Stopped. Below the

Trace Annotation

The instrument gives you the ability to add an identifying label, bearing your own text, to a waveform display:

For each waveform, you can create multiple labels and turn them all on or all off. Also, you can position them on the waveform by dragging or

by specifying an exact horizontal position.

To Annotate a Waveform

1. Touch the waveform you want to annotate, then

you are creating a label for the first time for this waveform,

under

If the dialog for the trace you want to annotate is currently displayed, you can touch the label button at the bottom to

Note 1:

display the Trace Annotation setup dialog.

You may place a label anywhere you want on the waveform. Labels are numbered sequentially according to the order in which they

Note 2:

are added, and not according to their placement on the waveform.

2. If you want to change the label's text, touch inside the

3. To place the label precisely, touch inside the

4. To add another label, touch the

5. To make the labels visible, touch the

on the keyboard when you are done. Your edited text will automatically appear in the label on the waveform.

O.K.

touch the label you want to change.

Labels

Add label

iew labels

Set label...

Horizontal Pos.

button. To delete a label, select the label from the list, then touch the

checkbox.

in the pop-up menu. A dialog box

is displayed with default text. If you are modifying an existing label,

Label1

Label Text

field. A pop-up keyboard appears for you to enter your text. Touch

field and enter a horizontal value, using the pop-up numeric keypad.

opens in which to create the label. If

Remove label

button.

Page 26

To Turn On a Trace

z

On the front panel, press a channel select button, such as , to display the trace label for that input channel and turn on the

channel. Touch the channel trace label to open the dialog box.

z To turn on a math function trace, press the

front panel button or touch

ATH

M

in the menu bar, then

Math

Math Setup...

in the drop-

down menu. Touch the On checkbox for the trace you want to activate.

z You can also quickly create traces (and turn on the trace label) for math functions and memory traces, without leaving the Vertical

Adjust dialog, by touching the icons at the bottom of the Vertical Adjust dialog: , , ,

.

Whenever you turn on a channel, math, or memory trace via the menu bar, the dialog at the bottom of the screen automatically switches to the

vertical setup or math setup dialog for that selection. You can configure your traces from here, including math setups.

The channel number appears in the tab of the "Vertical Adjust" dialog, signifying that all controls and data entry fields are dedicated to the

selected trace.

Top of Page

Page 27

SCREEN LAYOUT

The instrument's screen is divided into three areas:

z menu bar

z signal display area

z dialog area

Menu Bar

The top of the screen contains a toolbar of commonly used functions. Whenever you touch one of these buttons, the dialog area at the bottom

of the screen switches to show the setup for that function.

Signal Display Grid

You can set up the signal display area by touching in the toolbar, then the tab. The display dialog offers a choice

of grid combinations and a means to set the grid intensity.

Dialog Area

The lower portion is where you make selections and input data. The dialog area is controlled by both toolbar touch buttons and front panel

push buttons.

Top of Page

Page 28

HARDWARE INSTALLATION

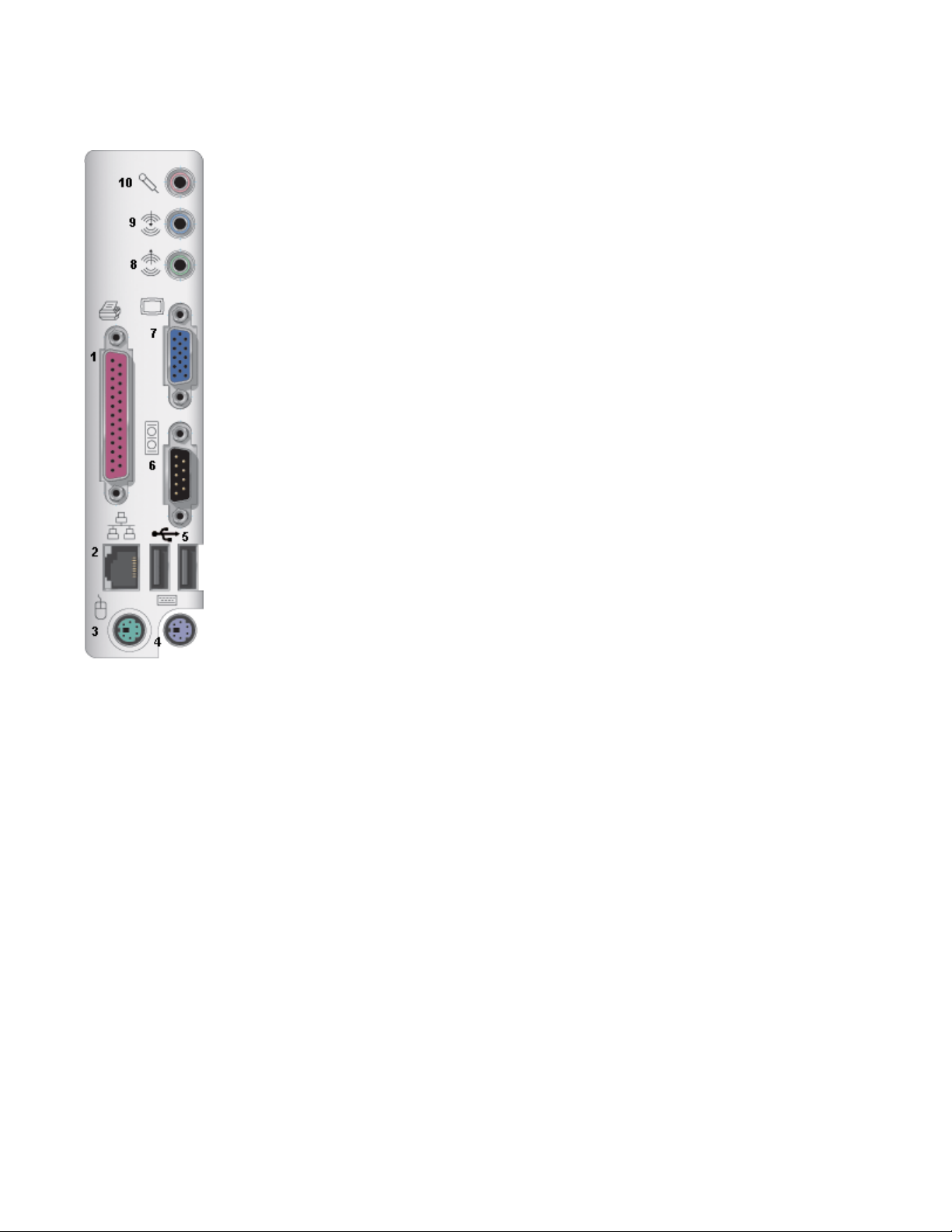

Instrument I/O Panel

(1) Centronics Port; (2) Ethernet Port; (3) Mouse; (4) Keyboard; (5) USB Ports; (6) RS-232-C Port; (7) External VGA Monitor; (8) Line

In; (9) Speakers; (10) Microphone

Page 29

SOFTWARE

Checking the Scope Status

To find out the scope's software and hardware configuration, including software version and installed options, proceed as follows:

1. In the menu bar, touch .

2. Touch the tab.

You can find information related to hard drive memory, etc. as follows:

1. Minimize the instrument application by touching , then selecting

2. Touch the

Top of Page

taskbar button and, per usual Windows® operation, open Windows Explorer.

Start

Minimize

in the drop-down menu.

Page 30

DEFAULT SETTINGS

WaveMaster and WavePro 7000 Series DSOs

You can reset the scope to default settings by simply pressing the

Channel1 and Channel 2, with no processing enabled.

Other default settings are as follows:

Vertical Timebase Trigger

50 mV/div 50.0 ns/div DC50Ω (WaveMaster, DDA, SDA), AC1MΩ (WavePro), C1, 0 mV level

EFAULT SETUP

D

push button on the front panel. This feature turns on

0 V offset 10.0 GS/s

0 s delay Auto trigger mode

edge trigger

positive edge

DDA, SDA, and WaveRunner DSOs

On your front panel, the

1. Press the

You can also touch

Note:

2. Touch the "Recall Setup" tab in the dialog.

3. Then touch the on-screen

Top of Page

EFAULT SETUP

D

AVE/RECALL

S

in the menu bar, then

File

push button does not exist. For these instruments, therefore, to recall a default setup

push button to the left of the

Recall Default Setup

RIVE ANALYSIS

D

Recall Setup...

button

.

push button.

in the drop-down menu.

Page 31

ADDING A NEW OPTION

To add a software option you need a key code to enable the option. Call your local salesman or LeCroy Customer Support to place an order

and receive the code.

To add the software option do the following:

1. In the menu bar, touch .

2. In the dialog area, touch the tab.

3. Touch .

4. Use the pop-up keyboard to type the key code. Touch

5. The name of the feature you just installed is shown below the list of key codes. You can use the scroll buttons to see the name of the

option installed with each key code listed:

on the keyboard to enter the information.

O.K.

Top of Page

Page 32

RESTORING SOFTWARE

Restarting the Application

Upon initial power-up, the scope will load the instrument application software automatically. If you exit the application and want to reload it,

touch the shortcut icon on the desktop: .

If you minimize the application, touch the appropriate task bar or desktop button to maximize it:

.

Restarting the Operating System

If you need to restart the Windows® operating system, you will have to reboot the scope by pressing and holding in the power switch for 10

seconds, then turning the power back on.

Top of Page

Page 33

PROBUS INTERFACE

LeCroy's ProBus® probe system provides a complete measurement solution from probe tip to oscilloscope display. ProBus allows you to

control transparent gain and offset directly from your front panel. It is particularly useful for voltage, differential, and current active probes. It

uploads gain and offset correction factors from the ProBus EPROMs and automatically compensates to achieve fully calibrated

measurements.

This intelligent interconnection between your instrument and a wide range of accessories offers important advantages over standard BNC and

probe ring connections. ProBus ensures correct input coupling by auto-sensing the probe type, thereby eliminating the guesswork and errors

that occur when attenuation or amplification factors are set manually.

Top of Page

Page 34

AUXILIARY OUTPUT SIGNALS

In addition to a standard 1 V, 1 kHz calibration signal on the front panel, the following signals can be output through the AUX OUTPUT

connector at the rear of the scope:

Trigger Out -- can be used to trigger another scope.

Trigger Enabled -- can be used as a gating function to trigger another instrument when the scope is ready.

Pass/Fail -- allows you to set a pulse duration from 1 ms to 500 ms; generates a pulse when pass/fail testing is active and

conditions are met.

Aux Output Off -- turns off the auxiliary output signal.

To Set Up Auxiliary Output

1. In the menu bar, touch

2. Touch the

3. Touch one of the buttons under

Top of Page

Aux Output

Utilities

tab.

, then

Utilities Setup...

Use Auxiliary Output For

in the drop-down menu.

.

Page 35

SAMPLING MODES

Depending on your timebase, you can choose either Single-shot (Real Time) , RIS , or Roll mode sampling.

To Select a Sampling Mode

1. In the menu bar, touch

2. In the "Horizontal" dialog, touch a

Top of Page

Timebase

, then

Horizontal Setup...

Sample Mode

in the drop-down menu.

button.

Page 36

SINGLE-SHOT SAMPLING MODE

A

To Select a Sampling Mode

Basic Capture Technique

single-shot acquisition is a series of digitized voltage values sampled on the input signal at a uniform rate. It is also a series of measured

data values associated with a single trigger event. The acquisition is typically stopped a defined number of samples after this event occurs: a

number determined by the selected trigger delay and measured by the timebase. The waveform's horizontal position (and waveform display in

general) is determined using the trigger event as the definition of time zero.

You can choose either a pre- or post-trigger delay. Pre-trigger delay is the time from the left-hand edge of the display grid forward to the

trigger event, while post-trigger delay is the time back to the event. You can sample the waveform in a range starting well before the trigger

event up to the moment the event occurs. This is 100% pre-trigger, and it allows you to see the waveform leading up to the point at which the

trigger condition was met and the trigger occurred. (The instrument offers up to the maximum record length of points of pre-trigger

information.) Post-trigger delay, on the other hand, allows you to sample the waveform starting at the equivalent of 10,000 divisions after the

event occurred.

Because each instrument input channel has a dedicated ADC (Analog-to-Digital Converter), the voltage on each is sampled and measured at

the same instant. This allows very reliable time measurements between the channels.

On fast timebase settings, the maximum single-shot sampling rate is used. But for slower timebases, the sampling rate is decreased and the

number of data samples maintained.

The relationship between sample rate, memory, and time can be simply defined as:

and

Top of Page

Page 37

RIS SAMPLING MODE -- FOR HIGHER SAMPLE RATES

To Select a Sampling Mode

RIS (Random Interleaved Sampling) is an acquisition technique that allows effective sampling rates higher than the maximum single-shot

sampling rate. It is used on repetitive waveforms with a stable trigger. The maximum effective sampling rate of 50 GS/s can be achieved with